Everything You Need to Know About Alum Trim Sourcing in 2025

Introduction: Navigating the Global Market for alum trim

In today’s global market, sourcing high-quality aluminum trim can pose significant challenges for international B2B buyers. With a plethora of options available, from edge trims to decorative finishes, the complexity of selecting the right product can be daunting. This guide is designed to simplify the process of navigating the diverse landscape of aluminum trim. We cover essential aspects, including various types of trims, their applications across industries, effective supplier vetting strategies, and an analysis of cost considerations.

By equipping decision-makers with comprehensive insights and actionable information, this guide empowers buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Germany—to make informed purchasing decisions. Understanding the nuances of aluminum trim not only enhances product quality but also optimizes project timelines and budgets.

As you delve into the sections of this guide, expect to uncover valuable knowledge that will aid you in identifying reputable suppliers, evaluating product specifications, and understanding market trends. Ultimately, our goal is to facilitate your journey toward sourcing the best aluminum trim solutions tailored to your specific business needs, ensuring durability and aesthetic appeal in your projects.

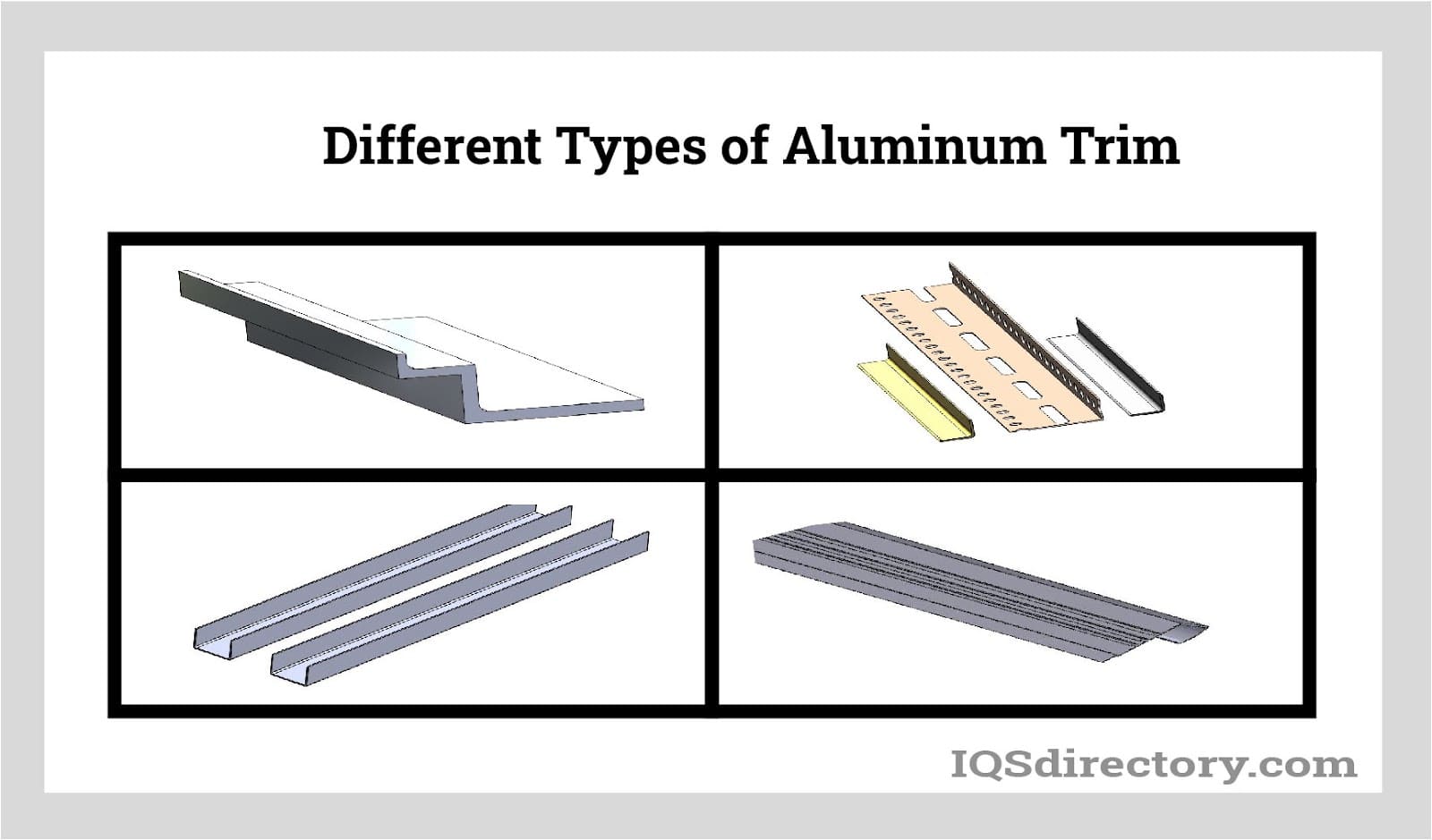

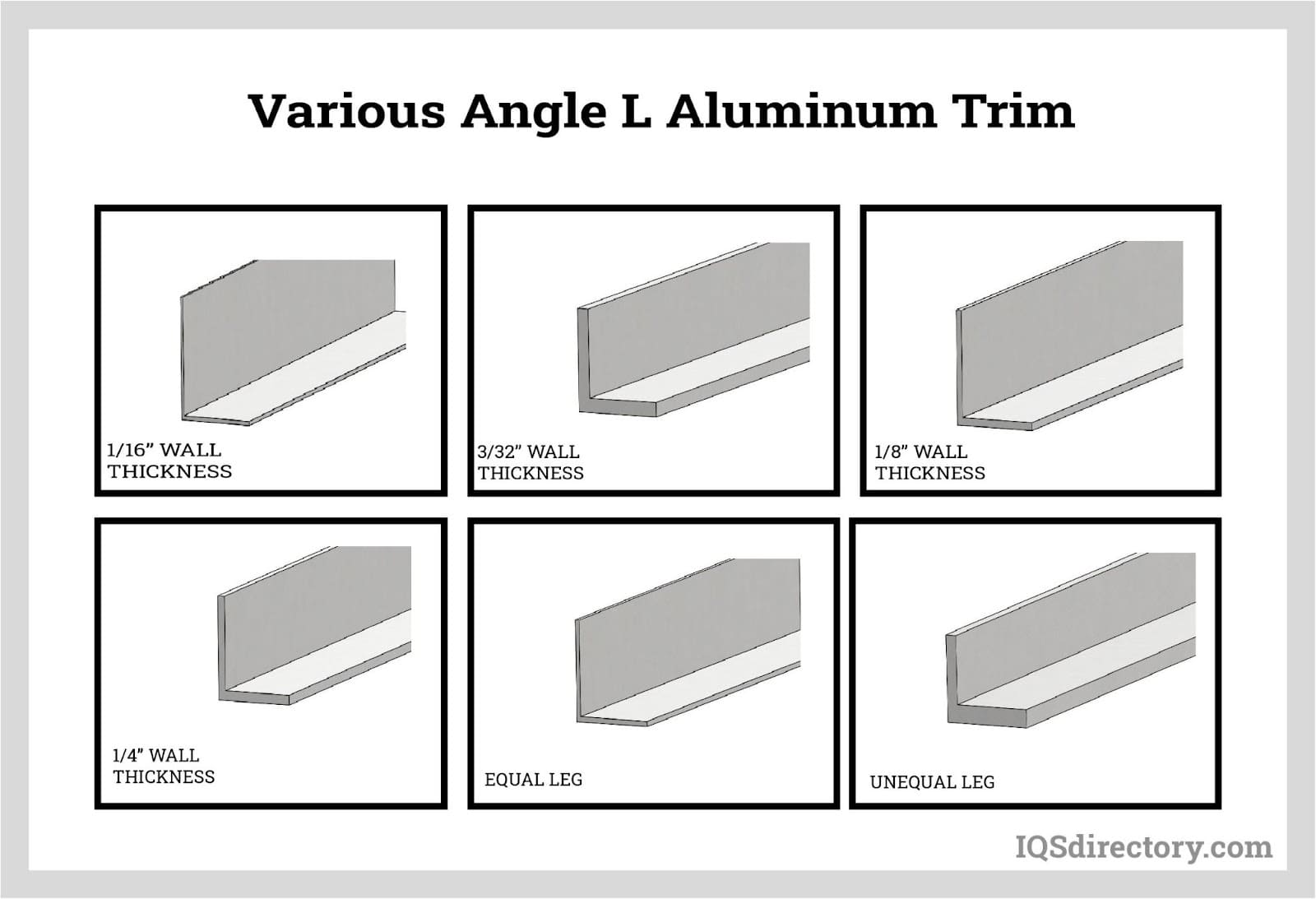

Understanding alum trim Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Edge Trims | Lightweight, corrosion-resistant, seamless edge transition. | Cabinetry, architectural millwork, displays. | Pros: Protects edges, easy installation. Cons: Limited color options may not match all designs. |

| Finish Trims | Available in various colors, baked enamel finish for durability. | Interior and exterior applications, residential and commercial. | Pros: Aesthetic appeal, resistant to chipping. Cons: Custom orders may delay delivery. |

| Extruded Trims | Customizable profiles, robust construction for various uses. | Drywall, plaster, and stucco applications. | Pros: Tailored solutions, excellent durability. Cons: Higher upfront costs for custom designs. |

| Transition Trims | Designed to create smooth connections between different materials. | Flooring, wall systems, and ceiling installations. | Pros: Enhances visual continuity, minimizes damage. Cons: Requires precise installation for best results. |

| J-Mold Trims | U-shaped profile for drywall edges, provides a clean finish. | Drywall installations, particularly for ceilings. | Pros: Simplifies drywall finishing, reduces labor time. Cons: Not suitable for all edge types. |

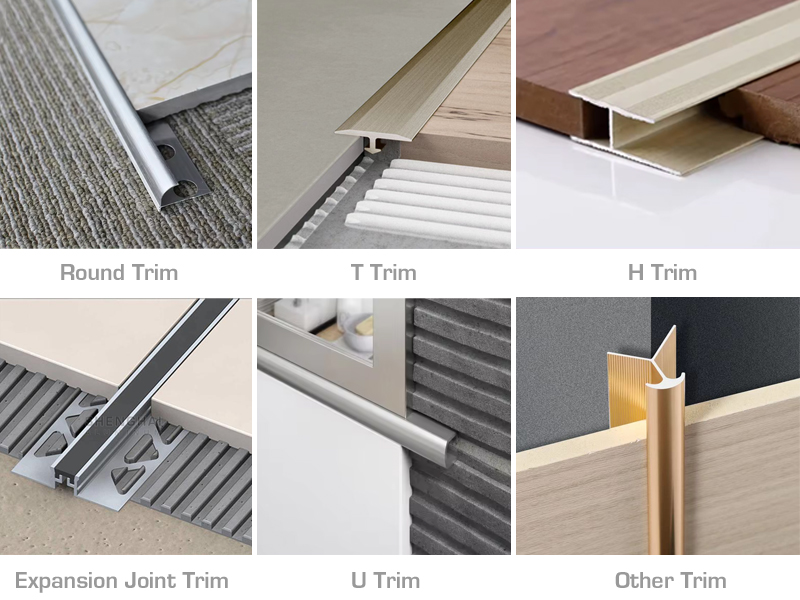

What Are Edge Trims and How Are They Used in B2B Applications?

Edge trims serve as protective finishing elements for exposed edges on various surfaces like panels and countertops. Their lightweight and corrosion-resistant properties make them ideal for applications in cabinetry and architectural millwork. When purchasing edge trims, B2B buyers should consider factors such as compatibility with existing materials and available color options to ensure a seamless integration into their projects.

