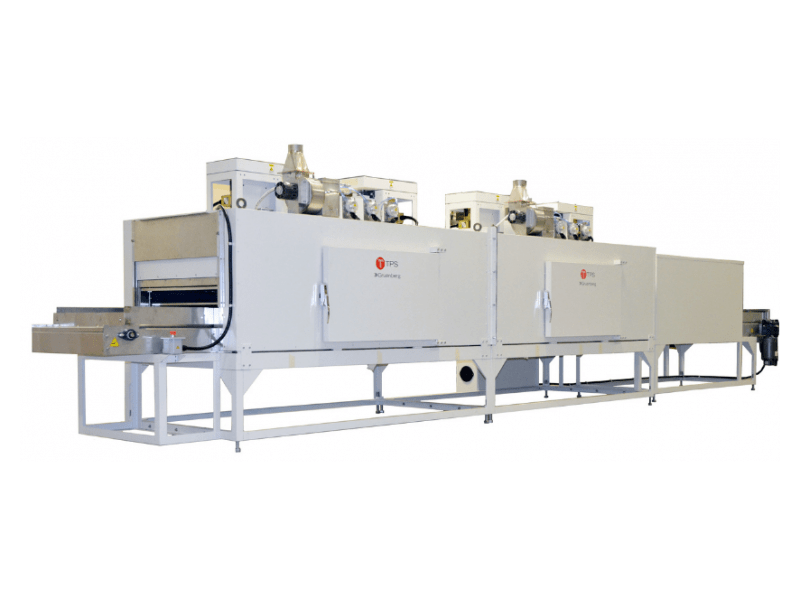

Top 4 Conveyer Oven Suppliers (And How to Choose)

Introduction: Navigating the Global Market for conveyer oven

In today’s fast-paced foodservice industry, sourcing the right conveyor oven can be a pivotal challenge for businesses aiming to enhance efficiency and maintain quality. With the growing demand for high-volume cooking solutions, international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including key markets such as Germany and Nigeria—must navigate a diverse landscape of options. This comprehensive guide delves into the various types of conveyor ovens available, their applications across different culinary contexts, and essential factors to consider when vetting suppliers.

From understanding the differences between electric and gas models to exploring multi-deck configurations that optimize kitchen space, this guide equips buyers with the insights needed to make informed purchasing decisions. Additionally, we will address cost considerations and the importance of energy efficiency in selecting equipment that aligns with operational goals. By empowering buyers with knowledge about the latest industry trends and best practices, this resource aims to streamline the procurement process, ultimately leading to improved productivity and customer satisfaction in high-demand culinary environments. Whether you are a restaurant operator or a foodservice distributor, understanding the nuances of conveyor ovens will enable you to enhance your offerings and meet the evolving needs of your clientele.

Understanding conveyer oven Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gas Conveyor Oven | Uses gas as a heating source, faster preheating | Pizzerias, high-volume kitchens | Pros: Faster heating, high efficiency. Cons: Requires ventilation, higher installation costs. |

| Electric Conveyor Oven | Uses electric elements for heating, often ventless | Cafeterias, sandwich shops | Pros: Easier installation, no need for ventilation. Cons: Slower heating, may have higher energy costs. |

| Impingement Conveyor Oven | Features high-velocity air for faster cooking | Fast-casual restaurants, bakeries | Pros: Quick cooking times, even browning. Cons: More expensive upfront, requires careful maintenance. |

| Double/Triple Stack Conveyor Oven | Multiple decks for increased capacity | Large-scale operations, chain restaurants | Pros: Maximizes cooking space, suitable for high volume. Cons: Requires more floor space, higher cost. |

| Compact Conveyor Oven | Smaller footprint, ideal for limited kitchen space | Small restaurants, food trucks | Pros: Space-saving design, versatile. Cons: Limited cooking capacity, may not handle high volumes. |

What Are the Characteristics of Gas Conveyor Ovens?

Gas conveyor ovens are designed for high efficiency, utilizing gas as their primary heating source. They typically offer faster preheating times compared to electric models, making them ideal for busy environments like pizzerias and high-volume kitchens. When considering a gas conveyor oven, buyers should evaluate installation costs and ventilation requirements, as these ovens often demand proper exhaust systems to ensure safety and compliance with local regulations.

How Do Electric Conveyor Ovens Differ in Functionality?

Electric conveyor ovens are favored for their ease of installation and the potential for ventless operation. They are particularly suitable for environments such as cafeterias and sandwich shops where space may be limited. While they generally have slower heating times than gas models, their operational simplicity and reduced need for complex ventilation make them appealing for many B2B buyers. It’s essential to assess energy costs and the specific cooking needs of the menu when selecting an electric oven.

What Are the Benefits of Impingement Conveyor Ovens?

Impingement conveyor ovens utilize high-velocity air to enhance cooking speed and ensure even browning of food items. This technology is especially beneficial for fast-casual restaurants and bakeries that require consistent results and quick turnaround times. While the initial investment for impingement ovens may be higher, their ability to cook food faster can lead to increased productivity and customer satisfaction. Buyers should consider maintenance requirements and the overall return on investment when evaluating these ovens.

Why Consider Double or Triple Stack Conveyor Ovens for Large Operations?

Double and triple stack conveyor ovens provide multiple cooking decks, allowing for increased capacity and efficiency in large-scale operations such as chain restaurants. These ovens are designed to handle high volumes of food, making them essential for businesses that experience peak hours. However, potential buyers must take into account the larger footprint required and the higher costs associated with these models. A thorough analysis of kitchen space and volume demands is crucial when opting for stacked configurations.

What Advantages Do Compact Conveyor Ovens Offer?

Compact conveyor ovens are specifically designed for small kitchens or food trucks, maximizing cooking capabilities while occupying minimal space. These ovens are versatile and can handle various menu items, making them a great choice for small restaurants. However, buyers should be mindful of the limited cooking capacity, as these models may not be suitable for high-volume operations. Evaluating kitchen layout and expected service demand is essential for businesses considering a compact solution.

