Unlocking Value: A Strategic Analysis of the Mitre Gears Market

Introduction: Navigating the Global Market for mitre gears

As global industries increasingly rely on precision engineering, sourcing high-quality mitre gears presents a unique challenge for international B2B buyers. With their ability to change the direction of power transmission without altering speed, mitre gears are essential components across various sectors, including automotive, aerospace, and machinery. This guide serves as a comprehensive resource, addressing the complexities of selecting the right mitre gears, understanding their diverse applications, and navigating the intricacies of supplier vetting.

Buyers from regions such as Africa, South America, the Middle East, and Europe, including markets like Vietnam and Brazil, will find valuable insights on different types of mitre gears, including straight, spiral, and angular variants. Additionally, we delve into critical factors such as material selection, manufacturing processes, and cost considerations that can significantly influence purchasing decisions.

By equipping buyers with actionable information and expert recommendations, this guide aims to empower organizations to make informed choices, ensuring they procure mitre gears that meet their specific operational needs while optimizing performance and cost-efficiency. Whether you are looking to enhance your supply chain or innovate your product offerings, understanding the global landscape of mitre gears is crucial for sustaining competitive advantage in today’s dynamic market.

Understanding mitre gears Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Straight Miter Gears | Same number of teeth, simple design, easy to manufacture | Basic machinery, automotive systems | Pros: Cost-effective, easy to source. Cons: No speed reduction or increase. |

| Spiral Miter Gears | Helical tooth design, quieter operation, better load capacity | Robotics, conveyor systems | Pros: Higher strength, smoother operation. Cons: More complex, potentially higher cost. |

| Angular Miter Gears | Available in various angles (e.g., 45°, 60°, 120°) | Specialized machinery, aerospace | Pros: Versatile configurations. Cons: Limited stock availability. |

| Plastic Miter Gears | Lightweight, lubricant-free operation, lower cost | Consumer products, light machinery | Pros: Corrosion-resistant, low weight. Cons: Limited load capacity. |

| Stainless Steel Miter Gears | Rust-resistant, durable, suitable for harsh environments | Food processing, medical equipment | Pros: Long lifespan, hygienic. Cons: Higher initial investment. |

What Are the Characteristics of Straight Miter Gears?

Straight miter gears are characterized by their straightforward design and equal number of teeth. This simplicity makes them easy to manufacture and cost-effective, making them a popular choice in basic machinery and automotive systems. When considering purchasing straight miter gears, buyers should assess the application requirements, particularly if speed modification is necessary, as these gears do not facilitate such adjustments.

How Do Spiral Miter Gears Enhance Performance?

Spiral miter gears feature a helical tooth design that allows for smoother engagement and quieter operation compared to their straight counterparts. Their ability to handle higher loads makes them suitable for applications in robotics and conveyor systems. However, buyers should be aware that the increased complexity in design may lead to higher costs and longer lead times, making it crucial to evaluate the total cost of ownership versus performance benefits.

Why Choose Angular Miter Gears for Specialized Needs?

Angular miter gears are available in various angles, including 45°, 60°, and 120°, which allows for versatile configurations in specialized machinery and aerospace applications. This adaptability is a significant advantage for manufacturers requiring specific directional changes in their systems. Buyers should consider the availability of these gears, as they may not be as readily stocked as standard types, potentially impacting lead times.

What Are the Advantages of Plastic Miter Gears?

Plastic miter gears, made from materials like nylon, are lightweight and do not require lubrication, making them ideal for consumer products and light machinery. Their corrosion resistance is an added benefit for applications in humid or corrosive environments. However, buyers must be cautious about their load capacity, as plastic gears may not withstand heavy-duty applications, necessitating a careful assessment of their suitability for the intended use.

When Are Stainless Steel Miter Gears the Best Choice?

Stainless steel miter gears are known for their durability and rust resistance, making them suitable for harsh environments such as food processing and medical equipment. Their hygienic properties and long lifespan justify the higher initial investment for many businesses. Buyers should evaluate their specific application needs and consider the total cost of ownership, as the durability and reliability of stainless steel gears can lead to reduced maintenance costs over time.

Key Industrial Applications of mitre gears

| Industry/Sector | Specific Application of mitre gears | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Efficiently redirecting motion to optimize space | Precision in tooth design for smooth operation and longevity |

| Automotive | Drive Train Assemblies | Reliable transmission of power in compact spaces | Material selection for durability and resistance to wear |

| Robotics | Articulated Robot Arms | Enhanced maneuverability and precision in movements | Compatibility with existing systems and adaptability in design |

| Food Processing | Automated Packaging Machines | Improved efficiency in product handling | Hygiene standards for materials, especially in stainless steel |

| Renewable Energy | Wind Turbine Gearboxes | Effective conversion of wind energy to mechanical power | Sourcing for high-strength materials to withstand harsh conditions |

How Are Mitre Gears Utilized in Manufacturing Conveyor Systems?

In manufacturing, mitre gears are crucial in conveyor systems where the direction of movement needs to be changed efficiently. They facilitate the redirection of power between shafts at various angles, optimizing the layout of production lines. International buyers must focus on precision in gear design to ensure smooth operation and minimize wear, leading to lower maintenance costs and increased productivity.

