Heater Type Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for heater type

In today’s fast-paced global market, sourcing the right type of heater can be a daunting challenge for B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. The diverse range of heater types—spanning electric fan heaters, oil-filled radiators, convection units, and innovative infrared models—can leave procurement professionals overwhelmed with choices. This guide aims to simplify the decision-making process by providing a comprehensive overview of various heater types, their applications, and essential factors to consider when sourcing.

Understanding the nuances of different heating technologies is crucial for businesses looking to optimize energy efficiency and reduce operational costs. From evaluating the installation methods and specific use cases to vetting suppliers and analyzing costs, this guide empowers international B2B buyers with actionable insights. Whether you’re in Nigeria searching for an energy-efficient solution for your office or in Vietnam assessing the best heaters for industrial applications, our structured approach will help you make informed purchasing decisions.

By demystifying the complexities of the heater market, this guide ensures that you can confidently navigate your sourcing journey, ultimately leading to better thermal comfort, improved energy savings, and enhanced productivity for your business. Get ready to explore the heater landscape and discover solutions tailored to your unique operational needs.

Understanding heater type Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fan Heater | Compact, quick heat distribution using a fan | Small offices, workshops | Pros: Affordable, portable. Cons: Noisy, can dry out air. |

| Oil Heater | Uses oil as a heat reservoir, retains heat longer | Warehouses, larger spaces | Pros: Safe operation, energy-efficient. Cons: Heavy, slower to heat. |

| Convection Heater | Heats air through natural circulation, wall-mounted options | Retail spaces, showrooms | Pros: Quick to heat, constant temperature control. Cons: Requires wall space, can be less portable. |

| Infrared Heater | Directly heats objects and people, energy-efficient | Gyms, outdoor patios | Pros: High efficiency, low energy consumption. Cons: Requires professional installation, limited area coverage. |

| Micathermic Heater | Combines infrared and convection heating, low surface temperature | Residential buildings, schools | Pros: Safe for children, quick heating. Cons: Higher upfront cost, less common. |

What Are the Key Characteristics of Fan Heaters for B2B Buyers?

Fan heaters are compact and typically affordable, making them ideal for small-scale applications like workshops and small offices. They operate by using a fan to blow air over a heated element, providing immediate warmth. While they are portable, their noise level and tendency to dry out the air can be drawbacks for environments where comfort is a priority. B2B buyers should consider the size of the space and the need for a quick heating solution when selecting this type.

How Do Oil Heaters Stand Out in Commercial Settings?

Oil heaters are designed to provide consistent warmth over extended periods. They work by heating oil, which then radiates heat into the surrounding area. This makes them suitable for larger spaces such as warehouses. B2B buyers appreciate their safety features and energy efficiency, as they do not burn oxygen and can maintain warmth even after being turned off. However, their weight and slower heating time can be limiting factors in dynamic work environments.

Illustrative image related to heater type

Why Choose Convection Heaters for Retail Spaces?

Convection heaters are efficient at heating spaces quickly due to their ability to circulate warm air effectively. They are often wall-mounted, making them a space-saving option for retail environments and showrooms. Buyers should consider their need for precise temperature control, as many models come with built-in thermostats. While they provide quick heating, the requirement for wall installation may limit flexibility in some settings.

What Makes Infrared Heaters a Good Choice for Specific B2B Applications?

Infrared heaters are unique as they directly heat objects and people rather than the air, offering high energy efficiency. This makes them particularly suitable for gyms and outdoor patios, where instant warmth is desired. B2B buyers should note that while they can save on electricity costs, proper installation is crucial for maximizing their effectiveness. Their coverage area can be limited, so strategic placement is necessary.

How Do Micathermic Heaters Combine Features for Enhanced Safety and Efficiency?

Micathermic heaters utilize a blend of infrared and convection heating, providing a safe option for environments with children. They heat quickly and maintain a lower surface temperature, reducing burn risks. Their applications range from residential buildings to schools. While they may come with a higher price tag, their efficiency and safety features can justify the investment for B2B buyers seeking long-term solutions.

Key Industrial Applications of heater type

| Industry/Sector | Specific Application of heater type | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Process Heating in Production Lines | Enhanced efficiency and productivity in manufacturing processes | Energy consumption, safety certifications, and maintenance requirements |

| Food & Beverage | Food Processing and Cooking | Consistent temperature control for quality assurance | Compliance with health standards, energy efficiency, and equipment durability |

| Agriculture | Greenhouse Heating | Extended growing seasons and improved crop yields | Climate adaptability, energy source availability, and installation expertise |

| Construction | Site Heating for Curing and Drying | Improved project timelines and quality of construction | Mobility, power requirements, and safety features |

| Healthcare | Patient Care and Equipment Sterilization | Ensures patient comfort and equipment reliability | Compliance with health regulations, energy efficiency, and operational costs |

How is Heater Type Utilized in Manufacturing Processes?

In manufacturing, heaters are crucial for process heating, where they maintain specific temperatures for various materials during production. For instance, in plastic molding or metal fabrication, consistent heat ensures optimal material properties and reduces defects. International buyers must consider energy efficiency to minimize operational costs, as well as safety certifications to comply with local regulations, especially in regions with strict industrial standards.

What Role Do Heaters Play in Food Processing and Beverage Production?

In the food and beverage sector, heaters are used for cooking and processing food products. They ensure that food is cooked evenly and at the right temperatures, which is vital for quality control and food safety. Buyers in this industry must prioritize equipment that meets health regulations, offers energy efficiency, and can withstand frequent cleaning cycles, particularly in tropical climates where humidity can affect equipment performance.

Illustrative image related to heater type

How Can Heaters Benefit Agricultural Operations?