Key Industrial Applications of conveyer oven

| Industry/Sector | Specific Application of Conveyor Oven | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Foodservice | High-volume pizza production | Increases output and consistency, reducing labor costs | Energy efficiency, size, and adaptability to menu items |

| Bakery | Continuous baking of bread and pastries | Ensures even cooking and reduces manual labor | Temperature control, adjustable speed, and stackable designs |

| Fast-Food Chains | Quick toasting and heating of sandwiches and wraps | Speeds up service times, enhancing customer satisfaction | Ventilation requirements and compact models for limited space |

| Catering Services | Preparing large quantities of baked goods for events | Streamlines cooking process, allowing for higher volume | Durability for heavy use and easy maintenance features |

| Institutional Foodservice | Cooking for schools and hospitals | Meets high demand for consistent meal quality | Compliance with health regulations and energy efficiency |

How Are Conveyor Ovens Utilized in the Foodservice Industry?

In the foodservice sector, conveyor ovens are indispensable for high-volume pizza production. These ovens allow for continuous cooking, ensuring that pizzas are baked evenly and consistently, which is crucial during peak hours. By automating the cooking process, businesses can significantly reduce labor costs while increasing output. For international buyers, especially in regions like Africa and the Middle East, sourcing energy-efficient models that can handle local power conditions is essential.

What Role Do Conveyor Ovens Play in Bakeries?

Bakeries use conveyor ovens to maintain a steady workflow for baking bread and pastries. The continuous belt system ensures that products are evenly baked without the need for manual rotation. This efficiency not only enhances product quality but also frees up staff for other tasks. Buyers should consider ovens with adjustable temperature controls and speed settings to meet diverse baking requirements, particularly in South America, where varying product types are common.

How Do Fast-Food Chains Benefit from Conveyor Ovens?

Fast-food chains leverage conveyor ovens for rapid toasting and heating of sandwiches and wraps. This technology allows for quick service, which is essential in fast-paced environments. The ability to adjust belt speed and temperature helps accommodate different menu items, ensuring that food is served hot and fresh. Buyers should focus on models that meet local ventilation codes and fit within limited kitchen spaces, particularly in urban areas in Europe.

Why Are Conveyor Ovens Important for Catering Services?

Catering services utilize conveyor ovens to prepare large quantities of baked goods efficiently for events. The ability to cook multiple items simultaneously streamlines the food preparation process, allowing caterers to meet high demand during events. Durability and ease of maintenance are critical factors for buyers in this sector, especially when considering the rigorous use during events across diverse locations in Africa and Europe.

How Do Conveyor Ovens Serve Institutional Foodservice Needs?

In institutional foodservice settings, such as schools and hospitals, conveyor ovens are vital for cooking large volumes of meals consistently. These ovens help maintain quality and safety standards, ensuring that meals are cooked evenly. Compliance with health regulations is a key consideration for buyers in this sector, along with energy efficiency to manage operational costs effectively.

3 Common User Pain Points for ‘conveyer oven’ & Their Solutions

Scenario 1: Inefficient Cooking Times Leading to Long Waits

The Problem: In high-volume kitchens, such as those in fast-casual restaurants or pizzerias, operational efficiency is paramount. Many B2B buyers find themselves frustrated when their conveyor ovens do not keep up with demand during peak hours. Slow cooking times can lead to longer customer wait times, decreased satisfaction, and ultimately a loss of revenue. This issue often arises from the oven’s inability to maintain consistent temperatures or from improper loading practices that hinder airflow.

The Solution: To combat these inefficiencies, buyers should consider investing in high-quality conveyor ovens with adjustable belt speeds and temperature zones. Models that allow for precise control over cooking times are essential. For instance, a dual-zone conveyor oven can provide different cooking temperatures for various menu items, such as pizzas and sandwiches, simultaneously. Additionally, training staff on proper loading techniques—ensuring that items are spaced adequately on the belt for optimal airflow—can enhance cooking consistency. Regular maintenance checks should also be scheduled to ensure that heating elements are functioning correctly and that the oven is cleaned frequently to prevent buildup that can affect performance.

Scenario 2: Space Limitations in Kitchen Layout

The Problem: Many international buyers face the challenge of limited kitchen space, particularly in urban areas where real estate is at a premium. Standard conveyor ovens can take up significant room, leading to overcrowded workspaces and inefficiencies. This lack of space can hinder workflow and make it difficult for staff to operate effectively during busy service periods.

