Screw Bolt: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for screw bolt

In today’s competitive landscape, sourcing reliable screw bolts that meet specific project requirements can be a daunting challenge for B2B buyers across the globe. Whether you are in Nigeria, Brazil, or anywhere in Europe, understanding the nuances of screw bolt specifications, materials, and applications is crucial for making informed purchasing decisions. This guide is designed to demystify the global market for screw bolts, providing you with a comprehensive overview that encompasses various types, applications, and supplier vetting processes.

Throughout this guide, you will discover essential insights into the diverse range of screw bolts available, from high-performance anchors suitable for heavy-duty applications to specialized fasteners designed for unique environments. We will also delve into the critical factors influencing cost, helping you to optimize your procurement strategy while ensuring quality and compliance with international standards.

Furthermore, we emphasize the importance of thorough supplier evaluation, empowering you to establish partnerships that align with your business goals. By equipping yourself with this knowledge, you will not only enhance your purchasing strategy but also streamline your operations, ensuring your projects are completed on time and within budget. Prepare to navigate the complexities of the screw bolt market with confidence and clarity, transforming sourcing into a strategic advantage for your business.

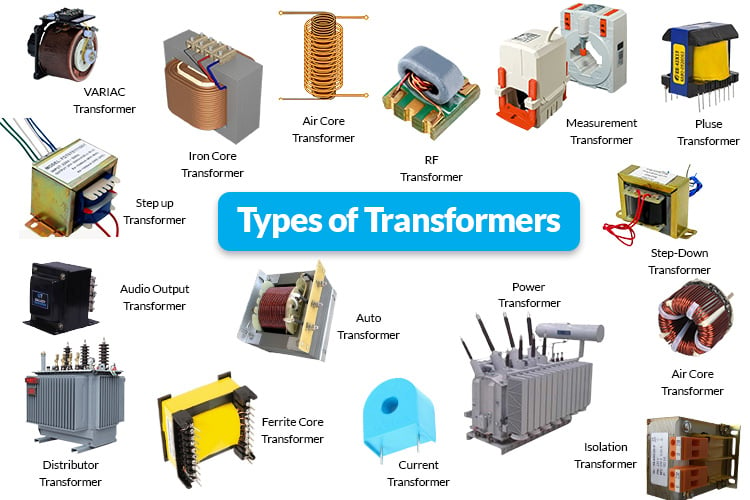

Understanding screw bolt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hex Head Bolt | Hexagonal head, offers better grip and torque application | Heavy machinery, construction, automotive | Pros: High torque resistance; Cons: Requires specific wrench size. |

| Carriage Bolt | Rounded head with square neck, prevents spinning during installation | Wood and metal fastening, outdoor structures | Pros: Easy to install; Cons: Limited to certain applications. |

| Lag Bolt | Large diameter, coarse threads for heavy-duty applications | Timber construction, deck building | Pros: Strong hold in wood; Cons: Requires pre-drilling. |

| Eye Bolt | Looped head for attaching cables or ropes | Rigging, lifting applications, marine use | Pros: Versatile for lifting; Cons: Limited load capacity. |

| Flange Bolt | Integrated washer, distributes load over a larger area | HVAC systems, automotive assembly | Pros: Reduces risk of loosening; Cons: Higher cost than standard bolts. |