Heaters are employed in agriculture for greenhouse heating, allowing farmers to extend growing seasons and improve crop yields. By maintaining optimal temperatures, heaters help protect plants from frost and promote healthier growth. Buyers should focus on heaters that can adapt to varying climate conditions, considering energy sources that are readily available in their regions, such as solar or biomass options, particularly in developing areas.

Why Are Heaters Essential in Construction Sites?

In construction, heaters are vital for curing concrete and drying materials, which helps to maintain project timelines and ensure the quality of finished structures. Fast and efficient drying can prevent delays caused by weather conditions. When sourcing heaters for construction, businesses should consider models that are portable and have sufficient power outputs to accommodate large areas, while ensuring compliance with safety regulations to protect workers on-site.

How Do Heaters Support Patient Care in Healthcare Facilities?

In healthcare settings, heaters are essential for maintaining comfortable temperatures for patients and ensuring the sterilization of medical equipment. This is particularly important in surgical environments where precision and cleanliness are paramount. B2B buyers in healthcare must ensure that their heating solutions comply with strict health regulations, offer energy efficiency to reduce costs, and provide reliable performance to avoid any disruptions in patient care.

3 Common User Pain Points for ‘heater type’ & Their Solutions

Scenario 1: High Energy Costs from Inefficient Heating Solutions

The Problem: Many B2B buyers, especially those managing facilities in regions with fluctuating energy prices like Africa and South America, face the challenge of high energy costs due to inefficient heating solutions. Electric heaters, while convenient, can lead to soaring electricity bills if not chosen wisely. Buyers often find themselves in a dilemma between upfront costs and long-term operational efficiency. The result can be a frustrating cycle of selecting heaters that appear cost-effective but end up costing significantly more over time due to poor energy efficiency.

Illustrative image related to heater type

The Solution: To combat high energy costs, B2B buyers should focus on sourcing energy-efficient heating solutions. Consider investing in infrared heaters, which directly warm objects and people rather than the air, significantly reducing energy consumption. When specifying heaters, look for models with programmable thermostats and energy monitoring capabilities to optimize usage. Furthermore, conducting a thorough energy audit before purchasing can help identify the most suitable heater type for the specific space, ensuring that the chosen solution aligns with both budget and efficiency goals. Collaborating with manufacturers who offer warranties and support can also provide peace of mind regarding long-term performance.

Scenario 2: Inadequate Heating for Large Spaces

The Problem: In commercial settings, such as warehouses or large office spaces, B2B buyers frequently encounter the issue of inadequate heating. Many conventional electric heaters struggle to provide sufficient warmth for expansive areas, leading to discomfort for employees and inefficiency in operations. The challenge lies in selecting a heater that can effectively cover larger spaces without incurring excessive energy costs or requiring complex installation.

The Solution: To address the need for effective heating in large areas, buyers should consider convection heaters that are designed to circulate air efficiently. These heaters can be strategically placed along walls to maximize airflow and heat distribution. It’s advisable to consult with heating specialists to evaluate the specific heating requirements of the space, including volume and insulation levels. Opting for wall-mounted convection models can save floor space while providing consistent warmth. Additionally, integrating smart heating controls can allow for zoning, enabling different areas to be heated according to usage patterns, thus ensuring optimal comfort and energy efficiency.

Scenario 3: Safety Concerns with Heating Equipment

The Problem: Safety is a paramount concern for B2B buyers when selecting heating solutions, particularly in environments with children, elderly individuals, or flammable materials. Traditional heaters, especially those with exposed elements, can pose risks of burns or fire hazards. This concern often leads to hesitation in choosing certain types of heaters, creating a barrier to effective heating solutions in sensitive environments.

Illustrative image related to heater type

The Solution: To mitigate safety risks, buyers should prioritize heaters with built-in safety features, such as overheat protection, tip-over switches, and cool-to-the-touch exteriors. For example, oil heaters and micathermic heaters typically offer safer operational characteristics due to their design. Furthermore, investing in infrared heaters can also enhance safety, as they do not have exposed elements and primarily heat objects rather than the surrounding air. Buyers should also ensure that installation is done according to local safety standards, and regular maintenance checks are conducted to keep the equipment in optimal working condition. Providing training for employees on safe heater usage can further enhance safety and ensure a comfortable working environment.

Strategic Material Selection Guide for heater type

When selecting materials for heater types, it is essential to consider their properties, advantages, and limitations, especially from a B2B perspective. This analysis focuses on four common materials used in heater construction: aluminum, stainless steel, ceramic, and mica. Each material has unique characteristics that can significantly influence product performance, durability, and overall suitability for various applications.

What Are the Key Properties of Aluminum in Heater Types?

Aluminum is a lightweight and highly conductive metal, making it an excellent choice for heaters that require efficient heat transfer. Its temperature rating can typically withstand up to 600°C, and it exhibits good corrosion resistance, especially when anodized. However, aluminum can be prone to oxidation, which may affect its long-term performance in humid environments.

Pros & Cons: Aluminum heaters are generally cost-effective and easy to manufacture, allowing for rapid production. However, they may not be as durable as other materials, particularly in high-pressure applications. Additionally, while aluminum is suitable for many heating applications, it may not be the best choice for environments with high humidity or corrosive elements.

Impact on Application: Aluminum heaters are well-suited for residential and commercial heating applications where weight and heat transfer efficiency are critical. However, buyers in regions with high humidity, such as parts of Africa and South America, should consider the potential for corrosion.

How Does Stainless Steel Perform in Heater Applications?

Stainless steel is known for its exceptional strength and corrosion resistance, making it a popular choice for industrial heaters. It can withstand high temperatures (up to 800°C) and pressures, making it suitable for various heating applications, including those involving aggressive media.

