The Definitive Guide to Centrifugal Fans And Blowers: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for centrifugal fans and blowers

In the rapidly evolving landscape of industrial equipment, sourcing the right centrifugal fans and blowers can pose significant challenges for B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. These essential components play a critical role in various applications, from material handling to HVAC systems, and understanding their nuances is vital for optimizing operational efficiency and cost-effectiveness. This guide provides an in-depth exploration of centrifugal fans and blowers, addressing key considerations such as types, applications, performance specifications, and supplier vetting processes.

As international buyers navigate this complex market, they must contend with varying regional requirements, technological advancements, and fluctuating costs. This guide empowers decision-makers by outlining essential criteria for selecting the right products, including performance metrics like airflow and pressure capabilities, as well as construction materials suitable for specific environments. Additionally, it offers insights into the best practices for supplier evaluation, ensuring that buyers can confidently identify reliable partners who meet their unique needs.

With a focus on actionable insights tailored to the specific challenges faced by B2B buyers in key markets, this comprehensive resource serves as a vital tool for making informed purchasing decisions. By leveraging the information presented here, businesses can not only streamline their procurement processes but also enhance their operational resilience in a competitive global market.

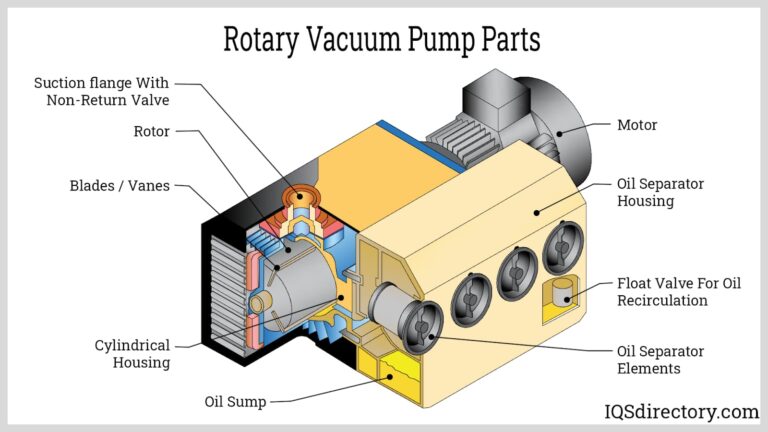

Understanding centrifugal fans and blowers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Backward Curved Fans | Efficient at high volumes, low pressure; curved blades | HVAC systems, industrial ventilation | Pros: High efficiency, low noise; Cons: Limited pressure capability compared to other types. |

| Forward Curved Fans | Blades curve in the direction of rotation; compact design | General ventilation, air conditioning | Pros: Compact, good for low pressure; Cons: Less efficient at high pressures. |

| Radial Fans | Straight blades for high pressure and flow | Material handling, dust collection | Pros: High pressure capabilities; Cons: Noisy operation, may require sound dampening. |

| Plug Fans | Direct drive design, compact size | Clean air applications, HVAC systems | Pros: Space-saving, energy-efficient; Cons: Installation may be complex in tight spaces. |

| Pressure Blowers | Designed for high pressure, large airflow | Industrial processes, pneumatic conveying | Pros: Handles high pressure effectively; Cons: Higher initial costs and maintenance needs. |

What Are the Key Characteristics of Backward Curved Fans?

Backward curved fans are designed with blades that are curved away from the direction of airflow. This design allows for efficient operation at high volumes and low pressures, making them ideal for HVAC systems and industrial ventilation applications. When purchasing, consider the fan’s efficiency ratings and noise levels, as backward curved fans typically operate quieter than other types. Their ability to handle varying airflows while maintaining performance makes them a popular choice among B2B buyers.

Why Choose Forward Curved Fans for General Ventilation?

Forward curved fans feature blades that curve in the direction of rotation, which allows them to generate a compact design suitable for applications requiring moderate airflow at low pressures. They are commonly used in air conditioning and general ventilation systems. Buyers should weigh the space-saving benefits against the fans’ lower efficiency at high pressures. Forward curved fans are particularly beneficial for businesses needing a balance between size and airflow.

How Do Radial Fans Perform in Material Handling Applications?

Radial fans utilize straight blades that can handle high pressures and substantial airflow, making them well-suited for material handling and dust collection applications. Their robust construction allows them to manage challenging environments, but they can be noisy, necessitating sound dampening solutions in some settings. B2B buyers should evaluate the noise levels and ensure the fan meets specific pressure and airflow requirements for their operations.

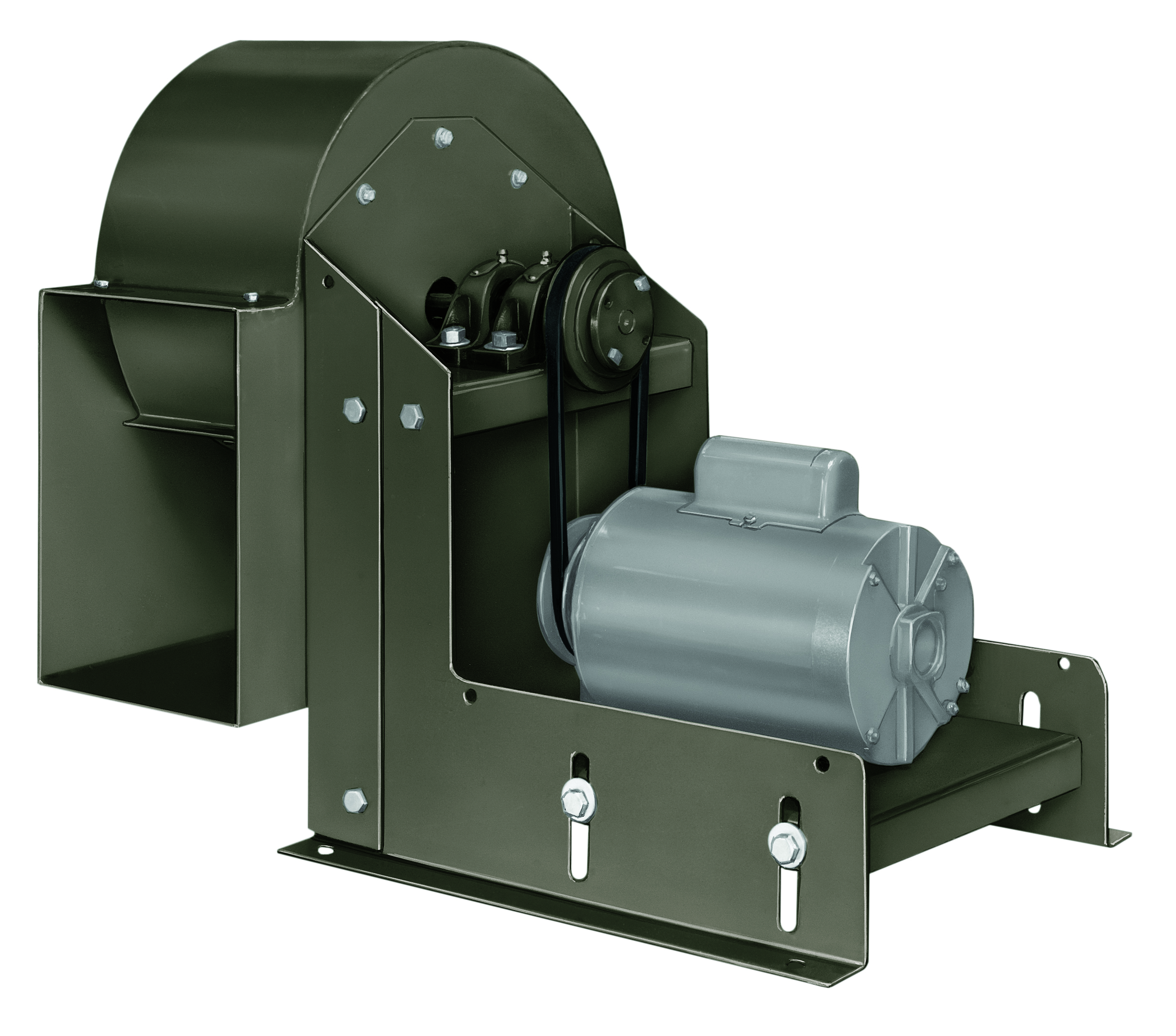

Illustrative image related to centrifugal fans and blowers

What Are the Advantages of Plug Fans in Clean Air Applications?

