A B2B Buyer’s Guide to Resin Washed Stone: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for resin washed stone

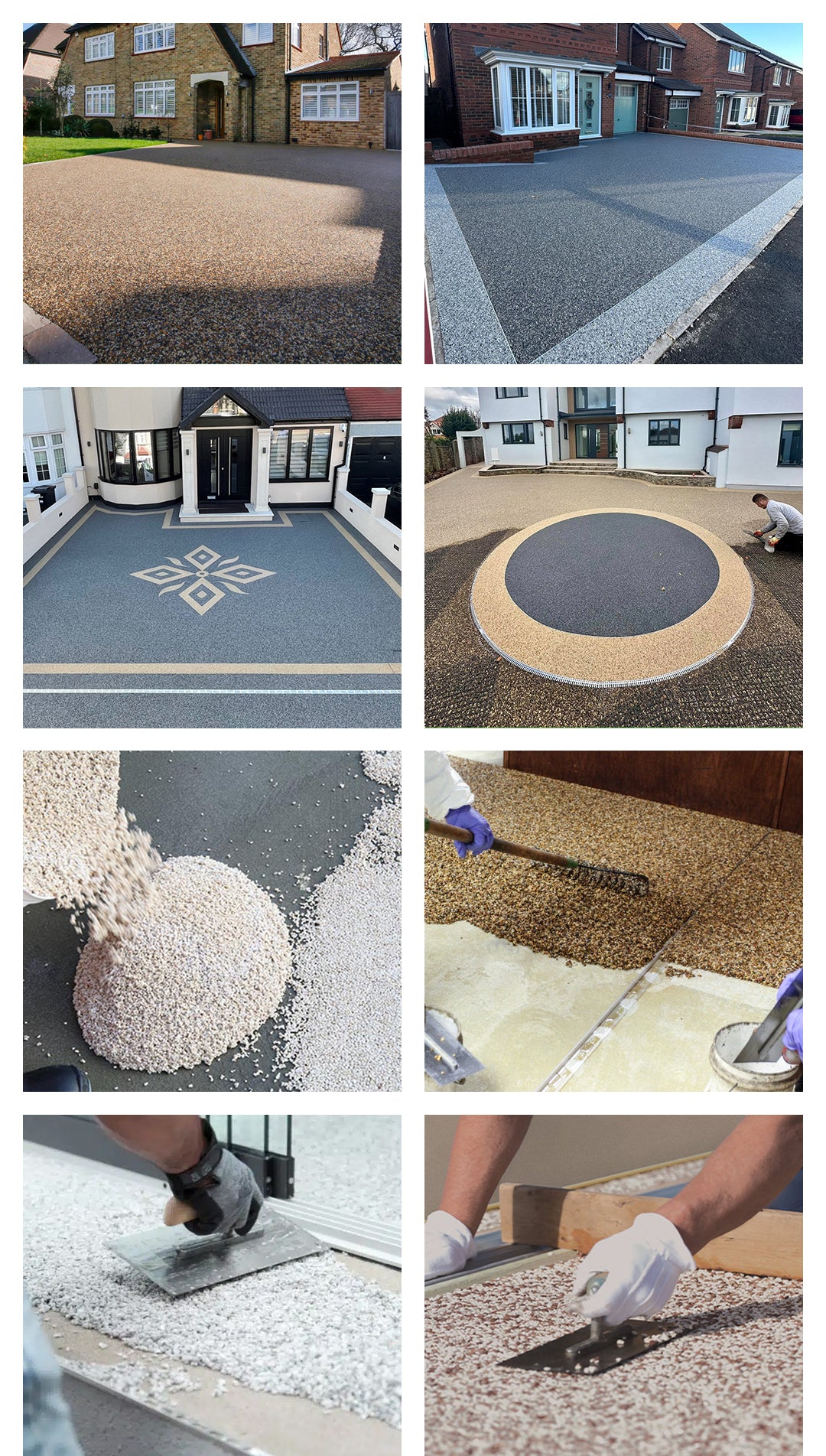

In today’s competitive landscape, sourcing high-quality resin washed stone can pose significant challenges for international B2B buyers, particularly when navigating diverse supplier markets across Africa, South America, the Middle East, and Europe. This innovative material, which combines natural stone with durable polymer resin, is increasingly sought after for its aesthetic appeal and functional benefits in both indoor and outdoor applications. However, understanding the nuances of resin washed stone—such as its various types, installation processes, and maintenance requirements—is crucial for making informed purchasing decisions.

This comprehensive guide aims to demystify the global market for resin washed stone by providing actionable insights into its diverse applications, ranging from residential landscapes to commercial projects. Buyers will learn how to effectively vet suppliers, evaluate costs, and assess the long-term benefits of different resin washed stone products. Additionally, we will explore the latest trends in design and sustainability, ensuring that your choices align with both aesthetic desires and environmental considerations.

By equipping B2B buyers with the necessary tools and knowledge, this guide empowers you to make strategic decisions that enhance your projects and ultimately drive business success. Whether you are based in bustling urban centers like Vietnam or Germany, or emerging markets, understanding the intricacies of resin washed stone will position you to capitalize on this versatile material effectively.

