Flyknit Racer 1688 Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for flyknit racer 1688

The global demand for innovative footwear like the Flyknit Racer 1688 is surging, presenting significant sourcing challenges for B2B buyers in diverse markets, particularly in Africa, South America, the Middle East, and Europe. Buyers often grapple with identifying reliable suppliers, understanding the nuances of product specifications, and navigating fluctuating prices. This guide aims to address these challenges by providing a comprehensive overview of the Flyknit Racer 1688, including its various styles, applications, and features that cater to both athletic and casual wear.

Within this guide, you will find detailed insights into the different types of Flyknit Racers available in the market, along with expert advice on supplier vetting processes to ensure quality and reliability. Additionally, we will explore pricing structures, helping you to make informed purchasing decisions that align with your business objectives.

By equipping international B2B buyers with actionable insights and thorough market analysis, this guide empowers you to make strategic sourcing decisions that enhance your product offerings. Whether you are looking to expand your inventory or optimize your supply chain, understanding the dynamics of the Flyknit Racer 1688 market will provide you with a competitive edge in today’s rapidly evolving footwear landscape.

Understanding flyknit racer 1688 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Flyknit Racer | Lightweight knit upper, sock-like fit, minimalistic design | Retail, E-commerce, Sports Retail | Pros: Versatile for casual and athletic wear. Cons: Limited color options may affect branding. |

| Air Max Flyknit Racer | Incorporates Air Max cushioning, enhanced comfort and support | Performance Running, Lifestyle Branding | Pros: Excellent cushioning for long use. Cons: Higher price point may deter budget-conscious buyers. |

| Flyknit Racer ‘Cookies & Cream’ | Iconic colorway, adaptive and breathable knit construction | Fashion Retail, Limited Edition Drops | Pros: High demand for unique colorways. Cons: May have limited stock availability. |

| Flyknit Racer Black/White Neon | Bold color contrast, dynamic Flywire lacing system | Trendy Footwear Retail, Youth Markets | Pros: Eye-catching design appeals to younger demographics. Cons: May not be suitable for all markets. |

| Flyknit Racer Prototype | Sample model showcasing innovative design and sustainability | Design Exhibitions, Sustainable Fashion | Pros: Represents cutting-edge technology and eco-friendliness. Cons: Not available for mass retail. |

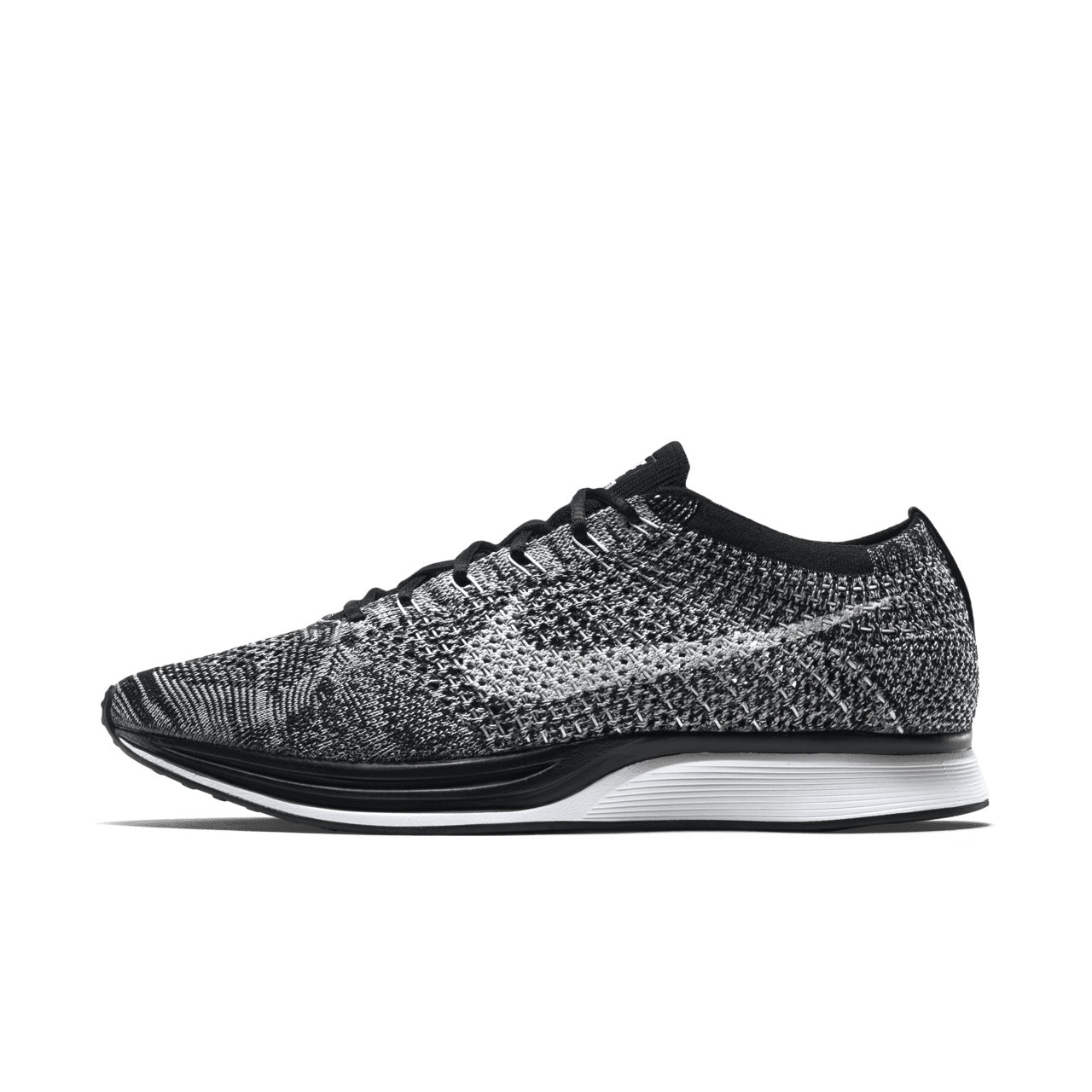

What are the characteristics of the Classic Flyknit Racer?

The Classic Flyknit Racer is known for its lightweight construction and sock-like fit, making it an ideal choice for both casual and athletic wear. Its minimalistic design allows for versatility in styling, appealing to a wide range of consumers. B2B buyers in retail and e-commerce can leverage this model for diverse customer bases, although they should consider the limited color options that may restrict branding opportunities.

How does the Air Max Flyknit Racer enhance performance?

This variation combines the traditional Flyknit upper with Nike’s Air Max cushioning technology, offering superior comfort and support during extended wear. It is particularly suited for performance running and lifestyle branding, making it appealing to businesses focused on athletic markets. However, the higher price point may be a consideration for budget-conscious buyers looking to maximize profit margins.

