How to Source Pvc Roller Mop Buckets Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for pvc roller mop buckets

In an increasingly competitive global market, sourcing high-quality PVC roller mop buckets can pose significant challenges for international B2B buyers. With diverse applications across industries—from hospitality to healthcare—selecting the right mop bucket requires a deep understanding of product specifications, supplier reliability, and cost efficiency. This guide serves as a comprehensive resource, exploring the various types of PVC roller mop buckets available, their specific applications, and the nuances of supplier vetting to ensure quality and compliance with local standards.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Saudi Arabia—will find valuable insights tailored to their unique market dynamics. The guide delves into key factors influencing purchasing decisions, such as material durability, design features like wringers, and cost considerations that can impact overall budget allocations. By equipping buyers with essential knowledge about market trends and product specifications, this resource empowers informed purchasing decisions, ultimately enhancing operational efficiency and cleaning effectiveness. Whether you’re looking to streamline your procurement process or ensure compliance with industry standards, this guide offers actionable insights that can lead to successful sourcing of PVC roller mop buckets.

Understanding pvc roller mop buckets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard PVC Roller Mop Bucket | Durable PVC construction, integrated wringer, 5-gallon capacity | Commercial cleaning, facilities | Pros: Cost-effective, lightweight. Cons: Limited chemical resistance. |

| Heavy-Duty PVC Roller Mop Bucket | Reinforced design, larger capacity (up to 10 gallons), wheels | Industrial cleaning, warehouses | Pros: High durability, mobility. Cons: Heavier, higher cost. |

| Cleanroom PVC Roller Mop Bucket | Smooth surfaces, autoclavable, designed for sterile environments | Pharmaceutical, laboratories | Pros: Easy to sterilize, prevents contamination. Cons: Expensive, specialized use. |

| Multi-Compartment PVC Mop Bucket | Dual buckets for clean and dirty water, side press wringer | Janitorial services, hospitals | Pros: Reduces cross-contamination, efficient. Cons: Bulkier, requires more storage space. |

| Compact PVC Roller Mop Bucket | Smaller size, portable design, ideal for tight spaces | Small businesses, residential use | Pros: Space-saving, easy to handle. Cons: Limited capacity, less robust. |

What are the Characteristics of Standard PVC Roller Mop Buckets?

Standard PVC roller mop buckets are designed for general cleaning tasks and are typically made from durable PVC material. With a capacity of around 5 gallons, these buckets are lightweight and easy to maneuver, making them ideal for commercial cleaning in offices, schools, and retail spaces. Buyers should consider their cost-effectiveness and ease of use, but note that they may not withstand harsh chemicals.

How Do Heavy-Duty PVC Roller Mop Buckets Differ?

Heavy-duty PVC roller mop buckets are built for more rigorous applications, featuring a reinforced design that allows for larger capacities, often up to 10 gallons. Equipped with wheels for mobility, these buckets are suitable for industrial cleaning and large facilities like warehouses. While they offer enhanced durability and convenience, buyers should be prepared for a higher price point and increased weight.

What Makes Cleanroom PVC Roller Mop Buckets Unique?

Cleanroom PVC roller mop buckets are specifically engineered for sterile environments, such as pharmaceutical labs and medical facilities. Their smooth surfaces are designed to minimize particle retention, and many models are autoclavable for easy sterilization. Although they provide essential features for maintaining cleanliness in sensitive areas, they tend to be more expensive and are intended for specialized use.

Why Choose Multi-Compartment PVC Mop Buckets?

Multi-compartment PVC mop buckets are designed to separate clean and dirty water, often featuring a side press wringer. This design is particularly beneficial for janitorial services and healthcare facilities, as it helps reduce cross-contamination during cleaning. While efficient, these buckets may be bulkier and require more storage space, which buyers should consider based on their operational needs.

What Are the Advantages of Compact PVC Roller Mop Buckets?

Compact PVC roller mop buckets are ideal for smaller spaces, providing a portable solution for light cleaning tasks in small businesses or residential settings. Their space-saving design makes them easy to handle and store, but they typically have a lower capacity and may not be as robust as larger models. Buyers should assess their cleaning volume and space constraints when considering these options.

Key Industrial Applications of pvc roller mop buckets

| Industry/Sector | Specific Application of pvc roller mop buckets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Daily cleaning of restaurants and hotels | Enhances cleanliness, improves guest satisfaction, and reduces slip hazards | Durability, ease of use, and compatibility with various mop types |

| Healthcare | Infection control in hospitals and clinics | Ensures a sterile environment, minimizes cross-contamination | Compliance with hygiene standards, material safety, and ease of sterilization |

| Manufacturing | Maintenance of production floors | Increases safety and operational efficiency through cleanliness | Resistance to chemicals, capacity, and mobility for large areas |

| Education | Regular cleaning in schools and universities | Promotes a healthy learning environment and reduces absenteeism | Size, weight, and ease of transport across different facilities |

| Retail | Maintenance of store cleanliness | Enhances customer experience and brand image | Aesthetic appeal, functionality, and cost-effectiveness |

How Are PVC Roller Mop Buckets Used in the Hospitality Sector?

