Is Your Meaning Of Deburring Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for meaning of deburring

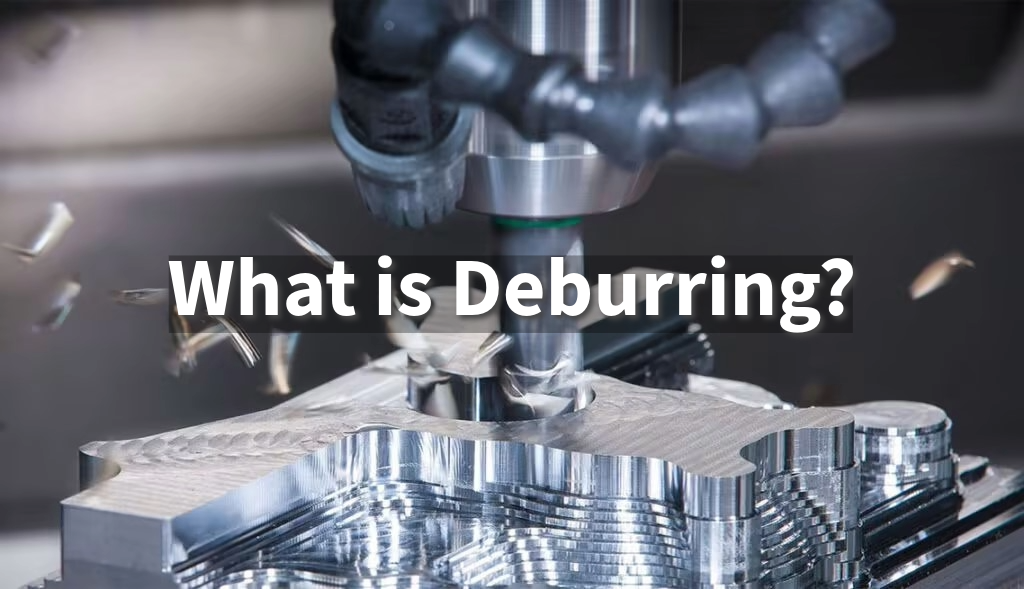

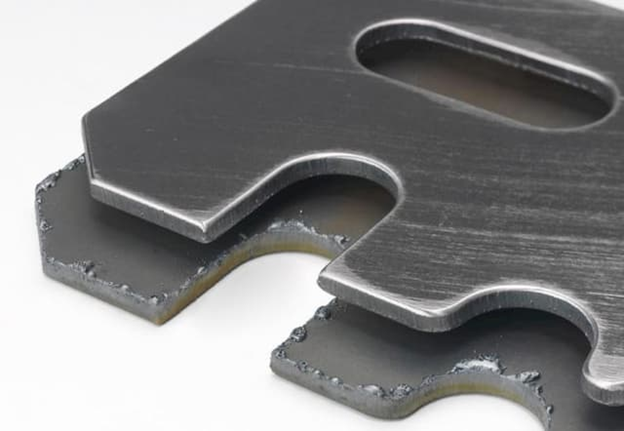

In today’s competitive manufacturing landscape, understanding the meaning of deburring is crucial for international B2B buyers seeking to enhance product quality and operational efficiency. Burrs—those unwanted metal protrusions resulting from machining processes—can compromise not only the aesthetic appeal but also the functionality and safety of components. As buyers from regions such as Africa, South America, the Middle East, and Europe (including Nigeria and Saudi Arabia) navigate the complexities of sourcing deburring solutions, they face the challenge of selecting the right techniques and equipment that align with their specific needs and quality standards.

This comprehensive guide delves into the various types of deburring processes, including manual, mechanical, thermal, and electrochemical methods, providing insights into their applications across different industries. Furthermore, we explore critical factors to consider when vetting suppliers, including technological capabilities, service offerings, and cost-effectiveness. By equipping you with actionable knowledge on deburring, this guide empowers you to make informed purchasing decisions, ensuring that your operations not only meet but exceed industry benchmarks for quality and safety. Whether you’re looking to enhance production efficiency or improve the longevity of your products, understanding deburring is the first step towards achieving your operational goals.

Understanding meaning of deburring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Deburring | Involves hand tools; labor-intensive; customizable | Small workshops, low-volume production | Pros: Cost-effective; Cons: Time-consuming, inconsistent quality. |

| Mechanical Deburring | Utilizes machines for efficiency; various tool configurations | Medium to large manufacturing facilities | Pros: High productivity; Cons: Higher initial investment. |

| Thermal Deburring | Uses thermal energy for hard-to-reach burrs; ideal for complex shapes | Aerospace, automotive, and medical industries | Pros: Effective for intricate designs; Cons: Complex setup and operation. |

| Electrochemical Deburring | Employs chemical reactions to remove burrs; suitable for precision | High-tech industries, precision engineering | Pros: High precision; Cons: Requires specialized equipment and expertise. |

| Automated Deburring | Fully automated systems; high throughput; consistent results | Large-scale production environments | Pros: Maximizes efficiency and consistency; Cons: Significant upfront costs. |

What Are the Characteristics of Manual Deburring?

Manual deburring is a traditional method that involves skilled technicians using hand tools to remove burrs from metal parts. This approach allows for a high degree of customization and flexibility, making it suitable for small workshops or low-volume production environments where unique or intricate pieces are common. However, while it is cost-effective, manual deburring can be time-consuming and may lead to inconsistent quality across batches, which could impact overall product reliability.

How Does Mechanical Deburring Enhance Productivity?

Mechanical deburring employs machines equipped with various tools, such as brushes, discs, or belts, to automate the burr removal process. This method is especially effective in medium to large manufacturing facilities where speed and efficiency are critical. Mechanical deburring significantly increases productivity, reducing labor costs and minimizing the risk of human error. However, it requires a higher initial investment and ongoing maintenance, making it essential for buyers to evaluate their production volume and budget carefully.

