Plastic Gears: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for plastic gears

In today’s competitive landscape, sourcing high-quality plastic gears can be a daunting challenge for international B2B buyers. As industries increasingly lean towards lightweight, durable, and rust-proof solutions, understanding the nuances of plastic gear specifications is crucial for optimizing performance and cost-efficiency. This guide serves as a comprehensive resource, exploring various types of plastic gears, including spur, helical, and worm gears, along with their diverse applications across sectors such as consumer electronics, food production, and medical equipment.

Navigating the global market for plastic gears requires an informed approach to supplier vetting, ensuring that manufacturers adhere to stringent quality standards while offering competitive pricing. Additionally, the guide delves into critical aspects such as material selection—highlighting the advantages of engineering plastics like polyacetal and nylon—and the implications of environmental factors on gear performance.

By equipping B2B buyers from Africa, South America, the Middle East, and Europe—such as Brazil and Germany—with actionable insights and data-driven strategies, this guide empowers them to make informed purchasing decisions. Whether you are seeking to enhance product reliability or reduce operational costs, understanding the intricacies of plastic gears will enable you to choose the right components for your applications.

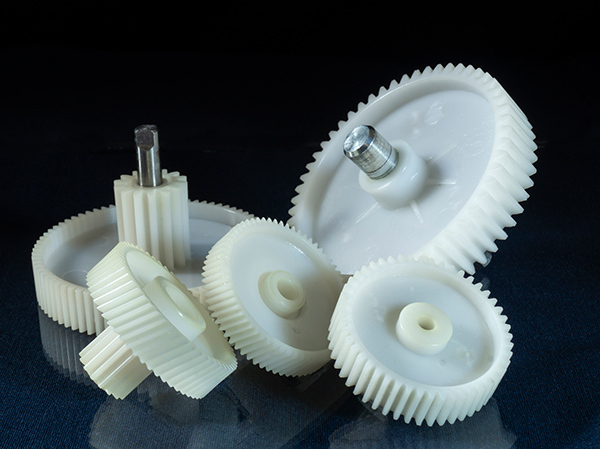

Understanding plastic gears Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic Spur Gears | Straight teeth, simple design, high load capacity | Consumer electronics, food machinery | Pros: Lightweight, cost-effective. Cons: Lower strength than metal. |

| Plastic Helical Gears | Angled teeth for smoother operation, reduced noise | Automotive, industrial machinery | Pros: Quieter operation, better load distribution. Cons: More complex design. |

| Plastic Worm Gears | Screw-like design for high torque, low speed applications | Robotics, conveyor systems | Pros: High reduction ratios, compact design. Cons: Less efficient, wear over time. |

| Plastic Bevel Gears | Cone-shaped for angular motion transfer | Aerospace, automotive | Pros: Versatile direction changes, space-saving. Cons: Complex manufacturing. |

| Plastic Gear Racks | Linear gear system, converts rotational motion to linear | Automation, robotics | Pros: Simplifies linear motion applications. Cons: Limited load capacity. |

What Are Plastic Spur Gears and Their Applications?

Plastic spur gears are characterized by their straightforward design and straight teeth, making them easy to manufacture and install. They are commonly used in consumer electronics and food production machinery due to their lightweight nature and cost-effectiveness. However, their lower strength compared to metal gears can be a drawback in high-load applications. Buyers should consider the specific load requirements and operational environment when selecting these gears to ensure optimal performance.

How Do Plastic Helical Gears Enhance Performance?

Plastic helical gears feature angled teeth, which provide smoother and quieter operation compared to spur gears. This design allows for better load distribution, making them suitable for applications in the automotive and industrial machinery sectors. While they tend to be more complex and costly to produce, the benefits of reduced noise and increased efficiency can justify the investment for many B2B buyers. It is crucial to assess the application’s noise sensitivity and load conditions when considering helical gears.

What Advantages Do Plastic Worm Gears Offer?

Plastic worm gears are designed with a screw-like shape that allows them to achieve high torque at low speeds, making them ideal for robotics and conveyor systems. Their compact nature enables high reduction ratios, which is advantageous in space-constrained applications. However, they can be less efficient than other gear types and may experience wear over time. Buyers should evaluate the specific torque and speed requirements of their applications when opting for worm gears.

Why Are Plastic Bevel Gears Important in Various Industries?

Plastic bevel gears are essential for applications requiring direction changes, as they can transfer motion at various angles. Their cone-shaped design makes them suitable for use in aerospace and automotive applications. While they offer versatility and save space, the complexity of their manufacturing process can increase costs. B2B buyers should weigh the benefits of space-saving designs against the potential higher costs and ensure compatibility with existing systems.

How Do Plastic Gear Racks Function in Automation?

Plastic gear racks are linear gear systems that convert rotational motion into linear motion, making them invaluable in automation and robotics. Their ability to simplify linear motion applications is a significant advantage; however, they typically have a limited load capacity compared to other gear types. Buyers need to consider the specific linear motion requirements and load conditions when integrating gear racks into their systems, ensuring they choose the right configuration for their operational needs.

