Aluminum Extrusion Profiles: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for aluminum extrusion profiles

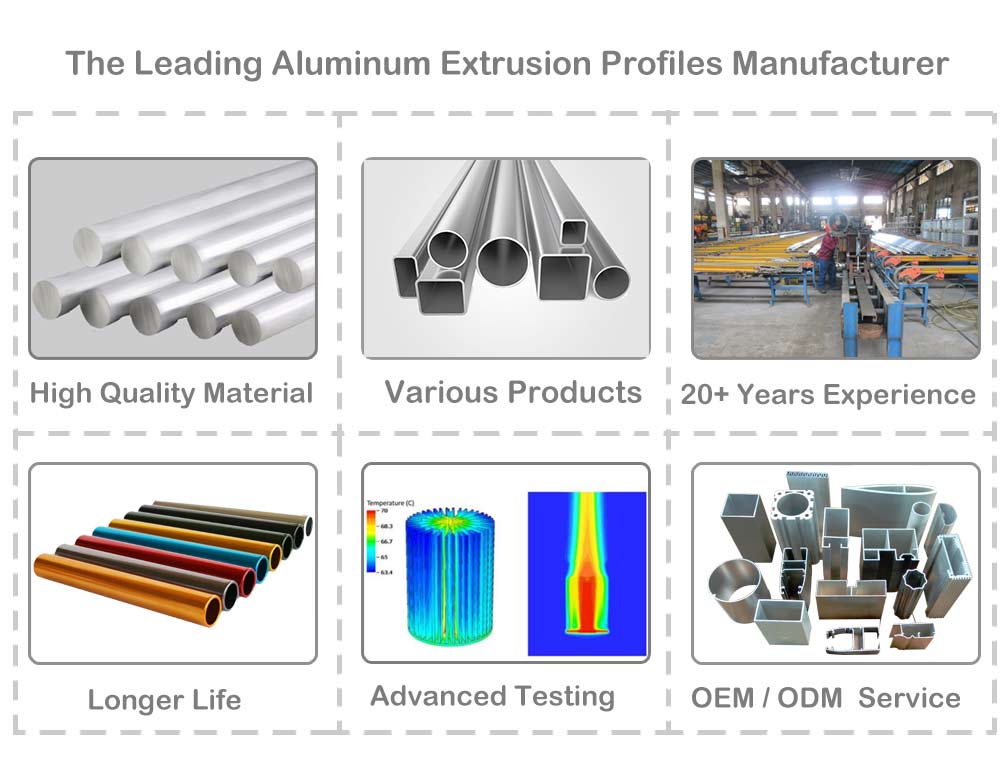

In today’s fast-paced industrial landscape, sourcing aluminum extrusion profiles can be a daunting task for international B2B buyers. With a myriad of options available, from T-slotted profiles to standard shapes, the challenge lies not only in selecting the right type for your application but also in ensuring the quality and reliability of your suppliers. This comprehensive guide is designed to demystify the global market for aluminum extrusion profiles, addressing key concerns such as types, applications, supplier vetting processes, and cost considerations.

As you navigate through the complexities of sourcing aluminum extrusion profiles, you’ll gain valuable insights into the various alloys suitable for different applications, from construction to electronics. We will also explore how to effectively evaluate suppliers, ensuring they meet industry standards like ISO and SGS certifications, which are crucial for maintaining quality and reliability.

This guide empowers B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, such as Nigeria and Vietnam, to make informed purchasing decisions. By understanding the nuances of aluminum extrusion profiles and the global market landscape, you can streamline your sourcing process, reduce costs, and enhance your operational efficiency, ultimately positioning your business for sustainable growth.