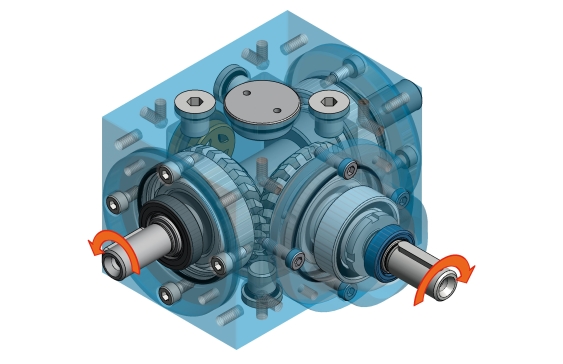

What Role Do Mitre Gears Play in Automotive Drive Train Assemblies?

Mitre gears are integral to automotive drive train assemblies, where they help transmit power from the engine to the wheels through compact and efficient setups. This application is vital for maintaining performance while maximizing space within the vehicle’s design. Buyers need to consider the material’s strength and the gear’s ability to withstand continuous operation under high stress, ensuring reliability and safety.

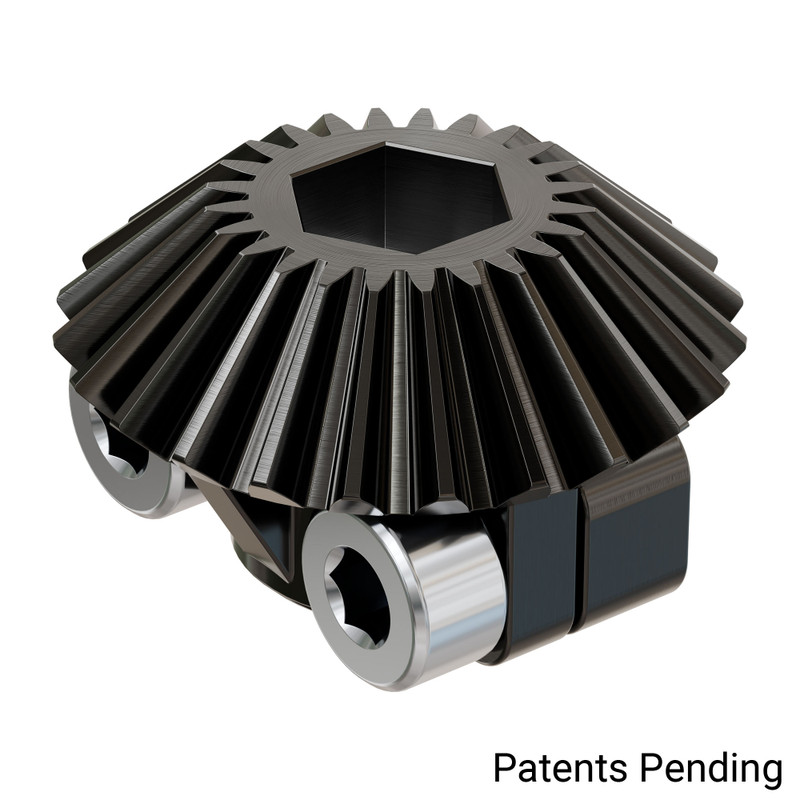

Illustrative image related to mitre gears

How Are Mitre Gears Used in Robotics for Articulated Robot Arms?

In robotics, mitre gears are employed in articulated robot arms to achieve precise movements and flexibility in positioning. These gears enable the change of direction in power transmission, allowing for complex maneuvers that are essential in automated tasks. Buyers should prioritize sourcing gears that can withstand repetitive motion and offer compatibility with existing robotic systems to ensure seamless integration.

Why Are Mitre Gears Important in Food Processing Automated Packaging Machines?

In the food processing industry, mitre gears are vital for automated packaging machines, where they assist in the efficient handling and movement of products. They help ensure that the machinery operates smoothly and maintains hygiene standards, crucial in food safety. When sourcing, businesses should opt for stainless steel gears to meet industry regulations and ensure longevity in harsh processing environments.

How Do Mitre Gears Contribute to Wind Turbine Gearboxes in Renewable Energy?

Mitre gears play a significant role in wind turbine gearboxes, where they are used to convert the rotational motion of the blades into mechanical energy. This application is critical for enhancing the efficiency of energy conversion processes in renewable energy systems. Sourcing considerations include selecting high-strength materials to withstand the environmental challenges faced in wind energy applications, ensuring durability and performance.

3 Common User Pain Points for ‘mitre gears’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Miter Gear for Specific Applications

The Problem: B2B buyers often face challenges when trying to select the right miter gear for their specific applications. With various types, such as straight, spiral, and angular miter gears, each offering unique characteristics, the task can quickly become overwhelming. This complexity is exacerbated when buyers need to consider factors like load requirements, speed, and the operating environment, which can vary significantly across industries. In particular, buyers from diverse regions, such as Africa and South America, may encounter additional hurdles in understanding the specific performance metrics and standards that apply to their local markets.

The Solution: To effectively navigate this selection process, buyers should start by conducting a thorough analysis of their application requirements. This includes understanding the load capacity, speed, and the angle at which the gears will operate. A well-structured inquiry process can help. Reach out to manufacturers with specific questions about their gear specifications, including materials, tooth design, and manufacturing tolerances. Utilizing gear selection tools available on manufacturer websites can streamline this process. Additionally, collaborating with an experienced engineer or a technical consultant can provide insights into the most suitable gear type for specific applications. For instance, if high torque and speed are critical, opting for ground spiral miter gears may be the best choice due to their strength and abrasion resistance.

