Everything You Need to Know About Crochet Machine Sourcing in 2025

Introduction: Navigating the Global Market for crochet machine

In the fast-evolving landscape of textile manufacturing, sourcing the right crochet machine can pose a significant challenge for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. With a plethora of options available, businesses must navigate through various types, applications, and technological advancements to find the machine that best suits their production needs. This comprehensive guide serves as a vital resource for discerning buyers, offering insights into the diverse categories of crochet machines, from high-speed industrial models to specialized machines for medical applications.

Throughout this guide, we delve into critical aspects such as the capabilities of different crochet machines, their specific applications in various industries, and essential tips for vetting suppliers. Furthermore, we provide a detailed analysis of cost factors, ensuring that buyers can make informed purchasing decisions that align with their operational budgets. By addressing these key areas, this guide empowers B2B buyers to streamline their sourcing processes and enhance their production efficiency.

Understanding the intricacies of crochet machines can significantly impact your competitive edge in the global market. Whether you are looking to expand your product line or improve production efficiency, this guide equips you with the knowledge needed to select the right equipment and partner effectively with suppliers in a diverse range of markets.

Understanding crochet machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flat Crochet Machine | Produces flat crochet fabrics, often with multiple needles. | Apparel, home textiles, and decorative items. | Pros: Versatile, ideal for flat pieces. Cons: Limited to flat designs, may require skilled operators. |

| Circular Crochet Machine | Creates tubular fabrics with continuous loops; often high-speed. | Medical textiles, elastic bands, and hosiery. | Pros: High efficiency, suitable for mass production. Cons: Less flexibility in design; may need specialized yarns. |

| High-Speed Crochet Machine | Optimized for rapid production with advanced technology. | Industrial applications, large-scale apparel. | Pros: Increases output, reduces labor costs. Cons: Higher initial investment, maintenance may be complex. |

| Specialized Crochet Machine | Tailored for specific applications (e.g., medical or automotive). | Niche markets, medical supplies, automotive textiles. | Pros: Custom features enhance product quality. Cons: Limited use outside specific applications, potentially higher costs. |

| Electronic Crochet Machine | Incorporates computerized controls for precision and automation. | Fashion design, intricate patterns, and samples. | Pros: Greater design flexibility, automated processes. Cons: Requires training, potential for technical issues. |

What Are the Characteristics of Flat Crochet Machines?

Flat crochet machines are designed to produce flat crochet fabrics, utilizing multiple needles to create intricate patterns. These machines are particularly suitable for applications in the apparel industry, home textiles, and decorative items. When purchasing a flat crochet machine, buyers should consider the complexity of designs they wish to produce, as well as the skill level of their operators. While these machines offer versatility, they may require more skilled labor to operate effectively.

Why Choose Circular Crochet Machines for Production?

Circular crochet machines excel in creating tubular fabrics, making them ideal for high-speed production of items like medical textiles, elastic bands, and hosiery. Their design allows for continuous looping, which significantly enhances efficiency in mass production environments. B2B buyers should evaluate their production volume needs and the types of materials they intend to use, as these machines are often limited in design flexibility. However, their high output can offset the cost for larger manufacturers.

What Benefits Do High-Speed Crochet Machines Offer?

High-speed crochet machines are optimized for rapid production, making them a preferred choice for industrial applications where large-scale output is necessary. They are commonly used in the apparel sector and for producing various textiles. Buyers should consider the initial investment required, as these machines can be more expensive than standard models. However, the potential for reduced labor costs and increased output makes them a valuable asset for businesses aiming to scale their production.

How Do Specialized Crochet Machines Cater to Niche Markets?

Specialized crochet machines are designed with unique features tailored to specific applications, such as medical supplies or automotive textiles. This customization allows manufacturers to produce high-quality products that meet stringent industry standards. For B2B buyers, the key consideration is the specific requirements of their market, as these machines often come with a higher price tag due to their tailored nature. However, the investment can yield significant returns in niche markets where quality is paramount.

What Are the Advantages of Electronic Crochet Machines?

Electronic crochet machines leverage computerized controls to enhance precision and automate the production process. They are particularly beneficial for fashion design and creating intricate patterns or samples. Buyers interested in these machines should assess their need for design flexibility and the ability to produce complex items. While they offer significant advantages in automation and precision, potential technical issues and the requirement for operator training should be considered when making a purchasing decision.

Key Industrial Applications of crochet machine

| Industry/Sector | Specific Application of crochet machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical | Production of elastic bands and gauzes for surgical use | Ensures quality and compliance with health regulations | Certifications, machine speed, and gauge options |

| Fashion and Apparel | Creation of intricate lace and decorative elements | Enhances product appeal and differentiation in the market | Design flexibility, material compatibility, and speed |

| Home Textiles | Manufacturing of crochet bed linens and curtains | Provides unique aesthetic and increased market value | Fabric compatibility, machine size, and stitch options |

| Automotive | Production of crochet seat covers and upholstery components | Improves comfort and style in vehicle interiors | Durability, resistance to wear, and customization options |

| Sporting Goods | Creation of specialized nets and protective gear | Enhances safety and performance in sports equipment | Material strength, production speed, and design versatility |

How Are Crochet Machines Used in the Medical Industry?