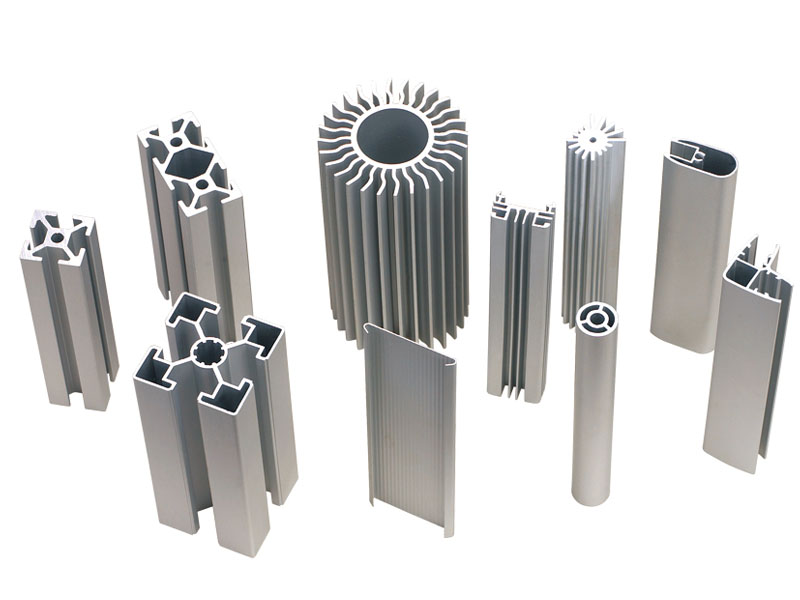

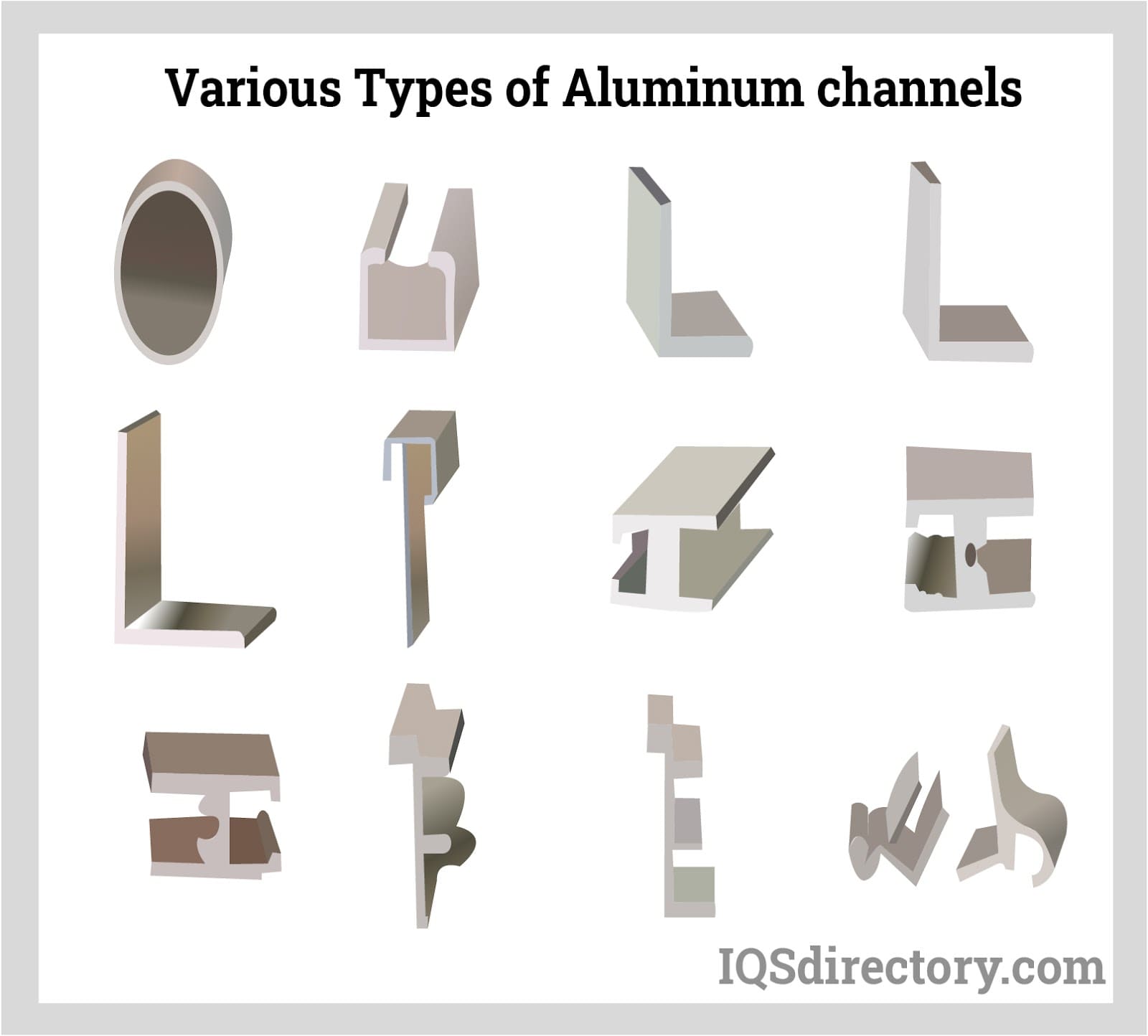

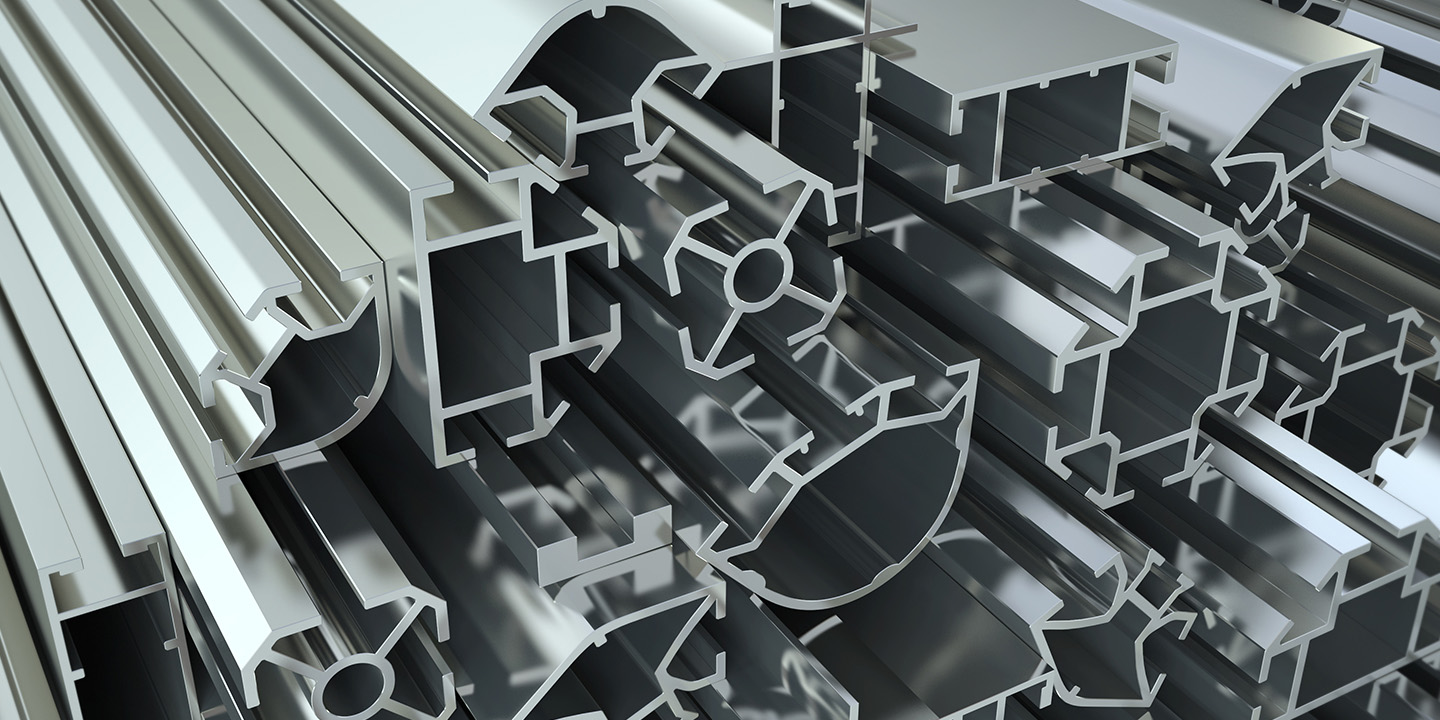

Understanding aluminum extrusion profiles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| T-Slot Profiles | Modular design with T-shaped slots for easy assembly | Automation, furniture, framing | Pros: Versatile, customizable; Cons: May require additional connectors. |

| Standard Structural Profiles | Solid, robust shapes like angles, I-beams, and channels | Construction, structural supports | Pros: High strength; Cons: Limited customization compared to other types. |

| Custom Profiles | Tailored designs to meet specific project requirements | Specialized applications, unique architectural needs | Pros: Exact fit for unique projects; Cons: Higher cost and longer lead times. |

| Architectural Profiles | Aesthetic designs with various finishes for visual appeal | Facades, interior design, decorative elements | Pros: Enhances appearance; Cons: May sacrifice some structural integrity. |

| Heat Sink Profiles | Optimized designs for thermal management | Electronics, LED lighting, HVAC systems | Pros: Effective heat dissipation; Cons: Design limitations for size and shape. |

What are T-Slot Profiles and Their Benefits for B2B Buyers?

T-slot profiles are characterized by their modular design, featuring T-shaped slots that allow for easy assembly and reconfiguration. These profiles are particularly popular in automation and furniture applications, where flexibility and adaptability are crucial. When purchasing T-slot profiles, buyers should consider the compatibility with existing systems, the availability of connectors, and the ease of assembly, as these factors can significantly affect project timelines and costs.

Illustrative image related to aluminum extrusion profiles

How Do Standard Structural Profiles Serve Industrial Needs?

Standard structural profiles include shapes like angles, I-beams, and channels, designed for high strength and stability. These profiles are commonly used in construction and as structural supports in various industries. Buyers should focus on the load-bearing capacity, alloy type (commonly 6061 or 6063), and compliance with local building codes when sourcing these profiles, as these factors ensure safety and durability in their applications.

What Advantages Do Custom Profiles Offer to B2B Buyers?

Custom profiles are tailored to meet specific project requirements, making them ideal for specialized applications or unique architectural designs. While they provide an exact fit, buyers should be aware of the higher costs and longer lead times associated with custom orders. When considering custom profiles, it’s essential to collaborate closely with manufacturers to ensure design feasibility and material selection aligns with project goals.

Why Choose Architectural Profiles for Aesthetic Applications?

Architectural profiles are designed with aesthetics in mind, offering various finishes that enhance visual appeal. Commonly used in facades and interior designs, these profiles can elevate the overall look of a project. Buyers should weigh the aesthetic benefits against potential trade-offs in structural integrity, as some decorative profiles may not provide the same strength as standard structural options.

Illustrative image related to aluminum extrusion profiles

What Makes Heat Sink Profiles Essential in Electronics?

Heat sink profiles are specifically designed to optimize thermal management, making them crucial for electronics, LED lighting, and HVAC systems. These profiles facilitate effective heat dissipation, ensuring the longevity and reliability of electronic components. When sourcing heat sink profiles, buyers should consider the thermal efficiency, material quality, and compatibility with existing systems to maximize performance and minimize overheating issues.