Plug fans are characterized by their direct drive design and compact size, making them ideal for clean air applications and HVAC systems. Their energy efficiency and space-saving capabilities are significant advantages, especially in environments where space is limited. However, buyers should consider the complexity of installation, particularly in confined areas. Plug fans provide a reliable solution for businesses focused on energy efficiency and effective airflow management.

Why Are Pressure Blowers Essential for Industrial Processes?

Pressure blowers are engineered to handle high pressure and large airflow, making them critical in industrial processes and pneumatic conveying systems. Their robust design allows for reliable performance even under demanding conditions. While they may come with higher initial costs and maintenance requirements, the efficiency and effectiveness in handling high-pressure applications often justify the investment for B2B buyers. Understanding the specific needs of your operations will be crucial in selecting the appropriate blower type.

Key Industrial Applications of centrifugal fans and blowers

| Industry/Sector | Specific Application of Centrifugal Fans and Blowers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC and Building Services | Ventilation and air conditioning systems | Enhances air circulation, improving indoor air quality and energy efficiency. | Energy ratings, noise levels, and compliance with local regulations. |

| Manufacturing | Dust collection and material handling systems | Reduces downtime and maintenance costs by efficiently managing airborne particulates. | Durability of materials, capacity requirements, and integration with existing systems. |

| Food and Beverage | Drying processes and cooling systems | Ensures consistent product quality and compliance with hygiene standards. | Food-grade materials, temperature control, and energy efficiency. |

| Mining and Minerals | Ventilation in underground operations | Improves worker safety by ensuring adequate air supply and removing harmful gases. | High-pressure capabilities, resistance to dust and moisture, and safety certifications. |

| Waste Management | Odor control and air pollution control systems | Enhances environmental compliance and community relations by managing emissions effectively. | Regulatory compliance, energy consumption, and maintenance ease. |

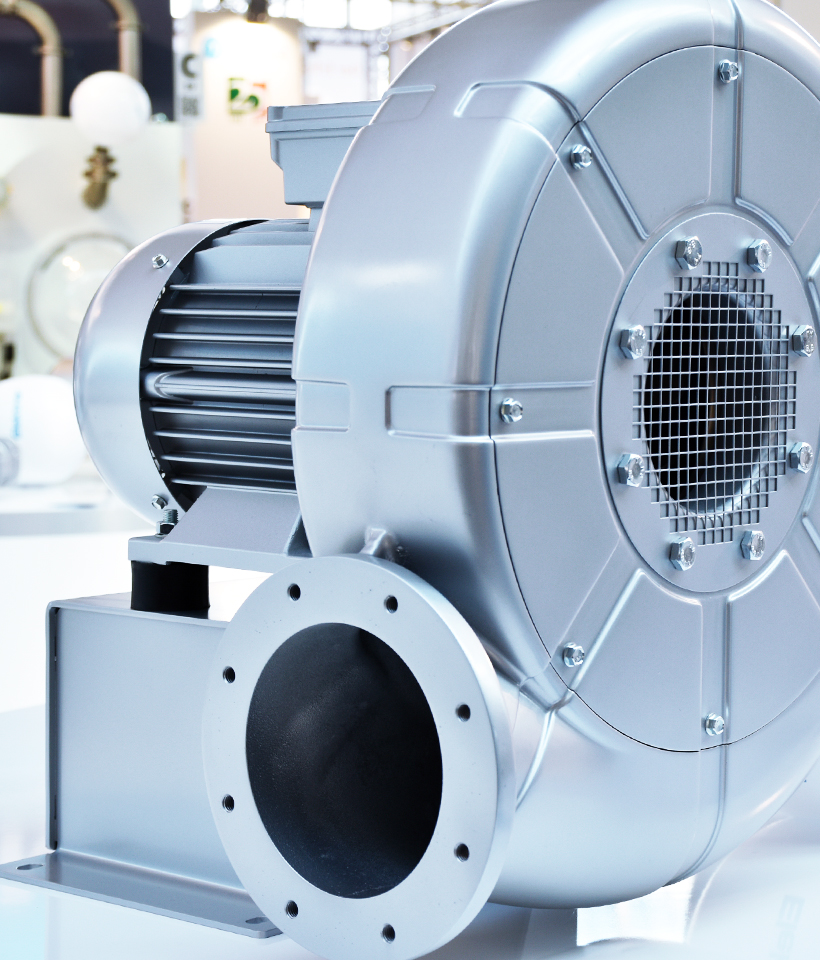

How Are Centrifugal Fans and Blowers Used in HVAC and Building Services?

In HVAC systems, centrifugal fans and blowers are pivotal for providing ventilation and maintaining air quality. They facilitate the movement of air through ductwork, ensuring even distribution and temperature control. This application is critical in commercial buildings, where energy efficiency can significantly reduce operational costs. International buyers should consider energy ratings and noise levels, as these factors directly impact user comfort and operational expenses, especially in densely populated areas in Europe and the Middle East.

What Role Do Centrifugal Fans Play in Manufacturing Processes?

Within manufacturing, centrifugal fans are essential for dust collection and material handling. They help remove airborne particles generated during production, thus minimizing health risks and equipment wear. Effective dust management leads to reduced downtime and maintenance costs, enhancing overall productivity. Buyers should focus on the durability of materials used in fan construction and their capacity to handle specific dust loads, which is crucial for compliance with safety regulations in regions like South America and Africa.

How Are Centrifugal Fans and Blowers Utilized in the Food and Beverage Sector?

In the food and beverage industry, centrifugal fans are used in drying processes and cooling systems to maintain product quality and safety. These fans help regulate temperatures and humidity levels, ensuring that products meet stringent hygiene standards. For B2B buyers in this sector, sourcing fans made from food-grade materials and those that offer energy efficiency is vital, particularly in highly regulated markets such as Germany, where compliance with health standards is mandatory.