In the medical sector, crochet machines are vital for producing elastic bands and gauzes used in surgical applications. These machines ensure that the materials meet stringent health regulations, providing a reliable supply of products that are both safe and effective. Buyers in this sector must consider certifications for the machines, the speed of production, and the availability of various gauge options to cater to different medical requirements.

What Role Do Crochet Machines Play in Fashion and Apparel?

Crochet machines are integral to the fashion industry, particularly for creating intricate lace designs and decorative elements that enhance garments. These machines allow manufacturers to produce unique styles that stand out in a competitive market. International buyers should focus on the design flexibility of the machines, their compatibility with various materials, and the production speed to meet fashion trends efficiently.

How Are Crochet Machines Transforming Home Textiles?

In the home textiles industry, crochet machines are used to manufacture beautiful bed linens, curtains, and other decorative items. The unique textures and patterns produced by these machines can significantly increase the market value of home textile products. When sourcing machines for this application, buyers should evaluate fabric compatibility, the size of the machine for production capacity, and the variety of stitch options available to meet diverse consumer preferences.

Why Are Crochet Machines Important in the Automotive Sector?

Crochet machines are increasingly utilized in the automotive industry for producing custom seat covers and upholstery components. These machines enhance the comfort and style of vehicle interiors, catering to consumer demands for personalized options. Buyers from this sector should prioritize durability and resistance to wear in the materials produced, as well as the ability to customize designs to fit various vehicle models.

How Do Crochet Machines Contribute to Sporting Goods Production?

In the sporting goods industry, crochet machines are essential for creating specialized nets, protective gear, and other equipment. The strength and flexibility of materials produced using crochet machines enhance safety and performance in sports. Buyers should look for machines that offer material strength, production speed, and design versatility to accommodate the specific needs of different sports and activities.

3 Common User Pain Points for ‘crochet machine’ & Their Solutions

Scenario 1: Inefficient Production and High Downtime Costs

The Problem: Many B2B buyers in the textile industry face challenges with crochet machines that lead to inefficient production processes. Frequent machine breakdowns and lengthy downtimes can severely impact output and profitability. For instance, a manufacturer producing elastic bands for medical masks may experience delays due to equipment failures, resulting in lost contracts and increased operational costs. This can be particularly detrimental for businesses operating in competitive markets where timely delivery is crucial.

The Solution: To mitigate these issues, buyers should prioritize sourcing high-quality crochet machines that come with robust warranties and reliable customer support. Investing in machines from reputable manufacturers like Merrow, known for their engineering excellence and spare parts availability, can significantly reduce downtime. Additionally, implementing a proactive maintenance schedule can help identify potential issues before they escalate into major failures. Training staff on proper operation and maintenance of the machines can further enhance performance and longevity. Moreover, consider integrating machine monitoring technology that can provide real-time data on performance, allowing for timely interventions and minimizing production interruptions.

Scenario 2: Difficulty in Adapting to Market Trends

The Problem: The textile market is constantly evolving, and B2B buyers often struggle to adapt their production capabilities to meet changing consumer demands. For example, a company specializing in crochet garments might find it challenging to switch between different stitch styles or fabric types quickly. This inability to pivot can lead to missed opportunities in capitalizing on emerging trends, such as eco-friendly materials or specific fashion styles, ultimately affecting the bottom line.

The Solution: To address this challenge, buyers should consider investing in versatile crochet machines that allow for easy adjustments in stitching techniques and fabric types. Look for machines that offer a range of stitch patterns and can handle various materials, from lightweight fabrics to heavier textiles. Additionally, establishing strong relationships with suppliers who provide access to trending materials and techniques can help companies stay ahead of the curve. Regularly attending industry trade shows or workshops can also provide insights into upcoming trends and innovations, enabling businesses to adapt their offerings proactively.

Scenario 3: High Initial Investment with Uncertain ROI

The Problem: B2B buyers often face the dilemma of high initial investment costs when purchasing crochet machines, which can lead to uncertainties regarding return on investment (ROI). This is particularly true for startups or smaller manufacturers who may lack the financial resources to invest heavily in machinery without a guaranteed outcome. The fear of making a costly mistake can lead to hesitation, stunting growth and innovation in their product lines.

The Solution: To alleviate these concerns, buyers should conduct thorough market research and analysis before making a purchase. Engaging with industry experts or consultants to evaluate the specific needs of their production process can help in selecting the right machine. Additionally, exploring financing options or leasing agreements can reduce the financial burden of an upfront purchase. It is also beneficial to request demos or trial periods from manufacturers, allowing buyers to assess the machine’s performance and suitability for their operations before committing fully. Establishing clear metrics for measuring success and ROI post-purchase can also provide reassurance and guide future investments.