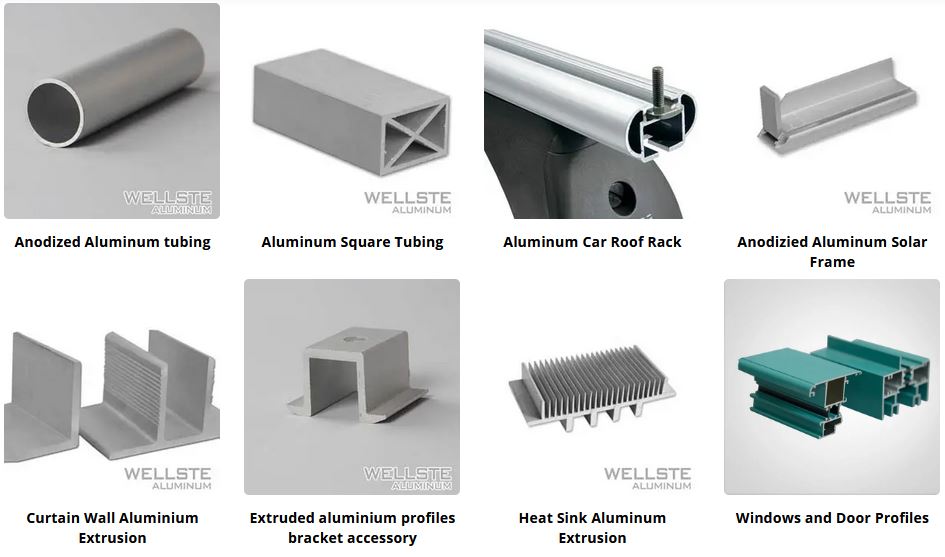

Key Industrial Applications of aluminum extrusion profiles

| Industry/Sector | Specific Application of aluminum extrusion profiles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural framing for buildings and facades | Lightweight yet strong, reducing overall construction costs | Material certifications (e.g., ISO, SGS), local availability, and delivery timelines |

| Transportation | Lightweight vehicle components | Enhances fuel efficiency and reduces wear on parts | Compliance with regional safety standards and corrosion resistance properties |

| Electronics | Heat sinks and enclosures | Improved thermal management for electronics | Specific alloy requirements for conductivity and thermal properties |

| Industrial Equipment | Custom machinery frames and supports | Increased durability and customizable design | Precision in dimensions and surface finish options |

| Home Decor | Decorative trims and fixtures | Aesthetic appeal combined with durability | Variety in surface treatments and colors to match design specifications |

How Are Aluminum Extrusion Profiles Utilized in the Construction Industry?

In the construction sector, aluminum extrusion profiles are integral for structural framing in buildings and facades. Their lightweight nature allows for easier handling and installation, reducing labor costs and time. Additionally, aluminum’s corrosion resistance enhances the longevity of structures. International buyers should focus on sourcing profiles that meet local building codes and certifications, ensuring compliance with safety and environmental standards.

What Role Do Aluminum Extrusion Profiles Play in Transportation?

Aluminum extrusion profiles are increasingly used in the transportation industry for manufacturing lightweight vehicle components such as chassis and frames. The reduction in weight directly correlates with improved fuel efficiency, making vehicles more economical and environmentally friendly. Buyers in regions like Africa and South America should consider sourcing profiles that comply with local safety regulations and can withstand harsh environmental conditions.

How Are Aluminum Extrusion Profiles Important for Electronics?

In the electronics sector, aluminum extrusion profiles serve critical functions as heat sinks and enclosures. They facilitate effective thermal management, ensuring devices operate within safe temperature limits. Buyers must prioritize sourcing profiles made from specific alloys that offer excellent thermal conductivity and are tailored to the unique requirements of their electronic applications. Compliance with international standards for electronic components is also essential.

What Are the Benefits of Aluminum Extrusion Profiles in Industrial Equipment?

Aluminum extrusion profiles are widely utilized in the manufacturing of custom machinery frames and supports. Their customizable nature allows businesses to design equipment that meets specific operational needs, enhancing productivity and reducing downtime. For international buyers, it is crucial to ensure precision in dimensions and select appropriate surface finishes that can withstand the rigors of industrial environments.

How Do Aluminum Extrusion Profiles Enhance Home Decor?

In the home decor industry, aluminum extrusion profiles are used for decorative trims and fixtures, combining aesthetic appeal with durability. Their versatility allows for various designs and finishes, making them ideal for modern interiors. Buyers should look for suppliers that offer a wide range of surface treatments and colors, allowing for customization to match specific design themes. Ensuring quality and consistency in the profiles is key for maintaining brand reputation in the market.

3 Common User Pain Points for ‘aluminum extrusion profiles’ & Their Solutions

Scenario 1: Sourcing Quality Materials for Projects

The Problem: Many B2B buyers struggle with sourcing high-quality aluminum extrusion profiles that meet their specific project requirements. With varying standards and quality levels across suppliers, it can be challenging to ensure that the materials they purchase are durable and reliable. This is especially concerning for industries like construction and manufacturing, where the integrity of materials directly impacts safety and performance. Buyers may also face issues with inconsistent product specifications, leading to project delays and increased costs.

The Solution: To overcome these challenges, buyers should prioritize sourcing from reputable suppliers that adhere to international quality standards, such as ISO and SGS certifications. Conducting thorough research on potential suppliers is crucial—look for those with a proven track record and positive customer reviews. Request detailed product specifications, including material properties, tolerances, and any relevant test certificates. Establishing a clear communication channel with the supplier can also help address any uncertainties regarding product quality and specifications before placing an order. Additionally, consider engaging in a sample procurement process to evaluate the materials firsthand before committing to larger orders.

Scenario 2: Navigating Complex Customization Needs

The Problem: Customization is often essential for B2B buyers looking to create unique products or solutions, but the aluminum extrusion process can be complex and overwhelming. Buyers may have specific requirements regarding dimensions, alloy types, or surface finishes, yet many suppliers lack the flexibility to accommodate these needs. This can lead to frustration, miscommunication, and ultimately, a failure to deliver the desired outcomes on time.

The Solution: To effectively navigate customization challenges, buyers should engage with suppliers that offer comprehensive design and engineering support. Look for manufacturers that have in-house capabilities for mold design and prototyping, as they can provide valuable insights into the feasibility of custom profiles. Clearly outline your customization requirements, including precise dimensions, alloy specifications, and surface treatments, when communicating with potential suppliers. Establishing a collaborative relationship can facilitate a smoother design process, allowing for adjustments and iterations based on real-time feedback. Additionally, consider utilizing digital tools such as CAD software to visualize the designs and ensure alignment with your specifications before production begins.

Scenario 3: Understanding and Managing Lead Times

The Problem: B2B buyers often face unpredictability in lead times for aluminum extrusion profiles, which can disrupt project timelines and operational efficiency. Factors such as supplier production capacity, order complexity, and material availability can lead to delays that affect downstream processes, causing frustration and financial implications for businesses relying on timely delivery.

The Solution: To manage lead times effectively, buyers should proactively discuss delivery expectations with suppliers during the initial inquiry phase. Request clear timelines based on order complexity and ensure that the supplier has the capacity to meet your demands, especially during peak seasons. Establishing a buffer in project planning can also mitigate the impact of unforeseen delays. Consider partnering with suppliers that offer expedited services or have a robust inventory of standard profiles that can be shipped quickly. Regularly communicating with your supplier about your ongoing project needs and timelines can foster a responsive relationship that helps both parties stay aligned and proactive in managing any potential delays.

