Grating Pacific: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for grating pacific

In today’s competitive landscape, sourcing high-quality grating solutions can pose significant challenges for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The need for reliable and durable grating products—ranging from metal bar grating to advanced fiberglass and slip-resistant options—requires a strategic approach to ensure compliance with regional safety standards and project specifications. This guide provides an in-depth exploration of the grating market, addressing various product types, applications, and essential considerations for supplier vetting.

B2B buyers will benefit from a comprehensive overview of the diverse applications of grating products, including industrial flooring, architectural designs, and safety solutions. Additionally, we delve into critical factors such as cost assessment, material selection, and the importance of customization in meeting specific project needs. By equipping buyers with the knowledge to evaluate suppliers effectively, this guide empowers them to make informed purchasing decisions that enhance operational efficiency and ensure the success of their projects.

Whether you’re based in Brazil, Saudi Arabia, or elsewhere, understanding the nuances of the global grating market is essential. This resource serves as your strategic partner in navigating complexities, enabling you to secure the best products that meet your business’s unique requirements while fostering long-term supplier relationships.

Understanding grating pacific Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

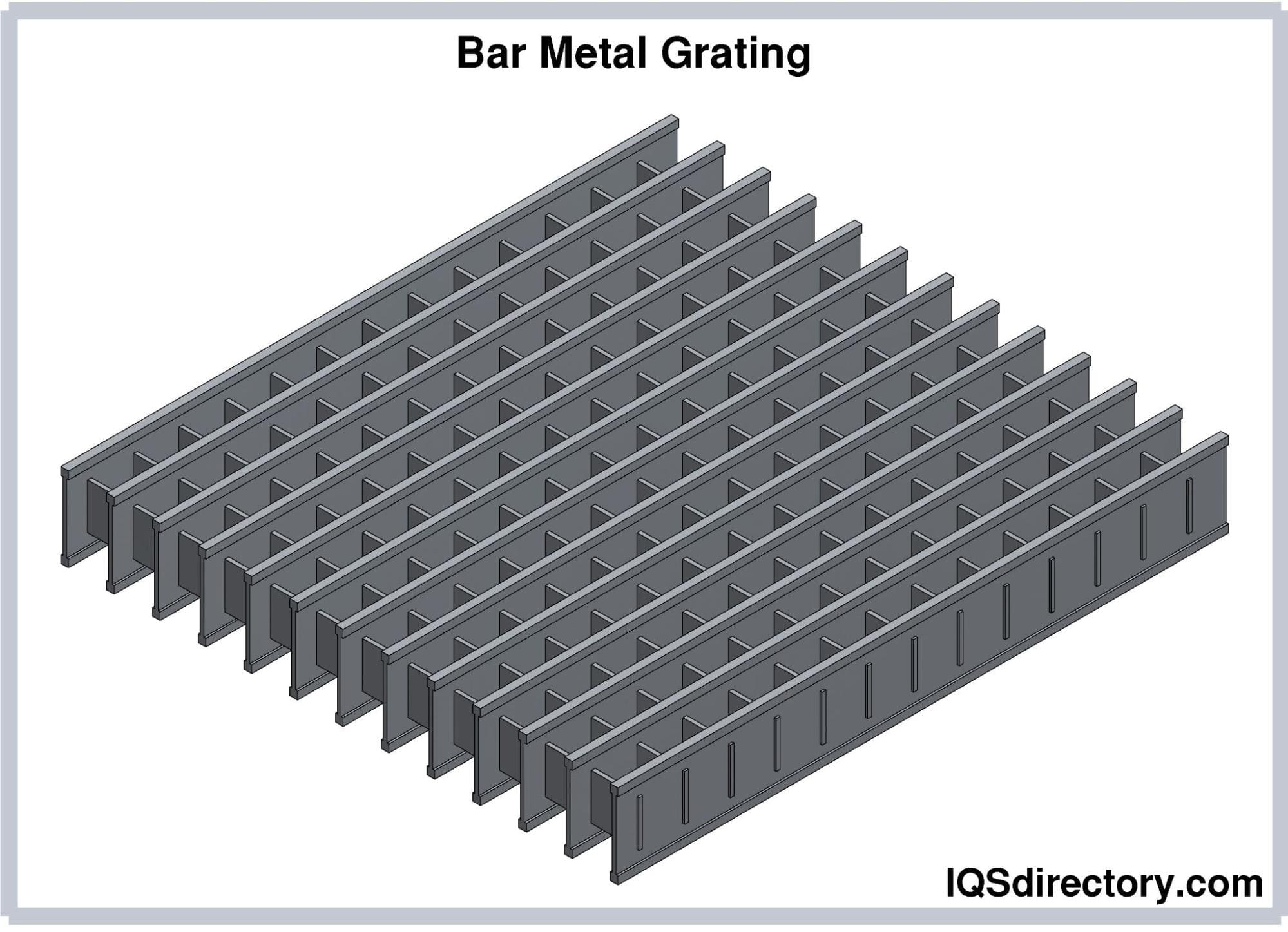

| Metal Bar Grating | Made from welded or press-locked steel, offering high strength. | Flooring, platforms, catwalks, and mezzanines. | Pros: Durable, high load capacity. Cons: Heavier and may require more maintenance. |

| Fiberglass Grating | Lightweight, corrosion-resistant, and slip-resistant. | Chemical processing, wastewater treatment, and marine applications. | Pros: Low maintenance, resistant to chemicals. Cons: Lower load capacity than metal. |

| Perforated Metal Products | Available in various hole patterns and materials for ventilation. | Architectural accents, filtration, and ventilation. | Pros: Customizable aesthetics, lightweight. Cons: May not provide structural support. |

| Expanded Metal | Created by slitting and stretching metal sheets, forming a mesh. | Fencing, security applications, and walkways. | Pros: Lightweight, good visibility. Cons: Limited load-bearing capacity. |

| Wire Mesh Products | Made from woven or welded wire, versatile in applications. | Screening, filtration, and reinforcement. | Pros: Highly customizable, various material options. Cons: May require additional framing for support. |

What Are the Characteristics of Metal Bar Grating and Its Applications?