Pros & Cons: The durability of stainless steel leads to a longer lifespan for heaters, reducing replacement costs. However, the manufacturing process can be more complex and expensive compared to aluminum. Additionally, while stainless steel is robust, it can be heavier, which may affect installation and mobility.

Impact on Application: Stainless steel heaters are ideal for industrial applications in harsh environments, such as chemical processing plants in the Middle East or Europe. International buyers should ensure compliance with standards like ASTM A240 for stainless steel grades.

What Advantages Do Ceramic Materials Offer in Heater Types?

Ceramic materials are often used in electric heaters due to their excellent thermal insulation properties and ability to withstand high temperatures (up to 1200°C). They are resistant to thermal shock and corrosion, making them suitable for various heating applications.

Illustrative image related to heater type

Pros & Cons: Ceramic heaters are efficient and can maintain a consistent temperature, which is beneficial for energy savings. However, they can be brittle and may require careful handling during installation. The cost of ceramic components can also be higher than metals like aluminum.

Impact on Application: Ceramic heaters are commonly used in residential and commercial settings, especially in regions like Europe where energy efficiency is a priority. Buyers should verify compliance with local energy standards and regulations.

Why is Mica Considered a Modern Choice for Heater Types?

Mica is a natural mineral that offers excellent thermal and electrical insulation properties. It can withstand high temperatures (up to 1000°C) and is often used in micathermic heaters, which combine infrared and convection heating technologies.

Pros & Cons: Mica heaters are lightweight and safe for families, as they do not overheat. However, the manufacturing process can be more complex, leading to higher costs. Additionally, mica may not be as widely available in some regions, which could affect supply chains.

Impact on Application: Mica heaters are particularly suitable for residential applications in regions with stringent safety regulations, such as Europe. B2B buyers should ensure that mica products comply with relevant safety standards, such as IEC 60335.

Summary Table of Material Selection for Heater Types

| Material | Typical Use Case for heater type | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Residential and commercial heaters | Lightweight and excellent heat transfer | Prone to corrosion in humid climates | Low |

| Stainless Steel | Industrial heaters in harsh environments | High durability and corrosion resistance | Higher manufacturing complexity | High |

| Ceramic | Residential and commercial heating | Excellent thermal insulation | Brittle and potentially higher cost | Medium |

| Mica | Residential micathermic heaters | Lightweight and safe for families | Higher manufacturing complexity | Medium |

This analysis provides a comprehensive overview for international B2B buyers, helping them make informed decisions based on material properties, application suitability, and regional considerations.

Illustrative image related to heater type

In-depth Look: Manufacturing Processes and Quality Assurance for heater type

What Are the Main Stages of Manufacturing Electric Heaters?

The manufacturing process for electric heaters involves several critical stages that ensure the production of high-quality, energy-efficient products. Understanding these stages can help B2B buyers evaluate potential suppliers and their capabilities.

Material Preparation: What Materials Are Used in Electric Heater Manufacturing?

The first step in the manufacturing process is material preparation. Manufacturers typically use a variety of materials depending on the heater type. Common materials include:

- Metals: Steel or aluminum for the housing and structural components.

- Heating Elements: Nickel-chromium alloys for resistive heating, ceramic for infrared models, and oil for oil-filled heaters.

- Insulation Materials: Mica or fiberglass to minimize heat loss and ensure safety.

- Plastics: Used for controls, fans, and other non-heat-conductive parts.

Quality sourcing of these materials is crucial, as it directly impacts the heater’s efficiency, durability, and safety.

Forming: How Are Electric Heater Components Shaped?

The forming stage involves shaping the prepared materials into specific components. This can include processes such as:

- Stamping and Molding: Used for creating metal housings and plastic parts.

- Extrusion: Commonly used for producing heating elements in a continuous form.

- Machining: Precision cutting and drilling to create mounting points and channels for air circulation.

Advanced forming techniques, such as CNC machining, ensure high precision and consistency, which are vital for product performance.

Assembly: What Is the Process of Putting Together Electric Heaters?

During the assembly stage, various components are brought together to create the final product. This typically involves:

Illustrative image related to heater type

- Component Integration: Attaching heating elements, insulation, and housing together.

- Wiring: Connecting electrical components, ensuring proper insulation and safety measures.

- Quality Checks: Immediate inspections are conducted to ensure that each component meets specifications before proceeding to the next stage.

Efficient assembly techniques can significantly reduce production time and costs, a factor crucial for B2B buyers looking for competitive pricing.

Finishing: How Is the Final Product Prepared for Market?

The finishing stage includes several processes aimed at enhancing the product’s appearance and functionality:

- Surface Treatment: Painting or powder coating to prevent corrosion and enhance aesthetics.

- Final Assembly: Adding knobs, digital displays, or remote controls.

- Packaging: Ensuring that the products are securely packaged for shipment, preventing damage during transit.

This stage is vital for establishing brand reputation, as the appearance and perceived quality can influence buyer decisions.

What Are the Quality Control Measures in Electric Heater Manufacturing?

Quality assurance is integral to the manufacturing of electric heaters, ensuring that products meet international standards and customer expectations. Here’s a breakdown of the key quality control measures.

Illustrative image related to heater type

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with various international standards that manufacturers adhere to, including:

- ISO 9001: This standard focuses on quality management systems and is crucial for ensuring consistent product quality.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Standards: For heaters used in industrial applications, compliance with American Petroleum Institute standards may be necessary.

Understanding these certifications helps buyers assess the credibility of suppliers.

What Are the Key QC Checkpoints in Electric Heater Manufacturing?

Quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival at the manufacturing facility to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early. This can include visual inspections and measurements at various stages.

- Final Quality Control (FQC): Before products leave the facility, a comprehensive inspection ensures that all units meet quality standards and function as intended.