Key Industrial Applications of plastic gears

| Industry/Sector | Specific Application of Plastic Gears | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Production | Conveyor systems for packaging and processing | Lightweight, rust-proof, and low noise levels | Material compliance with food safety regulations |

| Consumer Electronics | Gear mechanisms in appliances and gadgets | Cost-effective production and quiet operation | High precision and compatibility with metal gears |

| Medical Equipment | Drive systems in diagnostic and surgical tools | Non-corrosive, lightweight, and lubrication-free | Reliability under varying temperatures and sterilization processes |

| Toy Manufacturing | Movement mechanisms in toys | Durable, safe materials that are cost-efficient | Compliance with safety standards for children’s products |

| Automotive Components | Actuation systems in vehicle controls | Lightweight and energy-efficient solutions | High strength-to-weight ratio and resistance to wear |

How Are Plastic Gears Used in Food Production Systems?

In the food production industry, plastic gears are integral to conveyor systems that facilitate the packaging and processing of food products. Their lightweight and rust-proof characteristics ensure compliance with hygiene standards, while their quiet operation minimizes noise in production environments. International buyers must prioritize materials that meet food safety regulations, ensuring that the gears can withstand cleaning processes and harsh conditions typically found in food processing facilities.

What Role Do Plastic Gears Play in Consumer Electronics?

Plastic gears are widely used in consumer electronics, such as appliances and gadgets, where they drive various mechanisms. Their cost-effectiveness and ability to operate quietly make them an attractive choice for manufacturers aiming to enhance user experience. Buyers should focus on sourcing gears that offer high precision and compatibility with metal counterparts, ensuring smooth operation and longevity in devices that require frequent use.

How Are Plastic Gears Essential in Medical Equipment?

In the medical equipment sector, plastic gears are crucial for the drive systems found in diagnostic and surgical tools. Their non-corrosive and lightweight properties allow for easy handling and maintenance, while also facilitating lubrication-free operation, which is vital in sterile environments. Buyers should look for gears that maintain reliability under fluctuating temperatures and can withstand sterilization processes, ensuring consistent performance in critical applications.

Why Are Plastic Gears Important in Toy Manufacturing?

Plastic gears are essential in the toy manufacturing industry, where they enable movement mechanisms in various toys. The use of durable and safe materials ensures that products are cost-efficient while meeting safety standards for children’s toys. Buyers must consider the compliance of materials with safety regulations and the durability of the gears to withstand rough usage, ensuring both safety and longevity in the final products.

How Do Plastic Gears Contribute to Automotive Components?

In the automotive sector, plastic gears are employed in actuation systems for vehicle controls, providing lightweight and energy-efficient solutions. Their ability to reduce overall vehicle weight contributes to improved fuel efficiency, which is increasingly important in today’s eco-conscious market. When sourcing plastic gears, buyers should focus on their strength-to-weight ratio and wear resistance, ensuring they can withstand the demanding conditions of automotive applications.

3 Common User Pain Points for ‘plastic gears’ & Their Solutions

Scenario 1: Challenges with Heat Resistance in Plastic Gears

The Problem: Many B2B buyers encounter significant issues when plastic gears are used in environments with fluctuating temperatures. For instance, industries such as food processing or medical equipment often operate under high heat conditions. The challenge arises when the plastic gears expand or lose their structural integrity due to heat, leading to gear failure and downtime in production. This not only affects operational efficiency but can also lead to costly repairs and replacements, as well as potential safety hazards.

The Solution: To mitigate the risks associated with heat sensitivity, buyers should prioritize sourcing plastic gears made from heat-resistant materials such as PEEK or specialized nylon composites. It’s crucial to work closely with suppliers who can provide detailed specifications regarding the thermal properties of their products. Additionally, consider incorporating metal hubs in the gear design to enhance strength and durability under thermal stress. When ordering gears, specify your operational temperature ranges and ask for recommendations on materials that can withstand your specific conditions. Regularly monitor the performance of these gears, especially in critical applications, and establish a preventative maintenance schedule to identify potential failures before they occur.

Illustrative image related to plastic gears

Scenario 2: Inconsistent Gear Performance Due to Moisture Absorption

The Problem: In humid environments, plastic gears can absorb moisture, leading to dimensional changes that affect performance. Buyers in industries such as consumer electronics or automotive manufacturing often find that moisture absorption leads to increased backlash and misalignment, ultimately causing machinery to operate inefficiently or fail. This is particularly problematic in precision applications where exact gear meshing is critical.

The Solution: To combat moisture-related issues, buyers should select plastic gears engineered for low moisture absorption, such as those made from polyacetal (POM) or specially treated nylons. When specifying gears, inquire about the moisture absorption rates of the materials used and request options that have been tested for stability in humid conditions. Furthermore, implementing protective coatings or selecting gears with sealed designs can further enhance moisture resistance. Regular inspections for signs of wear or dimensional changes should also be part of your maintenance routine, enabling you to address issues proactively rather than reactively.

Scenario 3: Difficulty in Achieving Precise Gear Specifications

The Problem: One of the most common pain points for B2B buyers is the challenge of achieving the exact specifications required for their applications. This includes precise tooth profiles, bore sizes, and materials that meet specific operational demands. In industries such as robotics or aerospace, even minor deviations in gear specifications can lead to significant performance issues and increased manufacturing costs.