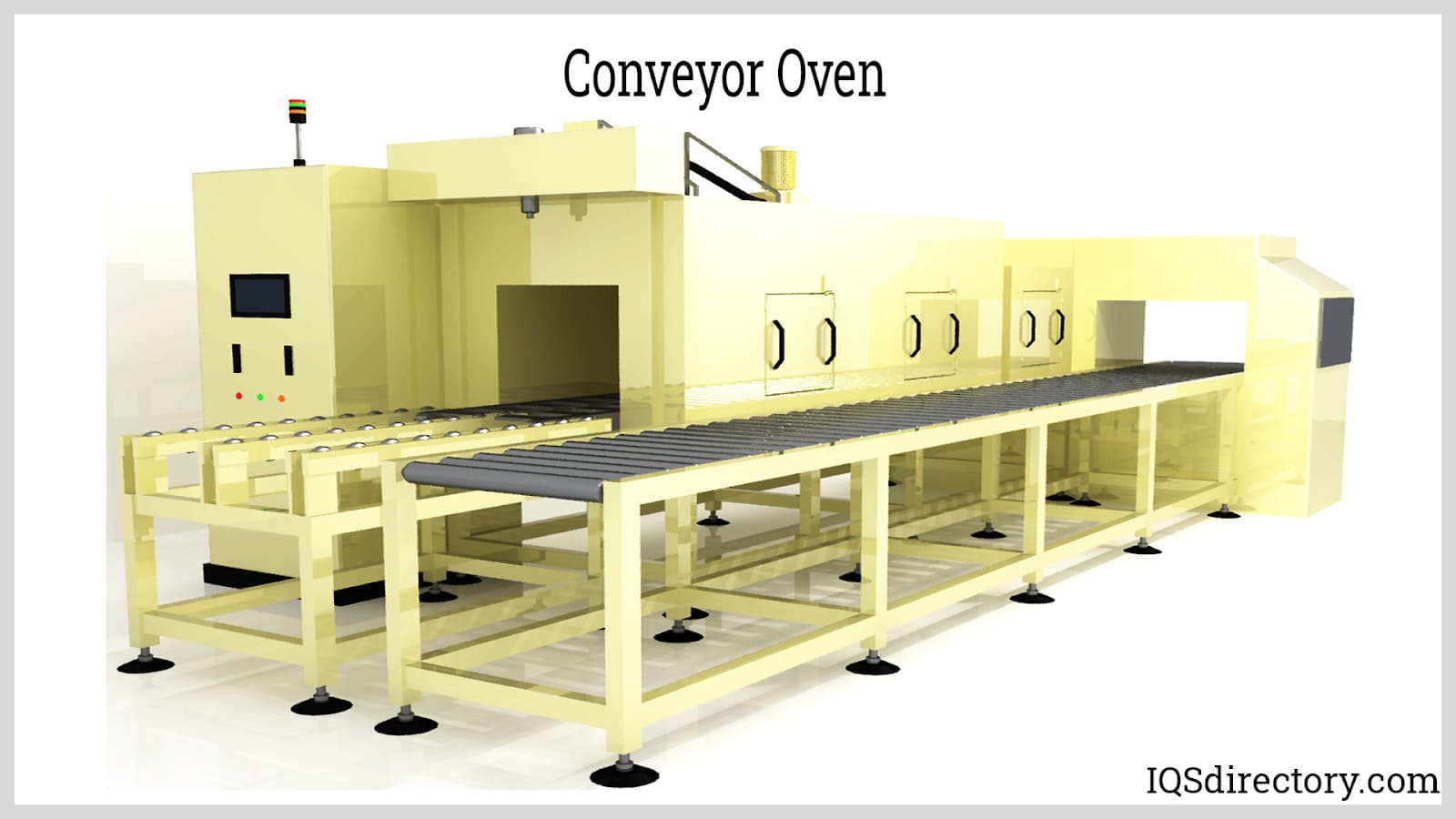

Illustrative image related to conveyer oven

The Solution: Buyers should look for compact or stackable conveyor oven models that maximize vertical space while minimizing the footprint. Brands that offer modular designs can be particularly beneficial, as they allow operators to configure their kitchens according to specific workflow needs. Additionally, assessing the kitchen layout before purchasing a conveyor oven can help identify the best placement to ensure an efficient flow of operations. For buyers in regions with unique space challenges, consulting with kitchen design specialists can provide tailored solutions that incorporate the latest technology while optimizing available space.

Scenario 3: Compliance with Local Ventilation Regulations

The Problem: Operating a commercial kitchen often comes with strict regulations regarding ventilation, especially for gas-powered conveyor ovens. Many buyers are unaware of the local compliance requirements, which can lead to costly fines and operational delays if an oven is installed without proper ventilation systems. This is particularly pertinent in regions like Europe and the Middle East, where regulations can be stringent.

The Solution: To ensure compliance, B2B buyers should conduct thorough research on local regulations concerning kitchen ventilation before purchasing a conveyor oven. It is advisable to engage with local food service equipment suppliers who have experience navigating these regulations. Investing in ovens that are designed with integrated venting options or those that are ventless can be advantageous. Furthermore, buyers should consult with HVAC professionals to design an effective ventilation system that meets all local codes and ensures a safe working environment. By proactively addressing these requirements, businesses can avoid disruptions and maintain a smooth operation while adhering to necessary safety standards.

Strategic Material Selection Guide for conveyer oven

What Are the Key Materials Used in Conveyor Ovens?

When selecting a conveyor oven, the choice of materials significantly influences performance, durability, and operational efficiency. Below, we analyze four common materials used in conveyor ovens, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Stainless Steel: The Industry Standard

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high-temperature tolerance, and durability. It can withstand extreme temperatures, making it suitable for the demanding environments of commercial kitchens.

Pros & Cons:

The primary advantage of stainless steel is its longevity and ease of cleaning, which is vital in food service applications. However, it can be more expensive than other materials, and its manufacturing complexity can lead to higher costs.

Impact on Application:

Stainless steel is compatible with various cooking media and is ideal for applications requiring high hygiene standards. Its resistance to rust and stains makes it a preferred choice for conveyor ovens used in pizza and sandwich shops.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with local food safety standards, which often mandate the use of food-grade stainless steel. Familiarity with standards such as DIN and ASTM is crucial for procurement.

Aluminum: Lightweight and Cost-Effective

Key Properties:

Aluminum is lightweight and has good thermal conductivity, allowing for efficient heat distribution. It is less resistant to corrosion compared to stainless steel but can be anodized for added protection.

Pros & Cons:

The main advantage of aluminum is its lower cost and weight, making it easier to handle and install. However, its susceptibility to warping under high heat and lower durability compared to stainless steel can be drawbacks.

Impact on Application:

Aluminum is suitable for applications where weight is a concern, such as mobile food trucks or temporary setups. However, it may not be the best choice for high-volume cooking environments due to its lower durability.

Considerations for International Buyers:

For buyers in Africa and South America, understanding local climate conditions is essential, as high humidity can accelerate corrosion in untreated aluminum. Compliance with local manufacturing standards should also be verified.

Carbon Steel: Strength and Versatility

Key Properties:

Carbon steel offers high strength and excellent heat retention, making it suitable for heavy-duty applications. It is less resistant to corrosion but can be treated with coatings to enhance durability.