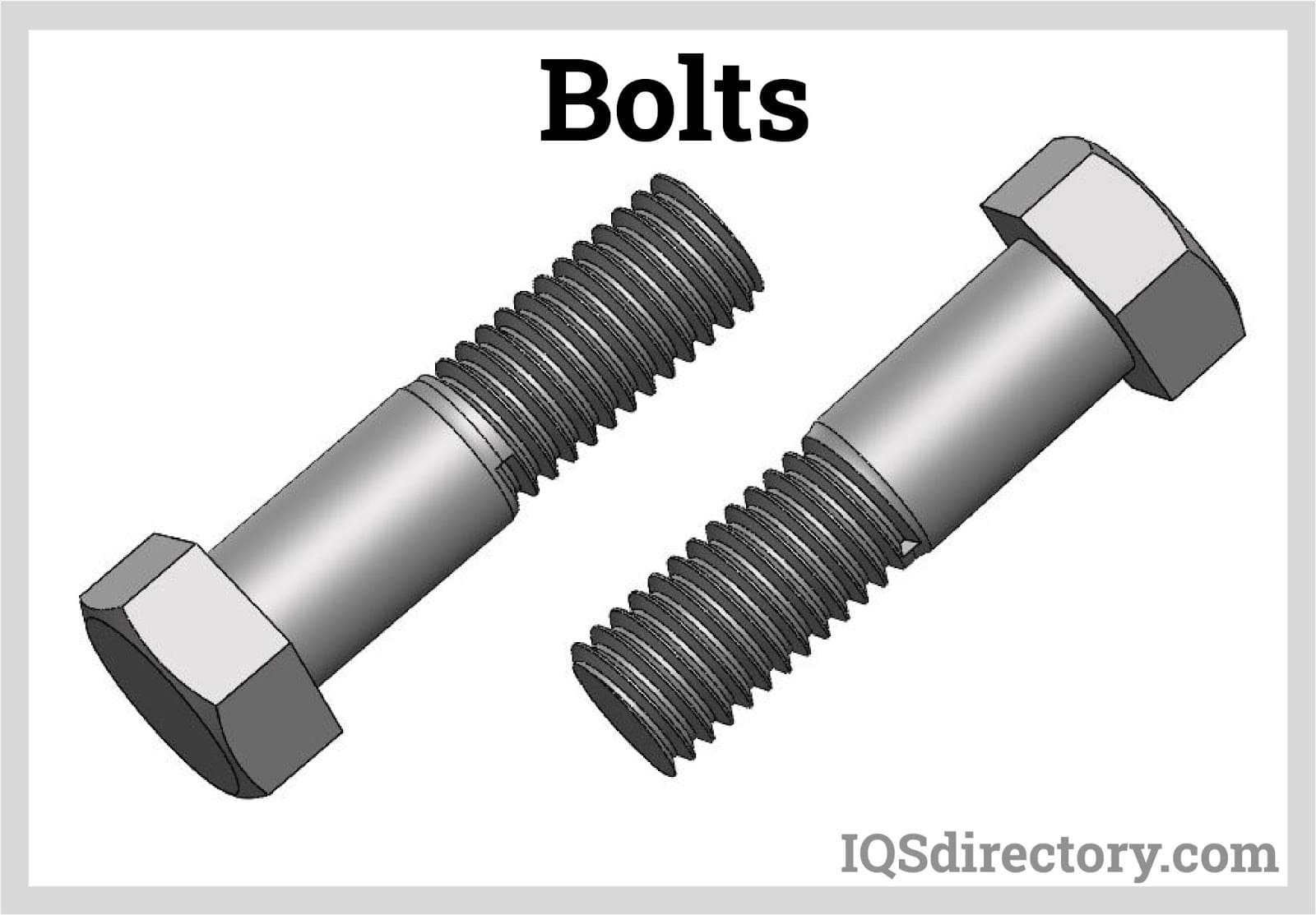

What are the Characteristics of Hex Head Bolts and Their Suitability in B2B Applications?

Hex head bolts are characterized by their hexagonal heads, which allow for a higher torque application than other bolt types. They are primarily used in heavy machinery, construction, and automotive applications, where strong fastening is essential. When purchasing hex head bolts, buyers should consider the required torque specifications and the corresponding wrench sizes to ensure compatibility with their tools.

How Do Carriage Bolts Stand Out in Fastening Applications?

Carriage bolts feature a rounded head and a square neck that prevents them from spinning when tightened. They are ideal for fastening wood to metal and are commonly used in outdoor structures like decks and fences. Buyers should evaluate the material and environmental conditions, as carriage bolts may require coatings to prevent rust in outdoor applications.

Why Choose Lag Bolts for Heavy-Duty Applications?

Lag bolts are designed with a large diameter and coarse threads, making them suitable for heavy-duty applications, particularly in timber construction and deck building. Their strong hold is ideal for fastening large wooden structures. When sourcing lag bolts, buyers should assess the need for pre-drilling to ensure proper installation and the weight requirements of the application.

What Makes Eye Bolts a Versatile Choice for Rigging?

Eye bolts are uniquely designed with a looped head, allowing for easy attachment of cables or ropes. They are widely used in rigging and lifting applications, particularly in marine environments. Buyers should consider the load capacity and material of the eye bolts to ensure they meet the specific lifting requirements of their operations.

How Do Flange Bolts Provide Enhanced Performance in Specific Applications?

Flange bolts come with an integrated washer that helps distribute the load over a larger surface area, reducing the risk of loosening. They are commonly used in HVAC systems and automotive assemblies. Buyers should weigh the benefits of enhanced stability against the higher cost compared to standard bolts, especially when planning large-scale projects.

Key Industrial Applications of screw bolt

| Industry/Sector | Specific Application of screw bolt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Anchoring structural elements in concrete | Provides strong, reliable connections that enhance safety and stability. | Ensure compliance with local building codes and standards. |

| Manufacturing | Assembling machinery and equipment | Facilitates quick assembly and disassembly for maintenance and repairs. | Consider the specific load requirements and corrosion resistance. |

| Automotive | Attaching components in vehicle assembly | Ensures durability and reliability of vehicle parts under stress. | Look for high-strength materials suitable for automotive applications. |

| Renewable Energy | Securing wind turbine components | Enhances the structural integrity and longevity of renewable energy installations. | Evaluate weather resistance and environmental impact on materials. |

| Infrastructure Development | Fixing railings and barriers in public spaces | Improves safety and accessibility in urban environments. | Source materials that meet international safety standards. |

How is ‘screw bolt’ Used in Construction and What Problems Does it Solve?

In the construction industry, screw bolts are extensively used for anchoring structural elements to concrete. They provide strong, reliable connections that are critical for ensuring the safety and stability of buildings and other structures. For international buyers, especially in regions like Africa and South America where construction standards may vary, sourcing screw bolts that comply with local building codes is essential. Additionally, understanding the load-bearing capacity and environmental conditions of the installation site can significantly impact the choice of screw bolts.

What are the Applications of Screw Bolts in Manufacturing?

In manufacturing, screw bolts play a vital role in assembling machinery and equipment. Their design allows for quick assembly and disassembly, facilitating maintenance and repairs without extensive downtime. Buyers should consider the specific load requirements of their machinery and select screw bolts that offer corrosion resistance, particularly in humid environments prevalent in the Middle East and parts of Europe. This ensures that the machinery remains operational and safe over time.

How Do Screw Bolts Contribute to the Automotive Sector?

In the automotive industry, screw bolts are essential for attaching various components during vehicle assembly. They ensure the durability and reliability of parts, which is crucial given the stress and vibrations experienced during vehicle operation. B2B buyers in this sector need to focus on sourcing high-strength materials that meet automotive specifications, particularly in regions like Brazil where automotive manufacturing is significant. The right screw bolts can enhance vehicle performance and safety.

What Role Do Screw Bolts Play in Renewable Energy Projects?