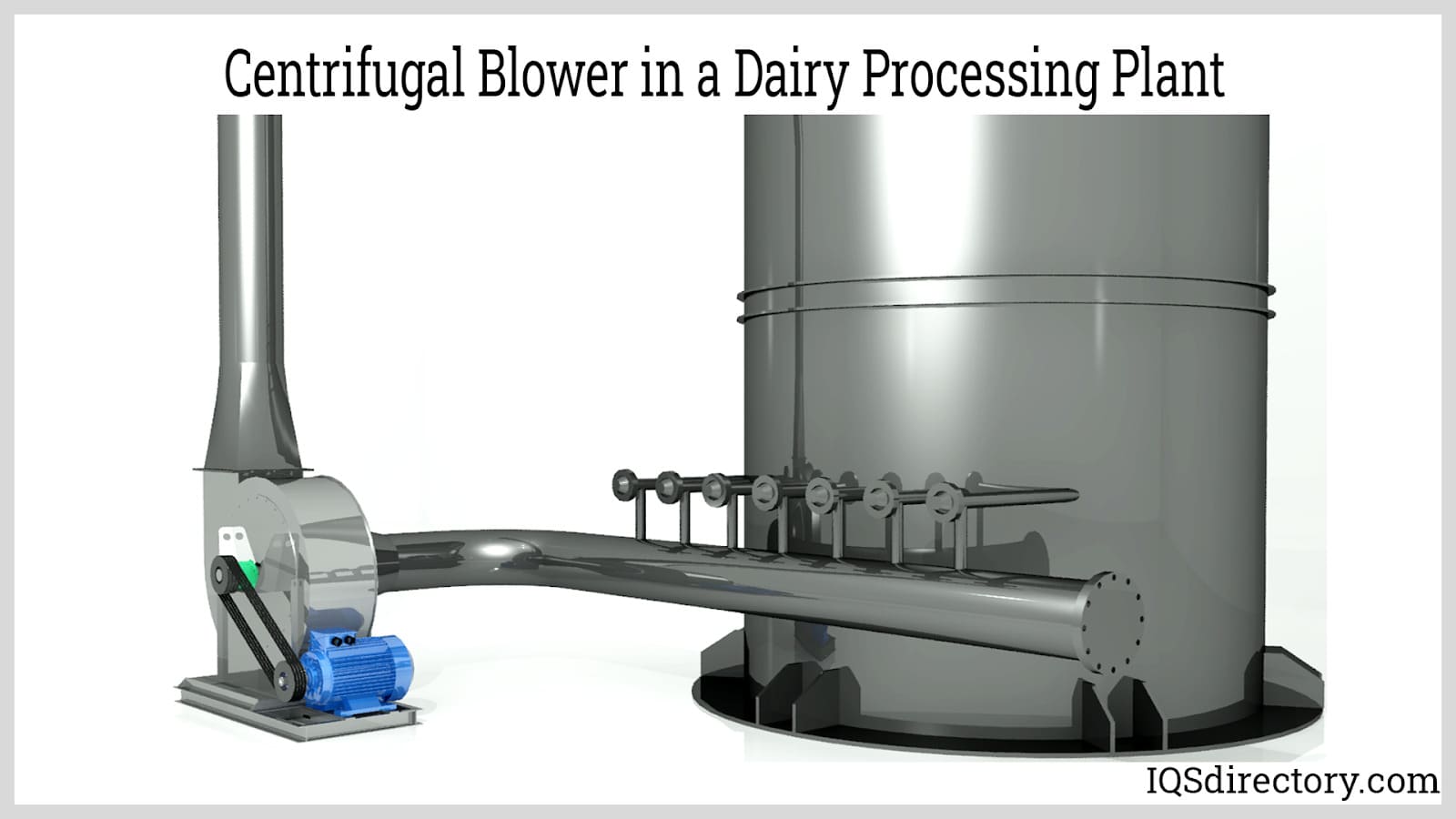

Illustrative image related to centrifugal fans and blowers

Why Are Centrifugal Fans Important in Mining and Minerals?

Centrifugal fans are crucial for providing ventilation in underground mining operations. They ensure a continuous supply of fresh air while removing harmful gases, significantly enhancing worker safety. In this sector, the ability to handle high pressures and resist dust and moisture is paramount. Buyers should prioritize fans with proven reliability and safety certifications to meet the stringent requirements of mining operations, especially in remote areas of Africa and South America.

How Do Centrifugal Fans Contribute to Waste Management Efforts?

In waste management, centrifugal fans are instrumental in odor control and air pollution control systems. They help manage emissions effectively, thereby improving environmental compliance and community relations. B2B buyers need to consider regulatory compliance and energy consumption when sourcing these fans, as these factors can influence operational efficiency and public perception in regions facing environmental challenges.

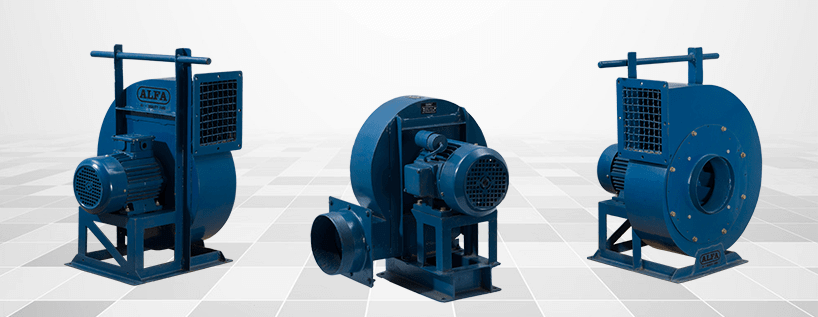

3 Common User Pain Points for ‘centrifugal fans and blowers’ & Their Solutions

Scenario 1: Inconsistent Airflow Leading to Operational Disruptions

The Problem:

Many industrial facilities face significant challenges with inconsistent airflow from their centrifugal fans and blowers. This inconsistency can stem from several factors, including improper fan sizing, wear and tear, or even system design flaws. For example, a manufacturing plant may find that their blowers are unable to maintain the necessary airflow for dust collection systems, leading to production slowdowns, increased downtime, and potential safety hazards. B2B buyers in these situations often feel frustrated as they struggle to identify the root cause of airflow issues and the subsequent impact on their operations.

The Solution:

To tackle airflow inconsistency, buyers should start by conducting a thorough assessment of their existing fan and blower systems. This includes reviewing the specifications of the fans installed and analyzing the airflow requirements of their applications. It may be beneficial to engage with a specialist who can perform an airflow analysis and provide insights into whether the current fans are appropriately sized for the application. In some cases, upgrading to a more robust model that can handle varying pressures, such as backward inclined centrifugal fans, may be necessary. Buyers should also consider implementing regular maintenance schedules to monitor wear and tear on the fans, ensuring they operate at peak efficiency. Additionally, investing in variable frequency drives (VFDs) can help in adjusting the fan speed to better match the operational needs, thereby stabilizing airflow.

Scenario 2: High Energy Costs Due to Inefficient Fan Systems

The Problem:

A common pain point for businesses utilizing centrifugal fans and blowers is the rising energy costs associated with their operation. Many B2B buyers encounter outdated or inefficient fan systems that consume excessive power, leading to inflated utility bills. This is particularly pressing for industries like HVAC, where energy efficiency is critical. Buyers may feel overwhelmed by the prospect of replacing their entire system and unsure of how to effectively lower their energy consumption without compromising performance.

Illustrative image related to centrifugal fans and blowers

The Solution:

To address high energy costs, companies should conduct an energy audit to evaluate the efficiency of their current centrifugal fans and blowers. This audit can identify models that are underperforming or poorly suited to their applications. Transitioning to high-efficiency models, such as those designed with energy-saving features, can significantly reduce power consumption. Additionally, opting for centrifugal blowers with adjustable speed settings allows for better matching of airflow demands, further enhancing energy efficiency. Buyers should also explore the integration of advanced control systems that monitor performance in real-time, enabling them to make informed adjustments and optimize energy use. Implementing these solutions not only helps in reducing energy costs but also supports sustainability initiatives.