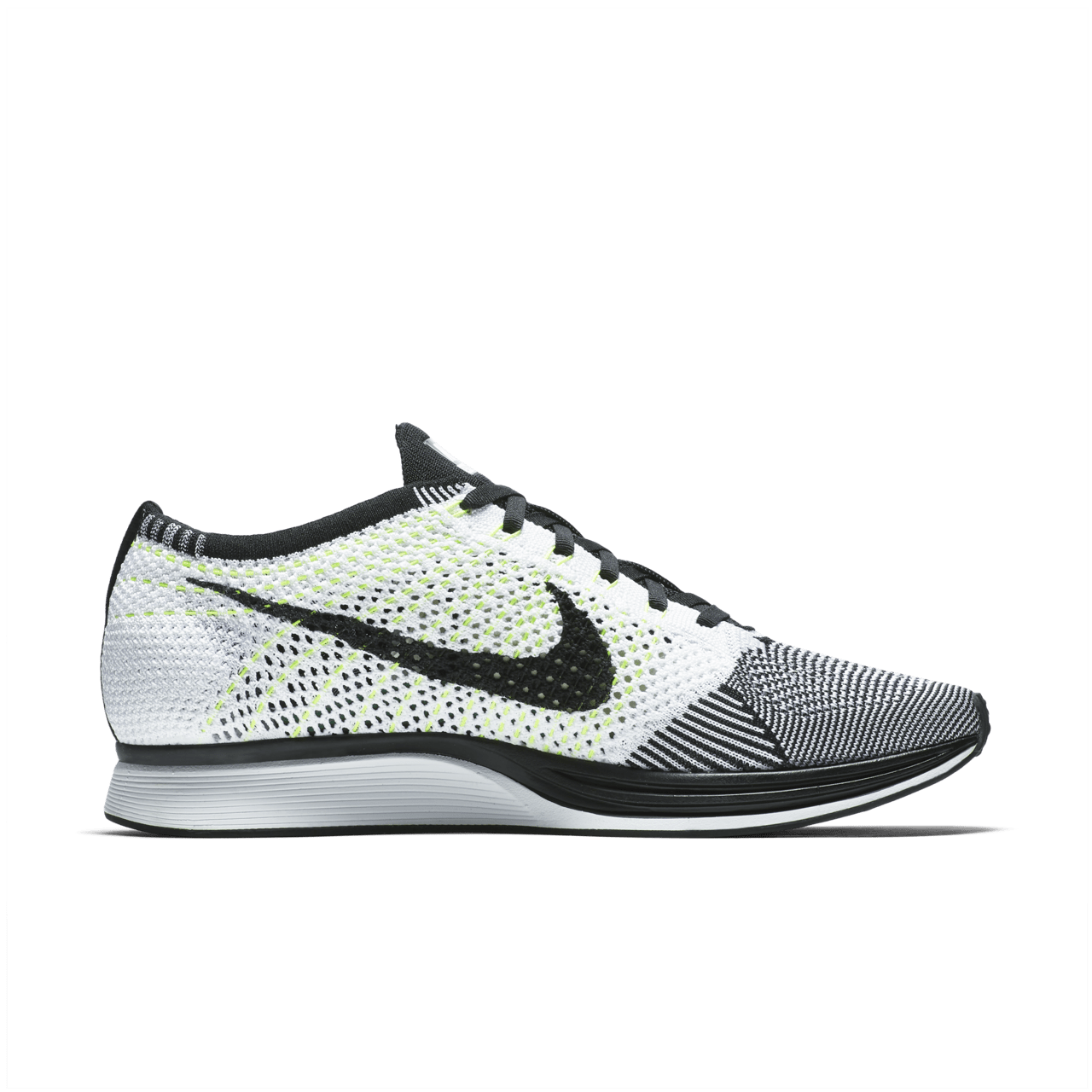

Illustrative image related to flyknit racer 1688

Why is the Flyknit Racer ‘Cookies & Cream’ popular among B2B buyers?

The Flyknit Racer ‘Cookies & Cream’ features a classic black and white colorway that is both stylish and versatile. Its adaptive and breathable knit construction makes it suitable for everyday wear, which can drive high demand in fashion retail and limited edition drops. However, buyers should be cautious of stock availability, as popular models may sell out quickly.

What makes the Flyknit Racer Black/White Neon appealing to youth markets?

With its bold color contrast and dynamic Flywire lacing system, the Flyknit Racer Black/White Neon is designed to capture the attention of younger demographics. This model is perfect for trendy footwear retail, but businesses should assess whether this design aligns with their target market, as it may not appeal universally.

How does the Flyknit Racer Prototype contribute to sustainable fashion?

As a sample model, the Flyknit Racer Prototype showcases Nike’s commitment to innovative design and sustainability, featuring a knitted upper that minimizes material waste. This aspect makes it particularly relevant for businesses involved in design exhibitions and sustainable fashion. However, since it is not available for mass retail, its application is limited to specific contexts focused on showcasing cutting-edge technology.

Illustrative image related to flyknit racer 1688

Key Industrial Applications of flyknit racer 1688

| Industry/Sector | Specific Application of flyknit racer 1688 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Production of high-performance running shoes | Enhanced product appeal and market competitiveness | Supplier reliability, material quality, and cost efficiency |

| Sports Retail | Retailing lifestyle and athletic footwear | Increased sales from trendy, innovative designs | Stock availability, marketing support, and distribution channels |

| Athletic Apparel | Integration in sports clothing lines | Cross-selling opportunities and brand synergy | Branding alignment, customization options, and MOQ flexibility |

| E-commerce | Online sales of niche footwear collections | Access to a global market and customer base | Logistics capabilities, return policies, and payment security |

| Sustainable Fashion | Development of eco-friendly footwear | Meeting consumer demand for sustainable products | Certifications for sustainability, production transparency, and sourcing ethics |

How is flyknit racer 1688 Used in Footwear Manufacturing?

In the footwear manufacturing sector, the flyknit racer 1688 is leveraged to create high-performance running shoes that cater to both amateur and professional athletes. The unique Flyknit technology provides a lightweight, breathable, and form-fitting upper, which enhances comfort and performance. For international B2B buyers, sourcing considerations include ensuring the quality of materials used and the reliability of suppliers to meet production timelines while maintaining cost efficiency.

What Role Does the flyknit racer 1688 Play in Sports Retail?

In sports retail, the flyknit racer 1688 serves as a key product that appeals to consumers seeking trendy and innovative footwear. Retailers can capitalize on the unique design and performance features of these shoes, which can drive increased sales. For buyers in regions like Africa and South America, stock availability and effective marketing support are crucial to successfully promote these products in competitive markets.

How Can Athletic Apparel Brands Benefit from flyknit racer 1688?

Athletic apparel brands can integrate the flyknit racer 1688 into their product lines, creating synergy between footwear and clothing collections. This integration allows for cross-selling opportunities, enhancing brand visibility and customer loyalty. Buyers should consider branding alignment and customization options when sourcing these products to ensure they resonate with their target audience.

Why is E-commerce a Suitable Channel for flyknit racer 1688?