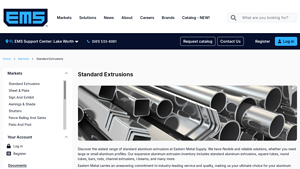

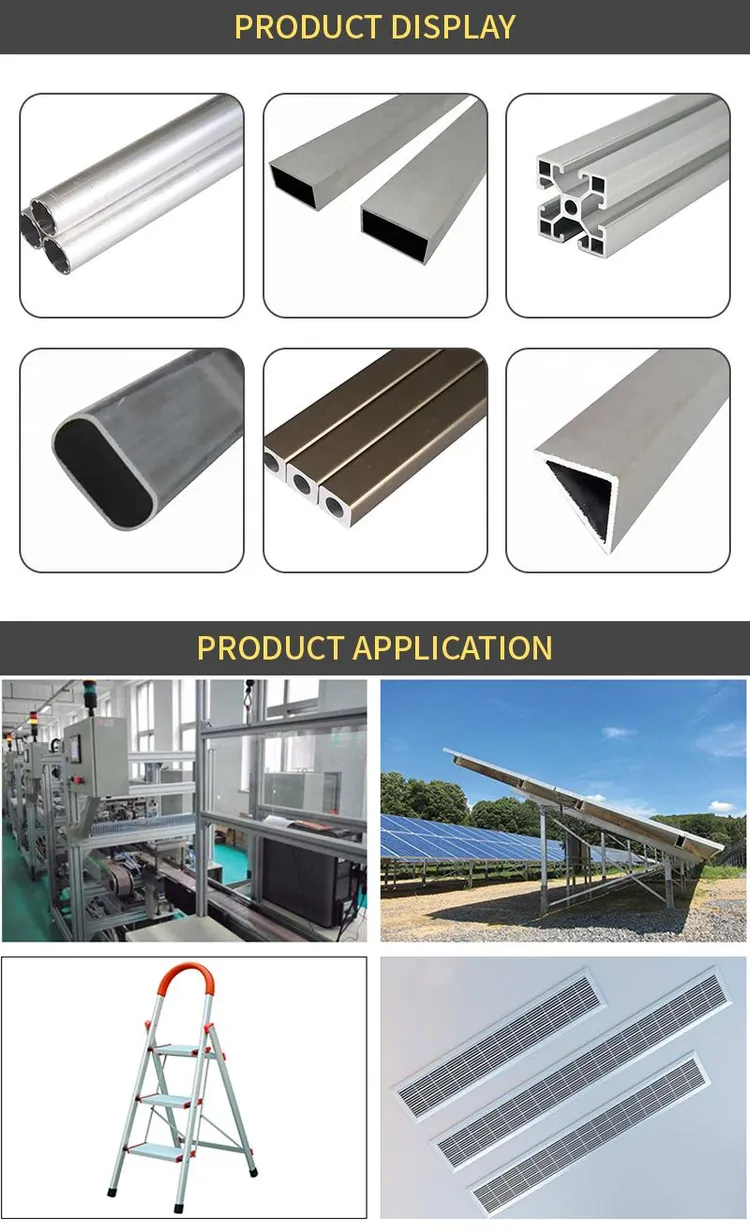

Strategic Material Selection Guide for aluminum extrusion profiles

What are the Key Properties of Common Materials Used in Aluminum Extrusion Profiles?

When selecting aluminum extrusion profiles, understanding the properties of various materials is essential for ensuring optimal performance in specific applications. Here, we analyze four common materials used in the manufacturing of aluminum extrusion profiles: 6061, 6063, 6082, and 7075 aluminum alloys.

1. 6061 Aluminum Alloy

Key Properties:

6061 aluminum is known for its excellent mechanical properties and weldability. It has a medium strength-to-weight ratio and can withstand temperatures up to 150°C (302°F). Its corrosion resistance is moderate, making it suitable for various environments.

Pros & Cons:

The alloy’s durability and ease of fabrication make it a popular choice for structural applications. However, it can be more expensive than other alloys, and its moderate corrosion resistance may require additional surface treatments in harsh environments.

Impact on Application:

6061 is often used in aerospace, automotive, and marine applications due to its strength and lightweight characteristics. It is compatible with various media, including water and mild chemicals.

Considerations for International Buyers:

Buyers in regions like Africa and South America should ensure compliance with local standards such as ASTM and ISO. The availability of 6061 may vary, so sourcing from reputable suppliers is crucial.

2. 6063 Aluminum Alloy

Key Properties:

6063 aluminum is characterized by its excellent extrudability and surface finish. It has a lower strength compared to 6061 but offers good corrosion resistance and is ideal for architectural applications.

Pros & Cons:

This alloy is widely used for its aesthetic appeal and ease of machining. However, its lower strength may limit its use in structural applications. It is generally more cost-effective than 6061.

Impact on Application:

6063 is commonly used in window frames, door frames, and other architectural elements, making it suitable for environments where aesthetics are important.

Illustrative image related to aluminum extrusion profiles

Considerations for International Buyers:

Compliance with architectural standards is vital, particularly in Europe and the Middle East. Buyers should also consider the surface treatment options available to enhance corrosion resistance.

3. 6082 Aluminum Alloy

Key Properties:

6082 aluminum offers higher strength than both 6061 and 6063, with good corrosion resistance and weldability. It can withstand temperatures up to 120°C (248°F).

Pros & Cons:

The alloy’s strength makes it suitable for heavy-duty applications, but it can be more challenging to machine than other alloys. Its cost is typically higher due to its enhanced properties.

Impact on Application:

6082 is often utilized in construction, transportation, and machinery applications, where strength and durability are paramount.

Illustrative image related to aluminum extrusion profiles

Considerations for International Buyers:

For buyers in regions with stringent quality standards, ensuring that 6082 complies with local regulations is essential. The availability of this alloy may vary, necessitating careful supplier selection.

4. 7075 Aluminum Alloy

Key Properties:

7075 aluminum is one of the strongest aluminum alloys, with a high strength-to-weight ratio. It is suitable for applications requiring high mechanical properties, with a temperature tolerance of around 120°C (248°F).

Pros & Cons:

While its strength is a significant advantage, 7075 is more expensive and less corrosion-resistant than other alloys. It is also more challenging to weld.

Impact on Application:

This alloy is primarily used in aerospace and military applications where strength is critical. It is compatible with various media but may require protective coatings in corrosive environments.

Considerations for International Buyers:

International buyers should be aware of the high costs associated with 7075 and ensure compliance with aerospace standards, particularly in Europe and the Middle East.

Illustrative image related to aluminum extrusion profiles

Summary Table of Material Selection for Aluminum Extrusion Profiles

| Material | Typical Use Case for Aluminum Extrusion Profiles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 6061 | Aerospace, automotive, marine | Excellent mechanical properties | Moderate corrosion resistance | Medium |

| 6063 | Architectural applications | Aesthetic appeal and extrudability | Lower strength | Low |

| 6082 | Construction, transportation | High strength | Challenging to machine | High |

| 7075 | Aerospace, military | Highest strength | Expensive and less corrosion-resistant | High |

This strategic material selection guide provides a comprehensive overview for B2B buyers, enabling informed decisions based on application requirements, cost considerations, and compliance with international standards.

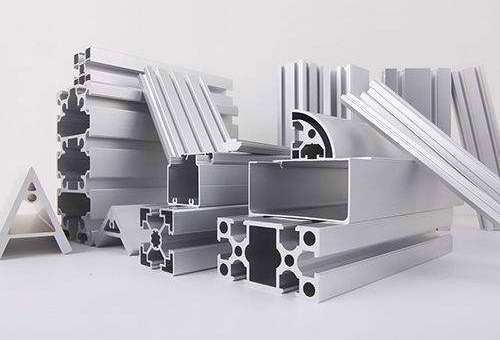

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum extrusion profiles

What Are the Key Stages in the Manufacturing Process of Aluminum Extrusion Profiles?