Understanding resin washed stone Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Resin Bound Stone | Fully bound aggregate with a smooth finish | Driveways, walkways, patios | Pros: Durable, seamless finish; Cons: Higher installation cost. |

| Resin Bonded Stone | Aggregate bonded to a surface with a layer of resin | Garden paths, pool surrounds | Pros: Cost-effective; Cons: Less durable than resin bound. |

| Decorative Stone Carpet | Customizable blends of stones and resins for aesthetics | Indoor flooring, outdoor terraces | Pros: Highly aesthetic; Cons: Requires careful installation. |

| Eco-Friendly Resin Stone | Made with sustainable materials and processes | Landscaping, eco-sensitive projects | Pros: Environmentally friendly; Cons: Potentially higher price point. |

| Textured Resin Stone | Features a varied surface texture for grip and comfort | High-traffic areas, commercial spaces | Pros: Slip-resistant; Cons: May require more maintenance. |

What are the Characteristics of Resin Bound Stone?

Resin Bound Stone is characterized by its fully bound aggregates, creating a smooth and continuous surface. This type is ideal for high-traffic applications like driveways and walkways, providing a durable solution that withstands heavy loads. For B2B buyers, the seamless finish enhances aesthetic appeal, but the installation costs can be higher due to the specialized labor and materials required.

How Does Resin Bonded Stone Differ?

Resin Bonded Stone involves applying a layer of resin to an existing surface before embedding loose aggregates. This method is often more cost-effective than resin bound solutions, making it suitable for projects with budget constraints, such as garden paths and pool surrounds. However, its durability is generally lower, which may require more frequent maintenance or replacement, a key consideration for buyers.

What Makes Decorative Stone Carpet a Unique Option?

Decorative Stone Carpet allows for a high degree of customization, combining various stones and resins to create unique patterns and colors. This option is particularly appealing for indoor flooring and outdoor terraces where aesthetics are paramount. B2B buyers should consider the installation complexity, as achieving a flawless finish requires skilled labor, impacting overall project timelines and costs.

Why Choose Eco-Friendly Resin Stone?

Eco-Friendly Resin Stone is formulated with sustainable materials, appealing to environmentally conscious businesses. It is increasingly used in landscaping and eco-sensitive projects, providing a green alternative without sacrificing durability. However, the potential for a higher price point can deter some buyers, necessitating a clear value proposition that highlights long-term environmental benefits and compliance with sustainability goals.

What are the Advantages of Textured Resin Stone?

Textured Resin Stone offers enhanced grip and comfort, making it particularly suitable for high-traffic areas and commercial spaces. The varied surface texture not only increases safety but also adds a unique aesthetic appeal. Buyers should weigh the benefits of slip resistance against the possibility of increased maintenance needs, as textured surfaces may collect debris more readily, necessitating regular cleaning.

Key Industrial Applications of resin washed stone

| Industry/Sector | Specific Application of resin washed stone | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Renovation | Flooring for commercial and residential buildings | Durable, aesthetically pleasing surfaces that enhance property value | Ensure compliance with local building regulations and standards |

| Landscaping & Outdoor Design | Pathways, patios, and pool surrounds | Creates seamless, slip-resistant surfaces for outdoor areas | Availability of various colors and textures to match design needs |

| Hospitality & Tourism | Resort and hotel outdoor areas | Provides a luxurious and natural look, improving guest experience | Consider weather resistance and maintenance requirements |

| Retail & Commercial Spaces | Parking lots and driveways | High durability and ease of installation reduce long-term costs | Assess load-bearing capacity and local climate conditions |

| Sports & Recreation | Sports courts and playgrounds | Offers a safe, impact-resistant surface for active use | Evaluate drainage capabilities and surface texture options |

How is Resin Washed Stone Used in Construction & Renovation?

In the construction and renovation sector, resin washed stone is predominantly utilized for flooring in both commercial and residential buildings. Its high durability and aesthetic appeal provide an excellent finish that can significantly enhance property value. This material effectively addresses issues such as uneven surfaces and damage, ensuring a smooth and visually appealing outcome. Buyers should consider local building regulations, the environmental impact of materials, and the availability of skilled labor for installation when sourcing resin washed stone.

What are the Benefits of Resin Washed Stone in Landscaping & Outdoor Design?

Resin washed stone finds extensive application in landscaping, particularly for pathways, patios, and pool surrounds. Its unique combination of natural stone and resin allows for seamless integration into various landscapes, creating slip-resistant and visually striking surfaces. This is particularly advantageous in regions with high foot traffic or moisture, as it reduces the risk of slips and falls. Buyers in this sector should prioritize sourcing options that offer a range of colors and textures to ensure compatibility with their design vision.

How Does Resin Washed Stone Enhance Hospitality & Tourism?

In the hospitality and tourism industry, resin washed stone is often employed in outdoor areas of resorts and hotels. It creates a luxurious and inviting atmosphere that can significantly elevate the guest experience. The material is not only aesthetically pleasing but also practical, as it is designed to withstand various weather conditions. When sourcing, businesses should focus on the material’s resistance to fading and wear, ensuring longevity and minimal maintenance in high-use areas.

What Advantages Does Resin Washed Stone Offer for Retail & Commercial Spaces?