E-commerce platforms provide an ideal channel for selling the flyknit racer 1688, allowing businesses to reach a global customer base. This accessibility can significantly enhance sales potential, especially in regions with growing online shopping trends. B2B buyers should focus on logistics capabilities and return policies when sourcing these products to ensure a smooth customer experience.

How Does Sustainable Fashion Incorporate flyknit racer 1688?

Sustainable fashion initiatives can incorporate the flyknit racer 1688 by focusing on its eco-friendly production methods, which minimize waste through precise material usage. This aligns with the increasing consumer demand for sustainable products. Buyers should verify sustainability certifications and ensure transparency in sourcing to meet market expectations and enhance brand reputation.

Illustrative image related to flyknit racer 1688

3 Common User Pain Points for ‘flyknit racer 1688’ & Their Solutions

Scenario 1: Sourcing Quality Flyknit Racer 1688 Shoes for Retail

The Problem: B2B buyers often face the challenge of sourcing high-quality Flyknit Racer 1688 shoes that meet the standards of their customer base. In regions like Africa and South America, where counterfeit products are prevalent, it can be difficult to distinguish between authentic and inferior quality items. Retailers are concerned about their reputation and the potential for financial loss if they stock subpar products that do not meet customer expectations.

The Solution: To successfully source genuine Flyknit Racer 1688 shoes, buyers should establish direct relationships with authorized distributors or manufacturers. Conduct thorough research to identify reputable suppliers who can provide verified proof of authenticity, such as product certifications or quality assurance documentation. Attending industry trade shows and exhibitions can also facilitate connections with trustworthy suppliers. Additionally, consider implementing a small-scale trial order to assess product quality before making larger purchases. This approach not only minimizes risk but also allows buyers to evaluate customer response to the product.

Scenario 2: Managing Inventory for Seasonal Demand Fluctuations

The Problem: Buyers in the B2B market frequently struggle with managing inventory levels for the Flyknit Racer 1688, especially during seasonal peaks. For instance, in Europe, demand can spike during the spring and summer months as consumers seek stylish and breathable footwear. Conversely, excess inventory during off-peak seasons can lead to increased holding costs and reduced cash flow.

The Solution: To optimize inventory management, B2B buyers should utilize data analytics tools that forecast demand based on historical sales trends and market insights. Implementing just-in-time (JIT) inventory practices can also help in aligning stock levels with actual demand, reducing the risk of overstocking. Establishing a flexible supply chain with suppliers who can respond quickly to changing demand will further enhance inventory control. Additionally, consider diversifying the product line by including complementary items, such as socks or apparel, to maintain sales momentum during slower periods.

Illustrative image related to flyknit racer 1688

Scenario 3: Addressing Consumer Concerns Over Sustainability

The Problem: There is a growing consumer focus on sustainability, particularly in the European market. B2B buyers may encounter challenges when trying to convince their customers that the Flyknit Racer 1688 aligns with environmentally-friendly practices. Concerns about production processes and material sourcing can deter potential buyers who prioritize eco-conscious products.

The Solution: To address these concerns, B2B buyers should educate themselves and their customers about the sustainability features of the Flyknit Racer 1688. Highlight the innovative Flyknit technology, which reduces waste by using precise knitting techniques that minimize leftover material. Providing transparency about the supply chain and production practices can build trust with consumers. Additionally, consider developing marketing materials that emphasize these eco-friendly aspects and position the Flyknit Racer 1688 as a sustainable choice. Engaging in partnerships with sustainability-focused organizations can also enhance credibility and appeal to environmentally-conscious customers.

Strategic Material Selection Guide for flyknit racer 1688

What Are the Key Materials Used in the Flyknit Racer 1688?

The Flyknit Racer 1688 utilizes a variety of materials that enhance its performance, comfort, and aesthetic appeal. Understanding these materials is crucial for international B2B buyers looking to make informed purchasing decisions.

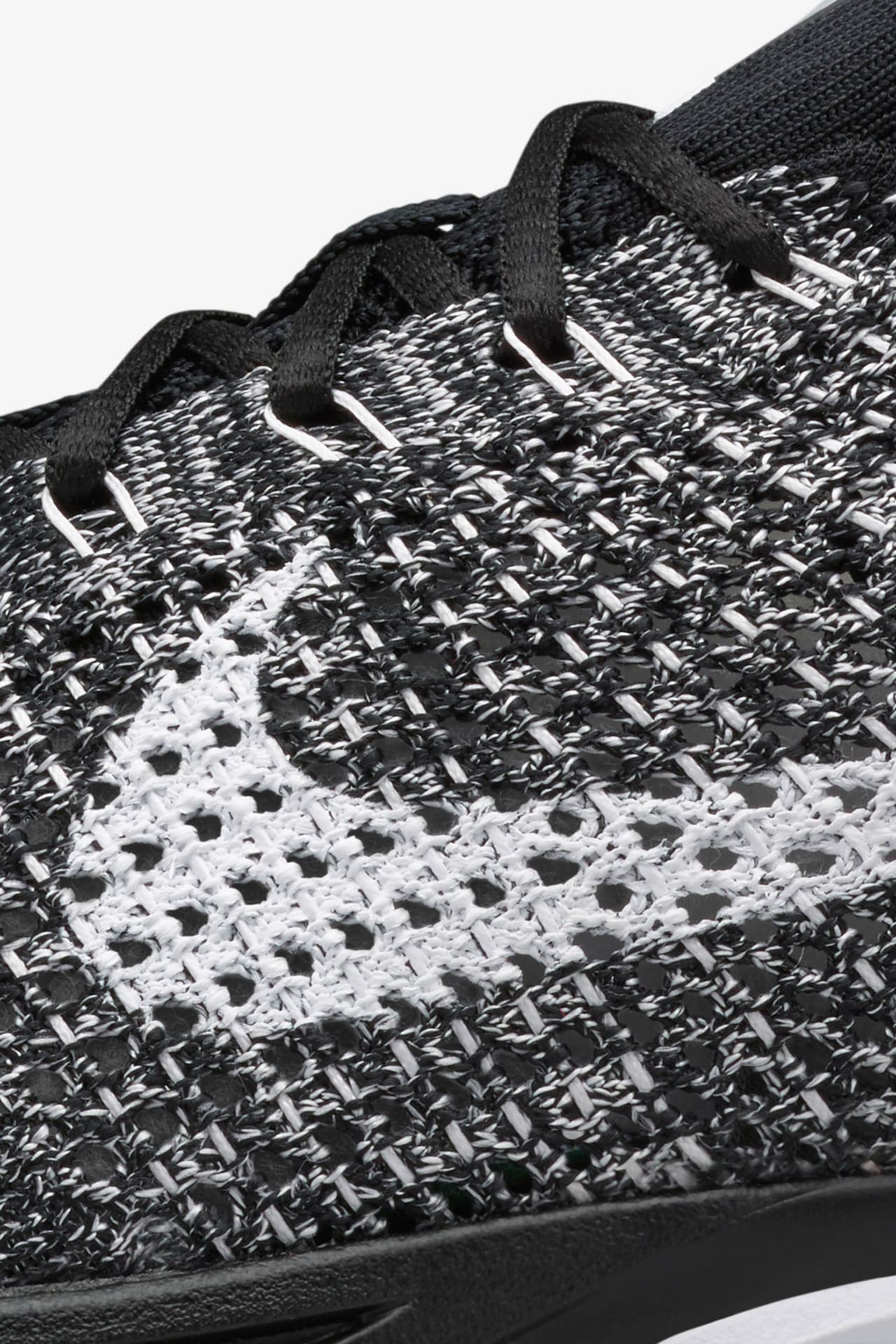

How Does Flyknit Technology Enhance Performance?

