A B2B Buyer’s Guide to Linear Actuator 12V: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for linear actuator 12v

In today’s rapidly evolving industrial landscape, sourcing reliable 12V linear actuators poses a significant challenge for B2B buyers across the globe. With various applications ranging from automation in manufacturing to precision in medical equipment, understanding the nuances of these devices is crucial for making informed purchasing decisions. This comprehensive guide is designed to demystify the global market for 12V linear actuators, providing insights into different types, applications, and key considerations for supplier vetting.

As international buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Saudi Arabia and Nigeria—navigate the complexities of actuator sourcing, this guide serves as a vital resource. It outlines critical factors such as performance specifications, pricing strategies, and the importance of durability and maintenance requirements. By equipping buyers with actionable insights and a clear understanding of market dynamics, this guide empowers them to select the most suitable linear actuators for their unique applications.

Ultimately, whether you’re looking to enhance operational efficiency or improve product functionality, this guide will enable you to approach your procurement process with confidence, ensuring that your investment aligns with both immediate needs and long-term strategic goals.

Understanding linear actuator 12v Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Premium Linear Actuators | High IP rating, corrosion-resistant, various stroke lengths (1″-30″) | Automation, robotics, marine applications | Pros: Superior durability, reliable performance. Cons: Higher cost compared to standard models. |

| Industrial Linear Actuators | Compact design, high force capacity (up to 3000 lbs), IP68M rating | Heavy machinery, solar tracking, manufacturing | Pros: Exceptional strength and protection. Cons: May require specific power supply configurations. |

| Adjustable Stroke Linear Actuators | Customizable stroke length (1″-29″), moderate force (35-200 lbs) | Custom machinery, automotive applications | Pros: Versatile for various applications. Cons: Limited force compared to heavy-duty options. |

| Mini Industrial Actuators | Small footprint, optional feedback, force up to 330 lbs | Robotics, automated systems in confined spaces | Pros: Ideal for tight spaces, lightweight. Cons: Limited load capacity compared to larger models. |

| Heavy Duty Linear Actuators | High load capacity (up to 2000 lbs), robust design, optional feedback | Construction, transportation, agriculture | Pros: Suitable for demanding applications. Cons: Bulkier design may limit installation options. |

What Are the Characteristics of Premium Linear Actuators?

Premium linear actuators are designed for high performance and durability, featuring enhanced IP ratings that provide water and dust resistance. They offer stroke lengths ranging from 1 to 30 inches and can exert forces between 35 to 400 lbs, making them suitable for a variety of applications such as automation and robotics. B2B buyers should consider the actuator’s build quality and maintenance requirements, as these units promise reliable performance with minimal upkeep, although they may come at a higher price point.

How Do Industrial Linear Actuators Stand Out?

Industrial linear actuators are characterized by their compact design and high force capacity, with some models capable of handling loads up to 3000 lbs. Their IP68M rating ensures they can operate effectively in harsh environments, making them ideal for applications like solar tracking and heavy machinery. When purchasing, businesses should evaluate the actuator’s suitability for their specific load requirements and environmental conditions, while also considering the potential need for specialized power supply configurations.

Why Choose Adjustable Stroke Linear Actuators?

Adjustable stroke linear actuators provide flexibility with customizable stroke lengths from 1 to 29 inches and moderate force capabilities ranging from 35 to 200 lbs. These features make them well-suited for custom machinery and automotive applications where precision is key. B2B buyers should weigh the versatility of these actuators against their lower force ratings compared to more robust options, ensuring they align with project specifications.

What Are the Benefits of Mini Industrial Actuators?

Mini industrial actuators are designed for applications with space constraints, offering a small footprint while still providing a force capacity of up to 330 lbs. Their optional feedback feature enhances control in automated systems, making them ideal for robotics and other compact setups. When considering a purchase, businesses should assess the actuator’s load capacity in relation to their specific needs, acknowledging that while they are lightweight and easy to integrate, they may not handle the same loads as larger models.

What Makes Heavy Duty Linear Actuators a Reliable Choice?

Heavy duty linear actuators are built to handle substantial loads, with capacities reaching up to 2000 lbs. Their robust design and optional feedback capabilities make them suitable for demanding applications in construction, transportation, and agriculture. Buyers should consider the actuator’s size and installation requirements, as the bulkier design may limit placement options, but the strength and reliability offered make them a preferred choice for high-stress environments.

Key Industrial Applications of linear actuator 12v

| Industry/Sector | Specific Application of linear actuator 12v | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automated assembly lines | Increases efficiency and reduces labor costs | Reliability, load capacity, and environmental ratings |

| Agriculture | Precision irrigation systems | Enhances crop yield and conserves water | Corrosion resistance, stroke length, and force |

| Renewable Energy | Solar panel tracking systems | Maximizes energy capture and efficiency | Durability, weather resistance, and compatibility |

| Automotive | Adjustable seats and mirrors | Improves user comfort and vehicle functionality | Compact design, weight capacity, and power supply |

| Medical Equipment | Hospital beds and patient lifts | Enhances patient care and operational efficiency | Safety standards, load capacity, and ease of integration |

How Are Linear Actuators Used in Manufacturing, and What Problems Do They Solve?