The manufacturing of aluminum extrusion profiles is a multi-step process that transforms raw aluminum into finished products suitable for various applications. This process includes several critical stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Aluminum Extrusion?

The process begins with material preparation, where aluminum billets are carefully selected based on the desired alloy and specifications. Common alloys used in extrusion include 6063 and 6061, chosen for their distinct properties—6063 is often utilized for architectural applications, while 6061 is more suited for structural uses. The billets are heated to approximately 400-500 degrees Celsius, making them malleable for the extrusion process.

Illustrative image related to aluminum extrusion profiles

What Techniques Are Employed in the Forming Stage?

Once the aluminum is sufficiently heated, it moves to the forming stage. This involves a hydraulic press that forces the heated aluminum through a die, shaping it into the desired profile. Different types of dies can be used to create various cross-sectional shapes, including T-slots, angles, and channels. This process is known as direct extrusion, where the material is pushed through the die. Some manufacturers may also use indirect extrusion, where the die is pushed into the billet, which can offer different benefits in terms of profile quality and material efficiency.

How Is Assembly Managed in Aluminum Extrusion Manufacturing?

After extrusion, the profiles may undergo an assembly process depending on the complexity of the final product. This could involve cutting the extruded profiles to specific lengths, machining, or joining multiple profiles together to create more intricate structures. Techniques such as welding, riveting, or using mechanical fasteners are commonly employed to ensure structural integrity.

What Finishing Techniques Enhance Aluminum Profiles?

The final stage in the manufacturing process is finishing, which is crucial for both aesthetics and performance. Surface treatments such as anodizing, powder coating, and electrophoresis are applied to enhance corrosion resistance and improve appearance. Anodizing creates a protective oxide layer, while powder coating provides a durable, colored finish. These finishes not only add visual appeal but also significantly increase the lifespan of the aluminum profiles in various environments.

How Is Quality Assurance Implemented in Aluminum Extrusion Manufacturing?

Quality assurance is a vital component of the aluminum extrusion manufacturing process. Suppliers must adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system, and industry-specific certifications like CE and API, ensuring that products meet regulatory and safety requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated at several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial phase involves inspecting the raw materials and components to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During the extrusion process, continuous monitoring is performed to detect any deviations from quality standards. This can include checks on temperature, pressure, and dimensions.

-

Final Quality Control (FQC): After production, finished profiles undergo thorough inspections to verify that they meet the required specifications. This may include dimensional checks, surface finish evaluations, and performance testing.

What Common Testing Methods Are Used for Quality Assurance?

Common testing methods include tensile strength tests, hardness tests, and visual inspections. Tensile testing measures the material’s ability to withstand pulling forces, while hardness tests evaluate resistance to deformation. Visual inspections check for surface defects and dimensional accuracy. Moreover, suppliers often provide manufacturing test certificates, confirming that products meet both chemical composition and mechanical performance standards.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance practices is essential. Here are several ways to ensure that potential suppliers meet your quality expectations:

-

Conduct Audits: Regular audits can help assess a supplier’s manufacturing processes, quality control systems, and adherence to international standards. Buyers may engage third-party auditing firms to provide an impartial assessment.

-

Request Documentation: Suppliers should provide detailed quality assurance documentation, including ISO certifications, quality control reports, and manufacturing test certificates. This documentation serves as proof of compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide additional assurance regarding the quality of the products before shipment. These inspections can help identify any potential issues early in the process.

-

Seek References: Requesting references from other international buyers can provide insight into a supplier’s reliability and quality. This feedback can be invaluable in making informed purchasing decisions.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International B2B buyers must also be mindful of specific nuances related to quality control. Different regions may have varying standards and regulations, so it’s crucial to align product specifications with local requirements. Understanding the logistics of shipping and handling is equally important, as improper transportation can affect product integrity.

Moreover, cultural differences in business practices may impact communication regarding quality expectations. Establishing clear, written agreements on quality standards and expectations can mitigate misunderstandings and ensure that both parties are aligned.

Conclusion

The manufacturing processes and quality assurance practices for aluminum extrusion profiles are complex yet essential for delivering high-quality products. By understanding the key stages of manufacturing and the importance of stringent quality control measures, B2B buyers can make informed decisions when selecting suppliers. Ensuring compliance with international standards and verifying quality assurance practices will help mitigate risks and enhance the overall success of procurement strategies in the global aluminum market.

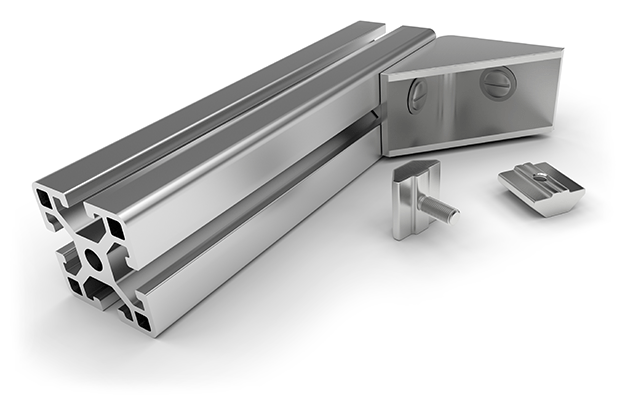

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminum extrusion profiles’

Introduction

Sourcing aluminum extrusion profiles requires careful consideration to ensure that the products meet your specific needs and that you partner with reliable suppliers. This checklist provides a structured approach for B2B buyers looking to procure aluminum extrusion profiles, ensuring you cover all essential aspects of the sourcing process.

1. Define Your Technical Specifications

Begin by clearly outlining the specifications for the aluminum profiles you need. This includes dimensions, alloy types (such as 6063 for architectural applications or 6061 for structural purposes), and any surface finish requirements. Precise specifications help suppliers understand your requirements and provide accurate quotes.

2. Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in aluminum extrusion profiles. Look for companies with a proven track record in your region or industry. Key factors to consider include:

– Experience: Suppliers with years of experience are often more reliable.

– Production Capacity: Ensure they can meet your volume requirements.

Illustrative image related to aluminum extrusion profiles

3. ✅ Verify Supplier Certifications

Before making any commitments, verify that your chosen suppliers hold relevant certifications. Look for ISO certifications and compliance with international quality standards. Certification not only assures you of quality but also reflects the supplier’s commitment to maintaining high production standards.

4. Request Samples and Test Quality

Always request samples of the aluminum extrusion profiles before placing a bulk order. This allows you to assess the quality of the materials and the accuracy of the specifications. Pay attention to:

– Finish Quality: Check for surface defects or inconsistencies.

– Dimensional Accuracy: Ensure the samples meet your specified dimensions.

5. Evaluate Delivery Capabilities

Assess the supplier’s ability to deliver on time, especially if you are working with tight deadlines. Confirm their lead times, especially during peak seasons. Reliable suppliers should provide:

– Clear Delivery Schedules: Understand how they handle delays.

– Logistics Support: Inquire about their shipping options and packaging methods to prevent damage during transit.

6. Understand Pricing Structure

Get a detailed breakdown of the pricing structure from your suppliers. This should include not just the cost of the profiles but also any additional charges for finishing, shipping, or tooling. Comparing prices helps you determine the best value for your investment while ensuring you’re not compromising on quality.

7. Negotiate Terms and Conditions

Finally, negotiate favorable terms and conditions, including payment terms, minimum order quantities, and warranties. Clear agreements on these aspects can help prevent misunderstandings and ensure a smooth transaction. Always document everything in a formal contract to protect your interests.