For retail and commercial spaces, resin washed stone is an ideal choice for parking lots and driveways. Its durability and low maintenance requirements translate into long-term cost savings for businesses. The material can withstand significant weight and traffic, making it suitable for various applications. Key sourcing considerations include evaluating the load-bearing capacity and compatibility with local climate conditions to ensure optimal performance.

How is Resin Washed Stone Used in Sports & Recreation Facilities?

In sports and recreation, resin washed stone is utilized for constructing sports courts and playgrounds. Its impact-resistant surface provides a safe environment for active use, making it an excellent choice for facilities catering to children and athletes. The material also allows for creative designs that can enhance the visual appeal of recreational areas. Buyers should assess the drainage capabilities and surface texture options to meet specific safety and performance standards in their region.

3 Common User Pain Points for ‘resin washed stone’ & Their Solutions

Scenario 1: Inconsistent Quality in Resin Washed Stone Products

The Problem: B2B buyers often face challenges related to the inconsistent quality of resin washed stone products. This inconsistency can stem from variations in resin composition, stone particle size, or the manufacturing process itself. When sourcing materials for large projects, such as landscaping or commercial flooring, these discrepancies can lead to mismatched aesthetics, structural weaknesses, and overall dissatisfaction among clients. As a result, buyers may find themselves in a position where they must replace subpar materials, leading to project delays and increased costs.

The Solution: To mitigate the risk of inconsistent quality, buyers should establish strong relationships with reputable suppliers who prioritize quality control in their production processes. It’s essential to request samples of the resin washed stone before making bulk orders. Conducting thorough testing on these samples will help verify their durability, texture, and resistance to environmental factors. Furthermore, buyers should ensure that suppliers provide detailed specifications and certifications for their products, including resin hardness ratings and compliance with environmental standards. This approach not only guarantees a reliable supply of high-quality materials but also fosters trust and accountability in supplier relationships.

Scenario 2: Challenges with Installation and Application

The Problem: Another common pain point for B2B buyers is the complexity involved in the installation of resin washed stone. Many buyers may not have the technical expertise or experience necessary for proper application, leading to uneven surfaces, improper adhesion, and ultimately, a compromised finish. This situation can be particularly detrimental for projects with tight deadlines, as installation errors could result in costly repairs and extended timelines.

The Solution: To ensure a successful installation, buyers should seek out comprehensive installation guidelines and training materials from their suppliers. Many manufacturers offer detailed manuals and instructional videos that outline the step-by-step process for applying resin washed stone. Additionally, buyers can consider partnering with experienced contractors or installers who specialize in resin-based materials. Investing in professional installation not only enhances the quality of the finished product but also provides peace of mind that the project will be completed efficiently and to specification. Regular communication with the installation team throughout the process can further help address any challenges that arise.

Scenario 3: Environmental and Maintenance Concerns

The Problem: B2B buyers are increasingly aware of the environmental impact of the materials they choose, and resin washed stone is no exception. Concerns about the long-term durability of resin products and their environmental footprint can lead to hesitation when making purchasing decisions. Additionally, maintenance requirements for resin washed stone can be unclear, leading to uncertainty about ongoing costs and labor for upkeep.

The Solution: Buyers should prioritize sourcing environmentally friendly resin washed stone products that are designed for durability and minimal maintenance. Inquire about the eco-certifications of the resin used, as well as the sourcing of the natural stone components. Many suppliers now offer low-VOC (volatile organic compounds) resins that are safer for both the environment and end-users. Furthermore, buyers should obtain detailed maintenance guidelines from suppliers to understand the care required to preserve the integrity of the surface over time. This might include regular cleaning routines, recommended cleaning agents, and information on how to repair any minor damages. Establishing a clear maintenance plan will not only prolong the life of the resin washed stone but also ensure that it remains aesthetically pleasing, ultimately protecting the buyer’s investment.

Strategic Material Selection Guide for resin washed stone

When selecting materials for resin washed stone applications, it is essential to consider various factors that affect performance, durability, and compatibility with specific environments. This guide analyzes four common materials used in resin washed stone, focusing on their properties, advantages, disadvantages, and implications for international buyers.

What are the Key Properties of Natural Stone Aggregate?

Natural stone aggregates, such as granite, marble, and limestone, are commonly used in resin washed stone applications. These materials exhibit high durability, resistance to weathering, and aesthetic appeal. Granite, for instance, has a high compressive strength, making it suitable for high-traffic areas. However, its weight can complicate transportation and installation processes.

Pros: Natural stone aggregates provide a unique aesthetic and are highly durable, making them ideal for both indoor and outdoor applications. They also offer excellent temperature resistance, ensuring performance in various climates.

Cons: The cost of high-quality natural stone can be significant, and sourcing may be limited based on geographic location. Additionally, the installation process may require specialized skills, increasing manufacturing complexity.

How Does Polymer Resin Enhance Performance?

Polymer resins, specifically epoxy and polyurethane, are critical components in resin washed stone formulations. These materials bond the stone aggregates together, creating a seamless and durable surface. Epoxy resins are known for their excellent adhesion and chemical resistance, while polyurethane offers flexibility and UV stability.

Pros: The use of polymer resins enhances the overall strength and longevity of the resin washed stone. They provide waterproofing and stain resistance, making maintenance easier for end-users.