Scenario 2: Issues with Gear Compatibility and Interchangeability

The Problem: Another common pain point for B2B buyers is the compatibility and interchangeability of miter gears within existing machinery. Many buyers may find themselves in situations where they need to replace or upgrade their gears but are unsure whether new parts will mesh correctly with existing components. This is particularly true for international buyers who may be working with varying manufacturing standards and specifications, leading to costly downtime if gears do not fit or function as intended.

The Solution: To mitigate compatibility issues, buyers should prioritize sourcing gears from reputable manufacturers who provide detailed specifications and compatibility charts. Before making a purchase, it’s crucial to cross-reference the specifications of the existing gears with those of potential replacements. This includes the number of teeth, module, and tooth profile. Furthermore, buyers should consider standardized gear options that are more likely to be interchangeable across different manufacturers. Engaging in discussions with suppliers about the specific application and existing setups can also yield tailored recommendations. Lastly, conducting a trial fit with sample gears can help ensure that the new miter gears will operate smoothly within the existing system.

Scenario 3: High Costs and Long Lead Times for Custom Gears

The Problem: Many B2B buyers find themselves facing high costs and extended lead times when ordering custom miter gears. This is often due to the need for specialized designs that meet unique specifications, which can lead to delays in production and increased project costs. Buyers in emerging markets, such as in parts of the Middle East and South America, may find these challenges particularly pronounced due to limited local manufacturing capabilities and reliance on overseas suppliers.

The Solution: To address these challenges, buyers should explore the option of using standard miter gears that can meet their application requirements. Manufacturers often provide a range of stock gears that can be delivered quickly and at a lower cost compared to custom solutions. When customization is necessary, consider collaborating with manufacturers early in the design phase to streamline production and reduce lead times. Additionally, leveraging advanced manufacturing technologies, such as 3D printing for prototypes, can allow buyers to test designs before committing to large-scale production. Finally, fostering long-term relationships with manufacturers can lead to better pricing agreements and improved lead times for future orders. This proactive approach not only helps in managing costs but also enhances supply chain reliability.

Strategic Material Selection Guide for mitre gears

What are the Key Materials for Mitre Gears and Their Properties?

When selecting materials for mitre gears, it is crucial to understand the properties, advantages, disadvantages, and application impacts of each material. Below, we analyze four common materials used in the manufacturing of mitre gears: steel, stainless steel, plastic, and sintered metal.

How Does Steel Perform in Mitre Gear Applications?

Key Properties: Steel, particularly grades like S45C and SCM415, offers excellent strength and wear resistance. It can withstand high loads and has good machinability, making it suitable for various applications.

Pros & Cons: Steel is durable and can be hardened through processes like carburizing, enhancing its longevity. However, it is susceptible to corrosion if not properly treated, which can be a significant drawback in humid or corrosive environments. Manufacturing complexity is moderate, as secondary operations are often required for optimal performance.

Impact on Application: Steel mitre gears are ideal for high-load applications in machinery and automotive sectors. Buyers in regions with high humidity, such as parts of Africa and South America, should consider additional protective coatings or treatments.

Why Choose Stainless Steel for Mitre Gears?

Key Properties: Stainless steel, particularly SUS303, is known for its corrosion resistance and strength. It maintains its integrity in harsh environments, which is crucial for applications in food processing or chemical industries.

Pros & Cons: The primary advantage of stainless steel is its resistance to rust and corrosion, making it suitable for applications where hygiene is critical. However, it is generally more expensive than regular steel and may require specialized machining techniques, increasing manufacturing complexity.

Impact on Application: Stainless steel mitre gears are commonly used in food machinery and medical devices, where cleanliness is paramount. B2B buyers in Europe and the Middle East often prefer stainless steel for its compliance with food safety standards.

Illustrative image related to mitre gears

What Are the Benefits of Using Plastic in Mitre Gears?

Key Properties: Plastic materials, such as MC nylon, are lightweight and can operate without lubrication. They are suitable for lower load applications and can resist certain chemicals.

Pros & Cons: The main advantage of plastic mitre gears is their low cost and ease of manufacturing, especially through injection molding. However, they have lower strength and wear resistance compared to metal gears, which limits their application scope.

Impact on Application: Plastic gears are ideal for light-duty applications in consumer products and electronics. Buyers in regions like South America may find plastic gears appealing due to their affordability, but they should be cautious about load limitations.

Illustrative image related to mitre gears

How Do Sintered Metal Gears Compare?

Key Properties: Sintered metal gears, made from powdered metal, offer a balance of strength and cost-effectiveness. They are lightweight and can be produced in high volumes.

Pros & Cons: Sintered gears are relatively inexpensive and can be produced with complex shapes. However, they may not achieve the same strength levels as forged or machined gears and can have porosity issues that affect performance.

Impact on Application: These gears are suitable for applications requiring mass production at a lower cost, such as in automotive and appliance industries. B2B buyers should consider the specific load requirements and environmental conditions when choosing sintered gears.