Flyknit Upper: The Flyknit upper is a hallmark of the Flyknit Racer, made from a lightweight polyester blend. This material offers excellent breathability and flexibility, allowing the shoe to adapt to the wearer’s foot shape. The seamless construction minimizes weight and enhances comfort, making it suitable for both athletic and casual use. However, while Flyknit is durable, it may not withstand extreme abrasion as well as traditional materials.

Illustrative image related to flyknit racer 1688

Pros: Lightweight, breathable, customizable fit.

Cons: Less resistant to wear in rugged environments, potentially higher manufacturing complexity due to the knitting process.

What Role Does Synthetic Suede Play in Design?

Synthetic Suede Detailing: Synthetic suede is often used in detailing on the Flyknit Racer, providing a classic touch to the modern design. This material is known for its soft texture and aesthetic appeal, which can enhance the shoe’s overall look. It is also relatively easy to clean and maintain, making it suitable for various environments.

Pros: Aesthetically pleasing, easy to maintain, adds a premium feel.

Cons: Can be less durable than genuine leather, may not provide the same level of breathability.

Illustrative image related to flyknit racer 1688

How Important is the Foam Midsole for Comfort?

Foam Midsole: The foam midsole is crucial for cushioning and shock absorption, providing a springy feel during activities. This material is lightweight and helps reduce fatigue during prolonged wear, making it ideal for both running and casual use. However, the foam may compress over time, potentially affecting long-term comfort.

Pros: Excellent cushioning, lightweight, enhances comfort.

Cons: May degrade faster than other materials, potentially requiring replacement sooner.

What Benefits Does Rubber Provide for Traction?

Rubber Outsole: The rubber outsole is essential for traction and durability. It provides grip on various surfaces, making the Flyknit Racer suitable for both indoor and outdoor activities. Rubber is highly resistant to wear and tear, ensuring longevity. However, the weight of the rubber can slightly increase the overall weight of the shoe.

Pros: High durability, excellent traction, resistant to wear.

Cons: Can add weight to the shoe, may not be as flexible as other materials.

What Should International Buyers Consider When Selecting Materials?

International B2B buyers must consider various factors when selecting materials for the Flyknit Racer 1688. Compliance with local regulations and standards, such as ASTM in the U.S. or DIN in Germany, is crucial. Additionally, preferences for sustainable materials are growing, especially in markets like Europe. Buyers from Africa and South America should also be aware of local climate conditions that may affect material performance.

Summary Table of Key Materials for Flyknit Racer 1688

| Material | Typical Use Case for Flyknit Racer 1688 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flyknit Upper | Upper construction for breathability | Lightweight and flexible | Less abrasion-resistant | Medium |

| Synthetic Suede | Detailing for aesthetics | Soft texture, easy to maintain | Less durable than genuine leather | Medium |

| Foam Midsole | Cushioning and shock absorption | Excellent comfort | May compress over time | Medium |

| Rubber Outsole | Traction and durability | High durability and grip | Can add weight | Low |

This comprehensive analysis provides B2B buyers with actionable insights into the materials used in the Flyknit Racer 1688, helping them make informed decisions that align with their market needs and preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for flyknit racer 1688

What Are the Key Stages in the Manufacturing Process of the Flyknit Racer 1688?

The manufacturing process of the Flyknit Racer 1688 is a sophisticated operation that integrates advanced technology and traditional craftsmanship. The production typically involves four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality materials. The Flyknit upper is made from a lightweight, breathable polyester yarn that is engineered for performance. This material is carefully selected for its strength and flexibility, ensuring a snug fit that adapts to the wearer’s foot. Additionally, the rubber soles are sourced for their durability and traction.

-

Forming: The Flyknit technology allows for precise knitting of the upper material. This is achieved through a computer-aided design system that programs the knitting machines to create the desired patterns and structures. The seamless construction minimizes waste, aligning with sustainable manufacturing practices. This stage is crucial as it defines the shoe’s fit and comfort.

-

Assembly: Once the upper is formed, it is combined with the sole. The assembly process involves a dynamic Flywire lacing system that provides additional support. This system is integrated into the upper during assembly to ensure a secure fit. The combination of the Flyknit upper and the Zoom Air unit in the heel is designed to deliver responsive cushioning, making this stage critical for performance.

-

Finishing: The final stage includes quality checks and aesthetic enhancements. Each pair is inspected for any defects in stitching or material. Branding elements are applied, and the shoes are cleaned and packaged for distribution. This stage ensures that the final product meets the brand’s high standards and is ready for the market.

How Is Quality Assurance Implemented in the Production of Flyknit Racer 1688?

Quality assurance (QA) is a fundamental aspect of the Flyknit Racer 1688 manufacturing process. It ensures that the product meets both industry standards and customer expectations. The QA framework typically includes adherence to international standards such as ISO 9001, which focuses on quality management systems, and may also encompass industry-specific certifications like CE and API.

-

Quality Control Checkpoints: Several quality control checkpoints are established throughout the manufacturing process:

– Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality and compliance with specifications. Any materials that do not meet the required standards are rejected.

– In-Process Quality Control (IPQC): During the forming and assembly stages, random samples are taken to ensure that production standards are being upheld. This includes checks on stitch density, material integrity, and the fit of the shoe.

– Final Quality Control (FQC): After finishing, each pair undergoes a thorough inspection. This includes checking for defects, ensuring proper branding, and verifying that the packaging meets quality standards. -

Common Testing Methods: Various testing methods are employed to assess the performance and durability of the Flyknit Racer 1688. This includes:

– Abrasion Resistance Testing: To ensure the shoes can withstand wear and tear.

– Flexibility Testing: To confirm that the shoe maintains its shape and comfort over time.

– Breathability Testing: To verify that the Flyknit upper performs under different conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential for ensuring product reliability. Here are actionable steps buyers can take:

Illustrative image related to flyknit racer 1688

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. During these audits, buyers should assess compliance with international standards and the effectiveness of the QC checkpoints outlined earlier.

-

Requesting Quality Reports: Buyers should ask suppliers for documented quality reports. These reports should detail the results of IQC, IPQC, and FQC processes, including any corrective actions taken for non-compliance.