Cons: The initial cost of high-quality resins can be high, and the curing process requires specific environmental conditions. Additionally, improper mixing or application can lead to performance issues, necessitating skilled labor.

What Role Does Color Pigment Play in Aesthetic Appeal?

Color pigments are often added to resin washed stone to achieve desired aesthetics. These pigments can be derived from natural sources or synthetic materials, allowing for a wide range of colors and finishes. The choice of pigment can significantly affect the final appearance of the surface.

Pros: Color pigments enhance the visual appeal of resin washed stone, allowing for customization to meet client preferences. They can also improve UV resistance, preventing color fading over time.

Cons: Some pigments may be less durable than others, leading to potential fading or discoloration. Additionally, the cost of high-quality pigments can add to the overall expense of the project.

How Do Environmental Considerations Impact Material Selection?

In regions like Africa, South America, the Middle East, and Europe, environmental regulations and sustainability practices are increasingly influencing material selection. Buyers must consider the environmental impact of sourcing materials, particularly natural stone and resins.

Pros: Selecting environmentally friendly materials can enhance brand reputation and compliance with local regulations. Sustainable practices may also lead to cost savings in the long run.

Cons: Sourcing sustainable materials may limit options and increase costs. Additionally, compliance with international standards such as ASTM, DIN, or JIS may require additional documentation and testing.

Summary Table of Material Selection for Resin Washed Stone

| Material | Typical Use Case for resin washed stone | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Stone Aggregate | Outdoor walkways, patios | High durability and aesthetic appeal | High sourcing costs and weight | High |

| Polymer Resin | Bonding agent in resin washed stone | Excellent adhesion and waterproofing | Requires skilled application | Medium |

| Color Pigment | Customization of surface appearance | Enhances visual appeal and UV resistance | Potential fading over time | Medium |

| Environmentally Friendly Materials | Sustainable construction projects | Compliance with regulations and sustainability | Limited sourcing options | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties and implications of different materials used in resin washed stone applications. Understanding these factors will aid in making informed purchasing decisions that align with project requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for resin washed stone

What Are the Main Stages of Manufacturing Resin Washed Stone?

The manufacturing of resin washed stone involves several critical stages that ensure the final product meets the high standards required for both aesthetic appeal and durability. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process involves selecting high-quality natural stones, such as pebbles or gravel. These stones are screened and cleaned to remove impurities and dust, ensuring a consistent appearance and excellent adhesion with the resin. The choice of stone size—typically between 1-3mm and 3-5mm—can affect the texture and application of the final product. Additionally, environmentally friendly high-hardness resin components are sourced, which play a crucial role in the durability and performance of the resin washed stone.

Forming the Mixture

Once the materials are prepared, the next step involves mixing the selected stones with the polymer resin. This is a critical phase where precise ratios are maintained to ensure optimal binding and performance characteristics. Advanced mixing techniques, such as using force action concrete mixers, are employed to achieve a homogeneous blend, which is essential for the integrity of the final product.

Assembly and Application

Following the mixing process, the resin washed stone mixture is applied to the desired surfaces. This stage can be executed using various methods, including troweling or pouring, depending on the area to be covered and the specific application requirements. The seamless application capability allows for the creation of unique patterns and designs that can enhance the aesthetic value of both indoor and outdoor spaces.

Finishing Touches

After the resin washed stone is laid, it undergoes a curing process, which is vital for achieving its full hardness and durability. The curing time can vary based on environmental conditions, but typically ranges from 24 to 72 hours. Once cured, the surface is inspected for consistency and quality, ensuring it meets the required specifications.

How Is Quality Assurance Implemented in Resin Washed Stone Manufacturing?

Quality assurance is integral to the manufacturing of resin washed stone, ensuring that the final product meets international standards and customer expectations. Various quality control checkpoints are established throughout the manufacturing process.

What International Standards Are Relevant for Resin Washed Stone?

To ensure quality and safety, manufacturers often comply with international standards such as ISO 9001, which outlines the requirements for a quality management system. Additionally, certifications such as CE marking indicate that the products meet European health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Quality control in the manufacturing of resin washed stone typically involves several checkpoints:

-

Incoming Quality Control (IQC): At this stage, raw materials such as stones and resin are inspected for quality and conformity to specifications. This includes checks for size, cleanliness, and material properties.

-

In-Process Quality Control (IPQC): During the manufacturing process, samples are taken at various stages to monitor the mixture’s consistency and performance characteristics. This ensures that any deviations are identified and corrected promptly.

-

Final Quality Control (FQC): After the resin washed stone has been cured, a final inspection is conducted. This includes visual inspections for surface defects, testing for hardness, and verifying adherence to specified dimensions.

What Common Testing Methods Are Used in Quality Assurance?

Several testing methods are employed to ensure the quality and performance of resin washed stone:

-

Compression Testing: This test assesses the hardness and durability of the cured resin washed stone, ensuring it can withstand the expected loads.

-

Water Absorption Testing: Given the outdoor applications of resin washed stone, testing for water absorption is essential to determine its waterproof properties and suitability for different environments.

-

Stain Resistance Testing: This evaluates how well the surface resists staining from common substances, ensuring longevity and ease of maintenance.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is paramount to securing high-quality products.