By understanding these checkpoints, B2B buyers can better evaluate a manufacturer’s commitment to quality.

What Common Testing Methods Are Used to Ensure Heater Quality?

Manufacturers employ various testing methods to ensure the quality and safety of electric heaters, including:

- Electrical Testing: Checking for insulation resistance, continuity, and grounding to prevent electrical hazards.

- Performance Testing: Assessing the heater’s efficiency, heat output, and energy consumption under different conditions.

- Safety Testing: Ensuring compliance with safety standards, such as overheat protection and flame resistance.

These tests not only ensure compliance with standards but also enhance customer satisfaction through reliable product performance.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that potential suppliers maintain rigorous quality control standards, B2B buyers can take several actions:

- Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality management systems. This can include facility visits and process evaluations.

- Request Quality Reports: Suppliers should be able to provide documentation, including quality control reports and compliance certificates, demonstrating adherence to relevant standards.

- Engage Third-Party Inspectors: Utilizing independent inspection services can provide an unbiased assessment of a supplier’s quality control practices and product reliability.

This proactive approach helps mitigate risks associated with poor quality, especially in international transactions.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

- Regulatory Compliance: Different regions may have varying regulations and standards. It’s essential for buyers to understand the specific requirements for their market.

- Cultural Considerations: Communication styles and business practices can differ significantly across cultures. Building strong relationships with suppliers can facilitate better quality control.

- Logistical Challenges: International shipping can introduce risks such as damage or delays. Ensuring that suppliers have robust packaging and shipping protocols is crucial.

By addressing these factors, B2B buyers can enhance their procurement strategies and ensure they receive high-quality electric heaters tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heater type’

In the competitive landscape of B2B procurement, acquiring the right type of heater is pivotal for ensuring energy efficiency and operational effectiveness. This guide provides a step-by-step checklist tailored for international buyers looking to source heaters that meet their specific needs.

Step 1: Define Your Heating Requirements

Understanding the specific heating needs of your facility is the first step. Consider the size of the area to be heated, the type of activities conducted within the space, and the desired temperature range. This will help you determine the appropriate heating capacity and technology required, whether it be convection, infrared, or oil-based heating systems.

Step 2: Research Available Heater Types

Familiarize yourself with the various types of heaters available in the market. Each type, such as fan heaters, oil heaters, and infrared models, operates on different principles and has unique advantages and drawbacks. Make note of their energy consumption rates and heating efficiency to align with your operational goals and budget constraints.

Step 3: Evaluate Energy Efficiency Standards

Energy efficiency is a crucial factor in selecting heaters, particularly for long-term operational cost savings. Look for models that have high energy efficiency ratings and consider the energy consumption per hour. Efficient heaters not only reduce operational costs but also contribute to sustainability initiatives, which can be a selling point for your business.

Step 4: Check for Compliance with Local Regulations

Ensure that the heaters comply with local safety and environmental regulations. Different regions may have specific certifications or standards that heaters must meet, which can affect usability and legal compliance. Verify that the products are certified by recognized organizations, as this can safeguard against potential liabilities.

Step 5: Assess Supplier Reliability

The reliability of your supplier can significantly impact your procurement process. Investigate their market reputation, financial stability, and customer service track record. Request references from other businesses in similar industries or regions to gauge their reliability and responsiveness.

Step 6: Request Product Samples or Demonstrations

Before making a bulk purchase, it’s advisable to request samples or demonstrations of the heaters you are considering. This allows you to assess the product’s performance, ease of use, and suitability for your specific environment. Pay attention to factors like noise levels, heating speed, and safety features during the evaluation.

Step 7: Negotiate Terms and Conditions

Once you have selected potential suppliers, engage in negotiations to secure the best terms. Discuss payment options, warranty provisions, delivery timelines, and after-sales support. A well-structured agreement can enhance your procurement experience and establish a beneficial relationship with the supplier.

By following this checklist, B2B buyers can ensure a well-informed and strategic procurement process for heaters that will meet their operational needs and enhance overall efficiency.

Comprehensive Cost and Pricing Analysis for heater type Sourcing

What Are the Key Cost Components in Heater Type Sourcing?

Understanding the cost structure of heater types is crucial for international B2B buyers. The primary components of cost include:

-

Materials: The choice of materials significantly impacts the cost. For instance, infrared heaters may utilize advanced ceramics or glass, while oil heaters rely on durable metal casings. The quality and type of materials will affect both the price and longevity of the product.

-

Labor: Labor costs vary by region. In countries with lower labor costs, such as Vietnam or certain parts of Africa, manufacturers may offer competitive pricing. However, labor quality can also influence the final product’s reliability and safety.

-

Manufacturing Overhead: This includes the costs associated with running a factory, such as utilities, maintenance, and administrative expenses. Factories with high efficiency and automation typically have lower overhead costs, which can translate to lower prices for buyers.

-

Tooling: Initial tooling costs for molds and equipment can be substantial, particularly for customized heater designs. These costs are often amortized over the production run, meaning that larger orders can lead to lower per-unit costs.

-

Quality Control (QC): Ensuring product reliability through quality control can incur additional costs. Robust QC processes may elevate the manufacturing costs but are essential for ensuring compliance with international safety standards and certifications.

-

Logistics: Shipping and handling expenses must be factored into the total cost. Factors such as distance, mode of transport, and customs duties will vary significantly based on the supplier’s location and the buyer’s market.

-

Margin: Suppliers typically add a profit margin to cover their costs and generate profit. This margin can vary based on market competition, brand reputation, and perceived product value.

How Do Price Influencers Affect Heater Type Sourcing?

Several factors can influence the pricing of heaters, particularly for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs to optimize costs.