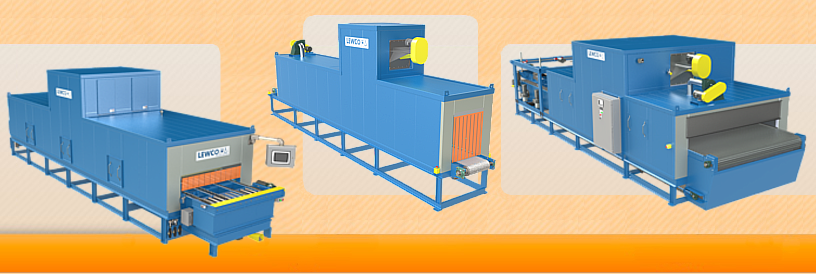

Illustrative image related to conveyer oven

Pros & Cons:

The key advantage of carbon steel is its robustness, making it ideal for high-volume operations. However, it requires more maintenance to prevent rust and may not be suitable for all food types due to potential reactions with acidic foods.

Impact on Application:

Carbon steel is often used in conveyor ovens that require heavy-duty construction, such as those found in large-scale food processing facilities. Its strength allows it to handle substantial loads without warping.

Considerations for International Buyers:

Buyers should be aware of the need for regular maintenance and protective coatings, particularly in regions with high moisture levels. Familiarity with local standards regarding food safety is critical.

Ceramic: Innovative and Efficient

Key Properties:

Ceramic materials are excellent insulators and can withstand high temperatures without degrading. They provide uniform heat distribution, which is essential for consistent cooking results.

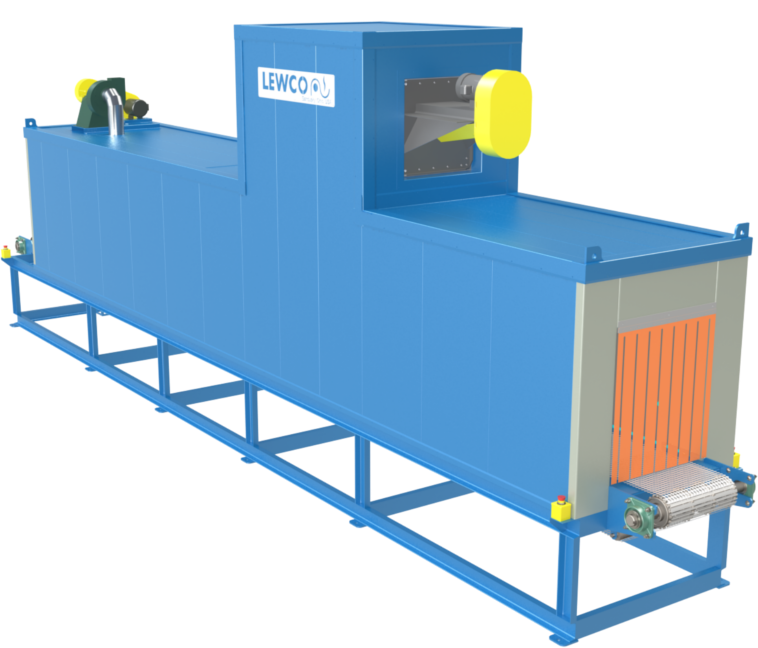

Illustrative image related to conveyer oven

Pros & Cons:

Ceramic’s primary advantage is its efficiency in retaining heat, reducing energy costs. However, it can be brittle and may require careful handling during installation and operation.

Impact on Application:

Ceramic is particularly beneficial in applications where energy efficiency is a priority, such as in environmentally conscious kitchens. Its ability to maintain consistent temperatures makes it suitable for various baked goods.

Considerations for International Buyers:

International buyers should consider the availability of replacement parts and repair services, as ceramic components may be more challenging to source. Compliance with thermal insulation standards is also essential.

Summary Table

| Material | Typical Use Case for Conveyor Oven | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-volume pizza and sandwich shops | Excellent durability and hygiene | Higher cost | High |

| Aluminum | Mobile food trucks, temporary setups | Lightweight and cost-effective | Less durable under high heat | Low |

| Carbon Steel | Heavy-duty food processing facilities | High strength and heat retention | Requires maintenance to prevent rust | Medium |

| Ceramic | Energy-efficient baking applications | Superior heat retention | Brittle and requires careful handling | Medium |

This comprehensive analysis of materials provides B2B buyers with the insights necessary to make informed decisions when selecting conveyor ovens that meet their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for conveyer oven

What Are the Key Stages in the Manufacturing Process of Conveyor Ovens?

The manufacturing process of conveyor ovens involves several critical stages that ensure the final product meets industry standards and customer expectations. Understanding these stages can help B2B buyers assess the reliability and quality of the ovens they are considering.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage in manufacturing conveyor ovens is material preparation. Manufacturers typically use high-quality stainless steel due to its durability, resistance to corrosion, and ability to withstand high temperatures. This material is sourced from certified suppliers to ensure consistency and reliability.

Once the materials are selected, they undergo processes like cutting and shaping to meet the specific dimensions required for the oven’s components. Advanced technologies, such as laser cutting and CNC machining, are often employed to achieve precision in these initial stages.

Illustrative image related to conveyer oven

What Techniques Are Used for Forming Conveyor Oven Components?

The forming stage includes various techniques, such as bending, welding, and stamping, to create the essential parts of the conveyor oven.

-

Bending: This process shapes metal sheets into specific angles and curves, crucial for creating the oven’s outer shell and internal structures.

-

Welding: High-strength welding techniques, such as MIG or TIG welding, are utilized to join various components securely. This ensures the structural integrity of the oven, which is vital for long-term use.

-

Stamping: For parts like racks or internal trays, stamping is used to produce uniform shapes quickly and efficiently.

How Is the Assembly Process Structured for Conveyor Ovens?

After individual components are formed, they move to the assembly stage. Here, skilled technicians or automated systems assemble the parts into a complete oven.

-

Modular Assembly: Many manufacturers use a modular approach, allowing for easier assembly and disassembly. This is particularly beneficial for maintenance and repair.

-

Integration of Technology: During assembly, advanced technologies, such as digital controls and sensor systems, are integrated. These features enhance the oven’s functionality, allowing for precise temperature and speed adjustments.

What Finishing Techniques Are Applied to Ensure Quality?

The final stage in the manufacturing process is finishing. This involves several steps to enhance durability and aesthetic appeal:

-

Surface Treatment: Treatments such as electro-polishing and powder coating are applied to improve corrosion resistance and ease of cleaning.