Scenario 3: Difficulty in Sourcing Reliable Replacement Parts

The Problem:

B2B buyers often experience challenges in sourcing reliable replacement parts for centrifugal fans and blowers. This can be due to a lack of standardization among different manufacturers or difficulties in obtaining parts for older models. When fans and blowers break down, the inability to quickly find the right components can lead to prolonged downtime, which significantly impacts productivity and operational costs. Buyers may feel anxious about potential losses and are often left scrambling for solutions.

The Solution:

To mitigate sourcing issues for replacement parts, buyers should establish relationships with reputable manufacturers and distributors who specialize in centrifugal fans and blowers. It’s essential to maintain a comprehensive inventory of commonly used parts to minimize downtime during repairs. Additionally, opting for manufacturers that offer extensive support and after-sales service can provide peace of mind, as they often have dedicated teams to assist in finding the right components quickly. Buyers should also consider investing in newer, modular fan designs that allow for easier upgrades and part replacements. Keeping detailed records of equipment specifications, including model numbers and part lists, can streamline the process of identifying and ordering necessary parts when the need arises. By taking these proactive steps, businesses can enhance their operational resilience and reduce the risks associated with equipment failure.

Illustrative image related to centrifugal fans and blowers

Strategic Material Selection Guide for centrifugal fans and blowers

What Are the Key Materials Used in Centrifugal Fans and Blowers?

When selecting centrifugal fans and blowers, the choice of materials is crucial for ensuring optimal performance, durability, and suitability for specific applications. Below, we analyze four common materials used in the manufacturing of centrifugal fans and blowers, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Steel Perform in Centrifugal Fan Applications?

Key Properties: Steel is known for its high strength and ability to withstand significant pressure and temperature variations. It can handle high static pressures and is often treated to resist corrosion.

Pros & Cons: Steel fans are durable and can be manufactured at a relatively low cost. However, they are heavier than other materials, which may complicate installation and increase shipping costs. Additionally, untreated steel can corrode in humid or chemically aggressive environments, necessitating protective coatings.

Impact on Application: Steel is suitable for applications that involve high-pressure airflows, such as dust collection systems and material handling. However, it may not be ideal for corrosive environments unless properly coated.

Considerations for International Buyers: Compliance with standards such as ASTM for material quality and durability is essential. Buyers from regions with high humidity or corrosive environments, like parts of Africa and South America, should prioritize coated or stainless steel options.

Illustrative image related to centrifugal fans and blowers

Why Choose Aluminum for Centrifugal Fans and Blowers?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can handle moderate pressure and temperature levels effectively.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which simplifies installation and reduces shipping costs. However, aluminum is less durable than steel and may not be suitable for high-stress applications. It is also more expensive than steel.

Impact on Application: Aluminum fans are ideal for applications requiring lightweight components, such as HVAC systems and ventilation in commercial buildings. They are also suitable for environments where corrosion resistance is critical.

Considerations for International Buyers: Buyers should be aware of the varying standards for aluminum quality across regions. In Europe, for instance, compliance with DIN standards is crucial, while buyers in the Middle East may prioritize corrosion resistance due to environmental factors.

Illustrative image related to centrifugal fans and blowers

What Role Does Stainless Steel Play in Centrifugal Fan Design?

Key Properties: Stainless steel offers excellent corrosion resistance and can withstand high temperatures and pressures. It maintains structural integrity in challenging environments.

Pros & Cons: The main advantage of stainless steel is its durability and resistance to corrosion, making it ideal for harsh environments. However, it is significantly more expensive than both standard steel and aluminum, which may impact budget considerations.

Impact on Application: Stainless steel is particularly suited for applications involving corrosive materials, such as chemical processing or food production. Its longevity can lead to lower maintenance costs over time.

Considerations for International Buyers: Compliance with international standards for food safety or chemical resistance is vital for buyers in industries like food processing in Europe or chemical manufacturing in South America. Buyers should also consider the availability of stainless steel options in their region.

How Effective Are Composite Materials in Centrifugal Fans?

Key Properties: Composite materials, often made from a combination of plastics and fibers, are lightweight and resistant to corrosion and chemical damage. They can handle moderate pressures and temperatures.

Pros & Cons: Composites are highly resistant to corrosion and can be molded into complex shapes, allowing for innovative designs. However, they may not be as strong as metals, which can limit their use in high-pressure applications. Their cost can also be higher than traditional materials.

Impact on Application: Composites are ideal for applications in corrosive environments, such as wastewater treatment or chemical processing, where traditional materials may fail.

Considerations for International Buyers: Buyers should ensure that composite materials meet relevant international standards, such as ASTM or ISO, particularly in industries with strict compliance requirements. Understanding the local market for composite materials is also essential, especially in regions like Africa and the Middle East.

Summary Table of Material Selection for Centrifugal Fans and Blowers

| Material | Typical Use Case for centrifugal fans and blowers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-pressure airflows, dust collection systems | Durable and cost-effective | Heavier, potential for corrosion | Medium |

| Aluminum | HVAC systems, commercial ventilation | Lightweight, corrosion-resistant | Less durable, higher cost | Medium |

| Stainless Steel | Chemical processing, food production | Excellent corrosion resistance | High cost, limited availability | High |

| Composite | Wastewater treatment, chemical processing | Highly resistant to corrosion | Lower strength, higher cost | High |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in centrifugal fans and blowers, helping them make informed decisions based on application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for centrifugal fans and blowers

What Are the Main Stages of Manufacturing Centrifugal Fans and Blowers?

The manufacturing process of centrifugal fans and blowers involves several critical stages, each essential for ensuring the final product meets performance and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Centrifugal Fans and Blowers?

Material preparation begins with sourcing high-quality raw materials suitable for the specific application of the fans and blowers. Common materials include cast aluminum, stainless steel, and carbon steel, chosen for their strength, durability, and resistance to corrosion. Suppliers should provide certifications verifying the material’s quality and compliance with international standards.

Illustrative image related to centrifugal fans and blowers

Once the materials are sourced, they undergo inspection to ensure they meet required specifications. This initial quality check, known as Incoming Quality Control (IQC), helps prevent defects from entering the manufacturing process.

What Forming Techniques Are Used in Manufacturing?

The forming stage involves transforming raw materials into components of the centrifugal fans and blowers. Techniques such as casting, machining, and fabrication are common.

- Casting: For components like impellers and housings, casting techniques (e.g., sand casting or die casting) are often used. This process allows for intricate designs and high-volume production.

- Machining: Machining processes, such as CNC milling and turning, refine the dimensions and surface finish of components to achieve precise specifications.

- Fabrication: Involves processes like bending and welding to assemble various parts, ensuring structural integrity and alignment.

Each component undergoes a Quality Control (QC) checkpoint during forming, often referred to as In-Process Quality Control (IPQC), to monitor tolerances and specifications closely.

Illustrative image related to centrifugal fans and blowers

How Are Centrifugal Fans and Blowers Assembled?

The assembly stage is crucial for the performance of centrifugal fans and blowers. This process involves combining the various components—such as the motor, impeller, housing, and inlet—into a complete unit.

During assembly, technicians follow detailed work instructions and checklists to ensure each part is installed correctly and securely. Common assembly methods include:

- Direct Drive Assembly: Where the motor is directly connected to the impeller, leading to improved efficiency and reduced maintenance.

- Belt Drive Assembly: Involves connecting the motor to the impeller via a belt system, allowing for flexibility in speed and torque adjustments.

Quality checks during assembly focus on alignment, balance, and secure fastening. These checks are critical, as improper assembly can lead to operational inefficiencies and premature failure.