Why Is Thermal Deburring Ideal for Complex Shapes?

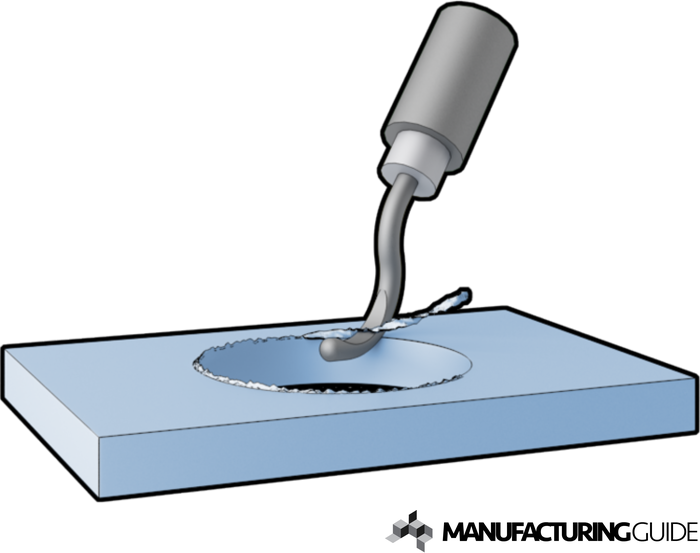

Thermal deburring is a specialized process that uses combustive gases to generate heat and remove burrs from intricate or hard-to-reach areas. It is particularly advantageous in industries like aerospace and automotive, where precision and reliability are paramount. While thermal deburring effectively addresses complex geometries, it involves a more complex setup and operational requirements, which can be a consideration for potential buyers looking for efficiency without compromising quality.

What Makes Electrochemical Deburring Suitable for Precision Work?

Electrochemical deburring utilizes a chemical solution to conduct electrical energy that selectively removes burrs while preserving the integrity of the surrounding metal. This method is ideal for high-tech industries and precision engineering applications, where tight tolerances and surface finishes are critical. While electrochemical deburring offers high precision and is suitable for challenging materials, it necessitates specialized equipment and expertise, which can be a barrier for some companies.

How Does Automated Deburring Transform Large-Scale Production?

Automated deburring systems are designed for high-throughput environments, providing consistent results across large volumes of parts. These machines can operate continuously, significantly enhancing production efficiency and ensuring uniform quality. While the upfront costs for automated systems can be substantial, the long-term benefits in productivity and reduced labor costs often justify the investment. Companies considering automated deburring should evaluate their production needs and the potential return on investment to make informed decisions.

Key Industrial Applications of meaning of deburring

| Industry/Sector | Specific Application of meaning of deburring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision component manufacturing | Ensures safety and compliance with stringent regulations | Need for high-precision deburring machines that can handle various materials and meet aerospace standards. |

| Automotive | Engine and transmission parts production | Enhances part reliability and performance, reducing warranty claims | Sourcing machines that can efficiently process high volumes while maintaining quality standards. |

| Medical Devices | Surgical instruments and implants | Critical for patient safety and device functionality | Requirement for machines that allow for clean, burr-free finishes to avoid contamination and ensure sterility. |

| Electronics | Circuit board fabrication | Improves electrical connectivity and reduces failure rates | Need for specialized deburring solutions that can handle delicate components without damage. |

| Heavy Machinery | Components for construction equipment | Increases durability and reduces maintenance costs | Consideration for robust deburring equipment that can handle tough materials and large volumes. |

How is Deburring Applied in Aerospace Manufacturing?

In the aerospace industry, deburring is crucial for the production of precision components such as engine parts and structural elements. The presence of burrs can lead to catastrophic failures, making it essential to ensure that all parts meet strict safety and quality standards. Buyers in this sector must prioritize sourcing deburring machines that offer high precision and can handle various materials while adhering to regulatory requirements. Additionally, the ability to produce consistent results is vital for maintaining compliance with industry standards.

Illustrative image related to meaning of deburring

What Role Does Deburring Play in Automotive Parts Production?

In automotive manufacturing, deburring is applied extensively to engine and transmission parts to enhance reliability and performance. Burrs can lead to mechanical failures, causing increased warranty claims and customer dissatisfaction. Consequently, businesses need to invest in efficient deburring solutions that can handle high volumes without compromising quality. Sourcing considerations should include the machine’s capability to process different materials and its efficiency in meeting production demands.

Why is Deburring Essential for Medical Device Manufacturing?

The medical device industry relies heavily on deburring processes for surgical instruments and implants, where even the smallest imperfection can compromise patient safety. Burr-free finishes are critical to ensure that devices function correctly and remain sterile. Buyers in this sector must look for deburring machines that provide clean finishes and are capable of working with materials that require stringent quality controls. Additionally, sourcing equipment that minimizes contamination risks during the deburring process is vital.

How Does Deburring Impact Electronics Manufacturing?

In electronics manufacturing, deburring is vital for circuit board fabrication, where burrs can disrupt electrical connectivity and lead to device failures. The use of specialized deburring solutions that can handle delicate components without causing damage is essential. Buyers should consider sourcing machines that offer precision deburring capabilities while ensuring that they can meet the specific requirements of electronic components. The ability to maintain high-quality standards is crucial for minimizing return rates and enhancing product reliability.

What is the Importance of Deburring in Heavy Machinery Production?

In the heavy machinery sector, deburring is applied to components used in construction equipment to enhance durability and reduce maintenance costs. Burrs can lead to increased wear and tear, ultimately affecting the lifespan of machinery parts. Businesses need to invest in robust deburring equipment capable of handling tough materials and high volumes. Key sourcing considerations include the machine’s durability, efficiency, and ability to provide consistent, high-quality results, which are essential for maintaining operational efficiency and reducing downtime.