Screw bolts are critical in securing components of renewable energy installations, such as wind turbines. They contribute to the structural integrity and longevity of these systems, which are often exposed to harsh environmental conditions. Buyers should evaluate the weather resistance of screw bolts, particularly in regions with extreme climates, to ensure that their renewable energy projects remain efficient and durable over time.

How are Screw Bolts Used in Infrastructure Development?

In infrastructure development, screw bolts are commonly used for fixing railings and barriers in public spaces, enhancing safety and accessibility. This application is particularly relevant in urban environments across Europe and Africa, where public safety regulations are stringent. When sourcing screw bolts for these applications, it is crucial to select materials that comply with international safety standards to ensure public confidence and regulatory compliance.

3 Common User Pain Points for ‘screw bolt’ & Their Solutions

Scenario 1: Difficulty in Identifying the Right Screw Bolt Type for Specific Applications

The Problem: One of the most common challenges faced by B2B buyers in sectors such as construction and manufacturing is selecting the appropriate screw bolt for their specific applications. With various types of screw bolts available, including hex head, carriage bolts, and lag bolts, it can be overwhelming to determine which type best suits the project’s material requirements and load-bearing needs. For example, a buyer might mistakenly choose a standard screw bolt for a high-load application, leading to potential structural failures or costly rework.

The Solution: To mitigate this issue, buyers should prioritize comprehensive material and application assessments before procurement. This involves understanding the load specifications, environmental conditions, and the base materials involved. Utilizing resources such as product datasheets, which often detail load ratings and material compatibility, is crucial. Additionally, engaging with suppliers who offer expert consultations can provide insights tailored to specific project needs. Implementing a checklist for project requirements, including factors like bolt type, finish (e.g., galvanized for corrosion resistance), and installation methods, will streamline the selection process and enhance project efficiency.

Scenario 2: Challenges with Installation Efficiency and Torque Requirements

The Problem: Many B2B buyers experience frustration with the installation of screw bolts, particularly in terms of achieving the correct torque without damaging the materials. Over-tightening can lead to stripping threads or damaging the substrate, while under-tightening may result in insufficient hold, risking structural integrity. This is especially problematic in regions where manual labor is prevalent, and the workforce may not always be trained in best practices for fastener installation.

Illustrative image related to screw bolt

The Solution: To enhance installation efficiency and accuracy, buyers should consider investing in screw bolts with patented designs that minimize torque requirements, such as the Screw-Bolt+™. These anchors are engineered to reduce installation torque while providing strong engagement with the material. Additionally, using power tools with torque settings can help achieve the desired tightness without overdoing it. Providing training sessions for installation teams on proper techniques and using torque wrenches can further ensure that bolts are installed correctly. Moreover, creating a culture of quality assurance can lead to long-term benefits, reducing errors and rework associated with improper installations.

Scenario 3: Concerns Over Corrosion and Longevity in Various Environments

The Problem: For B2B buyers operating in diverse climates, especially in regions with high humidity or exposure to chemicals, the longevity of screw bolts can be a significant concern. Corrosion can weaken fasteners over time, leading to structural failures and increased maintenance costs. Buyers often struggle to find the right balance between cost and corrosion resistance, which is crucial for the durability of their projects.

The Solution: To combat corrosion concerns, it is essential for buyers to select screw bolts that come with appropriate protective coatings, such as hot-dip galvanization or stainless steel finishes, depending on the environmental exposure. When sourcing screw bolts, buyers should verify the material specifications and consider the expected environmental conditions. Conducting a life cycle analysis can help quantify the cost implications of corrosion versus the upfront costs of higher-quality materials. Additionally, establishing relationships with reliable suppliers who understand local environmental challenges can lead to better product recommendations and long-term solutions tailored to specific needs. Regular maintenance checks and replacement schedules can also extend the lifespan of fasteners and ensure ongoing structural integrity.

Strategic Material Selection Guide for screw bolt

What Are the Key Properties of Common Screw Bolt Materials?

When selecting materials for screw bolts, it’s essential to consider their properties, as these directly influence performance in various applications. Below are analyses of four common materials used in screw bolt manufacturing.

Steel: A Versatile and Durable Option

Steel is one of the most widely used materials for screw bolts due to its excellent strength-to-weight ratio and durability. It typically has a high tensile strength, making it suitable for applications requiring significant load-bearing capabilities. Steel bolts can be treated for corrosion resistance through galvanization or coating, which enhances their longevity in harsh environments.

Illustrative image related to screw bolt

Pros: Steel bolts are cost-effective and readily available. They can be manufactured with varying grades to meet specific strength requirements.

Cons: Without proper treatment, steel is susceptible to rust and corrosion, especially in humid or saline environments. Additionally, high-temperature applications may require special grades of steel, which can increase costs.

Impact on Application: Steel bolts are ideal for construction and industrial applications where strength and reliability are paramount. However, in coastal regions or areas with high humidity, the risk of corrosion must be managed.

Stainless Steel: Corrosion Resistance for Challenging Environments

Stainless steel is an alloy known for its corrosion resistance, making it an excellent choice for applications exposed to moisture or chemicals. The addition of chromium provides a protective layer that prevents rust and degradation.

Pros: Stainless steel bolts maintain their integrity in harsh environments, making them suitable for marine applications and chemical processing. They also have a polished finish, enhancing aesthetic appeal.

Cons: The cost of stainless steel is generally higher than that of carbon steel, which can be a limiting factor for large-scale projects. Additionally, while they resist corrosion, they may not be as strong as some carbon steel grades.

Impact on Application: In regions like Brazil and Nigeria, where humidity can be high, stainless steel bolts are preferred for outdoor structures and equipment exposed to the elements.

Aluminum: Lightweight and Non-Corrosive

Aluminum bolts are known for their lightweight properties and resistance to corrosion. They are often used in applications where weight savings are critical, such as in aerospace and automotive industries.