In the hospitality industry, PVC roller mop buckets are essential for the daily cleaning of restaurants and hotels. These buckets enable staff to efficiently wring out mops, ensuring that floors are cleaned thoroughly without excessive water retention, which can lead to slip hazards. The use of durable and easy-to-maneuver mop buckets also allows for faster turnaround times in busy environments, ultimately enhancing guest satisfaction. For B2B buyers, sourcing high-quality, resilient mop buckets that can withstand frequent use is crucial, especially in regions with varying climates, such as Africa and the Middle East.

What Role Do PVC Roller Mop Buckets Play in Healthcare Settings?

In healthcare facilities, maintaining strict hygiene standards is critical. PVC roller mop buckets are utilized for infection control, allowing for efficient cleaning of patient areas and common spaces. These buckets help minimize cross-contamination by facilitating the separation of clean and dirty water, which is vital in hospitals and clinics. Buyers in the healthcare sector should prioritize mop buckets that comply with health regulations, are made from non-toxic materials, and can be easily sterilized to maintain a sterile environment.

How Are PVC Roller Mop Buckets Beneficial in Manufacturing?

Manufacturing facilities require rigorous cleaning protocols to ensure safety and efficiency. PVC roller mop buckets are commonly used to maintain production floors, where spills and debris can pose safety risks. The ability to easily wring out mops means that floors can be cleaned quickly, which minimizes downtime. For international buyers in manufacturing, considerations such as the bucket’s chemical resistance and capacity are essential, especially in regions like South America where industrial cleaning standards may vary.

Illustrative image related to pvc roller mop buckets

Why Are PVC Roller Mop Buckets Important in Educational Institutions?

Schools and universities benefit from the use of PVC roller mop buckets for regular cleaning to promote a healthy learning environment. These buckets allow janitorial staff to manage large areas efficiently, ensuring that floors are clean and safe for students. Reducing absenteeism due to illness is a significant advantage of maintaining cleanliness in educational settings. B2B buyers in the education sector should consider the size and weight of mop buckets for ease of transport across campuses, especially in regions with diverse infrastructure challenges.

How Do PVC Roller Mop Buckets Enhance Retail Environments?

In retail settings, cleanliness plays a vital role in customer experience and brand image. PVC roller mop buckets are used to maintain store cleanliness, allowing staff to quickly address spills and dirt without disrupting shopping activities. The aesthetic appeal of these mop buckets can also contribute to a store’s overall presentation. For B2B buyers in retail, sourcing mop buckets that are functional yet visually appealing is important, along with ensuring they are cost-effective for large-scale operations.

3 Common User Pain Points for ‘pvc roller mop buckets’ & Their Solutions

Scenario 1: Difficulty in Ensuring Effective Cleaning with PVC Roller Mop Buckets

The Problem: Many businesses, particularly those in the hospitality and healthcare sectors, struggle with ensuring that their cleaning tools, such as PVC roller mop buckets, effectively sanitize surfaces. Buyers often report that traditional mopping methods do not adequately remove dirt or disinfect floors, leading to potential health risks and reduced customer satisfaction. The challenge is compounded when workers use inefficient techniques that result in water pooling, which can breed bacteria and create slip hazards.

The Solution: To address this issue, B2B buyers should focus on investing in high-quality PVC roller mop buckets designed for optimal efficiency. Look for buckets with integrated wringers that allow for better water extraction, minimizing residual moisture left on floors. Additionally, consider sourcing mop heads that are specifically designed for your flooring type, as they can better trap dirt and grime. Training staff on the correct use of these tools is equally important; conducting regular workshops on effective mopping techniques can significantly improve cleaning outcomes. Establish a routine maintenance schedule for the mop buckets to ensure they remain in good condition and continue performing at their best.

Scenario 2: Challenges with Durability and Longevity of Cleaning Equipment

The Problem: Buyers often face frustration when PVC roller mop buckets do not withstand the rigors of daily use, especially in environments like warehouses or large retail spaces. Frequent replacements not only incur additional costs but also disrupt cleaning operations. The wear and tear on cheaper, lower-quality products can lead to leaks and breakage, which can slow down the cleaning process and impact overall productivity.

The Solution: To mitigate these concerns, businesses should prioritize sourcing PVC roller mop buckets made from high-grade materials that are specifically designed for commercial use. Look for products that come with warranties, as these often indicate a manufacturer’s confidence in their durability. Additionally, consider choosing buckets that are reinforced at stress points to withstand heavy usage. Regular inspections and maintenance can also extend the life of the mop buckets; replacing worn-out parts like wheels or wringers can prevent the need for complete replacements. Creating a budget that accounts for quality over quantity will lead to long-term savings and improved efficiency.

Scenario 3: Managing the Risk of Cross-Contamination in Cleaning Processes

The Problem: In environments such as healthcare facilities or food service areas, the risk of cross-contamination during cleaning is a significant concern. B2B buyers often find that using a single mop bucket for both clean and dirty water can lead to the spread of germs and contaminants, jeopardizing hygiene standards and compliance with health regulations.