What Finishing Processes Are Essential for Quality?

Finishing processes enhance the durability and performance of centrifugal fans and blowers. These processes may include surface treatments, painting, or powder coating, which protect against corrosion and wear.

Additionally, balancing the impeller is vital to minimize vibrations during operation. Dynamic balancing techniques help ensure that the fan operates smoothly, reducing noise and extending the lifespan of the product.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance in the manufacturing of centrifugal fans and blowers is paramount, particularly for international buyers who may have varying regulatory standards.

Which International Standards Are Relevant?

ISO 9001 is a foundational standard for quality management systems and is widely recognized across the globe. Manufacturers adhering to this standard demonstrate a commitment to consistent quality and customer satisfaction. Other relevant certifications might include:

- CE Marking: Ensures that products meet EU safety, health, and environmental protection standards.

- API Standards: Applicable for fans used in the oil and gas industry, ensuring they meet specific performance and safety criteria.

Buyers should request documentation of these certifications from potential suppliers to verify compliance.

What Are the Key QC Checkpoints in Manufacturing?

Quality control checkpoints are integral to maintaining product integrity throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Verifies the quality of materials before they enter the manufacturing process.

- In-Process Quality Control (IPQC): Monitors production to ensure components meet specifications during various stages.

- Final Quality Control (FQC): Conducted on the finished product to ensure it meets all performance and safety standards before shipment.

What Testing Methods Are Commonly Used?

Common testing methods for centrifugal fans and blowers include:

- Performance Testing: Measures airflow, pressure, and efficiency to ensure the product meets specified performance criteria.

- Noise Testing: Evaluates sound levels to ensure compliance with industry standards, particularly for applications in noise-sensitive environments.

- Vibration Testing: Assesses the operational stability of the fan or blower, identifying any imbalances that could lead to premature wear.

How Can B2B Buyers Verify Supplier Quality Assurance?

B2B buyers should conduct thorough due diligence when selecting suppliers. Here are several strategies to verify quality assurance:

- Supplier Audits: Conduct on-site audits to evaluate the manufacturing process, quality control measures, and overall facility conditions.

- Request Quality Reports: Ask for detailed quality reports that outline testing results and compliance with international standards.

- Third-party Inspections: Consider hiring independent third-party inspectors to assess the quality and performance of the fans and blowers before shipment.

What Are the Nuances of QC for International Buyers?

International buyers, particularly those in Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and compliance. Different regions may have unique regulatory requirements and standards that suppliers must meet.

For instance, European buyers may prioritize CE certification, while buyers in the Middle East may require compliance with local safety regulations. Understanding these regional differences is crucial for ensuring that the products meet local market requirements.

In conclusion, the manufacturing processes and quality assurance for centrifugal fans and blowers are complex and multi-faceted. B2B buyers must be diligent in their assessment of suppliers to ensure they receive high-quality products that meet their operational needs and comply with relevant standards.

Illustrative image related to centrifugal fans and blowers

Practical Sourcing Guide: A Step-by-Step Checklist for ‘centrifugal fans and blowers’

In the competitive landscape of industrial equipment procurement, specifically for centrifugal fans and blowers, having a structured approach is vital. This guide provides a step-by-step checklist to help international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for your application. Consider the airflow (CFM), static pressure (in wg), and temperature range your system will operate under. Additionally, determine if you need a centrifugal fan or a blower based on whether your priority is high volume or high pressure.

- Airflow Requirements: Specify the maximum and minimum CFM needed.

- Pressure Needs: Identify the static pressure required for efficient operation.

Step 2: Assess Application Needs

Evaluate the intended use of the centrifugal fans or blowers. Different applications—such as HVAC systems, material handling, or dust collection—may have unique demands. Understanding these needs will guide you in selecting the right type of fan or blower.

- Material Handling: If handling bulk materials, consider fans designed for rugged conditions.

- Clean Air Requirements: For applications demanding high air quality, look for fans that can manage dust and moisture effectively.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions to gauge their reliability and performance history.

- Supplier Credentials: Ensure suppliers have relevant certifications and a solid reputation in your target market.

- After-Sales Support: Investigate the availability of local service and maintenance support.

Step 4: Request Detailed Proposals

Once you’ve shortlisted suppliers, request comprehensive proposals that include technical specifications, pricing, delivery timelines, and warranty information. This will allow you to compare options effectively.

- Cost Breakdown: Look for transparency in pricing to avoid hidden costs later.

- Lead Times: Confirm the expected delivery schedule to align with your project timelines.

Step 5: Conduct Performance Testing

If possible, arrange for performance testing of the fans or blowers before finalizing your purchase. This will help verify that the equipment meets your operational requirements and performs as specified.

- Sample Testing: Request a trial run to assess airflow and pressure under real conditions.

- Feedback Loop: Engage with engineers who will operate the equipment for insights on performance expectations.

Step 6: Review Warranty and Service Agreements

Before finalizing the purchase, scrutinize the warranty terms and service agreements. A robust warranty can protect your investment and ensure peace of mind.

- Warranty Duration: Confirm the length and coverage of the warranty.

- Service Options: Understand the terms of service for maintenance and repairs.

Step 7: Finalize Purchase and Arrange Logistics

Once you’ve selected a supplier and confirmed all details, finalize the purchase. Coordinate logistics to ensure timely delivery and installation of the centrifugal fans or blowers.

Illustrative image related to centrifugal fans and blowers

- Shipping Arrangements: Discuss shipping options that best suit your operational timeline.

- Installation Support: Inquire about installation assistance to ensure proper setup.

By following this checklist, B2B buyers can navigate the complexities of sourcing centrifugal fans and blowers, ensuring they select the right products for their specific needs while also fostering long-term supplier relationships.

Comprehensive Cost and Pricing Analysis for centrifugal fans and blowers Sourcing

What Are the Key Cost Components in Sourcing Centrifugal Fans and Blowers?

When sourcing centrifugal fans and blowers, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects pricing. Common options include cast aluminum, steel, and stainless steel. More durable materials, like stainless steel, may incur higher costs but can offer long-term savings through reduced maintenance and replacement needs.

-

Labor: Labor costs can vary based on the manufacturing location and the complexity of the product. Skilled labor is essential for high-quality manufacturing, especially for customized solutions, which can increase overall costs.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and indirect labor associated with production. Companies with advanced manufacturing technologies may have lower overhead costs, impacting their pricing strategy.

-

Tooling: Customization often requires specialized tooling, which can be a significant upfront cost. Buyers should inquire about tooling costs, especially when considering unique specifications.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability and compliance with industry standards, but it also adds to costs. Certifications for quality and safety (like ISO or ATEX) can influence pricing.

-

Logistics: Transportation and shipping costs are critical, particularly for international buyers. Factors such as distance, shipping method, and Incoterms can greatly affect logistics expenses.

-

Margin: Suppliers typically include a margin that reflects their operational costs, market conditions, and desired profit levels. Understanding this can help buyers negotiate better pricing.

How Do Price Influencers Affect Centrifugal Fans and Blowers Sourcing?

Several factors can influence the pricing of centrifugal fans and blowers:

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs. Minimum Order Quantities (MOQs) can vary by supplier, so negotiating terms that align with your purchasing strategy is essential.

-

Specifications and Customization: Custom features, such as specific airflow rates or materials, can drive up costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials Quality and Certifications: Higher-quality materials and certifications can elevate prices. However, investing in quality often translates to enhanced performance and longevity, reducing the Total Cost of Ownership (TCO).

