Spline Shaft Coupling: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for spline shaft coupling

In an increasingly interconnected global market, sourcing high-quality spline shaft couplings can pose significant challenges for B2B buyers. As industries across Africa, South America, the Middle East, and Europe continue to expand, the need for reliable and efficient power transmission solutions becomes paramount. This guide delves into the multifaceted world of spline shaft couplings, exploring various types, their applications, and critical factors influencing sourcing decisions.

From understanding the intricacies of splined shafts and hubs to assessing the long-term benefits of flexible drive couplings, our comprehensive resource equips international buyers with the knowledge needed to navigate this complex landscape. We address essential aspects such as supplier vetting processes, pricing structures, and regional market trends, ensuring that you can make informed purchasing decisions tailored to your specific operational requirements.

By leveraging the insights provided in this guide, you can optimize your supply chain, enhance operational efficiency, and foster partnerships with reputable suppliers. Whether you are based in the bustling markets of Vietnam or the industrial hubs of Germany, this guide serves as your authoritative resource in procuring the right spline shaft couplings to meet your business needs. Empower your purchasing strategy with the knowledge and tools necessary to thrive in today’s dynamic global market.

Understanding spline shaft coupling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rigid Spline Couplings | Fixed connection, high torque capacity | Heavy machinery, automotive, industrial | Pros: High strength, minimal backlash. Cons: Limited flexibility, can transmit vibrations. |

| Flexible Spline Couplings | Allows for misalignment, shock absorption | Robotics, conveyors, pumps | Pros: Reduces stress on components, accommodates misalignment. Cons: Lower torque capacity than rigid types. |

| Clamp Spline Couplings | Easy installation, adjustable fit | General machinery, automotive | Pros: Simple to install and adjust. Cons: May require regular tightening. |

| Bellows Spline Couplings | Elastic element for flexibility and damping | Precision equipment, medical devices | Pros: Excellent vibration damping, compact design. Cons: Can be more expensive, limited torque capacity. |

| Custom Spline Couplings | Tailored to specific applications and needs | Specialized machinery, custom projects | Pros: Optimized performance for unique applications. Cons: Longer lead times and potentially higher costs. |

What Are the Characteristics of Rigid Spline Couplings?

Rigid spline couplings are designed for applications requiring a solid connection between shafts. They excel in transmitting high torque and are commonly used in heavy machinery, automotive, and industrial applications. Buyers should consider the potential for vibration transmission and limited flexibility, which can affect system dynamics. When selecting rigid couplings, assess the specific torque requirements and ensure compatibility with existing machinery.

How Do Flexible Spline Couplings Enhance Performance?

Flexible spline couplings are engineered to accommodate misalignment and absorb shocks, making them ideal for robotics, conveyors, and pumps. Their ability to reduce stress on connected components is a significant advantage, particularly in dynamic environments. However, buyers should note that while these couplings offer flexibility, they typically have a lower torque capacity compared to rigid counterparts. Evaluating the operational environment and alignment needs is critical when choosing flexible couplings.

What Are the Benefits of Clamp Spline Couplings?

Clamp spline couplings are appreciated for their straightforward installation and adjustable fit, making them suitable for general machinery and automotive applications. Their design allows for easy adjustments, which can be beneficial in maintenance scenarios. However, buyers should be aware that these couplings may require periodic tightening to maintain optimal performance. It’s essential to consider the ease of access for adjustments in the application design.

Why Choose Bellows Spline Couplings for Precision Equipment?

Bellows spline couplings incorporate an elastic element that provides flexibility and excellent vibration damping, making them ideal for precision equipment and medical devices. Their compact design allows for space-saving solutions in intricate applications. While they offer superior performance in terms of damping, they generally come with a higher price tag and limited torque capacity. Buyers should weigh the benefits of precision against cost and torque requirements when considering bellows couplings.

What Are the Considerations for Custom Spline Couplings?

Custom spline couplings are tailored to meet specific application needs, providing optimized performance for specialized machinery and unique projects. They can address unique challenges that standard couplings may not solve. However, potential buyers should factor in longer lead times and higher costs associated with custom designs. When considering custom couplings, a thorough assessment of application requirements and expected performance outcomes is crucial.

Key Industrial Applications of spline shaft coupling

| Industry/Sector | Specific Application of Spline Shaft Coupling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Connecting drive shafts in electric and hybrid vehicles | Ensures efficient torque transmission, enhancing vehicle performance | Compatibility with specific models and torque requirements |

| Agriculture Equipment | Integrating splined couplings in tractors and harvesters | Improves durability and reduces maintenance costs | Resistance to harsh environmental conditions and load ratings |

| Oil & Gas | Used in drilling rigs for connecting rotary equipment | Increases reliability and operational efficiency | High strength materials to withstand extreme conditions |

| Construction Machinery | Linking hydraulic pumps and motors in heavy machinery | Enhances power transfer and reduces downtime | Sizing and load capacity to match machinery specifications |

| Industrial Automation | Facilitating motion transfer in conveyor systems | Streamlines operations and improves productivity | Precision in dimensions and material selection for durability |

How is Spline Shaft Coupling Used in Automotive Manufacturing?

In the automotive sector, spline shaft couplings are crucial for connecting drive shafts in electric and hybrid vehicles. They provide reliable torque transmission, which is essential for optimizing vehicle performance and efficiency. Buyers in this industry must ensure that the couplings are compatible with specific vehicle models and meet the required torque specifications. This is particularly important for international buyers who may need to navigate varying standards across regions.

What Role Does Spline Shaft Coupling Play in Agriculture Equipment?

Agricultural equipment, such as tractors and harvesters, utilizes spline shaft couplings to enhance durability and reduce maintenance costs. These couplings can handle the high torque loads generated during operation, ensuring that machinery runs smoothly even in challenging conditions. Buyers should consider the resistance of these couplings to harsh environmental factors, as well as their load ratings to ensure they can withstand the demands of agricultural applications.