The Solution: To combat this issue, businesses should invest in a dual-bucket system or separate PVC roller mop buckets specifically for clean and dirty water. These systems help maintain a clear distinction between clean and contaminated liquids, significantly reducing the risk of cross-contamination. When sourcing these buckets, ensure they are color-coded to help staff easily identify which bucket to use for each purpose. Additionally, implement a strict cleaning protocol that includes regular washing and sanitizing of the mop buckets after each use. Training staff on these protocols will further enhance compliance and promote a culture of cleanliness within the organization.

Strategic Material Selection Guide for pvc roller mop buckets

When selecting materials for PVC roller mop buckets, it is essential to consider the properties and performance characteristics that will best meet the needs of various cleaning environments. Below is an analysis of four common materials used in the construction of these buckets, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of PVC in Roller Mop Buckets?

Polyvinyl Chloride (PVC) is widely used in mop bucket manufacturing due to its favorable properties. PVC exhibits excellent chemical resistance, making it suitable for a variety of cleaning solutions. It can withstand temperatures up to 60°C (140°F), which is adequate for most cleaning applications. Moreover, PVC is lightweight and easy to mold, allowing for complex designs that improve functionality, such as integrated wringers.

Pros: PVC is cost-effective, durable, and resistant to corrosion, making it an excellent choice for high-volume cleaning operations. Its lightweight nature facilitates easy handling and transportation.

Cons: However, PVC has limitations in terms of temperature resistance compared to other materials like polypropylene. It can become brittle in extreme cold and may not hold up well under prolonged exposure to high temperatures. Additionally, while PVC is recyclable, its environmental impact is a concern in regions with strict sustainability regulations.

How Does Polypropylene Compare for Mop Bucket Applications?

Polypropylene (PP) is another popular material for mop buckets, particularly in commercial settings. It offers superior chemical resistance and can handle temperatures up to 100°C (212°F), making it suitable for hot water cleaning applications. Polypropylene is also lightweight and has a high impact resistance.

Pros: The enhanced temperature tolerance and chemical stability of polypropylene make it ideal for rigorous cleaning tasks. It is also less prone to warping or cracking than PVC.

Cons: The primary drawback of polypropylene is its higher cost compared to PVC. Additionally, it may not have the same level of UV resistance, which can be a concern for outdoor cleaning applications.

What Role Does Stainless Steel Play in Mop Bucket Durability?

Stainless Steel is often used for mop buckets in environments requiring high hygiene standards, such as hospitals or food processing facilities. Type 304 stainless steel is common due to its excellent corrosion resistance and mechanical properties. It can withstand high temperatures and is easy to clean.

Pros: Stainless steel is incredibly durable and resistant to rust and corrosion, making it a long-lasting option. Its aesthetic appeal and ease of sterilization make it suitable for sanitary applications.

Cons: The primary disadvantage is the cost; stainless steel mop buckets are significantly more expensive than plastic options. Additionally, they are heavier, which may pose handling challenges in some situations.

What are the Benefits of Using High-Density Polyethylene (HDPE)?

High-Density Polyethylene (HDPE) is known for its strength and resistance to impact and chemicals. It is often used in applications where durability is paramount. HDPE can withstand temperatures up to 120°C (248°F), making it suitable for hot water cleaning.

Pros: HDPE is lightweight, resistant to many chemicals, and has a long service life. It is also more environmentally friendly than PVC, being fully recyclable.

Cons: However, HDPE can be more expensive than PVC and may not offer the same level of rigidity. It can also be less effective in high-temperature applications compared to polypropylene.

Summary for International B2B Buyers

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider compliance with local standards such as ASTM, DIN, or JIS when selecting materials. Preferences may vary based on environmental regulations and specific cleaning applications. Understanding the material properties and their implications on performance will aid in making informed purchasing decisions.

Illustrative image related to pvc roller mop buckets

| Material | Typical Use Case for PVC Roller Mop Buckets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General cleaning in low to moderate heat | Cost-effective and lightweight | Limited temperature resistance | Low |

| Polypropylene | Commercial cleaning requiring hot water | High chemical resistance and durability | Higher cost than PVC | Medium |

| Stainless Steel | High hygiene environments (hospitals, food) | Durable and easy to clean | High cost and heavier weight | High |

| HDPE | Durable applications with chemical exposure | Lightweight and recyclable | More expensive than PVC | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for pvc roller mop buckets

What Are the Key Stages in the Manufacturing Process of PVC Roller Mop Buckets?

The manufacturing of PVC roller mop buckets involves several critical stages designed to ensure both functionality and durability.

Material Preparation

The first step in manufacturing PVC roller mop buckets is the preparation of raw materials. Polyvinyl chloride (PVC) pellets are sourced based on specific qualities required for the buckets, such as flexibility, impact resistance, and UV stability. Suppliers often conduct tests to confirm the chemical composition of the PVC, ensuring it meets international standards for safety and durability.