3 Common User Pain Points for ‘meaning of deburring’ & Their Solutions

Scenario 1: Overcoming Inefficient Manual Deburring Processes

The Problem: Many manufacturing facilities still rely heavily on manual deburring techniques. This approach not only consumes excessive time but also leads to inconsistencies in product quality. Workers may experience fatigue and repetitive strain injuries, resulting in decreased productivity and increased operational costs. Additionally, the variability in finishes can lead to customer dissatisfaction and returns, as the quality of the deburred parts may not meet the required specifications.

The Solution: To address these challenges, B2B buyers should invest in automated deburring systems. These machines can significantly enhance efficiency and consistency by performing deburring tasks at a faster pace and with uniform results. When selecting a deburring machine, buyers should consider the specific needs of their operations, such as the types of materials processed and the volume of production. It’s crucial to consult with suppliers who can provide tailored solutions and demonstrate how their machines can integrate seamlessly into existing workflows. Investing in training for staff on the new machinery will also ensure that the transition is smooth and that operators can maximize the capabilities of the automated systems.

Illustrative image related to meaning of deburring

Scenario 2: Managing Burrs on Complex Geometries

The Problem: In industries such as aerospace and medical manufacturing, parts often feature intricate geometries that can trap burrs, making them difficult to remove without damaging the component. This challenge not only complicates the deburring process but also raises concerns about the structural integrity and safety of the final products. B2B buyers in these sectors face the risk of non-compliance with stringent industry standards if burrs remain on critical components.

The Solution: To effectively manage burrs on complex geometries, B2B buyers should explore advanced deburring technologies such as thermal and electrochemical deburring. Thermal deburring can reach hard-to-access areas by using high temperatures to eliminate burrs without mechanical contact, thus preserving the integrity of delicate structures. On the other hand, electrochemical deburring utilizes controlled chemical reactions to remove burrs while leaving the surrounding metal untouched. Buyers should partner with reputable suppliers who offer demonstrations and pilot programs to assess the effectiveness of these methods on their specific parts. Additionally, establishing a routine inspection and quality control process can help catch any burrs before the final product reaches customers.

Scenario 3: Addressing Safety Hazards Associated with Burrs

The Problem: Burrs can pose significant safety risks in manufacturing environments, especially when they lead to sharp edges or protrusions on parts. These hazards not only increase the likelihood of workplace injuries but can also result in costly legal liabilities and insurance claims. B2B buyers are often concerned about the implications of unsafe products reaching their customers, which can harm their reputation and lead to financial losses.

The Solution: To mitigate safety hazards associated with burrs, it is essential for B2B buyers to prioritize comprehensive deburring solutions as part of their quality assurance processes. This includes investing in deburring machines designed with safety features, such as dust suppression systems and ergonomic designs to protect workers. Additionally, implementing strict deburring protocols and training programs can enhance awareness and compliance among employees regarding the importance of burr removal. Regular audits of the deburring process can also help identify potential safety issues before they escalate. By fostering a culture of safety and investing in the right technology, buyers can significantly reduce workplace accidents and enhance their overall product safety profile.

Strategic Material Selection Guide for meaning of deburring

What Materials Are Commonly Used in Deburring Processes?

When selecting materials for deburring applications, understanding the properties and suitability of various materials is crucial for optimizing performance and ensuring compliance with international standards. Below, we analyze four common materials used in deburring processes, highlighting their key properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Aluminum Oxide

Key Properties: Aluminum oxide is characterized by its hardness and durability. It has a high melting point (over 2000°C) and excellent wear resistance, making it suitable for high-temperature applications. It is also chemically stable, providing good corrosion resistance.

Pros & Cons: The primary advantage of aluminum oxide is its cost-effectiveness and availability. It is widely used in various deburring applications due to its affordability. However, it can be less effective on softer materials, leading to potential wear and tear on the abrasive itself.

Impact on Application: Aluminum oxide is particularly effective for deburring ferrous and non-ferrous metals. Its compatibility with various media makes it a versatile choice for different deburring processes.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure that the aluminum oxide products meet local and international standards (e.g., ASTM). Understanding the specific grades available can also influence performance outcomes.

2. Silicon Carbide

Key Properties: Silicon carbide is known for its exceptional hardness and thermal conductivity. It can withstand high temperatures (up to 1600°C) and exhibits good chemical resistance, making it suitable for a variety of industrial applications.

Pros & Cons: The key advantage of silicon carbide is its effectiveness in deburring hard materials, such as ceramics and hardened steels. However, it tends to be more expensive than aluminum oxide, which may affect overall production costs.

Impact on Application: Silicon carbide is ideal for applications requiring aggressive deburring and surface preparation. Its sharp cutting edges allow for efficient removal of burrs, particularly in high-precision environments.

Considerations for International Buyers: Compliance with standards such as DIN or JIS is essential for buyers in Europe and the Middle East. Additionally, understanding the local availability of silicon carbide can impact procurement strategies.

3. Ceramic Abrasives

Key Properties: Ceramic abrasives are engineered for high durability and thermal stability. They can operate effectively at elevated temperatures and are resistant to wear and tear, making them suitable for heavy-duty applications.

Pros & Cons: The primary advantage of ceramic abrasives is their longevity and ability to maintain cutting efficiency over time. However, they can be more expensive than traditional abrasives, which may deter cost-sensitive operations.

Impact on Application: Ceramic abrasives are particularly effective in applications requiring consistent performance, such as automotive and aerospace industries. Their ability to produce a smooth finish makes them a preferred choice for high-quality deburring.

Considerations for International Buyers: Buyers should be aware of varying regulations regarding abrasive materials in different regions. Ensuring compliance with local standards can facilitate smoother operations.

Illustrative image related to meaning of deburring

4. Diamond Abrasives

Key Properties: Diamond abrasives offer the highest level of hardness and thermal stability, making them suitable for the most challenging materials. They can withstand high temperatures and provide exceptional cutting performance.