In the manufacturing sector, 12V linear actuators are integral to automating assembly lines. They facilitate precise movements for tasks such as positioning, lifting, and sliding components. This automation leads to increased efficiency, reduced labor costs, and minimized human error. When sourcing, businesses should prioritize reliability and load capacity, ensuring the actuators can withstand the operational demands of high-volume production environments. Additionally, environmental ratings are crucial, especially in industries that may expose equipment to dust and moisture.

What Role Do Linear Actuators Play in Agriculture and Their Benefits?

In agriculture, 12V linear actuators are employed in precision irrigation systems, allowing for controlled water distribution based on real-time needs. This not only enhances crop yield but also conserves water resources, addressing sustainability concerns. For international buyers, particularly in regions like Africa and South America where water scarcity is an issue, sourcing actuators with high corrosion resistance and appropriate stroke lengths is vital. The ability to operate efficiently in varying environmental conditions is also a key consideration.

How Are Linear Actuators Enhancing Renewable Energy Solutions?

In renewable energy, particularly solar energy, 12V linear actuators are used in solar panel tracking systems. These systems adjust the angle of solar panels throughout the day to maximize energy capture. The use of these actuators significantly improves the efficiency of solar energy systems, making them more economically viable. Buyers should focus on sourcing actuators that offer high durability and weather resistance, especially in regions prone to extreme weather conditions, ensuring long-term operational reliability.

In What Ways Are Linear Actuators Beneficial in the Automotive Industry?

In the automotive sector, 12V linear actuators are used to adjust seats and mirrors, enhancing user comfort and vehicle functionality. Their compact design allows for easy integration into various vehicle models, providing smooth and reliable adjustments. For automotive manufacturers, sourcing actuators with sufficient weight capacity and compatibility with existing electrical systems is critical. This ensures that the actuators perform optimally without compromising vehicle safety or performance.

How Do Linear Actuators Improve Medical Equipment Functionality?

In the medical field, 12V linear actuators are essential for the operation of hospital beds and patient lifts, enabling smooth adjustments for patient comfort and care. These actuators enhance operational efficiency in healthcare settings, allowing for quick and safe repositioning of patients. When sourcing, businesses must consider safety standards, load capacity, and ease of integration into existing medical systems. This is especially important in regions with stringent healthcare regulations, ensuring compliance and reliability in patient care.

3 Common User Pain Points for ‘linear actuator 12v’ & Their Solutions

Scenario 1: Inconsistent Performance in Harsh Environments

The Problem: Many B2B buyers in industries such as agriculture, construction, and manufacturing often face the challenge of linear actuators failing in harsh environments. These environments can include exposure to dust, moisture, or extreme temperatures, which can lead to inconsistent performance or complete actuator failure. This not only disrupts operations but also incurs additional costs for replacements and repairs, affecting productivity and profitability.

The Solution: To combat this issue, it is essential to choose linear actuators with high protection ratings, such as IP66 or IP68, which indicate their resistance to dust and water ingress. B2B buyers should prioritize suppliers that offer actuators specifically designed for heavy-duty applications and harsh conditions. Furthermore, investing in models with corrosion-resistant materials can significantly enhance the lifespan of the actuators. Buyers should also consider acquiring actuators with built-in feedback systems to monitor performance and detect issues early, preventing costly downtime.

Scenario 2: Difficulty in Sizing and Specifying Actuators for Unique Applications

The Problem: Sizing and specifying the correct linear actuator for a particular application can be daunting for B2B buyers, especially when dealing with complex machinery or unique operational requirements. Miscalculating the required force, stroke length, or voltage can lead to inefficient performance or even catastrophic failures, resulting in operational delays and financial losses.

The Solution: To ensure accurate specifications, B2B buyers should utilize actuator selection tools and calculators provided by reputable manufacturers. These tools help determine the necessary force and stroke length based on the specific application requirements. Additionally, engaging in direct communication with manufacturers can provide insights and recommendations tailored to unique needs. It is advisable to request detailed datasheets and technical support, which can guide the selection process and ensure that the chosen actuator meets all operational criteria. Always consider the potential for future scaling and select actuators that can handle increased loads or longer strokes if needed.

Illustrative image related to linear actuator 12v

Scenario 3: Integration Challenges with Existing Systems

The Problem: Many B2B buyers encounter difficulties integrating new 12V linear actuators into existing systems or machinery. Compatibility issues with power supplies, control systems, and mechanical fittings can lead to increased installation time and costs, and sometimes even necessitate the redesign of existing infrastructure.

The Solution: To facilitate smoother integration, buyers should conduct thorough compatibility assessments prior to purchase. This involves reviewing the specifications of both the actuator and the existing systems, particularly focusing on voltage ratings, current requirements, and control box compatibility. Engaging with manufacturers for guidance on suitable control systems or wiring configurations can also streamline the integration process. Additionally, opting for actuators with adjustable features or modular designs can enhance flexibility and compatibility, making it easier to adapt to various systems without extensive modifications. Consideration of pre-assembled kits or solutions designed for easy installation can further minimize integration challenges.