Why Choose Finish Trims for Your Projects?

Finish trims are available in a wide range of colors and are typically coated with a baked enamel finish that enhances durability. These trims are suitable for both interior and exterior applications, making them a versatile choice for residential and commercial projects alike. Buyers should evaluate the finish’s longevity and warranty options, as well as the possibility of custom orders, which can affect lead times.

Illustrative image related to alum trim

How Do Extruded Trims Benefit Construction Projects?

Extruded trims are known for their robust construction and customizable profiles, making them ideal for various applications, including drywall and stucco installations. They provide tailored solutions that enhance both the aesthetic and structural integrity of a project. B2B buyers should weigh the benefits of durability against the higher upfront costs associated with custom extrusions, especially for large-scale projects.

What Role Do Transition Trims Play in Enhancing Design?

Transition trims are specifically designed to create smooth connections between different materials, such as flooring and wall systems. They not only enhance the visual continuity of a space but also minimize the risk of damage at transition points. When sourcing transition trims, buyers should focus on the precision of installation to maximize their effectiveness.

What Are J-Mold Trims and Their Advantages in Drywall Finishing?

J-Mold trims feature a U-shaped profile that simplifies the finishing process for drywall edges, offering a clean and professional appearance. They are particularly effective in ceiling applications. B2B buyers should consider the specific edge types they are working with, as J-Mold trims may not be suitable for all installations. Their ability to reduce labor time can be a significant advantage in project planning.

Illustrative image related to alum trim

Key Industrial Applications of alum trim

| Industry/Sector | Specific Application of alum trim | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Exterior and interior wall systems | Enhances aesthetic appeal while providing structural integrity. | Ensure compliance with local building codes and weather resistance standards. |

| Furniture Manufacturing | Edging for cabinetry and countertops | Improves durability and visual appeal, reducing wear and tear. | Consider custom color options and finishes to match design specifications. |

| Automotive | Interior trims for vehicle design | Provides a lightweight, corrosion-resistant solution enhancing vehicle aesthetics. | Focus on lightweight materials and compatibility with existing vehicle designs. |

| Retail Displays | Edge trims for shelving and display units | Elevates product presentation and protects edges from damage. | Evaluate stock availability and customization options for unique display needs. |

| HVAC Systems | Trim for ductwork and ventilation systems | Facilitates seamless integration while improving overall system efficiency. | Confirm precision in manufacturing to ensure proper fit and function. |

How Is Alum Trim Used in Construction and Architecture?

