Unlocking Value: A Strategic Analysis of the Thermal Expansion Joint Market

Introduction: Navigating the Global Market for thermal expansion joint

In an increasingly interconnected global marketplace, sourcing the right thermal expansion joints can be a complex challenge for B2B buyers. The ability to manage thermal expansion and contraction in piping systems is critical to ensuring operational efficiency and preventing costly failures. This guide delves into the multifaceted world of thermal expansion joints, covering various types, applications, and key considerations for suppliers. From understanding the technical specifications to evaluating cost factors, we aim to equip international buyers—especially from Africa, South America, the Middle East, and Europe, including Germany and Saudi Arabia—with the insights necessary for informed purchasing decisions.

Navigating the intricacies of thermal expansion joints involves more than just selecting a product; it requires an understanding of how different materials and designs perform under specific conditions. This comprehensive guide addresses essential topics such as the calculation of thermal expansion, the importance of material selection, and the critical role of proper installation. Additionally, we will provide strategies for vetting suppliers to ensure reliability and quality, helping you minimize risks associated with system failures. By leveraging this guide, B2B buyers can confidently approach their sourcing needs, ensuring that they select the right thermal expansion joints to enhance the integrity and longevity of their piping systems.

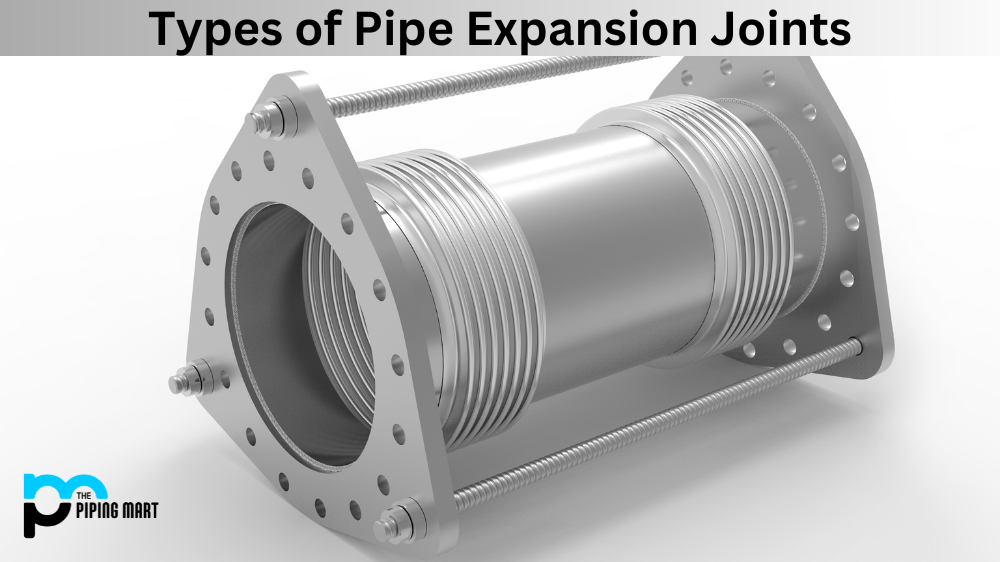

Understanding thermal expansion joint Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Corrugated Bellows | Compact, cost-effective, limited axial movement | High-temperature exhaust systems | Pros: Inexpensive, effective for specific movements. Cons: Requires anchoring, limited movement capacity. |

| Packed Joints (Slip Joints) | Repackable while in service, high anchor loads | High-pressure steam systems | Pros: Absorbs significant expansion, ideal for maintenance. Cons: Prone to leaks, requires ongoing maintenance. |

| Externally Pressurized Bellows | Stability due to external pressure application | Chemical processing, oil & gas industries | Pros: Handles greater movement, stable under pressure. Cons: More complex installation. |

| Copper Compensators | In-line design, maintenance-free, axial movement only | Heating systems, HVAC applications | Pros: Reliable, low maintenance. Cons: Limited to axial movement, less flexible. |

| Metraloop | Versatile, accommodates axial, lateral, and angular movement | High-movement industrial applications | Pros: Low anchor load, minimal guiding needed. Cons: Higher cost compared to traditional joints. |

What are the Characteristics and Suitability of Corrugated Bellows?

Corrugated bellows are designed for high-temperature applications, particularly in exhaust systems. Their compact design and affordability make them a popular choice for many industries. However, they are limited to axial movement and require proper anchoring and guiding to prevent system failures. B2B buyers should consider the specific movement requirements of their piping systems and assess whether the cost savings justify the potential limitations in larger systems.

How Do Packed Joints (Slip Joints) Function in High-Pressure Applications?

Packed joints, or slip joints, are unique in their ability to be repacked while in operation, which is particularly beneficial in high-pressure steam applications such as university steam tunnels. While they can absorb significant thermal expansion, they generate high anchor loads and can develop leaks if the chrome plating is damaged. Buyers should evaluate the maintenance capabilities of their teams, as these joints require regular upkeep to ensure optimal performance.

What Advantages Do Externally Pressurized Bellows Offer for Industrial Applications?

Externally pressurized bellows are engineered to provide stability by applying pressure externally, allowing for greater axial movement. This design is particularly suitable for chemical processing and oil and gas industries, where significant movement is common. Although they offer enhanced stability, the complexity of their installation may require specialized knowledge, making it crucial for buyers to assess installation capabilities and long-term maintenance plans.

Why Choose Copper Compensators for Heating Systems?

Copper compensators are known for their reliability and maintenance-free operation, making them ideal for heating systems and HVAC applications. They are designed for axial movement only and utilize the pipe itself as a protective liner. While they offer excellent durability, their limited flexibility could be a drawback in systems requiring multi-directional movement. B2B buyers should weigh the importance of maintenance and flexibility when considering this option.

What Makes Metraloop a Preferred Choice in High-Movement Areas?

Metraloops are versatile thermal expansion joints that can accommodate axial, lateral, and angular movements, making them suitable for high-movement industrial applications. Constructed from various materials, including carbon and stainless steel, they have the lowest anchor load of any expansion joint, requiring minimal guiding. Despite their higher cost, the advantages in flexibility and reduced stress on piping systems can lead to long-term savings, making them a worthwhile investment for B2B buyers focused on performance and durability.