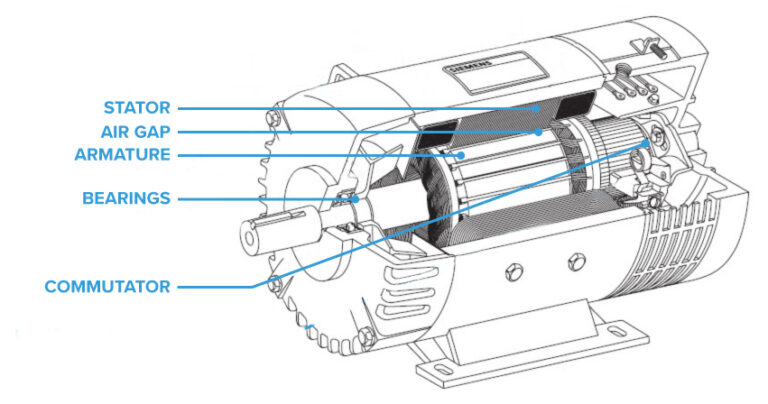

Forming Techniques

Once the materials are prepared, they undergo forming processes. The most common method for creating PVC mop buckets is injection molding. This technique involves melting the PVC pellets and injecting the molten material into molds that shape the buckets. Advanced molding techniques, such as blow molding or rotational molding, may also be used for specific designs or functionalities. These processes ensure uniform wall thickness and structural integrity.

Illustrative image related to pvc roller mop buckets

Assembly Process

After forming, the components, including the bucket body, wringer, and any additional features (such as handles or wheels), are assembled. The assembly process may involve manual labor or automated systems, depending on the scale of production. Quality checks during assembly ensure that all parts fit correctly and that the mechanism operates smoothly.

Finishing Touches

The final stage of manufacturing is finishing, which includes surface treatment, painting, and applying any necessary labels. For mop buckets, this may involve adding anti-slip features, ensuring that the product is both functional and safe for use. Additionally, UV-resistant coatings may be applied to enhance longevity, especially for products intended for outdoor use.

How is Quality Assurance Implemented During Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process for PVC roller mop buckets. It ensures that products meet the required standards and specifications.

What International Standards Should B2B Buyers Be Aware Of?

Manufacturers often adhere to international quality standards, such as ISO 9001, which focuses on quality management systems. Compliance with ISO standards indicates that a company follows rigorous processes to ensure product quality and customer satisfaction. Additionally, products may require certification for specific markets, such as CE marking in Europe, which signifies compliance with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated at various stages of production:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival. Suppliers should provide certification or test results confirming the quality of the PVC used.

-

In-Process Quality Control (IPQC): During the production process, random samples are taken for testing to ensure consistency in manufacturing. This can include checking the dimensions, weight, and functionality of the buckets.

-

Final Quality Control (FQC): Once production is complete, the final products undergo thorough testing. This may include stress testing, leak testing, and visual inspections to detect any defects.

What Testing Methods Are Commonly Used for PVC Roller Mop Buckets?

Testing methods for PVC roller mop buckets are essential to confirm that they can withstand regular use and maintain performance standards. Some common methods include:

-

Drop Testing: To assess the impact resistance of the buckets, drop tests simulate accidental falls or impacts.

-

Chemical Resistance Testing: Since mop buckets are often exposed to various cleaning agents, manufacturers test how well the PVC holds up against different chemicals.

-

UV Exposure Testing: For buckets intended for outdoor use, UV exposure tests determine how well the material resists degradation from sunlight.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive measures to verify the quality control practices of their suppliers. Here are some strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This can include reviewing production records and quality testing results.

-

Quality Assurance Reports: Requesting detailed QA reports from suppliers provides insights into their compliance with international standards and internal QC processes.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased review of the manufacturing practices. These agencies can perform random inspections during the production process and offer certification that aligns with international standards.

What Are the Unique QC Considerations for International B2B Buyers?

When dealing with international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, B2B buyers need to consider several nuances:

-

Regulatory Compliance: Different countries have varying regulations regarding product safety and quality. Buyers should ensure that their suppliers comply with local laws and international standards.

-

Cultural Differences in Manufacturing Practices: Understanding the cultural context can help buyers navigate potential challenges in communication and expectations regarding quality and delivery timelines.

-

Supply Chain Transparency: Buyers should seek suppliers who are transparent about their supply chains, including sourcing materials and labor practices. This can enhance trust and ensure ethical production practices.

By focusing on these aspects of the manufacturing processes and quality assurance for PVC roller mop buckets, B2B buyers can make informed decisions that align with their quality expectations and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc roller mop buckets’

Introduction

Sourcing PVC roller mop buckets requires careful consideration of various factors to ensure that you select products that meet your operational needs while providing value for your investment. This guide outlines a step-by-step checklist designed for B2B buyers, particularly those operating in international markets like Africa, South America, the Middle East, and Europe. By following these steps, you can streamline your procurement process and make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to define the technical specifications for the PVC roller mop buckets you need. Consider the size, capacity, and design features that will best serve your cleaning operations.