Pros & Cons: The main advantage of diamond abrasives is their unmatched efficiency in deburring hard materials, such as composites and ceramics. However, their high cost can limit their use to specialized applications.

Impact on Application: Diamond abrasives are ideal for applications where precision and surface finish are critical, such as in the semiconductor and optical industries.

Considerations for International Buyers: For buyers in regions like Saudi Arabia and Europe, understanding the specific certifications required for diamond abrasives is crucial. Compliance with international standards can enhance product acceptance in local markets.

Summary Table

| Material | Typical Use Case for meaning of deburring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Oxide | General metal deburring | Cost-effective and widely available | Less effective on softer materials | Low |

| Silicon Carbide | Hard material deburring | Effective on ceramics and hardened steels | Higher cost than aluminum oxide | Medium |

| Ceramic Abrasives | Automotive and aerospace applications | Long-lasting and consistent performance | More expensive than traditional abrasives | High |

| Diamond Abrasives | Precision deburring in specialized industries | Unmatched efficiency on hard materials | Very high cost, limited to specialized applications | High |

This analysis provides B2B buyers with critical insights into selecting the right materials for deburring applications, ensuring they can make informed decisions that align with their operational needs and compliance requirements.

Illustrative image related to meaning of deburring

In-depth Look: Manufacturing Processes and Quality Assurance for meaning of deburring

What Are the Typical Manufacturing Processes Involved in Deburring?

The manufacturing process for deburring involves several key stages that ensure the production of high-quality metal components. Understanding these stages can help B2B buyers assess the capabilities of potential suppliers.

How Is Material Prepared for Deburring?

Material preparation is the first stage in the manufacturing process. It typically involves selecting the right type of metal for the intended application, whether it be aluminum, steel, or titanium. The material is then cut to size using techniques such as sawing or shearing. During this stage, considerations for the deburring process should include the thickness and hardness of the metal, as these factors will influence the choice of deburring technique later on.

What Forming Techniques Are Commonly Used Prior to Deburring?

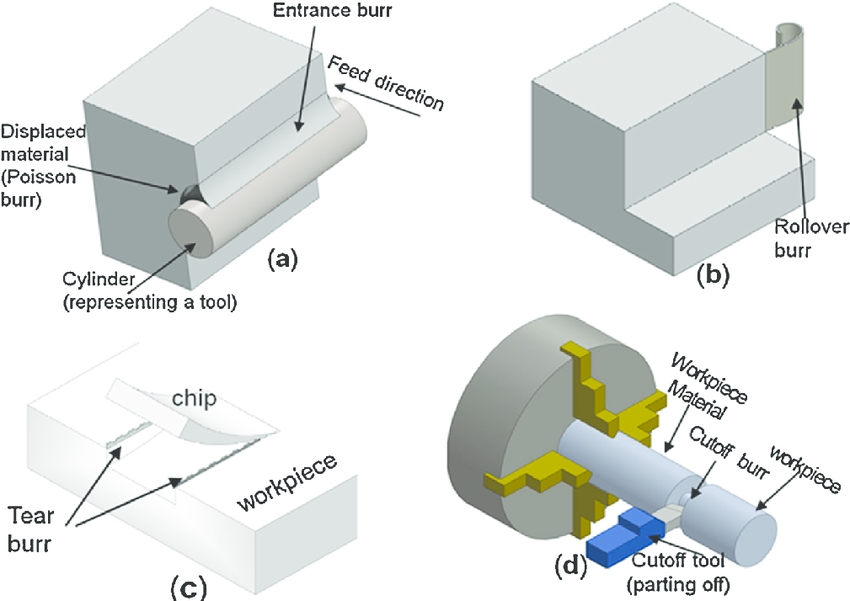

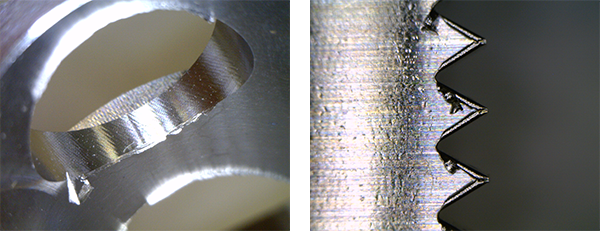

After material preparation, the next step is forming. This stage can involve various machining processes such as milling, turning, or laser cutting. Each of these methods can create burrs due to the nature of how the metal is shaped. For instance, laser cutting can leave behind rollover burrs, while milling may generate breakout burrs. Understanding the forming techniques used is critical for B2B buyers, as certain methods may require specific deburring solutions.

How Does Assembly Affect Deburring Processes?

In some manufacturing environments, assembly occurs before deburring. This can be particularly true in complex assemblies where multiple parts are joined together. However, it is crucial to deburr components before final assembly to ensure they fit properly and function as intended. Burrs can interfere with joint integrity and lead to mechanical failures. Therefore, buyers should inquire whether their suppliers perform deburring pre- or post-assembly, as this can significantly impact product quality.

What Finishing Techniques Are Integrated with Deburring?

Finishing is the final stage of the manufacturing process where deburring plays a vital role. Techniques such as polishing, coating, or painting often follow deburring to enhance the aesthetic and functional properties of the metal parts. Proper deburring ensures a smooth surface that improves adhesion for coatings and minimizes corrosion potential. B2B buyers should ensure that their suppliers have a well-defined finishing process that complements deburring efforts.

How Is Quality Assurance Implemented in Deburring Processes?

Quality assurance is an essential aspect of deburring, ensuring that the final products meet international standards and client specifications. Understanding the quality control mechanisms in place can help B2B buyers select reliable partners.

What International Standards Should B2B Buyers Be Aware Of?