Metal bar grating is a robust solution primarily made from welded or press-locked steel. This type of grating is designed for high-load applications, making it ideal for flooring in industrial settings, platforms, and catwalks. When considering metal bar grating, B2B buyers should evaluate the load-bearing requirements of their specific applications, as well as the potential for corrosion depending on the environment. While its durability is a significant advantage, the weight may necessitate more substantial support structures.

How Does Fiberglass Grating Differ and What Are Its Benefits?

Fiberglass grating offers a lightweight alternative to traditional metal grating, with excellent corrosion resistance. Its slip-resistant surface makes it particularly suitable for environments such as chemical processing plants or marine applications where exposure to harsh elements is common. Buyers should consider the specific chemical compatibility of fiberglass with their operational environment, as well as its lower load capacity compared to metal options. This type of grating is highly valued for its low maintenance needs and longevity.

What Are the Advantages of Perforated Metal Products?

Perforated metal products are characterized by their variety of hole patterns and materials, which allow for excellent ventilation and aesthetic appeal. This type of grating is commonly used in architectural applications, such as infill panels and sunscreens, where design flexibility is crucial. B2B buyers should assess the specific design requirements and the intended use of the perforated panels, as well as the potential need for custom patterns. While these products enhance visual appeal, they typically do not provide structural support.

Why Choose Expanded Metal for Security Applications?

Expanded metal is manufactured by slitting and stretching metal sheets to create a mesh-like structure. This type of grating is popular in security applications, such as fencing and walkways, due to its visibility and lightweight nature. Buyers should consider the specific security needs and the environment where expanded metal will be used. Although it is cost-effective and allows for airflow, its limited load-bearing capacity may restrict its application in more demanding environments.

What Makes Wire Mesh Products Versatile for Various Industries?

Wire mesh products are constructed from either woven or welded wire, making them versatile for numerous applications, including screening and filtration. They can be tailored to meet specific requirements, such as size and material type, making them suitable for industries ranging from construction to food processing. B2B buyers should evaluate the necessary strength and durability for their intended use, as well as any additional framing that may be required for support. The customization options available with wire mesh products can significantly enhance operational efficiency.

Key Industrial Applications of grating pacific

| Industry/Sector | Specific Application of grating pacific | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Flooring and walkways in commercial buildings | Provides durable, slip-resistant surfaces enhancing safety standards | Compliance with local safety regulations and load-bearing requirements |

| Oil & Gas | Trench covers and platforms in refineries | Ensures safety and accessibility in hazardous environments | Material selection for corrosion resistance and durability |

| Water Treatment | Grating for filtration systems | Enhances operational efficiency and reduces maintenance costs | Custom sizing and design to fit specific filtration systems |

| Mining | Catwalks and stair treads in processing facilities | Improves worker safety and operational efficiency | Heavy-duty specifications and resistance to harsh environmental conditions |

| Architectural Design | Decorative infill panels and sunscreens | Aesthetic appeal while maintaining structural integrity | Custom patterns and finishes to meet design specifications |

How is Grating Pacific Used in Construction Projects?

In the construction industry, Grating Pacific products are extensively utilized for flooring and walkways in commercial buildings. Their metal bar grating provides a slip-resistant surface, enhancing safety for pedestrians and machinery alike. Given the diversity of climates in regions such as Africa and South America, the materials selected must withstand local environmental conditions, making corrosion resistance a crucial consideration for international buyers. Compliance with local safety regulations and load-bearing requirements is also essential, ensuring that the grating can support the intended use without compromising structural integrity.

What Role Does Grating Pacific Play in the Oil & Gas Sector?

In the oil and gas industry, Grating Pacific supplies trench covers and platforms that are critical for safety and accessibility in refineries. These products are designed to endure harsh conditions while providing reliable access points for maintenance and operations. Businesses in this sector must consider the materials’ resistance to corrosion and chemical exposure, particularly in regions like the Middle East where such conditions are prevalent. Additionally, ensuring that the products meet stringent safety standards is paramount for minimizing risks in hazardous environments.

How is Grating Pacific Applied in Water Treatment Facilities?

Water treatment facilities utilize Grating Pacific’s products for filtration systems, where grating solutions enhance operational efficiency and reduce maintenance costs. The design of these grating products allows for effective water flow while filtering out debris, which is essential for maintaining system performance. International buyers must consider custom sizing and design to fit specific filtration systems, as well as compliance with environmental regulations that govern water quality in their respective regions.

What Benefits Does Grating Pacific Provide to the Mining Industry?