-

Third-Party Inspections: Engaging third-party inspection agencies can add another layer of verification. These agencies can conduct independent assessments of the manufacturing facilities and processes, ensuring that they adhere to both local and international quality standards.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers face unique challenges when it comes to quality control. Understanding these nuances can help in making informed purchasing decisions:

-

Cultural Differences in Quality Standards: Different regions may have varying expectations regarding quality. For example, European standards may be more stringent compared to those in other regions. B2B buyers should be aware of these differences and communicate their expectations clearly with suppliers.

-

Regulatory Compliance: Depending on the destination market, specific regulatory compliance may be required. For instance, products sold in Europe must comply with CE marking requirements, while other regions may have different standards. Buyers should ensure that suppliers are familiar with and adhere to these regulations.

-

Logistical Considerations: Quality assurance doesn’t end at the factory. Buyers must consider how products are handled during transportation. Ensuring that suppliers have robust logistics practices in place can help maintain product quality from the manufacturing facility to the end user.

In conclusion, understanding the manufacturing processes and quality assurance measures for the Flyknit Racer 1688 is crucial for B2B buyers. By focusing on the key manufacturing stages, implementing effective quality control practices, and verifying supplier standards, buyers can ensure that they procure high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flyknit racer 1688’

Introduction

Sourcing the ‘Flyknit Racer 1688’ requires a strategic approach to ensure quality, price competitiveness, and timely delivery. This guide provides a step-by-step checklist designed specifically for B2B buyers, particularly those operating in diverse international markets such as Africa, South America, the Middle East, and Europe. By following these steps, you can streamline the procurement process and secure a reliable supply of this innovative footwear.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for sourcing Flyknit Racers. Detail the materials, sizes, and colorways you require, as well as any performance features, such as breathability or cushioning technology. This ensures that potential suppliers understand your needs and can provide the appropriate products.

- Material Requirements: Specify the type of Flyknit and any additional materials (e.g., rubber soles).

- Performance Features: Include desired technologies like Air Max cushioning or Dynamic Flywire lacing.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in Flyknit technology and have a proven track record. Look for manufacturers with experience in producing high-quality running shoes.

Illustrative image related to flyknit racer 1688

- Supplier Directories: Utilize platforms like Alibaba or global trade directories.

- Industry Events: Attend trade shows or exhibitions to meet suppliers in person.

Step 3: Evaluate Supplier Certifications

Before proceeding with a supplier, verify their certifications and compliance with international quality standards. Certifications such as ISO 9001 or relevant environmental standards can indicate a commitment to quality and sustainability.

- Quality Assurance Processes: Inquire about their quality control measures.

- Sustainability Practices: Assess their environmental policies, particularly in relation to the Flyknit manufacturing process.

Step 4: Request Samples for Testing

Always request samples before making a bulk order. Testing samples allows you to assess the quality, fit, and comfort of the Flyknit Racers to ensure they meet your specifications.

- Testing Criteria: Evaluate the breathability, flexibility, and overall comfort of the shoes.

- Feedback Loop: Gather feedback from your team or target market to make informed decisions.

Step 5: Negotiate Terms and Pricing

Engage in negotiations with potential suppliers to finalize pricing, payment terms, and delivery schedules. It’s essential to establish clear terms to avoid misunderstandings later.

Illustrative image related to flyknit racer 1688

- Volume Discounts: Discuss pricing based on order quantities.

- Payment Methods: Explore secure payment options that protect both parties.

Step 6: Establish a Clear Communication Channel

Maintain open lines of communication with your chosen supplier throughout the procurement process. Clear communication can prevent delays and misunderstandings regarding production timelines and order specifications.

- Regular Updates: Schedule check-ins to discuss production progress.

- Crisis Management: Agree on procedures for addressing any potential issues.

Step 7: Plan for Quality Assurance Upon Delivery

Once the order is delivered, implement a quality assurance process to inspect the Flyknit Racers. This step is crucial to ensure that the products meet your initial specifications and quality expectations.

- Inspection Criteria: Check for defects, color discrepancies, and sizing issues.

- Feedback for Future Orders: Document any concerns to address with the supplier for future orders.

By following this checklist, B2B buyers can effectively navigate the sourcing process for the Flyknit Racer 1688, ensuring a successful procurement experience that aligns with their business objectives.

Comprehensive Cost and Pricing Analysis for flyknit racer 1688 Sourcing

What Are the Key Cost Components for Sourcing Flyknit Racer 1688?

When evaluating the total cost structure for sourcing the Flyknit Racer 1688, several key components come into play:

-

Materials: The Flyknit technology involves high-quality, lightweight materials that contribute to the shoe’s performance and comfort. Key components include polyester for the upper, rubber for the sole, and foam for cushioning. The cost of these materials can fluctuate based on market demand, sourcing locations, and supplier negotiations.

-

Labor: Labor costs can vary significantly by region. In countries with lower labor costs, such as some Southeast Asian nations, the overall production costs may be reduced. Conversely, sourcing from regions with higher labor standards, like parts of Europe, may increase costs but could also enhance quality assurance.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment depreciation. Efficient production processes can help minimize overhead, while advanced manufacturing technologies can offer cost-saving advantages.

-

Tooling: Customization options, such as unique colorways or design modifications, often require specific tooling. The initial investment in tooling can be substantial, but it becomes more cost-effective at higher production volumes.

-

Quality Control (QC): Ensuring product quality is essential, particularly for international markets. Implementing stringent QC processes may incur additional costs but is critical to minimize returns and maintain brand reputation.

-

Logistics: Shipping and handling costs vary based on the chosen Incoterms and shipping methods. Air freight is faster but more expensive than sea freight, which is more cost-effective for larger orders. Understanding the implications of logistics on total costs is crucial for B2B buyers.

-

Margin: Manufacturers typically add a profit margin to cover their business expenses and desired profit. This margin can vary based on the supplier’s pricing strategy, market competition, and perceived value of the product.

How Do Price Influencers Impact Sourcing Flyknit Racer 1688?

Several factors influence pricing for the Flyknit Racer 1688:

-

Volume/MOQ: Minimum Order Quantities (MOQs) significantly impact pricing. Larger orders generally lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their market demand.

-

Specifications and Customization: Custom features or specific design requirements may increase costs. Buyers should clearly define their specifications to avoid unexpected expenses during production.

-

Materials and Quality Certifications: Premium materials and recognized quality certifications can elevate costs. Buyers should assess whether the quality justifies the higher price, especially for target markets that prioritize durability and performance.

-

Supplier Factors: The supplier’s reputation, production capabilities, and geographic location can influence pricing. Established suppliers with proven track records may command higher prices but often provide greater reliability.

-

Incoterms: Understanding Incoterms is vital for cost management. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) affect who bears shipping costs and risks, impacting the total cost of ownership.

What Tips Can Buyers Use to Optimize Costs When Sourcing Flyknit Racer 1688?