-

Supplier Factors: Supplier reputation, reliability, and geographic location can impact pricing. Established suppliers may command higher prices due to their proven track record.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) can affect the final cost. Understanding these terms is vital for budgeting and financial planning.

What Are the Best Negotiation Tips for B2B Buyers of Centrifugal Fans and Blowers?

To secure the best pricing and terms, consider the following negotiation strategies:

-

Research and Benchmarking: Gather data on market prices and competitor offerings to inform your negotiations. Knowledge of industry standards can provide leverage when discussing costs.

-

Leverage Volume Discounts: If you anticipate purchasing large quantities, use this as a bargaining tool. Suppliers often offer better rates for bulk orders.

-

Clarify Total Cost of Ownership: Discuss the long-term implications of pricing, including maintenance, energy efficiency, and potential downtime costs. Emphasizing TCO can shift the focus from initial price to overall value.

-

Build Relationships: Developing a rapport with suppliers can lead to better terms and faster responses to inquiries. Trust can often result in more favorable pricing and conditions.

-

Flexibility in Specifications: If possible, consider being flexible with specifications to align with standard products offered by suppliers. This can reduce costs associated with customization.

What Should International Buyers Consider When Sourcing Centrifugal Fans and Blowers?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, several nuances come into play:

-

Currency Fluctuations: Be aware of exchange rates, as they can significantly impact pricing when sourcing from overseas suppliers.

-

Import Duties and Taxes: Factor in potential tariffs and taxes that may apply when importing equipment. This can affect the total cost and should be included in budget calculations.

-

Cultural Differences: Understand the cultural nuances in negotiation styles and business practices in the supplier’s country. This can enhance communication and foster better relationships.

-

Regulatory Compliance: Ensure that products meet local regulatory requirements, which can influence costs. Non-compliance can lead to delays and additional expenses.

Disclaimer on Indicative Prices

It’s important to note that pricing for centrifugal fans and blowers can vary significantly based on the aforementioned factors. Therefore, the prices provided by suppliers should be viewed as indicative and subject to change based on market conditions, customization, and order specifics. Always request detailed quotes and verify all costs before finalizing any agreements.

Illustrative image related to centrifugal fans and blowers

Alternatives Analysis: Comparing centrifugal fans and blowers With Other Solutions

When considering industrial air movement solutions, it’s vital to evaluate not only centrifugal fans and blowers but also alternative technologies that can meet similar needs. Understanding the strengths and weaknesses of these alternatives can help B2B buyers make informed decisions tailored to their operational requirements.

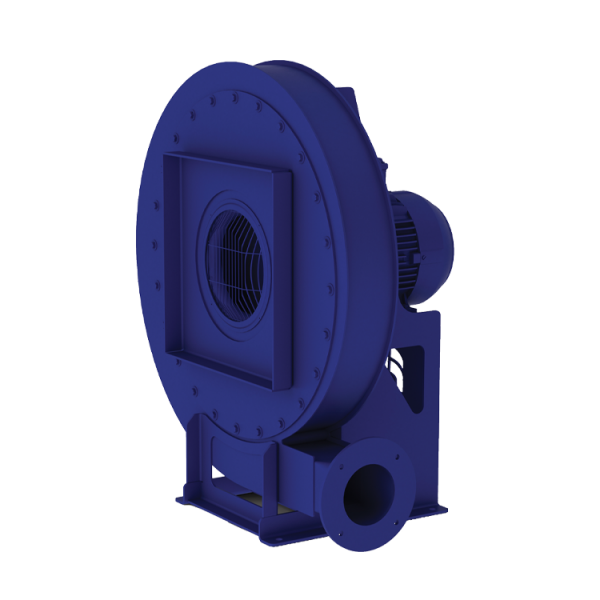

| Comparison Aspect | Centrifugal Fans and Blowers | Axial Fans | Positive Displacement Blowers |

|---|---|---|---|

| Performance | High pressure, moderate flow | High flow, low pressure | Steady flow, high pressure |

| Cost | Moderate initial investment | Lower initial investment | Higher initial investment |

| Ease of Implementation | Requires more space and support structures | Compact and easier to install | Complex installation required |

| Maintenance | Moderate; accessible parts | Low; fewer moving parts | High; more components to maintain |

| Best Use Case | Material handling, HVAC, dust control | Ventilation, cooling | High-pressure applications like pneumatic conveying |

What are the Pros and Cons of Axial Fans as an Alternative?

Axial fans are designed to move air parallel to the fan’s axis, making them suitable for high-flow, low-pressure applications. They are often less expensive and easier to install due to their compact design. However, their efficiency diminishes in high-pressure environments, which can limit their use in applications requiring significant air resistance or bulk material handling. For operations focused primarily on ventilation or cooling, axial fans present a cost-effective solution but may fall short in scenarios demanding higher pressure.

How do Positive Displacement Blowers Compare?

Positive displacement blowers operate by trapping a fixed volume of air and forcing it into the discharge pipe. They excel in applications requiring a consistent air flow at high pressures, such as pneumatic conveying systems. While they provide steady performance, their initial cost is generally higher, and they can be complex to install and maintain. Their intricate design requires more frequent servicing, making them less appealing for companies looking for low-maintenance solutions. However, for industries that prioritize reliability in high-pressure air movement, they can be the ideal choice.

Illustrative image related to centrifugal fans and blowers

Making the Right Choice for Your Needs

Choosing the right air movement solution involves understanding the specific needs of your application. Centrifugal fans and blowers are versatile, able to handle a range of pressures and flows, making them suitable for diverse industrial uses. If your requirements lean towards high-volume air movement without significant pressure, axial fans may be a more economical option. Conversely, if your operations demand high pressure and consistent flow, positive displacement blowers could be the best fit despite their higher investment and maintenance needs. By carefully considering these factors, B2B buyers can align their choice with operational goals and budget constraints, ensuring optimal performance and efficiency.

Essential Technical Properties and Trade Terminology for centrifugal fans and blowers

What Are the Key Technical Properties of Centrifugal Fans and Blowers?

Understanding the technical specifications of centrifugal fans and blowers is crucial for B2B buyers seeking efficient and reliable solutions. Here are some essential properties to consider:

-

Airflow Capacity (CFM)

Airflow capacity, measured in Cubic Feet per Minute (CFM), indicates the volume of air that a fan can move. This specification is vital for determining whether a fan can meet the demands of your specific application, whether for ventilation, material handling, or dust collection. For instance, high-capacity models can handle larger volumes, making them suitable for industrial environments. -

Static Pressure (SP)

Static pressure, typically measured in inches of water gauge (in wg), reflects the resistance that the fan must overcome to move air through a system. Understanding static pressure is essential for selecting a fan that can effectively manage the required airflow against system restrictions, ensuring optimal performance and energy efficiency. -

Material Grade

The material used in the construction of centrifugal fans and blowers (e.g., cast aluminum, stainless steel) significantly influences their durability and suitability for various environments. For instance, stainless steel fans are ideal for corrosive environments, while aluminum fans are lightweight and cost-effective for general use. Choosing the right material helps ensure longevity and reduces maintenance costs. -

Drive Type

Fans can be classified as direct drive or belt drive. Direct drive fans offer simpler installation and lower maintenance due to fewer moving parts, while belt drive fans allow for greater flexibility in speed control and can accommodate larger fan sizes. This choice can impact operational efficiency and overall costs. -

Noise Levels

Noise level, often measured in decibels (dB), is a critical consideration, especially in environments where sound control is essential. Understanding noise specifications can help in selecting fans that meet regulatory requirements or minimize disruption in workplaces. -

Temperature Tolerance

Different applications may expose fans to varying temperature ranges. Knowing the maximum operating temperature is crucial for ensuring that the fan can perform effectively without risk of failure, particularly in high-heat environments.