International standards like ISO 9001 set the framework for quality management systems across various industries, including metalworking. Compliance with ISO standards indicates that a supplier has a systematic approach to managing quality. Additionally, industry-specific certifications such as CE (for European markets) and API (for the oil and gas sector) can provide further assurance of quality and safety.

What Are the Key Quality Control Checkpoints in Deburring?

Quality control checkpoints play a critical role throughout the manufacturing and deburring processes. These typically include:

- Incoming Quality Control (IQC): This phase involves inspecting raw materials upon receipt to ensure they meet specified standards before processing begins.

- In-Process Quality Control (IPQC): Ongoing checks during manufacturing help identify defects early. This can include monitoring burr formation during machining processes.

- Final Quality Control (FQC): This final inspection checks the completed parts for compliance with quality standards, ensuring that all burrs have been effectively removed.

B2B buyers should inquire about these checkpoints to understand how suppliers maintain quality throughout the production process.

Illustrative image related to meaning of deburring

What Common Testing Methods Are Used for Quality Assurance?

Several testing methods are commonly employed to ensure the quality of deburred products. These include:

- Visual Inspection: A simple yet effective method for identifying visible burrs or surface imperfections.

- Dimensional Measurement: Tools such as calipers and gauges are used to verify that parts meet specified dimensions.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing can identify internal defects without damaging the part.

- Surface Roughness Measurement: This assesses the smoothness of the deburred surface, which is crucial for applications requiring high precision.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying the quality control processes of potential suppliers is vital for B2B buyers, particularly in international markets. There are several methods to ensure a supplier’s QC standards meet expectations.

What Role Do Audits Play in Supplier Quality Assurance?

Conducting audits is one of the most effective ways to verify a supplier’s quality control processes. Buyers can perform on-site audits to assess the manufacturing environment, equipment, and adherence to quality standards. This provides a firsthand look at the supplier’s commitment to quality assurance.

How Can Reports and Documentation Support Quality Verification?

Suppliers should provide comprehensive documentation that outlines their quality control processes, including inspection reports and compliance certifications. Buyers should request these documents to verify that the supplier adheres to international standards and industry best practices.

What Is the Importance of Third-Party Inspections?

Engaging third-party inspection services can add an extra layer of assurance. These independent organizations can conduct audits and inspections, providing unbiased evaluations of a supplier’s quality control processes. For international buyers, this is especially important as it helps to mitigate risks associated with cross-border transactions.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, may encounter specific challenges related to quality control.

How Do Regional Standards Impact Quality Assurance?

Different regions may have varying quality standards and regulations that suppliers must comply with. Buyers should familiarize themselves with these standards, as non-compliance can lead to issues with product acceptance in their home markets.

What Should Buyers Consider Regarding Cultural Differences in Quality Practices?

Cultural differences can also affect how quality assurance is perceived and implemented. Buyers should communicate clearly about their expectations and ensure that suppliers understand the importance of maintaining high-quality standards to meet international demands.

Illustrative image related to meaning of deburring

By understanding the manufacturing processes and quality assurance measures related to deburring, B2B buyers can make informed decisions when selecting suppliers, ultimately ensuring the delivery of high-quality products that meet their specifications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘meaning of deburring’

Introduction

In the manufacturing sector, deburring is a critical process that ensures the quality, safety, and functionality of machined metal parts. This guide aims to provide B2B buyers with a practical checklist to navigate the procurement of deburring services and equipment. By following these steps, organizations can enhance their production efficiency while maintaining high standards in their output.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to establish clear technical specifications for your deburring needs. This includes identifying the types of materials you work with, the specific deburring processes required (manual, mechanical, thermal, or electrochemical), and the desired finish quality.

– Key Considerations:

– Material type and hardness.

– Tolerance levels for burr removal.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in deburring services or machinery. Focus on suppliers with a solid reputation in the industry and positive reviews from previous clients.

– Action Points:

– Utilize industry-specific directories and platforms.

– Engage in forums or trade shows to gather insights and recommendations.

Step 3: Evaluate Supplier Capabilities

Once you have a list of potential suppliers, assess their capabilities in relation to your specific needs. This involves evaluating their technology, equipment, and expertise in deburring processes.

– Important Aspects to Review:

– Types of deburring machines available (e.g., brush, disc, or belt heads).

– Ability to handle your material types and sizes.

Illustrative image related to meaning of deburring

Step 4: Request Samples and Demonstrations

Before making a commitment, request samples or demonstrations of the supplier’s deburring processes. This hands-on evaluation will provide you with insights into the quality of their work and the effectiveness of their equipment.

– Focus Areas:

– Examine the finish quality of the samples.

– Assess the efficiency and speed of their deburring methods.

Step 5: Verify Compliance and Certifications

Ensure that the suppliers you are considering comply with relevant industry standards and possess necessary certifications. Compliance with safety and quality standards is crucial for maintaining operational integrity.

– Key Certifications to Look For:

– ISO certifications.

– Environmental and safety compliance certifications.

Step 6: Discuss Pricing and Terms

Engage in discussions regarding pricing structures and payment terms with your shortlisted suppliers. It’s essential to understand the total cost of ownership, including potential hidden costs such as maintenance and operational expenses.

– Considerations:

– Compare pricing among different suppliers while considering service quality.

– Inquire about warranties and after-sales support.

Illustrative image related to meaning of deburring

Step 7: Establish a Long-Term Relationship

After selecting a supplier, work towards establishing a long-term partnership. A strong relationship can lead to better pricing, priority service, and collaboration on future projects.

– Action Items:

– Schedule regular check-ins to review performance and discuss improvements.

– Explore opportunities for joint ventures or further technology investments.

By following this checklist, B2B buyers can ensure a systematic and informed approach to sourcing deburring solutions that meet their operational requirements and enhance product quality.

Comprehensive Cost and Pricing Analysis for meaning of deburring Sourcing

What Are the Key Cost Components in Deburring Processes?