The Solution: To ensure that the plastic gears meet your exact requirements, engage with suppliers that offer customization options. Before placing an order, provide detailed specifications, including the gear module, number of teeth, and operational environment. Utilize CAD modeling tools to visualize the gear design and confirm that it meets your specifications. Additionally, request prototypes or sample gears for testing in your application before committing to a large order. Establishing a strong relationship with your supplier can facilitate better communication and more flexible solutions, ensuring that you receive high-quality gears that fit your needs precisely.

Strategic Material Selection Guide for plastic gears

What Are the Key Properties of Common Materials Used for Plastic Gears?

When selecting materials for plastic gears, it’s essential to consider their properties, as they directly influence performance, durability, and suitability for specific applications. Here, we analyze four common materials: Polyacetal (POM), Nylon (MC Nylon), Polyethylene (U-PE), and Polyether Ether Ketone (PEEK).

How Does Polyacetal (POM) Perform in Plastic Gears?

Polyacetal, known for its excellent mechanical properties, is a popular choice for plastic gears. It has a high tensile strength and low friction coefficient, making it suitable for applications requiring precision and durability. POM can withstand temperatures up to 100°C and offers good resistance to chemicals and moisture.

Pros: Its lightweight nature, combined with low wear and tear, makes it ideal for high-speed applications. Additionally, POM gears can be manufactured with high dimensional stability, ensuring precise gear meshing.

Cons: However, POM is sensitive to UV light and may degrade over time if exposed. Its cost can also be higher than other plastic materials, which may impact budget-sensitive projects.

Impact on Application: POM is often used in automotive and consumer electronics, where precision and reliability are paramount. International buyers should ensure compliance with standards such as ASTM and JIS, particularly for applications in regulated industries.

What Advantages Does Nylon (MC Nylon) Offer for Plastic Gears?

Nylon, specifically MC Nylon, is another widely used material for plastic gears due to its high impact resistance and ability to absorb shock. It can operate effectively in temperatures up to 80°C and is resistant to many chemicals, making it versatile for various applications.

Pros: The material’s excellent wear resistance and ability to operate without lubrication can lead to lower maintenance costs. Its availability in various grades also allows for tailored solutions based on specific needs.

Cons: Nylon can absorb moisture, which may lead to dimensional changes over time. This property requires careful consideration in environments with fluctuating humidity levels.

Impact on Application: Nylon gears are commonly found in the toy, medical, and food processing industries. Buyers in regions like Africa and South America should consider local humidity conditions and ensure compliance with relevant safety standards.

How Does Polyethylene (U-PE) Compare for Plastic Gears?

Polyethylene, particularly U-PE, is known for its excellent chemical resistance and low moisture absorption. It operates well in temperatures ranging from -40°C to 80°C, making it suitable for a variety of environments.

Pros: U-PE is lightweight and cost-effective, making it an attractive option for large-scale production. Its low friction properties contribute to quieter operation in machinery.

Cons: However, U-PE has lower mechanical strength compared to POM and Nylon, which may limit its application in high-load scenarios. Its lower temperature resistance can also be a drawback in demanding environments.

Impact on Application: U-PE is often used in food processing and packaging industries. Buyers should verify compliance with food safety standards, particularly in European markets, where regulations can be stringent.

Illustrative image related to plastic gears

What Makes Polyether Ether Ketone (PEEK) a Premium Choice for Plastic Gears?

PEEK is a high-performance engineering plastic known for its exceptional thermal stability and mechanical strength. It can withstand temperatures up to 250°C and offers excellent chemical resistance, making it suitable for harsh environments.

Pros: PEEK’s durability and ability to maintain performance under extreme conditions make it ideal for aerospace and medical applications. Its high strength-to-weight ratio also contributes to reduced overall system weight.

Cons: The primary drawback of PEEK is its high cost, which can be prohibitive for some applications. Additionally, its manufacturing complexity may lead to longer lead times.

Impact on Application: PEEK gears are often used in high-end applications, including aerospace and automotive sectors. International buyers, especially from Europe and the Middle East, should ensure compliance with industry-specific standards and certifications.

Summary of Material Selection for Plastic Gears

| Material | Typical Use Case for Plastic Gears | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyacetal (POM) | Automotive, consumer electronics | High strength, low friction | UV sensitivity | Medium |

| Nylon (MC Nylon) | Toys, medical devices | Impact resistance, low maintenance | Moisture absorption | Medium |

| Polyethylene (U-PE) | Food processing, packaging | Cost-effective, lightweight | Lower strength | Low |

| PEEK | Aerospace, medical applications | Exceptional durability, thermal stability | High cost | High |

This strategic material selection guide provides valuable insights for B2B buyers looking to make informed decisions when sourcing plastic gears. Understanding the properties, advantages, and limitations of each material can lead to better product performance and compliance with industry standards.

Illustrative image related to plastic gears

In-depth Look: Manufacturing Processes and Quality Assurance for plastic gears

What Are the Key Stages in the Manufacturing Process of Plastic Gears?

Manufacturing plastic gears involves several critical stages, each crucial to ensuring high-quality end products. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

– The selection of materials is fundamental in the production of plastic gears. Common materials include engineering plastics such as polyacetal (POM) and nylon (MC Nylon). These materials offer advantages such as lightweight properties, rust resistance, and low friction coefficients.