In mining operations, Grating Pacific is instrumental in providing catwalks and stair treads within processing facilities. These products are engineered to improve worker safety by offering sturdy and reliable walking surfaces in often hazardous environments. Buyers in this sector should prioritize heavy-duty specifications that can withstand the rigors of mining operations, as well as resistance to harsh environmental conditions. This focus on durability not only enhances safety but also contributes to overall operational efficiency.

How Does Grating Pacific Enhance Architectural Design?

Grating Pacific’s architectural offerings, such as decorative infill panels and sunscreens, serve to marry aesthetics with functionality. These products allow architects and builders to incorporate contemporary designs while ensuring structural integrity. For international buyers, sourcing considerations include the availability of custom patterns and finishes that align with specific design visions. This flexibility not only enhances visual appeal but also meets the diverse needs of various projects across different regions.

3 Common User Pain Points for ‘grating pacific’ & Their Solutions

Scenario 1: Navigating Complex Project Specifications

The Problem: B2B buyers often encounter difficulties when trying to specify the exact type of grating products needed for their projects. Given the range of materials (steel, aluminum, fiberglass) and various applications (flooring, stair treads, trench covers), the risk of miscommunication can lead to costly errors. Buyers may struggle to determine the appropriate load-bearing capacity, slip resistance, or aesthetic requirements, particularly when serving diverse industries such as construction and manufacturing.

The Solution: To address these challenges, buyers should initiate a thorough consultation with Grating Pacific’s engineering and sales teams early in the project planning phase. This can involve sharing detailed project requirements, including load specifications, environmental conditions, and intended use cases. Additionally, utilizing Grating Pacific’s design services can facilitate the selection of the most suitable materials and configurations. Requesting samples for testing and reviewing case studies of similar applications can further enhance decision-making and ensure that the final selection meets both functional and aesthetic criteria.

Scenario 2: Ensuring Compliance with Safety Standards

The Problem: Another common issue faced by B2B buyers is ensuring that their grating products comply with relevant safety standards and regulations. This is particularly crucial in industries like construction and food processing, where non-compliance can lead to significant liabilities. Buyers may find it challenging to understand which standards apply to their specific applications, leading to potential delays and increased costs.

The Solution: To mitigate compliance risks, buyers should leverage Grating Pacific’s expertise in safety regulations and standards. Engaging with their team can provide insights into applicable codes, such as the Americans with Disabilities Act (ADA) for slip resistance and load requirements. Buyers should also ensure that they request documentation and certifications for the products being sourced. By involving Grating Pacific’s team in the early stages of the project, buyers can incorporate compliant solutions from the outset, thereby avoiding costly modifications later.

Scenario 3: Managing Lead Times and Supply Chain Disruptions

The Problem: B2B buyers frequently face supply chain disruptions that affect the lead times of their grating products. In today’s global market, unexpected delays can stem from material shortages, logistics challenges, or fluctuating demand. These delays can jeopardize project timelines, resulting in financial penalties and strained client relationships.

The Solution: To effectively manage lead times, buyers should establish proactive communication with Grating Pacific regarding their project schedules and material needs. It’s advisable to place orders well in advance and consider bulk purchasing or inventory agreements for recurring needs. Additionally, Grating Pacific’s commitment to continuous improvement and investment in technology can provide buyers with real-time updates on order status and production timelines. By developing a strong partnership and utilizing Grating Pacific’s capabilities for custom fabrication, buyers can enhance their supply chain resilience and ensure timely project delivery.

Strategic Material Selection Guide for grating pacific

What Are the Key Properties of Common Materials Used in Grating Pacific Products?

When selecting materials for grating products, it is essential to consider their properties, benefits, and drawbacks. Below, we analyze four common materials used in Grating Pacific’s offerings: carbon steel, aluminum, stainless steel, and fiberglass.

Carbon Steel: What Are Its Key Properties and Applications?

Carbon steel is a widely used material in the manufacturing of grating products due to its excellent strength and durability. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications. Additionally, carbon steel can be treated for corrosion resistance, although it is inherently prone to rusting if not properly coated.

Pros: Carbon steel is relatively inexpensive and offers high load-bearing capacity. It is also easy to fabricate, allowing for custom shapes and sizes.

Cons: The primary drawback is its susceptibility to corrosion, which can limit its longevity in harsh environments. Maintenance is required to prevent rust, especially in coastal areas or regions with high humidity.

Impact on Application: Carbon steel grating is ideal for industrial environments, such as factories and warehouses, where strength is a priority. However, it may not be suitable for applications involving corrosive chemicals or wet conditions.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards (e.g., ASTM A36) and consider the need for protective coatings to enhance corrosion resistance.

Aluminum: What Advantages Does It Offer for Grating Products?

Aluminum is another popular choice for grating products, known for its lightweight and corrosion-resistant properties. It performs well in various temperatures and is often used in applications where weight is a critical factor.

Pros: The lightweight nature of aluminum makes it easy to handle and install. It is naturally resistant to corrosion, reducing maintenance costs over time.

Cons: Aluminum is generally more expensive than carbon steel and may not provide the same load-bearing capacity. It can also be susceptible to deformation under extreme loads.

Impact on Application: Aluminum grating is ideal for applications such as walkways, platforms, and architectural features where aesthetics and weight are important. It is commonly used in marine environments due to its corrosion resistance.

Considerations for International Buyers: Buyers in the Middle East and Europe should be aware of standards such as EN 10025 for structural steel and ensure that the aluminum used meets local specifications.