Understanding the cost structure associated with deburring is crucial for B2B buyers, especially those operating in diverse regions like Africa, South America, the Middle East, and Europe. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of materials used in deburring processes can significantly impact costs. For instance, high-quality abrasives, cutting fluids, and specialized machinery can be more expensive but offer better performance and longevity. Buyers should evaluate whether investing in premium materials can reduce overall operational costs over time.

-

Labor: Labor costs vary widely depending on geographic location and the complexity of the deburring process. Manual deburring is often labor-intensive and can lead to higher costs due to time consumption and potential for human error. In contrast, automated deburring solutions, while initially more expensive, can lead to long-term savings through increased efficiency and reduced labor costs.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and administrative expenses. Efficient deburring operations can minimize overhead by streamlining processes and reducing waste.

-

Tooling: The tools used in deburring, such as machines and hand tools, represent a significant investment. The choice between manual and automated tools can affect both the initial capital expenditure and ongoing maintenance costs.

-

Quality Control (QC): Investing in QC processes ensures that deburred parts meet required specifications, reducing the risk of defects that could lead to costly rework or warranty claims. This is particularly important in industries where precision is critical, such as aerospace and medical manufacturing.

-

Logistics: Shipping costs can vary based on distance, mode of transport, and the nature of the materials being transported. Understanding Incoterms and their implications can help buyers negotiate better terms with suppliers.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market dynamics can help buyers negotiate more effectively.

What Factors Influence Pricing for Deburring Services?

Several key factors influence pricing in the deburring market, particularly for international buyers.

Illustrative image related to meaning of deburring

-

Volume and Minimum Order Quantity (MOQ): Larger orders can often result in lower per-unit costs. Buyers should assess their production needs to take advantage of volume pricing.

-

Specifications and Customization: Customized solutions may come at a premium. However, tailored services can enhance operational efficiency and product quality, ultimately justifying the higher cost.

-

Material Quality and Certifications: Higher-quality materials and certified processes can lead to increased pricing. Buyers should consider the long-term benefits of investing in certified suppliers for critical applications.

-

Supplier Factors: The reputation, reliability, and location of suppliers can significantly influence pricing. Building relationships with suppliers can lead to better pricing and service terms.

-

Incoterms: Understanding shipping terms is crucial for cost management. Buyers should clarify responsibilities for shipping, insurance, and duties to avoid unexpected costs.

How Can Buyers Optimize Costs in Deburring Processes?

To maximize cost efficiency, buyers should consider the following strategies:

-

Negotiation: Engage in discussions with suppliers about pricing structures, potential discounts for bulk orders, and payment terms. A collaborative approach can lead to mutually beneficial agreements.

-

Total Cost of Ownership (TCO): Assess not just the purchase price but the total cost associated with deburring, including maintenance, downtime, and operational efficiency. This holistic view can help in making informed purchasing decisions.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa and South America may face unique challenges such as currency fluctuations, import tariffs, and longer shipping times. Building a buffer into budgets for these variables can mitigate risks.

-

Continuous Improvement: Regularly evaluate deburring processes and supplier performance. Embracing innovations in technology and methods can lead to significant cost savings over time.

Disclaimer on Indicative Prices

Prices for deburring services can vary widely based on numerous factors including geographic location, material quality, and supplier capabilities. Buyers are encouraged to obtain multiple quotes and conduct thorough market research to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing meaning of deburring With Other Solutions

Introduction to Alternative Solutions for Deburring

In the competitive landscape of metalworking, achieving a flawless finish on machined parts is crucial for functionality, safety, and aesthetic appeal. While deburring effectively removes imperfections, several alternative methods and technologies exist that can also achieve similar results. Understanding these alternatives can help B2B buyers make informed decisions tailored to their specific needs and operational contexts.

Comparison Table

| Comparison Aspect | Meaning Of Deburring | Alternative 1 Name: Manual Deburring | Alternative 2 Name: Thermal Deburring |

|---|---|---|---|

| Performance | High consistency and quality results | Variable results; dependent on skill | Excellent for hard-to-reach areas |

| Cost | Moderate initial investment for machines | Low cost for tools; high labor costs | Higher operational cost due to energy use |

| Ease of Implementation | Requires specialized machinery | Simple tools; easy to implement | Complex setup; requires training |

| Maintenance | Regular machine upkeep needed | Minimal; tools require occasional replacement | Moderate; equipment needs calibration |

| Best Use Case | High-volume production with consistent quality | Small-scale or bespoke projects | Complex geometries and intricate designs |

Detailed Breakdown of Alternatives

Manual Deburring: Pros and Cons

Manual deburring involves skilled technicians using hand tools to remove burrs from metal parts. This method is advantageous due to its low initial investment in tools and flexibility in application, making it suitable for small-scale projects or custom parts. However, the performance can vary significantly based on the technician’s skill level, leading to inconsistent results. Additionally, manual deburring can be time-consuming, resulting in higher labor costs and potential safety risks due to repetitive motion injuries.

Illustrative image related to meaning of deburring

Thermal Deburring: Pros and Cons

Thermal deburring employs combustive gases to generate heat, effectively removing burrs from intricate geometries and hard-to-reach areas. This method excels in high-precision applications, making it ideal for industries such as aerospace and automotive where part integrity is critical. However, the initial setup can be complex, requiring specialized equipment and training for operators. Moreover, the operational costs are higher due to energy consumption, which may not be feasible for all businesses, particularly those focused on cost-efficiency.

Conclusion: Choosing the Right Deburring Solution

For B2B buyers navigating the options for burr removal, the choice between deburring and its alternatives should be driven by specific operational needs, production volume, and budget constraints. If consistency and efficiency are paramount, investing in automated deburring machines may yield the best long-term results. Conversely, for smaller operations or unique projects, manual deburring may suffice, despite its drawbacks. Finally, for complex or precision-critical applications, thermal deburring can offer unparalleled results, albeit at a higher cost. Ultimately, understanding each method’s strengths and weaknesses allows buyers to align their choice with their strategic objectives and operational capabilities.