– Material preparation involves the careful sourcing and testing of raw materials to ensure they meet the required specifications. This may include assessing their mechanical properties, thermal stability, and chemical resistance. -

Forming Techniques

– The most prevalent method for forming plastic gears is injection molding. This process allows for high-volume production and intricate shapes with minimal waste. During injection molding, heated plastic is injected into a mold where it cools and solidifies into the desired shape.

– Other techniques may include machining or 3D printing for custom applications or lower production volumes. Each technique has its advantages and is chosen based on the specific requirements of the gear, including size, complexity, and production volume. -

Assembly

– In cases where gears require additional components, such as metal hubs for increased strength, assembly is a critical stage. Gears can be fused with metal hubs using screws or adhesives to form a robust connection. This hybrid approach allows manufacturers to leverage the advantages of both materials.

– Automated assembly lines are often employed to ensure precision and efficiency, especially in high-volume production scenarios. -

Finishing

– The finishing stage involves processes such as trimming, deburring, and surface treatment. This is essential to enhance the gear’s performance and longevity. For example, surface treatments can improve wear resistance and reduce friction, leading to quieter operation.

– Quality control checks are often integrated into the finishing process to ensure that the gears meet the specified tolerances and surface finish requirements.

How Is Quality Assurance Implemented in Plastic Gear Manufacturing?

Quality assurance (QA) is essential in the manufacturing of plastic gears, ensuring that products are reliable and meet international standards. The QA process typically involves adherence to relevant standards, multiple checkpoints, and various testing methods.

-

Relevant International Standards

– Compliance with international standards such as ISO 9001 is crucial for manufacturers targeting global markets. ISO 9001 sets the criteria for a quality management system (QMS), ensuring consistent quality across production processes.

– Additionally, industry-specific certifications like CE and API are important for manufacturers supplying sectors such as automotive, aerospace, and medical equipment. These certifications demonstrate compliance with safety and performance regulations. -

Quality Control Checkpoints

– Quality control checkpoints are strategically placed throughout the manufacturing process:- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before production begins. Testing may involve visual inspections and mechanical testing to ensure compliance with specifications.

- In-Process Quality Control (IPQC): During manufacturing, IPQC monitors processes to detect any deviations from quality standards. This may include regular inspections of molded parts for dimensional accuracy and surface finish.

- Final Quality Control (FQC): Once production is complete, FQC involves comprehensive testing of finished gears. This includes dimensional checks, functional tests, and performance assessments to ensure they meet the required standards.

-

Common Testing Methods for Plastic Gears

– Various testing methods are employed to verify the quality and performance of plastic gears:- Mechanical Testing: This includes tensile strength, impact resistance, and wear testing to evaluate the gear’s durability under operational conditions.

- Dimensional Inspection: Utilizing precision measuring tools, manufacturers assess critical dimensions such as pitch diameter, tooth spacing, and overall gear profile to ensure they meet specified tolerances.

- Functional Testing: Gears are often subjected to operational tests to assess performance in real-world scenarios, including load testing and noise assessment.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those sourcing from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to mitigate risks associated with product quality.

-

Supplier Audits

– Conducting supplier audits is a fundamental step in evaluating a manufacturer’s quality assurance processes. These audits can be performed by the buyer or through third-party inspection services. An audit typically assesses the supplier’s adherence to their quality management system and international standards.

– During the audit, buyers should review documentation, observe processes, and assess the conditions of the manufacturing facility. This comprehensive evaluation provides insight into the supplier’s commitment to quality. -

Requesting Quality Reports

– Buyers should request regular quality reports from suppliers, which detail the results of inspections and testing conducted throughout the manufacturing process. These reports should include metrics on defect rates, compliance with specifications, and any corrective actions taken in response to quality issues.

– Transparency in quality reporting is a strong indicator of a supplier’s reliability and commitment to maintaining high standards. -

Third-Party Inspections

– Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services can conduct inspections at various stages of production, ensuring compliance with specified standards and identifying any potential issues before shipment.

– Third-party inspections are particularly beneficial for international buyers who may not have the resources to conduct on-site audits.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, B2B buyers must navigate various quality control nuances that can impact their sourcing decisions.

Illustrative image related to plastic gears

-

Cultural and Regulatory Differences

– Different countries have varying regulations and standards for manufacturing and quality assurance. Buyers must familiarize themselves with these differences to ensure compliance and mitigate risks.

– Understanding cultural attitudes toward quality can also play a role. In some regions, there may be a greater emphasis on price over quality, leading to potential compromises in manufacturing standards. -

Logistical Considerations

– Logistics can affect the quality of plastic gears, especially when transporting materials over long distances. Buyers should ensure that suppliers have robust logistics plans to prevent damage during transit and maintain quality integrity.

– Additionally, buyers should consider the impact of climate conditions on plastic materials, such as temperature fluctuations that could affect dimensional stability. -

Building Long-Term Relationships

– Establishing long-term relationships with suppliers can enhance quality assurance. Regular communication and collaboration can lead to continuous improvements in quality and innovation in product design.

– Building trust allows buyers to work closely with suppliers to address any quality concerns proactively, ensuring a consistent supply of high-quality plastic gears.