What Methods Can Buyers Use to Verify Quality?

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insight into their manufacturing processes, quality control systems, and adherence to international standards.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality reports that outline testing methods, results, and any certifications obtained. This documentation can help assess the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures and product quality. This is particularly useful for buyers unfamiliar with local manufacturing practices.

What Are the Quality Control Nuances for International Buyers?

Navigating quality control nuances can be complex for international B2B buyers. Different regions may have varying standards and regulations, and understanding these can impact purchasing decisions.

-

Regional Standards: Buyers should familiarize themselves with local regulations regarding construction materials in their respective markets. For example, European buyers may prioritize CE marking, while Middle Eastern buyers may look for compliance with local building codes.

-

Cultural Expectations: Cultural differences can influence perceptions of quality and service. Buyers should communicate their expectations clearly and ensure that suppliers understand the specific requirements of their market.

-

Logistical Considerations: Quality assurance processes may vary based on logistical capabilities. Buyers should consider how transportation and storage conditions could affect the quality of resin washed stone during transit.

By understanding the manufacturing processes and quality assurance measures associated with resin washed stone, B2B buyers can make informed decisions that align with their project requirements and regional standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘resin washed stone’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring resin washed stone, a versatile and durable decorative material suitable for both indoor and outdoor applications. By following this step-by-step checklist, you can ensure that you select the right product and supplier to meet your business needs.

Step 1: Define Your Technical Specifications

Before beginning the sourcing process, clearly outline your technical requirements for resin washed stone. Consider factors such as the desired particle size (1-3mm or 3-5mm), color preferences, and specific application areas (e.g., driveways, walkways, or pool areas). Defining these specifications will help you communicate effectively with suppliers and ensure that the product meets your project’s requirements.

Step 2: Research Suppliers

Conduct thorough research to identify potential suppliers of resin washed stone. Utilize online directories, industry forums, and trade shows to find reputable manufacturers or distributors. Pay attention to their market presence, years in business, and customer reviews. A well-established supplier is likely to offer better product quality and customer service.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who have experience with large-scale projects or specific applications relevant to your needs. This step will help you identify trustworthy partners and avoid potential pitfalls.

Step 4: Verify Product Certifications and Compliance

Ensure that the resin washed stone complies with relevant industry standards and environmental regulations. Verify any certifications related to durability, safety, and sustainability. Suppliers should provide documentation that proves their products meet these standards, which is essential for maintaining quality and regulatory compliance in your projects.

Step 5: Request Samples

Before finalizing your order, request samples of the resin washed stone. This allows you to assess the product’s quality, texture, and color in real-world conditions. Sampling can help you make informed decisions and avoid costly mistakes when placing a larger order.

Step 6: Discuss Pricing and Terms

Engage in discussions regarding pricing, payment terms, and delivery schedules with your shortlisted suppliers. Be sure to inquire about bulk purchase discounts or shipping options, especially if you are sourcing for large projects. Transparent communication about costs and terms will help prevent misunderstandings and ensure a smooth procurement process.

Step 7: Plan for Installation and Maintenance

Consider the installation process and any maintenance requirements for the resin washed stone. Discuss with your supplier about recommended installation methods and whether they provide support or training. Understanding the maintenance needs will also help you ensure the longevity of the product in your projects.

By following this checklist, you can streamline your sourcing process for resin washed stone, ensuring that you find a reliable supplier and a product that meets your business needs.

Comprehensive Cost and Pricing Analysis for resin washed stone Sourcing

What Are the Key Cost Components in Resin Washed Stone Sourcing?

When analyzing the cost structure for resin washed stone, several components contribute to the overall pricing. The primary cost components include:

-

Materials: The quality of the natural stones and resin significantly impacts the cost. Higher-grade stones and environmentally friendly resin formulations typically command a premium. Bulk purchasing can reduce costs, making it essential for buyers to evaluate their needs and potential volume discounts.

-

Labor: Installation and manufacturing labor costs vary by region and expertise. Skilled labor is often required for proper application, which can add to the overall expense. Understanding local labor rates is crucial for accurate budgeting.

-

Manufacturing Overhead: This includes the costs associated with production facilities, utilities, and administrative expenses. Manufacturers that invest in quality control and efficient processes may have slightly higher overhead but can offer better quality products.

-

Tooling: Initial setup costs for machinery and tools used in producing resin washed stone can be significant. These costs are typically amortized over production runs, influencing the final product price.

-

Quality Control (QC): A robust QC process ensures that the final product meets industry standards. While this adds to the initial costs, it is crucial for minimizing defects and enhancing customer satisfaction.

-

Logistics: Shipping costs can vary widely based on the distance, mode of transport, and weight of the materials. Buyers should consider the total logistics costs, especially when sourcing from international suppliers.

-

Margin: Finally, supplier margin varies depending on the market dynamics and the supplier’s business model. A balance between competitive pricing and the supplier’s need for profitability is essential.

How Do Price Influencers Affect Resin Washed Stone Costs?

Several factors influence the pricing of resin washed stone, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize pricing.

-

Specifications and Customization: Custom colors, textures, and sizes can increase costs. Buyers should clearly define their specifications to avoid unexpected charges.