Stainless Steel: Why Is It a Preferred Material for Harsh Environments?

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it suitable for a wide range of applications, especially in harsh environments. It can withstand high temperatures and is often used in food processing and chemical industries.

Pros: The primary advantage of stainless steel is its durability and resistance to corrosion, which extends the lifespan of grating products. It also requires minimal maintenance.

Cons: The cost of stainless steel is significantly higher than that of carbon steel and aluminum. Additionally, it can be more challenging to fabricate due to its hardness.

Impact on Application: Stainless steel grating is ideal for environments exposed to corrosive substances, such as chemical plants or food processing facilities. Its hygienic properties also make it suitable for sanitary applications.

Considerations for International Buyers: Compliance with standards like ASTM A240 for stainless steel is crucial for buyers in Europe and South America, where strict regulations on material properties are enforced.

Fiberglass: What Are the Unique Benefits of Using This Material?

Fiberglass grating is a composite material that offers unique advantages, particularly in environments where corrosion is a significant concern. It is lightweight and can be molded into various shapes.

Pros: Fiberglass is highly resistant to corrosion and chemicals, making it suitable for use in harsh environments. It is also non-conductive, which is beneficial in electrical applications.

Cons: The main limitation of fiberglass is its lower load-bearing capacity compared to metal options. It can also be more expensive and less aesthetically pleasing than metal grating.

Impact on Application: Fiberglass grating is commonly used in wastewater treatment plants, chemical processing, and marine applications where corrosion resistance is paramount.

Considerations for International Buyers: Buyers should ensure that the fiberglass products meet relevant standards, such as ASTM D638 for tensile properties, particularly in regions like Africa and the Middle East.

Summary Table of Material Selection for Grating Pacific Products

| Material | Typical Use Case for grating pacific | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Industrial flooring and walkways | High strength and durability | Susceptible to corrosion | Low |

| Aluminum | Walkways and architectural features | Lightweight and corrosion-resistant | Higher cost and lower load capacity | Medium |

| Stainless Steel | Chemical processing and food industry | Excellent corrosion resistance | High cost and difficult to fabricate | High |

| Fiberglass | Wastewater treatment and marine use | Corrosion and chemical resistance | Lower load capacity and aesthetics | Medium |

This guide should empower international B2B buyers to make informed decisions regarding material selection for grating products, ensuring compliance with local standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for grating pacific

What Are the Key Stages in the Manufacturing Process of Grating Pacific Products?

The manufacturing process at Grating Pacific involves several critical stages, each designed to ensure the highest quality and performance of their metal grating products. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and How Are They Processed?

Grating Pacific utilizes a variety of materials, including carbon steel, stainless steel, aluminum, and fiberglass. The material selection is crucial, as it directly affects the durability and application of the final products. The preparation stage involves sourcing high-quality raw materials, which are then inspected for any defects. These materials are cut to size according to specific project requirements, ensuring that they meet both customer specifications and industry standards.

How Are Grating Products Formed and Assembled?

The forming stage employs several techniques such as welding, press-locking, and mechanical fastening. For metal bar grating, the bars are welded or pressed together to create a sturdy grid structure. The assembly of products like slip-resistant flooring or custom architectural elements follows, where components are carefully aligned and secured to ensure structural integrity. Advanced machinery and skilled labor are employed throughout this phase to maintain precision and efficiency.

What Finishing Techniques Enhance the Quality of Grating Pacific Products?

Finishing processes include powder coating, galvanizing, and anodizing, which not only enhance aesthetic appeal but also improve corrosion resistance and longevity. The powder coating process allows for a variety of colors and textures, making it suitable for both industrial and architectural applications. This stage is vital for ensuring that the products are ready for diverse environments, particularly in regions with harsh weather conditions, such as those found in Africa and the Middle East.

How Does Grating Pacific Ensure Quality Control Throughout Manufacturing?

Grating Pacific adheres to international quality standards, including ISO 9001, to ensure consistent product quality and customer satisfaction. Their quality assurance framework is structured around several critical checkpoints.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

-

Incoming Quality Control (IQC): This initial checkpoint involves the inspection of raw materials as they arrive at the facility. Materials are verified against specifications to ensure compliance before they enter the production line.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the forming and assembly processes. This includes checking tolerances, alignment, and welding quality. Any deviations are immediately addressed to prevent defects from progressing further in the production cycle.

-

Final Quality Control (FQC): Once products are completed, a final inspection is performed to ensure that they meet all specifications and quality standards. This includes visual inspections, dimensional checks, and functional testing as necessary.

What Testing Methods Are Commonly Used for Grating Pacific Products?

Grating Pacific employs various testing methods to verify product performance and safety. Common methods include tensile strength tests, load-bearing capacity tests, and slip resistance tests. These tests are crucial for ensuring that products are capable of withstanding the demands of their intended applications, particularly in industrial settings.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are several methods to ensure compliance and quality assurance:

-

Supplier Audits: Conducting on-site audits can provide insight into the manufacturing processes and quality control measures employed by Grating Pacific. This allows buyers to assess the facilities, equipment, and practices firsthand.

-

Quality Control Reports: Requesting detailed reports on quality assurance practices can help buyers understand the frequency and outcomes of quality checks. This documentation should include results from IQC, IPQC, and FQC.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s adherence to quality standards. These inspections can be particularly valuable for buyers who may not have the capacity to conduct their own audits.