Summary Table of Mitre Gear Materials

| Material | Typical Use Case for mitre gears | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-load machinery and automotive | Excellent strength and wear resistance | Susceptible to corrosion | Medium |

| Stainless Steel | Food processing and medical devices | Corrosion resistance | Higher cost and machining complexity | High |

| Plastic | Consumer products and electronics | Lightweight and low-cost | Lower strength and wear resistance | Low |

| Sintered Metal | Mass production in automotive appliances | Cost-effective for high volumes | Lower strength and potential porosity | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of various materials for mitre gears, facilitating informed purchasing decisions tailored to specific industry needs.

In-depth Look: Manufacturing Processes and Quality Assurance for mitre gears

What Are the Main Stages in the Manufacturing Process of Mitre Gears?

The manufacturing of mitre gears involves several critical stages, each contributing to the final product’s performance and reliability. Understanding these stages is essential for B2B buyers looking to source quality mitre gears.

Material Preparation: What Materials Are Commonly Used?

The first step in the manufacturing process is material selection. Common materials for mitre gears include carbon steel (like S45C and SCM415), stainless steel (such as SUS303), and plastic composites (like MC901). The choice of material is crucial, as it affects the gear’s strength, durability, and suitability for specific applications. For instance, stainless steel is often preferred in food processing applications due to its corrosion resistance.

Once the material is selected, it undergoes various preparation processes, including cutting and shaping, to ensure it meets the required specifications for the gear’s dimensions and properties.

How Are Mitre Gears Formed?

The forming stage involves several key techniques to create the gear shape and tooth profile. The most common methods include:

-

Hobbing: This technique uses a rotating cutting tool to form the gear teeth. It is efficient for mass production and can produce complex tooth shapes.

-

Shaping: This method involves a reciprocating cutter to shape the gear teeth. It is particularly useful for producing gears with specific profiles that hobbing may not achieve.

-

Grinding: For high-precision applications, grinding is employed to refine the tooth surfaces and achieve tight tolerances. This process can significantly enhance the gear’s performance by reducing noise and improving wear resistance.

-

Sintering: For plastic and some metal gears, sintering is a popular method. This process involves compacting and heating the material without melting it, allowing for the production of lightweight and cost-effective gears.

What Finishing Processes Are Used to Ensure Quality?

After forming, mitre gears undergo various finishing processes to enhance their performance characteristics. These may include:

-

Heat Treatment: This process, such as carburizing or induction hardening, improves the gear’s hardness and wear resistance, which is crucial for applications involving high torque.

-

Surface Treatment: Techniques like coating or polishing may be applied to reduce friction and enhance corrosion resistance.

-

Final Machining: This involves precision machining to ensure that all dimensions meet strict specifications, which is critical for proper meshing and operation.

How Is Quality Assurance Implemented in Mitre Gear Manufacturing?

Quality assurance is paramount in the manufacturing of mitre gears, ensuring they meet both international and industry-specific standards.

Which International Standards Are Relevant for Mitre Gears?

Many manufacturers adhere to ISO 9001, which outlines criteria for a quality management system. Compliance with this standard ensures that companies consistently provide products that meet customer and regulatory requirements. Other relevant certifications may include CE marking for European markets and API standards for oil and gas applications.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated into the manufacturing process at various stages:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they enter the production process. Suppliers must provide certifications and reports to confirm compliance with material specifications.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the production process. This includes checking dimensions, tooth profiles, and surface finishes to ensure adherence to specifications.

-

Final Quality Control (FQC): Once the gears are finished, a comprehensive inspection is performed. This may include functional testing, dimensional checks, and visual inspections to confirm that the final products meet quality standards.

What Common Testing Methods Are Used for Mitre Gears?

Several testing methods are employed to ensure the quality and performance of mitre gears:

-

Dimensional Inspection: Utilizing precision measurement tools, manufacturers check critical dimensions and tolerances.

-

Load Testing: Gears may undergo load testing to simulate real-world conditions, ensuring they can handle the expected stress during operation.

-

Noise and Vibration Testing: These tests assess the operational smoothness and performance of the gears, which is especially important for applications where noise reduction is critical.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control practices is essential for ensuring product reliability. Here are several strategies:

-

Audits: Conducting on-site audits allows buyers to review the manufacturing processes and quality control measures directly. This provides insights into the supplier’s operational standards.

-

Quality Reports: Requesting detailed quality reports, including data from IQC, IPQC, and FQC, can help buyers understand the consistency of the supplier’s quality assurance practices.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product quality.

What Nuances Should International Buyers Be Aware Of?

When sourcing mitre gears from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of several nuances:

-

Regulatory Compliance: Different regions may have varying regulations regarding material safety and environmental impact. Understanding these can prevent delays in the supply chain.

-

Cultural Differences: Communication styles and business practices may differ significantly across cultures. Establishing clear expectations and maintaining open lines of communication can facilitate smoother transactions.

-

Logistics and Shipping: International shipping can introduce additional challenges, including customs regulations and tariffs. Buyers should factor these into their sourcing strategies to avoid unexpected costs and delays.

By understanding the manufacturing processes and quality assurance practices for mitre gears, B2B buyers can make informed decisions that align with their operational needs and standards.