Strategic Material Selection Guide for crochet machine

What Are the Key Materials for Crochet Machines and Their Properties?

When selecting materials for crochet machines, understanding the properties, advantages, and limitations of each material is crucial for optimizing performance and ensuring compatibility with various applications. Here, we analyze four common materials used in crochet machine construction: steel, aluminum, plastic, and composite materials.

How Does Steel Impact the Performance of Crochet Machines?

Steel is a widely used material in crochet machines due to its strength and durability. It offers excellent temperature and pressure ratings, making it suitable for high-stress applications. Steel components are often resistant to wear and tear, providing longevity in industrial settings.

Pros: Steel’s durability translates into a longer lifespan for machine parts, reducing the frequency of replacements. It is also cost-effective in terms of raw material procurement.

Cons: However, steel is susceptible to corrosion if not properly treated, which can be a significant drawback in humid or wet environments. Additionally, manufacturing complexity can increase due to the need for specialized coatings or treatments.

For international buyers, especially in regions with varying humidity levels, it’s essential to consider corrosion-resistant treatments and compliance with local standards such as ASTM for material specifications.

What Role Does Aluminum Play in Crochet Machine Design?

Aluminum is another popular choice for crochet machines, valued for its lightweight nature and resistance to corrosion. It typically has a lower temperature rating compared to steel but compensates with excellent machinability and ease of fabrication.

Pros: The primary advantage of aluminum is its weight, which can reduce operational strain on the machine. Its natural resistance to corrosion makes it ideal for environments where moisture is a concern.

Cons: On the downside, aluminum may not withstand as much mechanical stress as steel, leading to potential durability issues in high-load applications. Additionally, it can be more expensive than steel, impacting overall project budgets.

For B2B buyers, especially in regions like Europe and the Middle East where lightweight materials are preferred for energy efficiency, aluminum’s compliance with DIN standards can be a significant advantage.

How Do Plastics Contribute to Crochet Machine Functionality?

Plastics, particularly engineered thermoplastics, are increasingly used in crochet machines for components that require flexibility and resistance to chemicals. These materials can withstand moderate temperatures and offer excellent corrosion resistance.

Pros: The main advantage of plastics is their versatility and low weight, which can enhance machine efficiency. They are also less expensive than metals, making them an attractive option for manufacturers looking to reduce costs.

Cons: However, plastics may not be suitable for high-stress applications as they can deform under pressure. Additionally, their temperature resistance is generally lower than that of metals, which can limit their use in certain environments.

International buyers should consider the specific chemical compatibility of plastics with the materials they will be processing, as well as compliance with international standards like JIS for quality assurance.

What Are the Benefits of Composite Materials in Crochet Machines?

Composite materials, often a blend of fibers and resins, are becoming popular in crochet machines for their high strength-to-weight ratio and resistance to environmental factors. They can be engineered to meet specific performance criteria, making them highly adaptable.

Pros: The key advantage of composites is their ability to provide tailored properties, such as enhanced strength and reduced weight. They also offer excellent resistance to corrosion and temperature fluctuations.

Cons: However, composites can be more expensive to produce and may require specialized manufacturing processes, which can complicate production. Additionally, their long-term durability under continuous mechanical stress can be uncertain compared to metals.

For international B2B buyers, especially those in Africa and South America, understanding the specific regulations regarding composite materials is crucial, as compliance with local standards can vary significantly.

Summary Table of Material Selection for Crochet Machines

| Material | Typical Use Case for crochet machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components | High durability and strength | Susceptible to corrosion | Medium |

| Aluminum | Lightweight parts | Corrosion resistance | Lower mechanical stress tolerance | High |

| Plastic | Flexible components | Versatile and cost-effective | Limited temperature resistance | Low |

| Composite | Specialized high-performance parts | Tailored properties and lightweight | Higher production costs | High |

This guide provides a comprehensive overview of material selection for crochet machines, enabling international B2B buyers to make informed decisions based on their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for crochet machine

What Are the Key Manufacturing Processes for Crochet Machines?

The manufacturing of crochet machines involves several critical stages that ensure high-quality output and operational efficiency. Understanding these processes can help B2B buyers make informed decisions when selecting suppliers.

What Are the Main Stages in the Manufacturing Process?

-

Material Preparation

The first step in manufacturing crochet machines involves selecting and preparing raw materials. Typically, high-grade metals and plastics are used for components such as frames, gears, and motors. Suppliers often conduct material inspections to ensure compliance with specifications before production begins. This can include checking for material grade, thickness, and surface integrity. -

Forming

The forming stage involves shaping the raw materials into the required components. Techniques such as casting, machining, and stamping are commonly employed. For instance, high-precision CNC machining is used to create intricate parts that require tight tolerances. This process is crucial for the performance of the crochet machine, as poorly formed components can lead to mechanical failures. -

Assembly

Once the components are prepared, they move to the assembly stage. This typically involves manual and automated processes to assemble the various parts into a complete machine. Skilled technicians ensure that all parts fit together correctly and function as intended. During assembly, quality checks are performed to identify any issues early in the process, reducing the risk of defects in the final product. -

Finishing

The final manufacturing stage is finishing, which includes surface treatments, painting, and final inspections. This not only enhances the aesthetic appeal of the machine but also provides protection against corrosion and wear. Finishing processes might include powder coating or anodizing, depending on the material used. This stage is essential for ensuring the longevity and durability of the machine, particularly for those intended for heavy industrial use.