How Are Spline Shaft Couplings Applied in the Oil & Gas Industry?

In the oil and gas industry, spline shaft couplings are used to connect rotary equipment in drilling rigs. Their design allows for increased reliability and operational efficiency, which are critical in an industry where downtime can be costly. International buyers should focus on sourcing couplings made from high-strength materials that can endure extreme conditions, such as high temperatures and corrosive environments, typical in oil and gas extraction.

Why Are Spline Shaft Couplings Important for Construction Machinery?

Construction machinery relies on spline shaft couplings to link hydraulic pumps and motors, facilitating efficient power transfer. This application is vital for minimizing downtime and ensuring that heavy machinery operates effectively. When sourcing these couplings, buyers must pay attention to sizing and load capacity to align with the specifications of the machinery in use, particularly in regions where machinery standards may differ.

How Do Spline Shaft Couplings Enhance Industrial Automation?

In industrial automation, spline shaft couplings are integral to the motion transfer in conveyor systems. They help streamline operations, leading to improved productivity across various manufacturing processes. Buyers in this sector should prioritize precision in dimensions and material selection to ensure durability and performance, especially when dealing with international suppliers who may offer varying quality standards.

3 Common User Pain Points for ‘spline shaft coupling’ & Their Solutions

Scenario 1: Inconsistent Spline Alignment Leading to Equipment Downtime

The Problem: A common challenge faced by B2B buyers is the misalignment of spline shafts when connecting machinery components. This misalignment can occur due to wear and tear or improper installation, leading to vibration, noise, and ultimately, equipment failure. For businesses relying on high-performance machinery, such downtime can result in significant productivity losses and increased operational costs. Buyers may feel frustrated as they attempt to pinpoint the cause of failure, often leading to prolonged maintenance periods and disruptions in service delivery.

The Solution: To mitigate misalignment issues, it is crucial to conduct a thorough assessment of the installation area and the components involved before sourcing spline shaft couplings. Buyers should prioritize couplings with a flexible design that can accommodate minor misalignments, such as splined flexible drive couplings. Additionally, regular maintenance checks can help identify wear patterns early, allowing for timely replacements. When sourcing couplings, ensure to select reputable manufacturers that offer detailed specifications and installation guides. This proactive approach not only ensures better performance but also minimizes the risk of future misalignment.

Scenario 2: Difficulty in Selecting the Right Spline Shaft Coupling

The Problem: With numerous options available on the market, selecting the appropriate spline shaft coupling can be a daunting task for B2B buyers. Different applications may require specific coupling types, sizes, and materials, leading to confusion and potential mismatches. A wrong selection can result in inefficiencies, increased wear on machinery, and additional costs associated with returns or replacements. Buyers may feel overwhelmed by the technical specifications and the need to match them precisely to their machinery requirements.

The Solution: To simplify the selection process, buyers should develop a comprehensive understanding of their machinery’s requirements. Begin by documenting the key specifications such as bore size, spline type, and the operational environment (e.g., temperature, exposure to chemicals). Engage with suppliers who provide technical support and can recommend couplings based on these specifications. Utilizing online tools and resources, such as coupling configurators or comparison charts, can also assist in narrowing down choices. Furthermore, consider opting for custom solutions if standard options do not meet specific needs, ensuring that the selected coupling is perfectly tailored to the application.

Scenario 3: High Costs Due to Frequent Coupling Failures

The Problem: Frequent failures of spline shaft couplings can lead to escalating maintenance costs and operational inefficiencies. B2B buyers often face the dilemma of purchasing cheaper couplings that may not withstand the rigors of their applications, leading to a cycle of replacements and repairs. This not only strains budgets but also impacts production schedules and can compromise the quality of end products, causing frustration among stakeholders.

The Solution: Investing in high-quality spline shaft couplings is essential to reduce long-term costs associated with frequent failures. Buyers should prioritize couplings made from durable materials that can withstand operational stresses, such as solid steel or magnesium alloys known for their strength-to-weight ratios. Additionally, working with trusted suppliers who offer warranties and technical support can provide added assurance of product reliability. Implementing a robust maintenance program that includes regular inspections and timely replacements based on usage patterns will further enhance the lifespan of couplings. This strategic approach not only minimizes costs but also ensures smoother operations and improved overall efficiency.