In the construction and architecture sectors, aluminum trim is essential for finishing both exterior and interior wall systems. It not only enhances the aesthetic appeal of buildings but also contributes to their structural integrity. By providing a clean and polished finish, aluminum trim helps prevent damage to edges and corners, which can be particularly important in high-traffic areas. International buyers should prioritize suppliers who comply with local building codes and offer weather-resistant products, especially in regions with extreme climates like the Middle East and Africa.

What Role Does Alum Trim Play in Furniture Manufacturing?

In furniture manufacturing, aluminum trim is commonly used for edging on cabinetry and countertops. This application is vital for improving durability and visual appeal, as it protects surfaces from chipping and wear over time. For businesses focused on custom furniture designs, sourcing aluminum trim that offers various color options and finishes can help create cohesive and attractive products. Buyers should also consider the compatibility of the trim with different materials to ensure seamless integration into their furniture designs.

How Is Alum Trim Beneficial in Automotive Applications?

Aluminum trim finds significant application in the automotive industry, particularly for interior design elements. Its lightweight and corrosion-resistant properties make it an ideal choice for enhancing vehicle aesthetics without adding unnecessary weight. This is crucial for improving fuel efficiency and overall vehicle performance. When sourcing aluminum trim for automotive applications, businesses should focus on compatibility with existing vehicle designs and ensure that the materials meet industry standards for safety and durability.

In What Ways Does Alum Trim Enhance Retail Displays?

Retail displays benefit greatly from the use of aluminum trim, particularly as edge trims for shelving and display units. This application not only elevates product presentation but also protects edges from damage, ensuring that displays remain appealing over time. Businesses in the retail sector should evaluate suppliers for stock availability and customization options to meet unique display needs. The right trim can significantly impact the customer experience and enhance brand perception.

How Does Alum Trim Improve HVAC Systems?

In HVAC systems, aluminum trim is utilized for ductwork and ventilation systems, facilitating a seamless integration that enhances overall system efficiency. Properly designed trims can help in achieving better airflow and reducing energy loss, which is critical for maintaining cost-effectiveness in operations. Buyers in this sector should confirm precision in manufacturing to ensure that the trim fits correctly, as even minor discrepancies can lead to inefficiencies.

3 Common User Pain Points for ‘alum trim’ & Their Solutions

Scenario 1: Sourcing Quality Aluminum Trim for Diverse Applications

The Problem: B2B buyers often struggle to find aluminum trim that meets both their quality standards and specific project requirements. This challenge is particularly pronounced when dealing with diverse applications, such as construction, cabinetry, or vehicle interiors. Buyers may receive inconsistent product quality or face delays due to sourcing from multiple suppliers, resulting in project setbacks and increased costs. Additionally, with the global market’s complexities, understanding local regulations and standards can add another layer of difficulty.

The Solution: To ensure you source high-quality aluminum trim, start by establishing relationships with reputable suppliers who specialize in your specific application needs. Look for vendors that provide detailed specifications, including aluminum grades, finishes, and gauge thickness. Request samples before making bulk purchases to assess the quality firsthand. Consider suppliers that offer customization options, as this can help tailor the trim to meet your unique project requirements. Collaborating with suppliers who are knowledgeable about local standards can also streamline the sourcing process and ensure compliance, minimizing the risk of delays and additional costs.

Scenario 2: Installation Challenges of Aluminum Trim

The Problem: Another significant pain point for B2B buyers is the installation of aluminum trim, which can be complicated and time-consuming. Improper installation can lead to aesthetic issues, structural weaknesses, and even damage to the trim itself. This is particularly relevant in high-stakes environments such as commercial buildings or luxury residential projects, where the finish needs to be perfect. Buyers may find it hard to identify the best installation methods or tools, leading to mistakes that could have been avoided with proper guidance.

Illustrative image related to alum trim

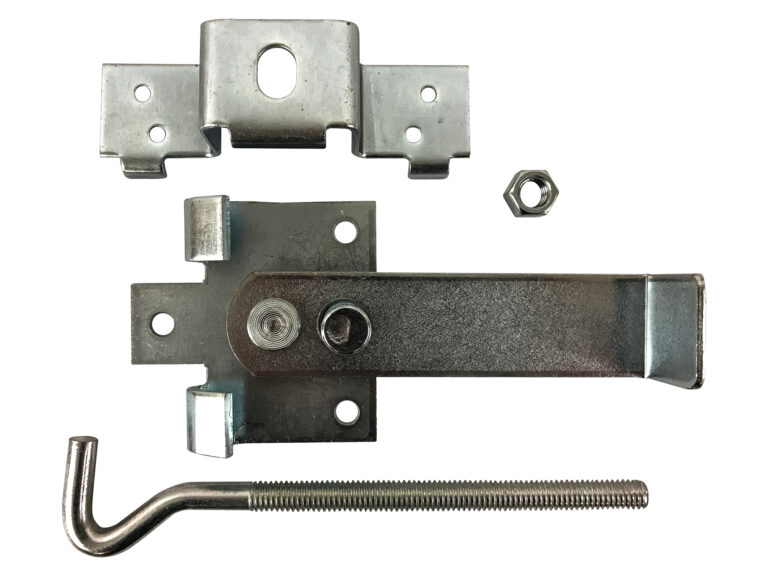

The Solution: To overcome installation challenges, invest in thorough training for your installation team. Partner with your aluminum trim supplier to access installation guides, videos, and on-site training sessions. Select trim products that are designed for ease of installation, such as those with pre-drilled holes or snap-fit designs. Additionally, ensure that your team has the right tools for the job, including specialized cutting equipment and fasteners that are compatible with the aluminum trim. Before commencing installation, conduct a comprehensive review of the project plans to ensure that all team members are aligned on the installation process and any potential challenges that may arise.

Scenario 3: Managing Supply Chain Disruptions

The Problem: Supply chain disruptions pose a significant concern for B2B buyers of aluminum trim, particularly in a global market subject to fluctuations in availability and pricing. Unexpected delays can lead to project stalls, resulting in missed deadlines and potential financial penalties. Buyers may also struggle with finding alternative sources quickly, which can affect project timelines and budgets.

The Solution: To mitigate supply chain risks, diversify your supplier base and avoid reliance on a single source for aluminum trim. Establish relationships with multiple suppliers across different regions, which can provide a buffer in case of disruptions. Additionally, monitor market trends and lead times regularly to anticipate potential shortages. Implementing a just-in-time inventory system can help manage stock levels effectively while reducing the risk of over-ordering or stockouts. Finally, maintaining open lines of communication with your suppliers can foster transparency, allowing you to receive timely updates on inventory and potential disruptions, enabling you to adjust your planning accordingly.

Strategic Material Selection Guide for alum trim

What are the Key Properties of Common Materials for Aluminum Trim?

When selecting materials for aluminum trim, it’s essential to consider various options that can meet specific application needs. Here, we analyze four common materials used in aluminum trim manufacturing, focusing on their properties, advantages, disadvantages, and relevance to international B2B buyers.

1. Standard Aluminum Alloy (6063)

Key Properties: Standard aluminum alloy 6063 is known for its excellent corrosion resistance and good mechanical properties. It can withstand moderate temperatures and pressures, making it suitable for various applications.