-

Specifications and Customization: Custom features can significantly increase costs. Buyers should balance the need for specific functionalities against their budget constraints, considering whether standard models can suffice.

-

Materials and Quality Certifications: Higher-quality materials and products that meet international safety certifications may command higher prices. However, they can provide better performance and lower maintenance costs over time.

-

Supplier Factors: The reputation and reliability of suppliers can also influence pricing. Established suppliers with a proven track record may charge a premium, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the total cost of ownership, as they dictate responsibility for shipping costs and risks.

What Are Some Tips for Negotiating Heater Prices?

Effective negotiation is key to achieving favorable pricing. Here are practical tips for B2B buyers:

-

Conduct Market Research: Understand the prevailing market rates for different heater types. This knowledge will empower you during negotiations and help you identify reasonable price ranges.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also the operational costs, including energy consumption and maintenance. Highlighting the long-term savings from energy-efficient models can justify higher upfront costs.

-

Leverage Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication and feedback can foster loyalty and encourage suppliers to offer discounts or improved terms.

-

Be Prepared for Trade-offs: Be ready to compromise on certain specifications or features to achieve cost savings. Flexibility can often lead to more favorable deals without sacrificing essential performance aspects.

Final Thoughts on Heater Pricing for International Buyers

Navigating the complexities of heater pricing requires an understanding of both cost structures and market dynamics. While indicative prices can provide a starting point, it’s essential to engage directly with suppliers to get accurate quotes tailored to specific needs. By focusing on the aforementioned components and strategies, international B2B buyers can make informed purchasing decisions that align with their operational goals.

Alternatives Analysis: Comparing heater type With Other Solutions

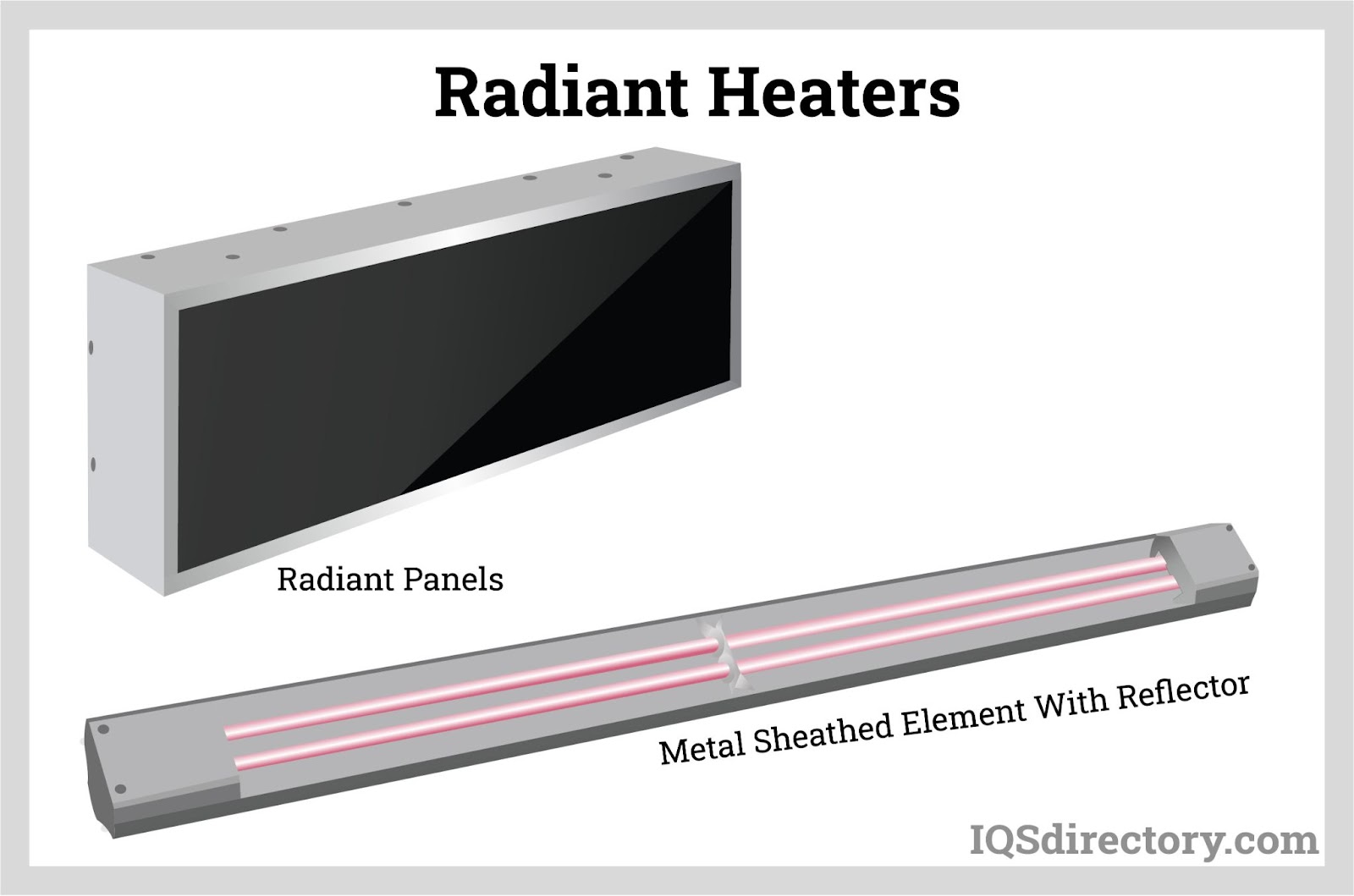

Understanding Alternative Heating Solutions for Businesses

When considering heating solutions for commercial spaces, it’s essential to explore various options beyond the conventional heater type. Different technologies can serve similar functions but may vary significantly in performance, cost, and applicability. This analysis will compare ‘heater type’ with two viable alternatives: radiant floor heating and heat pumps, allowing B2B buyers to make informed decisions based on their specific needs.