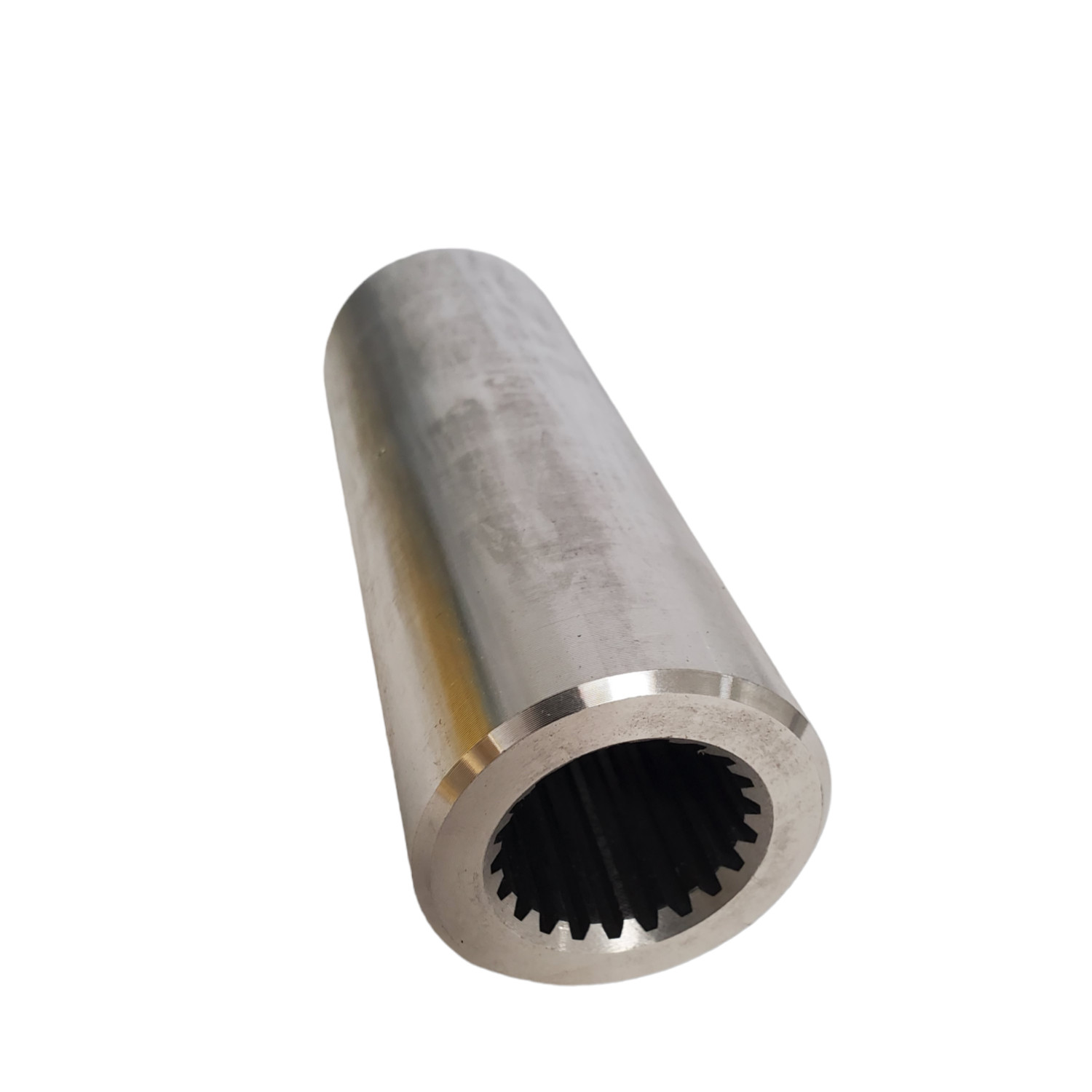

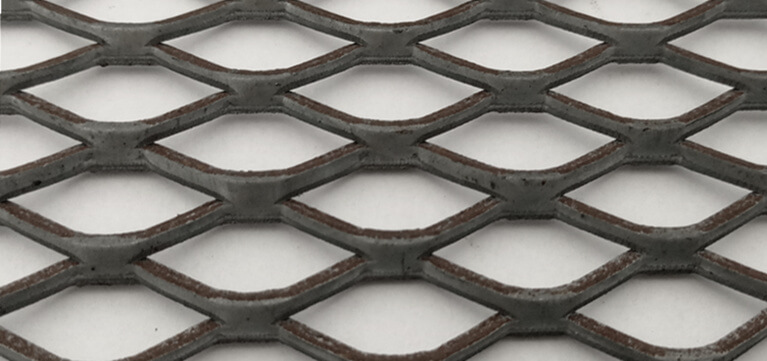

Illustrative image related to spline shaft coupling

Strategic Material Selection Guide for spline shaft coupling

When selecting materials for spline shaft couplings, it’s essential to consider the specific operational demands, environmental conditions, and regulatory standards that may apply in different regions. Here, we analyze four common materials used in spline shaft couplings, highlighting their properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Steel for Spline Shaft Couplings?

Steel is a widely used material for spline shaft couplings due to its excellent mechanical properties. It typically offers high tensile strength, good fatigue resistance, and the ability to withstand high temperatures and pressures. Steel couplings can also be treated for enhanced corrosion resistance, making them suitable for various applications, including automotive and industrial machinery.

Pros: Steel is durable and can handle significant loads, making it ideal for high-performance applications. It is relatively cost-effective and readily available, which is advantageous for large-scale production.

Cons: On the downside, steel can be prone to rust if not properly treated, and its weight may be a concern in applications where weight reduction is critical. Additionally, manufacturing processes such as machining can be complex and costly.

Impact on Application: Steel couplings are compatible with a wide range of media, including oils and hydraulic fluids, but may not be suitable for highly corrosive environments unless treated.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as DIN or ASTM for steel quality. In contrast, buyers in Africa and South America may need to consider local availability and cost factors.

How Does Aluminum Compare for Spline Shaft Couplings?

Aluminum is another popular choice, particularly in applications where weight savings are crucial. It offers a favorable strength-to-weight ratio and is inherently corrosion-resistant, making it suitable for marine and outdoor applications.

Pros: Aluminum’s lightweight nature reduces the overall weight of machinery, which can enhance efficiency. Its corrosion resistance also minimizes maintenance needs.

Cons: However, aluminum has lower tensile strength compared to steel, which may limit its use in high-load applications. Additionally, it can be more expensive than steel, affecting overall project budgets.

Impact on Application: Aluminum couplings are compatible with various media, including water and some chemicals, but caution is advised with aggressive solvents.

Considerations for International Buyers: Compliance with JIS standards is crucial for buyers in Asia, while European buyers may look for EN standards. Understanding local market dynamics is essential for cost-effective sourcing.

What Role Does Plastic Play in Spline Shaft Couplings?

Plastic materials, particularly reinforced composites, are increasingly being used in spline shaft couplings for specific applications. They offer good chemical resistance and can handle moderate loads.

Illustrative image related to spline shaft coupling

Pros: Plastics are lightweight and often more cost-effective than metals. They can also be molded into complex shapes, providing design flexibility.

Cons: The primary limitation is their lower mechanical strength and temperature resistance compared to metals, which may restrict their use in high-stress environments.

Impact on Application: Plastic couplings are ideal for applications involving corrosive chemicals or environments where weight is a significant factor.

Considerations for International Buyers: Buyers should ensure that the plastic materials meet relevant safety and performance standards in their region, such as ASTM for the U.S. or EN for Europe.

How Does Magnesium Alloy Enhance Spline Shaft Couplings?