Pros & Cons: This alloy is lightweight and easy to extrude, which simplifies manufacturing processes. However, it may not be as strong as other alloys, which can limit its use in high-stress applications. The cost is relatively low, making it an attractive option for budget-conscious projects.

Impact on Application: 6063 is often used in architectural applications, such as window frames and curtain walls, due to its aesthetic appeal and ability to be anodized or painted.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN for structural integrity. In regions like Europe and the Middle East, preference may lean towards materials that meet stringent environmental regulations.

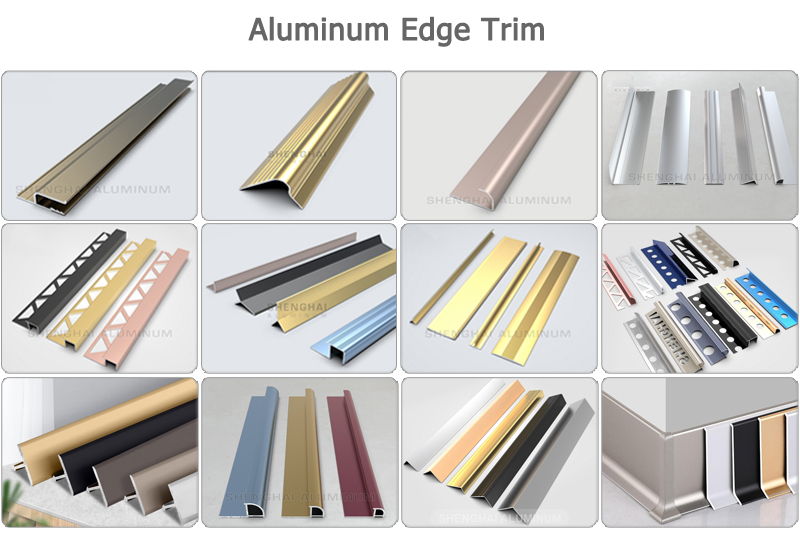

2. Anodized Aluminum

Key Properties: Anodized aluminum undergoes an electrochemical process that enhances its corrosion resistance and surface hardness. It can withstand higher temperatures compared to standard aluminum.

Pros & Cons: The anodizing process allows for a variety of color finishes, enhancing aesthetic appeal. However, this process can increase manufacturing complexity and costs, making it a more expensive option.

Impact on Application: Anodized aluminum is ideal for applications requiring both durability and visual appeal, such as in high-end residential or commercial projects.

Considerations for International Buyers: Buyers in regions like Saudi Arabia, where environmental conditions can be harsh, may find anodized aluminum particularly beneficial. Compliance with local standards for coatings and finishes is essential.

3. Aluminum Composite Material (ACM)

Key Properties: ACM consists of two thin layers of aluminum enclosing a non-aluminum core, offering excellent thermal insulation and sound-dampening properties. It is lightweight and has good fire resistance.

Pros & Cons: ACM provides a modern aesthetic and is highly versatile, suitable for both interior and exterior applications. However, its composite nature can complicate recycling and disposal processes, and it may have a higher initial cost.

Impact on Application: Commonly used in façade systems and signage, ACM is favored for its sleek appearance and performance in urban environments.

Illustrative image related to alum trim

Considerations for International Buyers: Buyers should be aware of local regulations concerning fire safety and material sustainability, particularly in Europe where stringent standards apply.

4. Marine-Grade Aluminum (5052)

Key Properties: Marine-grade aluminum, particularly 5052, is designed to withstand harsh environments, offering superior corrosion resistance, especially in saltwater conditions.

Pros & Cons: This material is highly durable and suitable for marine applications, but it comes at a higher cost compared to standard aluminum alloys. Its increased weight can also be a drawback in applications where weight savings are critical.

Impact on Application: Ideal for marine applications, this aluminum is often used in boat fittings, docks, and other structures exposed to saltwater.

Considerations for International Buyers: Buyers in coastal regions, such as those in South America, should prioritize marine-grade aluminum for its longevity in challenging environments. Compliance with maritime standards is crucial for ensuring safety and performance.

Summary Table of Material Selection for Aluminum Trim

| Material | Typical Use Case for alum trim | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Standard Aluminum Alloy (6063) | Architectural applications | Lightweight and cost-effective | Limited strength for high-stress use | Low |

| Anodized Aluminum | High-end residential/commercial | Enhanced corrosion resistance | Higher manufacturing complexity | High |

| Aluminum Composite Material (ACM) | Façade systems/signage | Modern aesthetic and insulation | Complicated recycling process | Medium |

| Marine-Grade Aluminum (5052) | Marine applications | Superior corrosion resistance | Higher cost and weight | High |

This strategic material selection guide provides insights into the various materials available for aluminum trim, enabling international B2B buyers to make informed decisions based on performance requirements, cost considerations, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for alum trim

What Are the Key Manufacturing Processes for Aluminum Trim?

The manufacturing of aluminum trim involves several critical stages that ensure the final product meets both aesthetic and functional requirements. These stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Aluminum Trim Production?

The first step in the manufacturing process is material preparation. High-quality aluminum alloy sheets are sourced based on specific project requirements, considering factors such as thickness, alloy type, and mechanical properties. These sheets undergo an inspection process to ensure they are free from defects. Once approved, the sheets are cut into predetermined sizes using precision cutting tools to facilitate further processing.