What Are the International Quality Certification Nuances for B2B Buyers?

When sourcing products internationally, B2B buyers must be aware of the nuances in quality certification that may vary by region. For example, certifications such as CE marking in Europe or API certification in the oil and gas sector can be critical for compliance with local regulations. Buyers should ensure that Grating Pacific’s products meet these certifications, particularly if they are being exported to specific markets.

In addition, understanding local standards and regulations in the buyer’s region is essential. Buyers in Brazil, Saudi Arabia, and other countries may have specific requirements for safety and quality that must be met. Engaging in dialogue with suppliers about these certifications can help streamline the purchasing process and avoid potential compliance issues.

Conclusion: Why Choose Grating Pacific for Quality Manufacturing?

Grating Pacific’s commitment to quality manufacturing processes and stringent quality control measures makes them a reliable partner for B2B buyers across the globe. By understanding the manufacturing stages and quality assurance practices, buyers can confidently select Grating Pacific as their go-to supplier for durable and high-quality grating products. With a focus on international standards and local compliance, Grating Pacific is equipped to meet the diverse needs of businesses in various industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘grating pacific’

This guide is designed to assist B2B buyers in efficiently sourcing products and services from Grating Pacific. By following this checklist, you can ensure that your procurement process is thorough, informed, and aligned with your project requirements.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is essential for successful sourcing. Determine the type of grating products you need—metal bar grating, fiberglass, perforated metals, etc.—and consider specific dimensions, load capacities, and environmental conditions. This clarity will help suppliers provide you with the most accurate solutions tailored to your needs.

Step 2: Research Supplier Capabilities

Investigate the capabilities of Grating Pacific and other suppliers. Review their product range, including available materials such as carbon steel, stainless steel, and aluminum, and assess their custom fabrication services. Understanding their manufacturing processes and technology will give you insight into their ability to meet your demands.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct a thorough evaluation. Request company profiles, case studies, and references from other clients, especially those in your industry or region. This step ensures that you are partnering with a reliable supplier who has a proven track record of delivering high-quality products.

Step 4: Check Certifications and Compliance

Ensure that the supplier adheres to industry standards and possesses relevant certifications. Look for compliance with safety regulations and quality assurance standards, such as ISO certifications. This verification is vital for minimizing risk and ensuring that the products meet your project’s specifications.

Step 5: Request Samples and Prototypes

Before making a large order, request samples or prototypes of the grating products you intend to purchase. Testing these samples in your specific application will help you assess their performance and suitability. It also allows you to evaluate the quality and finish of the products firsthand.

Step 6: Negotiate Pricing and Terms

Once you’ve identified a suitable supplier, initiate discussions on pricing and payment terms. Be clear about your budget constraints and explore options for bulk purchasing discounts or flexible payment plans. A well-negotiated agreement can lead to significant cost savings and ensure a mutually beneficial partnership.

Step 7: Plan for Logistics and Delivery

Finally, coordinate logistics and delivery timelines. Discuss shipping options, lead times, and any potential import duties if sourcing internationally. Having a clear understanding of the delivery process will help you manage your project timeline effectively and avoid delays.

By adhering to this checklist, you can streamline your sourcing process for grating products, ensuring that you partner with a reliable supplier who meets your technical and budgetary requirements.

Comprehensive Cost and Pricing Analysis for grating pacific Sourcing

What Are the Key Cost Components in Grating Pacific Sourcing?

When sourcing products from Grating Pacific, understanding the cost structure is essential for effective budgeting. The primary cost components include:

-

Materials: The choice of raw materials significantly impacts pricing. Grating Pacific offers various options, including carbon steel, aluminum, stainless steel, and fiberglass. Each material has its own cost implications based on market fluctuations and availability.

-

Labor: Skilled labor is required for manufacturing and custom fabrication. Labor costs can vary depending on the complexity of the product and the region of production. High-quality craftsmanship typically commands a premium.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, such as utilities, equipment maintenance, and facility management. Efficient operations can help mitigate these costs.

-

Tooling: Custom projects may require specialized tools or molds, which can incur additional costs. Understanding tooling requirements upfront can help buyers plan more effectively.

-

Quality Control (QC): Ensuring that products meet industry standards and client specifications necessitates a robust QC process. This adds to the overall cost but is essential for maintaining product integrity.

-

Logistics: Transportation costs depend on the size, weight, and destination of the products. International shipping may involve customs duties and import fees, which can significantly affect the total cost.

-

Margin: Grating Pacific, like any manufacturer, includes a profit margin in their pricing. This margin can vary based on market competition and the uniqueness of the product offering.

How Do Price Influencers Affect Grating Pacific Costs?

Several factors influence the final price of grating products from Grating Pacific:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often qualify for discounts, making it more cost-effective for large-scale projects. Understanding MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Custom products tailored to specific project needs may come at a higher price. Buyers should weigh the benefits of customization against potential cost increases.

-

Material Selection: The choice of material not only affects upfront costs but also the long-term performance and maintenance expenses. High-grade materials may have a higher initial cost but offer better durability and longevity.

-

Quality and Certifications: Products that meet stringent industry certifications may incur additional costs but provide assurance of quality and safety. Buyers should consider the importance of these certifications in their purchasing decisions.