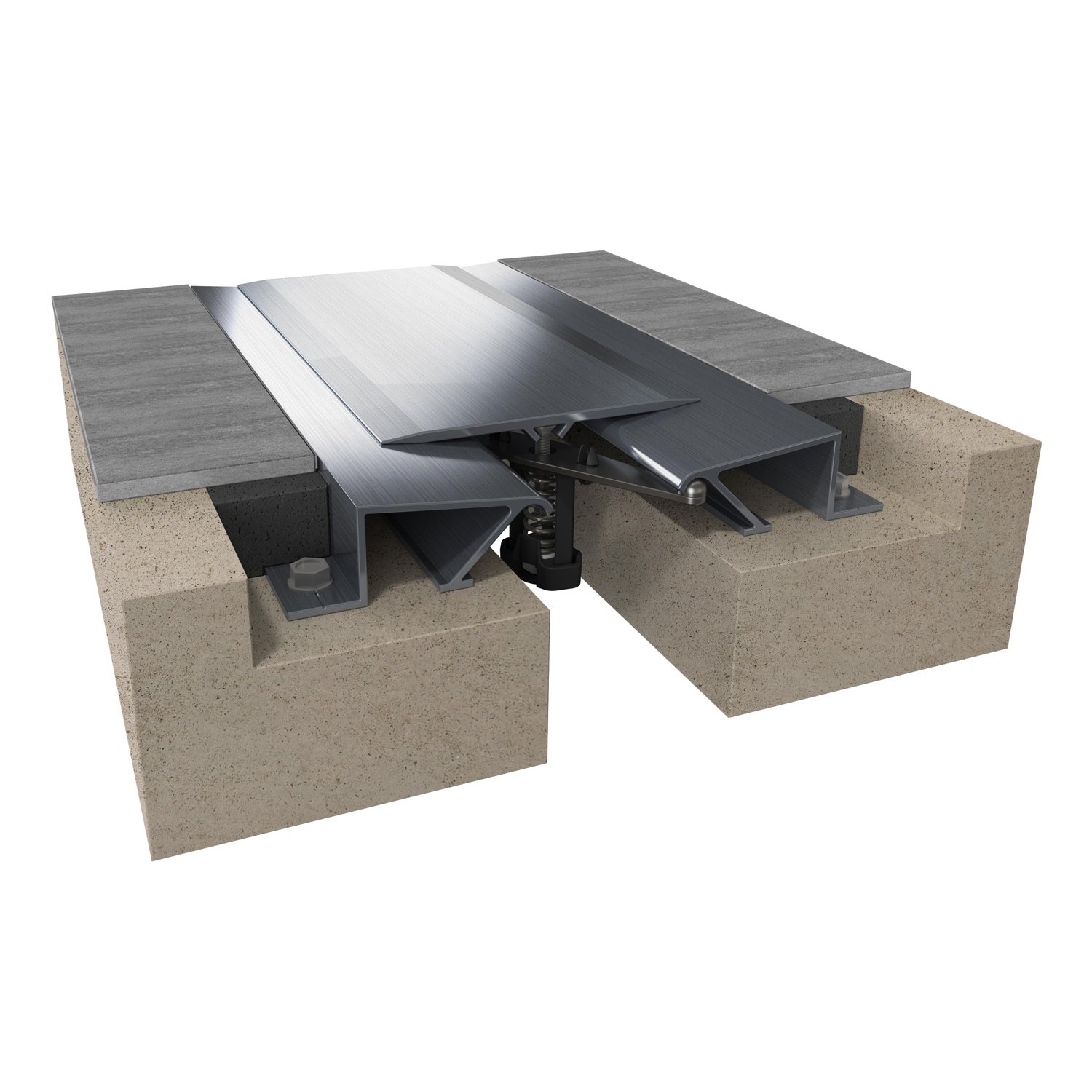

Illustrative image related to thermal expansion joint

Key Industrial Applications of thermal expansion joint

| Industry/Sector | Specific Application of thermal expansion joint | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Pipeline systems for transporting crude oil and gas | Prevents leaks and catastrophic failures, ensuring operational safety | Material compatibility, pressure ratings, and environmental conditions |

| Power Generation | Steam and hot water piping in power plants | Enhances system reliability and efficiency, reducing downtime | High-temperature resistance, maintenance requirements, and certifications |

| Chemical Processing | Chemical transport and processing systems | Minimizes risk of leaks and ensures safe handling of volatile substances | Corrosion resistance, temperature tolerance, and compliance with safety standards |

| HVAC Systems | Heating and cooling systems in commercial buildings | Increases energy efficiency and system longevity | Flexibility in movement, material choice, and installation ease |

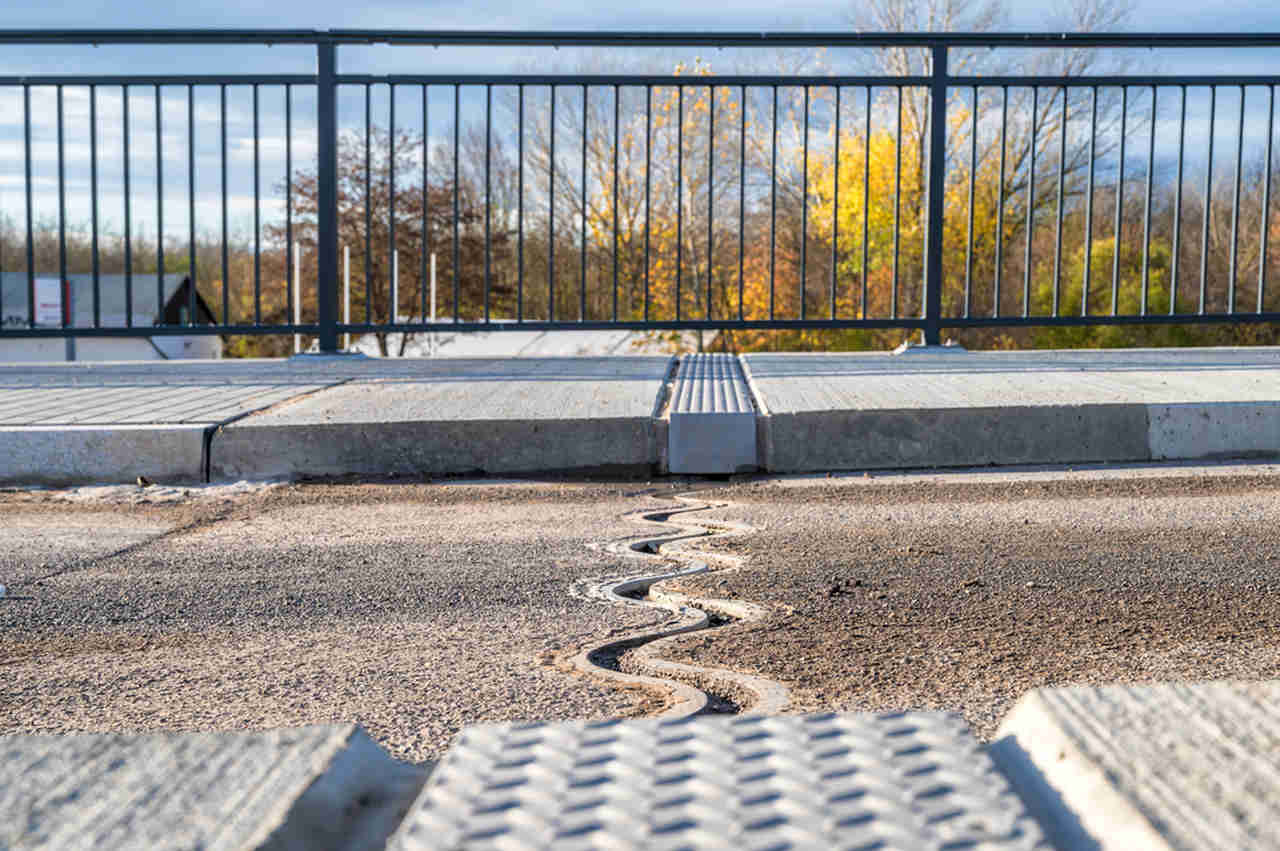

| Transportation Infrastructure | Railways and roadways expansion joints | Mitigates structural damage and enhances safety | Load-bearing capacity, environmental impact, and maintenance intervals |

How Are Thermal Expansion Joints Used in the Oil & Gas Industry?