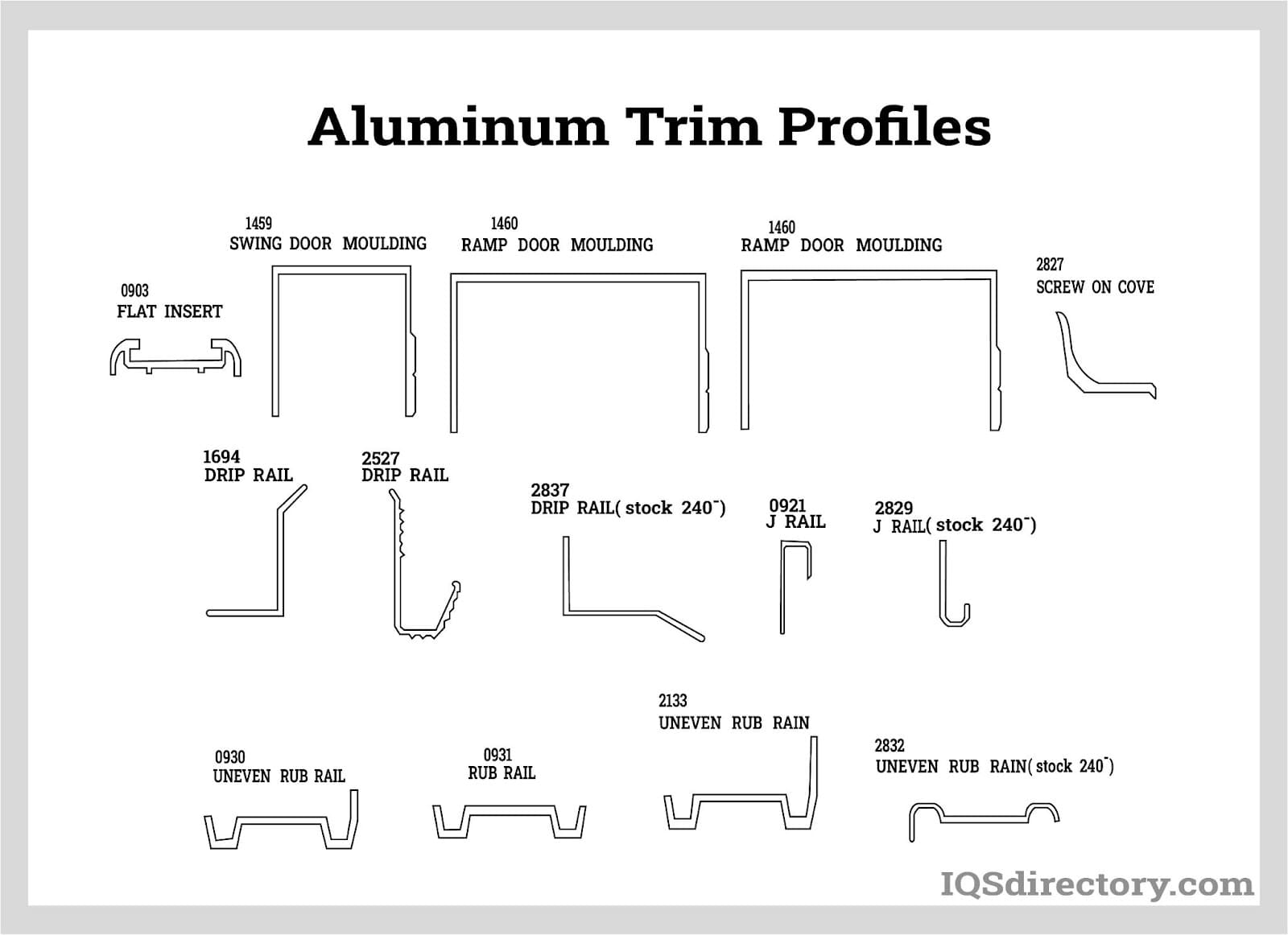

What Techniques Are Used in Forming Aluminum Trim?

The forming stage employs various techniques to shape the aluminum into desired profiles. Extrusion is a prevalent method, where heated aluminum is forced through a die to create specific cross-sectional shapes. This process allows for the creation of complex profiles that are consistent in dimensions. For more intricate designs, processes such as bending, rolling, and stamping are utilized. Each technique ensures that the aluminum trim maintains its structural integrity while achieving the necessary design specifications.

How Is Assembly Conducted in Aluminum Trim Manufacturing?

Assembly involves integrating various components into a cohesive product. In the case of aluminum trim, this might include attaching additional features such as clips, fasteners, or protective coatings. The assembly process is often guided by detailed engineering drawings and specifications to guarantee that the final product aligns with the intended design. Automated machinery may be used to enhance efficiency and precision during this stage.

What Are the Finishing Processes for Aluminum Trim?

Finishing is essential for both aesthetic appeal and durability. Common finishing techniques include anodizing and powder coating. Anodizing enhances corrosion resistance by forming a protective oxide layer on the aluminum surface, while powder coating provides a variety of color options and additional protection against scratches and UV exposure. The finishing process is often followed by a thorough inspection to ensure consistency in color and texture, as well as adherence to quality standards.

What Quality Assurance Practices Are Critical in Aluminum Trim Manufacturing?

Quality assurance (QA) is an integral aspect of aluminum trim production. It encompasses a series of checks and balances throughout the manufacturing process, ensuring that the final product meets international standards and customer expectations.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with relevant international standards such as ISO 9001, which outlines requirements for quality management systems. Compliance with ISO 9001 indicates that a manufacturer has established a robust framework for maintaining quality throughout its operations. Additionally, certifications like CE (Conformité Européenne) may be necessary for products sold in the European market, ensuring compliance with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are crucial in maintaining product integrity. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify issues before they escalate.

- Final Quality Control (FQC): A thorough inspection of the finished product ensures it meets all specifications and quality standards before shipment.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Buyers can take several steps to verify a supplier’s quality control processes. Conducting audits of the manufacturing facility is an effective way to assess compliance with quality standards. Buyers can also request quality assurance reports and documentation of certifications. Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures and product quality.

What Common Testing Methods Are Used to Ensure Quality?

To ensure the quality of aluminum trim, various testing methods are employed. These may include:

- Dimensional Inspection: Utilizing precise measuring tools to ensure that the aluminum trim meets specified dimensions.

- Mechanical Testing: Assessing properties such as tensile strength, yield strength, and hardness to ensure the material can withstand operational stresses.

- Corrosion Resistance Testing: Evaluating the material’s ability to resist oxidation and degradation in various environments.

- Adhesion Testing: For coated products, testing the bond strength of the coating to the aluminum substrate is crucial to ensure durability.

How Do Quality Control Nuances Vary for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must consider specific nuances in quality control. Different countries may have varying regulations and standards that affect product acceptance. Buyers should ensure that suppliers are familiar with local compliance requirements and can provide necessary certifications.

Additionally, logistics and shipping practices can impact product quality. Ensuring that suppliers utilize appropriate packaging and handling methods during transport is essential to prevent damage. Buyers should also be aware of any import regulations that may affect product compliance upon arrival.

Conclusion: Why Understanding Manufacturing and Quality Assurance Is Essential for B2B Buyers

A comprehensive understanding of the manufacturing processes and quality assurance practices for aluminum trim is vital for B2B buyers. By recognizing the stages involved in production and the importance of adhering to quality standards, buyers can make informed decisions that ensure the reliability and performance of their aluminum trim purchases. Engaging with suppliers who prioritize quality can lead to enhanced project outcomes and long-term partnerships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alum trim’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure aluminum trim. It outlines essential steps to ensure you make informed decisions, establish reliable supplier relationships, and secure high-quality products that meet your specific needs.

Illustrative image related to alum trim

1. Define Your Technical Specifications

Before you begin sourcing, it’s vital to clarify your project requirements. This includes determining the dimensions, gauge, and finish of the aluminum trim needed for your applications.

– Consider factors such as whether you require custom profiles or standard shapes.

– Understanding the technical specifications will also aid in communicating effectively with potential suppliers.

2. Research Available Suppliers

Conduct thorough research to identify potential suppliers in the aluminum trim market. Look for manufacturers and distributors who specialize in the type of trim you need.

– Utilize online platforms, trade directories, and industry associations to compile a list of candidates.

– Pay attention to suppliers that have a strong reputation in your target regions, such as Europe or the Middle East, to ensure compliance with local standards.

3. Evaluate Potential Suppliers

Before making a commitment, it is crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Assess their production capabilities and quality control measures to ensure they can meet your specifications.

– Don’t just rely on their website; consider visiting their facilities if feasible or requesting virtual tours.

Illustrative image related to alum trim

4. Verify Product Quality and Certifications

Ensure that the aluminum trim meets industry standards and regulations. Verify if the products are certified by relevant bodies, such as ISO or ASTM.

– Ask for material test reports and quality assurance documentation.

– This step is vital to mitigate risks associated with subpar products that could impact your project’s integrity.