-

Quality Inspection: Before the ovens leave the factory, they undergo thorough inspections to ensure that all components meet specified tolerances and performance standards.

What Quality Assurance Measures Are Essential for Conveyor Ovens?

Quality assurance (QA) is critical in the manufacturing process of conveyor ovens, ensuring that products meet international standards and customer requirements.

Which International Standards Should B2B Buyers Be Aware Of?

International standards like ISO 9001 are essential in the quality management systems of manufacturers. This standard emphasizes consistent quality, customer satisfaction, and continuous improvement. Compliance with ISO 9001 indicates that a manufacturer has established processes to consistently deliver high-quality products.

Additionally, industry-specific certifications such as CE marking (for compliance with European health, safety, and environmental protection standards) and API standards (for products related to the oil and gas industry) may also apply, depending on the intended use of the conveyor oven.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure product integrity:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards. This is crucial for preventing defects later in the production process.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC involves monitoring processes and components to ensure they meet quality criteria. This may include measuring dimensions and checking for welding integrity.

-

Final Quality Control (FQC): Before shipment, a final inspection verifies that the assembled conveyor ovens meet all specifications and performance requirements. This may include operational testing to ensure proper functionality.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

For B2B buyers, verifying a supplier’s quality assurance processes is vital for ensuring they receive reliable products. Here are some practical steps to take:

What Are Effective Methods for Conducting Supplier Audits?

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality assurance systems firsthand. This provides insight into the supplier’s adherence to international standards and their commitment to quality.

-

Documentation Review: Requesting access to quality assurance documentation, including certificates and inspection reports, can help buyers assess compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These inspections typically cover all stages of production and can help identify potential issues.

What Are the Nuances of Quality Certification for International Buyers?

For international B2B buyers, understanding the nuances of quality certification is essential. Different regions may have specific requirements or certifications that must be met. For instance:

-

European Union: Products sold within the EU must meet CE marking requirements, which may involve specific tests and documentation.

-

Africa and South America: Buyers should be aware of local regulations and standards, which can vary significantly by country. Understanding these local requirements can help ensure compliance and avoid potential delays in shipping or customs clearance.

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Crucial for B2B Buyers?

In the competitive landscape of commercial kitchen equipment, understanding the manufacturing processes and quality assurance measures of conveyor ovens is critical for B2B buyers. By focusing on these elements, buyers can make informed decisions, ensuring they invest in high-quality, reliable ovens that meet their operational needs while adhering to international standards. This knowledge not only enhances purchasing confidence but also fosters long-term relationships with suppliers committed to quality and excellence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘conveyer oven’

In the competitive landscape of commercial kitchens, selecting the right conveyor oven is essential for optimizing efficiency and ensuring consistent food quality. This checklist serves as a comprehensive guide for B2B buyers to make informed decisions when procuring a conveyor oven, ensuring that the chosen equipment meets the operational demands of their business.

Step 1: Define Your Technical Specifications

Before starting your search, it’s critical to outline your specific needs. Consider factors such as the type of food you will be cooking, the expected volume, and the available kitchen space.

– Types of food: Different conveyor ovens are optimized for various menu items, from pizzas to sandwiches.

– Volume and space: Assess how much space you can allocate and how many dishes you need to prepare simultaneously.

Illustrative image related to conveyer oven

Step 2: Research the Different Types of Conveyor Ovens

Familiarize yourself with the types of conveyor ovens available, including gas, electric, and propane models. Each type has its advantages and disadvantages that can impact your operational efficiency.

– Gas vs. Electric: Gas ovens typically heat faster, while electric models may offer better energy efficiency in some setups.

– Single vs. Double Deck: Consider whether a single or double-deck oven suits your kitchen’s workflow better.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers before making a commitment. Look for company profiles, case studies, and references from other businesses in your industry or region.

– Supplier reputation: Research online reviews and testimonials to gauge reliability.

– Customer service: Assess their responsiveness and support options, as these can be crucial for maintenance and troubleshooting.

Step 4: Verify Compliance with Local Regulations

Ensure that the conveyor ovens you are considering meet local health, safety, and environmental regulations. Non-compliance can lead to costly fines or operational shutdowns.

– Ventilation requirements: Particularly for gas models, check local codes regarding ventilation systems.

– Energy efficiency standards: Look for ovens that meet or exceed local energy regulations to reduce operational costs.

Step 5: Request Demonstrations or Samples

If possible, request live demonstrations or trial periods for the ovens on your shortlist. This step allows you to evaluate the performance and ease of use in a real kitchen environment.

– Performance assessment: Observe cooking times, quality of food, and ease of operation.

– Staff feedback: Gather input from kitchen staff regarding usability and functionality.

Step 6: Compare Pricing and Warranty Options

Gather quotes from multiple suppliers and compare not just the prices but also the warranty options and after-sales support. A lower price may not always equate to better value if service is lacking.

– Cost of ownership: Factor in potential energy savings and maintenance costs over time.

– Warranty terms: Look for comprehensive warranties that cover parts and labor for a reasonable duration.

Step 7: Make Your Decision and Finalize the Purchase

After thorough evaluation, select the conveyor oven that best meets your operational needs and budget. Ensure that all terms, including delivery, installation, and training, are clearly outlined in your purchase agreement.

– Documentation: Confirm that you receive all necessary manuals and installation guides.

– Post-purchase support: Establish a relationship with your supplier for ongoing support and future needs.

By following this checklist, B2B buyers can confidently navigate the procurement process for conveyor ovens, ensuring they select equipment that enhances productivity and maintains food quality in their operations.

Comprehensive Cost and Pricing Analysis for conveyer oven Sourcing

What Are the Key Cost Components in Conveyor Oven Sourcing?

When sourcing conveyor ovens, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The quality of materials directly impacts both the performance and durability of conveyor ovens. Stainless steel is commonly used for its strength and ease of cleaning, while high-grade insulation materials are essential for energy efficiency.

-

Labor: Labor costs vary based on geographical location and the complexity of manufacturing processes. Skilled labor is required for precise assembly and quality control, which can add to the overall cost.