Essential Technical Properties and Trade Terminology for meaning of deburring

What Are the Key Technical Properties of Deburring?

When evaluating deburring processes and equipment, understanding specific technical properties is crucial for B2B buyers. Here are some critical specifications to consider:

-

Material Grade

Material grade refers to the composition and quality of the metal being processed. Different materials, such as aluminum, stainless steel, or titanium, have varying hardness levels and tolerances for burr formation. For B2B buyers, knowing the material grade is essential for selecting appropriate deburring methods and equipment that will effectively handle the specific type of metal without causing damage. -

Tolerance Levels

Tolerance levels indicate the allowable deviation from a specified dimension in a machined part. In deburring, tighter tolerances mean that even the smallest burrs must be removed to meet industry standards. This is particularly important in sectors such as aerospace or medical manufacturing, where precision is critical. Buyers should ensure that the deburring process can consistently meet the required tolerances to maintain part integrity and safety. -

Surface Finish Quality

The surface finish quality defines the smoothness and texture of a part after deburring. This property is vital as it affects not only the aesthetic appeal but also the performance and longevity of components. Buyers should specify their surface finish requirements to ensure that the deburring method used can achieve the desired results, particularly for parts that will undergo further finishing processes. -

Deburring Method Efficiency

Different deburring methods (manual, mechanical, thermal, electrochemical) have varying efficiencies and throughput rates. Understanding the efficiency of each method helps buyers optimize production schedules and labor costs. For instance, automated mechanical deburring systems can significantly reduce processing time compared to manual techniques, thus enhancing productivity and consistency. -

Dust and Hazard Management

The generation of dust during deburring can pose health and safety risks. Buyers should be aware of whether the deburring machines are designed to manage dust effectively, either through wet processing or integrated dust collection systems. This consideration is crucial for maintaining workplace safety and compliance with local regulations. -

Machine Versatility

Versatility refers to a machine’s ability to handle different types of parts and materials. A versatile deburring machine can adapt to various configurations, which is especially beneficial for companies that work with multiple product lines. Understanding machine versatility allows buyers to invest in equipment that can grow with their business needs.

What Are Common Terms Used in the Deburring Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common terms related to deburring:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In deburring, OEMs often provide specialized machines or tools designed for specific applications. Understanding the role of OEMs helps buyers source high-quality equipment tailored to their needs. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers as it impacts inventory management and cost efficiency. Buyers should negotiate MOQs that align with their production requirements to avoid excess inventory costs. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. In the context of deburring, submitting an RFQ can help buyers gather competitive quotes from various manufacturers, facilitating better decision-making. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers to clarify shipping, risk, and cost responsibilities when sourcing deburring equipment or services from global suppliers. -

Lead Time

Lead time refers to the amount of time from placing an order to receiving it. In the deburring industry, lead times can vary significantly based on the complexity of the equipment and supplier capabilities. Buyers should consider lead times when planning their production schedules to avoid delays. -

Burr Types

Burr types classify the various forms of burrs that can occur during machining processes, such as rollover, Poisson, and breakout burrs. Understanding these classifications helps buyers communicate their specific deburring needs and select the right equipment or methods for effective burr removal.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions that enhance operational efficiency and product quality in their deburring processes.

Navigating Market Dynamics and Sourcing Trends in the meaning of deburring Sector

What Are the Global Drivers Influencing the Deburring Market?

The deburring market is experiencing significant growth, driven by a combination of technological advancements and increasing demand for high-quality metal components across various industries. Automation in manufacturing processes is a crucial factor; businesses are adopting automated deburring machines to enhance production efficiency and maintain consistent quality. Furthermore, the rising complexity of products, especially in sectors such as aerospace, automotive, and medical devices, necessitates precise deburring techniques to ensure safety and functionality.

Emerging technologies like electrochemical and thermal deburring are gaining traction, offering innovative solutions for challenging applications. This trend is particularly relevant for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, who seek to adopt advanced manufacturing practices. The push for efficiency is also reflected in the increasing use of integrated systems that combine deburring with other finishing processes, streamlining operations and reducing labor costs.

How Are Sustainability and Ethical Sourcing Shaping the Deburring Industry?

Sustainability is becoming a critical consideration for B2B buyers in the deburring sector. As industries face mounting pressure to reduce their environmental impact, the demand for sustainable practices in the sourcing of materials and machinery is on the rise. Buyers are increasingly looking for suppliers who can provide eco-friendly deburring solutions, such as machines that minimize waste and use biodegradable cutting fluids.

Illustrative image related to meaning of deburring

Ethical sourcing is also paramount, as companies are held accountable for their supply chains. This includes ensuring that raw materials are sourced responsibly and that manufacturing processes adhere to environmental regulations. Buyers are encouraged to seek out suppliers with recognized green certifications, such as ISO 14001, which demonstrates a commitment to environmental management. Utilizing ‘green’ materials not only enhances a company’s reputation but can also lead to cost savings through reduced waste and improved efficiency.

What Is the Evolution of Deburring Technology Over Time?

The deburring process has evolved significantly since its inception, transitioning from manual methods to advanced automated systems. Initially, deburring was performed by hand, a time-consuming and labor-intensive task that varied greatly in quality. As manufacturing technologies advanced, mechanical deburring machines emerged, drastically improving efficiency and consistency.

In recent years, the introduction of high-tech solutions like thermal and electrochemical deburring has revolutionized the industry. These methods allow for precise removal of burrs in hard-to-reach areas and on complex geometries, catering to the needs of modern manufacturing. This evolution reflects a broader trend in manufacturing toward automation and precision, meeting the demands of increasingly sophisticated products across various sectors. International B2B buyers can leverage these advancements to enhance their operational capabilities and maintain a competitive edge in the global market.

