The Definitive Guide to Nylon Tube: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for nylon tube

In an increasingly interconnected world, sourcing high-quality nylon tubing can present significant challenges for international B2B buyers. From navigating diverse supplier landscapes to understanding compliance with regional regulations, the complexities can be daunting. This guide aims to demystify the global market for nylon tubes by providing insights into various types, applications, and the nuances of supplier vetting. Whether you are in industries such as automotive, agriculture, or chemical processing, having a comprehensive understanding of nylon tubing options is essential for making informed purchasing decisions.

Our guide delves into critical factors such as cost considerations, material specifications, and the importance of selecting the right suppliers. It also highlights how to assess product quality and compliance with international standards, ensuring that your sourcing decisions align with your operational needs and regional requirements. By equipping B2B buyers, particularly from Africa, South America, the Middle East, and Europe, with actionable knowledge, this resource empowers you to streamline your procurement processes and enhance your supply chain efficiency.

Ultimately, our goal is to help you navigate the complexities of the nylon tubing market, enabling you to secure the best products for your business while mitigating risks associated with supplier selection and compliance.

Understanding nylon tube Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Nylon Tubing | Flexible, moisture-resistant, high heat tolerance | Pneumatic systems, automotive, robotics | Pros: Cost-effective, versatile. Cons: Limited pressure ratings. |

| High Pressure Nylon Tubing | Enhanced strength for high-pressure applications | Hydraulic systems, fuel lines | Pros: Excellent durability. Cons: Higher cost compared to standard. |

| Super Soft Nylon Tubing | Exceptional flexibility and ease of handling | Medical devices, food processing | Pros: Lightweight, easy to maneuver. Cons: Not suitable for high-pressure applications. |

| D.O.T. Nylon Tubing | Compliance with Department of Transportation standards | Automotive fuel lines, air brake systems | Pros: Regulatory compliance, high safety standards. Cons: May be more expensive due to certifications. |

| Nylon Mini Coils | Compact coiled design for space-saving applications | Robotics, automated machinery | Pros: Space-efficient, easy to store. Cons: Limited length options. |

What Are the Characteristics of Standard Nylon Tubing?

Standard nylon tubing is characterized by its flexibility, resistance to moisture, and ability to withstand high temperatures, with a melting point around 374°F (190°C). This type is commonly used in pneumatic systems and automotive applications due to its cost-effectiveness and versatility. When purchasing, buyers should consider the specific diameter and length requirements, as well as the working pressure limits, which may vary based on the application.

How Does High Pressure Nylon Tubing Differ from Other Types?

High pressure nylon tubing is specifically designed to handle elevated pressures, making it ideal for hydraulic systems and fuel lines. Its enhanced strength and durability are key selling points, but this type typically comes at a higher price than standard nylon tubing. B2B buyers must evaluate the pressure ratings against their operational needs and consider the long-term value of investing in higher-quality materials.

What Advantages Does Super Soft Nylon Tubing Offer?

Super soft nylon tubing is known for its exceptional flexibility and lightweight properties, making it suitable for applications in medical devices and food processing. It is easy to handle and can be maneuvered in tight spaces, which is a significant advantage in complex installations. However, it is not recommended for high-pressure environments, so buyers should assess the specific demands of their applications before making a decision.

Why Choose D.O.T. Nylon Tubing for Automotive Applications?

D.O.T. nylon tubing is manufactured to meet the stringent requirements set by the Department of Transportation, making it an ideal choice for automotive fuel lines and air brake systems. Its compliance with safety standards ensures reliability in critical applications. While it may be priced higher due to certification costs, the assurance of safety and performance can justify the investment for many businesses.

What Are the Benefits of Using Nylon Mini Coils?

Nylon mini coils are designed for applications where space is limited, such as in robotics and automated machinery. Their compact coiled design allows for easy storage and transport, making them highly practical. However, buyers should be mindful of the limited length options available, as this may restrict their use in larger systems. Evaluating the specific needs of the project is essential when considering this type of tubing.

Key Industrial Applications of nylon tube

| Industry/Sector | Specific Application of nylon tube | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Fuel and vapor lines | Enhanced safety and efficiency in fuel transport | Compliance with industry standards, temperature resistance |

| Agriculture | Tool lubricating systems | Improved equipment longevity and reduced maintenance | Chemical resistance, durability under various conditions |

| Robotics | Pneumatic systems | Precision control and reliability in automated processes | Customization options, pressure ratings, and flexibility |

| Chemical Processing | Chemical transfer lines | Safe handling of corrosive materials | Material compatibility, temperature and pressure ratings |

| Packaging | Pick and place automation | Increased efficiency and speed in packaging operations | Custom sizes and colors, resistance to wear and tear |

How is Nylon Tube Utilized in the Automotive Sector?

In the automotive industry, nylon tubes are essential for fuel and vapor lines, providing a lightweight yet durable solution that enhances safety and efficiency in fuel transport. The high resistance to heat and chemicals ensures that these tubes can withstand the harsh conditions typically found in automotive applications. Buyers in this sector need to consider compliance with industry standards and the temperature resistance of the tubing to ensure optimal performance and safety.

What Role Does Nylon Tube Play in Agriculture?

Nylon tubes find significant applications in agriculture, particularly in tool lubricating systems. These tubes facilitate the efficient transfer of lubricants, which is critical for maintaining machinery and extending equipment longevity. For international buyers, especially in regions with varying climate conditions, sourcing nylon tubes with high chemical resistance and durability is vital to prevent breakdowns and reduce maintenance costs.