-

Manufacturing Overhead: This encompasses indirect costs such as factory rent, utilities, and administrative expenses. Efficient manufacturing processes can help minimize these costs.

-

Tooling: The initial investment in tooling is significant, especially for custom designs. This includes molds and machinery specifically designed for conveyor oven production.

-

Quality Control (QC): Ensuring that every oven meets safety and performance standards incurs additional costs. Implementing rigorous QC processes can prevent costly recalls and enhance brand reputation.

-

Logistics: Shipping costs can vary dramatically based on distance, mode of transport, and local tariffs. Proper logistics planning is essential to manage these expenses effectively.

-

Margin: Suppliers typically mark up prices to maintain profit margins. Understanding average margins in the industry can provide leverage during negotiations.

How Do Price Influencers Affect Conveyor Oven Costs?

Several factors can influence the pricing of conveyor ovens:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to lower per-unit costs. Negotiating for larger orders can significantly reduce overall expenses.

-

Specifications and Customization: Customized ovens tailored to specific needs or menu items will generally cost more. Buyers should clearly define their requirements to avoid unexpected costs.

-

Materials and Quality Certifications: High-quality materials and certifications (e.g., NSF, CE) may increase initial costs but can offer long-term savings through durability and compliance with safety standards.

-

Supplier Factors: Established suppliers with a reputation for quality may charge premium prices. However, their reliability can reduce risks associated with sourcing.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) affect the final price by determining who is responsible for shipping costs and risks during transport. Understanding these terms can lead to better negotiation outcomes.

What Are the Best Buyer Tips for Sourcing Conveyor Ovens?

B2B buyers should consider several strategies to optimize their sourcing process:

-

Negotiation Tactics: Effective negotiation can lead to significant savings. Prepare by researching market prices and understanding your supplier’s cost structure.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the total cost over the oven’s lifecycle, including maintenance, energy consumption, and potential downtime. This holistic view can guide better purchasing decisions.

-

Pricing Nuances for International Buyers: For buyers from regions like Africa, South America, the Middle East, and Europe, consider currency fluctuations, import duties, and local regulations that may affect pricing. Establishing relationships with local distributors can mitigate some of these challenges.

-

Long-Term Partnerships: Building long-term relationships with suppliers can lead to better pricing, priority service, and access to the latest innovations in conveyor oven technology.

What Should Buyers Be Aware of Regarding Indicative Prices?

While indicative prices for conveyor ovens can range significantly—often from $4,000 to over $40,000—these figures can fluctuate based on the factors discussed. Buyers should treat these prices as starting points for negotiations rather than fixed costs. Always request detailed quotes that outline all components to ensure transparency and avoid hidden fees.

By understanding the cost structure and pricing influencers, B2B buyers can make informed decisions when sourcing conveyor ovens, ensuring they achieve the best value for their investment.

Alternatives Analysis: Comparing conveyer oven With Other Solutions

In the competitive landscape of commercial kitchens, operators constantly seek efficient cooking solutions that enhance productivity and meet diverse culinary demands. While conveyor ovens are a robust option for high-volume cooking, several alternative technologies can also achieve similar goals. Understanding the strengths and weaknesses of these alternatives is crucial for B2B buyers aiming to optimize their kitchen operations.

Comparison Table

| Comparison Aspect | Conveyer Oven | Impingement Oven | Traditional Oven |

|---|---|---|---|

| Performance | High throughput with consistent results | Fast cooking with even heat distribution | Variable results, slower cooking |

| Cost | Moderate to high initial investment | Higher initial investment | Lower initial investment |

| Ease of Implementation | Requires specific kitchen layout | May need ventilation and space | Easy to implement in most kitchens |

| Maintenance | Regular cleaning of belts and trays | Requires periodic maintenance of fans | Generally low maintenance |

| Best Use Case | Ideal for pizzas and baked goods | Suitable for quick-service menus | Versatile for various cooking methods |

What Are the Advantages and Disadvantages of Impingement Ovens?

Impingement ovens utilize a fan to blow hot air directly onto food, significantly reducing cooking times while ensuring even heat distribution. This technology is particularly effective for items like sandwiches, pizzas, and pastries. The primary advantage is speed, as food can cook faster than in traditional ovens. However, the initial investment can be higher, making it less attractive for smaller operations. Additionally, they require more maintenance due to the intricate fan systems, which can be a consideration for kitchens with limited staff.

How Do Traditional Ovens Compare with Conveyor Ovens?

Traditional ovens are a staple in many kitchens due to their versatility and lower initial costs. They can be used for a wide range of cooking methods, including baking, roasting, and broiling. While traditional ovens may not offer the speed or consistency of conveyor ovens, they are generally easier to implement and maintain. The downside is that they can produce variable results, particularly in high-volume settings where timing and uniformity are critical. For operations that require flexibility and a diverse menu, traditional ovens may be a suitable choice, but they may struggle to keep pace with peak demands.

Conclusion: Which Cooking Solution Is Right for Your Business?

When evaluating cooking solutions, it is essential for B2B buyers to consider their specific operational needs, volume requirements, and budget constraints. Conveyor ovens excel in high-volume environments where consistency and speed are paramount, making them ideal for pizzerias and fast-casual dining. Impingement ovens offer a balance of speed and versatility for quick-service menus, while traditional ovens provide flexibility at a lower upfront cost. Ultimately, the right choice will depend on your kitchen’s workflow, the type of cuisine you serve, and your long-term operational goals.

Essential Technical Properties and Trade Terminology for conveyer oven

What Are the Key Technical Properties of Conveyor Ovens?

When selecting a conveyor oven, understanding its technical properties is crucial for optimizing performance and ensuring it meets the demands of a commercial kitchen. Here are some essential specifications to consider:

1. Construction Material

The material used in the construction of conveyor ovens is vital for durability and performance. Most high-quality conveyor ovens are made from stainless steel, which offers resistance to corrosion, ease of cleaning, and longevity under high-heat conditions. This is particularly important in high-volume environments where consistent performance is needed over long periods.