How Is Quality Assurance Implemented in Crochet Machine Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that each crochet machine meets international standards and customer expectations.

What Are the Relevant International Standards for Quality Assurance?

International standards such as ISO 9001 are fundamental in maintaining quality management systems. These standards outline requirements for a quality management system that organizations must follow to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. In the context of crochet machines, compliance with ISO 9001 ensures that the manufacturing processes are efficient and that the products are reliable.

In addition to ISO standards, industry-specific certifications such as CE marking (for compliance with European safety standards) and API (American Petroleum Institute) certifications may be applicable depending on the machine’s intended use. These certifications provide assurance that the products meet rigorous safety and performance criteria.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated into various stages of the manufacturing process through several checkpoints:

-

Incoming Quality Control (IQC)

This initial inspection occurs when raw materials arrive at the manufacturing facility. The goal is to verify that materials meet specifications before production begins. Any non-conforming materials are rejected or returned to suppliers. -

In-Process Quality Control (IPQC)

Throughout the manufacturing process, IPQC ensures that each stage adheres to quality standards. This includes monitoring the forming and assembly processes. Statistical process control (SPC) methods may be used to track performance and detect variations that could lead to defects. -

Final Quality Control (FQC)

After assembly and finishing, the final quality control checks are conducted. This includes functional testing of the crochet machine, ensuring it operates as intended. Detailed inspection reports are generated, documenting the performance and any areas of concern.

What Common Testing Methods Are Used for Crochet Machines?

Testing methods vary based on the specific requirements of the crochet machine but typically include:

- Functional Testing: Verifies that the machine operates correctly under various conditions, including speed and load.

- Durability Testing: Assesses the machine’s performance over extended periods to identify potential failures.

- Safety Testing: Ensures compliance with safety standards, focusing on electrical safety, mechanical hazards, and user protection.

These tests help ensure that the machines are not only functional but also safe for end-users.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, ensuring supplier quality control is essential for mitigating risks associated with product defects and ensuring compliance with local regulations.

What Steps Can Buyers Take to Assess Supplier QC?

-

Conduct Audits

Regular audits of suppliers’ manufacturing facilities can provide insights into their quality control processes. These audits can be performed by the buyer or a third-party inspection service to ensure impartiality. -

Request Quality Control Reports

Suppliers should provide detailed QC reports that outline their processes, checkpoints, and results from various testing methods. These documents can help buyers understand how quality is maintained throughout production. -

Engage Third-Party Inspectors

Utilizing third-party inspection services can add an extra layer of assurance. These services can perform independent assessments of the manufacturing process and product quality, providing unbiased feedback.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Understanding the nuances of quality control and certification is crucial for B2B buyers, especially those sourcing from different regions.

- Regional Compliance: Different regions may have varying regulations and standards. Buyers should familiarize themselves with the specific requirements of their target markets, such as CE marking in Europe or ANSI standards in the United States.

- Cultural Considerations: Communication and cultural differences can impact quality assurance practices. Establishing clear expectations and maintaining open lines of communication with suppliers can mitigate misunderstandings.

- Supply Chain Transparency: Buyers should seek suppliers who prioritize transparency in their manufacturing processes. This includes sharing information about sourcing, production methods, and quality assurance measures.

By understanding the manufacturing processes and quality assurance measures involved in crochet machine production, B2B buyers can make informed decisions that align with their business needs and market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘crochet machine’

Introduction

Sourcing a crochet machine requires a strategic approach to ensure that the selected equipment meets your production needs while also aligning with your business goals. This guide outlines a practical checklist for B2B buyers, focusing on key steps to take when procuring a crochet machine, particularly for industries in Africa, South America, the Middle East, and Europe. By following these steps, you can make informed decisions that enhance your operational efficiency and product quality.

1. Define Your Technical Specifications

Establishing clear technical specifications is crucial for selecting the right crochet machine. Consider factors such as the type of materials you will be working with, the desired stitch types, and production volume requirements. This clarity will help you communicate effectively with potential suppliers and ensure that the machines they offer meet your specific needs.

2. Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers of crochet machines. Utilize online directories, trade shows, and industry forums to compile a list of manufacturers. Focus on suppliers with a proven track record in your region, as local support can significantly enhance your procurement experience.

3. ✅ Verify Supplier Certifications

Before making a commitment, ensure that potential suppliers possess relevant certifications and compliance with international standards. Check for ISO certifications, CE markings, or industry-specific accreditations that demonstrate quality assurance and reliability. This verification is critical to mitigate risks associated with substandard machinery.