Illustrative image related to aluminum extrusion profiles

Following this checklist will help you navigate the complexities of sourcing aluminum extrusion profiles and ensure you make informed decisions that align with your business needs.

Comprehensive Cost and Pricing Analysis for aluminum extrusion profiles Sourcing

Understanding the cost structure and pricing dynamics of aluminum extrusion profiles is essential for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. This analysis will explore the key components influencing costs, price determinants, and strategic tips for negotiating effectively.

What Are the Key Cost Components in Aluminum Extrusion Profiles?

-

Materials: The primary raw material for aluminum extrusion is aluminum alloy, with 6063 and 6061 being the most common. The cost of aluminum fluctuates based on global market conditions, impacting overall pricing. Suppliers often source aluminum from various suppliers, which can affect costs based on location and availability.

-

Labor: Labor costs can vary significantly by region. In countries with higher wage standards, such as those in Europe, labor costs contribute more substantially to the final price. Conversely, regions with lower labor costs may offer more competitive pricing, but this can also affect quality and service levels.

-

Manufacturing Overhead: This includes costs related to utilities, maintenance, and facility operations. Efficient production lines can help keep these costs lower, impacting the overall price competitiveness of the supplier.

-

Tooling: Creating custom molds and dies for specific extrusion profiles can be a significant upfront investment. Tooling costs are typically amortized over the production volume, meaning larger orders can lead to lower per-unit tooling costs.

-

Quality Control (QC): Robust QC processes ensure that products meet specified standards and certifications. Suppliers with stringent QC measures may have higher costs but can offer enhanced reliability and quality assurance, which is vital for B2B buyers.

-

Logistics: Shipping costs can vary based on distance, shipping method, and Incoterms used. For international buyers, understanding these costs is crucial, as they can significantly affect the total landed cost of products.

-

Margin: Suppliers apply a margin to cover their costs and generate profit. This margin can vary based on market competition, supplier reputation, and the complexity of the product.

How Do Price Influencers Affect Sourcing Decisions?

Several factors can influence the pricing of aluminum extrusion profiles:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for larger orders. Understanding the MOQ can help buyers negotiate better terms and pricing.

-

Specifications and Customization: Custom profiles or specific finishes (e.g., anodizing, powder coating) can increase costs. Buyers should weigh the benefits of customization against the added expense.

-

Material Quality and Certifications: Profiles with higher-quality materials or certifications (like ISO or SGS) often command higher prices. Buyers should evaluate the necessity of these certifications based on their application.

-

Supplier Factors: Supplier experience, reputation, and production capabilities can affect pricing. Established suppliers with proven track records may offer better reliability but at a higher price.

-

Incoterms: The choice of Incoterms affects shipping responsibilities and costs. Buyers should negotiate terms that align with their logistics capabilities to manage costs effectively.

What Are the Best Tips for B2B Buyers to Negotiate Pricing Effectively?

-

Understand Total Cost of Ownership (TCO): Beyond the initial price, consider logistics, quality assurance, and lifecycle costs. A lower upfront cost may result in higher long-term expenses due to quality issues or shipping delays.

-

Leverage Volume Discounts: If possible, consolidate orders to meet or exceed MOQs. This can significantly reduce per-unit costs.

-

Negotiate Terms: Don’t hesitate to negotiate payment terms and delivery schedules. Flexible terms can enhance cash flow and reduce financial pressure.

-

Research Multiple Suppliers: Gathering quotes from various suppliers can provide leverage in negotiations. This also helps identify competitive pricing and service offerings.

-

Consider Local Suppliers: For buyers in regions like Africa or South America, sourcing from local suppliers can reduce shipping costs and lead times, enhancing overall cost efficiency.

Conclusion

While pricing for aluminum extrusion profiles is influenced by various factors, international B2B buyers can navigate this landscape effectively by understanding the cost components, price influencers, and negotiation strategies. By doing so, they can make informed sourcing decisions that align with their business objectives and operational needs. As always, consider indicative prices as a guide rather than a fixed standard, as market conditions can fluctuate.

Alternatives Analysis: Comparing aluminum extrusion profiles With Other Solutions

Understanding Alternatives to Aluminum Extrusion Profiles

In the realm of manufacturing and construction, selecting the right material or method is crucial for project success. Aluminum extrusion profiles have gained popularity due to their versatility and strength. However, there are alternatives that may better suit specific project requirements, depending on factors like performance, cost, and ease of implementation. This section will compare aluminum extrusion profiles with two viable alternatives: steel fabrication and 3D printing.

Comparison Table

| Comparison Aspect | Aluminum Extrusion Profiles | Steel Fabrication | 3D Printing |

|---|---|---|---|

| Performance | High strength-to-weight ratio; corrosion-resistant | Very strong; excellent load-bearing capacity | Good for complex designs; material properties vary |

| Cost | Moderate initial investment; lower long-term maintenance costs | Higher initial costs; potential for higher long-term costs | Variable costs depending on material and complexity |

| Ease of Implementation | Easy assembly with T-slot systems; requires minimal tools | Requires skilled labor for assembly and welding | User-friendly for prototyping; complex for large-scale production |

| Maintenance | Low maintenance; resistant to corrosion | Moderate maintenance; susceptible to rust without treatment | Minimal maintenance; dependent on material used |

| Best Use Case | Structural applications, framing, and enclosures | Heavy-duty applications, structural beams, and supports | Custom parts, prototypes, and intricate designs |

Detailed Breakdown of Alternatives

Steel Fabrication: A Strong Contender

Steel fabrication is a traditional method known for its robustness and versatility. It excels in applications requiring high load-bearing capacities, making it ideal for construction and heavy machinery. However, the initial investment can be significantly higher than aluminum extrusion profiles due to labor costs and material prices. Additionally, while steel is strong, it is also prone to rust if not properly treated, leading to higher maintenance costs over time. B2B buyers should consider steel fabrication for projects demanding superior strength but must weigh the increased costs and potential maintenance issues.

Illustrative image related to aluminum extrusion profiles

3D Printing: The Future of Customization

3D printing offers a modern approach to manufacturing, allowing for the production of complex and customized designs with reduced waste. It is particularly beneficial for prototyping and small-scale production runs, where traditional methods may not be cost-effective. However, the material properties of 3D printed parts can vary widely based on the filament used, which may not always meet the strength requirements of structural applications. Additionally, while the upfront costs can be low, the price may increase significantly for larger parts or higher-quality materials. Companies looking for innovative solutions may find 3D printing advantageous, especially for niche markets or custom designs.

Making the Right Choice for Your Business Needs

When considering aluminum extrusion profiles versus alternatives like steel fabrication and 3D printing, B2B buyers must evaluate their specific project requirements. Key factors include the desired performance characteristics, budget constraints, and the complexity of the designs. Aluminum extrusion profiles offer a balanced solution with a moderate investment and low maintenance, making them suitable for a wide range of applications. In contrast, steel fabrication provides unmatched strength for heavy-duty projects, while 3D printing opens doors for customization and innovative designs. By carefully assessing these alternatives, businesses can make informed decisions that align with their operational goals and market demands.