- Capacity Requirements: Determine the volume of liquid the bucket should hold, typically ranging from 5 to 10 gallons.

- Ergonomics: Look for features such as comfortable handles and easy-to-maneuver wheels to enhance user experience.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing is crucial for making competitive purchases. Take the time to analyze the latest developments in mop bucket technology and pricing fluctuations across different regions.

- Competitive Pricing: Compare prices across various suppliers and platforms to identify the best deals.

- Emerging Technologies: Stay informed about innovations in mop bucket designs that could enhance cleaning efficiency.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s vital to conduct a thorough evaluation. This ensures you are partnering with a reliable company that can meet your needs consistently.

- Supplier Background: Request company profiles and check their history in the industry.

- References and Reviews: Look for testimonials from other B2B buyers who have sourced similar products.

Step 4: Verify Quality Standards and Certifications

Quality assurance is critical when procuring cleaning equipment. Ensure that the PVC roller mop buckets comply with relevant industry standards and certifications.

- Material Quality: Confirm that the buckets are made from durable, high-quality PVC that can withstand regular use.

- Certifications: Look for certifications such as ISO or other local standards that indicate product reliability.

Step 5: Request Product Samples

Before finalizing your order, request samples of the PVC roller mop buckets to evaluate their quality firsthand. This step helps you ascertain whether the products meet your specifications and expectations.

- Physical Inspection: Check the durability, design, and functionality of the samples.

- User Feedback: Involve your cleaning staff in evaluating the samples to gather practical feedback.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, negotiate the terms and conditions of the purchase. This includes pricing, delivery timelines, and payment terms.

- Volume Discounts: Discuss potential discounts for bulk purchases to maximize your budget.

- Delivery Schedules: Ensure that the supplier can meet your required delivery timelines to avoid disruptions in your operations.

Step 7: Establish a Long-term Relationship

After the initial purchase, consider establishing a long-term relationship with the supplier. This can lead to better pricing, priority service, and access to new products.

- Regular Communication: Maintain open lines of communication for future needs and updates on new offerings.

- Feedback Loop: Provide feedback on the products and service to foster a mutually beneficial relationship.

By following this checklist, you can effectively source PVC roller mop buckets that align with your operational needs and contribute to the efficiency of your cleaning processes.

Comprehensive Cost and Pricing Analysis for pvc roller mop buckets Sourcing

What Are the Key Cost Components in Sourcing PVC Roller Mop Buckets?

When sourcing PVC roller mop buckets, understanding the cost structure is essential for B2B buyers. The primary cost components include:

Illustrative image related to pvc roller mop buckets

-

Materials: PVC is the main material used, which can vary in quality and price based on supplier sourcing and market demand. High-quality PVC may incur higher costs but offers better durability and longevity.

-

Labor: Labor costs can fluctuate based on the manufacturing location. Regions with lower labor costs can provide significant savings, but this might also impact quality.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and other indirect costs associated with production. Efficient manufacturing processes can reduce overhead and, consequently, the final price.

-

Tooling: Initial tooling costs for molds and machinery can be substantial, particularly for customized designs. However, these costs are amortized over production runs, making them less significant per unit in larger orders.

-

Quality Control (QC): Investing in QC ensures that the products meet safety and performance standards. This can add to the upfront costs but is crucial for maintaining brand reputation and minimizing returns.

-

Logistics: Transportation costs, including shipping and customs duties, can vary significantly based on the destination. Incoterms will influence who bears these costs, impacting the overall pricing structure.

-

Margin: Suppliers typically mark up prices to maintain profitability. Understanding the markup strategies of different suppliers can aid in negotiations.

How Do Price Influencers Impact the Cost of PVC Roller Mop Buckets?

Several factors influence the pricing of PVC roller mop buckets:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk orders. Understanding the MOQ can help buyers optimize costs.

-

Specifications and Customization: Custom designs or specific features (like specialized wringers or color options) can lead to increased costs. Standardized products generally provide better pricing.

-

Materials Quality and Certifications: Higher quality materials and certifications (like ISO) may result in higher prices but can assure buyers of product reliability and safety.

-

Supplier Factors: The reputation, reliability, and location of the supplier can greatly influence pricing. Established suppliers with a track record may charge more but can offer better service and support.

-

Incoterms: These define the responsibilities of buyers and sellers in international trade, affecting the overall cost. Choosing the right Incoterms can help buyers manage shipping costs and risks effectively.

What Buyer Tips Can Help Optimize Costs for PVC Roller Mop Buckets?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate: Always engage in price negotiations. Suppliers may have flexibility in pricing, especially for larger orders or repeat business.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Evaluate the durability, maintenance costs, and potential replacement frequency of the mop buckets to understand the long-term financial impact.

-

Pricing Nuances for International Buyers: Be aware of additional costs such as tariffs, taxes, and shipping fees that can affect overall pricing. Understanding local market conditions can also help you negotiate better deals.