Why is Nylon Tube Important for Robotics?

In robotics, nylon tubes are widely used in pneumatic systems, where they contribute to precision control and reliability in automated processes. Their flexibility allows for intricate designs and configurations, essential for robotic movement and operation. Buyers should focus on customization options, pressure ratings, and overall flexibility to ensure the tubing meets the specific requirements of their robotic systems.

How is Nylon Tube Used in Chemical Processing?

Nylon tubes are crucial for chemical processing applications, particularly for chemical transfer lines. They provide a safe means of handling corrosive materials, minimizing the risk of leaks and contamination. Buyers in this sector must prioritize material compatibility with the chemicals being transported, as well as temperature and pressure ratings to guarantee safe and efficient operations.

What Benefits Does Nylon Tube Offer in Packaging Automation?

In the packaging industry, nylon tubes are integral to pick and place automation systems. They enhance the efficiency and speed of packaging operations by facilitating quick and reliable movement of products. Sourcing considerations for this application include the need for custom sizes and colors, as well as resistance to wear and tear, ensuring that the tubes can withstand the demands of high-speed packaging environments.

3 Common User Pain Points for ‘nylon tube’ & Their Solutions

Scenario 1: Difficulties in Sourcing High-Quality Nylon Tubing

The Problem: B2B buyers often face significant challenges when sourcing nylon tubing that meets their specific application requirements. Many suppliers may provide generic products that do not comply with industry standards or are not tailored to the unique needs of the buyer’s operational environment. For example, a buyer in the automotive industry might require nylon tubing with specific heat resistance properties, but they encounter products that fail to meet the necessary temperature thresholds, resulting in potential system failures and costly downtimes.

Illustrative image related to nylon tube

The Solution: To address this issue, it is crucial for buyers to conduct thorough research and establish relationships with reliable manufacturers who offer a range of nylon tubing options. Buyers should request detailed product specifications, including chemical resistance, temperature ratings, and compliance with industry standards such as UL94HB or RoHS. Moreover, leveraging custom solutions, such as tailored tubing dimensions or specific material formulations, can ensure that the nylon tubing will perform effectively in their applications. Engaging directly with manufacturers can facilitate this process, allowing buyers to communicate their precise needs and receive expert recommendations.

Scenario 2: Challenges with Compatibility and Installation

The Problem: Another common pain point for B2B buyers is the compatibility of nylon tubing with existing systems and fittings. For instance, when integrating new nylon tubing into a pre-existing pneumatic system, buyers often discover that the tubing does not align with the existing fittings, leading to leaks and inefficiencies. This can be particularly frustrating when projects are time-sensitive, as delays can result in significant financial losses.

The Solution: To mitigate compatibility issues, buyers should focus on precise measurements and specifications when selecting nylon tubing. It is advisable to utilize tubing with standard outer diameters and wall thicknesses that match commonly used fittings. Additionally, engaging with suppliers who provide comprehensive fitting solutions can streamline the installation process. Buyers may also benefit from consulting with technical experts to identify the right fittings and installation techniques that ensure a secure and leak-free connection. Implementing these strategies will not only enhance operational efficiency but also minimize the risk of future complications.

Scenario 3: Performance Limitations Under Extreme Conditions

The Problem: Many B2B buyers encounter performance limitations of nylon tubing when subjected to extreme environmental conditions, such as high temperatures or corrosive substances. For example, in the chemical processing industry, nylon tubing may degrade rapidly when exposed to specific chemicals, leading to leaks and safety hazards. This scenario can jeopardize not only operational efficiency but also compliance with safety regulations, potentially resulting in costly fines or legal issues.

The Solution: To overcome these challenges, it is essential for buyers to select nylon tubing specifically engineered for harsh environments. This includes choosing high-pressure nylon tubing or variants designed with enhanced chemical resistance properties. Buyers should invest time in reviewing chemical compatibility charts provided by manufacturers to ensure the selected tubing can withstand the intended exposure without compromising integrity. Additionally, considering alternatives such as reinforced nylon tubing or hybrid materials that combine nylon with other polymers can provide superior performance under extreme conditions. Regular maintenance and monitoring of tubing conditions will also help in early detection of wear or damage, allowing for timely replacements and maintaining system reliability.

Strategic Material Selection Guide for nylon tube

What Are the Key Materials Used in Nylon Tubing?

When selecting nylon tubing for various applications, understanding the different materials available is crucial. Each material has unique properties that affect performance, durability, and suitability for specific applications. Below is an analysis of four common materials used in nylon tubing, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Nylon 6 Tubing?

Nylon 6 is one of the most widely used types of nylon tubing. It is known for its excellent flexibility and strength, making it suitable for a variety of applications.

- Key Properties: Nylon 6 has a temperature range of -40°F to 210°F (-40°C to 99°C) and offers good resistance to abrasion and chemicals. It also has a relatively low moisture absorption rate, which enhances its dimensional stability.

- Pros & Cons: The advantages of Nylon 6 include its high tensile strength and flexibility, which make it durable in demanding applications. However, it can be more expensive than other materials and may not perform well in extreme temperatures.

- Impact on Application: Nylon 6 is compatible with a wide range of media, including air, water, and mild chemicals, making it ideal for pneumatic and hydraulic applications.

- Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential, particularly in regions like Europe and South America. Buyers should also consider local regulations regarding chemical resistance and safety.

How Does Nylon 11 Compare in Terms of Performance?

Nylon 11 is another popular choice for tubing, particularly in applications requiring flexibility and chemical resistance.

- Key Properties: With a temperature range of -60°F to 200°F (-51°C to 93°C), Nylon 11 offers superior flexibility and lower moisture absorption compared to Nylon 6. It also exhibits excellent chemical resistance, particularly against hydrocarbons.

- Pros & Cons: The primary advantage of Nylon 11 is its flexibility, which allows it to be used in tight spaces. However, it is generally more expensive and may not have the same tensile strength as Nylon 6.

- Impact on Application: Nylon 11 is well-suited for applications involving oil and fuel lines, making it a preferred choice in the automotive and aerospace industries.

- Considerations for International Buyers: Buyers should ensure that the material meets specific industry standards, especially in regions where stringent regulations apply, such as the Middle East and Europe.

What Are the Benefits of High-Pressure Nylon Tubing?

High-pressure nylon tubing is designed for applications that require enhanced strength and durability.

- Key Properties: This type of tubing can withstand pressures up to 3000 psi and operates effectively within a temperature range of -40°F to 200°F (-40°C to 93°C). It also features a high resistance to abrasion and impact.

- Pros & Cons: High-pressure nylon tubing is ideal for demanding environments, providing excellent performance under stress. However, its manufacturing process can be more complex, leading to higher costs.

- Impact on Application: This material is commonly used in hydraulic systems, pneumatic applications, and heavy machinery, where high pressure is a critical factor.

- Considerations for International Buyers: Compliance with safety standards and certifications is vital, particularly in industries such as automotive and manufacturing, where failure can have severe consequences.

How Does Super Soft Nylon Tubing Enhance Flexibility?

Super soft nylon tubing is engineered for applications requiring extreme flexibility and ease of handling.

- Key Properties: It offers a temperature range of -40°F to 200°F (-40°C to 93°C) and is designed for low-pressure applications. Its soft structure allows for tight bends and configurations.

- Pros & Cons: The main advantage is its flexibility, making it suitable for applications where space is limited. However, it may not be as durable as standard nylon tubing and could be prone to kinking under high pressure.

- Impact on Application: Ideal for robotics, medical devices, and applications requiring frequent movement, super soft nylon tubing can accommodate various fluids.

- Considerations for International Buyers: Ensure that the material complies with medical and safety standards, particularly in regions with strict regulations such as Europe and the Middle East.

Summary Table of Material Selection for Nylon Tubing

| Material | Typical Use Case for nylon tube | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon 6 | Pneumatic and hydraulic systems | High tensile strength and flexibility | Higher cost and temperature limitations | Medium |

| Nylon 11 | Oil and fuel lines | Superior flexibility and chemical resistance | More expensive than Nylon 6 | High |

| High-Pressure Nylon | Hydraulic systems, heavy machinery | Excellent performance under high pressure | Complex manufacturing process | High |

| Super Soft Nylon | Robotics, medical devices | Extreme flexibility | Prone to kinking under high pressure | Medium |

This guide provides a comprehensive overview of the strategic material selection for nylon tubing, helping international B2B buyers make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for nylon tube

What Are the Key Stages in the Manufacturing Process of Nylon Tubing?

The manufacturing of nylon tubing involves several critical stages that ensure the final product meets the stringent requirements of various applications. Understanding these stages can help B2B buyers assess the quality and reliability of their suppliers.

Material Preparation: How Is Nylon Resin Processed?

The first step in the nylon tubing manufacturing process is the preparation of nylon resin, typically nylon 6 or nylon 11. The resin is dried to remove moisture, which is crucial for preventing defects during the extrusion process. This drying process often involves using dehumidifying dryers, which maintain the resin’s integrity and performance characteristics. The choice of nylon grade can affect the tubing’s flexibility, strength, and resistance to various chemicals, making it important for buyers to specify their needs clearly.

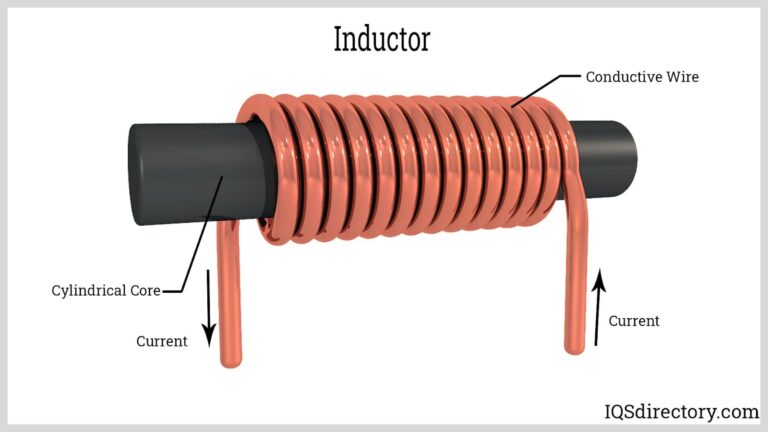

Forming: What Techniques Are Used to Shape Nylon Tubing?