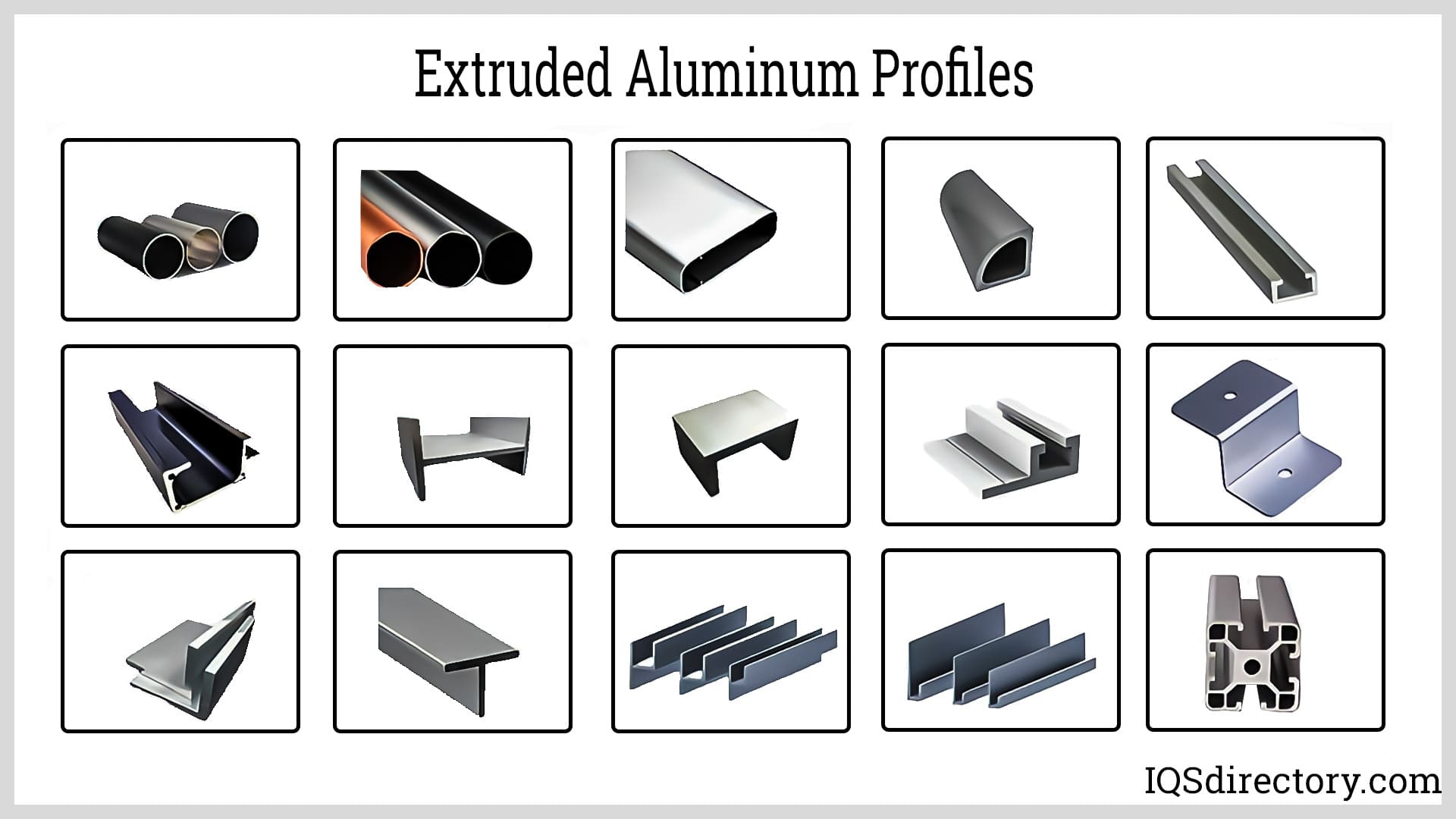

Essential Technical Properties and Trade Terminology for aluminum extrusion profiles

What Are the Key Technical Properties of Aluminum Extrusion Profiles?

Understanding the essential technical properties of aluminum extrusion profiles is critical for B2B buyers to make informed purchasing decisions. Here are the key specifications that should be prioritized:

1. Material Grade (Alloy Type)

Aluminum extrusion profiles are available in various alloy grades, with 6063 and 6061 being the most common. The 6063 alloy is typically used for architectural applications due to its excellent surface finish and workability, while 6061 is favored for structural applications due to its superior strength and resistance to corrosion. Selecting the appropriate alloy is vital for ensuring the profile meets the performance requirements of specific applications.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension or measurement of the extrusion. It is crucial in ensuring that components fit together correctly, especially in precision applications. Tight tolerances can result in higher production costs but are essential for applications where precision is non-negotiable, such as in aerospace or automotive industries.

Illustrative image related to aluminum extrusion profiles

3. Surface Finish

Aluminum profiles can undergo various surface treatments, including anodizing, powder coating, and electrophoresis. These finishes enhance durability, corrosion resistance, and aesthetic appeal. Understanding the specific surface treatment required for an application can significantly impact the longevity and performance of the final product.

4. Weight

The weight of aluminum profiles is another critical property, as it affects transportation costs and structural design. Aluminum is lightweight yet strong, making it ideal for applications in construction, transportation, and manufacturing. Buyers should assess the weight specifications to ensure they align with their project requirements.

5. Dimensions

Aluminum extrusion profiles come in a range of dimensions, often categorized into metric and fractional sizes. Buyers must ensure that the dimensions match their project specifications to avoid delays and additional costs associated with custom orders.

What Are Common Trade Terms in the Aluminum Extrusion Industry?

Familiarity with industry-specific jargon is essential for effective communication and negotiation in B2B transactions. Here are some key trade terms relevant to aluminum extrusion profiles:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of aluminum extrusion, an OEM may use extruded profiles to produce their final product. Understanding OEM relationships can help buyers identify potential partnerships and streamline the supply chain.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to manage inventory and ensure cost-effectiveness. Suppliers often set MOQs to cover production costs, so understanding this term can aid in negotiating better terms.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. For aluminum extrusion profiles, an RFQ typically includes specifications, quantities, and delivery timelines. Utilizing RFQs can help buyers obtain competitive pricing and select the best supplier based on their needs.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms such as FOB (Free On Board) or CIF (Cost Insurance and Freight) is essential for buyers to clarify shipping costs and responsibilities.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. In the aluminum extrusion industry, lead times can vary significantly based on the complexity of the extrusion, tooling requirements, and supplier capabilities. Being aware of lead times allows buyers to plan their projects effectively and avoid delays in production.

Illustrative image related to aluminum extrusion profiles

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions, ensuring that they select the right aluminum extrusion profiles for their specific applications while optimizing their supply chain processes.

Navigating Market Dynamics and Sourcing Trends in the aluminum extrusion profiles Sector

What Are the Key Trends Influencing the Aluminum Extrusion Profiles Market?

The aluminum extrusion profiles market is witnessing significant growth, driven by various global factors. Key among these is the increasing demand for lightweight materials across industries such as automotive, construction, and electronics. The trend towards sustainable building materials and energy-efficient products is also reshaping market dynamics, as businesses seek to reduce carbon footprints. Moreover, the rise of automation and digitalization in manufacturing is enhancing operational efficiencies, allowing suppliers to respond more swiftly to customer needs.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly leveraging advanced sourcing technologies. Platforms that facilitate real-time tracking of orders, inventory management, and supplier evaluation are becoming essential tools for procurement professionals. Additionally, the growing emphasis on customization is prompting suppliers to develop a broader array of profiles, including metric and fractional dimensions, to cater to diverse customer requirements. Buyers are advised to keep abreast of these trends, as they can significantly impact sourcing strategies and supplier selection.

How Is Sustainability Shaping the Sourcing of Aluminum Extrusion Profiles?

Sustainability has emerged as a critical concern in the aluminum extrusion profiles sector. The environmental impact of aluminum production, particularly regarding energy consumption and greenhouse gas emissions, necessitates a focus on sustainable practices. Ethical sourcing is becoming increasingly important, with buyers favoring suppliers who adhere to stringent environmental standards. Certifications such as ISO 14001 and the use of recycled aluminum are indicators of a supplier’s commitment to sustainability.