By understanding the manufacturing processes and quality assurance practices associated with plastic gears, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive products that meet their specifications and performance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic gears’

To successfully procure plastic gears for your business needs, it is essential to follow a structured approach that ensures you select the right products and suppliers. This checklist will guide you through the key steps in sourcing plastic gears, helping you make informed decisions that align with your operational requirements.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications for the plastic gears you need. Consider factors such as:

– Material Type: Determine whether you require gears made from polyacetal, nylon, or other engineering plastics.

– Dimensions: Specify module size, number of teeth, bore type, and face width.

By defining these parameters, you can streamline your search and ensure compatibility with existing machinery.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in plastic gears. Use platforms like industry directories, trade shows, and online marketplaces to compile a list of potential partners.

– Check Reviews and Ratings: Look for feedback from previous customers to gauge reliability and product quality.

– Evaluate Industry Experience: Suppliers with a proven track record in your industry can often provide tailored solutions.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify the certifications of your shortlisted suppliers.

– Quality Management Systems: Look for ISO certifications that indicate adherence to quality control standards.

– Material Compliance: Ensure that the materials used in the gears comply with relevant safety and industry standards, especially for sectors like food and pharmaceuticals.

Step 4: Request Samples

Once you have narrowed down your list, request samples of the plastic gears you intend to purchase.

– Assess Performance: Evaluate the samples for strength, durability, and compatibility with your applications.

– Check for Tolerances: Ensure that the samples meet your dimensional specifications and that there is no excessive backlash.

Step 5: Review Pricing Structures

Discuss pricing with potential suppliers to understand their pricing models and any bulk order discounts.

– Transparent Quotations: Ensure that the quotes include all costs, such as shipping and handling.

– Compare Value: Don’t just settle for the lowest price; consider the overall value, including quality and service.

Step 6: Negotiate Terms and Conditions

Before finalizing your order, negotiate the terms of sale, including payment terms, delivery schedules, and warranty conditions.

– Clear Agreements: Ensure that all agreements are documented to avoid misunderstandings later.

– Flexibility in Orders: Discuss the possibility of adjusting order quantities in case of changing demands.

Step 7: Establish a Long-term Partnership

After your initial order, consider establishing a long-term relationship with your supplier.

– Feedback Loop: Provide feedback on product performance to help the supplier improve.

– Continuous Improvement: Collaborate on innovations or customizations that could benefit both parties in the long run.

By following these steps, you can efficiently source high-quality plastic gears that meet your business needs while fostering strong relationships with reliable suppliers.

Comprehensive Cost and Pricing Analysis for plastic gears Sourcing

What Are the Key Cost Components in Plastic Gears Sourcing?

Understanding the cost structure for sourcing plastic gears is essential for B2B buyers aiming to make informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common materials for plastic gears include polyacetal (POM) and nylon (MC Nylon), which offer benefits such as lightweight and non-rusting properties. However, specialized materials like PEEK or reinforced nylon can increase costs due to their superior performance characteristics.

-

Labor: Labor costs encompass the workforce involved in manufacturing, which can vary by region. Countries with lower labor costs may offer competitive pricing, but this can also affect quality and lead times.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient production processes can help minimize overhead costs, thereby affecting the final price of the gears.

-

Tooling: Initial tooling costs can be significant, especially for custom gears. Buyers should consider whether the investment in tooling is justified by the anticipated volume of orders.

-

Quality Control (QC): Ensuring high quality through rigorous testing and quality control processes can add to costs. Certifications and compliance with international standards may also be required, influencing the pricing structure.

-

Logistics: Shipping and handling costs vary based on the distance from the supplier to the buyer, the mode of transportation, and the chosen Incoterms. Buyers should factor these logistics costs into their total pricing considerations.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. Understanding the market dynamics and competition can provide insights into reasonable margins.

How Do Price Influencers Affect the Cost of Plastic Gears?

Several factors can influence the pricing of plastic gears in the B2B market:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Suppliers may set a MOQ, which can affect pricing strategies for smaller buyers.

-

Specifications and Customization: Custom designs and specific technical requirements can lead to increased costs. Buyers should be clear about their specifications to avoid unexpected charges.

-

Material Selection: The choice of material not only affects the cost but also the performance of the gears. Premium materials can enhance durability but may significantly increase prices.

-

Quality and Certifications: The demand for high-quality gears with certifications (such as ISO) can drive up costs. Buyers should weigh the importance of these certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may command higher prices due to their proven track record and quality assurance.

-

Incoterms: The agreed-upon Incoterms can significantly affect the total cost of ownership. Understanding these terms helps buyers gauge who is responsible for shipping, insurance, and customs duties.

What Tips Can Buyers Use to Negotiate Better Prices?

B2B buyers can leverage several strategies to ensure cost-efficiency when sourcing plastic gears:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Highlighting competitive offers from other suppliers can strengthen your bargaining position.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but all associated costs, including logistics, maintenance, and potential downtime due to gear failures. A slightly higher upfront cost may lead to lower TCO if the gear performs better.

-

Be Aware of Pricing Nuances for International Purchases: When sourcing from suppliers in different regions, be mindful of currency fluctuations, tariffs, and import duties, which can affect overall costs.