Once the nylon resin is prepared, it undergoes the extrusion process. This involves melting the nylon pellets and forcing them through a die to form the desired shape of the tubing. The extrusion process can be adjusted to create various diameters and wall thicknesses, allowing manufacturers to cater to specific requirements. In addition to standard extrusion, some manufacturers may employ co-extrusion techniques to produce multi-layer tubing with enhanced properties, such as improved chemical resistance or barrier capabilities.

Assembly: How Are Components Integrated into the Final Product?

For applications requiring additional features, such as fittings or specialized end connections, assembly may be necessary. This stage can involve several methods, including welding, bonding, or using mechanical fittings. Quality control during assembly is essential to ensure that all components fit correctly and maintain the integrity of the tubing under various operating conditions.

Finishing: What Processes Enhance the Quality of Nylon Tubing?

The finishing stage includes various processes aimed at enhancing the product’s performance and aesthetics. This may involve surface treatments to improve chemical resistance, UV stabilization to prevent degradation from sunlight, or color customization for branding purposes. Manufacturers often employ rigorous testing during this stage to ensure that the finished product meets all specifications and quality standards.

What Are the Key Quality Assurance Practices in Nylon Tubing Manufacturing?

Quality assurance (QA) is critical in the manufacturing of nylon tubing, as it directly impacts product performance and customer satisfaction. Understanding the QA processes can help B2B buyers ensure that their suppliers adhere to international standards.

Which International Standards Are Relevant for Nylon Tubing?

Many nylon tubing manufacturers comply with international quality standards such as ISO 9001, which outlines a framework for quality management systems. Compliance with these standards helps ensure that manufacturers maintain consistent quality throughout their production processes. Additionally, industry-specific certifications like CE marking for products sold in Europe or API standards for oil and gas applications can further affirm the quality and safety of the tubing.

What Are the Critical Quality Control Checkpoints?

Quality control checkpoints during the manufacturing process typically include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- IPQC focuses on monitoring the manufacturing process in real-time to identify any deviations from quality standards.

- FQC is the final inspection stage where the completed nylon tubing is tested for performance against established criteria.

This multi-tiered approach helps to catch defects early and ensures that only products meeting quality standards reach the market.

What Testing Methods Are Commonly Used for Nylon Tubing?

Common testing methods for nylon tubing include:

- Burst Testing: To assess the maximum pressure the tubing can withstand before failure.

- Tensile Testing: To determine the strength and elongation properties of the nylon material.

- Chemical Resistance Testing: To evaluate how well the tubing performs when exposed to various chemicals.

- Thermal Testing: To ensure that the tubing maintains integrity under high temperature conditions.

These tests help to validate the performance characteristics of nylon tubing, ensuring it is suitable for its intended application.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers should take proactive steps to verify the quality control measures employed by their suppliers. Here are some effective strategies:

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits is one of the most effective methods for assessing a manufacturer’s quality control practices. Buyers should develop a checklist that includes compliance with international standards, documentation of quality control processes, and evidence of regular testing. During the audit, buyers can review records, inspect facilities, and interview staff to gain a comprehensive understanding of the supplier’s quality management system.

Illustrative image related to nylon tube

How Can Buyers Request Quality Assurance Reports?

Buyers should request detailed quality assurance reports from suppliers, including test results and compliance documentation. These reports should outline the results of various tests conducted on the nylon tubing, as well as any corrective actions taken in response to quality issues. A transparent supplier will readily provide these documents, which can serve as a valuable resource for buyers when assessing reliability.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging a third-party inspection service can provide an unbiased assessment of a supplier’s quality control practices. These organizations can perform audits, conduct testing, and verify compliance with international standards, giving buyers added confidence in their supplier’s capabilities. It is particularly important for buyers in regions like Africa, South America, and the Middle East, where regulatory standards may vary significantly.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

International B2B buyers must navigate various nuances related to quality control when sourcing nylon tubing.

- Regulatory Compliance: Different regions may have specific regulations regarding materials and manufacturing practices. Buyers should ensure that their suppliers are compliant with local laws and international standards applicable in their target markets.

- Cultural Differences: Understanding cultural differences in business practices can help buyers communicate more effectively with suppliers, ensuring that quality expectations are clearly understood and met.

- Logistics and Supply Chain Management: Quality control extends beyond manufacturing to include logistics. Buyers should assess how suppliers manage their supply chains, as delays or mishandling during transportation can affect product quality.

By addressing these factors, B2B buyers can make more informed decisions and establish long-term partnerships with reliable suppliers of nylon tubing.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nylon tube’

Introduction

Sourcing nylon tubing effectively is essential for international B2B buyers looking to meet specific operational needs. This guide offers a step-by-step checklist to streamline your procurement process, ensuring you select the right products and suppliers. By following these actionable steps, you can make informed decisions that align with your business objectives.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s crucial to establish clear technical specifications for the nylon tubing you require. Consider factors such as diameter, wall thickness, and temperature resistance. This clarity will help you communicate effectively with suppliers and ensure the products meet your application needs.

- Temperature and Pressure Ratings: Identify the operating temperature range and pressure requirements relevant to your application.

- Chemical Compatibility: Assess the chemical resistance of the nylon tubing to avoid degradation and ensure longevity.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in nylon tubing. Look for manufacturers with a proven track record and positive customer reviews. This foundational step will help you shortlist potential partners who can meet your specifications.

- Industry Reputation: Check online reviews, testimonials, and case studies to gauge supplier reliability.