What Are Common Trade Terms Used in the Centrifugal Fans and Blowers Industry?

Familiarity with industry jargon helps facilitate smoother transactions and clearer communication between buyers and suppliers. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers who need specific components that match existing systems or equipment. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is important for buyers to understand as it affects purchasing decisions, inventory management, and overall cost-effectiveness. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for a specific quantity of goods. This process is essential for comparing prices and terms among different suppliers, ensuring buyers get the best value. -

Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms used internationally to define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms is vital for B2B transactions, as they clarify who is responsible for shipping costs, insurance, and risk during transit. -

CFM (Cubic Feet per Minute)

As mentioned earlier, CFM measures airflow capacity. It is a critical term in the selection process for fans and blowers, influencing performance expectations and application suitability. -

Static Pressure (SP)

This term, also previously defined, is used to describe the resistance encountered by the fan when moving air. It is essential for ensuring that the selected fan meets system requirements.

Incorporating these technical properties and trade terms into your procurement process can enhance decision-making, ensuring that you select the right centrifugal fans and blowers for your business needs.

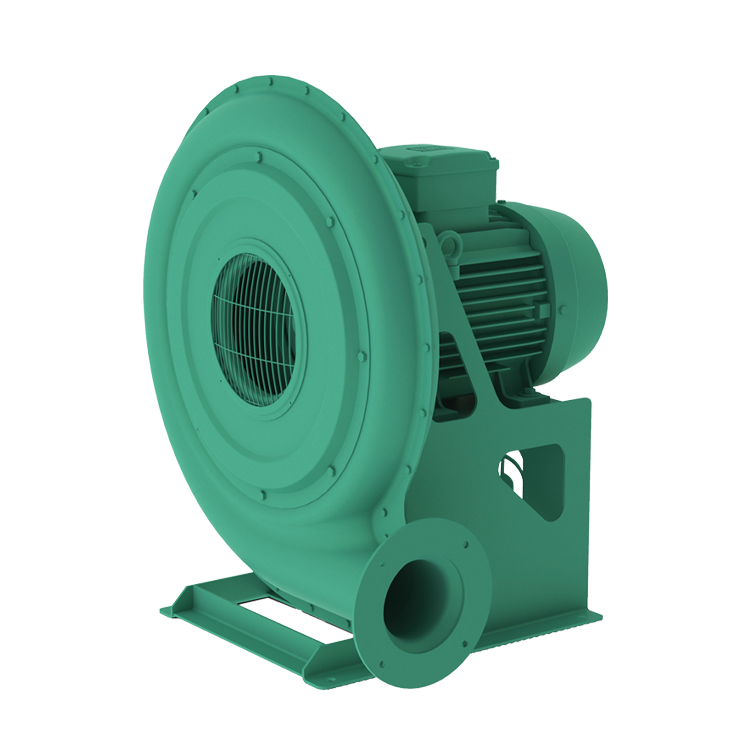

Navigating Market Dynamics and Sourcing Trends in the centrifugal fans and blowers Sector

What Are the Current Market Dynamics and Key Trends in the Centrifugal Fans and Blowers Sector?

The centrifugal fans and blowers market is experiencing significant growth, driven by industrialization and the increasing demand for efficient air handling systems across various sectors, including HVAC, material handling, and environmental management. As global industries strive for enhanced operational efficiency, the need for reliable and high-performance fans and blowers has surged. This demand is particularly pronounced in emerging markets in Africa, South America, and the Middle East, where rapid urbanization and industrialization are taking place.

Key trends shaping the market include the integration of advanced technologies such as IoT and smart sensors, which allow for real-time monitoring and predictive maintenance of fan systems. These innovations help companies reduce downtime and optimize energy consumption, aligning with the global push for sustainability. Additionally, manufacturers are increasingly focusing on modular designs that allow for customization based on specific application needs, enhancing the versatility of centrifugal fans and blowers.

International B2B buyers must also navigate the complexities of supply chain management in a globalized economy. Geopolitical factors, trade regulations, and fluctuating raw material prices can impact sourcing strategies. It is essential for buyers to establish strong relationships with suppliers who demonstrate resilience and adaptability to market fluctuations, ensuring consistent supply and quality.

How Is Sustainability and Ethical Sourcing Influencing the Centrifugal Fans and Blowers Market?

Sustainability has become a cornerstone of business strategy, influencing procurement decisions in the centrifugal fans and blowers sector. The environmental impact of manufacturing processes and product lifecycle is under scrutiny, prompting buyers to prioritize suppliers who adopt sustainable practices. This includes using energy-efficient motors, recyclable materials, and minimizing waste during production.

Moreover, ethical sourcing is gaining traction, with buyers increasingly demanding transparency in supply chains. This shift is driven by consumer expectations and regulatory pressures, particularly in regions like Europe where stringent environmental laws are in place. Suppliers that can demonstrate compliance with green certifications, such as ISO 14001 for environmental management systems or LEED certifications for sustainable building practices, will have a competitive advantage.

Illustrative image related to centrifugal fans and blowers

Investing in ‘green’ materials not only enhances a company’s sustainability profile but also opens new market opportunities. For instance, centrifugal fans made from recycled or eco-friendly materials appeal to businesses looking to reduce their carbon footprint. As a result, international buyers should actively seek partnerships with manufacturers committed to sustainable and ethical practices, ensuring alignment with global sustainability goals.

What Is the Evolution of Centrifugal Fans and Blowers in the B2B Landscape?

The evolution of centrifugal fans and blowers has been marked by significant technological advancements and a shift in application focus. Initially designed for basic air movement, these systems have transformed into sophisticated machines capable of handling complex industrial processes. The introduction of high-efficiency designs and materials has improved their performance, enabling them to meet the demands of modern applications.

In the late 20th century, the rise of environmental regulations led to innovations aimed at reducing emissions and energy consumption. Manufacturers began developing fans that not only provided effective air movement but also contributed to cleaner air standards. This evolution continues today, with ongoing research and development focused on enhancing energy efficiency and reducing environmental impact.

As industries increasingly prioritize sustainability, the centrifugal fans and blowers sector is likely to see further advancements in eco-friendly technologies and materials, shaping the future of B2B procurement strategies. Buyers who stay informed about these developments will be better positioned to make strategic decisions that align with market trends and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of centrifugal fans and blowers

-

How do I select the right centrifugal fan for my application?

Selecting the appropriate centrifugal fan involves assessing several factors including the required airflow (CFM), static pressure (in wg), and the specific application environment (e.g., HVAC, material handling, or dust collection). Begin by defining the operational parameters such as temperature tolerance, airflow direction, and the physical space available for installation. Consulting with a manufacturer or supplier can provide valuable insights into which fan models are best suited for your needs, including considerations for efficiency and noise levels. -

What are the key differences between centrifugal fans and blowers?

Centrifugal fans are primarily designed for high volume, low-pressure applications, making them ideal for general ventilation. In contrast, centrifugal blowers are engineered for higher pressures while maintaining airflow, making them suitable for applications that require pushing air against resistance, such as in dust collection or pneumatic conveying. Understanding these differences is crucial for selecting the right equipment for your specific industrial or commercial needs. -

What customization options are available for centrifugal fans and blowers?