In the oil and gas sector, thermal expansion joints are critical in pipeline systems that transport crude oil and natural gas. These joints accommodate the significant thermal expansion and contraction caused by temperature fluctuations, preventing leaks and potential catastrophic failures. Buyers in this sector must consider material compatibility with hydrocarbons, pressure ratings that meet operational demands, and the ability to withstand harsh environmental conditions, particularly in remote locations.

What Role Do Thermal Expansion Joints Play in Power Generation?

In power generation, thermal expansion joints are essential for steam and hot water piping systems. They absorb thermal movement, ensuring the integrity of the piping under extreme temperatures and pressures. This not only enhances operational reliability but also reduces maintenance costs and downtime, which is crucial for continuous energy supply. Buyers should focus on high-temperature resistance, the need for regular maintenance, and certifications that comply with industry standards.

Why Are Thermal Expansion Joints Important in Chemical Processing?

Thermal expansion joints are vital in chemical processing applications, where they facilitate the safe transport and processing of various chemicals. These joints help minimize the risk of leaks and ensure the safe handling of volatile substances, which is critical for operational safety. For international buyers, sourcing considerations include corrosion resistance specific to the chemicals handled, temperature tolerance, and compliance with strict safety standards to mitigate risks associated with chemical exposure.

How Do Thermal Expansion Joints Enhance HVAC Systems?

In HVAC systems, thermal expansion joints are used to manage the thermal movement of pipes in heating and cooling applications. By accommodating these movements, they increase energy efficiency and extend system longevity, contributing to lower operational costs. Buyers should prioritize flexibility in movement, material selection to prevent thermal fatigue, and ease of installation to ensure optimal system performance.

What Is the Significance of Thermal Expansion Joints in Transportation Infrastructure?

In transportation infrastructure, thermal expansion joints are employed in railways and roadways to manage expansion and contraction due to temperature changes. This function is crucial for maintaining structural integrity and enhancing safety, preventing damage to the infrastructure. When sourcing these joints, buyers need to consider load-bearing capacity, the environmental impact on materials used, and maintenance intervals to ensure long-term reliability.