Illustrative image related to mitre gears

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mitre gears’

In the competitive landscape of B2B procurement, sourcing mitre gears requires a strategic approach. This guide provides a practical checklist to help international buyers streamline their purchasing process, ensuring that they acquire high-quality products that meet their operational needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to clearly outline your technical requirements for mitre gears. Consider factors such as gear size, tooth count, material type (e.g., steel, stainless steel, or plastic), and the specific application (e.g., industrial machinery, automotive, etc.). This clarity will help in communicating effectively with suppliers and ensuring that the products you receive meet your operational standards.

Step 2: Research and Identify Potential Suppliers

Invest time in researching potential suppliers who specialize in mitre gears. Look for manufacturers with a robust reputation in the industry, particularly those with experience in your region, such as Africa, South America, or Europe. Utilize online directories, industry forums, and trade shows to gather a list of suppliers that meet your criteria.

Step 3: Evaluate Supplier Capabilities

Assess the technical and production capabilities of each supplier on your shortlist. Inquire about their manufacturing processes, quality control measures, and certifications (e.g., ISO 9001). Understanding a supplier’s capacity to meet your volume requirements and deadlines is crucial for maintaining your operational flow.

- Key Considerations:

- Ask for detailed product catalogs.

- Request information on their production lead times and flexibility for custom orders.

Step 4: Request Samples and Specifications

Before making a bulk purchase, request samples of the mitre gears. This allows you to evaluate the quality, fit, and performance of the products in your specific application. Ensure that the samples align with your technical specifications and operational requirements to avoid costly mistakes later on.

Step 5: Verify Supplier Certifications

It is vital to ensure that your chosen suppliers have the necessary certifications and compliance with international standards. This not only guarantees product quality but also minimizes risks associated with legal liabilities. Verify if the supplier adheres to industry standards that are relevant to your geographic region and sector.

Step 6: Assess Pricing and Payment Terms

Once you have narrowed down your options, compare pricing among suppliers. While cost is an important factor, consider the overall value, including quality, service, and reliability. Discuss payment terms and conditions to ensure they align with your financial processes and cash flow management.

Illustrative image related to mitre gears

Step 7: Establish Clear Communication Channels

Effective communication is key to successful sourcing. Establish clear lines of communication with your suppliers, including points of contact for technical inquiries, order tracking, and problem resolution. Regular updates and feedback will help foster a strong partnership and ensure that your needs are consistently met.

By following this checklist, B2B buyers can efficiently navigate the sourcing process for mitre gears, ensuring they select the right products from reliable suppliers while minimizing risks and maximizing value.

Comprehensive Cost and Pricing Analysis for mitre gears Sourcing

When sourcing mitre gears, understanding the cost structure is crucial for international B2B buyers. The pricing of mitre gears can vary significantly based on several components, each influencing the final price.

What Are the Key Cost Components in Mitre Gears Pricing?

The overall cost of mitre gears is comprised of several essential components:

-

Materials: The choice of material plays a significant role in the cost. Common materials include steel, stainless steel, plastic, and sintered metals. Higher quality materials like SCM415 or SUS303 may incur additional costs due to their superior strength and corrosion resistance.

-

Labor: Labor costs are influenced by the complexity of the manufacturing process. For instance, gears that require intricate machining or custom specifications will have higher labor costs compared to standard products.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities and maintenance. Manufacturers with advanced machinery and technology may have higher overhead, which can affect pricing.

-

Tooling: The cost of tooling can vary based on whether the gears are produced using standard molds or require custom tooling for specific designs. Custom tooling can significantly increase initial costs.

-

Quality Control (QC): Rigorous quality control processes ensure that the products meet industry standards. The level of QC required can influence labor and overhead costs, thus affecting the final price.

-

Logistics: Shipping and handling costs can vary depending on the geographical location of the buyer and supplier. International shipping may introduce additional tariffs and duties, impacting the overall cost.

-

Margin: Suppliers will add a profit margin to cover their costs and generate profit. This margin can vary widely among suppliers based on their market positioning and operational efficiencies.

What Influences the Pricing of Mitre Gears?

Several factors can influence the pricing of mitre gears, especially for international buyers:

-

Volume/MOQ: Purchasing in bulk typically results in lower per-unit costs. Understanding the minimum order quantity (MOQ) can help buyers negotiate better pricing.

-

Specifications and Customization: Custom specifications, such as unique dimensions or special materials, will increase costs. Buyers should weigh the need for customization against budget constraints.

-

Quality and Certifications: Gears that meet specific industry certifications or quality standards (e.g., ISO) may come at a premium. Buyers should consider whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation, location, and production capabilities of the supplier can significantly impact pricing. Established suppliers may charge more due to their experience and reliability.

-

Incoterms: The terms of shipping (Incoterms) can affect the overall cost. Buyers should understand whether costs include shipping, insurance, and duties, as these can add to the total expense.

What Are the Best Practices for B2B Buyers in Sourcing Mitre Gears?

To ensure cost-efficiency when sourcing mitre gears, consider the following tips:

-

Negotiate Pricing: Always approach suppliers with a clear understanding of your needs and be prepared to negotiate prices based on volume and specifications.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial costs and consider the long-term implications, such as durability, maintenance, and replacement costs.

-

Be Aware of Pricing Nuances: International buyers should be conscious of currency fluctuations, import/export regulations, and regional market trends that may impact pricing.

-

Request Quotes from Multiple Suppliers: Gathering quotes from various suppliers can provide insight into market pricing and help identify the best value.