-

Conduct Market Research: Analyze competitors and market trends to ensure you are getting a competitive price. This research can provide leverage during negotiations.

-

Establish Long-term Relationships with Suppliers: Building strong relationships can lead to better pricing, improved service, and priority during product shortages.

Conclusion

In summary, when sourcing PVC roller mop buckets, a deep understanding of the cost components, pricing influencers, and strategic negotiation tips can empower B2B buyers to make informed decisions. By considering these factors, businesses can ensure they are optimizing their procurement processes while maintaining quality and reliability in their cleaning solutions.

Alternatives Analysis: Comparing pvc roller mop buckets With Other Solutions

Exploring Alternatives to PVC Roller Mop Buckets for Effective Cleaning Solutions

In the quest for efficient cleaning solutions, PVC roller mop buckets often stand out for their functionality and user-friendliness. However, various alternatives exist that may better suit specific operational needs or environments. This section compares PVC roller mop buckets with two viable alternatives: traditional mop and bucket systems and automated floor cleaning machines. Each option presents unique advantages and considerations that can impact purchasing decisions for B2B buyers.

| Comparison Aspect | PVC Roller Mop Buckets | Traditional Mop and Bucket Systems | Automated Floor Cleaning Machines |

|---|---|---|---|

| Performance | Effective for quick mopping; easy wringing | Variable performance; dependent on user technique | Consistent, high-quality cleaning; programmable features |

| Cost | Moderate initial investment ($30-$100) | Low-cost options available ($15-$50) | Higher upfront costs ($1,000+) |

| Ease of Implementation | Simple setup; minimal training required | Familiar to most staff; easy to use | Requires training and setup; complex operation |

| Maintenance | Moderate; regular cleaning of buckets needed | Low; simple rinsing suffices | High; requires routine servicing and repairs |

| Best Use Case | Small to medium-sized areas; quick cleanups | General cleaning in various settings | Large areas; high-traffic environments needing constant cleaning |

What Are the Pros and Cons of Traditional Mop and Bucket Systems?

Traditional mop and bucket systems are a longstanding solution in the cleaning industry. They are generally more affordable and widely understood by cleaning staff, which simplifies training and implementation. However, performance can vary based on the user’s technique, leading to inconsistent results. Maintenance is relatively low, but without proper technique, these systems may not effectively remove dirt and grime, especially in larger areas.

How Do Automated Floor Cleaning Machines Compare?

Automated floor cleaning machines represent a significant advancement in cleaning technology. They offer consistent and high-quality cleaning, particularly in large or high-traffic environments. Their programmable features allow for scheduled cleanings, which can enhance operational efficiency. However, the upfront costs are considerably higher, and they require ongoing maintenance and servicing, making them less accessible for smaller businesses. Additionally, staff will need training to operate these machines effectively, which may involve an initial investment in time and resources.

Conclusion: Which Cleaning Solution Should B2B Buyers Choose?

When selecting the right cleaning solution, B2B buyers should consider their specific operational needs, budget constraints, and the environments in which they operate. PVC roller mop buckets offer a balance of efficiency and ease of use, making them suitable for smaller spaces and quick cleanups. Traditional mop and bucket systems provide a cost-effective alternative for general cleaning tasks, while automated floor cleaning machines are ideal for businesses with larger areas requiring consistent upkeep. Ultimately, assessing these factors will help organizations choose a solution that optimally fits their cleaning requirements, enhancing overall operational efficiency.

Essential Technical Properties and Trade Terminology for pvc roller mop buckets

What Are the Key Technical Properties of PVC Roller Mop Buckets?

Understanding the technical specifications of PVC roller mop buckets is crucial for B2B buyers looking to make informed purchasing decisions. Here are some of the critical specifications to consider:

-

Material Grade

PVC (Polyvinyl Chloride) is a widely used thermoplastic polymer. The grade of PVC used in mop buckets affects durability, flexibility, and resistance to chemicals and environmental conditions. High-grade PVC is essential for commercial use, ensuring that the buckets can withstand rigorous cleaning tasks without cracking or degrading over time. -

Capacity

The capacity of mop buckets is typically measured in quarts or liters. Common sizes range from 26 to 35 quarts, with larger buckets suitable for extensive cleaning areas. A higher capacity allows for more efficient cleaning cycles, reducing the need for frequent refills, which is particularly advantageous in large commercial spaces such as hotels or hospitals. -

Weight Tolerance

Weight tolerance refers to the maximum weight the mop bucket can support, including water and cleaning solutions. This specification is vital for ensuring that the bucket can handle the demands of heavy-duty cleaning without risking structural failure. B2B buyers should consider the weight tolerance to match their operational needs. -

Wringer Design

The design of the wringer is a significant factor in the efficiency of the cleaning process. Common types include side press and down press wringers. The choice of wringer impacts the ease of use and the effectiveness of water extraction from the mop head. A well-designed wringer minimizes splashing and maximizes water removal, leading to faster drying times. -

Mobility Features

Mobility features such as wheels and ergonomic handles enhance the usability of mop buckets. Buckets equipped with wheels facilitate easy maneuvering across large surfaces, while a comfortable grip handle reduces strain on workers. These features are crucial in ensuring that cleaning staff can operate efficiently, particularly in extensive facilities. -

Graduation Markings

Graduation markings on the bucket assist in measuring cleaning solutions accurately. This feature is essential for maintaining the correct dilution ratios of cleaning agents, which can affect cleaning effectiveness and safety. Accurate measurements help in reducing waste and optimizing operational costs.