Illustrative image related to meaning of deburring

Frequently Asked Questions (FAQs) for B2B Buyers of meaning of deburring

-

How do I solve the problem of burrs on machined metal parts?

To effectively remove burrs from machined metal parts, consider using a combination of manual and mechanical deburring techniques. Manual deburring can be employed for delicate components, while mechanical deburring machines enhance efficiency and consistency in larger operations. Assess the type of burrs present—whether rollover, poisson, or breakout—and select appropriate tools such as brushes, discs, or belts. Additionally, automated deburring systems can significantly speed up the process, ensuring uniform quality and reducing labor costs. -

What is the best deburring method for different types of metals?

The best deburring method varies based on the metal type and application. For softer metals like aluminum, manual deburring or brush heads on machines work effectively. Harder metals, such as stainless steel, may require mechanical methods like belt or thermal deburring. Electrochemical deburring is ideal for intricate designs or hard-to-reach areas. Evaluate the specific requirements of your metal parts, such as finish quality and tolerances, to determine the most suitable deburring method. -

What are the key considerations for selecting a deburring machine?

When selecting a deburring machine, consider factors such as part size, material type, and desired finish quality. Analyze the specific burr types that need removal and the production volume to choose between manual, mechanical, or automated solutions. Additionally, assess the machine’s capabilities, such as the types of deburring heads (brush, disc, or belt) and whether it operates wet or dry. Understanding your operational needs will guide you in investing in a machine that enhances efficiency and quality in your production process. -

How can I ensure the quality of deburring processes in my manufacturing?

To ensure high-quality deburring, implement a robust quality assurance (QA) process that includes regular inspections of deburred parts for burr presence and surface finish quality. Utilize standardized operating procedures for deburring methods and machine settings. Training staff on proper deburring techniques and machine operation is crucial to maintaining consistency. Additionally, consider investing in advanced deburring machines with built-in quality monitoring features to streamline the process and enhance reliability. -

What are the typical payment terms when sourcing deburring equipment internationally?

Payment terms can vary widely among suppliers, but common options include upfront payment, partial payment with the balance upon delivery, or letters of credit. It’s essential to negotiate terms that protect both parties and align with your cash flow needs. Consider discussing payment in stages tied to milestones, such as order confirmation, production completion, and delivery. Always ensure that payment methods are secure and that you understand any currency exchange implications if dealing with international suppliers. -

What minimum order quantities (MOQs) should I expect from deburring machine suppliers?

Minimum order quantities (MOQs) for deburring machines can vary based on the supplier and the type of equipment. Some suppliers may offer machines with no MOQ, especially for customized solutions, while others may set MOQs to justify production costs. When sourcing, clarify MOQs upfront and discuss any flexibility based on your specific needs, such as trial orders or bulk discounts. Understanding MOQs will help you plan your procurement budget effectively. -

How do I vet suppliers for deburring machines in international markets?

To vet suppliers effectively, conduct thorough research on their reputation, industry experience, and customer reviews. Request references and case studies that demonstrate their capabilities in delivering high-quality deburring solutions. Verify certifications and compliance with international standards relevant to your industry, such as ISO certifications. Additionally, consider visiting their facilities or arranging virtual tours to assess their manufacturing processes and quality control measures directly. -

What logistics considerations should I keep in mind when importing deburring machines?

When importing deburring machines, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Select a reliable freight forwarder with expertise in handling machinery to navigate import duties and tariffs efficiently. Ensure that you have the necessary documentation, including commercial invoices and certificates of origin, to facilitate smooth customs clearance. Additionally, plan for the logistics of installation and training, which may involve coordinating with the supplier or local technicians.

Top 3 Meaning Of Deburring Manufacturers & Suppliers List

1. Merriam-Webster – Deburr Definition

Domain: merriam-webster.com

Registered: 1999 (26 years)

Introduction: Deburr is a transitive verb defined as the action of removing burrs (rough edges) from a piece of machined work. The term is derived from the prefix ‘de-‘ meaning removal and ‘burr’ referring to the rough edge.

2. Benchmark Abrasives – Deburring Solutions

Domain: benchmarkabrasives.com

Registered: 2009 (16 years)

Introduction: This company, Benchmark Abrasives – Deburring Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. James Engineering – MAX Finishing Machine

Domain: james-engineering.com

Registered: 2001 (24 years)

Introduction: The MAX is an all-encompassing finishing machine sold and manufactured by James Engineering. It is capable of grinding, polishing, and deburring concurrently, allowing a part to undergo all three processes in one go. The MAX offers consistent precision that surpasses hand-done methods and other machines. It is designed to make the processes of grinding, polishing, and deburring easy and affordable…

Strategic Sourcing Conclusion and Outlook for meaning of deburring

What Are the Key Benefits of Effective Deburring for B2B Buyers?

In conclusion, deburring is not merely a finishing step in metalworking; it is a crucial process that directly impacts product quality, safety, and operational efficiency. For international B2B buyers, particularly in emerging markets like Africa and South America, understanding the significance of deburring can lead to improved product reliability and reduced operational costs. Strategic sourcing of deburring technologies—whether mechanical, thermal, or electrochemical—ensures that manufacturers can meet stringent quality standards, enhancing competitiveness in the global market.

Investing in automated deburring solutions can significantly streamline production processes, minimize labor costs, and improve consistency across products. As industries continue to evolve, embracing advanced deburring techniques will not only mitigate risks associated with burrs but also enhance overall production capabilities.

Looking ahead, it is essential for B2B buyers in regions such as the Middle East and Europe to prioritize the integration of innovative deburring solutions into their sourcing strategies. By doing so, they can position themselves for long-term success in an increasingly competitive landscape. Take the next step in optimizing your manufacturing processes and explore the latest advancements in deburring technology today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.