4. Evaluate Supplier Experience and Reputation

Assess the experience and reputation of suppliers by reviewing their history in the industry. Look for case studies, client testimonials, and references from businesses similar to yours. A supplier with extensive experience in your specific market can provide valuable insights and support throughout the purchasing process.

5. Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that outline all costs involved, including machine price, shipping, installation, and after-sales support. Compare these quotations not just on price but also on the value offered, such as warranty periods and maintenance services. This step will help you avoid unexpected costs down the line.

6. Conduct a Site Visit or Virtual Tour

If feasible, arrange a site visit to the supplier’s manufacturing facility or request a virtual tour. This allows you to assess the production processes, quality control measures, and overall working conditions. Observing the machinery in operation can provide insights into its capabilities and help confirm that it meets your expectations.

7. Negotiate Terms and Finalize the Purchase

Engage in discussions to negotiate terms that are favorable for both parties. Ensure clarity on payment terms, delivery timelines, and service agreements. Once all terms are agreed upon, document everything comprehensively to protect your interests and ensure a smooth transaction.

By following this checklist, B2B buyers can confidently navigate the procurement process for crochet machines, ensuring they select equipment that enhances their production capabilities while minimizing risks.

Comprehensive Cost and Pricing Analysis for crochet machine Sourcing

What Are the Key Cost Components in Sourcing Crochet Machines?

When sourcing crochet machines, understanding the cost structure is vital for making informed purchasing decisions. The key components include:

-

Materials: The raw materials used in manufacturing crochet machines significantly impact the overall cost. High-quality steel, electronic components, and specialized parts can lead to higher initial costs but may enhance durability and performance.

-

Labor: Labor costs vary by region and can influence the final price. For instance, manufacturers in countries with higher wage standards may charge more than those in regions with lower labor costs. This factor is particularly relevant for international buyers.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with production. Efficient manufacturing processes can help reduce these costs, which may be reflected in the pricing of the machines.

-

Tooling: The cost of tools and machinery required to produce crochet machines adds to the overall expenditure. Custom tooling for specialized machines can significantly increase upfront costs but may be necessary for specific production needs.

-

Quality Control (QC): Implementing stringent QC measures ensures that the machines meet required standards. While this adds to costs, it can prevent future expenses associated with defects and repairs.

-

Logistics: Shipping costs, including freight and customs duties, must be considered, especially for international transactions. The choice of shipping method and distance from the supplier can lead to variations in logistics costs.

-

Margin: Suppliers will add a profit margin to cover their costs and risk. Understanding the typical margins in the industry can help buyers gauge whether they are receiving fair pricing.

How Do Price Influencers Affect the Cost of Crochet Machines?

Various factors can influence the pricing of crochet machines:

-

Volume/MOQ: Purchasing in larger quantities often leads to discounted pricing due to economies of scale. Buyers should consider minimum order quantities (MOQs) to negotiate better rates.

-

Specifications/Customization: Customized machines tailored to specific production needs will typically cost more than standard models. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials: The choice of materials can significantly affect pricing. For instance, machines made from premium or specialized materials may have higher upfront costs but offer greater longevity and efficiency.

-

Quality/Certifications: Machines that comply with international quality standards or possess certifications may command higher prices. These certifications can assure buyers of the machine’s reliability and performance.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a history of quality and service may charge more, but they often provide better support and warranties.

-

Incoterms: The terms of shipping (Incoterms) chosen can affect the final cost significantly. Buyers should understand whether costs like insurance, freight, and duties are included in the quoted price.

What Tips Can Help Buyers Negotiate Better Pricing for Crochet Machines?

For B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to cost savings:

-

Conduct Thorough Research: Understand market pricing, supplier capabilities, and industry trends. This knowledge will empower buyers during negotiations.

-

Focus on Total Cost of Ownership (TCO): When evaluating quotes, consider not just the initial price but also maintenance, operational costs, and potential downtime. A lower-priced machine may incur higher long-term costs.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Suppliers may offer discounts or favorable payment terms to loyal customers.

-

Be Prepared to Walk Away: Having alternative suppliers or options can strengthen your negotiating position. If a supplier is unwilling to meet your needs, being prepared to explore other options can lead to better deals.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and local market conditions that may affect pricing. These factors can lead to unexpected costs if not properly accounted for.

Disclaimer on Indicative Prices

Prices for crochet machines can vary widely based on the factors discussed above. This analysis provides a framework for understanding potential costs but should not be interpreted as definitive pricing. Buyers are encouraged to obtain multiple quotes and perform due diligence to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing crochet machine With Other Solutions

In the realm of textile production, particularly in the crafting of knitted and crocheted products, businesses often face a choice between various technologies and methods. While crochet machines offer specialized capabilities, alternative solutions can provide different advantages that may align better with specific production needs. Below, we explore how crochet machines compare to other viable options, including flat knitting machines and manual crochet techniques.

| Comparison Aspect | Crochet Machine | Flat Knitting Machine | Manual Crochet Technique |

|---|---|---|---|

| Performance | High-speed production, consistent stitch quality | High versatility, suitable for various fabrics | Labor-intensive, slower production |

| Cost | Moderate initial investment, but efficient in large runs | Higher initial cost, but flexible for diverse patterns | Low cost, minimal equipment needed |

| Ease of Implementation | Requires training for operation and maintenance | Complex setup, requires skilled operators | Easy to start, minimal training required |

| Maintenance | Regular maintenance needed for optimal performance | High maintenance due to complex machinery | Minimal maintenance, depends on user care |

| Best Use Case | Mass production of consistent, high-quality items | Custom designs and varied fabric types | Small-scale, artisanal production |

What Are the Advantages and Disadvantages of Flat Knitting Machines?