-

Supplier Factors: Reliability, reputation, and service level of the supplier can influence pricing. Partnering with a reputable supplier like Grating Pacific may lead to better overall value, including customer support and product reliability.

-

Incoterms: Understanding the shipping terms agreed upon in the contract can impact final pricing. Incoterms dictate the responsibilities of buyers and sellers regarding shipping, customs, and insurance, affecting total costs.

What Tips Can Buyers Use for Cost-Efficiency in Grating Pacific Sourcing?

To maximize cost-efficiency when sourcing from Grating Pacific, consider the following strategies:

-

Negotiate Terms: Engage in discussions about pricing, payment terms, and delivery schedules. Suppliers may offer flexibility, especially for repeat customers or bulk orders.

-

Focus on Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the product, including maintenance and replacement. Investing in higher-quality materials may reduce TCO over time.

-

Research Pricing Nuances for International Buyers: Understand the local market conditions, currency fluctuations, and import regulations in your region. This knowledge can provide leverage during negotiations and help anticipate costs.

-

Consider Logistics and Delivery Options: Evaluate different shipping methods and delivery options. Choosing the most efficient route can reduce logistics costs significantly.

-

Stay Informed About Market Trends: Keeping abreast of industry trends and material prices can help buyers make informed decisions and act swiftly when favorable pricing opportunities arise.

Disclaimer

The prices and cost structures discussed are indicative and may vary based on specific project requirements, market conditions, and supplier negotiations. Always consult with Grating Pacific directly for accurate pricing tailored to your needs.

Alternatives Analysis: Comparing grating pacific With Other Solutions

Understanding Alternatives to Grating Pacific Solutions

In the competitive landscape of industrial and architectural metal solutions, understanding the alternatives to Grating Pacific can empower B2B buyers to make informed decisions. Grating Pacific is known for its wide array of grating products and custom solutions, but there are other viable options available that may better suit specific project requirements or budget constraints. This section explores alternative solutions, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Grating Pacific | Alternative 1: SlipNOT Metal Safety Flooring | Alternative 2: Fiberglass Grating |

|---|---|---|---|

| Performance | High strength and durability | Excellent slip resistance and safety | Lightweight, corrosion-resistant |

| Cost | Moderate to high | Moderate to high | Generally lower than metal options |

| Ease of Implementation | Custom solutions available | Easy installation with pre-made options | Simple to install; versatile |

| Maintenance | Low maintenance required | Requires periodic cleaning for safety | Minimal maintenance; resistant to chemicals |

| Best Use Case | Industrial flooring, platforms | High-traffic areas needing slip resistance | Wet or corrosive environments |

Detailed Breakdown of Alternatives

SlipNOT Metal Safety Flooring

SlipNOT is a leading provider of slip-resistant flooring solutions, particularly suited for environments where safety is a priority. Its unique coating process enhances traction, making it an excellent choice for high-traffic areas such as factories, warehouses, and outdoor applications. While it typically comes at a moderate to high price point, the safety features can justify the investment. However, it does require periodic cleaning to maintain its slip-resistant properties, which can increase long-term maintenance efforts.

Fiberglass Grating

Fiberglass grating presents a lightweight and corrosion-resistant alternative to traditional metal grating options like those offered by Grating Pacific. This option is ideal for environments exposed to chemicals, moisture, or where weight is a concern, such as in marine applications or food processing facilities. The installation is straightforward, and the grating requires minimal maintenance, making it a cost-effective solution in the long run. However, its load-bearing capacity may not match that of metal alternatives, which could limit its use in heavy industrial settings.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between Grating Pacific and its alternatives, B2B buyers should carefully consider the specific requirements of their projects, including the environment, safety needs, and budget constraints. Grating Pacific’s robust offerings are well-suited for heavy-duty applications, while alternatives like SlipNOT and fiberglass grating can provide specialized benefits such as enhanced safety and corrosion resistance. By evaluating performance, cost, ease of implementation, and maintenance, decision-makers can choose the solution that best aligns with their operational goals and project specifications.

Essential Technical Properties and Trade Terminology for grating pacific

What Are the Key Technical Properties of Grating Pacific Products?

When selecting grating products for industrial applications, understanding their essential technical properties is crucial. Here are some critical specifications that international B2B buyers should consider:

-

Material Grade

The material grade refers to the type of metal used in the grating products, such as carbon steel, aluminum, stainless steel, or fiberglass. Each material offers distinct advantages; for instance, stainless steel is known for its corrosion resistance, making it ideal for outdoor or humid environments. Choosing the right material grade ensures longevity and suitability for specific applications, reducing the need for frequent replacements. -

Load Capacity

Load capacity is a critical specification that indicates how much weight a grating can support without failure. It is often measured in pounds per square foot (PSF) and varies based on the design and materials used. Understanding load capacity is essential for safety and compliance with industry standards, particularly in sectors like construction and manufacturing where heavy machinery or foot traffic is common. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension or measured value of the grating product. High tolerance levels ensure precise fit and functionality, which is vital for applications requiring exact specifications, such as in structural components. This property can affect the performance and installation efficiency, making it crucial for buyers to inquire about tolerances during procurement. -

Finish

The finish of grating products can significantly influence both aesthetics and performance. Options may include galvanized, powder-coated, or painted finishes. Each finish provides different levels of protection against environmental factors such as moisture and UV exposure. A proper finish enhances durability and can reduce maintenance costs, making it a key consideration for long-term investments. -

Slip Resistance

Slip resistance is a safety feature that measures how well a surface can prevent slips and falls. Grating products designed with slip-resistant properties are particularly important in environments exposed to water, oil, or other slippery substances. Ensuring adequate slip resistance can mitigate workplace accidents and compliance issues, enhancing overall safety.