Magnesium alloys are known for their exceptional strength-to-weight ratio, making them suitable for applications where weight reduction is critical without sacrificing performance.

Pros: Magnesium couplings are significantly lighter than steel and aluminum, reducing the load on connected components. They also exhibit good corrosion resistance.

Cons: The main drawback is their cost, as magnesium alloys can be more expensive than traditional materials. Additionally, they require careful handling during manufacturing due to their flammability.

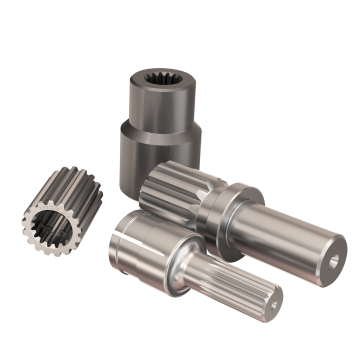

Illustrative image related to spline shaft coupling

Impact on Application: Magnesium alloys are compatible with various media, but extreme caution is needed in high-temperature environments.

Considerations for International Buyers: Buyers should be aware of specific regulations regarding magnesium use in their countries, particularly in Europe, where stringent environmental regulations may apply.

Summary Table of Material Selection for Spline Shaft Couplings

| Material | Typical Use Case for spline shaft coupling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Industrial machinery, automotive | High strength and durability | Prone to rust without treatment | Medium |

| Aluminum | Aerospace, marine applications | Lightweight and corrosion-resistant | Lower strength than steel | High |

| Plastic | Chemical processing, lightweight machinery | Cost-effective and flexible | Lower mechanical strength | Low |

| Magnesium Alloy | Aerospace, automotive | Excellent strength-to-weight ratio | Higher cost and flammability | High |

This guide provides insights into the strategic selection of materials for spline shaft couplings, enabling B2B buyers to make informed decisions based on their specific operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for spline shaft coupling

What Are the Key Stages in the Manufacturing Process of Spline Shaft Couplings?

Manufacturing spline shaft couplings involves several critical stages, each designed to ensure precision and durability. These stages include material preparation, forming, assembly, and finishing.

1. Material Preparation

The manufacturing process begins with the selection of appropriate materials, typically high-strength steel or aluminum alloys, chosen for their mechanical properties. The raw materials undergo rigorous inspections to ensure they meet the required specifications. This may include verifying chemical compositions and mechanical properties through techniques such as spectrometry and tensile testing. Proper material handling and storage practices are crucial to prevent contamination or degradation.

2. Forming Techniques

The forming process can vary based on the design of the spline shaft coupling. Common methods include:

-

CNC Machining: Utilizing Computer Numerical Control (CNC) machines allows for high precision in cutting, drilling, and milling the components. This method is particularly effective for creating complex spline profiles with tight tolerances.

-

Forging: For larger couplings, forging can enhance the strength and durability of the material. This involves shaping the metal through compressive forces, often resulting in a finer grain structure and improved mechanical properties.

-

Casting: Some couplings may be produced via casting methods, where molten metal is poured into molds. This is generally used for high-volume production but requires careful control to avoid defects.

3. Assembly

Once the individual components are formed, they are assembled. This stage may include fitting the splined hubs to the shafts, aligning components, and securing them with fasteners or welding. Precision alignment is crucial to ensure that the couplings operate smoothly and efficiently, minimizing wear and potential failure during operation.

4. Finishing

The final stage involves surface treatments and finishing processes, which can include:

-

Heat Treatment: Processes such as quenching and tempering enhance the strength and toughness of the couplings.

-

Surface Coatings: Applying coatings like zinc plating or anodizing helps prevent corrosion, especially important for couplings used in harsh environments.

-

Polishing: This improves the aesthetic appearance and can reduce friction during operation.

How Is Quality Assurance Implemented in Spline Shaft Coupling Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that the final products meet industry standards and customer expectations. Various international and industry-specific standards guide these QA processes.

1. International and Industry-Specific Standards

Manufacturers often adhere to international quality management standards such as ISO 9001, which outlines requirements for establishing, implementing, maintaining, and continually improving a quality management system. Additionally, industry-specific standards, such as CE marking for European markets and API standards for the oil and gas sector, may also apply. Compliance with these standards is crucial for international B2B transactions.

2. Quality Control Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage focuses on inspecting raw materials upon arrival. Ensuring that materials meet specified standards is essential for the overall quality of the final product.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to ensure that processes remain within specified tolerances. This may involve measurements of dimensions, surface finish, and mechanical properties at various stages.

-

Final Quality Control (FQC): After assembly and finishing, the final product undergoes rigorous testing. This may include functional tests to ensure that the coupling performs as intended under load conditions.

What Testing Methods Are Commonly Used for Spline Shaft Couplings?

Testing methods are essential for verifying the performance and reliability of spline shaft couplings. Some common testing techniques include:

-

Tensile Testing: Measures the strength of the material and ensures it can withstand operational stresses without failure.

-

Torque Testing: Determines the coupling’s ability to transmit torque without slipping, critical for applications requiring high torque transmission.

-

Fatigue Testing: Evaluates the coupling’s durability under cyclical loading, helping predict its lifespan in actual working conditions.

-

Non-Destructive Testing (NDT): Techniques like ultrasonic or magnetic particle testing identify internal or surface defects without damaging the component.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is paramount. Here are effective strategies:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing practices, quality control measures, and adherence to relevant standards. Audits can be performed by the buyer or third-party agencies specializing in supplier assessments.

-

Quality Reports and Certifications: Requesting documentation such as quality reports, certificates of compliance, and test results helps buyers verify that suppliers meet international and industry standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These services can conduct inspections at various stages of production, ensuring adherence to specifications.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers must be aware of certain nuances related to quality control when sourcing spline shaft couplings. These include:

-

Cultural and Regulatory Differences: Understanding local regulations and cultural expectations in different regions is essential. For instance, compliance requirements may vary significantly between Europe and Africa.