Pros: Aluminum bolts are easy to handle and install due to their low weight. They also have good thermal and electrical conductivity.

Illustrative image related to screw bolt

Cons: While aluminum has decent strength, it is generally not suitable for high-load applications compared to steel. Additionally, aluminum can be more expensive and may require special handling to avoid galling during installation.

Impact on Application: In sectors like aviation and automotive, where weight efficiency is crucial, aluminum bolts are highly valued. However, their use may be limited in heavy construction applications.

Brass: A Unique Choice for Specialized Applications

Brass bolts, composed of copper and zinc, offer good corrosion resistance and are often used in plumbing and electrical applications. Their non-magnetic properties make them suitable for specific electronic applications.

Pros: Brass bolts are resistant to corrosion from saltwater and are ideal for marine applications. They also have a pleasing appearance, making them suitable for decorative uses.

Cons: Brass is softer than steel, which limits its load-bearing capacity. It is also more expensive than standard steel options.

Impact on Application: In the Middle East, where saltwater exposure is common, brass bolts are preferred for marine and plumbing applications. However, their use in structural applications is limited due to lower strength.

Summary of Material Selection for Screw Bolts

| Material | Typical Use Case for screw bolt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Construction, industrial | High strength and cost-effective | Susceptible to corrosion without treatment | Medium |

| Stainless Steel | Marine, chemical processing | Excellent corrosion resistance | Higher cost, lower strength than some steels | High |

| Aluminum | Aerospace, automotive | Lightweight and easy to handle | Lower strength, more expensive | Medium |

| Brass | Plumbing, electrical | Good corrosion resistance, aesthetic | Softer material, limited load-bearing capacity | High |

This analysis provides a comprehensive overview of the materials commonly used in screw bolts, enabling international B2B buyers to make informed decisions based on their specific application needs and regional conditions.

Illustrative image related to screw bolt

In-depth Look: Manufacturing Processes and Quality Assurance for screw bolt

What Are the Key Manufacturing Processes for Screw Bolts?

The manufacturing of screw bolts involves several critical stages that ensure the final product meets quality standards and performance requirements. Each stage is designed to optimize efficiency while maintaining the integrity of the fasteners.

How Is Material Prepared for Screw Bolt Production?

The manufacturing process begins with material selection, typically high-grade steel, which is chosen for its strength and durability. The steel is then subjected to a series of treatments, including annealing, to enhance its ductility and toughness. Following this, the raw materials are cut into precise lengths according to the specifications of the screw bolt design.

What Forming Techniques Are Used in Screw Bolt Manufacturing?

Forming is a crucial stage where the prepared materials are shaped into screw bolts. Common techniques include:

- Cold Heading: This is the most widely used method, where metal is deformed at room temperature using a die. Cold heading enhances the material’s strength by aligning the grain structure.

- Thread Rolling: After the bolt is formed, threads are created through a rolling process, which not only shapes the threads but also strengthens the bolt by compressing the material.

- Hot Forging: For larger bolts or those requiring specific mechanical properties, hot forging may be employed, where the material is heated and then shaped under high pressure.

Each forming technique has its advantages, and the choice often depends on the application requirements, such as load capacity and environmental conditions.

How Are Screw Bolts Assembled and Finished?

After forming, screw bolts undergo assembly if they are part of a more complex fastener system. This may involve integrating components like washers or nuts. The finishing stage involves surface treatments to enhance corrosion resistance and aesthetic appeal. Common finishes include:

- Zinc Plating: Provides basic corrosion protection for indoor applications.

- Galvanization: Offers enhanced durability for outdoor or marine applications.

- Black Oxide Coating: Used for aesthetic purposes and mild corrosion resistance.

These finishing processes ensure that the screw bolts perform effectively in their intended environments.

What Quality Assurance Measures Are Commonly Implemented?

Quality assurance (QA) is vital in the manufacturing of screw bolts, ensuring that each product meets international standards and industry-specific requirements.

Which International Standards Govern Screw Bolt Quality?

Manufacturers often adhere to various international standards, with ISO 9001 being the most recognized for quality management systems. This standard ensures that companies have processes in place to consistently meet customer and regulatory requirements.

Illustrative image related to screw bolt

In addition to ISO standards, industry-specific certifications may be necessary, such as:

- CE Marking: Required for products sold within the European Economic Area, indicating compliance with EU safety, health, and environmental protection standards.

- API Spec Q1: Relevant for manufacturers supplying the oil and gas industry, ensuring quality in the production of equipment and materials.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are critical in maintaining the integrity of the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to detect and correct any deviations from standards.

- Final Quality Control (FQC): A thorough inspection of the finished product, including dimensional checks, mechanical property tests, and surface inspections.

These checkpoints are integral to the manufacturing process, allowing for timely interventions and maintaining product quality.

What Testing Methods Are Used to Ensure Screw Bolt Quality?

Various testing methods are employed to verify that screw bolts meet the required specifications:

- Tensile Testing: Determines the material’s strength and ductility.

- Hardness Testing: Assesses the material’s resistance to deformation.

- Corrosion Testing: Evaluates the effectiveness of surface treatments.

- Dimensional Inspection: Ensures that the bolt meets specified tolerances.

These tests provide manufacturers and buyers with confidence in the performance and reliability of the screw bolts.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

Illustrative image related to screw bolt

-

Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing practices, quality control measures, and compliance with international standards.

-

Request Quality Reports: Ask for detailed quality assurance reports, including results from tests and inspections, to gauge the supplier’s commitment to quality.

-

Engage Third-Party Inspectors: Utilize independent inspection services to verify that the products meet specified standards and are free from defects before shipment.