- Geographic Considerations: Consider suppliers located near your operations to reduce shipping times and costs.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications to ensure product quality and compliance with industry standards. Certifications such as ISO 9001 or compliance with RoHS and REACH regulations are indicators of a supplier’s commitment to quality.

- Quality Assurance Processes: Inquire about their quality control measures and testing protocols.

- Environmental Compliance: Ensure the supplier adheres to environmental standards, which can impact your company’s sustainability goals.

Step 4: Request Samples

Once you have narrowed down your suppliers, request samples of the nylon tubing. Testing samples allows you to evaluate the product’s performance and compatibility with your intended application.

- Physical Characteristics: Assess the flexibility, strength, and other physical attributes of the tubing.

- Testing for Specifications: Conduct tests to confirm that the samples meet your defined specifications under real-world conditions.

Step 5: Compare Pricing and Terms

After evaluating samples, gather pricing information and compare terms from different suppliers. Look beyond the initial cost to consider factors such as payment terms, minimum order quantities, and shipping options.

- Total Cost of Ownership: Factor in shipping, duties, and any additional costs to determine the true cost.

- Negotiation Opportunities: Identify areas where you can negotiate better terms, especially for bulk orders.

Step 6: Establish Communication Protocols

Effective communication is key to a successful partnership. Establish clear communication protocols with your chosen supplier to address any questions or issues that may arise during the order process.

- Regular Updates: Set expectations for regular updates on order status and any potential delays.

- Contact Points: Designate specific contacts for both your team and the supplier to streamline communication.

Step 7: Finalize and Place Your Order

Once you are satisfied with your supplier’s offerings and terms, finalize your order. Ensure all specifications are clearly documented in the purchase agreement to prevent misunderstandings.

- Documentation: Keep records of all correspondence and agreements for future reference.

- Follow-Up: Confirm order details with the supplier and establish a timeline for delivery to ensure smooth processing.

By following these steps, B2B buyers can effectively navigate the sourcing process for nylon tubing, ensuring they make informed decisions that support their operational needs.

Comprehensive Cost and Pricing Analysis for nylon tube Sourcing

What Are the Key Cost Components in Sourcing Nylon Tubing?

When sourcing nylon tubing, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality of nylon resin directly influences the cost. Nylon 6 and nylon 11 are common types, with nylon 11 typically commanding a higher price due to its superior properties, such as increased flexibility and resistance to chemicals.

-

Labor: Labor costs can vary significantly based on the manufacturing location. For instance, regions with higher wage standards, like parts of Europe, may result in elevated labor costs compared to manufacturers in Asia or South America.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and administrative expenses. Efficient manufacturing processes can help reduce overhead, thereby impacting the overall cost.

-

Tooling: Tooling costs include the initial setup of production machinery. Custom tooling for specialized nylon tubing can be a significant upfront investment but is necessary for producing unique specifications.

-

Quality Control (QC): Rigorous QC processes ensure that the nylon tubing meets industry standards. This can add to the cost but is essential for ensuring reliability, especially in critical applications like automotive or medical.

-

Logistics: Transportation costs vary depending on the origin and destination. Factors such as shipping distance, mode of transport, and customs duties can significantly affect the final price.

-

Margin: Suppliers typically include a margin to cover risks and profit. This can vary based on market competition and demand.

How Do Price Influencers Affect Nylon Tube Pricing?

Several factors can influence the pricing of nylon tubing:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQ) to maximize savings.

-

Specifications and Customization: Custom features, such as specific diameters or colors, can increase costs. Standard products generally have more competitive pricing.

-

Materials: The type and quality of nylon used will impact the price. For example, specialized nylon tubes designed for high-pressure applications will be more expensive than standard tubes.

-

Quality and Certifications: Certifications (e.g., ISO, RoHS) may add costs but are vital for compliance, especially in regulated industries. Suppliers that meet these standards may charge a premium.

-

Supplier Factors: The supplier’s reputation, reliability, and location can influence pricing. Suppliers with extensive experience and positive testimonials might command higher prices due to perceived quality.

-

Incoterms: Understanding Incoterms is essential for international transactions. Terms like FOB (Free On Board) or CIF (Cost Insurance and Freight) dictate who is responsible for shipping costs and risks, affecting the overall pricing structure.

What Are Effective Buyer Tips for Cost-Efficient Sourcing of Nylon Tubing?

For B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, strategic sourcing of nylon tubing can enhance cost-efficiency:

-

Negotiate: Always negotiate pricing and terms. Suppliers may offer discounts based on long-term partnerships or larger orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the operational costs associated with the nylon tubing, including maintenance, durability, and replacement frequency.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations can affect pricing when sourcing from overseas. Establishing contracts in stable currencies or using hedging strategies can mitigate risks.

-

Research and Compare Suppliers: Conduct thorough research on potential suppliers. Compare their offerings, quality, and pricing to ensure you get the best value.

-

Leverage Local Expertise: Engage with local distributors or agents who understand the regional market dynamics and can negotiate better terms on your behalf.

Final Thoughts

Navigating the complexities of nylon tube sourcing requires an understanding of various cost components and pricing influencers. By applying these insights and strategies, international B2B buyers can make informed decisions that optimize their sourcing processes while ensuring product quality and compliance with industry standards. Always keep in mind that indicative prices may vary based on market conditions and specific requirements.