Comparison Table

| Comparison Aspect | Heater Type | Radiant Floor Heating | Heat Pumps |

|---|---|---|---|

| Performance | Quick to heat spaces, effective for localized heating | Provides even heat distribution, ideal for large areas | Highly efficient, can provide both heating and cooling |

| Cost | Moderate initial investment; operational costs vary | High installation cost; low operating costs over time | Higher upfront cost; lower energy bills can offset initial investment |

| Ease of Implementation | Simple plug-and-play setup | Requires professional installation | Complex installation; may need ductwork |

| Maintenance | Low maintenance; occasional cleaning | Minimal maintenance; periodic checks needed | Moderate maintenance; regular servicing required |

| Best Use Case | Small to medium spaces requiring quick heating | Large open areas or spaces with high ceilings | Versatile for varying climates, suitable for residential and commercial use |

Analyzing Radiant Floor Heating

Radiant floor heating is an effective solution, particularly in settings where consistent temperature is crucial. This system involves installing heating cables or water tubing beneath the floor, providing warmth from the ground up. One of its main advantages is the even heat distribution, which enhances comfort and can reduce heating costs over time. However, the initial installation can be costly and disruptive, requiring professional expertise. It is best suited for new constructions or major renovations rather than retrofitting in existing spaces.

Evaluating Heat Pumps

Heat pumps are a versatile heating solution that can also function as air conditioners. They extract heat from the air or ground and transfer it indoors, making them highly efficient. The primary advantage of heat pumps is their energy efficiency; they can provide up to three times the energy they consume. However, the installation process can be complicated and expensive, particularly if ductwork is needed. Heat pumps are ideal for climates with moderate heating and cooling needs, making them suitable for both residential and commercial applications.

Conclusion: Choosing the Right Heating Solution for Your Business

Selecting the right heating solution hinges on understanding your specific requirements, including the size of the space, budget constraints, and long-term operational costs. While ‘heater type’ offers a straightforward and effective means of heating smaller areas, alternatives like radiant floor heating and heat pumps provide distinct advantages in specific scenarios. B2B buyers should carefully assess their unique circumstances and priorities—be it installation complexity, maintenance needs, or energy efficiency—before committing to a solution. By doing so, they can ensure a strategic investment that aligns with their operational goals and budgetary considerations.

Essential Technical Properties and Trade Terminology for heater type

What Are the Key Technical Properties of Heaters That B2B Buyers Should Know?

When sourcing heaters, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that B2B buyers should consider:

Illustrative image related to heater type

-

Heating Technology

Different heaters employ various technologies to generate heat, such as convection, infrared radiation, and micathermic heating. Each technology has its own efficiency and application suitability. For instance, infrared heaters are highly efficient for direct heating of objects and people, making them ideal for large open spaces, while convection heaters warm the air and are better for enclosed environments. Knowing the heating technology helps buyers select the most effective solution for their specific needs. -

Power Rating (Wattage)

The power rating, measured in watts, indicates how much energy a heater consumes and its heating capacity. Common ratings range from 500W for smaller models to over 2000W for larger units. A higher wattage typically means the heater can warm a larger area more quickly. B2B buyers should evaluate power requirements based on the intended space to ensure efficiency and cost-effectiveness in energy consumption. -

Material Grade

The materials used in heater construction affect durability, safety, and heat retention. Common materials include steel, aluminum, and ceramics. For example, ceramic heaters tend to provide safer, more efficient heating due to their ability to retain heat longer. Understanding material grades helps buyers assess the heater’s longevity and performance under various conditions, particularly in industrial or commercial settings. -

Thermal Efficiency

This property indicates how effectively a heater converts energy into heat. Higher thermal efficiency means less energy wastage and lower operating costs. Infrared heaters, for example, can achieve efficiencies of up to 70%, making them a preferred choice for energy-conscious buyers. Evaluating thermal efficiency is essential for long-term cost savings, especially in regions with high energy prices. -

Safety Features

Safety is paramount in heating equipment. Key features include overheat protection, tip-over switches, and child-safe designs. Heaters with built-in safety mechanisms reduce the risk of accidents, making them suitable for both residential and commercial environments. B2B buyers should prioritize safety certifications and features to ensure compliance with local regulations and standards.

What Common Trade Terms Should B2B Buyers Understand When Sourcing Heaters?

Familiarity with industry jargon is vital for navigating procurement processes effectively. Here are some common terms relevant to heater sourcing:

-

OEM (Original Equipment Manufacturer)

An OEM produces parts or equipment that may be marketed by another company. In the heating industry, sourcing from an OEM can ensure high-quality components tailored to specific requirements, which can be beneficial for custom installations or bulk orders. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell in one order. Understanding MOQ is critical for B2B buyers to manage inventory and budget. Suppliers often set MOQs to ensure production efficiency, so negotiating terms may be necessary for smaller businesses or first-time buyers. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. B2B buyers should prepare detailed RFQs that outline specifications, quantities, and delivery timelines to receive accurate quotes and streamline the purchasing process. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, risk, and insurance. Familiarity with terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) helps buyers understand their obligations and costs associated with transportation, making it easier to manage logistics and budgeting. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. Understanding lead times is essential for B2B buyers to plan their projects and inventory effectively. Suppliers often provide estimated lead times based on production schedules and shipping methods, which can influence procurement strategies.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing heaters, ensuring that they select the right products for their operational needs while optimizing costs and efficiency.

Navigating Market Dynamics and Sourcing Trends in the heater type Sector

What are the Current Market Dynamics and Key Trends in the Heater Type Sector?