-

Explore Alternative Suppliers: Diversifying your supplier base can help mitigate risks and enhance competitive pricing. Researching suppliers from various regions can uncover better deals.

-

Request Detailed Quotes: Ensure that quotes are itemized to understand the breakdown of costs. This transparency allows for better comparisons and negotiations.

Disclaimer

Prices for plastic gears can vary widely based on the factors discussed above. Buyers should always request updated quotes and consider the specific context of their purchasing needs before making decisions.

Alternatives Analysis: Comparing plastic gears With Other Solutions

When considering gear solutions for various applications, it is essential to evaluate alternatives to plastic gears. Plastic gears, known for their lightweight and corrosion-resistant properties, may not always be the ideal choice for every situation. Understanding the strengths and weaknesses of different gear technologies can aid B2B buyers in making informed decisions that align with their operational needs.

Comparison Table

| Comparison Aspect | Plastic Gears | Metal Gears | Composite Gears |

|---|---|---|---|

| Performance | Good for low-load applications; quieter operation | High strength; better for heavy loads | Balanced performance; good for moderate loads |

| Cost | Generally lower; economical for mass production | Higher initial cost; requires machining | Moderate; often more economical than metal but less than plastic |

| Ease of Implementation | Easy to mold and manufacture; can be customized | Requires precise machining; may be complex | Can be manufactured in various shapes but may need specialized tooling |

| Maintenance | Low maintenance; self-lubricating when paired with metal | Requires regular lubrication; prone to wear | Moderate maintenance; may need periodic checks |

| Best Use Case | Ideal for applications with low torque and noise constraints | Suitable for high-load and high-speed applications | Effective in environments needing a combination of strength and weight savings |

Detailed Breakdown of Alternatives

1. Metal Gears

Metal gears, often made from steel or aluminum, are renowned for their strength and durability. They excel in high-load applications where plastic gears may not perform adequately. However, they can be heavier and more expensive due to the machining processes required to create precise components. Maintenance is also a consideration, as metal gears typically require regular lubrication to prevent wear and tear. In industries such as automotive and aerospace, where strength and reliability are paramount, metal gears are often the preferred choice.

2. Composite Gears

Composite gears are made from a blend of materials that offer a balance between the advantages of plastic and metal gears. They can be designed to withstand moderate loads while being lighter than traditional metal gears. The manufacturing process for composite gears can be more flexible than that of metal, allowing for customization in shape and size. However, they may not offer the same level of strength as metal gears, making them less suitable for extreme conditions. They are often used in applications where weight savings are essential, such as in consumer electronics and automotive components.

Conclusion

Choosing the right gear solution hinges on understanding the specific requirements of your application. For B2B buyers, evaluating the performance, cost, and maintenance needs of plastic gears against metal and composite alternatives is crucial. While plastic gears may provide a cost-effective and lightweight solution for low-load applications, metal gears offer superior strength for heavy-duty needs. Composite gears can serve as a middle ground, providing a balance of performance and weight. Ultimately, aligning the choice of gears with operational demands and environmental conditions will lead to more efficient and effective outcomes.

Essential Technical Properties and Trade Terminology for plastic gears

What Are the Critical Technical Properties of Plastic Gears?

Understanding the essential technical properties of plastic gears is crucial for B2B buyers who seek reliability and performance in their applications. Here are some key specifications:

1. Material Grade

The material used for plastic gears typically includes engineering plastics such as polyacetal (POM) and nylon (MC Nylon). These materials offer a balance of strength, weight, and resistance to environmental factors. The choice of material affects durability and performance, making it imperative for buyers to select the right grade based on application requirements.

2. Module

The module is a critical parameter that defines the size of the teeth on the gear. It is calculated by dividing the pitch diameter by the number of teeth. A higher module indicates larger teeth, which can handle greater loads but may also increase backlash. For B2B buyers, understanding the module helps ensure compatibility with other gears in the system, promoting efficient power transmission.

3. Tolerance

Tolerance refers to the allowable deviation from a specified dimension in the gear’s design. Precision in manufacturing is crucial for ensuring proper meshing with other gears and minimizing wear. Tight tolerances lead to higher costs but can significantly enhance performance, especially in high-speed or high-load applications. Buyers must balance cost and performance when specifying tolerances.

4. Pressure Angle

The pressure angle indicates the angle at which the teeth of the gear engage. Common pressure angles are 20° and 14.5°. A higher pressure angle typically results in stronger teeth and reduced sliding friction, which is beneficial for load-bearing applications. Understanding pressure angles allows buyers to select gears that optimize performance for specific applications, such as in robotics or automotive systems.

5. Face Width

Face width is the width of the gear tooth, which influences the gear’s strength and load-carrying capacity. A wider face can distribute stress more evenly, reducing the risk of tooth failure. For B2B buyers, selecting the appropriate face width can enhance the longevity and reliability of gear systems in demanding environments.

6. Hub Design

The hub design, which may be plain or finished, impacts how the gear interfaces with the shaft. Finished hubs allow for precise fitting and can be critical in applications requiring high alignment accuracy. Buyers should evaluate the hub design based on assembly needs and operational requirements to ensure optimal performance.

Which Common Trade Terms Should B2B Buyers Know in the Plastic Gears Industry?