International B2B buyers can adopt several strategies to enhance cost-efficiency:

-

Negotiation: Engage suppliers in open discussions about pricing, payment terms, and potential discounts for bulk orders. Building long-term relationships can also lead to better terms over time.

-

Total Cost of Ownership: Consider not only the purchase price but also additional costs such as shipping, tariffs, and potential returns. A lower upfront cost may not always translate to the best value.

-

Pricing Nuances: Different markets may have varying price sensitivities. For example, buyers in Europe might prioritize quality over price, while those in Africa or South America may seek more budget-friendly options. Tailoring your approach based on market characteristics can yield better results.

-

Market Research: Regularly analyze market trends and competitor pricing. This insight allows for informed negotiations and helps identify the best suppliers.

-

Supplier Diversification: Avoid relying solely on one supplier. Engaging multiple suppliers can foster competition, potentially driving down costs while also reducing supply chain risks.

By understanding these cost components and price influencers, B2B buyers can make informed sourcing decisions that align with their business objectives and market demands.

Alternatives Analysis: Comparing flyknit racer 1688 With Other Solutions

Exploring Alternatives to Flyknit Racer 1688

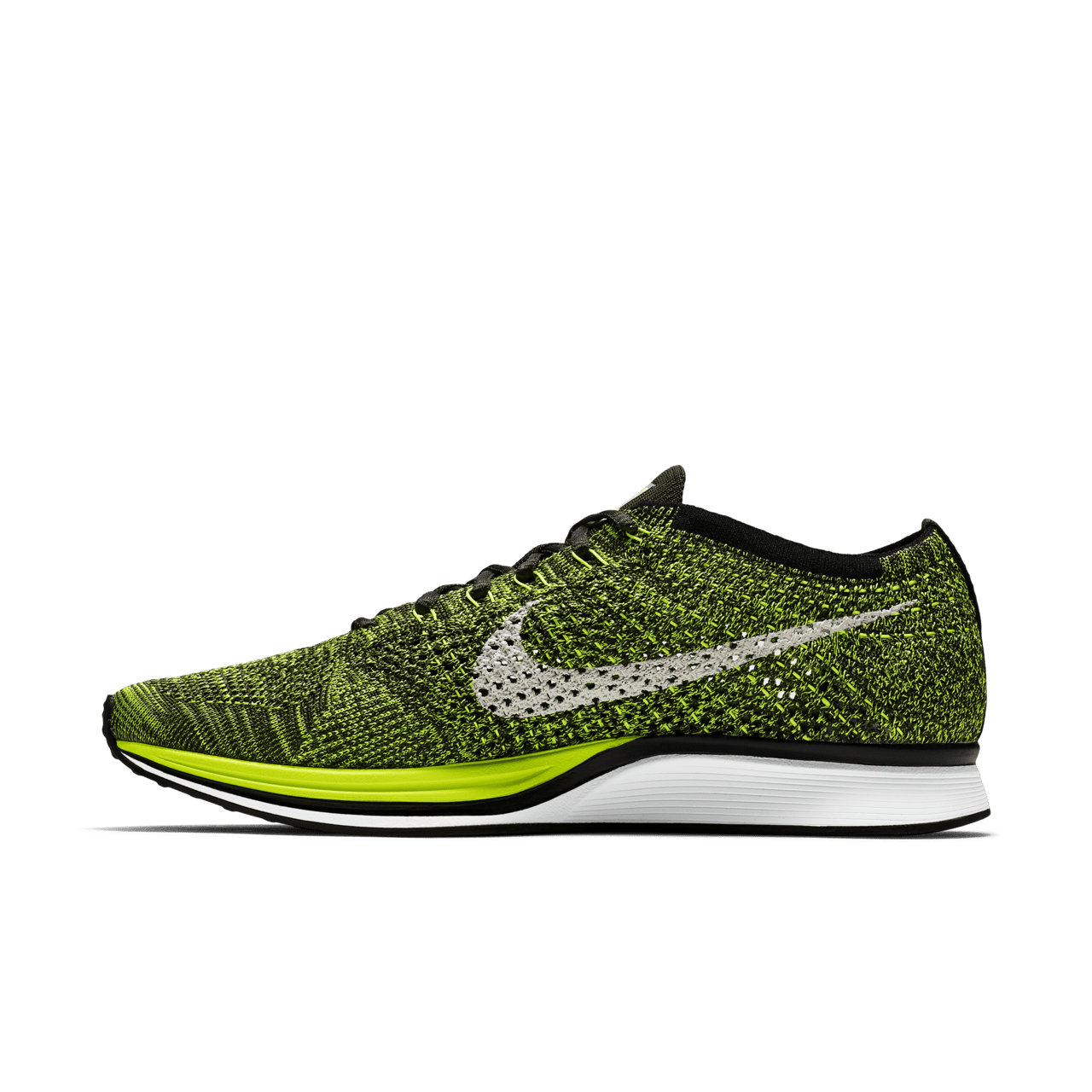

In the rapidly evolving world of athletic footwear, the Flyknit Racer 1688 stands out due to its innovative design and technology. However, buyers often seek alternatives that may better fit their specific needs, whether in terms of performance, cost, or application. This analysis will compare the Flyknit Racer 1688 against two viable alternatives: the Adidas Ultraboost and the New Balance Fresh Foam Zante. Each of these options offers unique advantages that may appeal to different segments of the market.

| Comparison Aspect | Flyknit Racer 1688 | Adidas Ultraboost | New Balance Fresh Foam Zante |

|---|---|---|---|

| Performance | Lightweight, breathable, responsive | Superior cushioning, energy return | Good cushioning, stable fit |

| Cost | $160 (standard retail) | $180 (standard retail) | $120 (standard retail) |

| Ease of Implementation | Requires careful fit adjustments | True to size; minimal adjustment needed | True to size; easy to wear |

| Maintenance | Easy to clean, durable materials | Machine washable, durable | Easy to clean, but less durable |

| Best Use Case | Casual wear and light running | Long-distance running and casual wear | Everyday wear and moderate running |

In-Depth Look at Alternatives

What Makes Adidas Ultraboost a Strong Contender?

The Adidas Ultraboost is celebrated for its superior cushioning and energy return, making it a top choice for long-distance runners. The Boost technology provides a soft yet responsive ride, which can be particularly appealing for athletes who prioritize comfort during extended runs. However, the Ultraboost comes at a higher price point than the Flyknit Racer 1688, which could be a deterrent for budget-conscious buyers. Additionally, while the shoe offers excellent performance, its slightly heavier weight may not appeal to those seeking a more minimalist design.

Why Choose New Balance Fresh Foam Zante?

The New Balance Fresh Foam Zante is an excellent alternative for those looking for a balance between comfort and price. Priced lower than both the Flyknit Racer 1688 and the Ultraboost, it offers good cushioning and a stable fit, making it suitable for everyday wear as well as moderate running. However, compared to the Flyknit Racer, it may lack some of the advanced technology and breathability features that serious runners seek. Its durability is also a concern for some users, as it may not withstand extensive wear over time.