The heater type market is experiencing dynamic growth driven by various global factors. As energy efficiency becomes a priority for consumers and businesses alike, electric heaters, particularly infrared and convection models, are gaining traction due to their ability to provide effective heating with lower energy consumption. In regions such as Africa and South America, where energy costs can be prohibitive, energy-efficient models are particularly appealing. Moreover, the rise of smart home technology is influencing purchasing decisions, with an increasing number of heaters equipped with IoT capabilities that allow for remote control and energy tracking via mobile applications.

Illustrative image related to heater type

Emerging trends also indicate a shift towards portable and versatile heating solutions. Buyers are looking for models that can adapt to different settings, whether it be residential, commercial, or industrial. In Europe and the Middle East, the demand for aesthetically pleasing designs is growing, as consumers prefer heaters that blend seamlessly with their interiors. Furthermore, sustainability is becoming a significant consideration, pushing manufacturers to innovate with eco-friendly materials and designs that minimize environmental impact.

How Can B2B Buyers Prioritize Sustainability and Ethical Sourcing in the Heater Type Sector?

The environmental impact of heating solutions is increasingly coming under scrutiny, making sustainability a critical factor for B2B buyers in the heater type sector. Companies are now expected to demonstrate a commitment to sustainable practices, including the sourcing of materials and the manufacturing processes used. Buyers should prioritize suppliers who provide transparent information about their supply chains and adhere to environmental regulations.

Incorporating ‘green’ certifications into purchasing criteria can help ensure that the products meet established environmental standards. Certifications such as Energy Star and EcoLabel signify that the heaters are energy-efficient and have a reduced carbon footprint. Additionally, buyers should consider suppliers who utilize recyclable materials in their products, which not only lessens environmental impact but also appeals to the growing consumer demand for sustainable goods.

Ethical sourcing extends beyond environmental concerns; it encompasses labor practices and the overall impact on local communities. Engaging with suppliers who uphold fair labor practices and contribute positively to their communities can enhance brand reputation and foster long-term partnerships.

Illustrative image related to heater type

How Has the Heater Type Market Evolved Over Time?

The heater type market has undergone significant evolution, particularly in response to technological advancements and changing consumer preferences. Historically, traditional heating solutions relied heavily on fossil fuels, which posed environmental and economic challenges. However, the introduction of electric heating technologies marked a turning point, enabling greater efficiency and ease of use.

Over the years, advancements in heating technology have led to the development of a diverse range of products, from basic fan heaters to sophisticated infrared models. The incorporation of smart technology has further transformed the market, allowing for enhanced user control and energy management. As global awareness of climate change intensifies, the heater type sector is poised to continue evolving, with an increasing emphasis on sustainability and innovative design that meets the demands of modern consumers.

In summary, international B2B buyers need to stay informed about market trends, prioritize sustainability, and understand the historical context of heater types to make strategic purchasing decisions that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of heater type

-

How do I choose the right type of heater for my business needs?

Selecting the right heater involves assessing your specific heating requirements, such as the size of the space and the desired heating efficiency. Consider the type of heater—fan, convection, infrared, or oil—based on the intended application. For instance, infrared heaters are ideal for larger spaces due to their efficiency in heating objects directly, while fan heaters are suitable for smaller areas. Evaluate energy consumption and cost-effectiveness, especially in regions with high energy prices. Always consult with suppliers to understand the best options available for your specific context. -

What is the best electric heater for industrial use?

For industrial applications, convection and infrared heaters often provide the best performance. Convection heaters are effective for larger spaces as they circulate warm air quickly, while infrared heaters target specific areas for direct heating. Consider models that offer programmable thermostats and safety features, such as overheat protection, to enhance operational efficiency. It’s also crucial to evaluate the heater’s energy consumption and output capacity to ensure it meets the demands of your facility. -

What factors should I consider when vetting suppliers for heaters?

When vetting suppliers, consider their industry reputation, product quality certifications, and customer reviews. Assess their experience in exporting to your region, especially if you’re sourcing from Africa, South America, the Middle East, or Europe. Verify their compliance with international safety and quality standards. Request samples or detailed product specifications to evaluate performance claims. Additionally, inquire about their after-sales support, warranty terms, and responsiveness to ensure a reliable partnership. -

What are common minimum order quantities (MOQs) for heater types?

Minimum order quantities can vary significantly by supplier and the type of heater. Typically, industrial suppliers may have MOQs ranging from 50 to 100 units, while more specialized or high-end models might have higher MOQs. Always discuss your specific needs with suppliers to negotiate acceptable terms. Some manufacturers may offer flexibility in MOQs for new customers or bulk orders, so it’s beneficial to communicate your projected demand clearly. -

How do payment terms work for international heater purchases?

Payment terms for international purchases can vary but often include options such as advance payments, letters of credit, or net 30/60 terms. Discuss payment methods that are secure and convenient for both parties. It’s advisable to choose methods that provide buyer protection, such as escrow services. Be aware of currency exchange rates and additional fees related to international transactions, as these can impact your overall cost. -

What quality assurance measures should I look for when purchasing heaters?

Quality assurance is critical when sourcing heaters. Look for suppliers that adhere to international quality standards, such as ISO certifications. Request documentation of testing procedures and results, including safety tests and energy efficiency ratings. Understand the warranty and return policy, as these reflect the supplier’s confidence in their product. Engaging in third-party inspections before shipment can also provide peace of mind regarding product quality. -

What logistical considerations should I keep in mind when importing heaters?

When importing heaters, consider shipping times, customs regulations, and potential duties or tariffs. Ensure that your supplier can provide the necessary documentation for customs clearance. Evaluate shipping methods that balance cost and delivery speed, especially if you have tight deadlines. Additionally, consider warehousing options in your region to facilitate quicker distribution once the heaters arrive. -

How can I customize heaters to suit my specific business needs?