Familiarity with industry terminology is vital for effective communication and negotiation in the B2B space. Here are some common terms:

Illustrative image related to plastic gears

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of plastic gears, OEMs often supply gears that are integral to larger machinery or consumer products. Understanding OEM relationships can help buyers identify reliable suppliers and ensure product quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for B2B buyers as it affects inventory management and cost-effectiveness. Knowing the MOQ can help businesses plan their purchasing strategies and avoid excess inventory or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It is a critical step in the procurement process, allowing buyers to compare offers from different suppliers. A well-prepared RFQ can facilitate better negotiations and ensure that buyers receive competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in the shipping process. They specify who is responsible for shipping, insurance, and tariffs. For B2B buyers, understanding Incoterms is essential for managing logistics and minimizing risks associated with international transactions.

5. CAD (Computer-Aided Design)

CAD refers to the use of software to create detailed 2D or 3D models of products. In the gear industry, CAD drawings are essential for understanding specifications and tolerances. Buyers can leverage CAD files to ensure that the gears will fit their applications correctly.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions and enhance their procurement processes for plastic gears.

Navigating Market Dynamics and Sourcing Trends in the plastic gears Sector

What Are the Current Market Dynamics and Key Trends in the Plastic Gears Sector?

The global plastic gears market is experiencing robust growth, driven by the increasing demand for lightweight, corrosion-resistant components in various industries such as automotive, electronics, and medical equipment. Key trends include the rising adoption of advanced materials like polyacetal and PEEK, which enhance performance under varying temperature and load conditions. Additionally, technological innovations in manufacturing processes, including injection molding and advanced CAD design, are enabling manufacturers to produce complex gear shapes more efficiently and at lower costs.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must be aware of these trends as they influence sourcing decisions. The shift toward automation and Industry 4.0 technologies is also impacting the plastic gears sector, as companies seek to integrate smarter, more efficient components into their machinery. This trend is particularly evident in countries like Brazil and Germany, where manufacturers are investing in automation to improve production efficiency and reduce costs.

Moreover, the market dynamics are characterized by a growing emphasis on customization. Buyers increasingly seek suppliers who can provide tailored solutions, including specific gear sizes, tooth configurations, and material specifications. As competition intensifies, suppliers who can adapt quickly to changing demands will have a competitive edge.

How Can Sustainability and Ethical Sourcing Impact B2B Plastic Gear Purchases?

Sustainability is becoming a critical consideration for B2B buyers in the plastic gears sector. The environmental impact of plastic production, particularly concerning waste and resource depletion, is prompting companies to prioritize ethical sourcing and sustainable practices. Suppliers who utilize eco-friendly materials and processes are not only reducing their environmental footprint but also enhancing their appeal to environmentally conscious buyers.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers’ practices to ensure compliance with environmental regulations and standards. Certifications such as ISO 14001 (Environmental Management) and the use of recycled or bio-based plastics are becoming essential criteria in the sourcing process. This trend is particularly relevant in Europe, where stringent regulations govern plastic use and waste management.

Furthermore, the shift towards circular economy principles is influencing sourcing trends. Companies are exploring options for recycling and reusing plastic gears, which can significantly lower costs and minimize environmental impact. Buyers are encouraged to collaborate with suppliers who are committed to sustainability, as this can lead to long-term partnerships and shared value creation.

How Has the Plastic Gears Sector Evolved Over Time?

The evolution of the plastic gears sector reflects broader technological advancements and changing market needs. Initially, plastic gears were seen as a cost-effective alternative to metal gears, primarily used in low-load applications. However, innovations in material science and manufacturing techniques have transformed their capabilities, allowing for applications in high-load and high-temperature environments.

Illustrative image related to plastic gears

Over the years, the development of engineering plastics such as POM and MC Nylon has enhanced the performance of plastic gears, making them suitable for a wider range of industries. The integration of automation and digital technologies into manufacturing processes has further propelled the industry forward, enabling rapid prototyping and customization.

Today, plastic gears are a vital component in various sectors, from consumer electronics to automotive systems, underscoring their versatility and importance in modern engineering solutions. As the industry continues to innovate, international B2B buyers must stay informed about these advancements to make strategic sourcing decisions that align with their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic gears

-

1. How do I select the right plastic gear for my application?

Selecting the right plastic gear involves considering several factors, including material compatibility, load capacity, and environmental conditions. For instance, materials like polyacetal (POM) are suitable for applications requiring low friction and high dimensional stability. Evaluate the gear’s tooth design, module size, and the number of teeth to ensure it meets your operational needs. Additionally, consider factors such as operating temperature and potential exposure to chemicals, as these can affect gear performance and longevity. -

2. What are the advantages of using plastic gears over metal gears?

Plastic gears offer several advantages, including being lightweight, rust-resistant, and quieter during operation. They can also be produced at a lower cost through injection molding, making them ideal for high-volume applications. Furthermore, plastic gears can operate without lubrication when paired with metal gears, reducing maintenance requirements. However, it’s essential to consider their lower strength and potential for thermal expansion compared to metal counterparts, which may impact their performance in certain applications. -