-

Logistics and Supply Chain Considerations: Quality assurance doesn’t stop at manufacturing; it extends to logistics. Ensuring that products remain undamaged during transportation is critical, and buyers should inquire about packaging standards and handling procedures.

-

Language and Communication Barriers: Effective communication is vital for ensuring that quality expectations are understood and met. Buyers should consider working with suppliers who can provide documentation and support in a language that is accessible.

By understanding the manufacturing processes and quality assurance measures associated with spline shaft couplings, B2B buyers can make informed decisions, ensuring they procure reliable components that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘spline shaft coupling’

To facilitate an efficient procurement process for spline shaft couplings, this guide provides a structured approach that B2B buyers can follow. The focus is on ensuring that all necessary aspects are considered to make an informed purchasing decision.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the foundation of sourcing the right spline shaft coupling. Key specifications include the bore diameter, spline type, and material composition. Consider the operational environment and load requirements, as these factors will influence the performance and longevity of the coupling.

- Bore Diameter: Ensure compatibility with existing shafts.

- Spline Type: Identify whether you need a regular spline or a specialized option like a steel bushing.

- Material Composition: Choose materials that withstand your operational conditions (e.g., corrosion resistance).

Step 2: Research Market Trends and Innovations

Stay informed about the latest advancements in spline shaft coupling technology. Innovations can offer improved performance, efficiency, and durability, which may lead to cost savings in the long run.

- Lightweight Materials: Look for options like magnesium alloys that reduce load on connected components.

- Flexible Designs: Explore couplings that accommodate misalignments to enhance operational reliability.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Review company profiles, case studies, and testimonials from other buyers in your industry or region to ensure credibility.

- Certifications: Verify that suppliers comply with international quality standards (e.g., ISO certifications).

- Experience: Prefer suppliers with a proven track record in your industry to ensure they understand your unique needs.

Step 4: Request Samples and Technical Documentation

Asking for product samples allows you to assess the quality and compatibility of the spline shaft coupling with your application. Additionally, request technical documentation to understand the specifications and installation requirements.

- Quality Assurance: Inspect the material and construction quality of the samples.

- Installation Guidelines: Ensure you receive detailed installation instructions to avoid operational issues.

Step 5: Compare Pricing and Terms of Sale

Once you have a shortlist of potential suppliers, compare their pricing structures and terms of sale. Look beyond just the initial cost and consider long-term value, including warranty periods and after-sales support.

- Volume Discounts: Inquire about pricing for bulk purchases, which can lead to significant savings.

- Payment Terms: Understand the payment options available to manage your cash flow effectively.

Step 6: Assess Customer Support and After-Sales Service

Robust customer support is essential for addressing any post-purchase issues. Evaluate the supplier’s responsiveness and willingness to assist with technical queries or warranty claims.

- Technical Support: Ensure that the supplier offers readily available technical assistance.

- Warranty and Returns: Understand the warranty policies and return procedures for defective products.

Step 7: Finalize Your Purchase Agreement

Before placing your order, ensure that all terms are clearly outlined in a purchase agreement. This document should include delivery timelines, payment terms, and any other relevant conditions.

- Clarity: Ensure there are no ambiguities in the agreement to avoid disputes later.

- Flexibility: Consider including terms for potential adjustments based on market conditions or project changes.

By following this structured checklist, B2B buyers can effectively navigate the procurement process for spline shaft couplings, ensuring they select the right products from reputable suppliers while optimizing their investment.

Comprehensive Cost and Pricing Analysis for spline shaft coupling Sourcing

When sourcing spline shaft couplings, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will delve into the various cost components, price influencers, and practical buyer tips tailored for businesses in regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components of Spline Shaft Couplings?

The cost structure for spline shaft couplings can be broken down into several essential components:

-

Materials: The choice of materials significantly affects pricing. Common materials include steel, aluminum, and magnesium alloys. High-quality materials often lead to higher initial costs but can offer improved durability and performance, resulting in lower maintenance costs over time.

-

Labor: Labor costs can vary by region and manufacturing method. For instance, manual machining may incur higher labor costs compared to automated processes. Countries with lower labor costs might offer more competitive pricing but could impact quality.

-

Manufacturing Overhead: This encompasses costs related to utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead, thereby reducing the overall cost of the coupling.

-

Tooling: Custom tooling for specific coupling designs can represent a significant upfront investment. However, for standard products, these costs may be amortized over larger production runs, decreasing per-unit pricing.

-

Quality Control (QC): Rigorous QC measures ensure that couplings meet specified standards, which can add to manufacturing costs. However, investing in quality checks can reduce the risk of defects and associated costs in the supply chain.

-

Logistics: The shipping and handling of couplings, especially for international buyers, can vary widely based on distance, shipping methods, and customs regulations. Incoterms (International Commercial Terms) play a crucial role in determining who bears these costs.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can fluctuate based on market demand, competition, and the supplier’s overall business strategy.

What Factors Influence the Pricing of Spline Shaft Couplings?

Several key factors influence the pricing of spline shaft couplings:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for bulk purchases. Understanding the MOQ can help buyers negotiate better prices, especially when planning for larger projects.

-

Specifications and Customization: Customized couplings tailored to specific applications may incur higher costs due to unique design requirements. Standardized products tend to be more competitively priced.

-

Materials and Quality Certifications: Higher-grade materials and certifications (e.g., ISO, CE) can significantly impact pricing. Buyers should evaluate the trade-off between upfront costs and long-term reliability.

-

Supplier Factors: Supplier reputation, reliability, and location can affect both pricing and lead times. Establishing a relationship with trusted suppliers may yield better pricing and service.

-

Incoterms: Understanding shipping terms can help buyers calculate the total landed cost of products. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly influence the overall cost structure.

What Are the Best Practices for Negotiating Spline Shaft Coupling Prices?

For international B2B buyers, effective negotiation and cost management are paramount:

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operational costs, and potential downtime. A slightly higher upfront cost may lead to significant savings in the long run.