Moreover, many companies are now prioritizing suppliers who can offer ‘green’ materials and processes. For instance, profiles that are anodized or powder-coated using environmentally friendly techniques are gaining traction. This shift not only aligns with corporate social responsibility goals but also meets the growing consumer demand for sustainable products. B2B buyers should actively seek out suppliers who demonstrate transparency in their sourcing practices and can provide documentation on the sustainability of their materials.

How Has the Aluminum Extrusion Profiles Market Evolved Over Time?

The aluminum extrusion profiles market has undergone a significant evolution since its inception. Initially, the focus was primarily on basic extrusion shapes for construction and manufacturing. However, advancements in technology and material science have led to the development of more complex profiles designed for specific applications, such as automotive frames and aerospace components.

Over the years, the industry has embraced innovations such as computer-aided design (CAD) and 3D modeling, which have revolutionized product development and customization. The introduction of various aluminum alloys has also expanded the application range, allowing for improved performance and durability. This evolution highlights the importance of staying informed about technological advancements, as they can provide B2B buyers with a competitive edge in selecting the right profiles for their projects.

Illustrative image related to aluminum extrusion profiles

In conclusion, understanding the market dynamics, sustainability considerations, and historical context of aluminum extrusion profiles is crucial for international B2B buyers aiming to make informed sourcing decisions. By aligning with trends and adopting sustainable practices, businesses can enhance their competitiveness and contribute positively to environmental stewardship.

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum extrusion profiles

-

How do I ensure the quality of aluminum extrusion profiles before purchasing?

To ensure quality, request detailed specifications and certifications from suppliers, such as ISO and SGS certifications. Verify their in-house quality control processes, including the availability of testing labs and inspection teams. Ask for samples to evaluate material properties and surface finishes. Additionally, review customer testimonials and case studies to gauge past performance and reliability. -

What is the best aluminum alloy for specific applications?

The choice of aluminum alloy depends on the intended application. For architectural applications, 6063 alloy is preferred due to its excellent corrosion resistance and aesthetic finish. For structural applications requiring higher strength, 6061 alloy is more suitable. Consult with suppliers to identify the best alloy based on your specific project requirements, including mechanical properties and environmental factors. -

What are the common surface finishes available for aluminum extrusion profiles?

Aluminum extrusion profiles can be finished in several ways, including anodizing, powder coating, and PVDF coatings. Anodizing enhances corrosion resistance and provides a decorative finish, while powder coating offers color variety and durability. PVDF is ideal for exterior applications due to its weather resistance. Discuss your project needs with suppliers to select the most appropriate finish. -

What is the minimum order quantity (MOQ) for aluminum extrusion profiles?

Minimum order quantities can vary widely among suppliers, typically ranging from 100 kg to several tons. Factors affecting MOQ include the complexity of the profile design, manufacturing capabilities, and supplier policies. Always inquire about MOQs upfront to avoid unexpected costs and ensure that your order aligns with your project scale. -

How do I vet suppliers for aluminum extrusion profiles in international trade?

To vet suppliers, conduct thorough research by checking their business credentials, certifications, and industry experience. Look for reviews and feedback from previous customers. Request references and verify their production capacity and lead times. Additionally, consider visiting their facility if possible, or using third-party inspection services to assess their operations and quality assurance processes. -

What payment terms are typically offered by suppliers of aluminum extrusion profiles?

Payment terms can vary, but common arrangements include upfront deposits (usually 30-50%) with the balance due before shipment. Some suppliers may offer credit terms or flexible payment options depending on the buyer’s creditworthiness and relationship with the supplier. Always clarify payment terms before placing an order to ensure alignment with your cash flow requirements. -

What logistics considerations should I keep in mind when sourcing aluminum extrusion profiles internationally?

When sourcing internationally, consider shipping methods, customs regulations, and import duties. Opt for suppliers who provide comprehensive logistics support, including freight forwarding and handling documentation. Discuss packaging standards to ensure safe transit and inquire about delivery timelines to align with your project schedule. Establish clear communication with the supplier regarding the entire shipping process. -

Can I customize aluminum extrusion profiles to meet specific design requirements?

Yes, many suppliers offer customization options for aluminum extrusion profiles. You can specify dimensions, alloy types, surface finishes, and even unique design features. It’s essential to communicate your design specifications clearly and provide any necessary drawings or prototypes. Collaborating closely with the supplier will help ensure that the final product meets your precise requirements and enhances your project’s success.

Top 3 Aluminum Extrusion Profiles Manufacturers & Suppliers List

1. MISUMI – Aluminum Extrusions

Domain: us.misumi-ec.com

Registered: 2007 (18 years)

Introduction: Aluminum Extrusions, also known as T-slot framing rails or profiles, provide a modular and flexible solution for various industrial applications. They feature slotted rails for easy assembly of carts, workstations, shelves, and barriers without welding. Designed for quick reconfiguration and expansion, they are ideal for adaptable manufacturing settings. Enhancements can include handles, hinges, p…

2. Extrude-A-Trim – Aluminum Extrusions Catalog

Domain: extrude-a-trim.com

Registered: 1998 (27 years)

Introduction: Aluminum Extrusions Catalog includes a variety of in-stock shapes such as Angles (Equal Leg, Unequal Leg, Rounded Inside), Channels (Architectural, Structural, Rounded Inside/Outside), Corner Moulding, Drawer & Finger Pulls, Glass Railing Systems, Hollow Tubes (Rectangular, Round, Square), Structural Square Hollow Tubes, J-Channels, Mirror Trim, Moulding & Trim, Awning Rails, Sliding Track Systems…

3. Eastern Metal – Standard Aluminum Extrusions

Domain: easternmetal.com

Registered: 1996 (29 years)

Introduction: Standard Aluminum Extrusions including Bar & Rod, Angle, Channel, Square Tube, Rectangular Tube, Round Tube, Pipe, I-Beams, Zees & Tees. Available in Painted & Anodized finishes. Additional products include Welding Rod & Wire, Sheet & Plate options such as 5052 H32 Mill Finish Sheet, 3003 H14 Mill Finish Sheet, 6061 Mill Finish Sheet & Plate, Anodized 5005 Sheet, 3003 H22/24 Tread Brite, 6061 T6 T…

Strategic Sourcing Conclusion and Outlook for aluminum extrusion profiles

What Are the Key Takeaways for Strategic Sourcing of Aluminum Extrusion Profiles?

In navigating the dynamic landscape of aluminum extrusion profiles, international B2B buyers must prioritize strategic sourcing to optimize their procurement processes. Emphasizing quality assurance, diverse product offerings, and reliable supply chains are essential to mitigate risks associated with fluctuating market demands. Suppliers with robust certifications, such as ISO and SGS, can provide reassurance regarding product quality and compliance with international standards.

Furthermore, understanding the variety of aluminum alloys and profiles available is crucial for aligning material properties with specific applications. By leveraging suppliers’ expertise, buyers can make informed decisions that enhance both product performance and cost efficiency.

How Should B2B Buyers Approach Future Sourcing Strategies?

Looking ahead, the aluminum extrusion market is poised for growth, driven by increasing demand across sectors like construction, transportation, and industrial applications. Buyers should actively seek partnerships with suppliers who demonstrate innovation in product development and customization capabilities.

Engaging with suppliers that offer comprehensive fabrication services can further streamline operations, reduce lead times, and enhance competitiveness in local markets. As the industry evolves, embracing strategic sourcing will not only empower buyers to make smarter procurement choices but also position them favorably in the global marketplace. Now is the time to reach out to potential suppliers and explore the vast opportunities within the aluminum extrusion sector.

Illustrative image related to aluminum extrusion profiles

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.