What Trade Terminology Should B2B Buyers Know for PVC Roller Mop Buckets?

Familiarity with industry-specific terminology can significantly enhance the purchasing process. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking for specific mop bucket designs or features that may not be available through standard retail channels. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers, as it impacts inventory costs and storage requirements. Suppliers often set MOQs to ensure profitability, which can influence purchasing decisions. -

RFQ (Request for Quotation)

An RFQ is a formal process through which buyers request pricing and terms from suppliers. This document typically outlines the specifications, quantities, and delivery schedules. Utilizing RFQs can help buyers ensure they receive competitive pricing and favorable terms. -

Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is vital for international transactions, as they clarify who bears the cost and risk at each stage of the shipping process. -

Lead Time

Lead time is the duration between placing an order and receiving the product. Understanding lead times is essential for inventory management and ensuring that cleaning operations can continue without interruption. Buyers should factor lead times into their purchasing schedules to avoid delays. -

Warranty Terms

Warranty terms specify the duration and conditions under which a product is covered for repairs or replacements. Familiarity with warranty terms is crucial for B2B buyers, as it reflects the manufacturer’s confidence in their product and can influence long-term operational costs.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions regarding the procurement of PVC roller mop buckets, ensuring they meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the pvc roller mop buckets Sector

What Are the Current Market Dynamics and Key Trends Affecting PVC Roller Mop Buckets?

The global market for PVC roller mop buckets is experiencing robust growth, driven by increasing demand for efficient cleaning solutions across various sectors, including hospitality, healthcare, and commercial cleaning. The rise of urbanization, particularly in Africa and South America, has led to a surge in the need for effective cleaning equipment to maintain hygiene standards in densely populated areas. Additionally, advancements in manufacturing technology are enabling the production of more durable and ergonomic mop buckets, enhancing user experience and operational efficiency.

Emerging B2B tech trends are also reshaping the sourcing landscape. The integration of e-commerce platforms is facilitating easier access to a wider range of products, allowing international buyers from regions like the Middle East and Europe to compare options more effectively. Furthermore, automated inventory management systems are becoming increasingly popular among suppliers, ensuring better stock availability and faster delivery times, which are critical for businesses that require consistent cleaning supplies.

Another significant trend is the growing preference for multipurpose mop buckets that offer features such as integrated wringers, wheels for mobility, and separate compartments for clean and dirty water. These innovations cater to the diverse needs of businesses, enabling them to enhance their cleaning processes while optimizing resource usage.

Illustrative image related to pvc roller mop buckets

How Is Sustainability and Ethical Sourcing Impacting the PVC Roller Mop Bucket Market?

Sustainability has become a pivotal concern in the B2B sector, particularly in manufacturing and sourcing practices. The environmental impact of plastic waste is prompting buyers to seek PVC roller mop buckets made from recyclable materials or those that meet stringent sustainability certifications. Companies that adopt eco-friendly practices not only contribute to environmental conservation but also appeal to a growing segment of consumers and businesses that prioritize sustainability in their purchasing decisions.

Ethical sourcing is equally important, as businesses are increasingly held accountable for their supply chains. Buyers are advised to engage with suppliers who demonstrate transparency and adhere to fair labor practices. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) can serve as indicators of a supplier’s commitment to sustainability and ethical operations.

The demand for ‘green’ materials is also influencing the design of mop buckets. Manufacturers are exploring alternatives to traditional PVC, such as bioplastics or recycled plastics, which can significantly reduce the carbon footprint associated with production. By prioritizing sustainable materials, companies can not only comply with regulatory requirements but also enhance their brand image in a competitive marketplace.

Illustrative image related to pvc roller mop buckets

What Is the Historical Evolution of PVC Roller Mop Buckets in the B2B Landscape?

The evolution of PVC roller mop buckets can be traced back to the broader development of cleaning technologies in the mid-20th century. Initially, mop buckets were simple containers without any wringing mechanism, relying heavily on manual labor for cleaning floors. The introduction of integrated wringers in the 1970s revolutionized the cleaning process, allowing users to efficiently remove excess water from mop heads, which improved cleaning effectiveness and reduced drying times.

Over the years, advancements in materials science have led to the adoption of PVC as a preferred material due to its durability, resistance to chemicals, and ease of cleaning. Today, PVC roller mop buckets are designed with ergonomics in mind, incorporating features such as wheels for mobility and integrated handles for ease of use. This evolution reflects not only changes in consumer preferences but also an increased focus on efficiency and sustainability in the cleaning industry, highlighting the ongoing innovations that continue to shape the market.