Flat knitting machines are notable for their flexibility and adaptability. They can produce a wide variety of fabric types and patterns, making them ideal for businesses looking to diversify their product offerings. However, the initial investment is generally higher than that of crochet machines, which may deter smaller enterprises. Additionally, the complexity of the machines requires skilled operators, which can complicate staffing.

How Does Manual Crochet Compare?

Manual crochet techniques are the most accessible option for small businesses or artisans, requiring little more than yarn and a hook. This method allows for unique, handcrafted products that can appeal to niche markets. However, the production speed is significantly slower compared to machine methods, making it less viable for larger-scale operations. Furthermore, the quality and consistency of the finished products can vary greatly based on the skill level of the crocheter.

Which Solution Is Right for Your Business Needs?

Choosing the right solution depends on several factors, including production scale, budget, and desired product quality. For businesses focused on high-volume production with consistent quality, crochet machines are often the best option. However, if flexibility and the ability to produce diverse styles are priorities, investing in flat knitting machines may yield better long-term results. On the other hand, for those operating in artisanal markets or smaller scales, manual crochet can be a cost-effective and appealing method.

In conclusion, B2B buyers should carefully assess their operational needs, budget constraints, and market demands when selecting between crochet machines, flat knitting machines, and manual crochet techniques. A thorough understanding of each alternative’s strengths and weaknesses will ensure that businesses make informed decisions that align with their strategic goals.

Essential Technical Properties and Trade Terminology for crochet machine

What Are the Key Technical Properties of Crochet Machines?

When considering crochet machines for industrial applications, understanding their technical specifications is crucial for making informed purchasing decisions. Here are several critical specifications to keep in mind:

-

Working Width

– Definition: This refers to the maximum width of fabric that the machine can process, typically measured in millimeters.

– B2B Importance: Different applications require varying widths. For instance, a machine with a wider working width is essential for producing larger items like blankets or curtains, while narrower machines may suffice for smaller garments. Buyers must match the working width to their production needs to avoid inefficiencies. -

Gauge

– Definition: Gauge indicates the number of needles per unit length of the machine and affects the fineness of the stitches.

– B2B Importance: A finer gauge allows for more delicate fabrics, which is important in sectors like fashion and lingerie. Understanding gauge helps buyers select machines that produce the desired fabric quality and texture for specific markets. -

Speed

– Definition: This refers to the maximum number of stitches produced per minute.

– B2B Importance: Higher speeds can significantly increase production efficiency, allowing businesses to meet larger orders in shorter timeframes. However, speed must be balanced with stitch quality; hence, buyers should consider their production volume needs alongside quality expectations. -

Material Compatibility

– Definition: This specification outlines the types of yarns and fabrics the machine can handle, such as cotton, polyester, or specialty blends.

– B2B Importance: Different markets may demand specific fabric types. A machine that supports a wide range of materials offers versatility, making it a valuable asset for manufacturers targeting diverse product lines. -

Power Consumption

– Definition: The amount of energy the machine uses during operation, usually measured in watts.

– B2B Importance: Energy efficiency is a growing concern for manufacturers. Understanding power consumption can help businesses manage operational costs and comply with sustainability initiatives. Choosing energy-efficient machines can lead to long-term savings.

What Are Common Trade Terms Used in the Crochet Machine Industry?

In the B2B landscape, specific jargon helps streamline communication and ensure clarity among manufacturers, suppliers, and buyers. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is vital for buyers seeking high-quality components and machines. It helps in identifying trusted manufacturers who can provide reliable equipment. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers gauge their purchasing power and plan their inventory accordingly. It’s essential for budget management, especially for smaller businesses or startups. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing for specific products or services.

– Importance: An RFQ is a critical step in the procurement process. It allows buyers to compare costs and terms from different suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international trade.

– Importance: Familiarity with Incoterms helps businesses understand shipping costs, risks, and delivery obligations. This knowledge is crucial for effective contract negotiation and logistics planning. -

Lead Time

– Definition: The total time taken from placing an order to the delivery of goods.

– Importance: Understanding lead times is essential for supply chain management. It helps businesses plan their production schedules and manage customer expectations effectively.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of purchasing crochet machines, ensuring they select equipment that meets their specific operational needs.

Navigating Market Dynamics and Sourcing Trends in the crochet machine Sector

What are the Current Market Dynamics and Key Trends in the Crochet Machine Sector?