3. What customization options are available for plastic gears?

Many suppliers offer customization options for plastic gears, including modifications to tooth profiles, bore sizes, and materials. Customization can enhance compatibility with existing systems and improve performance in specific applications. When discussing customization with suppliers, provide detailed specifications and requirements to ensure that the gears meet your operational needs. Be sure to inquire about the lead times and costs associated with custom orders. -

4. What is the typical minimum order quantity (MOQ) for plastic gears?

The minimum order quantity (MOQ) for plastic gears varies by manufacturer and can range from a few dozen to several hundred pieces. Factors influencing MOQ include the complexity of the gear design, materials used, and the supplier’s production capabilities. When sourcing from international suppliers, consider negotiating the MOQ based on your specific needs and potential for future orders, as some manufacturers may be flexible, especially for long-term partnerships. -

5. How can I ensure the quality of plastic gears I am sourcing?

To ensure the quality of plastic gears, conduct thorough supplier vetting by reviewing their certifications, quality control processes, and production capabilities. Request samples to evaluate the gear’s performance and suitability for your application. It’s also beneficial to inquire about the supplier’s adherence to international quality standards, such as ISO certifications. Establishing clear quality assurance (QA) protocols in your procurement process can help mitigate risks associated with sourcing. -

6. What payment terms should I expect when sourcing plastic gears internationally?

Payment terms when sourcing plastic gears can vary significantly between suppliers. Common terms include upfront payment, partial payment upon order confirmation, and the balance due upon delivery. Some suppliers may offer credit terms based on your purchasing history. Always clarify payment terms before finalizing contracts, and consider using secure payment methods, such as letters of credit, to protect your investment in international transactions. -

7. What logistics considerations should I keep in mind when sourcing plastic gears?

Logistics plays a crucial role in sourcing plastic gears internationally. Consider shipping methods, lead times, and customs regulations that may impact delivery schedules. Collaborate with your supplier to understand their shipping options and any potential delays due to customs clearance. It’s also wise to account for additional costs such as shipping fees, import duties, and insurance to ensure accurate budgeting for your procurement process. -

8. How do I handle issues with defective plastic gears after purchase?

If you encounter issues with defective plastic gears, promptly contact your supplier to report the problem. Document the defects with photos and detailed descriptions to facilitate the return or replacement process. Most reputable suppliers will have a return policy that covers defective items, but it’s essential to understand their specific terms and conditions. Establishing open communication with your supplier can help resolve issues quickly and maintain a positive business relationship.

Top 5 Plastic Gears Manufacturers & Suppliers List

1. KHK Gears – Plastic Gears

Domain: khkgears.net

Introduction: Plastic Gears – Lightweight and Rust-proof

Materials: Engineering plastics such as polyacetal (POM), MC Nylon (polyamid resin), U-PE, PEEK. Metal hubs (S45C or stainless steel) may be used for large diameters or loads.

Characteristics: Lightweight, non-rusting, quiet, low-cost production via injection molding, operates without lubrication with metal gears.

Cautions: Low strength, heat retention, d…

2. McMaster – Gears and Gear Racks

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Gears and Gear Racks, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. igus – Wear-Resistant Plastic Gears

Domain: igus.com

Registered: 1995 (30 years)

Introduction: Wear-Resistant Plastic Gears from iglide® by igus® are made of high-performance polymers designed for dry-running, maintenance-free operation. Key features include:

– Composed of wear-resistant base materials, reinforcing fibers for high forces, and embedded solid lubricants.

– Low friction, lightweight, and resistant to dirt, dust, corrosion, and chemicals.

– Available types: iglide® bevel gea…

4. Plastic Gears – Robotics Essentials

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Plastic gears for robotics projects, available from suppliers like SDP-SI, HPC Gears, and BC Robotics. Options for purchasing include choosing specific gears rather than assorted sets.

5. IQS Directory – Plastic Gears

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Plastic gears are toothed wheels made from advanced engineering plastics, primarily used to alter the speed ratio between a motor and its connected components. Popular engineering plastics include nylon and polyacetal. Manufacturing methods include:

1. **Plastic Gear Hobbing**: Uses a hob to carve gear teeth into a flat plastic disk, producing spur gears, helical gears, splines, worm wheels, and s…

Strategic Sourcing Conclusion and Outlook for plastic gears

How Can Strategic Sourcing Enhance Your Plastic Gear Procurement?

In the rapidly evolving landscape of industrial applications, plastic gears offer a compelling solution for businesses seeking lightweight, corrosion-resistant, and cost-effective components. Strategic sourcing plays a crucial role in optimizing procurement processes, allowing buyers to leverage global supply chains, minimize costs, and ensure consistent quality. By focusing on suppliers who provide engineering-grade plastics and innovative designs, such as those incorporating metal hubs for enhanced strength, companies can significantly improve operational efficiency.

International buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize partnerships with manufacturers who understand the specific demands of their industries, whether in consumer electronics or food production machinery. As technology advances, the potential for customized solutions and enhanced performance in plastic gears will only increase.

Looking ahead, businesses must stay informed about emerging materials and manufacturing techniques to remain competitive. By investing in strategic sourcing and forming collaborative relationships with suppliers, you can ensure your operations are well-equipped for future challenges. Take action now to explore how strategic sourcing can optimize your plastic gear procurement and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.