5. Request Samples

Before finalizing your order, request samples of the aluminum trim. This allows you to assess the quality, finish, and suitability for your project.

– Evaluate the samples for color accuracy, gauge consistency, and overall craftsmanship.

– Sampling can also help you determine if the supplier can meet your aesthetic and functional needs.

6. Understand Pricing Structures and Terms

Once you have narrowed down your options, engage suppliers to discuss pricing, payment terms, and bulk order discounts.

– Ensure you understand the full cost implications, including shipping and handling fees.

– Transparent pricing is crucial for budgeting and financial planning, especially for large-scale projects.

7. Establish Clear Communication Channels

Effective communication is key to a successful sourcing process. Establish clear lines of communication with your chosen supplier to discuss timelines, expectations, and any potential challenges.

– Regular updates and feedback loops can help prevent misunderstandings and ensure timely delivery.

– This step will also foster a stronger business relationship, paving the way for future collaborations.

By following this checklist, B2B buyers can streamline their sourcing process for aluminum trim, ultimately leading to successful project outcomes and long-term supplier partnerships.

Comprehensive Cost and Pricing Analysis for alum trim Sourcing

What Are the Key Cost Components in Alum Trim Sourcing?

When sourcing aluminum trim, buyers must consider various cost components that contribute to the final price. The primary cost elements include:

- Materials: The type and quality of aluminum used significantly affect the cost. Standard grades are more affordable, while specialized alloys or finishes, like baked enamel coatings, increase the price.

- Labor: Labor costs encompass the workforce involved in manufacturing, cutting, and finishing the aluminum trim. Regions with higher labor costs will see increased pricing.

- Manufacturing Overhead: This includes expenses related to factory operations, utilities, equipment maintenance, and other indirect costs associated with production.

- Tooling: Custom profiles may require specific tooling, which can lead to higher initial costs. Buyers should factor this into their overall budget, particularly for unique specifications.

- Quality Control (QC): Ensuring product quality through rigorous QC processes incurs additional costs. However, investing in quality can reduce long-term costs associated with defects and returns.

- Logistics: Shipping costs vary widely based on distance, weight, and the chosen shipping method. For international buyers, customs duties and import taxes must also be considered.

- Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the typical margins in the industry can help buyers negotiate better.

How Do Pricing Influencers Impact Alum Trim Costs?

Several factors influence the pricing of aluminum trim, and understanding these can aid buyers in making informed decisions:

- Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced unit costs. Buyers should negotiate MOQs that align with their needs to capitalize on volume pricing.

- Specifications and Customization: Custom orders typically incur higher prices due to unique tooling and production processes. Standard sizes and finishes are generally more cost-effective.

- Materials and Quality Certifications: Higher-quality materials or those with specific certifications (like ISO or ASTM) can lead to increased costs. Buyers should balance quality with budget constraints.

- Supplier Factors: Supplier reputation, reliability, and location can affect pricing. Established suppliers may command higher prices due to their proven track record.

- Incoterms: The choice of Incoterms (International Commercial Terms) affects responsibility for shipping, insurance, and customs. Different terms can lead to variations in total costs.

What Are Effective Buyer Tips for Alum Trim Sourcing?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

- Negotiation: Engage suppliers in discussions about pricing, especially when placing bulk orders. Leverage potential long-term partnerships to secure better rates.

- Cost-Efficiency Strategies: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and disposal costs over the product’s life. This approach can reveal hidden savings.

- Understanding Pricing Nuances: Be aware of fluctuations in aluminum prices due to global market conditions. This knowledge can aid in timing purchases for cost savings.

- Local Regulations and Import Duties: Familiarize yourself with local regulations and potential tariffs that could affect the final price of imported aluminum trim. This knowledge is crucial for budgeting.

- Supplier Diversification: Consider multiple suppliers to compare prices and terms. This practice can also mitigate risks associated with reliance on a single source.

Disclaimer on Indicative Prices

Prices for aluminum trim can vary widely based on the factors outlined above. It is essential for buyers to conduct thorough market research and obtain quotes from multiple suppliers to ensure competitive pricing. Regularly reviewing supplier agreements and costs can lead to ongoing savings and improved sourcing strategies.

Alternatives Analysis: Comparing alum trim With Other Solutions

Exploring Alternative Solutions to Alum Trim

In the competitive landscape of building materials, B2B buyers must consider various solutions to achieve desired functionality and aesthetic appeal. While alum trim is a popular choice for its lightweight, corrosion-resistant, and visually appealing properties, several alternatives offer different advantages depending on project specifications and budget constraints. Below is a comparative analysis of alum trim against two viable alternatives: PVC trim and wood trim.

| Comparison Aspect | Alum Trim | PVC Trim | Wood Trim |

|---|---|---|---|

| Performance | Durable, corrosion-resistant, ideal for both interior and exterior applications. | Resistant to moisture and rot, but can warp in extreme heat. | Aesthetically pleasing, but susceptible to rot and pests without treatment. |

| Cost | Moderate initial investment; long-term savings due to durability. | Generally lower cost than alum, but may require replacements sooner. | Higher initial cost; ongoing maintenance can add to lifetime expense. |

| Ease of Implementation | Lightweight and easy to install; custom sizes available. | Easy to cut and install; often available in pre-fabricated lengths. | Heavier, requires more specialized tools for installation. |

| Maintenance | Minimal maintenance; resistant to fading and chipping. | Requires regular cleaning; can discolor over time. | High maintenance; needs regular painting or sealing to protect against elements. |

| Best Use Case | Ideal for commercial and residential projects requiring durability and a modern look. | Suitable for budget-conscious projects where moisture resistance is critical. | Best for traditional designs where aesthetics are prioritized. |

What Are the Pros and Cons of PVC Trim Compared to Alum Trim?

PVC trim presents a cost-effective alternative to alum trim, particularly beneficial in environments prone to moisture, such as bathrooms or kitchens. Its resistance to rot and warping makes it a reliable choice for areas where traditional materials may fail. However, PVC may not provide the same level of aesthetic appeal as alum trim, and its longevity can be questionable under extreme heat, leading to potential warping and discoloration.

How Does Wood Trim Compare to Alum Trim?

Wood trim remains a classic choice for many builders due to its natural beauty and versatility. It can be easily customized and is available in various styles, making it a favorite for high-end residential projects. However, wood trim requires significant maintenance to prevent rot and pest infestations, making it less cost-effective over time compared to alum trim. Moreover, the weight of wood can complicate installation, requiring specialized tools and expertise.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the appropriate trim solution hinges on understanding the specific requirements of a project. B2B buyers should evaluate factors such as performance expectations, budget constraints, and aesthetic goals. For projects demanding durability and minimal maintenance, alum trim is often the best choice. Conversely, if cost is the primary concern and the environment is less demanding, PVC trim may be suitable. For projects where aesthetics play a crucial role, wood trim could be the ideal solution, albeit with higher maintenance needs. Ultimately, the choice should align with project specifications, ensuring that it meets both functional and visual requirements effectively.

Essential Technical Properties and Trade Terminology for alum trim

What Are the Key Technical Properties of Aluminum Trim?