-

Consider Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, sourcing from local suppliers may reduce logistics costs and lead times.

Disclaimer

The prices provided in this analysis are indicative and can vary based on current market conditions, supplier negotiations, and specific buyer requirements. Always request detailed quotes to ensure accurate pricing.

Alternatives Analysis: Comparing mitre gears With Other Solutions

Understanding Alternative Solutions to Mitre Gears

When considering mechanical solutions for directional power transmission, mitre gears often come to mind. However, buyers should also evaluate alternatives that may better suit their specific applications or operational needs. This analysis compares mitre gears with bevel gears and chain drives, two common alternatives that fulfill similar functions but differ significantly in performance, cost, and usability.

Comparison Table

| Comparison Aspect | Mitre Gears | Bevel Gears | Chain Drives |

|---|---|---|---|

| Performance | Ideal for changing direction; no speed alteration | Capable of speed reduction/increase; versatile angles | High torque transfer; less slip |

| Cost | Moderate pricing; varies by material | Generally higher due to complexity | Lower initial cost; ongoing maintenance can add up |

| Ease of Implementation | Simple installation; limited adjustments | More complex; requires precise alignment | Requires space for chain and sprockets; can be noisy |

| Maintenance | Low maintenance; durable materials | Moderate; wear on teeth can be an issue | Regular lubrication and adjustment needed |

| Best Use Case | Compact spaces needing direction change | Applications needing speed variation | Heavy machinery requiring robust power transfer |

Detailed Breakdown of Alternatives

Bevel Gears

Bevel gears are designed to transmit power between shafts that intersect at an angle, typically 90 degrees. They come in various configurations, including straight and spiral types, which can alter speed and torque. The primary advantage of bevel gears is their versatility in speed modification, making them suitable for applications where speed changes are necessary. However, their complexity can lead to higher costs and more challenging installation, requiring precise alignment to function effectively. Maintenance is moderate, as wear on the gear teeth can affect performance over time.

Chain Drives

Chain drives consist of a series of interlinked chains and sprockets, providing a robust method for transmitting power over longer distances. They are particularly advantageous in applications that require high torque and can handle heavy loads without slipping. Chain drives tend to have a lower initial cost compared to gears, but they necessitate regular maintenance, including lubrication and tension adjustments, which can add to the total operational cost. Additionally, they require more space and can produce more noise than gear systems. Their best use case includes heavy machinery and conveyor systems where high durability and reliability are essential.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right power transmission solution involves a careful assessment of your specific operational requirements, including space constraints, load types, and maintenance capabilities. Mitre gears excel in compact applications where directional change is necessary without speed alteration. Conversely, if your application requires speed variation, bevel gears may be more suitable despite their higher complexity and cost. For heavy-duty applications, chain drives provide robust performance at a lower initial cost but require ongoing maintenance. By weighing these factors, B2B buyers can make informed decisions tailored to their operational needs and budget constraints.

Illustrative image related to mitre gears

Essential Technical Properties and Trade Terminology for mitre gears

What Are the Key Technical Properties of Miter Gears?

When selecting miter gears for industrial applications, understanding their technical specifications is crucial. Here are some of the most important properties:

-

Material Grade

Miter gears can be made from various materials, including steel (S45C, SCM415), stainless steel (SUS303), and plastics (MC nylon). The choice of material affects the gear’s strength, corrosion resistance, and suitability for specific environments, such as food processing or heavy machinery. Buyers should consider the operational environment to select the appropriate material that meets their durability and performance requirements. -

Tooth Finish

The finish of the gear teeth can significantly influence performance and noise levels. Options include ground (for precision and smooth operation) and cut (which may be more economical). Selecting the right tooth finish can enhance the gear’s efficiency and lifespan, which is vital for minimizing maintenance costs and ensuring reliable operation in machinery. -

Module

The module refers to the size of the gear teeth, which is crucial for compatibility between miter gears. It is defined as the ratio of the pitch diameter to the number of teeth. Understanding the module helps ensure proper meshing and load distribution in applications, preventing premature wear or failure. -

Hardening Type

Miter gears may undergo various hardening processes, such as carburizing or induction hardening. These processes enhance the gear’s wear resistance and strength. B2B buyers must consider the operational loads and expected wear to select gears with appropriate hardening treatments, which can lead to longer service life and reduced downtime. -

Tolerance

Tolerance indicates the permissible limit of variation in gear dimensions. High tolerance levels are essential for precision applications, where even slight misalignments can lead to performance issues. Ensuring that miter gears meet specified tolerance levels is crucial for maintaining operational efficiency and reliability. -

Angle Configuration

Miter gears are available in standard configurations (typically 90 degrees) and angular variations (45°, 60°, and 120°). The angle configuration affects the direction of power transmission and space utilization in machinery. Buyers should assess their design requirements to select the correct angle that aligns with their operational goals.

What Are the Common Trade Terms Associated with Miter Gears?