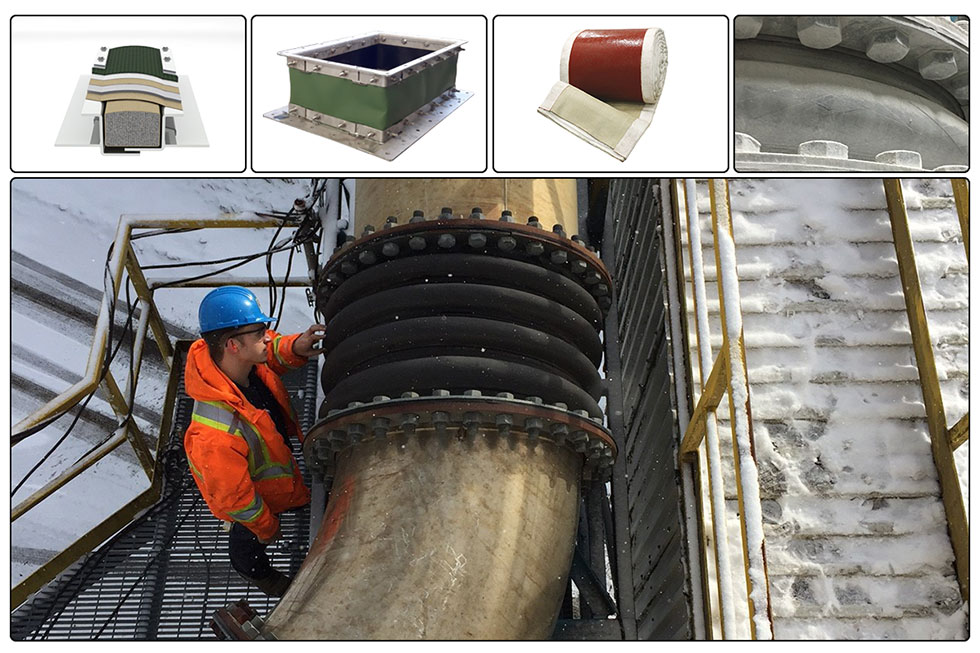

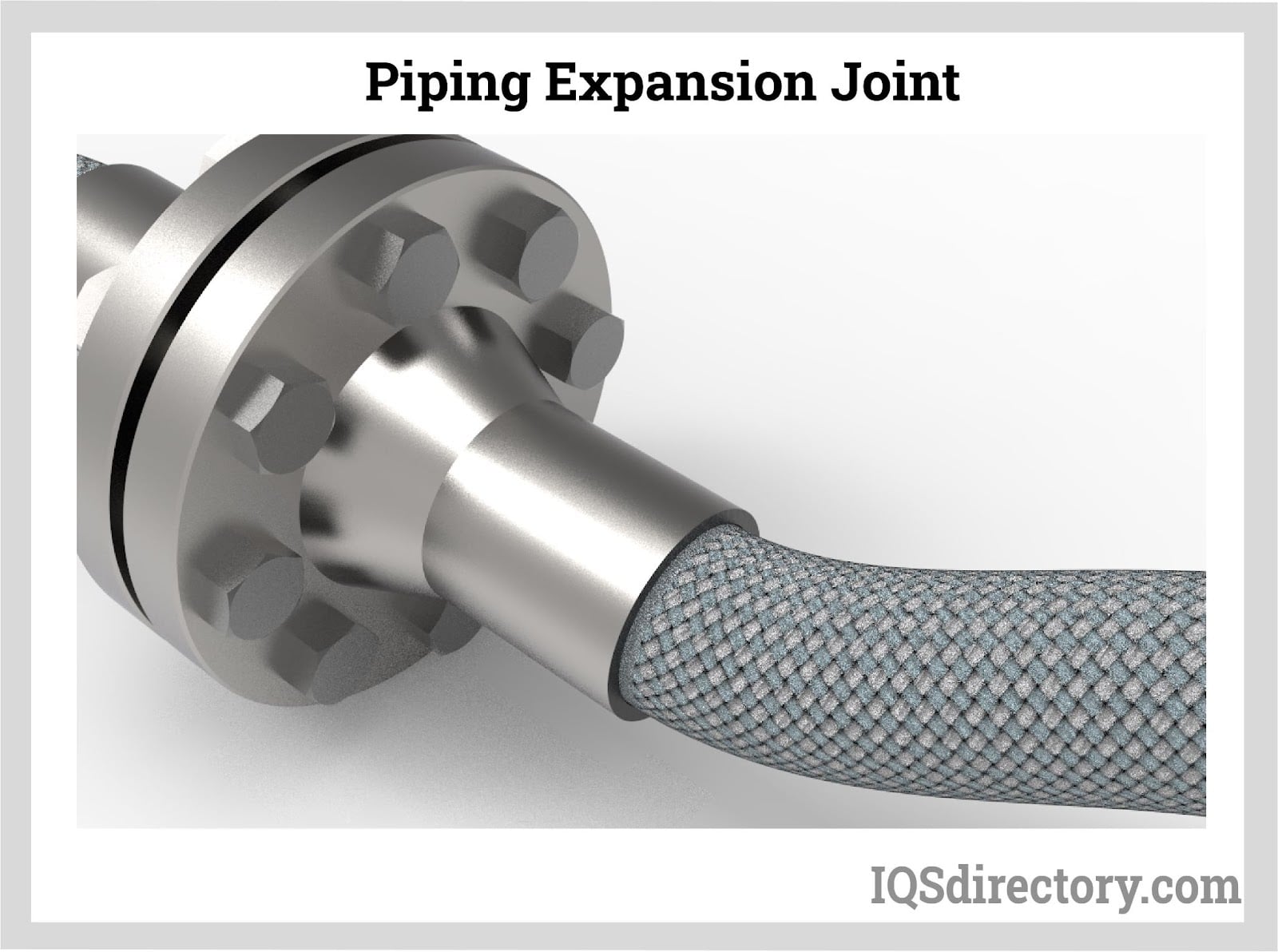

Illustrative image related to thermal expansion joint

3 Common User Pain Points for ‘thermal expansion joint’ & Their Solutions

Scenario 1: Managing High Thermal Expansion Forces in Piping Systems

The Problem: A manufacturing facility in Germany is experiencing significant challenges with its piping systems due to thermal expansion. As the temperature fluctuates, the pipes expand and contract, leading to excessive forces that have caused several leaks and even minor structural failures. The engineering team is struggling to find a solution that can effectively manage these thermal movements without necessitating extensive downtime or costly repairs.

The Solution: To address this issue, it is crucial to select the appropriate thermal expansion joints tailored to the specific conditions of the facility. Begin by conducting a thorough analysis of the piping system, including temperature ranges and materials used. Utilizing expansion joints such as corrugated bellows or externally pressurized bellows can effectively absorb the thermal movement. For high-temperature applications, ensure that the selected joints are rated to withstand the expected thermal forces. Furthermore, implementing a regular maintenance schedule to inspect and replace joints as necessary will help maintain system integrity and prevent future issues. By investing in high-quality joints and proper installation techniques, the facility can reduce leak occurrences and extend the lifespan of the piping system.

Scenario 2: Overcoming Maintenance Challenges in High-Pressure Environments

The Problem: A petrochemical company in Saudi Arabia operates under high-pressure conditions, where thermal expansion joints are critical for maintaining the integrity of their steam piping systems. However, the existing packed joints require frequent repacking, leading to substantial maintenance costs and operational delays. The team is frustrated with the constant need for service, which disrupts production schedules and increases labor costs.

Illustrative image related to thermal expansion joint

The Solution: Transitioning to externally pressurized expansion joints can significantly alleviate maintenance burdens. These joints are designed to handle higher pressures and offer greater stability, reducing the need for frequent servicing. When specifying these joints, ensure that they are compatible with the existing system and can accommodate the required axial movements. Additionally, training maintenance personnel on the correct installation and inspection procedures will enhance the longevity of the joints. Implementing a comprehensive inventory management system to keep track of joint conditions and proactively scheduling maintenance can further minimize downtime. By optimizing the choice of expansion joints and enhancing maintenance practices, the company can improve operational efficiency and reduce costs.

Scenario 3: Navigating Installation Challenges in Diverse Environments

The Problem: An international construction firm is undertaking a large project in South America that involves complex piping installations across varying environmental conditions. The engineering team is concerned about how to best install thermal expansion joints in areas with limited space and high seismic activity. The fear of improper installation leading to system failures is causing delays in the project timeline.

The Solution: To navigate these challenges, it is essential to select versatile thermal expansion joints, such as Metraloops, which can accommodate movement in multiple directions and are designed for constrained environments. Before installation, conduct a detailed site assessment to identify potential seismic risks and space limitations. Collaborating with the joint manufacturer for custom solutions can also lead to innovative designs that fit the specific project needs. Proper anchoring and guiding of the joints must be prioritized to ensure they function correctly under dynamic conditions. Providing training for installation crews on best practices will further mitigate risks associated with improper installation. By leveraging adaptable joint designs and thorough installation protocols, the firm can confidently proceed with the project, minimizing the risk of failures and ensuring compliance with safety standards.

Strategic Material Selection Guide for thermal expansion joint

What Are the Key Properties of Common Materials Used in Thermal Expansion Joints?

When selecting materials for thermal expansion joints, it is essential to consider their properties, as these will directly impact performance, durability, and suitability for specific applications. Here, we analyze four common materials: stainless steel, carbon steel, bronze, and PTFE.

How Does Stainless Steel Perform in Thermal Expansion Joints?

Stainless steel is renowned for its excellent corrosion resistance and high-temperature tolerance. It typically offers a temperature rating of up to 1,200°F (650°C) and can withstand high pressures, making it ideal for demanding environments.

Pros: Its durability ensures a long lifespan, reducing maintenance costs. Stainless steel is also compliant with various international standards, making it a preferred choice in industries like oil and gas, petrochemicals, and power generation.

Cons: The primary drawback is its cost, which is higher than carbon steel and some other materials. Additionally, manufacturing processes can be complex, requiring specialized techniques.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, making it suitable for various industrial applications.

Why Consider Carbon Steel for Thermal Expansion Joints?

Carbon steel is another common material, valued for its strength and cost-effectiveness. It typically has a temperature rating of up to 800°F (425°C) and can handle moderate pressure levels.

Pros: The cost is significantly lower than stainless steel, making it an attractive option for budget-conscious projects. It is also readily available and easy to fabricate.

Cons: Carbon steel is less resistant to corrosion, which can limit its use in harsh environments. It may require protective coatings to enhance its lifespan.

Impact on Application: Carbon steel is suitable for water and steam applications but may not be ideal for corrosive media unless adequately treated.

What Advantages Does Bronze Offer for Thermal Expansion Joints?

Bronze is often used for its excellent resistance to corrosion, particularly in marine environments. It can handle temperatures up to 600°F (315°C) and is typically used in applications requiring low friction and wear.

Illustrative image related to thermal expansion joint

Pros: Its anti-corrosive properties make bronze an excellent choice for applications involving seawater or other aggressive media. It also has good machinability, allowing for intricate designs.

Cons: The main limitation is its lower temperature and pressure ratings compared to stainless steel. Additionally, bronze can be more expensive than carbon steel.

Impact on Application: Bronze is particularly well-suited for applications in the maritime industry or where low friction is critical.

How Does PTFE Enhance Thermal Expansion Joint Performance?

PTFE (Polytetrafluoroethylene) is a synthetic fluoropolymer known for its exceptional chemical resistance and low friction properties. It can withstand temperatures up to 500°F (260°C) and is often used as a lining material in expansion joints.

Illustrative image related to thermal expansion joint

Pros: PTFE’s chemical inertness makes it ideal for aggressive media, and its low friction reduces wear on the joint. It is also lightweight, which can simplify installation.

Cons: PTFE is not suitable for high-pressure applications and can be more expensive than metals. Its mechanical strength is lower, which may limit its use in certain configurations.