Alternatives Analysis: Comparing nylon tube With Other Solutions

Introduction to Alternative Solutions for Tubing

When selecting tubing solutions for industrial applications, businesses often encounter a variety of options, including nylon tubing, polyethylene tubing, and polyurethane tubing. Each alternative presents unique advantages and disadvantages, making it essential for B2B buyers to evaluate them based on specific performance requirements, cost considerations, and application contexts. This analysis aims to provide a comparative overview to help international buyers make informed decisions tailored to their operational needs.

Comparison Table of Tubing Solutions

| Comparison Aspect | Nylon Tube | Polyethylene Tube | Polyurethane Tube |

|---|---|---|---|

| Performance | Excellent corrosion resistance, good flexibility, withstands high temperatures | Moderate chemical resistance, less flexible, lower temperature tolerance | High flexibility, excellent abrasion resistance, good chemical compatibility |

| Cost | Moderate to high | Low to moderate | Moderate to high |

| Ease of Implementation | Easy to install, available in various sizes and configurations | Simple to install, widely available | More complex due to various grades and configurations |

| Maintenance | Low maintenance required | Very low maintenance | Moderate maintenance needed |

| Best Use Case | Automotive, pneumatic systems, fuel lines | Water supply, irrigation, low-pressure applications | Robotics, pneumatic systems, high-stress applications |

Detailed Breakdown of Alternatives

Polyethylene Tube

Polyethylene (PE) tubing is a widely used alternative due to its cost-effectiveness and availability. It offers excellent flexibility and is resistant to moisture, making it suitable for various applications, including water supply and irrigation systems. However, its chemical resistance is moderate, and it may not perform well under high-temperature conditions compared to nylon tubing. For businesses focused on low-pressure applications where cost is a priority, polyethylene tubing is a viable choice.

Polyurethane Tube

Polyurethane (PU) tubing is recognized for its exceptional flexibility and abrasion resistance, making it ideal for high-stress applications such as robotics and pneumatic systems. It can withstand a wide range of chemicals, adding to its versatility. However, PU tubing typically comes at a moderate to high cost, and its installation can be more complex than that of nylon or polyethylene. Businesses that prioritize flexibility and durability in demanding environments may find polyurethane tubing to be the most suitable option.

Conclusion: Choosing the Right Tubing Solution

In selecting the appropriate tubing solution, B2B buyers should consider their specific application requirements, including performance needs, budget constraints, and maintenance capabilities. Nylon tubing excels in high-temperature environments and offers excellent chemical resistance, making it ideal for automotive and pneumatic systems. In contrast, polyethylene is a cost-effective solution for low-pressure applications, while polyurethane is best suited for high-stress scenarios requiring flexibility and abrasion resistance. By thoroughly assessing these factors, buyers can confidently choose the tubing solution that aligns with their operational goals and enhances efficiency.

Essential Technical Properties and Trade Terminology for nylon tube

What Are the Key Technical Properties of Nylon Tubing?

Understanding the essential technical properties of nylon tubing is crucial for B2B buyers, especially when selecting products that meet specific operational requirements. Here are several key specifications to consider:

-

Material Grade

Nylon tubing is typically made from polyamide resins, with Nylon 6 and Nylon 11 being the most common grades. Nylon 11 is particularly valued for its superior flexibility and lower moisture absorption, making it ideal for applications requiring high durability and resistance to environmental factors. Knowing the right material grade helps buyers ensure compatibility with their operational needs. -

Temperature Range

Nylon tubing can typically withstand a temperature range from -60°F to 200°F (-51°C to 93°C). This broad range indicates its suitability for diverse environments, from cold storage applications to high-heat machinery. Buyers must consider the operating temperatures of their applications to avoid material failure. -

Diameter Tolerance

Tolerance specifications, often around ± 0.005 inches, are critical for ensuring proper fit and function in pneumatic and hydraulic systems. Accurate diameter tolerances ensure that the tubing fits securely with fittings and connectors, preventing leaks or failures in critical systems. -

Working Pressure

Nylon tubing often features a working pressure rating based on a safety factor of 4:1, which is essential for applications involving pneumatic or hydraulic systems. This specification helps buyers determine the maximum pressure the tubing can safely handle, reducing the risk of catastrophic failure. -

UV Stabilization

UV stabilization is a property that enhances the longevity of nylon tubing when exposed to sunlight. This is particularly important for outdoor applications or environments with significant UV exposure. Buyers should ensure that the nylon tubing they select is UV stabilized to prevent degradation over time. -

Chemical Resistance

Nylon has inherent resistance to many chemicals, making it suitable for applications in industries such as chemical processing and agriculture. Understanding the chemical compatibility of nylon tubing with specific fluids is vital for ensuring operational safety and longevity.

What Common Trade Terms Should B2B Buyers Know About Nylon Tubing?

Familiarity with industry-specific terminology can greatly enhance communication and efficiency in B2B transactions. Here are some common trade terms related to nylon tubing:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the role of OEMs helps buyers identify reliable sources for high-quality nylon tubing that meets specific industry standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is a crucial consideration for buyers, as it impacts inventory management and cost-efficiency. Knowing the MOQ helps in planning purchases and budgeting. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process allows buyers to compare offers from multiple suppliers, ensuring they get the best deal and terms for their nylon tubing needs. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risk management, and delivery responsibilities. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is essential for planning production schedules and ensuring that operational timelines are met. -

Custom Configurations

This term refers to the ability to modify tubing specifications, such as size, color, or material properties, to meet specific customer requirements. Buyers should inquire about customization options to ensure they receive products tailored to their operational needs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational requirements and industry standards, ensuring successful procurement of nylon tubing.