The global crochet machine market is experiencing transformative shifts driven by technological advancements and evolving consumer preferences. Key factors propelling growth include increased demand for automation in textile manufacturing and a rising focus on customization. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, explore new sourcing opportunities, they should note the increasing integration of smart technologies in crochet machines. Innovations like IoT-enabled machinery and AI-driven design capabilities are enhancing production efficiency and reducing lead times, making them attractive options for manufacturers aiming to scale operations.

Additionally, sustainability is becoming a critical consideration in sourcing decisions. More manufacturers are adopting eco-friendly materials and processes, responding to global calls for responsible production. This trend is particularly relevant in regions like Europe, where regulatory frameworks are pushing for greener manufacturing practices. As a result, buyers should prioritize suppliers that demonstrate a commitment to sustainability, ensuring that their sourcing aligns with both market expectations and regulatory requirements.

How Important is Sustainability and Ethical Sourcing for B2B Buyers in the Crochet Machine Sector?

Sustainability and ethical sourcing are increasingly vital in the crochet machine sector, reflecting broader shifts in global consumer expectations and regulatory landscapes. The environmental impact of textile production has led to heightened scrutiny of supply chains, compelling manufacturers to adopt more responsible practices. This includes utilizing recycled materials, reducing water consumption, and minimizing waste throughout the production process.

For B2B buyers, the importance of partnering with suppliers who uphold sustainability standards cannot be overstated. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® provide assurance that products meet rigorous environmental and social criteria. Furthermore, buyers should seek suppliers that engage in ethical labor practices, ensuring fair wages and safe working conditions for all employees involved in the production of crochet machines and textiles.

Investing in suppliers with strong sustainability credentials not only enhances brand reputation but also aligns with the growing consumer preference for eco-friendly products. As markets in Africa, South America, the Middle East, and Europe continue to evolve, embracing sustainability can serve as a competitive differentiator for businesses in the crochet machine sector.

What is the Brief Evolution and History of Crochet Machines in the B2B Context?

The history of crochet machines dates back to the 19th century, when manual crochet techniques began to be mechanized, allowing for increased production capacity and efficiency. Early machines were primarily used in the textile industry to create lace and intricate patterns, catering to high-demand markets in Europe and North America. As technology advanced, these machines evolved to accommodate various applications, including garment manufacturing and home textiles.

Today, crochet machines are integral to the global textile supply chain, with innovations in automation and digitalization reshaping production methods. The introduction of computerized machines has enabled manufacturers to produce complex designs with precision, thus expanding their product offerings. This evolution is particularly significant for B2B buyers looking to optimize their production processes, reduce costs, and meet the increasing demand for personalized textile solutions. As the industry continues to innovate, staying informed about these historical advancements can provide valuable insights for strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of crochet machine

-

How do I choose the right crochet machine for my production needs?

Selecting the ideal crochet machine involves assessing your specific production requirements, such as the type of fabric you intend to use, the desired stitch patterns, and the volume of production. Consider machines that offer versatility in stitch types and gauges, as well as high-speed capabilities for efficiency. It’s beneficial to consult with manufacturers or suppliers who can provide samples of their machines in action, allowing you to evaluate their performance and suitability for your product line. -

What are the common applications for crochet machines in different industries?

Crochet machines are widely used in various sectors, including apparel, home textiles, and medical applications. Common uses include creating elastic bands for garments, decorative lace for home decor, and specialized fabrics for medical products like masks and bandages. Understanding the specific applications of different machines will help you select one that aligns with your business goals and market demands. -

What customization options are typically available for crochet machines?

Many manufacturers offer customization options for crochet machines to meet specific production needs. Customizations can include modifications in machine size, stitch types, and additional features like automatic threading or tension control. Discuss your requirements with potential suppliers to explore available options and ensure the machine can be tailored to your unique production processes. -

What is the minimum order quantity (MOQ) for crochet machines?

The MOQ for crochet machines can vary significantly between manufacturers. Some may allow single-unit purchases, while others might require a minimum of five or more machines to fulfill an order. It is essential to clarify the MOQ with suppliers before placing an order, as this can affect your budgeting and inventory management strategies. -

What payment terms should I expect when sourcing crochet machines internationally?

Payment terms can differ based on the supplier’s policies and your negotiation. Common terms include a deposit upfront (usually 30-50% of the total cost), with the balance payable upon shipment or delivery. Ensure to discuss and confirm payment methods (e.g., wire transfer, letter of credit) that are secure and convenient for both parties. Familiarize yourself with international payment practices to avoid potential complications. -

How can I ensure quality assurance (QA) when purchasing crochet machines?

To ensure quality assurance when sourcing crochet machines, it is advisable to conduct thorough research on the manufacturer’s reputation and quality control processes. Request certifications or quality standards they adhere to, such as ISO certifications. Additionally, consider asking for samples or visiting the factory to observe the production process firsthand, which can provide insights into their commitment to quality. -

What logistics considerations should I keep in mind when importing crochet machines?