Illustrative image related to flyknit racer 1688

Making the Right Choice for Your Needs

When deciding between the Flyknit Racer 1688 and its alternatives, B2B buyers should consider their specific use cases and target market preferences. For those focused on performance and cushioning, the Adidas Ultraboost may be the ideal choice, despite its higher cost. Conversely, if affordability and everyday usability are key factors, the New Balance Fresh Foam Zante presents a compelling option. Ultimately, understanding the unique features and benefits of each product will empower buyers to make informed purchasing decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for flyknit racer 1688

What Are the Key Technical Properties of the Flyknit Racer 1688?

Understanding the essential technical properties of the Flyknit Racer 1688 is crucial for B2B buyers to make informed purchasing decisions. Here are some of the critical specifications:

-

Material Composition

The Flyknit Racer 1688 features a lightweight knit upper made from polyester and nylon. This unique material provides flexibility and breathability, ensuring comfort during extended wear. The importance of material composition cannot be overstated, as it directly impacts the shoe’s performance, durability, and overall user experience. -

Weight Specifications

Weighing approximately 200 grams (7 oz) per shoe, the Flyknit Racer is designed for optimal performance without compromising on support. A lightweight design is essential in the athletic footwear industry, as it enhances agility and reduces fatigue during physical activities, making it appealing to athletes and casual wearers alike. -

Cushioning Technology

The shoe incorporates Nike’s Zoom Air cushioning in the heel, providing responsive support and shock absorption. This cushioning technology is vital for reducing impact during high-intensity activities, offering a competitive edge in the market. B2B buyers should recognize the significance of cushioning systems when sourcing products for performance-oriented consumers. -

Fit and Sizing

The Flyknit Racer features a sock-like fit, enhanced by a Dynamic Flywire lacing system that adapts to the foot’s shape. Proper fit is critical in footwear, as it affects comfort and performance. Buyers should prioritize shoes that offer customizable fit options to cater to diverse consumer needs. -

Sustainability Features

The Flyknit technology allows for a significant reduction in material waste during production, which is increasingly important in today’s eco-conscious market. Sustainable manufacturing processes can enhance brand reputation and appeal to environmentally aware consumers, making it a valuable consideration for B2B buyers. -

Design Aesthetics

The Flyknit Racer is known for its minimalist yet striking design. Aesthetics play a vital role in the buying decision, especially in the fashion-forward sneaker segment. Buyers should evaluate design trends to ensure their inventory aligns with consumer preferences.

What Are the Common Trade Terms Associated with Flyknit Racer 1688?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some commonly used trade terms relevant to the Flyknit Racer 1688:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components or products that are sold by another brand under its own name. For B2B buyers, understanding OEM relationships can help in sourcing high-quality products while maintaining brand integrity. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to gauge financial commitments and inventory management. It also helps in planning procurement strategies to meet market demand without overextending resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. This term is vital in the procurement process, as it enables buyers to compare pricing and terms across different suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are standardized international shipping terms that define the responsibilities of buyers and sellers. Understanding these terms is essential for B2B transactions, as they clarify shipping costs, risk transfer, and delivery obligations, thereby minimizing potential disputes. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. For B2B buyers, understanding lead times is critical for inventory management and ensuring timely product availability in the market. -

Sample Order

A sample order is a request for a small quantity of a product for evaluation before placing a larger order. This practice is particularly important in footwear, as it allows buyers to assess quality, fit, and aesthetics before committing to significant purchases.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the complexities of sourcing the Flyknit Racer 1688 more effectively, leading to better purchasing decisions and enhanced market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the flyknit racer 1688 Sector

What Are the Key Market Dynamics and Trends Influencing the Flyknit Racer 1688 Sector?

The global footwear market, particularly the Flyknit Racer 1688 segment, is experiencing transformative shifts driven by various factors. Firstly, the growing demand for lightweight and breathable footwear among health-conscious consumers is propelling sales. The Flyknit technology, known for its adaptive fit and reduced weight, is becoming increasingly popular among athletes and casual users alike, especially in regions like Africa, South America, the Middle East, and Europe. For instance, the resurgence of retro styles and colorways, such as the ‘Cookies & Cream’ and ‘Volt’ variants, showcases a blend of nostalgia and modern innovation that appeals to diverse markets.

Moreover, advancements in e-commerce are reshaping how B2B buyers source Flyknit Racers. Online platforms are becoming essential for international buyers seeking competitive pricing and exclusive releases. This trend is particularly significant in emerging markets where traditional retail infrastructure may be lacking. B2B buyers are leveraging digital tools to analyze market trends, customer preferences, and inventory levels, enabling them to make informed purchasing decisions.

Another critical trend is the emphasis on personalization and customization. As brands explore ways to stand out in a crowded market, offering bespoke options is becoming a selling point. This trend aligns with the increasing expectation for unique products among consumers, especially in regions with a burgeoning sneaker culture, such as Brazil and Germany.

Illustrative image related to flyknit racer 1688

How Does Sustainability Influence Sourcing Trends in the Flyknit Racer 1688 Sector?

Sustainability is no longer a mere trend; it has become a vital consideration for international B2B buyers in the Flyknit Racer 1688 sector. The environmental impact of footwear production is substantial, with traditional manufacturing methods contributing to significant waste and pollution. In contrast, Flyknit technology offers a more sustainable approach. It utilizes a single thread to create the shoe’s upper, significantly reducing material waste compared to conventional shoe manufacturing processes.

Furthermore, ethical sourcing is gaining traction as consumers become increasingly aware of the social and environmental implications of their purchases. B2B buyers are now prioritizing suppliers who adhere to ethical practices, such as fair labor conditions and sustainable sourcing of materials. Green certifications, such as the Global Organic Textile Standard (GOTS) and the OEKO-TEX certification, are becoming essential for suppliers seeking to attract conscientious buyers. By aligning their sourcing strategies with sustainability goals, B2B companies can enhance their brand reputation and appeal to a growing segment of environmentally conscious consumers.

What Is the Historical Context of the Flyknit Racer Technology?

The evolution of the Flyknit Racer technology has been a significant milestone in the athletic footwear industry. Launched in 2012, this innovation stemmed from Nike’s commitment to creating a lightweight, form-fitting shoe that enhances performance while minimizing environmental impact. The development process took five years and involved extensive research and feedback from athletes, ensuring that the final product met the exact specifications required for optimal performance.

This technology not only redefined performance footwear but also set a precedent for sustainable manufacturing practices in the industry. As B2B buyers increasingly recognize the value of innovative and sustainable products, the Flyknit Racer continues to serve as a benchmark for quality and responsibility in the footwear market. Understanding this historical context allows buyers to appreciate the product’s value and the potential for future innovations in the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of flyknit racer 1688

-

How do I ensure the quality of Flyknit Racer 1688 sneakers from suppliers?