-

Check Certifications: Ensure that suppliers possess relevant certifications and adhere to recognized standards, which can provide assurance of their quality management practices.

What Are the Unique Considerations for International B2B Buyers?

B2B buyers in different regions may encounter unique challenges related to quality control. For instance, understanding local regulations and standards is essential. Buyers from Africa may face different compliance requirements compared to those in Europe.

Additionally, logistical considerations, such as shipping and customs regulations, can impact product quality during transport. It is advisable for buyers to establish clear communication channels with suppliers regarding these factors to ensure a smooth procurement process.

In summary, understanding the manufacturing processes and quality assurance practices for screw bolts is crucial for B2B buyers. By focusing on material preparation, forming techniques, assembly, finishing, and rigorous quality control measures, buyers can make informed decisions when sourcing screw bolts for their projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘screw bolt’

In the competitive landscape of B2B procurement, acquiring the right screw bolts is critical to ensure the integrity and safety of your projects. This guide provides actionable steps to facilitate a streamlined sourcing process for screw bolts, whether you are in Africa, South America, the Middle East, or Europe.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the screw bolts you need. Consider factors such as material type (e.g., stainless steel, galvanized), dimensions (length, diameter, thread type), and performance criteria (corrosion resistance, load capacity). Defining these specifications upfront helps prevent costly errors and mismatches later in the procurement process.

Illustrative image related to screw bolt

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to find suppliers who specialize in screw bolts. Look for companies with a strong track record and positive reviews from other B2B buyers. Utilize online platforms and industry-specific directories to gather a list of potential suppliers, focusing on those who have experience in your specific region or industry needs.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Pay attention to their experience with international shipping and compliance with local regulations, as these factors can significantly impact your procurement process.

Step 4: Request Samples for Testing

Always request samples of the screw bolts to evaluate their quality and suitability for your applications. Testing samples in your operational environment can help you assess performance under specific conditions, such as load-bearing and resistance to environmental factors. This step is essential to ensure that the products meet your technical specifications.

Step 5: Verify Certifications and Compliance

Ensure that the supplier’s products comply with relevant industry standards and certifications. Look for certifications such as ISO 9001 for quality management or specific regional standards that may apply to screw bolts in your market. Compliance not only guarantees product quality but also mitigates risks associated with safety and liability.

Step 6: Negotiate Terms and Conditions

Engage in discussions regarding pricing, payment terms, delivery schedules, and return policies. Ensure that the terms are favorable and reflect the value you expect from the supplier relationship. Clear communication on these aspects can prevent misunderstandings and foster a stronger partnership.

Step 7: Establish a Reliable Order and Delivery System

Set up an efficient ordering system to manage your inventory and ensure timely deliveries. Use technology to track orders, monitor stock levels, and forecast future needs based on project timelines. A reliable logistics plan is vital for maintaining operational continuity and avoiding project delays.

By following these steps, B2B buyers can confidently navigate the sourcing process for screw bolts, ensuring they acquire high-quality products that meet their specific project requirements.

Comprehensive Cost and Pricing Analysis for screw bolt Sourcing

What Are the Key Cost Components for Sourcing Screw Bolts?

When analyzing the cost structure of screw bolts, several critical components must be considered. Materials constitute the largest portion of the cost, influenced by the type of steel (e.g., carbon steel, stainless steel) and any additional coatings (like zinc plating for corrosion resistance). The labor involved in manufacturing varies by region and can significantly affect pricing, especially in developing markets where labor costs may be lower.

Illustrative image related to screw bolt

Manufacturing overhead includes expenses related to facility maintenance, utilities, and administrative costs. Tooling costs are also essential, particularly for custom screw bolts that require specialized molds or dies. Quality control (QC) processes ensure that products meet international standards, which can add to the overall cost but is crucial for maintaining reliability and safety.

Logistics is another significant factor, especially for international buyers. Shipping, customs duties, and storage can all impact the final cost. Finally, suppliers typically include a margin in their pricing to cover their own operating expenses and profit goals.

How Do Price Influencers Affect Screw Bolt Costs?

Several factors influence the pricing of screw bolts. Volume and Minimum Order Quantity (MOQ) play a significant role; larger orders often qualify for bulk discounts, which can dramatically reduce unit costs. Additionally, the specifications and customization required for particular applications can lead to higher prices. For instance, bolts with specific strength requirements or unique dimensions may necessitate more complex manufacturing processes.

The quality and certifications (such as ISO, ASTM) also impact cost. Suppliers that adhere to higher standards will typically charge more, reflecting the added expense of compliance and testing. Other supplier factors, including reliability, reputation, and geographic location, can also affect pricing dynamics. For example, suppliers in regions with high transportation costs may charge more to compensate for those expenses.

Incoterms also play a crucial role in determining the final cost. Understanding terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for accurately assessing total landed costs.

What Are the Best Negotiation Strategies for Screw Bolt Buyers?

For buyers looking to optimize their screw bolt sourcing, negotiation tactics are vital. Start by establishing clear cost-efficiency goals and understanding your Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, storage, and potential replacement costs. This comprehensive view allows for more informed discussions with suppliers.

When negotiating, emphasize long-term relationships. Suppliers may be more willing to offer discounts or favorable terms if they see potential for ongoing business. Additionally, leverage market knowledge—understanding regional price variations and competitor offerings can provide leverage in negotiations.

What Pricing Nuances Should International Buyers Consider?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances. Currency fluctuations can significantly impact costs, so consider securing fixed pricing agreements when possible. Also, be mindful of import tariffs and duties, as these can alter the final price dramatically.