What Are Common Trade Terms Used in Grating Pacific Transactions?

Familiarity with industry jargon can streamline communications and negotiations. Here are several essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of grating products, buyers may engage with OEMs for custom-designed solutions that meet specific project requirements, ensuring compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is vital for B2B buyers to manage inventory effectively and avoid excess costs associated with purchasing more than needed. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price offers from suppliers for specific products or services. Submitting an RFQ allows buyers to compare pricing, terms, and capabilities from various manufacturers, fostering informed decision-making and competitive sourcing. -

Incoterms

Incoterms, or International Commercial Terms, are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risk management, and delivery obligations, which is particularly important for companies importing grating products from overseas. -

Lead Time

Lead time refers to the time taken from the placement of an order to its delivery. Understanding lead times is critical for planning and inventory management, especially in industries where project timelines are tight and depend on timely product availability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and contribute to successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the grating pacific Sector

What Are the Key Trends Shaping the Grating Pacific Market?

The grating sector is experiencing transformative dynamics driven by globalization, technological advancements, and changing consumer preferences. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly prioritizing suppliers who can offer customized solutions and demonstrate flexibility in meeting specific project needs. For instance, the demand for high-quality metal grating products, including aluminum, stainless steel, and fiberglass, is on the rise due to their durability and versatility in various applications such as construction, industrial, and commercial sectors.

Emerging technologies are also reshaping sourcing trends. Automation in manufacturing and the use of advanced design software are enabling companies like Grating Pacific to offer customized products with shorter lead times. Additionally, the integration of e-commerce platforms is facilitating easier access for international buyers to source products efficiently. As buyers become more environmentally conscious, there is a growing trend toward sourcing from suppliers who prioritize sustainability and ethical practices.

Furthermore, the global supply chain landscape is evolving, influenced by geopolitical factors and economic shifts. International buyers need to stay informed about these changes to identify reliable suppliers and mitigate risks associated with sourcing. Understanding local regulations and market conditions in target regions is critical for successful procurement.

How Is Sustainability Influencing Sourcing Decisions in the Grating Pacific Sector?

Sustainability has become a pivotal factor in B2B sourcing decisions within the grating sector. With increasing awareness of environmental impacts, businesses are seeking suppliers that prioritize eco-friendly practices. Grating Pacific’s commitment to using recycled materials in products like the Duetto™ wire mesh exemplifies this trend. By opting for suppliers who incorporate sustainable materials and processes, international buyers can reduce their carbon footprint and enhance their corporate responsibility.

Ethical sourcing is equally important. Companies are now scrutinizing their supply chains to ensure that their partners adhere to fair labor practices and environmentally responsible production methods. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are valuable indicators for buyers looking to assess a supplier’s commitment to sustainability. Additionally, the demand for ‘green’ building materials is pushing suppliers to innovate and offer products that meet stringent environmental standards.

By aligning their sourcing strategies with sustainability goals, international buyers not only contribute to environmental preservation but also enhance their brand reputation and appeal to a growing market segment that values corporate responsibility.

What Is the Historical Context of Grating Pacific’s Development?

Grating Pacific has evolved significantly since its inception in 1971. Originally a regional supplier, it has expanded its footprint across the United States, establishing a reputation for quality and innovation in metal grating solutions. Over the years, the company has embraced technological advancements that have revolutionized manufacturing processes, allowing for greater customization and efficiency.

The historical focus on quality and customer service has positioned Grating Pacific as a trusted partner for various industries, including construction, industrial, and commercial sectors. By adapting to changing market dynamics and prioritizing customer needs, Grating Pacific has successfully navigated the complexities of the grating sector, making it a go-to supplier for international B2B buyers seeking reliable and durable products.

Frequently Asked Questions (FAQs) for B2B Buyers of grating pacific

-

How do I choose the right type of grating for my project?

Choosing the right grating involves assessing your specific application needs, including load-bearing requirements, environmental conditions, and safety regulations. Grating Pacific offers various materials like steel, aluminum, and fiberglass, each suited for different applications. Consider factors such as corrosion resistance for outdoor use, slip resistance for flooring, and aesthetic appeal for architectural projects. Consulting with Grating Pacific’s engineering team can help you identify the optimal grating type that meets your project specifications. -

What are the customization options available for grating products?

Grating Pacific provides extensive customization options, including various sizes, shapes, and hole patterns. You can select from materials such as carbon steel, stainless steel, and fiberglass to tailor the product to your project’s needs. Additionally, they offer custom fabrication services, allowing you to specify unique dimensions or finishes. Engaging with their design team early in the project can ensure that your customized grating meets both functional and aesthetic requirements. -

What is the minimum order quantity (MOQ) for grating products?

The minimum order quantity can vary based on the specific product and customization requirements. Grating Pacific typically accommodates both large and small orders, making them flexible for various project sizes. For international buyers, it’s advisable to discuss your project needs with their sales team to determine the MOQ that aligns with your budget and timeline. Bulk orders may also benefit from pricing discounts, so consider discussing your needs thoroughly. -

What payment terms does Grating Pacific offer for international buyers?