To guarantee quality, start by vetting suppliers through platforms like Alibaba or Global Sources, checking their ratings and reviews. Request samples before placing a bulk order to assess the material, stitching, and overall craftsmanship. Additionally, inquire about their quality assurance processes, such as inspections during production and before shipment. Establishing clear communication and setting quality standards in your contract can further ensure that the products meet your expectations. -

What customization options are available for Flyknit Racer 1688 sneakers?

Customization options for Flyknit Racer 1688 sneakers often include color choices, branding with logos, and specific material selections. Many manufacturers are willing to accommodate unique requests, especially for bulk orders. It’s advisable to clearly outline your customization needs during initial discussions and verify any associated costs. Ensure that the supplier has the capacity and technology to deliver your specific requirements to avoid delays in production. -

What is the minimum order quantity (MOQ) for Flyknit Racer 1688 sneakers?

The MOQ for Flyknit Racer 1688 sneakers can vary widely among suppliers, typically ranging from 100 to 1,000 pairs. This quantity often depends on the manufacturer’s production capabilities and the level of customization required. When negotiating with suppliers, express your needs clearly and inquire if they can accommodate smaller orders, especially if you are testing a new market or product line. -

What payment terms should I expect when sourcing Flyknit Racer 1688?

Payment terms for Flyknit Racer 1688 sneakers usually depend on the supplier’s policies and your negotiation. Common arrangements include a 30% deposit upfront with the balance due before shipment or upon delivery. Some suppliers may offer letters of credit or escrow services for added security. Always ensure that the payment terms are documented in your contract to avoid misunderstandings and to protect your investment. -

How do I handle logistics and shipping for Flyknit Racer 1688 orders?

Managing logistics involves selecting a reliable shipping method that aligns with your budget and timeline. Options include sea freight for cost-effectiveness or air freight for quicker delivery. Collaborate with your supplier to determine the best shipping method and ensure they provide necessary documentation, such as bills of lading and customs clearance forms. Engaging a freight forwarder can also streamline the process, especially for international shipments. -

What are the potential risks when sourcing Flyknit Racer 1688 from international suppliers?

Sourcing internationally carries risks such as quality discrepancies, shipping delays, and potential communication barriers. To mitigate these risks, conduct thorough due diligence on suppliers by checking their certifications and previous customer feedback. Establish clear contracts that outline responsibilities, quality standards, and timelines. Additionally, consider using escrow services for payment to protect your funds until you receive satisfactory products. -

How can I find reputable suppliers for Flyknit Racer 1688 sneakers?

To find reputable suppliers, utilize B2B marketplaces like Alibaba, Made-in-China, or Global Sources, focusing on suppliers with verified profiles and positive reviews. Attend trade shows or industry expos to meet potential manufacturers in person. Networking within industry-specific forums and groups can also lead to recommendations. Always request references and conduct background checks to ensure reliability before finalizing any agreements. -

What are the best practices for communicating with suppliers in different time zones?

Effective communication with suppliers across different time zones requires planning and flexibility. Utilize scheduling tools to identify overlapping work hours for meetings. Opt for clear, concise emails to minimize misunderstandings, and summarize key points for clarity. Tools like project management software can help track progress and deadlines. Establishing a primary point of contact on both sides can also streamline communication and ensure that messages are efficiently relayed.

Top 3 Flyknit Racer 1688 Manufacturers & Suppliers List

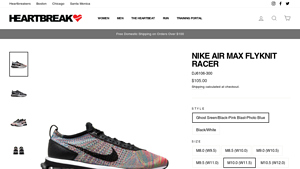

1. Nike – Flyknit Racer Multicolor US10.0

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {‘brand’: ‘Nike’, ‘model’: ‘Flyknit Racer’, ‘color’: ‘Multicolor’, ‘size’: ‘US10.0’, ‘condition’: ‘Pre-owned – Good’, ‘price’: ‘$150.00’, ‘shipping’: ‘Does not ship to Ukraine’, ‘location’: ‘Japan’, ‘returns’: ’30 days returns, buyer pays for return shipping’, ‘seller’: ‘japan-007’, ‘seller_feedback’: ‘99.5% positive’, ‘item_number’: ‘388613466123’}

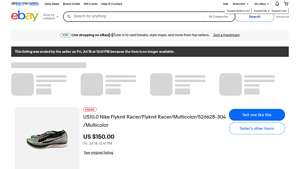

2. Nike – Air Max Flyknit Racer

Domain: heartbreak.run

Introduction: {“product_name”: “Nike Air Max Flyknit Racer”, “sku”: “DJ6106-300”, “regular_price”: “$160.00”, “sale_price”: “$105.00”, “savings”: “$55.00”, “available_colors”: [“Ghost Sreen/Black-Pink Blast-Photo Blue”, “Black/White”], “sizes”: [“M8.0 (W9.5)”, “M8.5 (W10.0)”, “M9.0 (W10.5)”, “M9.5 (W11.0)”, “M10.0 (W11.5)”, “M10.5 (W12.0)”, “M11.0 (W12.5)”, “M11.5 (W13.0)”, “M12.0 (W13.5)”, “M12.5 (W14.0)”, “M1…

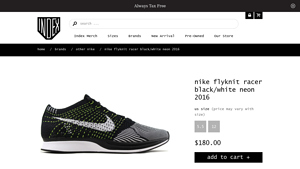

3. Nike – NIKE FLYKNIT RACER BLACK/WHITE NEON 2016

Domain: indexpdx.com

Registered: 2012 (13 years)

Introduction: {“Product Name”: “NIKE FLYKNIT RACER BLACK/WHITE NEON 2016”, “Brand”: “Nike”, “Condition”: “New”, “Colorway”: “BLACK/WHITE-WHITE”, “Year”: “2016”, “Product Number”: “526628 011”, “Price”: “$180.00”, “Available Sizes”: [5.5, 12, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30], “Current Stock”: “BRAND NEW WITH BOX”}

Strategic Sourcing Conclusion and Outlook for flyknit racer 1688

As the demand for innovative athletic footwear continues to rise, the Nike Flyknit Racer 1688 stands out as a prime candidate for strategic sourcing initiatives. The shoe’s lightweight design, adaptive Flyknit technology, and responsive cushioning make it appealing not only to runners but also to casual wearers seeking style and comfort. This product’s blend of heritage and innovation positions it favorably in the global market, particularly in regions like Africa, South America, the Middle East, and Europe, where a growing middle class is driving increased consumer spending.

Illustrative image related to flyknit racer 1688

Strategic sourcing offers international buyers the opportunity to leverage competitive pricing, optimize supply chain logistics, and ensure product authenticity. By partnering with reliable suppliers, buyers can tap into the expanding market for Flyknit Racers, ensuring a steady supply of this sought-after product.

Looking ahead, the potential for growth in the Flyknit Racer category is significant. B2B buyers are encouraged to act now—identify trusted suppliers and explore sourcing options that align with their business goals. By investing in this innovative footwear, companies can meet the evolving demands of consumers and enhance their market presence.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to flyknit racer 1688

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.