2. Temperature Range

The temperature range indicates the oven’s ability to cook various food items at different heat levels. Conveyor ovens typically operate between 300°F to 700°F (about 150°C to 370°C). Understanding the temperature capabilities is essential for B2B buyers, as it determines the types of food that can be efficiently prepared, from pizzas to baked goods.

3. Belt Speed Adjustment

Belt speed controls allow operators to customize cooking times for different menu items. This feature is critical in managing food quality and consistency, enabling kitchens to adapt to varying demands. Speed settings can typically range from 1 to 10 feet per minute, making it vital for operators to choose an oven with adjustable controls that match their workflow.

Illustrative image related to conveyer oven

4. Stackability and Footprint

In commercial kitchens where space is at a premium, the stackability of conveyor ovens is a significant consideration. Some models are designed to be stacked, maximizing vertical space without compromising performance. Understanding the footprint of the oven helps B2B buyers plan their kitchen layout effectively, ensuring optimal workflow and space utilization.

5. Energy Efficiency

Energy efficiency is increasingly becoming a priority for businesses, particularly in regions with high energy costs. Ovens designed with energy-efficient heating elements can significantly reduce operating costs over time. B2B buyers should inquire about the oven’s energy ratings and any available certifications that indicate energy performance.

6. Ventilation Requirements

Many commercial conveyor ovens, especially gas models, require specific ventilation systems to operate safely and efficiently. Understanding these requirements is essential for compliance with local regulations and ensuring that the kitchen environment remains safe for staff. Buyers should consider whether the model is ventless or requires a hood system based on their kitchen’s infrastructure.

What Are Common Trade Terms Associated with Conveyor Ovens?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B landscape. Here are some common terms related to conveyor ovens:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of conveyor ovens, working with OEMs can ensure that you receive high-quality components and reliable service.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units that a supplier is willing to sell. Understanding MOQs is vital for B2B buyers, as they affect inventory management and initial investment costs.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. B2B buyers should prepare detailed RFQs to ensure they receive accurate pricing and terms from manufacturers of conveyor ovens.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. They clarify aspects such as shipping costs, insurance, and risk transfer. Understanding Incoterms is critical for B2B buyers engaging with suppliers from different countries to avoid misunderstandings.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For conveyor ovens, lead times can vary based on the manufacturer and model. Knowing lead times helps businesses plan their operations and manage customer expectations effectively.

Illustrative image related to conveyer oven

6. Warranty Period

The warranty period is the time frame during which the manufacturer covers repairs or replacements due to defects. Understanding warranty terms is crucial for B2B buyers as it impacts long-term costs and product reliability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when investing in conveyor ovens, ensuring they select the right equipment to enhance operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the conveyer oven Sector

What Are the Key Drivers and Trends Shaping the Global Conveyor Oven Market?

The conveyor oven market is witnessing significant growth driven by the increasing demand for high-efficiency cooking solutions in the foodservice industry. Factors such as the rise in fast-casual dining, the expansion of quick-service restaurants, and the growing trend of on-demand food delivery are propelling the need for reliable, high-volume cooking equipment. In regions like Africa, South America, and the Middle East, the burgeoning middle class and urbanization are fueling restaurant growth, creating opportunities for conveyor oven suppliers.

Emerging technologies, such as IoT-enabled ovens, are also transforming the market by offering real-time monitoring and analytics. This capability allows businesses to optimize cooking times and energy usage, enhancing operational efficiency. Additionally, there is a shift towards electric models in urban areas with stricter emissions regulations, while gas-powered ovens remain popular in high-volume kitchens due to their rapid heating capabilities.

Illustrative image related to conveyer oven

International buyers, particularly in Europe and regions like Nigeria and Brazil, should be aware of the varying standards and certifications required in their respective markets. Understanding local regulations regarding safety, energy efficiency, and emissions will be crucial for successful sourcing. Furthermore, the trend towards stackable and compact designs caters to space-limited kitchens, making it essential for buyers to evaluate their kitchen layouts before making purchasing decisions.

How Are Sustainability and Ethical Sourcing Influencing Conveyor Oven Purchases?

In today’s market, sustainability and ethical sourcing have become paramount considerations for B2B buyers in the conveyor oven sector. The environmental impact of manufacturing and operating commercial kitchen equipment is under scrutiny, leading many businesses to seek ovens that minimize energy consumption and emissions. Buyers should prioritize ovens with energy-efficient features, such as variable speed controls and adjustable temperature zones, which can significantly reduce operational costs and carbon footprints.

Moreover, the importance of ethical supply chains cannot be overstated. B2B buyers are increasingly demanding transparency from suppliers about their sourcing practices and labor conditions. Certifications for sustainable practices, such as ENERGY STAR or eco-labels, are valuable indicators of an oven’s environmental credentials. Additionally, sourcing materials that are recyclable or made from sustainable resources not only contributes to environmental goals but also appeals to a growing consumer base that values corporate responsibility.

Investing in conveyor ovens with proven sustainability credentials can also enhance a company’s brand image, making it a competitive differentiator in the market. As businesses strive to meet their own sustainability goals, partnering with manufacturers who share these values will be crucial.

Illustrative image related to conveyer oven

How Has the Conveyor Oven Market Evolved Over Time?

The evolution of conveyor ovens can be traced back to the need for efficient cooking solutions in commercial kitchens. Initially designed for pizzerias, these ovens have diversified to accommodate a wide range of food items, including sandwiches, baked goods, and more. Over the years, advancements in technology have led to the development of electric and gas models that offer greater energy efficiency and cooking precision.

In the 1980s and 1990s, the introduction of impingement technology revolutionized conveyor ovens, allowing for faster cooking times and improved food quality. This innovation paved the way for the modern conveyor ovens used in high-volume kitchens today. As the foodservice industry continues to evolve, the demand for versatile, efficient, and sustainable cooking solutions will likely drive further innovations in conveyor oven design and functionality.

In summary, understanding the current market dynamics, focusing on sustainability, and recognizing the historical advancements in conveyor ovens will empower international B2B buyers to make informed purchasing decisions that align with their operational needs and values.