Understanding the essential technical properties of aluminum trim is vital for making informed purchasing decisions. Here are several critical specifications that B2B buyers should consider:

-

Material Grade: Aluminum trim is often categorized by its alloy composition, such as 6061 or 6063. These grades determine the trim’s strength, corrosion resistance, and suitability for specific applications. For example, 6061 is a versatile alloy that offers good mechanical properties and weldability, making it ideal for structural applications.

-

Thickness (Gauge): The thickness of aluminum trim is typically measured in gauges. A common standard is 0.019 inches, which is comparable to 25-26 gauge sheet metal. The thickness affects durability, weight, and the trim’s ability to withstand environmental stressors. Buyers should select a thickness that aligns with their project requirements, especially in high-traffic or exposed environments.

-

Finish Type: Aluminum trim is available in various finishes, including anodized, painted, and mill finish. The finish impacts both aesthetics and performance. Anodized finishes provide enhanced corrosion resistance and durability, while painted finishes can offer a broader range of color options. Understanding the implications of each finish helps in selecting the right product for specific design needs.

-

Tolerance Levels: Tolerance refers to the allowable deviation from specified dimensions. In aluminum trim, precise tolerances are crucial for ensuring proper fit and finish in construction projects. For instance, tighter tolerances might be necessary for applications in high-end architecture or where aesthetics are critical, while looser tolerances could suffice for more utilitarian projects.

-

Corrosion Resistance: Aluminum naturally resists corrosion, but the level can vary based on the alloy and finish. For projects in coastal or humid environments, it’s essential to select trims that have enhanced corrosion resistance properties, such as those with anodized or specialized coatings.

-

Weight: Aluminum is known for being lightweight yet strong. Understanding the weight of the trim can affect shipping costs and ease of installation. Lighter trims may be easier to handle and install, reducing labor costs, especially in large-scale projects.

What Are Common Trade Terms Used in the Aluminum Trim Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms that buyers should know:

Illustrative image related to alum trim

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the aluminum trim industry, buyers often engage with OEMs to procure custom solutions tailored to their specifications.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory planning, as it can influence purchasing strategies, particularly for smaller businesses or unique projects.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting a price quote for specific quantities and specifications of products. This process allows buyers to compare pricing and terms from different suppliers, ensuring they receive competitive offers.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps in understanding shipping costs, risk management, and delivery timelines, which are critical for international buyers.

-

Lead Time: This refers to the amount of time it takes from placing an order until it is delivered. Knowing the lead time helps businesses plan their projects effectively, ensuring that materials arrive when needed to avoid delays.

-

Custom Fabrication: This term refers to the process of creating specialized trim profiles or sizes that are not available off-the-shelf. Custom fabrication is important for unique projects where standard products do not meet specific design or functional requirements.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing aluminum trim, ultimately leading to successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the alum trim Sector

What Are the Key Trends Driving the Global Alum Trim Market?

The alum trim market is witnessing significant growth, driven by several global factors including urbanization, infrastructure development, and a rising demand for durable building materials. Particularly in regions such as Africa, South America, the Middle East, and Europe, there is an increasing focus on architectural aesthetics coupled with functionality. The shift towards lightweight materials like aluminum is notable, as these products offer both corrosion resistance and ease of installation, making them ideal for various applications ranging from cabinetry to architectural millwork.

Emerging technologies are reshaping sourcing trends, with digital platforms facilitating easier access to suppliers and enabling streamlined procurement processes. B2B buyers are increasingly leveraging online marketplaces to compare prices, assess product specifications, and read reviews, thereby making informed purchasing decisions. Additionally, the integration of AI and data analytics in supply chain management is enhancing forecasting accuracy, enabling companies to better anticipate market fluctuations and adjust their sourcing strategies accordingly.

Moreover, the growing trend of customization in alum trim products allows businesses to cater to specific project requirements. This is particularly beneficial for international buyers who seek tailored solutions that align with local design standards and preferences, ensuring their projects meet both aesthetic and functional needs.

Illustrative image related to alum trim

How Is Sustainability Influencing the Sourcing of Alum Trim Products?

Sustainability is becoming a cornerstone in the sourcing decisions of B2B buyers within the alum trim sector. The environmental impact of manufacturing processes, coupled with increased regulatory scrutiny, has led many companies to prioritize ethical sourcing practices. Buyers are now actively seeking suppliers who demonstrate a commitment to sustainable manufacturing methods, including the use of recycled materials and energy-efficient production techniques.

Certifications such as LEED (Leadership in Energy and Environmental Design) and ISO 14001 are gaining importance, as they assure buyers that the products meet rigorous environmental standards. Furthermore, the trend towards ‘green’ materials is reshaping product offerings, with many manufacturers developing eco-friendly finishes and coatings for alum trims that are free from harmful chemicals.

As a result, international B2B buyers, particularly those from Europe and regions with stringent environmental regulations, are more inclined to partner with suppliers who can provide transparency regarding their sourcing practices and environmental certifications. This not only aligns with corporate social responsibility goals but also enhances brand reputation in an increasingly eco-conscious market.

Illustrative image related to alum trim

What Is the Historical Context of the Alum Trim Industry?

The alum trim industry has evolved significantly since its inception, adapting to changing architectural styles and material innovations. Initially, aluminum trims were primarily used for functional purposes, such as protecting edges and finishes in various applications. However, as design trends shifted towards minimalism and modern aesthetics in the mid-20th century, aluminum trims began to be recognized for their visual appeal as well as their practicality.

Over the decades, advancements in manufacturing technology have allowed for greater customization and precision in alum trim products, catering to a diverse range of applications in both residential and commercial sectors. Today, the industry is characterized by a blend of traditional craftsmanship and modern technology, enabling suppliers to meet the complex demands of international B2B buyers. This evolution underscores the importance of staying attuned to market trends and technological advancements in order to remain competitive in this dynamic sector.

Frequently Asked Questions (FAQs) for B2B Buyers of alum trim

-

How do I choose the right aluminum trim for my project?

Selecting the right aluminum trim involves assessing your specific project needs, including the intended application, aesthetic preferences, and environmental conditions. Consider factors such as the trim’s thickness, finish, and resistance to corrosion. Additionally, evaluate the color options available and how they align with your design. It’s also beneficial to consult with suppliers for recommendations based on their experience with similar projects, ensuring you select a product that meets both functional and aesthetic criteria. -

What are the most common applications for aluminum trim in construction?

Aluminum trim is widely used in various construction applications, including cabinetry, architectural millwork, and commercial fixtures. It serves to provide a clean, polished finish to edges on panels, doors, countertops, and displays. Its lightweight and corrosion-resistant properties make it suitable for both interior and exterior projects, enhancing durability and visual appeal while preventing wear and damage over time. -

What customization options are available for aluminum trim?

Many suppliers offer extensive customization options for aluminum trim, including various shapes, sizes, and finishes. You can request specific colors and even custom profiles to match unique design requirements. When placing an order, be sure to communicate your specifications clearly, as this will help suppliers provide accurate quotes and ensure that the final product meets your expectations. -

What is the typical minimum order quantity (MOQ) for aluminum trim?