Familiarity with industry jargon can enhance communication and facilitate smoother transactions. Here are some essential trade terms relevant to miter gears:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that may be marketed by another company under its brand. When dealing with miter gears, understanding OEM relationships can help buyers identify reliable manufacturers that adhere to specific quality and performance standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers to understand their purchasing requirements, inventory management, and cost implications. Suppliers often set MOQs to ensure production efficiency and justify manufacturing costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for a specific product or service. For miter gears, submitting an RFQ can help buyers obtain detailed information about pricing, lead times, and bulk discounts, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers to manage shipping, risk, and costs effectively when sourcing miter gears from overseas suppliers. -

Lead Time

Lead time refers to the time taken from placing an order until the product is delivered. In the context of miter gears, understanding lead times is essential for project planning and inventory management. Buyers should discuss lead times with suppliers to align production schedules and avoid disruptions. -

Secondary Operations

Secondary operations refer to any processes performed on the gear after the initial manufacturing stage, such as additional machining or finishing. Recognizing the potential for secondary operations helps buyers evaluate the flexibility and adaptability of miter gears to meet specific application requirements.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing miter gears, ensuring that they select the right products for their applications while optimizing costs and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the mitre gears Sector

What Are the Key Trends Shaping the Mitre Gears Market?

The mitre gears sector is witnessing significant transformations driven by technological advancements and shifting market demands. One of the primary global drivers is the increasing automation across industries, leading to a higher demand for precision-engineered components like mitre gears. This trend is particularly pronounced in manufacturing, automotive, and robotics sectors. Moreover, the rise of Industry 4.0 has catalyzed the integration of IoT technologies, enabling real-time monitoring and optimization of gear performance, which is crucial for international buyers seeking efficiency.

Emerging trends also include the customization of gears to meet specific application needs. Buyers from diverse regions such as Africa, South America, the Middle East, and Europe are increasingly looking for suppliers who can offer tailored solutions, including angular mitre gears and various material options. Additionally, the shift towards digital procurement platforms is making sourcing easier and more efficient, allowing buyers to compare products and suppliers swiftly.

Illustrative image related to mitre gears

Market dynamics are also influenced by geopolitical factors and trade regulations, particularly in regions like Europe and South America. Buyers must remain vigilant about these changes as they can impact pricing and availability. As sustainability becomes a focal point for global industries, the demand for environmentally friendly manufacturing processes and materials is expected to rise, influencing sourcing strategies.

How Important is Sustainability and Ethical Sourcing in the Mitre Gears Industry?

In the context of growing environmental concerns, sustainability and ethical sourcing have become critical considerations for B2B buyers in the mitre gears sector. The environmental impact of gear manufacturing, including resource extraction and waste generation, has prompted many companies to seek suppliers committed to sustainable practices. This includes using recyclable materials and minimizing energy consumption during production.

Ethical supply chains are not just a trend but a necessity for businesses aiming to enhance their brand reputation and comply with regulatory standards. Buyers are increasingly favoring manufacturers that adhere to international sustainability certifications, such as ISO 14001, which demonstrates a commitment to reducing environmental impact. Furthermore, incorporating ‘green’ materials, such as biodegradable plastics for certain gear types, is becoming more prevalent.

In addition, the shift towards transparency in sourcing allows buyers to trace the origins of materials used in manufacturing mitre gears. This transparency fosters trust and long-term relationships between suppliers and buyers, particularly in regions where ethical sourcing is prioritized.

What Is the Historical Context of Mitre Gears That Affects Current B2B Trends?

The history of mitre gears dates back to the early days of mechanical engineering, where they were primarily used to change the direction of motion in machinery. Over the years, advancements in metallurgy and manufacturing techniques have significantly improved their strength, durability, and precision. The introduction of CNC machining and advanced grinding techniques has allowed for tighter tolerances and better performance, which are essential for modern applications.

In recent decades, the evolution of materials—from traditional metals to advanced composites and plastics—has expanded the potential applications of mitre gears. This evolution is particularly relevant for B2B buyers looking for lightweight, corrosion-resistant options suitable for various environments, including food processing and outdoor machinery.

Understanding the historical context of mitre gears not only highlights the technological advancements but also informs buyers about the reliability and performance expectations associated with different gear types. As the market continues to evolve, these historical insights will guide purchasing decisions and supplier relationships.

Frequently Asked Questions (FAQs) for B2B Buyers of mitre gears

-

How do I select the right mitre gears for my application?

Selecting the appropriate mitre gears involves considering factors such as the gear type (straight or spiral), the required shaft angle, and the application’s torque and speed requirements. Evaluate the material options, including steel, stainless steel, and plastic, based on environmental conditions and load-bearing needs. Additionally, consider the gear’s precision grade, as this impacts durability and performance. Consulting with a gear manufacturer or supplier can help you understand the best specifications for your unique application. -

What are the advantages of using spiral mitre gears over straight mitre gears?

Spiral mitre gears offer several advantages over straight mitre gears, including smoother operation and reduced noise due to their helical tooth design. They provide better load distribution and can handle higher torque levels, making them suitable for applications requiring greater strength and durability. However, they typically involve more complex manufacturing processes and may be more costly. Assess your specific application needs to determine if the benefits justify the investment in spiral mitre gears. -

What is the minimum order quantity (MOQ) for mitre gears?

The MOQ for mitre gears can vary significantly between suppliers, often ranging from a few pieces for standard items to larger quantities for customized or specialized gears. When sourcing from international suppliers, inquire about their MOQ policies upfront, as this can impact your project’s budget and timeline. Some manufacturers may be willing to accommodate smaller orders for prototyping or initial trials, so it’s essential to communicate your requirements clearly. -

How can I ensure the quality of the mitre gears I purchase?