Impact on Application: PTFE is commonly used in the chemical processing industry, where it can handle a wide variety of corrosive substances.

Summary of Material Selection for Thermal Expansion Joints

| Material | Typical Use Case for thermal expansion joint | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil and gas, petrochemicals | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Carbon Steel | Water and steam applications | Cost-effective and readily available | Less corrosion resistance | Low |

| Bronze | Marine applications, low-friction needs | Superior corrosion resistance | Lower temperature and pressure ratings | Med |

| PTFE | Chemical processing | Exceptional chemical resistance | Not suitable for high-pressure applications | High |

This analysis provides B2B buyers with crucial insights into material selection, ensuring they make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for thermal expansion joint

What Are the Main Stages of Manufacturing Thermal Expansion Joints?

The manufacturing of thermal expansion joints involves a series of precise stages designed to ensure quality and durability. Here’s a breakdown of the main stages:

Illustrative image related to thermal expansion joint

Material Preparation: What Materials Are Used and How Are They Processed?

The selection of materials is paramount, as different applications require specific properties. Common materials include stainless steel, carbon steel, and specialized alloys, each chosen for their thermal expansion characteristics and resistance to corrosion.

- Material Sourcing: Quality raw materials are sourced from reputable suppliers, often verified through certifications like ISO 9001.

- Cutting and Shaping: The raw materials are cut to size using techniques such as laser cutting, water jet cutting, or mechanical shearing. This precision is crucial for the subsequent forming process.

How Are Thermal Expansion Joints Formed?

The forming process involves shaping the cut materials into the required joint configurations. This can involve several techniques:

- Bending and Rolling: For components like bellows, metal sheets are rolled and bent into the desired shapes. This may include corrugated designs for flexibility.

- Welding and Joining: Different parts of the joint are welded together using techniques such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. This stage demands high precision to ensure structural integrity.

What Is Involved in the Assembly Stage?

Assembly is where all the components come together to create the final product. This stage includes:

- Component Integration: All parts are assembled, including bellows, flanges, and other fittings. Each component must fit perfectly to maintain the joint’s functionality.

- Installation of Seals and Gaskets: Proper sealing is critical to prevent leaks, especially in high-pressure applications. Gaskets are installed according to specific tolerances.

What Finishing Techniques Are Used for Thermal Expansion Joints?

Finishing processes enhance the durability and appearance of thermal expansion joints. Common techniques include:

- Surface Treatment: Processes like anodizing, galvanizing, or applying protective coatings are employed to enhance corrosion resistance.

- Quality Inspection: Before the final product is packaged, it undergoes rigorous inspections to ensure it meets the required specifications.

How Is Quality Assurance Implemented in Thermal Expansion Joint Manufacturing?

Quality assurance is a critical aspect of the manufacturing process, ensuring that every thermal expansion joint meets industry standards and customer expectations.

What International Standards Are Relevant for Quality Assurance?

Manufacturers must adhere to several international standards, including:

- ISO 9001: This standard outlines the criteria for a quality management system and is applicable to any organization, regardless of size or industry.

- CE Marking: Required for products sold within the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Standards: The American Petroleum Institute sets standards specifically for the oil and gas industry, ensuring that products can withstand extreme conditions.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are implemented at various stages of manufacturing to ensure compliance with standards:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): During manufacturing, operators conduct inspections at various stages to detect defects early.

- Final Quality Control (FQC): Once the product is assembled, a final inspection ensures it meets all specifications and standards before shipment.

What Common Testing Methods Are Used to Ensure Quality?

Testing methods vary depending on the application and required specifications. Common methods include:

- Hydrostatic Testing: This tests the joint’s ability to withstand high pressure by filling it with water and checking for leaks.

- Dimensional Inspection: Using tools like calipers and gauges, manufacturers verify that all components are within specified tolerances.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or radiography help identify internal defects without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are actionable steps:

What Auditing Practices Should Buyers Consider?

- Supplier Audits: Conduct regular audits of suppliers to assess their manufacturing processes and adherence to quality standards. This can be done through on-site visits or third-party audit services.

- Review of Quality Documentation: Request access to quality assurance documentation, including inspection reports, testing certifications, and compliance records.

How Can Buyers Utilize Third-Party Inspection Services?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s manufacturing processes. These services can:

- Conduct inspections at various manufacturing stages.

- Provide detailed reports on compliance with international standards.

- Offer recommendations for improvements if necessary.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must be aware of specific nuances in quality control:

- Cultural and Regulatory Differences: Understanding local regulations and industry standards is vital. For instance, European buyers might prioritize CE certification, while Middle Eastern buyers may focus on API standards.

- Logistical Considerations: Quality assurance can be affected by shipping conditions, so buyers should ensure that suppliers have measures in place to protect products during transit.

By understanding the manufacturing processes and quality assurance measures for thermal expansion joints, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their operational needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘thermal expansion joint’

Introduction

This practical sourcing guide is designed for B2B buyers seeking to procure thermal expansion joints. These components are essential for managing thermal movement in piping systems, and selecting the right joint can significantly impact system integrity and operational efficiency. By following this checklist, you can ensure that you make informed decisions throughout the procurement process.

Illustrative image related to thermal expansion joint

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for your thermal expansion joints. Consider factors such as the type of piping material, operating temperature range, pressure ratings, and the specific movements that need to be accommodated.

– Material Selection: Different materials (e.g., stainless steel, copper) have varying expansion rates. Choose one that aligns with your system’s needs.

– Movement Requirements: Determine whether you need axial, lateral, or angular movement capabilities.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in thermal expansion joints. Look for companies with a solid reputation and a history of serving your industry.

– Supplier Background: Check how long they’ve been in business and their market presence.

– Industry Experience: Prioritize suppliers who have experience with projects similar to yours, particularly in your geographical region.

Step 3: Evaluate Supplier Certifications

Before making a decision, verify that the suppliers hold relevant certifications and adhere to industry standards. This ensures that the products meet safety and quality benchmarks.

– ISO Certification: Look for ISO 9001 certification, which indicates a commitment to quality management systems.

– Material Compliance: Ensure compliance with industry standards such as ASME or ASTM, which govern material specifications.

Illustrative image related to thermal expansion joint

Step 4: Request Product Samples or Prototypes

Whenever possible, request samples or prototypes of the thermal expansion joints you are considering. Testing the product in your environment can help identify any potential issues before full-scale procurement.

– Functional Testing: Evaluate the joints under simulated operational conditions to assess performance.

– Quality Inspection: Check for manufacturing defects or inconsistencies in material quality.

Step 5: Assess Pricing and Terms

Once you have shortlisted suppliers, compare their pricing structures and payment terms. This will help you understand the total cost of ownership and ensure that you are getting value for your investment.

– Total Cost Analysis: Consider not just the purchase price, but also installation costs and maintenance requirements over time.

– Payment Flexibility: Look for suppliers offering favorable payment terms, such as extended payment periods or discounts for bulk orders.

Step 6: Review After-Sales Support and Warranty

A solid after-sales support and warranty policy is crucial for ongoing maintenance and troubleshooting. Ensure that the supplier provides adequate support after the sale.

– Technical Assistance: Confirm that technical support is available to assist with installation and operation.