-

Quality and Certifications: Products that meet specific quality standards or certifications may have higher price tags. Buyers should assess whether these certifications are necessary for their projects.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: Understanding Incoterms is essential for international transactions. They define the responsibilities of buyers and sellers in shipping and logistics, which can impact overall costs.

What Are the Essential Buyer Tips for Cost-Efficiency?

B2B buyers should consider several strategies to enhance cost-efficiency when sourcing resin washed stone:

-

Negotiate Effectively: Engage in discussions with suppliers to negotiate better prices, especially for larger volumes. Leverage multiple quotes to strengthen your position.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the initial purchase price but also the long-term costs associated with maintenance, installation, and durability. High-quality resin washed stone may have a higher upfront cost but lower maintenance expenses over time.

-

Understand Pricing Nuances for International Transactions: Buyers from Africa, South America, the Middle East, and Europe should be aware of potential tariffs, taxes, and currency fluctuations that can affect pricing. Establishing relationships with local distributors can mitigate some of these costs.

-

Request Samples and Test Products: Before committing to large orders, request samples to evaluate quality and suitability. This practice can prevent costly mistakes and ensure the product meets expectations.

Disclaimer on Indicative Prices

Prices for resin washed stone can vary significantly based on the aforementioned factors. Buyers should conduct thorough market research and consult with multiple suppliers to obtain accurate and competitive pricing. Always clarify all costs involved, including shipping and handling, to ensure transparency in pricing negotiations.

Alternatives Analysis: Comparing resin washed stone With Other Solutions

Exploring Alternatives to Resin Washed Stone for B2B Buyers

As businesses seek the best flooring solutions for various applications, understanding the alternatives to resin washed stone is essential. This section provides a comparative analysis of resin washed stone against other viable options, helping B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Resin Washed Stone | Porous Concrete | Natural Stone Pavers |

|---|---|---|---|

| Performance | High hardness, waterproof, stain-resistant | Strong but less durable than resin | Extremely durable, weather-resistant |

| Cost | Moderate cost, varies by region | Generally lower upfront cost | Higher initial investment |

| Ease of Implementation | Quick installation, ready in days | Requires skilled labor for pouring | Labor-intensive, requires precise fitting |

| Maintenance | Low maintenance, easy to clean | Moderate; may need sealing | High; requires regular sealing and cleaning |

| Best Use Case | Residential and commercial outdoor areas | Driveways, sidewalks, patios | High-end landscaping and aesthetics |

Detailed Breakdown of Alternatives

1. Porous Concrete

Porous concrete is a popular alternative to resin washed stone, particularly for outdoor applications like driveways and sidewalks. Its primary advantage lies in its ability to allow water drainage, which helps reduce surface water runoff. Additionally, it is cost-effective compared to resin washed stone, making it an attractive option for budget-conscious projects. However, while porous concrete is strong, it can be less durable than resin washed stone, especially under heavy loads or in extreme weather conditions. Furthermore, it may require sealing to maintain its integrity and prevent staining.

2. Natural Stone Pavers

Natural stone pavers offer a timeless and aesthetically pleasing option for various landscaping needs. They are highly durable and can withstand harsh weather conditions, making them ideal for high-end residential and commercial projects. However, the cost of natural stone pavers is generally higher than that of resin washed stone, which can be a significant factor for businesses with budget constraints. The installation process can also be labor-intensive, requiring skilled professionals to ensure proper fitting and alignment. Maintenance is another consideration, as natural stone requires regular sealing and cleaning to preserve its appearance and longevity.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating flooring solutions, B2B buyers should consider their specific requirements, including budget, installation timelines, and maintenance preferences. Resin washed stone stands out for its quick installation and low maintenance needs, making it ideal for various outdoor applications. In contrast, porous concrete may appeal to those seeking a more cost-effective solution, while natural stone pavers offer unmatched aesthetics and durability for premium projects. Ultimately, the right choice will depend on balancing performance, cost, and the intended use case to meet both functional and aesthetic needs.

Essential Technical Properties and Trade Terminology for resin washed stone

What Are the Key Technical Properties of Resin Washed Stone?

Understanding the critical technical properties of resin washed stone is essential for B2B buyers looking to make informed purchasing decisions. Here are some vital specifications:

1. Material Grade

Resin washed stone typically uses high-grade polymer resins combined with natural aggregates. The quality of the resin significantly impacts the durability and longevity of the surface. High-grade materials offer superior resistance to wear and tear, making them ideal for high-traffic areas both indoors and outdoors.

2. Particle Size

The particle size of the stone aggregates ranges from 1-3 mm and 3-5 mm. This specification is crucial as it affects the texture and aesthetics of the finished surface. Smaller particles create a smoother finish, while larger aggregates provide a more rugged appearance. Buyers can choose based on design preferences and functional requirements.

3. Water Absorption Rate

Resin washed stone is designed to be waterproof and stain-resistant, which is particularly important for outdoor applications. The water absorption rate indicates how much moisture the material can absorb over time. A low absorption rate is preferable as it enhances durability and prevents damage from freeze-thaw cycles.

4. Impact Resistance

This property measures the material’s ability to withstand sudden force or shock. Resin washed stone is engineered for high impact resistance, making it suitable for areas subject to heavy foot traffic or vehicular use. Understanding this specification helps buyers evaluate the suitability of the product for various applications.