-

Leverage Volume Discounts: If your business can commit to larger orders, use this leverage to negotiate better pricing.

-

Explore Alternative Suppliers: Don’t hesitate to source from multiple suppliers to compare pricing and service levels. Consider both local and international options.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, import duties, and shipping costs can all impact the final price. Factor these into your budget and negotiations.

Conclusion

When sourcing spline shaft couplings, a comprehensive understanding of cost components, pricing influencers, and effective negotiation strategies is essential. By taking these factors into account, B2B buyers can make informed decisions that align with their operational needs and budget constraints. While prices can vary widely, a strategic approach will help in achieving the best value for money. Always remember that prices quoted may vary, and it’s advisable to request detailed quotes from suppliers to get the most accurate and current pricing information.

Alternatives Analysis: Comparing spline shaft coupling With Other Solutions

Exploring Alternatives to Spline Shaft Couplings

In the realm of mechanical power transmission, selecting the right coupling solution is critical for optimizing performance and ensuring longevity. While spline shaft couplings are renowned for their efficiency in connecting shafts, it’s essential for B2B buyers to consider alternative coupling technologies that may better suit specific applications or budget constraints. Below, we compare spline shaft couplings with two viable alternatives: keyed couplings and flexible couplings.

| Comparison Aspect | Spline Shaft Coupling | Keyed Coupling | Flexible Coupling |

|---|---|---|---|

| Performance | Excellent torque transfer; minimal backlash | Good torque transfer; limited to specific alignment | High shock absorption; compensates for misalignment |

| Cost | Moderate to high cost | Generally lower cost | Varies widely, often moderate to high |

| Ease of Implementation | Requires precise machining | Simple installation; widely available | More complex due to flexibility requirements |

| Maintenance | Low maintenance needs; durable | Low maintenance; reliable | Regular checks needed for wear |

| Best Use Case | High-torque applications; precision machinery | General-purpose use; standard machinery | Applications with significant vibration or misalignment |

What Are the Advantages and Disadvantages of Keyed Couplings?

Keyed couplings are a traditional choice in power transmission, where a key fits into a slot on the shaft and coupling, ensuring a secure connection. The primary advantage of keyed couplings is their cost-effectiveness and straightforward installation process. They are readily available and suitable for general applications where precision is not critical. However, they may not handle high torque loads as effectively as spline couplings and can be prone to wear over time, especially under heavy usage.

How Do Flexible Couplings Compare to Spline Shaft Couplings?

Flexible couplings are designed to accommodate misalignment and absorb shock, making them ideal for applications involving vibrations or dynamic loads. These couplings excel in environments where equipment may experience movement, thus prolonging the lifespan of connected components. However, their complexity can pose challenges during installation, and they typically require more frequent maintenance checks to ensure optimal performance. They may also be more expensive, depending on the materials used and the design.

Making the Right Choice: How Can B2B Buyers Select the Best Coupling Solution?

When choosing between spline shaft couplings and their alternatives, B2B buyers should consider the specific requirements of their applications. Keyed couplings might be the best choice for cost-sensitive projects with standard machinery requirements. Conversely, if the application involves high torque or precision machinery, spline shaft couplings would be more suitable. For environments with significant vibrations or misalignment, flexible couplings could offer the best performance, despite potentially higher costs and maintenance needs. Ultimately, understanding the operational environment, performance needs, and budget will guide buyers to the most appropriate coupling solution for their applications.

Essential Technical Properties and Trade Terminology for spline shaft coupling

What Are the Key Technical Properties of Spline Shaft Couplings?

Understanding the essential technical properties of spline shaft couplings is crucial for B2B buyers to ensure they select the right components for their machinery. Here are some critical specifications to consider:

-

Material Grade

Spline shaft couplings are often made from various materials, including steel, aluminum, and magnesium alloys. Steel, particularly CNC machined steel, offers high strength and durability, making it suitable for high-torque applications. The choice of material affects the coupling’s weight, strength, and corrosion resistance, which are vital for performance and longevity. -

Bore Diameter

The bore diameter is a key measurement that indicates the inner diameter of the coupling, which must match the diameter of the shafts it will connect. Common bore sizes range from 1 inch to larger diameters, depending on the application. Ensuring the correct bore diameter is critical to achieving a secure fit and preventing slippage during operation. -

Tooth Count and Profile

The tooth count of the spline affects the coupling’s torque transmission capabilities. A higher tooth count generally allows for smoother operation and greater torque transfer. Additionally, the tooth profile—whether it is straight, involute, or other shapes—can influence the coupling’s efficiency and alignment. Understanding these profiles helps in selecting couplings that maximize performance. -

Tolerance Levels

Tolerance levels refer to the allowable deviation from specified dimensions. For spline couplings, tight tolerances are essential to ensure proper fit and function, especially in high-speed applications. Poor tolerances can lead to misalignment, increased wear, and potential failure of the coupling, making this specification critical for operational reliability. -

Length and Overall Dimensions

The overall length and diameter of the coupling must also be considered. These dimensions affect the coupling’s compatibility with existing machinery and its ability to handle axial loads. Buyers need to ensure that the selected coupling fits within the spatial constraints of their equipment while providing the necessary performance characteristics.

What Are Common Trade Terms Related to Spline Shaft Couplings?

In the B2B environment, familiarity with trade terminology is essential for effective communication and negotiation. Here are some common terms relevant to spline shaft couplings:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of spline couplings, OEMs often provide specific components that meet stringent quality and performance standards, making them reliable choices for buyers. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is important for buyers to manage inventory effectively and negotiate favorable terms, particularly when sourcing components like spline couplings from international suppliers. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. In the context of spline shaft couplings, an RFQ would detail the specifications needed, allowing suppliers to provide accurate pricing and availability. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Understanding Incoterms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), helps in clarifying shipping responsibilities and costs associated with the purchase of spline couplings. -

Lead Time

Lead time refers to the time it takes from placing an order to the delivery of the product. For B2B buyers, understanding lead times is essential for project planning and inventory management, especially when sourcing critical components like spline couplings from global suppliers. -

Certification

This term indicates that a product meets specific industry standards or regulations. Certifications for spline couplings can include ISO or ASTM standards, which assure buyers of the product’s quality and reliability, making certification a key consideration in procurement decisions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing spline shaft couplings, ensuring compatibility and performance that meets their operational needs.