– Warranty Coverage: Understand the warranty terms, including what is covered and the duration, to protect your investment.

Step 7: Finalize the Contract

Before finalizing your order, ensure that all terms are clearly defined in the contract. This includes delivery timelines, payment schedules, and any specific performance guarantees.

– Clear Deliverables: Specify the exact specifications and quantities required to avoid misunderstandings.

– Contingency Plans: Include clauses for potential delays or quality issues to safeguard against disruptions.

Illustrative image related to thermal expansion joint

By following these steps, you can streamline the sourcing process for thermal expansion joints and ensure that you select the most suitable products for your needs.

Comprehensive Cost and Pricing Analysis for thermal expansion joint Sourcing

What Are the Key Cost Components of Thermal Expansion Joints?

When sourcing thermal expansion joints, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials include stainless steel, carbon steel, and specialized alloys. Each material has varying costs based on market demand and properties such as corrosion resistance and temperature tolerance.

-

Labor: Labor costs encompass the wages of skilled workers involved in manufacturing, assembling, and testing the joints. Labor costs can fluctuate based on location and the complexity of the manufacturing process.

-

Manufacturing Overhead: This includes expenses related to production facilities, utilities, and administrative costs. Efficient manufacturing processes can help mitigate these overheads, ultimately affecting the pricing of the final product.

-

Tooling: The initial setup costs for molds and manufacturing tools can be substantial, particularly for custom designs. These costs are typically amortized over the production run, influencing unit pricing.

-

Quality Control (QC): Ensuring that thermal expansion joints meet industry standards and specifications incurs additional costs. Rigorous testing and certification processes are essential, especially for applications in critical industries like oil and gas.

-

Logistics: Shipping and handling fees can vary based on the weight, size, and destination of the joints. Incoterms also play a role in determining who bears these costs, influencing overall pricing.

-

Margin: Suppliers typically add a profit margin to cover their risks and operational costs. This margin can vary widely based on market competition and supplier reputation.

How Do Price Influencers Affect Thermal Expansion Joint Costs?

Several factors can influence the pricing of thermal expansion joints, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating MOQ can be beneficial, especially when sourcing for multiple projects.

-

Specifications and Customization: Custom designs tailored to specific applications may incur higher costs due to the additional engineering and production processes involved. Buyers should weigh the need for customization against budget constraints.

-

Materials Quality and Certifications: High-quality materials and necessary certifications (like ISO or ASME) can increase costs but are crucial for ensuring safety and reliability. Buyers should assess the value of these certifications in relation to the application.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their proven track record, while newer entrants might offer competitive rates to gain market share.

-

Incoterms: The choice of Incoterms can significantly affect total costs. Buyers should understand the implications of terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to manage risks and expenses effectively.

What Are Essential Buyer Tips for Sourcing Thermal Expansion Joints?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, several strategies can enhance sourcing effectiveness:

-

Negotiate Wisely: Building strong relationships with suppliers can lead to better pricing and terms. Don’t hesitate to negotiate based on volume, long-term contracts, or loyalty.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Factor in maintenance costs, expected lifespan, and potential downtime to understand the true cost of ownership.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations and potential tariffs that could affect overall pricing. Consider locking in prices or negotiating contracts that account for these variables.

-

Conduct Market Research: Stay informed about market trends and pricing benchmarks in your industry. This knowledge can empower buyers during negotiations and help identify fair pricing.

-

Request Samples: Before committing to larger orders, request samples to evaluate quality and ensure it meets project specifications. This step can prevent costly mistakes down the line.

In summary, a comprehensive understanding of the cost structure, price influencers, and strategic sourcing tips can help international B2B buyers make informed decisions when sourcing thermal expansion joints. Always consult multiple suppliers and consider the total value offered, not just the upfront costs.

Illustrative image related to thermal expansion joint

Alternatives Analysis: Comparing thermal expansion joint With Other Solutions

Exploring Alternatives to Thermal Expansion Joints in Piping Systems

When dealing with thermal expansion in piping systems, selecting the right solution is crucial for ensuring system integrity and longevity. While thermal expansion joints are a popular choice due to their effective performance in managing movement, several alternative solutions can also be considered. This analysis will compare thermal expansion joints with two viable alternatives: Flexible Hoses and Hard Pipe Loops.

Comparison Table

| Comparison Aspect | Thermal Expansion Joint | Flexible Hose | Hard Pipe Loop |

|---|---|---|---|

| Performance | Excellent for axial and lateral movement; absorbs thermal expansion effectively | Good for limited movement; flexible but can wear over time | Very effective for absorbing expansion; limited flexibility |

| Cost | Moderate initial investment; long-term savings due to low maintenance | Generally lower upfront cost; may require frequent replacement | High initial cost; cost-efficient in long-term applications |

| Ease of Implementation | Requires careful installation with anchoring and guiding | Easy to install; minimal structural modifications needed | Complex installation; may require significant space |

| Maintenance | Low maintenance; periodic inspections recommended | Moderate maintenance; prone to wear and tear | Low maintenance; durable over time |

| Best Use Case | High-temperature applications needing precise movement control | Applications with moderate movement or temporary setups | High-stress environments where space is not a constraint |

Detailed Breakdown of Alternatives

Flexible Hoses

Flexible hoses are an alternative solution that allows for some movement in piping systems. They are typically made from materials like rubber or braided stainless steel, providing a lightweight and cost-effective option. Their main advantage is ease of installation; they can be quickly adapted to various layouts without the need for extensive modifications. However, they are best suited for applications with limited movement, as they can wear out over time and may require regular replacements. This makes them less ideal for high-temperature or high-pressure scenarios where durability is critical.

Hard Pipe Loops

Hard pipe loops are another method of managing thermal expansion. This solution involves creating a loop in the piping system to absorb thermal movement. The primary benefit of hard pipe loops is their robustness, making them suitable for high-stress environments. They effectively handle significant thermal expansion without the need for frequent maintenance. However, they require more space and can be complex to install, which can increase labor costs. Furthermore, they lack flexibility, making them less adaptable for systems with variable configurations.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right solution for managing thermal expansion in piping systems, B2B buyers should consider several factors, including performance requirements, budget constraints, and installation complexities. Thermal expansion joints offer excellent performance and low maintenance, making them ideal for high-temperature applications. Flexible hoses provide a cost-effective solution for temporary or low-stress applications but may require more frequent replacements. Hard pipe loops are robust and low-maintenance but necessitate more space and careful installation. By evaluating these aspects, buyers can make an informed decision that aligns with their specific operational needs and long-term goals.

Essential Technical Properties and Trade Terminology for thermal expansion joint

What Are the Key Technical Properties of Thermal Expansion Joints?