5. UV Resistance

UV resistance indicates how well the material can withstand exposure to sunlight without degrading. This is particularly important in regions with high sun exposure. A product with excellent UV stability will maintain its color and integrity over time, ensuring long-lasting aesthetics.

What Are Common Trade Terms Associated with Resin Washed Stone?

Familiarity with industry jargon can enhance communication and facilitate smoother transactions. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are sold under another company’s brand. In the context of resin washed stone, understanding OEM relationships can help buyers source high-quality materials tailored to specific requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps businesses plan their purchases effectively, ensuring they meet supplier requirements while managing inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing and terms for specific products. For resin washed stone, submitting an RFQ allows buyers to gather competitive bids, making it easier to compare options before making a decision.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and delivery. Familiarity with these terms is essential for B2B buyers to understand their obligations and rights regarding shipping resin washed stone across borders.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times for resin washed stone is crucial for project planning, as delays can affect overall timelines and budgets.

6. Warranty

A warranty is a guarantee provided by the manufacturer or supplier regarding the quality and durability of the product. Knowing the warranty terms for resin washed stone can provide peace of mind and protection against defects, making it a critical consideration for B2B buyers.

By comprehensively understanding these technical properties and trade terminologies, B2B buyers can make more informed purchasing decisions, ensuring that they select the right resin washed stone products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the resin washed stone Sector

What Are the Key Market Drivers Influencing the Resin Washed Stone Sector?

The resin washed stone sector is witnessing a surge in demand, driven by several global factors. Urbanization and infrastructure development across regions such as Africa, South America, the Middle East, and Europe are key contributors. As cities expand, there is an increasing need for durable, aesthetically pleasing outdoor and indoor surfaces, particularly in residential and commercial landscapes. Additionally, the rise in eco-conscious consumerism has led to a preference for sustainable building materials, pushing suppliers to innovate and offer environmentally friendly products.

Emerging B2B technologies are also reshaping sourcing trends. Digital platforms enable buyers to connect directly with manufacturers, allowing for better price transparency and enhanced supply chain efficiency. Automation in production processes ensures consistent quality while reducing lead times. As a result, international buyers are increasingly favoring suppliers who adopt these technologies, aiming for both reliability and cost-effectiveness.

Market dynamics are further influenced by fluctuating raw material prices and geopolitical factors, which can affect sourcing strategies. Buyers need to stay informed about these trends to make strategic purchasing decisions and mitigate risks associated with price volatility.

How Is Sustainability Shaping the Sourcing of Resin Washed Stone?

Sustainability is becoming a cornerstone of B2B procurement in the resin washed stone sector. The environmental impact of sourcing and manufacturing practices is under scrutiny, prompting buyers to seek suppliers committed to ethical and sustainable practices. This includes assessing the carbon footprint of production, the sourcing of raw materials, and waste management strategies.

Ethical supply chains are increasingly important for B2B buyers who want to align with sustainable development goals. This means prioritizing suppliers who utilize recycled materials or offer products with certifications that demonstrate their commitment to environmental stewardship. Certifications such as ISO 14001 or Green Seal can provide reassurance about a supplier’s environmental management practices.

Furthermore, the resin used in these products is evolving; many manufacturers are now offering low-VOC (volatile organic compounds) options, contributing to healthier indoor air quality and reducing harmful emissions. Buyers who prioritize sustainability not only enhance their brand image but also meet the growing consumer demand for eco-friendly materials.

What Is the Historical Context of Resin Washed Stone in the B2B Landscape?

The evolution of resin washed stone as a popular choice in the construction and landscaping sectors can be traced back to the increasing need for durable yet aesthetically pleasing surface solutions. Initially developed as a response to the limitations of traditional paving materials, resin washed stone combines natural aggregates with high-performance resins to create surfaces that are not only visually appealing but also functional.

Over the past few decades, advancements in resin technology have significantly improved the performance characteristics of these products, making them more resistant to weathering, staining, and wear. This evolution has been particularly beneficial for international markets, where diverse climates and usage scenarios demand robust solutions. As the awareness of sustainable practices has grown, the market has shifted towards sourcing materials that not only perform well but also align with ethical and environmental considerations, marking a pivotal change in how buyers approach procurement in this sector.

In conclusion, understanding the market dynamics, sustainability imperatives, and historical context of resin washed stone can empower B2B buyers to make informed purchasing decisions, ensuring they align with both current trends and future developments in the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of resin washed stone

-

How do I choose the right resin washed stone supplier?

Selecting a reliable supplier for resin washed stone involves several key factors. Begin by researching potential suppliers’ reputations and customer reviews. Verify their production capabilities, including their sourcing of raw materials and adherence to quality standards. Request samples to assess the quality of their products firsthand. Additionally, consider their communication responsiveness and willingness to accommodate your specific needs, such as custom colors or particle sizes. Lastly, ensure they comply with international trade regulations relevant to your region. -

What is the best application for resin washed stone in outdoor settings?