Grating Pacific offers flexible payment terms, which can be tailored to accommodate international buyers. Typically, payment options may include wire transfers, letters of credit, or payment upon delivery, depending on the agreement. It’s essential to discuss your preferred payment method during the quotation phase to ensure smooth transactions. Always clarify any currency conversion implications and potential fees associated with international transactions. -

How does Grating Pacific ensure quality assurance in its products?

Grating Pacific is committed to maintaining high standards of quality assurance across its product lines. Their manufacturing processes adhere to industry standards, and they conduct rigorous testing for strength, durability, and safety. Additionally, the company offers complete fabrication and finishing services, allowing for quality control at every stage of production. Buyers can request certifications or quality reports to ensure that the products meet their specific requirements. -

What logistics solutions does Grating Pacific provide for international shipping?

Grating Pacific understands the complexities of international logistics and offers various shipping solutions tailored to your needs. They collaborate with trusted freight carriers to manage the shipping process efficiently, ensuring timely delivery. Depending on your location, you can choose between air or sea freight options. The sales team can assist in coordinating shipping logistics, including customs documentation and duties, to streamline the import process. -

How can I verify Grating Pacific as a reliable supplier?

To verify Grating Pacific as a reliable supplier, consider reviewing their industry reputation, customer testimonials, and years of experience. With over 50 years in the business, they have established a strong track record. Additionally, inquire about their certifications and affiliations with industry organizations. Engaging in direct communication with their sales and engineering teams can also provide insights into their customer service quality and responsiveness. -

What industries does Grating Pacific serve, and how can their products be applied?

Grating Pacific serves a diverse range of industries, including construction, industrial, and commercial sectors. Their products are utilized in various applications such as flooring systems, stair treads, trench covers, and catwalks. Each application has specific requirements for load capacity, slip resistance, and environmental durability, making it crucial to select the appropriate grating type. Their team can provide tailored recommendations based on the unique needs of your industry.

Top 5 Grating Pacific Manufacturers & Suppliers List

1. Grating Pacific – Metal Bar Grating Solutions

Domain: gratingpacific.com

Registered: 1997 (28 years)

Introduction: Grating Pacific offers a wide range of products including: Metal Bar Grating (Steel, Aluminum, Stainless Steel, Riveted), Bar Grating Stair Treads, Heavy Duty Bar Grating, Bridge Decking, Embed Frames, Trench & Inlet Systems, Architectural Products, and Metal Bar Grating Fabrication. They also provide Fiberglass Grating & Structural Components (Molded, Safe-T-Span® Pultruded, High Load Capacity, S…

2. Grating Pacific, Inc. – High-Quality Grating Products

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Grating Pacific, Inc. specializes in high-quality steel, aluminum, and fiberglass grating products. Their product offerings include steel bar grating, aluminum bar grating, and fiberglass grating, available in various sizes, styles, and configurations. Additionally, they provide accessories such as handrails, stair treads, and trench covers. The company also offers services including estimations, …

3. Grating Pacific – Comprehensive Grating Solutions

Domain: floor-gratings.com

Registered: 2002 (23 years)

Introduction: Grating Pacific, Inc. offers a comprehensive range of grating products including: welded steel, press-locked steel, aluminum, stainless steel, fiberglass, and slip-resistant grating. These products are available in various sizes, shapes, and configurations for applications such as flooring, stair treads, trench covers, catwalks, platforms, and mezzanines. The company also provides custom fabricati…

4. Grating Pacific – Metal and Fiberglass Fabrication

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: Grating Pacific offers metal and fiberglass fabrication services. They are located at 1398 Mariani Ct Ste 120, Tracy, California, and serve Northern and Central California. The business is unclaimed and has a 5.0 rating based on 1 review. Their phone number is (209) 832-6363, and their website is gratingpacific.com/tracy-ca.

5. Grating Pacific, Inc. – Wire Mesh Solutions

Domain: wire-cloth.net

Registered: 2001 (24 years)

Introduction: Grating Pacific, Inc. is a leading supplier of wire mesh products, offering a wide range of solutions for various industries. Key products include: woven wire mesh, welded wire mesh, expanded metal mesh, perforated metal mesh, and wire cloth. The company emphasizes quality by sourcing products from top manufacturers and provides exceptional customer service. Additionally, Grating Pacific offers va…

Strategic Sourcing Conclusion and Outlook for grating pacific

What Are the Key Benefits of Strategic Sourcing for Grating Pacific Products?

In conclusion, Grating Pacific stands as a pivotal partner for international B2B buyers seeking high-quality metal grating and related products. Their extensive range of offerings, including metal bar grating, fiberglass grating, and architectural solutions, caters to diverse industry needs while ensuring compliance with stringent safety and durability standards. By leveraging strategic sourcing, buyers can optimize their procurement processes, reduce costs, and enhance operational efficiency.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, businesses must prioritize partnerships that provide not only innovative products but also exceptional service. Grating Pacific’s commitment to customization and customer satisfaction positions them as a reliable source for unique project requirements.

Looking ahead, the demand for sustainable and adaptable building materials is set to rise. International buyers are encouraged to engage with Grating Pacific to explore tailored solutions that meet their specific operational needs while contributing to greener practices. Embrace the opportunity to enhance your projects with high-quality grating products from a trusted industry leader.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.