To ensure the quality of mitre gears, request certifications and quality assurance documentation from your supplier. Look for manufacturers that adhere to recognized standards such as ISO 9001. It’s also beneficial to ask for sample products to evaluate their performance and durability before committing to a larger order. Additionally, consider visiting the manufacturing facility if possible, or rely on third-party inspections to verify quality before shipment. -

What payment terms should I expect when sourcing mitre gears internationally?

Payment terms for international B2B transactions can vary widely. Common options include advance payment, letters of credit, or payment upon delivery. It’s crucial to discuss and negotiate terms that align with your cash flow needs and risk tolerance. Ensure that you understand any additional fees related to currency conversion, international transfers, or customs duties. Establishing a good relationship with your supplier can also facilitate more favorable payment conditions. -

How do I vet suppliers for mitre gears in international markets?

When vetting suppliers for mitre gears, start by researching their industry reputation and customer reviews. Look for companies with a proven track record of reliability and quality. Request references from previous clients and assess their experience with similar projects. Additionally, consider visiting their facilities or participating in industry trade shows to evaluate their capabilities firsthand. Certifications and compliance with international standards are also critical indicators of a reputable supplier. -

What logistics considerations should I keep in mind when importing mitre gears?

When importing mitre gears, consider factors such as shipping methods, lead times, and customs regulations in your country. Work closely with your supplier to understand their shipping practices and ensure that packaging meets international standards to prevent damage during transit. Additionally, factor in potential delays at customs and plan for any associated duties or taxes. Collaborating with a reliable freight forwarder can help streamline the logistics process and ensure timely delivery. -

Can I customize mitre gears to fit specific applications?

Yes, many manufacturers offer customization options for mitre gears to meet specific application requirements. Customizations can include modifications to tooth design, material selection, and gear dimensions. When requesting custom gears, provide detailed specifications and application information to ensure that the manufacturer can meet your needs effectively. Keep in mind that custom gears may have longer lead times and higher costs than standard options, so plan accordingly.

Top 7 Mitre Gears Manufacturers & Suppliers List

1. KHK – Miter Gears

Domain: khkgears.net

Registered: 2015 (10 years)

Introduction: Miter Gears are a type of bevel gear that change transmission direction without altering speed, as they have the same number of teeth. They can be produced with shaft angles ranging from 45 to 120 degrees. KHK offers various types of miter gears, including straight tooth and spiral miter gears, with different materials, hardening methods, tooth finishes, and grades. Key specifications include:

1….

2. KHK – Miter Gears

Domain: khkgears.us

Registered: 2015 (10 years)

Introduction: Miter gears are a special class of bevel gears where the shafts intersect at 90° and the gear ratio is 1:1. KHK stock miter gears are available in two types: spiral and straight tooth. They come in high precision grade for demanding torques and speeds, and commercial grade for economical applications. Key products include:

1. Ground Spiral Miter Gears (MMSG) – High strength, abrasion-resistant, c…

3. McMaster – Gears and Gear Racks

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Gears and Gear Racks, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Boston Gear – Bevel & Miter Gears

Domain: bostongear.com

Registered: 1997 (28 years)

Introduction: Bevel & Miter Gears (Straight & Spiral)

5. Gobilda – Bevel Gears

Domain: gobilda.com

Registered: 2015 (10 years)

Introduction: Bevel gears are designed to drive a shaft at a 90° angle, available in ratios of 1:1 (miter gears) and 2:1 for speed and torque tuning. Key products include:

– MOD 1.5 Bevel Gears (2:1 Ratio): Creates a 2:1 reduction, requires specific tooth profile.

– MOD 1 Miter Gears (1:1 Ratio): 2320 Series, two-piece steel, no slipping with pinch bolts, titanium nitride finish.

– MOD 1.25 Miter Gears (1:1 …

6. Grainger – Miter Gears

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – Miter Gears, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. AndyMark – 20 Tooth Steel Miter Gear

Domain: andymark.com

Registered: 1999 (26 years)

Introduction: {“name”: “20 Tooth 1.25 Module 8 mm Round Bore Steel Miter Gear”, “type”: “Miter Gear”, “tooth_count”: 20, “module”: 1.25, “bore_diameter”: “8 mm”, “material”: “Steel”}

Strategic Sourcing Conclusion and Outlook for mitre gears

Mitre gears play a crucial role in various mechanical systems, enabling efficient directional changes in transmission without altering speed. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, strategic sourcing of mitre gears can significantly enhance operational efficiency and product reliability. By prioritizing quality, material selection, and the specific requirements of your applications—such as angular configurations or material properties like rust resistance in stainless steel—buyers can ensure they are making informed purchasing decisions.

Moreover, understanding the diverse offerings available, from ground spiral to sintered metal options, allows businesses to tailor their gear choices to specific industry needs. This approach not only streamlines production but also minimizes downtime and maintenance costs, ultimately contributing to a stronger bottom line.

Illustrative image related to mitre gears

Looking ahead, as industries continue to evolve and demand for precision-engineered components grows, the importance of strategic sourcing will only increase. We encourage B2B buyers to engage with reputable suppliers, explore innovative gear solutions, and leverage partnerships that foster long-term success. Invest in your sourcing strategy today to stay ahead in a competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.