Navigating Market Dynamics and Sourcing Trends in the spline shaft coupling Sector

What Are the Current Market Dynamics and Key Trends in the Spline Shaft Coupling Sector?

The spline shaft coupling market is experiencing significant growth driven by increasing industrial automation and demand for power transmission solutions across various sectors. Key markets include manufacturing, automotive, and renewable energy, particularly in regions like Africa, South America, the Middle East, and Europe. These areas are witnessing a surge in infrastructure projects and industrial activities, necessitating reliable and efficient coupling solutions.

Emerging B2B technology trends such as the integration of IoT (Internet of Things) in machinery are influencing sourcing strategies. Smart couplings that provide real-time monitoring and diagnostics are becoming increasingly popular, allowing companies to enhance efficiency and minimize downtime. Additionally, the rise of e-commerce platforms is transforming how international buyers source spline shaft couplings, making it easier to compare products, prices, and suppliers globally.

Sourcing dynamics are also evolving due to geopolitical factors and supply chain disruptions. Buyers must be agile, considering local suppliers to mitigate risks associated with longer supply chains. This has led to a growing preference for suppliers who offer customization and flexibility in their product offerings, catering to specific application needs.

How Important Is Sustainability and Ethical Sourcing in the Spline Shaft Coupling Sector?

As global awareness of environmental issues increases, sustainability and ethical sourcing have become critical considerations for B2B buyers in the spline shaft coupling sector. The environmental impact of manufacturing processes, particularly in terms of resource consumption and waste generation, is under scrutiny. Buyers are increasingly seeking suppliers who prioritize sustainable practices, including the use of eco-friendly materials and energy-efficient production methods.

Ethical supply chains are also gaining traction. Companies are expected to ensure that their suppliers adhere to fair labor practices and maintain transparency throughout the supply chain. This is particularly relevant for international buyers from regions with stringent regulations on corporate social responsibility (CSR).

The adoption of ‘green’ certifications and materials is becoming a vital aspect of procurement. Buyers are encouraged to look for products that meet established environmental standards, which can also enhance their brand reputation. By prioritizing sustainability, companies can not only reduce their carbon footprint but also appeal to a growing segment of environmentally conscious consumers.

What Is the Historical Context of Spline Shaft Couplings and Their Evolution?

The evolution of spline shaft couplings dates back to the early 20th century, when industrial machinery began requiring more reliable methods of connecting rotating components. Traditional keyed couplings were soon supplemented by splined designs, which provided greater torque transmission and alignment capabilities. The development of advanced materials and manufacturing techniques has further enhanced the performance and durability of these couplings.

Over the decades, spline shaft couplings have adapted to meet the changing needs of various industries, including automotive, aerospace, and heavy machinery. Innovations such as flexible couplings have emerged to accommodate misalignments and reduce stress on components, thereby extending their life cycle. Today, the focus on high-performance materials and smart technologies is shaping the future of spline shaft couplings, ensuring they remain integral to efficient power transmission solutions worldwide.

In conclusion, understanding the market dynamics, sustainability considerations, and historical context of spline shaft couplings is essential for international B2B buyers. This knowledge equips them to make informed sourcing decisions that align with both their operational needs and corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of spline shaft coupling

-

How do I choose the right spline shaft coupling for my application?

Choosing the right spline shaft coupling involves assessing several factors, including the torque requirements, the size and type of the shafts being connected, and the environmental conditions of the application. For high-torque applications, a robust coupling with a high-strength material is essential. Additionally, consider the type of spline—whether it’s a standard or custom profile—as this affects compatibility. Always consult technical specifications and, if possible, work with suppliers who can provide samples or technical support to ensure the right fit for your needs. -

What are the common materials used in spline shaft couplings?

Spline shaft couplings are commonly made from materials like steel, aluminum, and magnesium alloys. Steel is typically preferred for its strength and durability, making it ideal for high-load applications. Aluminum offers a lighter alternative, suitable for applications where weight is a concern. Magnesium alloys are known for their excellent strength-to-weight ratio and corrosion resistance, making them suitable for harsh environments. When selecting materials, consider factors such as weight, strength, and environmental exposure to ensure optimal performance. -

What should I consider when vetting international suppliers for spline shaft couplings?

When vetting international suppliers, assess their manufacturing capabilities, quality certifications (like ISO 9001), and experience in the industry. It’s essential to check references and customer reviews to gauge reliability. Additionally, evaluate their logistics capabilities, including shipping options and lead times, to ensure they can meet your delivery needs. Request samples to verify quality and consider suppliers who offer customization options to better suit your specific requirements. Building a relationship with your supplier can also facilitate smoother transactions and better service. -

What are typical minimum order quantities (MOQs) for spline shaft couplings?

Minimum order quantities (MOQs) for spline shaft couplings can vary significantly based on the supplier and the complexity of the product. Standard couplings may have MOQs ranging from 10 to 100 units, while custom designs might require larger orders due to setup costs. It’s advisable to discuss your specific needs with suppliers, as some may be willing to accommodate smaller orders, especially if you are a repeat customer or if they have existing inventory. Negotiating terms that align with your production needs is crucial for maintaining cash flow. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely among international suppliers, but common practices include advance payment, net 30, or net 60 terms. For first-time orders, suppliers may require full payment upfront to mitigate risk. As you build a relationship, you may negotiate more favorable terms. Consider using secure payment methods like letters of credit or escrow services to protect your investment. Always clarify payment terms before finalizing orders to avoid misunderstandings and ensure a smooth transaction process. -

How can I ensure quality assurance (QA) for my spline shaft couplings?