Illustrative image related to screw bolt

Understanding local market dynamics is crucial. In countries like Nigeria and Brazil, regional suppliers may offer competitive pricing due to lower logistics costs compared to overseas shipping. However, ensure that these suppliers meet the necessary quality standards.

Conclusion: Are Indicative Prices Sufficient for Budgeting?

While indicative prices can provide a baseline for budgeting, they are not always reflective of actual costs due to the myriad of influencing factors. Always seek detailed quotes that include all cost components and clarify any uncertainties regarding specifications or additional fees. By taking a comprehensive approach to cost analysis and pricing strategy, buyers can make more informed decisions that align with their operational needs.

Alternatives Analysis: Comparing screw bolt With Other Solutions

Exploring Alternatives to Screw Bolts for Fastening Solutions

In the world of construction and manufacturing, selecting the right fastening solution is crucial for operational efficiency and safety. While screw bolts are widely used for their reliability and ease of use, various alternatives can provide distinct advantages depending on the application. This analysis compares screw bolts against two viable alternatives: Expansion Anchors and Adhesive Anchors.

| Comparison Aspect | Screw Bolt | Expansion Anchors | Adhesive Anchors |

|---|---|---|---|

| Performance | High load capacity; suitable for various materials | Effective in solid substrates; good for dynamic loads | Exceptional bonding; ideal for heavy loads |

| Cost | Moderate cost; varies by size and material | Generally lower upfront cost | Higher initial investment due to materials |

| Ease of Implementation | Simple installation with standard tools | Requires drilling and precise placement | Requires curing time; installation can be complex |

| Maintenance | Minimal maintenance; reusable | Limited; typically permanent unless removed | Low maintenance; may require replacement after demolition |

| Best Use Case | Structural applications, racking, and shelving | Concrete and masonry applications | Heavy-duty applications, retrofitting, and seismic zones |

What Are the Benefits and Drawbacks of Expansion Anchors?

Expansion anchors are a popular alternative to screw bolts, particularly in solid materials like concrete. They work by expanding against the walls of the drilled hole when a bolt is inserted and tightened. One of their key benefits is their lower initial cost compared to screw bolts, making them an attractive option for large projects. However, they require precise drilling and can be challenging to remove once installed, potentially complicating future renovations. Their effectiveness is closely tied to the quality of the substrate, which can limit their use in softer materials.

Illustrative image related to screw bolt

How Do Adhesive Anchors Compare to Screw Bolts?

Adhesive anchors utilize a bonding agent to secure the anchor in place, providing exceptional load-bearing capabilities. They are particularly useful in applications where high tensile strength is required, such as in seismic zones. The primary advantage of adhesive anchors is their ability to bond with various materials, offering versatility that screw bolts may lack. However, they typically involve a higher initial investment and require careful installation to ensure proper curing, which can extend project timelines. Additionally, while they offer low maintenance, they may need to be replaced after significant structural modifications.

How Can B2B Buyers Choose the Right Fastening Solution?

When evaluating fastening solutions, B2B buyers should consider several factors, including the specific requirements of their projects, budget constraints, and the material being used. Screw bolts remain a reliable choice for many applications due to their ease of installation and reusability. However, for projects involving concrete or requiring high load-bearing capacity, expansion or adhesive anchors may provide better performance and cost-effectiveness in the long run. Ultimately, understanding the distinct advantages and limitations of each option will empower buyers to make informed decisions that align with their operational needs and project specifications.

Essential Technical Properties and Trade Terminology for screw bolt

What are the Essential Technical Properties of Screw Bolts for B2B Buyers?

Understanding the critical specifications of screw bolts is vital for B2B buyers to make informed decisions. Here are the key properties to consider:

Illustrative image related to screw bolt

1. Material Grade

Screw bolts are typically made from various materials including carbon steel, stainless steel, and alloy steel. Material grade indicates the strength and corrosion resistance of the bolt. For example, stainless steel bolts (like A2 or A4) offer superior resistance to rust, making them suitable for marine or humid applications. This property is crucial for buyers in sectors like construction or manufacturing, where durability is essential.

2. Tolerance

Tolerance refers to the permissible limit of variation in a bolt’s dimensions. It is critical for ensuring that bolts fit properly with nuts or other components. A tighter tolerance means a more precise fit, reducing the risk of failure under load. In industries where safety is paramount, such as automotive or aerospace, understanding tolerance specifications can prevent costly malfunctions.

3. Coating and Finish

Screw bolts often come with various coatings, such as zinc plating or galvanization. These finishes enhance corrosion resistance and aesthetics. Buyers should consider the environment where the bolt will be used; for instance, galvanized bolts are ideal for outdoor applications, while zinc-plated ones may suffice for indoor use. Coating can significantly affect the longevity of the bolt, making it a vital consideration.

4. Load Capacity

The load capacity of a screw bolt indicates the maximum weight it can support before failure. This property is essential for applications involving heavy machinery or structural components. Buyers must ensure that the chosen bolt can handle the expected loads, particularly in construction and industrial applications where safety is a concern.

5. Length and Diameter

The length and diameter of screw bolts determine their suitability for specific applications. Longer bolts may be needed for thicker materials, while diameter affects the bolt’s strength. B2B buyers should assess the requirements of their projects carefully to select bolts that meet the necessary specifications without compromising performance.

6. Thread Type

Screw bolts come with different thread types, such as coarse or fine threads. Coarse threads provide better grip and are less likely to strip, making them ideal for applications requiring quick assembly. Fine threads, on the other hand, allow for better tension and are often used in precision applications. Understanding thread type is crucial for ensuring compatibility with nuts and other fastening components.

What Are Common Trade Terms Related to Screw Bolts?