These trends and insights are crucial for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, as they navigate the complexities of sourcing PVC roller mop buckets in a rapidly evolving marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of pvc roller mop buckets

-

How do I choose the right PVC roller mop bucket for my business needs?

When selecting a PVC roller mop bucket, consider the size, capacity, and features that align with your cleaning requirements. Look for buckets with durable construction and a reliable wringing mechanism to ensure efficiency. Assess your specific environment—commercial, industrial, or cleanroom—and choose a model that meets those standards. Reading product reviews and comparing specifications from multiple suppliers can also help you make an informed decision. -

What are the key features to look for in a PVC roller mop bucket?

Essential features include a sturdy wringer that effectively removes excess water, wheels for easy mobility, and a large capacity to minimize refill frequency. Additional features like graduated markings for measuring solutions and a durable handle for comfortable transport are also beneficial. Ensure the material is resistant to chemicals and easy to clean, especially if used in environments with strict hygiene requirements. -

What are the typical payment terms for purchasing PVC roller mop buckets internationally?

Payment terms can vary by supplier, but common options include advance payment, letters of credit, or installment payments. Many suppliers require a deposit upfront, with the balance due before shipment. Always clarify payment methods, currency, and any additional fees associated with international transactions. Establishing clear payment terms helps prevent misunderstandings and facilitates smoother transactions. -

How can I vet suppliers for PVC roller mop buckets?

To vet suppliers, start by researching their reputation and experience in the industry. Look for reviews, testimonials, and case studies from previous clients. Request references and check their compliance with international quality standards. It’s also advisable to verify their production capacity and delivery timelines to ensure they can meet your demand. A site visit or third-party audit can provide additional assurance of their operations. -

What is the minimum order quantity (MOQ) for PVC roller mop buckets?

MOQs for PVC roller mop buckets vary significantly by supplier and can range from a few dozen to several hundred units. Factors influencing MOQ include the supplier’s production capabilities, the specific model, and customization requirements. Discuss your needs with potential suppliers to negotiate terms that align with your purchasing strategy while ensuring you meet their minimum requirements. -

Can I customize PVC roller mop buckets for my brand?

Yes, many suppliers offer customization options such as color, branding, and specific features tailored to your needs. Customization may involve additional costs and longer lead times, so it’s essential to communicate your requirements clearly. Providing detailed specifications will help the supplier understand your vision and deliver products that align with your branding strategy. -

What logistics considerations should I keep in mind when importing PVC roller mop buckets?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder familiar with your destination country’s regulations. Calculate shipping costs and potential duties or tariffs to ensure they fit within your budget. Plan for potential delays, especially during peak seasons or due to regulatory inspections, to manage your inventory effectively. -

What quality assurance measures should I expect from suppliers of PVC roller mop buckets?

Reputable suppliers should adhere to strict quality assurance protocols, including regular inspections of raw materials, in-process checks during manufacturing, and final product evaluations. Request documentation of compliance with international standards such as ISO certifications. Understanding their quality control processes can give you confidence in the durability and performance of the mop buckets you purchase.

Top 3 Pvc Roller Mop Buckets Manufacturers & Suppliers List

1. Alpine Industries – 36 Quart PVC Side Wringer

Domain: rickandanns.com

Registered: 2002 (23 years)

Introduction: {“brand”:”Alpine Industries”,”capacity”:”36 Quart”,”material”:”PVC”,”features”:”Side Wringers”,”dimensions”:”34 X 15″}

2. Cleanroom World – Cleanroom Cleaning Supplies

Domain: cleanroomworld.com

Registered: 2007 (18 years)

Introduction: This company, Cleanroom World – Cleanroom Cleaning Supplies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Unoclean – PVC Mop Bucket and Wringer Combo

Domain: unoclean.com

Registered: 2004 (21 years)

Introduction: PVC Mop Bucket and Wringer Combo – 38 Quart

Strategic Sourcing Conclusion and Outlook for pvc roller mop buckets

In conclusion, the strategic sourcing of PVC roller mop buckets presents significant opportunities for international B2B buyers. As the demand for efficient and durable cleaning solutions continues to rise, understanding the diverse range of mop buckets available—including variations in size, material, and functionality—can help businesses optimize their cleaning operations. By focusing on reputable suppliers who prioritize quality and cost-effectiveness, buyers can ensure they are investing in products that enhance productivity while reducing operational costs.

For businesses in regions such as Africa, South America, the Middle East, and Europe, leveraging strategic sourcing not only improves supply chain efficiency but also opens doors to competitive pricing and innovative cleaning solutions. The global market is evolving, and now is the time to align sourcing strategies with the latest industry trends and technological advancements.

As you explore the sourcing landscape for PVC roller mop buckets, consider engaging with suppliers who can provide tailored solutions that meet your specific operational needs. By making informed purchasing decisions, you can elevate your cleaning standards and drive long-term success in your business. Embrace the future of cleaning with strategic sourcing today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.