Frequently Asked Questions (FAQs) for B2B Buyers of conveyer oven

-

How do I choose the right conveyor oven for my business needs?

Selecting the right conveyor oven involves assessing your kitchen’s volume, menu items, and space constraints. Consider the type of power source (gas vs. electric), as gas ovens generally heat faster. Additionally, evaluate the oven’s capacity—single or double-stack options may be ideal for smaller spaces but ensure they can handle your peak volume. Look for features like adjustable temperature zones and variable speed controls to optimize cooking for different dishes. -

What are the key features to look for in a commercial conveyor oven?

When sourcing a conveyor oven, prioritize features that enhance performance and durability. Look for variable speed controls to adjust cooking times and adjustable temperature settings for multi-stage cooking. Stainless steel construction is essential for longevity, while removable crumb trays facilitate easy cleaning. Energy efficiency is also critical; choose models that maintain consistent output to reduce operational costs and improve kitchen workflow. -

Can conveyor ovens be customized for specific cooking requirements?

Yes, many manufacturers offer customizable conveyor ovens to meet specific cooking needs. You can request features such as specialized belt sizes, unique temperature zones, or even custom finishes to match your kitchen aesthetic. When discussing customization options, ensure that the supplier understands your cooking volume and menu diversity to recommend the best modifications that will enhance efficiency and output. -

What are the minimum order quantities (MOQ) for conveyor ovens?

MOQs for conveyor ovens can vary significantly by supplier and location. Generally, larger manufacturers may have higher MOQs, often starting from 5 to 10 units, while smaller suppliers may accommodate lower quantities. When negotiating, consider your budget and storage capacity, and inquire if the supplier can offer flexible terms for your first order, especially if you plan to scale your operations in the future. -

What payment terms should I expect when purchasing conveyor ovens internationally?

Payment terms can differ widely depending on the supplier and your negotiation skills. Common arrangements include a deposit upon order placement, with the remaining balance due before shipment. Some suppliers may offer letters of credit or payment upon delivery, particularly in established trade relationships. Always clarify payment methods accepted, including wire transfers, credit terms, and any potential additional fees for international transactions. -

How do I ensure the quality and reliability of conveyor ovens from suppliers?

To ensure quality, conduct thorough research on potential suppliers, including checking their certifications, customer reviews, and industry reputation. Request product samples or references from previous clients to assess oven performance firsthand. Additionally, inquire about warranty terms and after-sales support, as reputable suppliers often provide comprehensive service packages to ensure their ovens meet your operational needs over time. -

What are the logistics considerations for importing conveyor ovens?

When importing conveyor ovens, consider shipping methods, customs regulations, and associated costs. Work with logistics partners who specialize in commercial kitchen equipment to navigate international shipping. Be aware of import duties and taxes that may apply in your country, and ensure that your supplier provides all necessary documentation for customs clearance. Timely communication with your logistics provider is crucial to avoid delays in delivery. -

Do conveyor ovens require special installation or ventilation?

Most conveyor ovens, particularly gas models, require proper ventilation to ensure safe operation and compliance with local health codes. Electric ovens may have more flexible ventilation options, with some designed to be ventless. Always consult the manufacturer’s guidelines and local regulations before installation. Additionally, consider hiring professional installers to ensure that your equipment is set up correctly for optimal performance and safety.

Top 4 Conveyer Oven Manufacturers & Suppliers List

1. WebstaurantStore – Conveyor and Impinger Ovens

Domain: webstaurantstore.com

Registered: 2003 (22 years)

Introduction: Conveyor ovens and impinger ovens are designed for high-volume cooking and baking. They utilize a conveyor belt system to move food through the cooking chamber, ensuring even cooking and consistent results. Impinger ovens use a unique airflow system that enhances cooking efficiency and reduces cooking times. These ovens are ideal for pizza, sandwiches, and other baked goods, making them a popular …

2. Equippers – Commercial Conveyor Ovens

Domain: equippers.com

Registered: 1999 (26 years)

Introduction: Commercial Conveyor Ovens: Gas, Electric, Propane

3. Middleby – CTX Conveyor Oven

Domain: middleby.com

Registered: 1995 (30 years)

Introduction: Commercial conveyor ovens provide consistency, ease of operation, and space maximization in foodservice operations. They can cook a variety of foods beyond pizza, including proteins, sandwiches, and vegetables. The Middleby Marshall CTX Oven offers automated cooking processes like grilling, baking, broiling, searing, steaming, and sous vide. Conveyor ovens can be stackable to save space, with opti…

4. Stainless Steel Solutions – Key Components

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Stainless steel chain 2. Stainless steel wire mesh 3. Frame made from stainless steel sheets with hinge, screws, etc. 4. Fire resistant insulating material 5. Pulleys and bearings 6. Heating elements (like Metal Heating Elements) 7. Microcontroller 8. DC motors with motor driver 9. DC power supply 10. Thermocouples 11. Switches, relays, and wires

Strategic Sourcing Conclusion and Outlook for conveyer oven

Why is Strategic Sourcing Essential for Conveyor Ovens?

In today’s competitive foodservice industry, strategic sourcing for conveyor ovens is critical for maximizing operational efficiency and ensuring consistent product quality. The ability to customize ovens for various cooking styles, while maintaining high throughput, allows businesses to adapt to diverse menu offerings and customer demands. By investing in reliable equipment that features energy-efficient designs and variable controls, operators can enhance their service speed and reduce labor costs.

How Can International Buyers Leverage Conveyor Ovens?

For B2B buyers in Africa, South America, the Middle East, and Europe, selecting the right conveyor oven involves considering local market needs, supply chain logistics, and compliance with regional regulations. Engaging with trusted suppliers who understand these dynamics can lead to significant cost savings and improved kitchen performance.

What’s Next for Your Business?

As the demand for quick-service and high-volume food preparation continues to rise, the outlook for conveyor ovens remains promising. Investing in advanced cooking technologies today will position your business for success tomorrow. Explore your options with leading manufacturers and distributors to find solutions that fit your operational needs. Take action now to elevate your kitchen capabilities and meet the evolving expectations of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.