Navigating Market Dynamics and Sourcing Trends in the nylon tube Sector

What Are the Current Market Dynamics and Key Trends in the Nylon Tube Sector?

The nylon tube market is experiencing significant growth, driven by various global factors. The increasing demand for lightweight, flexible, and durable materials across multiple industries—including automotive, aerospace, and healthcare—fuels this growth. Additionally, the rise of automation and the expansion of pneumatic systems in manufacturing processes are pivotal drivers. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should take note of emerging trends such as the integration of smart technologies in supply chains and the move towards just-in-time inventory systems. These advancements enhance operational efficiency and reduce costs, making them essential for competitive sourcing strategies.

Furthermore, the market is witnessing a shift towards customization, with suppliers offering tailored solutions to meet specific industry needs. For instance, high-pressure nylon tubing is gaining traction in sectors requiring robust, reliable materials capable of withstanding extreme conditions. Additionally, sustainability is becoming a core consideration, prompting suppliers to adopt eco-friendly practices and materials. Buyers should prioritize suppliers who demonstrate a commitment to innovation and sustainability, as these factors increasingly influence purchasing decisions.

How Can Sustainability and Ethical Sourcing Impact B2B Buyers in the Nylon Tube Market?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the nylon tube sector. The environmental impact of plastic production and disposal is significant, leading to increased scrutiny from consumers and regulators alike. Companies are now expected to demonstrate corporate social responsibility through transparent supply chains and sustainable practices. For B2B buyers, this means prioritizing suppliers who offer eco-friendly nylon tubes, such as those made from recycled materials or produced using energy-efficient methods.

Moreover, certifications like ISO 14001 for environmental management and compliance with regulations such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) are becoming essential criteria in supplier selection. Buyers should actively seek suppliers who hold these certifications, as they indicate a commitment to reducing environmental impact and ensuring product safety. By aligning with ethical suppliers, companies not only enhance their brand reputation but also contribute to a more sustainable industry.

What Is the Brief History and Evolution of Nylon Tubing in the B2B Landscape?

Nylon tubing has its roots in the early 20th century, emerging from the invention of nylon by DuPont in 1935. Initially used as a synthetic replacement for silk in textiles, the unique properties of nylon—such as its strength, flexibility, and resistance to wear—soon found applications in various industrial sectors. Over the decades, advancements in polymer technology have led to the development of specialized nylon tubes, catering to specific needs like high-pressure systems and chemical resistance.

The introduction of innovations such as coiling and customization has further broadened the scope of nylon tubing applications, making it a versatile choice for B2B buyers. As industries evolve, the demand for advanced nylon tubing solutions continues to rise, highlighting the importance of staying informed about historical trends to make better sourcing decisions in today’s market.

Frequently Asked Questions (FAQs) for B2B Buyers of nylon tube

-

How do I choose the right nylon tube for my application?

Choosing the right nylon tube depends on several factors including the operating environment, pressure requirements, and chemical compatibility. Assess the temperature range, flexibility, and diameter specifications needed for your application. For example, high-pressure applications may require nylon tubing with reinforced walls, while low-pressure systems can utilize standard nylon tubing. Additionally, consider the specific industry standards relevant to your sector, such as automotive or medical, to ensure compliance. -

What are the key advantages of using nylon tubes over other materials?

Nylon tubes offer several benefits, including excellent chemical resistance, high tensile strength, and flexibility. They are particularly suitable for pneumatic applications due to their lightweight and high-pressure capabilities. Unlike PVC or polycarbonate, nylon resists moisture absorption, which enhances durability in humid environments. Additionally, nylon has a higher melting point, making it suitable for applications involving heat exposure. -

What are the minimum order quantities (MOQs) for nylon tubing?

MOQs for nylon tubing can vary significantly by supplier and product type. Generally, standard sizes may have lower MOQs, often ranging from 100 to 500 meters, while custom specifications can require higher quantities. It is advisable to discuss your specific needs with potential suppliers to negotiate favorable terms that suit your procurement strategy. This is especially important for businesses operating in regions with unique supply chain dynamics. -

How can I verify the quality and compliance of nylon tubing suppliers?

To verify the quality and compliance of nylon tubing suppliers, request certifications such as ISO 9001 for quality management and material safety data sheets (MSDS) for chemical compatibility. Conduct background checks by reviewing customer testimonials and industry references. Additionally, consider requesting samples to evaluate the product quality firsthand. Engaging third-party inspection services can also provide an added layer of assurance regarding compliance with international standards. -

What payment terms should I expect when sourcing nylon tubing internationally?

Payment terms can vary based on the supplier’s policies and your negotiation. Common terms include advance payment, letters of credit, or net 30/60 days after delivery. For first-time transactions, suppliers may prefer partial upfront payments to mitigate risk. It’s crucial to clarify payment methods and terms during the negotiation phase to avoid misunderstandings that could impact cash flow and supply chain stability. -

What logistics considerations should I be aware of when importing nylon tubes?

Logistics considerations for importing nylon tubes include shipping methods, customs clearance, and delivery timelines. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your urgency and budget. Ensure compliance with local regulations, including import duties and taxes. Collaborating with a logistics provider familiar with international trade can streamline the process and minimize delays, especially when navigating customs documentation. -

Can nylon tubes be customized for specific applications?