Resin washed stone is ideal for various outdoor applications, including patios, walkways, pool areas, and driveways. Its slip-resistant surface and natural aesthetic enhance both safety and visual appeal. When selecting the right type, consider the stone particle size (1-3mm or 3-5mm) based on the specific area’s traffic and exposure to weather elements. This versatile material not only complements existing landscapes but also provides durability against harsh environmental conditions, making it a top choice for outdoor projects. -

What are the minimum order quantities (MOQs) for resin washed stone?

Minimum order quantities for resin washed stone can vary significantly among suppliers, typically ranging from 500 kg to several tons. It’s essential to discuss your project needs with potential suppliers to understand their specific MOQs. If your requirements are below their standard MOQ, inquire about the possibility of combining orders with other buyers or the availability of smaller DIY kits. Understanding MOQs helps you plan your budget and logistics more effectively. -

What payment terms should I expect when sourcing resin washed stone?

Payment terms for resin washed stone can vary based on the supplier and your negotiation. Common terms include a deposit upon order confirmation (usually 30-50%) with the balance due before shipping. Some suppliers may offer credit terms for established businesses. It’s crucial to clarify payment methods accepted, such as bank transfers, letters of credit, or payment platforms. Always ensure that the terms are documented in your purchase agreement to avoid any disputes later. -

How can I ensure the quality of resin washed stone products?

To ensure quality, request detailed product specifications from suppliers, including the composition of the resin and stone, as well as any certifications related to environmental impact or durability. Conduct quality assurance checks upon delivery, inspecting for consistency in color, size, and absence of defects. If possible, visit the supplier’s facility or request third-party quality assurance reports. Establishing a clear quality control process will help mitigate risks associated with product performance. -

What logistics considerations should I keep in mind when importing resin washed stone?

When importing resin washed stone, consider shipping options, lead times, and customs regulations. Coordinate with suppliers to understand their shipping methods and timelines, ensuring they align with your project schedule. Research import tariffs, taxes, and documentation required for your specific country to avoid delays. Partnering with a logistics provider experienced in handling bulk materials can streamline the process and ensure timely delivery. -

Can resin washed stone be customized for specific projects?

Yes, resin washed stone can be customized in terms of color, particle size, and mix ratios to meet specific project requirements. Many suppliers offer a range of colors and textures, allowing you to match the stone to your design vision. Discuss your customization needs with the supplier early in the sourcing process to understand any additional costs or lead times associated with tailored products. This flexibility makes resin washed stone a suitable option for unique architectural projects. -

What are the environmental impacts of using resin washed stone?

Resin washed stone is considered an environmentally friendly option due to its use of natural materials and the ability to create permeable surfaces that help manage stormwater runoff. However, it’s essential to ensure that the resin used is non-toxic and complies with environmental regulations. Inquire about the supplier’s sourcing practices and the sustainability of their materials. Opting for eco-friendly resin options can further enhance the environmental benefits of your project, aligning with global sustainability goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Resin Washed Stone Manufacturers & Suppliers List

1. Pinterest – Resin Washed Stone Paint

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Resin washed stone paint is a mixture of resin, paint, and a solvent, applied to stone surfaces to create a translucent finish. It does not require tiling or installation and can be used immediately after opening the bucket. Suitable for indoor flooring to replace tiles and outdoor stairs, it offers high cost performance. The product features a frosted texture, is non-slip, and wear-resistant. It …

2. StoneSet – Resin Bound Paving Kits

Domain: stoneset.com.au

Introduction: Stone & Resin Bound Paving Kits are pre-weighed kits that include either 3mm or 6mm stone and a single part resin ready for mixing. They are designed for DIY use, allowing customers to create their own surfaces with ease. The kits are available in various colors including Ash, Beach, Evergreen, Glensanda, Kaikōura, Koonunga, Pearl, Pitch Black, Southern Value, Southern White, Sterling, Tan, Tarawe…

3. Resin Architecte – Indoor Resin Bound Gravel

Domain: resinarchitecte.com

Registered: 2019 (6 years)

Introduction: Indoor resin bound gravel is a floor covering suitable for various surfaces including kitchens, bathrooms, and bedrooms. It is composed of marble granules or quartz aggregates mixed with resin, offering a wide range of colors and patterns for personalization. Key advantages include traffic resistance, stain resistance, and moisture resistance, making it ideal for high-traffic areas and wet rooms. …

Strategic Sourcing Conclusion and Outlook for resin washed stone

As the demand for durable and aesthetically pleasing flooring solutions continues to rise, resin washed stone emerges as a versatile option that meets the needs of diverse markets. Its blend of natural stone and polymer resin not only ensures high hardness and water resistance but also allows for creative design possibilities that can enhance both indoor and outdoor spaces. This adaptability makes it particularly appealing to international buyers looking to invest in quality materials that complement various architectural styles.

Strategic sourcing of resin washed stone can lead to significant cost savings and improved project timelines, as the installation process is swift and minimally disruptive. By partnering with reputable suppliers, buyers can access a wide range of colors and textures that align with their specific project requirements, thus enhancing the value of their offerings.

Looking ahead, the global market for resin washed stone is poised for growth, driven by increasing construction activities and a rising preference for sustainable materials. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are encouraged to explore strategic sourcing opportunities to capitalize on this trend. Embrace the potential of resin washed stone and elevate your projects to new heights.