Understanding the technical specifications of thermal expansion joints is crucial for ensuring optimal performance in piping systems. Here are some essential properties:

-

Material Grade

The material used in thermal expansion joints significantly impacts their performance. Common materials include stainless steel, carbon steel, and copper. Each material has distinct thermal expansion coefficients, corrosion resistance, and strength under pressure. Selecting the appropriate material is essential for meeting the specific demands of an application, especially in extreme environments typical in industries such as oil and gas or chemical processing. -

Movement Capacity

This property defines how much axial, lateral, and angular movement a thermal expansion joint can accommodate. It is critical for ensuring that the joint can handle the thermal expansion and contraction of the piping system without causing stress or damage. Understanding the required movement capacity helps in choosing the right joint design, which can prevent costly downtime and repairs due to system failures. -

Pressure Rating

The pressure rating indicates the maximum pressure that a thermal expansion joint can safely withstand. It is essential for applications involving high-pressure systems, such as steam lines. Properly matching the pressure rating with the system’s operational conditions ensures safety and reliability, preventing catastrophic failures that could result in severe operational disruptions. -

Temperature Range

Thermal expansion joints are designed to operate within specific temperature ranges. The ability to withstand high temperatures is particularly important in applications like exhaust systems or high-pressure steam lines. Choosing a joint that can handle the expected temperature fluctuations protects the integrity of the piping system and extends the joint’s lifespan. -

Tolerance Levels

Tolerance refers to the permissible limits of variation in the dimensions of the thermal expansion joint. Accurate tolerances ensure proper fit and function within the piping system. Understanding tolerance levels is vital for maintaining system integrity, as improper fit can lead to leaks or failures. -

Anchor Load

This specification relates to the forces exerted on the expansion joint due to internal pressure and thermal expansion. Knowing the anchor load is essential for proper installation and ensures that the joint can operate without undue stress. Calculating the anchor load helps in designing a robust system that can withstand operational demands.

What Are Common Trade Terms Used in the Thermal Expansion Joint Industry?

Familiarity with industry terminology can facilitate smoother transactions and communication among B2B buyers and suppliers. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM standards is crucial for buyers looking for quality and compatibility in thermal expansion joints, ensuring that the products meet industry-specific requirements. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For thermal expansion joints, knowing the MOQ can help buyers assess whether the supplier’s offering aligns with their project needs and budget constraints, particularly for international buyers looking to optimize their procurement strategy. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing an RFQ for thermal expansion joints helps in gathering competitive bids, ensuring they receive the best value for their investment. -

Incoterms (International Commercial Terms)

Incoterms are international standards for shipping and freight, defining the responsibilities of buyers and sellers. Understanding these terms is vital for B2B transactions, as they clarify who bears the risk and costs associated with transporting thermal expansion joints, especially when dealing with international suppliers. -

Lead Time

Lead time refers to the duration between placing an order and receiving the product. For thermal expansion joints, knowing the lead time is important for project planning, as delays can impact timelines and costs. -

Certification Standards

These are industry-specific standards that thermal expansion joints must meet for quality and safety. Familiarity with relevant certifications ensures that buyers are sourcing compliant products, which is particularly important in regulated industries.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance the reliability and efficiency of their piping systems.

Navigating Market Dynamics and Sourcing Trends in the thermal expansion joint Sector

What Are the Current Market Dynamics and Key Trends Affecting the Thermal Expansion Joint Sector?

The thermal expansion joint market is experiencing significant growth driven by several global factors. Increased industrial activity across sectors such as oil and gas, power generation, and manufacturing is propelling demand for effective thermal management solutions. Particularly in regions like Africa and the Middle East, expanding infrastructure projects necessitate reliable piping systems that can withstand temperature fluctuations. Additionally, in Europe, regulatory frameworks promoting energy efficiency and safety are influencing the selection of high-quality thermal expansion joints.

Emerging B2B technology trends, such as the integration of IoT and predictive maintenance analytics, are transforming how companies source and manage thermal expansion joints. These technologies enable real-time monitoring of piping systems, allowing for proactive maintenance and reducing the risk of catastrophic failures. Consequently, suppliers who offer smart thermal expansion joints with embedded sensors are gaining a competitive edge.

Furthermore, international buyers are increasingly seeking suppliers who can provide customized solutions tailored to specific applications. This trend is particularly pronounced in high-demand markets like Germany and Saudi Arabia, where industries require specialized products to meet unique operational challenges. As a result, suppliers that can demonstrate agility in their manufacturing processes and responsiveness to customer needs are poised to capture a larger share of the market.

How Is Sustainability Shaping the Sourcing of Thermal Expansion Joints?

Sustainability has become a pivotal consideration in the sourcing of thermal expansion joints. With growing awareness of environmental impact, international buyers are prioritizing suppliers who adhere to sustainable practices. This includes the use of recycled materials in manufacturing and energy-efficient production processes. By opting for sustainable thermal expansion joints, companies can not only reduce their carbon footprint but also enhance their corporate social responsibility profile.

Illustrative image related to thermal expansion joint

Ethical sourcing is equally important, especially for buyers in regions that are increasingly scrutinizing supply chain practices. Suppliers are now expected to provide transparency regarding their sourcing methods, labor practices, and environmental impact. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential benchmarks for evaluating suppliers.

Additionally, the move towards ‘green’ materials—like those that minimize environmental impact during production and disposal—is reshaping the market. Buyers are encouraged to seek out thermal expansion joints made from materials with lower environmental footprints, such as stainless steel or other alloys that offer durability and recyclability.

How Has the Thermal Expansion Joint Sector Evolved Over Time?

The evolution of the thermal expansion joint sector reflects broader trends in industrialization and engineering advancements. Initially, thermal expansion joints were rudimentary, primarily designed to accommodate linear movement in piping systems. However, as industries evolved, so did the complexity of these joints, with innovations leading to the development of various types—such as corrugated bellows and externally pressurized bellows—that cater to a wider range of applications and environmental conditions.

As technology progressed, the introduction of materials that offer superior performance under extreme temperatures and pressures allowed for the design of more sophisticated joints. Today, the focus is not just on functionality but also on the integration of smart technologies that enhance monitoring and predictive maintenance capabilities. This shift has transformed thermal expansion joints from mere components of a piping system into critical elements that contribute to overall system efficiency and reliability, making them indispensable in modern industrial applications.

In summary, navigating the thermal expansion joint market requires a keen understanding of current trends, sustainability considerations, and historical advancements. By aligning with these factors, international B2B buyers can make informed sourcing decisions that drive operational efficiency and support their sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of thermal expansion joint

-

How do I solve thermal expansion issues in piping systems?

To address thermal expansion in piping systems, the first step is to select appropriate thermal expansion joints designed to accommodate the specific movement expected in your application. Ensure that the expansion joints are strategically placed, following guidelines that suggest installing guides at specific distances from the joints to control movement. Regular maintenance checks are crucial to ensure that the joints remain functional and effective. Additionally, consider the material and design of the piping to ensure compatibility with the thermal expansion joint, as different materials expand at different rates. -

What is the best type of thermal expansion joint for high-temperature applications?

For high-temperature applications, corrugated bellows and externally pressurized bellows are among the best options. Corrugated bellows are effective in high-temperature environments due to their compact design and ability to absorb significant thermal movement. Externally pressurized bellows provide enhanced stability and can accommodate more significant movements, making them suitable for dynamic environments. When selecting a joint, consider factors such as the maximum temperature, pressure conditions, and the specific movement needs of your piping system. -

What factors should I consider when sourcing thermal expansion joints internationally?