Most manufacturers offer a range of customization options for centrifugal fans and blowers, including variations in wheel size, housing dimensions, materials (such as aluminum or stainless steel), and drive types (direct or belt-driven). Additionally, specialized features like ATEX certification for explosive environments or specific motor configurations can be tailored to meet unique operational requirements. Engage with suppliers to explore available custom solutions that align with your application demands. -

What is the minimum order quantity (MOQ) for centrifugal fans?

The minimum order quantity for centrifugal fans can vary significantly between manufacturers and depends on factors such as the fan model, customization options, and production capabilities. Generally, MOQs range from a single unit for standard models to larger quantities for customized designs. It’s advisable to discuss your specific requirements with potential suppliers to understand their MOQ policies and any associated pricing benefits for bulk orders. -

What payment terms should I expect when purchasing centrifugal fans internationally?

Payment terms for international purchases of centrifugal fans often include options such as advance payment, letter of credit, or net payment terms (e.g., 30 days post-delivery). These terms can vary based on the supplier’s policies, your credit history, and the size of the order. It’s essential to clarify payment terms upfront to avoid misunderstandings and ensure smooth transaction processes. -

How do I ensure quality assurance when sourcing centrifugal fans?

To ensure quality assurance when sourcing centrifugal fans, consider suppliers who provide certifications such as ISO 9001 or industry-specific approvals. Request detailed product specifications, performance data, and test results to assess quality. Additionally, visiting the manufacturer’s facility or seeking third-party inspections can further validate the quality of the fans. Building a relationship with reputable suppliers who prioritize quality control is crucial for long-term satisfaction. -

What are the logistics considerations for importing centrifugal fans?

When importing centrifugal fans, consider factors such as shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder who understands the complexities of international shipping. Ensure that all necessary documentation (e.g., commercial invoices, packing lists, and customs declarations) is prepared to facilitate smooth clearance. Additionally, plan for potential tariffs or duties that may apply to your specific region. -

How can I vet suppliers of centrifugal fans and blowers?

Vetting suppliers involves conducting thorough research on their reputation, experience, and customer reviews. Request references from previous clients and assess their production capabilities and quality control processes. It’s also beneficial to evaluate their customer service responsiveness and technical support. Attending industry trade shows or exhibitions can provide opportunities to meet potential suppliers in person and assess their offerings firsthand.

Top 8 Centrifugal Fans And Blowers Manufacturers & Suppliers List

1. Cincinnati Fan – Centrifugal Fan Models

Domain: cincinnatifan.com

Registered: 1998 (27 years)

Introduction: Centrifugal Fans Models: HDAF (Airfoil Fan) – up to 48,551 CFM, up to 21 in. wg; HDBC (Backward Curved Fan) – up to 270,000 CFM, up to 34 in. wg; HDBI (Backward Inclined Fan) – up to 150,000 CFM, up to 25 in. wg; CPAF (Airfoil Plug Fan) – up to 42,000 CFM, up to 18 in. wg; CPF (Backward Inclined Plug Fan) – up to 100,000 CFM, up to 25 in. wg; LM & LMF (Volume Fan) – up to 2,000 CFM, up to 4 in. wg…

2. Continental Fan – Centrifugal Blowers

Domain: continentalfan.com

Registered: 1999 (26 years)

Introduction: Continental Fan’s centrifugal blowers are designed for industrial, commercial, and OEM ventilation applications. The product range includes: 1. TFD Flange Mount BC Airfoil Blowers 2. TCD BC Airfoil Blowers 3. TCC Motorized Blower (BC) 4. CAB Cast Aluminum Blowers 5. CPB Cast Aluminum Blowers.

3. New York Blower Company – High Pressure & Industrial Fans

Domain: nyb.com

Registered: 1996 (29 years)

Introduction: High Pressure & Industrial Centrifugal Fans & Air Blowers from New York Blower Company. Key product types include: Inline Fans, Duct Fans, Tubeaxial, Vaneaxial, Centrifugal Fans (Backward Inclined, Forward Curved, Radial, Radial Tip), Pressure Blowers, Custom Fans, Centrifugal Ventilators, Axial Ventilators, Upblast Roof Ventilators, Hooded Roof Ventilators, Plenums, and DWDI Fans. Specific fan ca…

4. Elektror – Centrifugal Blowers

Domain: elektror.com

Registered: 2000 (25 years)

Introduction: Centrifugal blowers from Elektror include standard radial blowers, plug fans, and ATEX fans. They are designed for applications requiring higher pressure and airflow compared to axial fans. Key features include:

– Air is drawn in axially and deflected 90 degrees by impellers for radial extraction.

– Maximum airflow capacity: 9,500 m³/h.

– Maximum pressure: 20,800 Pa.

Product ranges include:

1. **…

5. Oriental Motor – MB Series Centrifugal Fan/Blower Kit

Domain: catalog.orientalmotor.com

Registered: 1997 (28 years)

Introduction: {“item_number”: “T-MB1665-B-A”, “size”: “6.30 in. (160 mm)”, “series”: “MB Series”, “type”: “Centrifugal Fan / Blower Kit”, “phase”: “Single-Phase”, “voltage”: “100/110/115 VAC”, “price”: “$441.00”, “features”: [“maximizes static pressure”, “provides concentrated airflow in one defined direction”, “can be used in fixed position or mounted on moving parts”, “optimal for local cooling and airflow th…

6. IQS Directory – Centrifugal Blowers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Centrifugal blowers are mechanisms designed to propel air using centrifugal force from a spinning impeller. Key components include the impeller, housing, and drive mechanism. Types of centrifugal blowers include: 1. Forward Curved Centrifugal Blowers: High static pressure and airflow, used in low-pressure, high-volume applications like HVAC systems. 2. Backward Inclined Centrifugal Blowers: Higher…

7. Newark – Centrifugal Blowers

Domain: newark.com

Registered: 1994 (31 years)

Introduction: This company, Newark – Centrifugal Blowers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Greenheck – Centrifugal Utility Set

Domain: greenheck.com

Registered: 1995 (30 years)

Introduction: This company, Greenheck – Centrifugal Utility Set, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for centrifugal fans and blowers

Why Is Strategic Sourcing Crucial for Centrifugal Fans and Blowers?

In the dynamic landscape of industrial operations, strategic sourcing for centrifugal fans and blowers is paramount. By prioritizing suppliers that offer a diverse range of products—such as high-pressure blowers and specialized fan designs—businesses can enhance efficiency and performance. Understanding the nuances between centrifugal fans and blowers, including their applications in material handling and HVAC systems, enables buyers to make informed decisions that align with their operational needs.

What Should International Buyers Consider When Sourcing?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, it’s essential to evaluate suppliers not only on price but also on the quality, customization capabilities, and local support. Engaging with manufacturers that provide tailored solutions and robust after-sales service can significantly reduce downtime and improve overall system reliability.

How Can Buyers Prepare for Future Trends?

Looking ahead, the demand for energy-efficient and versatile centrifugal fans and blowers is expected to grow. Buyers should consider investing in technology that supports sustainability and compliance with international standards. By staying proactive and aligning sourcing strategies with emerging industry trends, businesses can secure a competitive edge in their markets.

Call to Action

We encourage international B2B buyers to leverage this guide as a foundation for developing a strategic sourcing plan that meets both current and future needs. Connect with reputable manufacturers today to explore innovative solutions that drive operational success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to centrifugal fans and blowers

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.