Minimum order quantities for aluminum trim can vary significantly among suppliers. Generally, MOQs may range from a few hundred feet to several thousand, depending on the trim type and customization level. It’s advisable to inquire directly with potential suppliers about their MOQ policies, as some may accommodate smaller orders or offer flexibility for first-time buyers or specific projects. -

How do I ensure the quality of aluminum trim when sourcing internationally?

To ensure the quality of aluminum trim, it’s crucial to vet suppliers thoroughly. Request samples of their products to assess quality before making a bulk purchase. Additionally, check for certifications that verify compliance with international standards. Engaging in direct communication with suppliers and reading customer reviews can also provide insights into their reliability and product quality. -

What payment terms should I expect when purchasing aluminum trim internationally?

Payment terms for international purchases of aluminum trim vary by supplier. Common terms include upfront payments, deposits, or net payment options (e.g., net 30 or net 60 days). It’s essential to clarify these terms before finalizing your order to avoid misunderstandings. Consider using secure payment methods or escrow services to protect your investment, especially when dealing with new suppliers. -

What logistics considerations should I keep in mind when importing aluminum trim?

When importing aluminum trim, consider shipping methods, transit times, and associated costs. Ensure you understand the import regulations of your country, including customs duties and taxes. It’s beneficial to work with a freight forwarder who can help navigate the logistics and provide updates throughout the shipping process. Additionally, inquire about the supplier’s packaging and handling practices to prevent damage during transit. -

How can I address potential delays in aluminum trim delivery?

To mitigate potential delivery delays, maintain clear communication with your supplier regarding production and shipping timelines. Request updates on your order’s status, and consider setting realistic deadlines for your project. It’s also wise to plan for contingencies by ordering well in advance and discussing alternative solutions with your supplier in case of unforeseen delays. Having a reliable logistics partner can also help expedite the shipping process.

Top 7 Alum Trim Manufacturers & Suppliers List

1. Metals Depot – Aluminum Trim Shapes & Edging

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: Aluminum Trim Shapes & Edging: 1. Aluminum J Trim – 1/8″; Stock Number: JCAP18; Sizes: 48″, 96″, 144″. 2. Aluminum T Divider Trim; Stock Number: MDT-E110; Sizes: 48″, 96″. 3. Aluminum Outside Corner Trim; Stock Number: MDT-E93; Sizes: 48″, 96″. 4. Aluminum Inside Corner Trim; Stock Number: MDT-E85; Sizes: 48″, 96″. Pricing: $0.00 for all items. Custom Quote Service available. Customer Service Hour…

2. Trimbender – Aluminum Finish Trim

Domain: trimbender.com

Registered: 2008 (17 years)

Introduction: {“product_name”: “Aluminum Finish Trim”, “availability”: “In Stock”, “product_code”: “FT01”, “starting_price”: “$1.65/ft”, “sizes”: {“size_a”: [“1”, “1-1/16”, “1-1/8”, “1-1/4”, “1-3/8”, “1-1/2”, “1-5/8”, “1-3/4”, “1-7/8”, “2”, “2-1/8”, “2-1/4”], “size_b”: [“3/4”, “7/8”, “1”, “1-1/8”, “1-1/4”, “2”]}, “lengths”: [“4 Foot (47″)”, “6 Foot (72″)”, “8 Foot (94″ max)”], “colors”: [“White”, “Smooth Black”…

3. Orange Aluminum – Edge Trims

Domain: orangealuminum.com

Registered: 2006 (19 years)

Introduction: Aluminum edge trims offer clean, protective finishing for exposed edges on panels, doors, countertops, and displays. Commonly used in cabinetry, architectural millwork, vehicle interiors, and commercial fixtures, they help prevent chipping, wear, and damage while delivering a polished, professional look. Lightweight, corrosion-resistant, and easy to install, these trims are ideal for adding durabi…

4. Cap Drywall Trims – Aluminum Edge & Reveal Trim

Domain: capdrywalltrims.com

Registered: 2017 (8 years)

Introduction: Aluminum Trim Reglets include various types of trim such as ‘L’ Edge Trim and ‘F’ Reveal Trim, all primed for painting. Available sizes include: 1 1/4″ (ST-125), 1″ (ST-100), 5/8″ (ST-063), and 1/2″ (ST-050) Aluminum ‘L’ Edge Trim, each in 92″ lengths (7′-8″). ‘F’ Reveal Trim sizes include 1″ x 5/8″ (SWR-100U-063), 3/4″ x 5/8″ (SWR-075U-063), 5/8″ x 5/8″ (SWR-063U-063), and others, also in 92″ len…

5. Brand X Metals – Extruded Aluminum Trims

Domain: brandxmetals.com

Registered: 2007 (18 years)

Introduction: Extruded Aluminum Trims manufactured by Brand X Metals, designed for the lath, plaster, stucco, and drywall construction industry. Made from 6063 aluminum alloy, these trims come in a variety of finishes and sizes. Key products include: Eliminator Trim, Plaster Channel Screed, Streamline Channel Screed, F Mold Plaster Trim, 2pc Expansion Joint, 1/4″ Plaster Channel, Extruded J-Mold/Casing Bead, Dr…

6. EasyTrim Reveals® – Aluminum Trim Systems

Domain: engagebp.com

Registered: 2017 (8 years)

Introduction: EasyTrim Reveals® is an industry-leading aluminum trim system designed for compatibility with fiber cement, vinyl, and other siding products. It features a complete two-piece exterior design, available in various sizes including 5/16″, 7/16″, 3/4″, 1″, and 1 1/4″ trim systems, as well as transition trims and universal trims. The system is crafted from ultra-durable 6063-T6 extruded aluminum, makin…

7. Eagle Aluminum – Corner Trim Solutions

Domain: eagle-aluminum.com

Registered: 2010 (15 years)

Introduction: Aluminum Corner Trim – Inside & Outside Angles. Offers stability and protection with a seamless look. Available in varying sizes and shapes. Corrosion resistant, lightweight, and cost-effective. Ideal for large and small buildings. Exceptional customer service for project guidance. Product categories include Architectural Trims, Drywall Trims, Millwork Trims, and more. Specific products include: C…

Strategic Sourcing Conclusion and Outlook for alum trim

In today’s competitive landscape, effective strategic sourcing of aluminum trim is essential for international B2B buyers aiming to enhance their projects’ durability and aesthetic appeal. With the diverse range of aluminum trim options available—ranging from edge trims to custom extrusions—buyers can select products that not only meet their specific needs but also align with their sustainability goals. The lightweight yet robust nature of aluminum ensures that these trims offer long-lasting performance while minimizing maintenance costs, making them an attractive investment.

Additionally, strategic partnerships with reputable suppliers can lead to improved supply chain efficiency, reduced lead times, and access to innovative solutions tailored to regional market demands. As global trends shift towards eco-friendly construction materials, aluminum trim stands out as a sustainable choice that does not compromise on quality.

Looking ahead, we encourage international buyers from Africa, South America, the Middle East, and Europe to explore the vast potential of aluminum trim in their upcoming projects. Engage with suppliers who prioritize customization and offer comprehensive support to ensure your sourcing strategy is not only effective but also future-ready. Embrace the opportunity to elevate your designs with superior aluminum trim solutions today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.