When sourcing thermal expansion joints internationally, consider the supplier’s reputation, product quality, and compliance with international standards. Assess their manufacturing capabilities, lead times, and ability to provide customized solutions if necessary. Additionally, verify their experience in your industry and check for certifications that ensure product reliability. Establish communication to understand their logistics capabilities, including shipping options, delivery times, and handling of customs regulations, particularly for regions like Africa, South America, and the Middle East. -

How can I verify the reliability of a supplier for thermal expansion joints?

To verify a supplier’s reliability, conduct thorough due diligence by checking their industry reputation, customer reviews, and case studies. Request references from previous clients who have sourced similar products. Evaluate their certifications, such as ISO or industry-specific standards, which indicate a commitment to quality. Additionally, consider visiting their manufacturing facility if possible, or arrange for third-party inspections to ensure that their production processes meet your expectations for quality and compliance. -

What are typical minimum order quantities (MOQs) for thermal expansion joints?

Minimum order quantities (MOQs) for thermal expansion joints can vary significantly based on the supplier and the complexity of the product. Typically, MOQs can range from a few units to several hundred, depending on the material and design specifications. When negotiating with suppliers, inquire about flexibility in MOQs, particularly if you are testing a new product or entering a new market. Some suppliers may offer lower MOQs for customized orders, especially for repeat customers or long-term partnerships. -

What payment terms should I expect when sourcing thermal expansion joints?

Payment terms can vary widely among suppliers, but common practices include a deposit upon order confirmation followed by the balance before shipment. Some suppliers may offer net payment terms (e.g., 30, 60, or 90 days) for established customers, while others may require full payment upfront for new clients. It is essential to discuss and negotiate payment terms clearly before finalizing any agreements. Additionally, consider using secure payment methods and ensure that the terms are documented in your contract to avoid any potential disputes. -

How can I ensure quality assurance (QA) for thermal expansion joints?

To ensure quality assurance for thermal expansion joints, request detailed specifications and certifications from your supplier. Implement a robust inspection process that includes visual checks, dimensional verification, and pressure testing, depending on the application. Consider establishing a quality control agreement that outlines your QA expectations, including testing procedures and acceptance criteria. Additionally, regular audits of the supplier’s manufacturing processes can help maintain product quality over time, ensuring that the joints meet your operational requirements. -

What logistical considerations should I keep in mind when importing thermal expansion joints?

When importing thermal expansion joints, pay attention to shipping logistics, including lead times, freight costs, and the choice of shipping methods. Understand the customs regulations in your country and ensure that all necessary documentation is prepared, including invoices, certificates of origin, and compliance certificates. It’s also wise to consider the reliability of the logistics provider and their experience with handling industrial products. Lastly, factor in potential delays due to customs inspections or local regulations, which can affect your project’s timelines.

Top 7 Thermal Expansion Joint Manufacturers & Suppliers List

1. Eflex – Thermal Expansion Couplings

Domain: eflex.vn

Introduction: Thermal Expansion Coupling, also known as Thermal Expansion Joints, are devices used in civil and industrial piping systems to manage the thermal expansion and contraction of pipes due to temperature changes. Key features include:

– Made of stainless steel, designed to accommodate significant thermal expansion (up to -40/+20 CM).

– Two main types: Basic Expansion Joints (Axial) and External Pres…

2. Inpro – Floor Expansion Joint Covers

Domain: inprocorp.com

Registered: 1996 (29 years)

Introduction: Inpro offers a variety of Floor Expansion Joint Covers for both thermal and seismic applications. Key product series include: 432R Series (Shallow Recessed Mount), 787NS Series (Recessed Floor Expansion Joint Cover), 432 Series (Recessed Mount), 101 Series, 104 Series (Sheet Vinyl or Concrete Floor Expansion Joint Covers), 300 Series (Recessed Mount), 501 Series (Pan System), 806 Series, 801 Serie…

3. US Bellows – Metallic Expansion Joints

Domain: usbellows.com

Registered: 1997 (28 years)

Introduction: US Bellows offers a variety of expansion joints designed for thermal expansion solutions in piping systems. The types of metallic expansion joints include: Single Pipe Expansion Joint, Hinged Pipe Expansion Joint, Gimbal Pipe Expansion Joint, Universal Pipe Expansion Joint, Elbow Pressure Balanced Pipe Expansion Joint, In-line Pressure Balanced Pipe Expansion Joint, Toroidal Pipe Expansion Joint, …

4. Stourflex – Expansion Joints

Domain: stourflex.co.uk

Registered: 1996 (29 years)

Introduction: Expansion joints are devices containing a bellows membrane designed to absorb dimensional changes due to thermal expansion or contraction of pipelines, ducts, or vessels. They are used across various market sectors to control pipeline movement caused by temperature changes. There are two main types: unrestrained (axial) and restrained expansion joints. Unrestrained joints accommodate movement by c…

5. Proco Products – Expansion Joints

Domain: procoproducts.com

Registered: 1998 (27 years)

Introduction: Expansion joints are critical components in industrial applications involving piping or ducting, designed to mitigate thermal expansion, vibration, seismic activity, and ground settlement. They are manufactured from various materials including stainless steel, rubber, and Polytetrafluoroethylene (PTFE). Rubber expansion joints are flexible and suitable for applications requiring sound and thermal …

6. SLB – Expansion Joint

Domain: glossary.slb.com

Registered: 1987 (38 years)

Introduction: Expansion joint is a device or completion component designed to enable relative movement between two fixed assemblies in the event of thermal expansion or contraction. It prevents significant forces generated by thermal expansion or contraction from being transmitted to fixed components such as packers or tubing hangers.

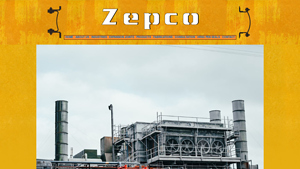

7. Zepco – High Temperature Expansion Joint Material

Domain: zepco.net

Registered: 2000 (25 years)

Introduction: High Temperature Expansion Joint Material from Zepco is designed for high-temperature applications in industries such as power generation, oil and gas, and chemical processing. It absorbs thermal expansion and protects critical systems under extreme conditions. Key features include: 1. Extended Joint Lifespan: Minimizes material degradation. 2. Reduced Downtime Risks: Prevents costly shutdowns by …

Strategic Sourcing Conclusion and Outlook for thermal expansion joint

The strategic sourcing of thermal expansion joints is paramount for businesses operating in regions with fluctuating temperatures and diverse piping system requirements. Understanding the intricacies of thermal expansion, along with the various types of joints available, enables buyers to make informed decisions that enhance system integrity and operational efficiency. By selecting the right expansion joint, companies can mitigate risks associated with thermal movement, such as leaks and catastrophic failures, ultimately protecting their investments and ensuring seamless operations.

As international markets continue to evolve, particularly in Africa, South America, the Middle East, and Europe, there is a growing emphasis on sourcing high-quality thermal expansion joints that meet specific application needs. Strategic partnerships with reliable suppliers can facilitate access to innovative solutions tailored to regional requirements, driving competitive advantage.

In conclusion, as you navigate the complexities of sourcing thermal expansion joints, prioritize collaboration with experienced manufacturers and suppliers. By aligning your sourcing strategy with the unique demands of your industry and region, you can position your business for success in an increasingly dynamic marketplace. Embrace this opportunity to enhance your piping systems and secure a sustainable future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.