Yes, many suppliers offer customization options for nylon tubes to meet specific application requirements. Customizations can include variations in diameter, wall thickness, color, and even the addition of printing or branding. Discuss your needs with potential suppliers early in the sourcing process to explore available options and ensure that your specifications can be met without compromising quality or lead times. -

What industries commonly use nylon tubing, and what are their specific applications?

Nylon tubing is widely used across various industries, including automotive, aerospace, agriculture, and medical. In the automotive sector, it’s often used for fuel and brake lines due to its high-pressure capabilities. In agriculture, nylon tubes facilitate chemical treatment and irrigation systems. Medical applications may involve pneumatic systems or fluid transport. Understanding the specific applications within your industry can guide you in selecting the appropriate nylon tubing for optimal performance.

Top 8 Nylon Tube Manufacturers & Suppliers List

1. Freelin-Wade – Flexible Nylon Tubing

Domain: freelin-wade.com

Registered: 1997 (28 years)

Introduction: Flexible Nylon Tubing made from polyamide resin. Key features include: lighter-weight wall, greater flexibility, smaller bend radius, higher corrosion resistance, and moisture absorption resistance. Heat resistant with a melting point of 374°F (190°C). Specifications: Temperature range: -60° to 200°F (-51° to 93°C), Vacuum rating: to 28” Hg, Diameter tolerance: ± 0.005” or better, Hardness: 78 Roc…

2. Curbell Plastics – Nylon Tube Natural Cast

Domain: curbellplastics.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “Nylon, Tube, Natural, Cast”, “Item Number”: “W03-00690”, “Dimensions”: {“Length”: “26 in”, “Outside Diameter”: “8 in”, “Inside Diameter”: “6.5 in”}, “Color”: “Natural”, “Shape”: “Tube”, “Grade”: “Unfilled”, “Manufacturing Method”: “Cast”, “Price”: “$374.85 /each”}

3. McMaster – Nylon Tubing

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Nylon Tubing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Polyconn – Nylon Tubing

Domain: polyconn.com

Registered: 1995 (30 years)

Introduction: Nylon tubing, also known as polyamide tubing, withstands higher temperatures, making it suitable for various applications. It features a lighter weight wall, greater flexibility, and smaller bend radius compared to other Nylon resins. This tubing is more corrosion resistant due to its moisture absorption resistance, and its heat and UV stabilization helps prevent stress-cracking, making it ideal f…

5. New Age Industries – NYLOTUBE® Nylon Tubing

Domain: newageindustries.com

Registered: 1998 (27 years)

Introduction: Nylon Tubing, specifically NYLOTUBE® made from nylon-12 formulation, recognized for its ruggedness, light weight, corrosion and abrasion resistance. It has exceptional elastic memory, withstands repeated flexing without fatigue or fracture, high-impact resistance at subfreezing temperatures, and low moisture absorption to minimize dimensional instability. Suggested applications include air conditi…

6. Pisco – Nylon Tubing

Domain: pisco.co.jp

Introduction: Nylon Tubing, RoHS2 Compliant, suitable for air, water, and thermal media oil. Excellent pressure resistance, usable under high pressure. Available in 9 colors and 11 sizes (inch sizes available). Bending radius: 9. Max operation pressure: 2.0MPa at 20ºC and 65%RH. Operating temperature range: Air -20~100ºC, Water and thermal oil -15~90ºC. Durometer: shore D 65. Port sizes: Inch (1/8×0.079, 3/16×0…

7. Gteek – Polyamide 6 Nylon Tubes

Domain: gteek.com

Registered: 2017 (8 years)

Introduction: This company, Gteek – Polyamide 6 Nylon Tubes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Abbey Extrusions – Nylon Tubing & Hose

Domain: abbeyextrusions.com

Registered: 2000 (25 years)

Introduction: Nylon Tube Supplier | Nylon Tubing & Hose UK Manufacturer. Flexible, lightweight, and durable over a wide temperature range. Suitable for pneumatic control systems, fuel lines, and food and beverage production lines. Manufactured from high-grade Nylon (FDA-compliant, meets UL standards). Features include: flexible over a wide temperature range, tough, lightweight, durable, chemical, moisture, and …

Strategic Sourcing Conclusion and Outlook for nylon tube

In the ever-evolving landscape of nylon tube procurement, strategic sourcing emerges as a crucial factor for international B2B buyers. The unique properties of nylon tubing, such as its lightweight design, high heat resistance, and chemical resilience, make it an invaluable asset across various industries, including automotive, agriculture, and robotics. By understanding the diverse options available—ranging from standard to high-pressure nylon tubing—buyers can tailor their purchases to meet specific operational needs.

Investing in robust supplier relationships and leveraging customized solutions can significantly enhance efficiency and reduce costs. Moreover, considering compliance with environmental and safety standards, such as RoHS and REACH, can safeguard your business from regulatory risks and ensure product reliability.

As global markets continue to expand, particularly in regions like Africa, South America, the Middle East, and Europe, now is the time for buyers to reassess their sourcing strategies. Embrace the potential of nylon tubing to drive innovation and improve operational performance. Reach out to experienced suppliers to explore how customized nylon solutions can elevate your business to new heights. The future of strategic sourcing is bright—take the next step today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.