When importing crochet machines, consider logistics aspects such as shipping methods, customs duties, and delivery timelines. It is crucial to work with a reliable logistics partner who understands the intricacies of international shipping and can handle customs clearance efficiently. Also, factor in storage solutions for the machines upon arrival, as delays in logistics can impact your production schedule. -

How do I vet suppliers of crochet machines to ensure reliability?

Vetting suppliers is essential to ensure reliability and quality. Start by researching their business history, customer reviews, and industry reputation. Request references from other clients, and look for evidence of successful partnerships. Additionally, consider visiting their facilities or participating in virtual meetings to gauge their professionalism and commitment to service. Establishing clear communication and understanding their support offerings will further solidify your decision.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Crochet Machine Manufacturers & Suppliers List

1. Reddit – Crochet Machine Development

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Crochet machines exist and were developed by the University of Bielefeld, Germany. The machine crochets like a left-handed person. A related peer-reviewed article was published in September 2023.

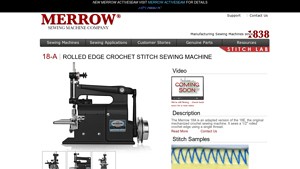

2. Merrow – 18-A Crochet Sewing Machine

Domain: merrow.com

Registered: 1996 (29 years)

Introduction: {“model”:”Merrow 18-A”,”type”:”Crochet Sewing Machine”,”operating_speed”:”1200 SPM”,”stitch_width”:”3/8\” – 1/2\”, 1/2\” Standard”,”stitch_range”:”4 – 10 SPI”,”standard_needle”:”10″,”merrow_needle_range”:[“8″,”10H”,”11″],”stitch_type”:”Rolled Crochet”,”motor_required”:”1725 RPM, 60 Hz, 1/2 HP, 110 or 220 volts, 1 or 3 phase”,”number_of_threads”:”1″,”description”:”The Merrow 18A is an adapted versi…

3. Creditocean – Automatic Crochet Machines

Domain: creditocean.net

Registered: 2020 (5 years)

Introduction: Automatic crochet machines are specialized devices used in the textile industry for mass production of intricate knitted products such as laces, bands, and decorative textiles. Key features include high-speed production, precision and consistency, versatility in handling various materials, and extensive customization options. Applications span across medical (compression garments, surgical bandage…

4. The Crocheting – Ready to Wear & Patterns

Domain: thecrocheting.com

Registered: 2018 (7 years)

Introduction: Free domestic shipping on all Ready to Wear orders $100+ USD. Patterns available by clothing type (Accessories, Bodysuits, Dresses, Jumpsuits/Rompers, Men’s Crochet Pants, Shorts, Skirts, Sweaters/Outerwear, Swim Tops, Two-Piece Sets), by yarn weight (Light, Worsted/Aran, Bulky), and by difficulty (Beginner, Intermediate, Advanced). Gift Card and 100 Patterns E-Book available.

5. Crochetville – Home Crochet Machine Solutions

Domain: forum.crochetville.com

Registered: 2004 (21 years)

Introduction: The discussion revolves around the search for a home crochet machine. Users mention that there are knitting machines available, but no crochet machines exist. Suggestions include considering outsourcing for increased production and researching electronic knitting machines for potential use in crochet-like projects.

6. Prym – MAXI Square Loom

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Prym – MAXI Square Loom, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Facebook – Crochet Machine

8. eBay – DIY Knitting Machines

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 1. DIY Knitting Machine Mini Spool Knitter Hand-Operated Weaver Tool – Price: ZAR 577.96 to ZAR 666.94, Delivery: ZAR 353.81, Location: China

2. 22 Needles DIY Plastic Hand Knitting Sewing Machine – Price: ZAR 236.95, Delivery: ZAR 566.31, Location: United Kingdom

3. DIY Hand-Knitting Machine Knitting Tools – Price: ZAR 179.59 to ZAR 181.09, Delivery: Free International Shipping, Location: China

4…

Strategic Sourcing Conclusion and Outlook for crochet machine

As the global textile industry evolves, the strategic sourcing of crochet machines presents significant opportunities for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. Key takeaways highlight the importance of investing in high-quality, efficient machines that enhance production capabilities while meeting diverse market demands. Notable brands like Merrow exemplify how advanced stitching technologies can deliver superior results, driving value through innovative applications ranging from apparel to medical textiles.

Investing in the right crochet machine not only optimizes operational efficiency but also positions businesses to respond effectively to changing consumer preferences. As global supply chains become more interconnected, sourcing from reputable manufacturers can mitigate risks and ensure a steady supply of parts and support, further enhancing production stability.

Looking ahead, the increasing focus on sustainability and technological advancements in textile machinery suggests a promising landscape for crochet machine procurement. International buyers are encouraged to explore partnerships that prioritize quality, innovation, and sustainability. Embrace these opportunities to elevate your production processes and stay ahead in a competitive market. The future of textile manufacturing is bright—take action now to secure your position in this dynamic industry.