Many manufacturers offer customization options for heaters, including size, design, and features. Discuss your specific requirements with potential suppliers, such as integrating smart technology for remote control or adjusting heating capacity to suit larger spaces. Understand the lead times for custom orders and any associated costs. Providing detailed specifications will help ensure that the final product meets your expectations and operational needs effectively.

Top 7 Heater Type Manufacturers & Suppliers List

1. Glen Dimplex – Electric Heaters Overview

Domain: cadet.glendimplexamericas.com

Registered: 2017 (8 years)

Introduction: Types of Electric Heaters: 1. Baseboard Heaters: Economical, hardwired, natural convection, longer to warm a room, requires 1 foot clearance, least expensive to install. 2. Floor Heating: Radiant floor heaters (electric cables, heated water tubes, electric mats), effective with concrete floors, retains heat, expensive installation, reduces room height. 3. Radiant Panels & Cove Heaters: Installed i…

2. Thomas Galbraith – Heating System Solutions

Domain: thomasgalbraith.com

Registered: 2009 (16 years)

Introduction: Heating System Options: 1. Central Forced Air Systems: Central furnaces and heat pumps (air source and ground source). 2. Boiler Systems: Condensing gas-fired and oil-fired boilers. 3. Hydronic Systems: Radiant floor heating and home heating/hot water systems. 4. Hybrid Heating and Cooling Systems: Generate heat and offer air conditioning. 5. Ductless Heat Pumps: Mini-split systems for zoned heati…

3. Lowe’s – Heater Buying Guide

Domain: lowes.com

Registered: 1995 (30 years)

Introduction: Heater Buying Guide: Types of Heaters to Buy. Key considerations when purchasing a heater include: 1. British Thermal Units (BTU) – measures heat output and space heating capacity. 2. Variable Settings – allows adjustment of output and energy consumption. 3. Built-In Blowers – distribute heat evenly, saving energy and increasing comfort. 4. Portability – enables heating specific areas. 5. Built-In…

4. The Spruce – Forced Air Heating/Cooling Systems

Domain: thespruce.com

Registered: 2009 (16 years)

Introduction: 1. Forced Air Heating/Cooling Systems:

– Best for: Multipurpose HVAC that heats and cools quickly

– Cost: $5,000 – $10,000

– Lifespan: Up to 25 years

– Fuel sources: Natural gas, liquid propane (LP), fuel oil, electricity

– Distribution: Ducts

– Pros: Air filters and humidifiers can be added, highest AFUE ratings, combines cooling with heating capability

– Cons: Require…

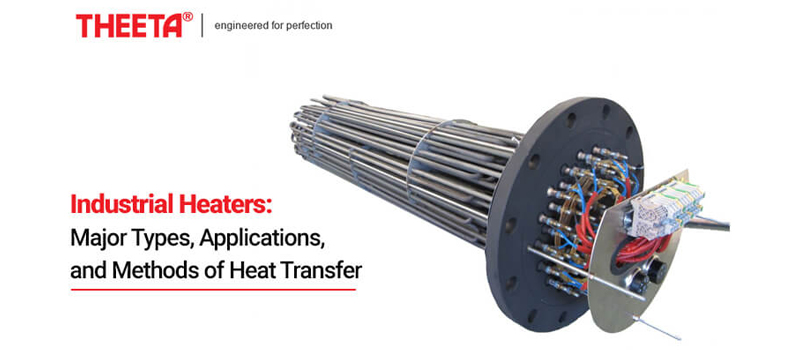

5. Omega – Industrial Electric Heaters

Domain: omega.co.uk

Registered: 1996 (29 years)

Introduction: Industrial electric heaters are used to increase the temperature of objects or processes. They convert electrical energy into heat, which is transferred through various methods: convective, conductive, and radiant heat transfer. Types of industrial electric heaters include: 1. Strip Heaters – Flat devices mounted on surfaces to heat the surface or surrounding air. 2. Ring Heaters – Designed to hea…

6. Sylvane – Heaters & Electric Fireplaces

Domain: sylvane.com

Registered: 2001 (24 years)

Introduction: This company, Sylvane – Heaters & Electric Fireplaces, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. ColdFactor – Types of Heaters

Domain: coldfactor.com

Registered: 2010 (15 years)

Introduction: Types of Heaters: Heat Pumps, Furnaces, Electric Heaters. Heat Pumps: Energy-efficient, dual function (heating and cooling), eco-friendly, effective in moderate climates. Furnaces: Gas-powered, powerful heating for larger spaces, requires maintenance, reliable in cold climates. Electric Heaters: Effective for smaller areas, less efficient for whole-home heating in colder climates. Considerations: …

Strategic Sourcing Conclusion and Outlook for heater type

In navigating the diverse landscape of electric heaters, international B2B buyers must prioritize energy efficiency, installation flexibility, and operational costs. Understanding the various types of heaters—ranging from fan and oil heaters to advanced infrared and micathermic models—enables businesses to select solutions tailored to their specific needs and environments.

Strategic sourcing plays a crucial role in this process, allowing companies to leverage supplier relationships and negotiate terms that enhance cost-effectiveness while ensuring quality. By considering factors such as energy consumption and the intended application of the heaters, buyers can make informed decisions that contribute to long-term operational success.

As we look to the future, the demand for energy-efficient and innovative heating solutions will only grow, particularly in regions like Africa, South America, the Middle East, and Europe. International buyers are encouraged to explore partnerships with reputable suppliers who offer cutting-edge technologies that align with sustainability goals. Embrace the opportunity to enhance your heating strategies today—invest in solutions that promise reliability and efficiency for a competitive edge in your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.