Familiarity with industry jargon can enhance communication and negotiation between buyers and suppliers. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in another company’s end product. Understanding whether a supplier is an OEM can help buyers assess quality and compatibility with existing components.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to plan their procurement effectively and avoid excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price proposals from suppliers. B2B buyers should prepare a detailed RFQ, including specifications and quantities, to ensure accurate pricing and timely responses.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, particularly regarding shipping and delivery. Familiarity with these terms helps buyers understand shipping costs, liability, and risk management during transport.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is crucial for planning projects and avoiding delays, especially in industries with tight deadlines.

6. Certification

Certification indicates that a product meets specific standards or regulations. Certifications can include ISO standards or industry-specific quality assurances, providing buyers with confidence in the product’s reliability and performance.

By mastering these technical properties and trade terms, B2B buyers can navigate the complexities of screw bolt procurement with greater confidence and efficiency.

Navigating Market Dynamics and Sourcing Trends in the screw bolt Sector

What Are the Current Market Dynamics and Key Trends Impacting the Screw Bolt Sector?

The screw bolt market is experiencing dynamic shifts driven by several global factors. As construction and manufacturing sectors rebound post-pandemic, demand for high-performance fasteners is rising, particularly in emerging markets like Nigeria and Brazil. The trend towards modular construction and prefabricated building methods is pushing the need for innovative screw bolt solutions that offer ease of installation and reliability. Additionally, the integration of technology in sourcing processes, such as e-commerce platforms and digital supply chains, is revolutionizing how international B2B buyers procure screw bolts. This tech-driven approach allows buyers to access real-time inventory data, streamline ordering processes, and enhance supply chain transparency.

Moreover, sustainability is becoming a pivotal concern. Buyers are increasingly seeking suppliers that demonstrate environmentally responsible practices, from sourcing raw materials to manufacturing processes. The emergence of advanced materials and coatings, such as corrosion-resistant finishes and recycled materials, is influencing product selection. International buyers must stay informed about regulatory changes and product certifications that ensure compliance with local and international standards.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing for Screw Bolts?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the screw bolt sector. The environmental impact of fasteners can be significant, particularly in terms of resource extraction, manufacturing emissions, and end-of-life disposal. Buyers are encouraged to seek suppliers that prioritize sustainable practices, such as using recycled materials or implementing energy-efficient manufacturing processes.

Certifications play an essential role in verifying the sustainability claims of suppliers. Look for products with recognized ‘green’ certifications, such as LEED (Leadership in Energy and Environmental Design) or ISO 14001, which indicate adherence to environmental management standards. Additionally, sourcing from manufacturers that commit to ethical labor practices ensures that the entire supply chain is responsible and transparent. By prioritizing sustainable and ethical sourcing, buyers not only mitigate risks associated with environmental regulations but also enhance their brand reputation and appeal to increasingly eco-conscious consumers.

What Is the Evolution of the Screw Bolt Industry and Its Relevance to B2B Buyers?

The screw bolt industry has evolved significantly from its inception in the early days of mechanized construction. Initially, bolts were simple, rudimentary fasteners made from basic materials. As engineering challenges grew, so did the complexity and performance requirements of screw bolts. The introduction of advanced materials, such as high-strength steel and specialty coatings, has enhanced the durability and application range of these fasteners.

In recent years, the focus has shifted towards innovation and technology integration. Modern screw bolts are now designed for specific applications, incorporating features that improve installation efficiency and strength. This evolution is particularly relevant for B2B buyers who must consider not only the price but also the long-term performance and sustainability of their fasteners. Understanding the historical context of screw bolts can provide valuable insights into selecting the right products that meet contemporary demands while ensuring reliability and compliance with industry standards.

Frequently Asked Questions (FAQs) for B2B Buyers of screw bolt

-

How do I solve issues with screw bolt installation in concrete?

To effectively solve installation issues with screw bolts in concrete, ensure that you are using the appropriate drill bit size and type as specified by the manufacturer. Check for the condition of the concrete; if it is cracked or compromised, consider using anchors designed for such conditions. Utilize a power tool for installation to achieve the necessary torque without excessive effort. Additionally, verify that the screw bolt is compatible with the specific application and load requirements to prevent failure. -

What is the best screw bolt type for high-strength applications?

For high-strength applications, the Screw-Bolt+™ with a patented thread design is recommended. This heavy-duty screw anchor is specifically engineered for concrete and masonry, providing excellent load capacity and reduced installation torque. Its ability to be installed closer to edges than traditional expansion anchors makes it ideal for projects requiring tight tolerances. Always consult technical specifications and load ratings to ensure the selected screw bolt meets your project’s demands. -

What are the key factors to consider when sourcing screw bolts internationally?

When sourcing screw bolts internationally, consider factors such as the supplier’s certifications and compliance with international standards. Assess the quality of materials used, including corrosion resistance for specific environments. Evaluate the supplier’s production capabilities, lead times, and logistics arrangements to ensure timely delivery. Additionally, familiarize yourself with import regulations, tariffs, and potential trade barriers in your region to avoid unexpected costs. -

How can I vet suppliers for screw bolts in different regions?

To vet suppliers, start by researching their reputation in the industry, checking for reviews and testimonials from previous clients. Request samples to assess product quality and ensure they meet your specifications. Verify their compliance with international standards and certifications relevant to your region. Establish clear communication regarding minimum order quantities, payment terms, and lead times. Engage in due diligence by visiting their facilities if possible or utilizing third-party audits. -

What are common minimum order quantities (MOQs) for screw bolts?

Minimum order quantities for screw bolts can vary significantly depending on the supplier and the type of bolt. Typically, MOQs range from 100 to 1,000 units, but some suppliers may offer flexible options for B2B buyers. When negotiating, consider your project’s scope and future needs to avoid overstocking. Suppliers may also provide discounts for larger orders, so it’s beneficial to discuss your requirements upfront. -

What payment terms should I expect when purchasing screw bolts internationally?