To ensure quality assurance for spline shaft couplings, request detailed product specifications and compliance certificates from your supplier. It’s beneficial to establish a quality control process that includes inspections upon receipt of goods. You may also consider third-party inspection services to validate product quality before shipment. Additionally, inquire about the supplier’s QA practices, including their testing methods and materials certification. Regular communication and feedback can help maintain quality standards throughout the supply chain. -

What logistics considerations should I keep in mind when importing spline shaft couplings?

When importing spline shaft couplings, consider shipping methods, lead times, and customs regulations in your country. Choose a reliable logistics partner who can navigate international shipping and handle customs clearance efficiently. It’s important to factor in potential delays, especially in regions with complex import regulations. Additionally, ensure that you have adequate insurance coverage for your shipments to protect against loss or damage during transit. Planning for these logistics aspects can help minimize disruptions in your supply chain. -

Can spline shaft couplings be customized to fit specific applications?

Yes, many manufacturers offer customization options for spline shaft couplings to meet specific application requirements. Customizations can include adjustments to dimensions, materials, or spline profiles to ensure compatibility with your equipment. When seeking custom solutions, provide detailed specifications and application requirements to the supplier. Collaborating closely during the design phase can lead to more effective and tailored solutions, ensuring that the couplings perform optimally in your unique operational context.

Top 8 Spline Shaft Coupling Manufacturers & Suppliers List

1. McMaster – Splined Shaft Couplings

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Splined Shaft Couplings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Huco – Splined Shafts & Hubs

Domain: huco.com

Registered: 1996 (29 years)

Introduction: Splined Shafts & Hubs, Clamp Collars, Splined Clamp Collars, Splined Hubs (Flanged and Round), Metric and Imperial Profiles available, Various sizes including KN and KW profiles with dimensions such as 42 x 48, 11 x 14, 26 x 32, 32 x 38, and more. Overall diameters range from 20.0 mm to 100.0 mm. Free shipping on orders over £30/$30/€30 for Europe & North America, weight limit of 25kg/55lbs, size …

3. Concentric – Keyed, Splined & Hex Couplers

Domain: surpluscenter.com

Registered: 1996 (29 years)

Introduction: Keyed, Splined & Hex 1 Piece Solid Couplers; Category: Shaft Couplers; Price Range: $7.30 – $53.35; Brands: Concentric, G & G Mfg; Available Sizes: 1/2″, 5/8″, 3/4″, 7/8″, 1″, 1-1/8″; Stock Availability: Ranges from 10 to 999+ items in stock for various couplers; Item Numbers: 1-1563-A, 1-1495, 1-1563-B, 1-2985, 1-5696-75, 1-1563-C, 1-5696-87, 1-1655, 1-1392, 1-1563-D, 1-5696-100, 1-1560, 1-1561, …

4. Hydro-Craft – Splined Flexible Drive Couplings

Domain: hydro-craft.com

Registered: 1997 (28 years)

Introduction: Splined Flexible Drive Couplings from Hydro-Craft® are lightweight, heavy-duty flexible drive couplings made from solid magnesium alloy permanent mold castings that are heat treated for maximum strength. They are 76% lighter than iron and 36% lighter than aluminum units of similar design, which reduces loads on bearings, shafts, and pumps, leading to longer component life. The couplings are rust-p…

5. OneHydraulics – Hydraulic & Pneumatic Equipment

Domain: onehydraulics.com

Registered: 2016 (9 years)

Introduction: This company, OneHydraulics – Hydraulic & Pneumatic Equipment, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Universal – 1 3/4 20 Spline Shaft Coupling

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Shaft Coupling Size”:”1 3/4″ 20 Splines”,”Length”:”6 inches”,”Material”:”1045 Carbon Steel”,”Condition”:”New”,”Compatible Equipment Make”:”Universal”,”Compatible Equipment Type”:”Tractor”,”Item Number”:”145707151551″,”Price”:”$65.99″,”Shipping Cost”:”$12.75″,”Estimated Delivery”:”Wed, Sep 10 – Sat, Sep 13″,”Seller Feedback”:”100% positive feedback”}

7. RuggedMade – 1 Inch Bore Spline Coupling

Domain: ruggedmade.com

Registered: 2012 (13 years)

Introduction: {“SKU”:”94-020-0902″,”Bore Diameter”:”1 inch”,”Material”:”CNC sintered steel”,”Outer Diameter”:”1.5 inches”,”Overall Length”:”2.25 inches”,”Manufacturer”:”RuggedMade”,”Part Number”:”163-1606″,”Product Weight”:”0.56 lbs”,”Shaft Style”:”1 inch bore, 2-1/4 inch length, 6-tooth spline”}

8. Regal Rexnord – Hub City® Involute Splined Couplings

Domain: regalrexnord.com

Registered: 2021 (4 years)

Introduction: Hub City® Involute Splined Couplings

Strategic Sourcing Conclusion and Outlook for spline shaft coupling

In the evolving landscape of industrial applications, the strategic sourcing of spline shaft couplings has become paramount for businesses seeking efficiency and reliability. As highlighted throughout this guide, the right coupling not only ensures the seamless transfer of torque between rotating shafts but also contributes to the longevity of equipment by reducing wear and tear. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should prioritize partnerships with suppliers who offer high-quality, durable products that meet specific operational needs.

Moreover, embracing a strategic sourcing approach allows companies to leverage competitive pricing, innovative designs, and superior materials, which are essential for optimizing performance and minimizing downtime. As the market continues to advance, the demand for lightweight and corrosion-resistant materials, such as magnesium alloys, is likely to increase, paving the way for more efficient manufacturing processes.

Looking ahead, international B2B buyers are encouraged to explore diverse sourcing options and foster relationships with manufacturers that prioritize technological innovation and customer service. By doing so, businesses can position themselves to thrive in a competitive marketplace, ensuring they remain at the forefront of industry advancements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.