Payment terms for international purchases of screw bolts can vary widely. Common terms include payment in advance, letters of credit, or payment upon delivery. Some suppliers may offer net 30 or net 60 terms, which allow you to pay after receiving the goods. Always clarify the terms in writing before finalizing the order to avoid misunderstandings. It’s advisable to use secure payment methods to protect against fraud. -

What quality assurance measures should I look for when buying screw bolts?

When purchasing screw bolts, look for suppliers who implement rigorous quality assurance measures. This includes third-party testing and certification of their products to ensure they meet industry standards. Request documentation such as material certifications, test reports, and compliance with relevant codes. Additionally, inquire about their manufacturing processes and whether they follow ISO or similar quality management systems. -

How do logistics and shipping impact the cost of screw bolts?

Logistics and shipping can significantly impact the overall cost of screw bolts. Factors such as shipping distance, method (air vs. sea), and volume can affect freight charges. Be mindful of customs duties and taxes when importing, as these can add to the total expenditure. To manage costs effectively, consider consolidating shipments and choosing suppliers who offer favorable shipping terms. Always factor in lead times to ensure timely project execution.

Top 7 Screw Bolt Manufacturers & Suppliers List

1. Bolt Depot – Fasteners

Domain: boltdepot.com

Registered: 1999 (26 years)

Introduction: Bolt Depot offers a wide range of fasteners including U.S. and metric wood screws, sheet metal screws, hex bolts, flange bolts, machine screws, carriage bolts, lag bolts, drywall screws, roofing screws, deck screws, socket screws, set screws, nuts, washers, studs, hanger bolts, dowel screws, furniture hardware, anchoring products, eye bolts, screw eyes, U-bolts, J-bolts with nuts, S-hooks, shackle…

2. Stanley Engineered Fastening – Screws and Bolts

Domain: stanleyengineeredfastening.com

Registered: 2012 (13 years)

Introduction: Screws and bolts are essential fasteners used in various applications. They come in different types, sizes, and materials to meet specific requirements. The product range includes standard screws, specialty screws, and bolts designed for durability and reliability in fastening solutions.

3. Tanner Bolt – Screw Bolt Plus Anchors

Domain: tannerbolt.com

Registered: 1997 (28 years)

Introduction: Screw Bolt Plus Anchors are designed for use in concrete and masonry applications. They provide a strong, secure hold and are easy to install. The anchors feature a unique design that allows for expansion within the base material, ensuring a reliable grip. They are available in various sizes to accommodate different load requirements and installation needs. The anchors are suitable for both indoor…

4. St. Louis Screw & Bolt – Structural Fasteners

Domain: slbolt.com

Registered: 2010 (15 years)

Introduction: St. Louis Screw & Bolt offers a variety of structural fasteners including: Structural Bolts, Lag & Carriage Bolts, Countersunk Bolts, Low Carbon Bolts (A307), Tension Control Bolts, Heavy Hex Structural Bolts, Washers (including Plate Washers and DTIs), Nuts, All Thread Anchor Bolts, Tie-Rods, Concrete Anchors, and Foundation Anchors.

5. All Points Screw – Hurricane Hardware

Domain: allpointsscrew.com

Registered: 1999 (26 years)

Introduction: Bolts, Nuts, Screws, Anchors, Hurricane Hardware, Washers, Tapcons®, Rivets, Drill Bits, Accessories, Heavy Duty Washered Wingnuts, Machine Screws, Painted Rivets, Self Drill Screws, Painted Tapcons, Concrete Screws. Leading supplier of hurricane hardware for DYI and OEM markets. Products from brands such as ITW, Stanley Black & Decker, Dewalt, Powers, Elco, and Marson.

6. Reddit – Fastener Identification Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around identifying a fastener, specifically whether it is a screw or a bolt. Key points include: it is likely a panhead machine screw, which is designed for use in machined threads. The size and type can be determined using a pitch gauge. Machine screws are measured by their major diameter and thread pitch, with an example given of an 8-24 screw, indicating a diameter based…

7. Fitch Lumber – Zinc Plated Steel Screw Bolt 1/2 x 6

Domain: fitchlumber.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “Screw Bolt”, “size”: “1/2 x 6”, “material”: “steel”, “finish”: “zinc plated”, “application”: “general fastening”, “quantity”: “1”, “weight”: “0.5 lbs”}

Strategic Sourcing Conclusion and Outlook for screw bolt

What Are the Key Insights for Sourcing Screw Bolts Effectively?

In today’s competitive market, strategic sourcing of screw bolts is paramount for businesses aiming to enhance operational efficiency and reduce costs. Understanding the diverse applications of screw bolts, from racking and shelving to fencing and structural support, enables buyers to select the right products that meet their specific needs. The emphasis on high-performance options, such as DEWALT’s Screw-Bolt+, underscores the importance of durability and ease of installation, which can significantly streamline project timelines.

Illustrative image related to screw bolt

How Can International Buyers Benefit from Strategic Sourcing?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can lead to better pricing, improved supply chain reliability, and access to superior quality products. Engaging with reputable suppliers who offer fast shipping and customer support ensures that businesses can maintain their operational momentum without interruptions.

What’s Next for Your Sourcing Strategy?

As you consider your sourcing strategies, prioritize suppliers that align with your quality and performance standards. Explore innovative products that enhance productivity and reduce installation time. By doing so, you position your business for success in an evolving marketplace. Reach out to trusted suppliers today to discuss how you can secure the right screw bolts for your upcoming projects, ensuring both quality and reliability in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.