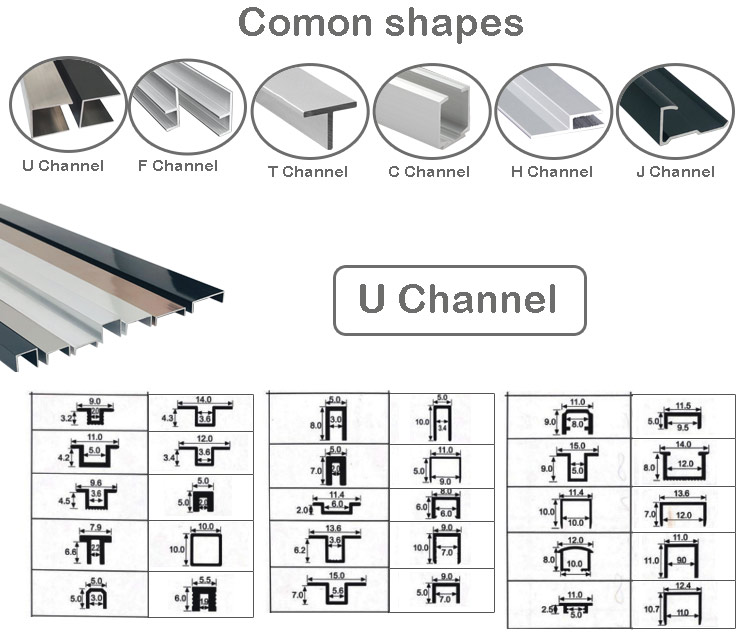

Strategic Material Selection Guide for linear actuator 12v

What Are the Key Materials Used in 12V Linear Actuators?

When selecting materials for 12V linear actuators, several factors must be considered, including performance properties, environmental conditions, and cost-effectiveness. Below, we analyze four common materials used in the construction of linear actuators: aluminum, stainless steel, plastic composites, and brass.

Illustrative image related to linear actuator 12v

How Does Aluminum Benefit 12V Linear Actuators?

Aluminum is a popular choice for linear actuator housings due to its lightweight nature and excellent strength-to-weight ratio. It typically has a temperature rating of up to 200°C and offers good corrosion resistance, particularly when anodized.

Pros: Aluminum is durable and relatively inexpensive, making it suitable for a wide range of applications. Its lightweight characteristic allows for easy installation and reduces the overall weight of the actuator system.

Cons: While aluminum is resistant to corrosion, it is not as robust as stainless steel in highly corrosive environments. Additionally, the manufacturing process can be more complex, especially for intricate designs.

Impact on Application: Aluminum is suitable for applications in moderate environments, such as automotive and light industrial uses. However, in regions with high humidity or saline conditions, additional coatings may be necessary.

Considerations for International Buyers: Compliance with standards such as ASTM and EN is crucial. Buyers in regions like the Middle East and Africa should consider the local climate’s impact on aluminum’s performance and ensure that the material meets local corrosion resistance requirements.

What Advantages Does Stainless Steel Offer?

Stainless steel is renowned for its exceptional strength and corrosion resistance, making it ideal for heavy-duty applications. It can withstand temperatures up to 600°C and is often used in environments exposed to chemicals or extreme weather.

Pros: Its durability and resistance to rust and corrosion make stainless steel a long-lasting option. It is also highly suitable for applications requiring high load capacities.

Cons: The primary drawback is its cost, as stainless steel is generally more expensive than aluminum. Additionally, its weight can be a disadvantage in applications where weight savings are critical.

Impact on Application: Stainless steel is perfect for industrial applications, especially in sectors like oil and gas, where exposure to harsh chemicals is common.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A276 or DIN 17440. In regions like Europe, the quality of stainless steel is often scrutinized, making it essential to source from reputable suppliers.

How Do Plastic Composites Enhance Performance?

Plastic composites are increasingly used in linear actuators due to their lightweight and versatile properties. They can operate effectively in a temperature range of -40°C to 100°C and offer good resistance to moisture and chemicals.

Pros: The lightweight nature of plastic composites reduces the overall actuator weight, which can be beneficial for mobile applications. They are also cost-effective and can be molded into complex shapes.

Cons: While they are resistant to corrosion, plastic composites may not withstand high temperatures or heavy loads as well as metals. Their mechanical properties can also degrade over time under UV exposure.

Impact on Application: Plastic composites are suitable for applications in consumer electronics and automotive sectors, where lightweight and cost-effective solutions are preferred.

Considerations for International Buyers: Ensure that the selected plastic composite meets relevant standards such as ISO 9001. Buyers should also consider the environmental impact of plastic materials, especially in regions with stringent regulations.

What Role Does Brass Play in Linear Actuators?

Brass is often used for components within linear actuators, such as gears and fittings, due to its excellent machinability and good corrosion resistance. It can operate at temperatures up to 300°C.

Pros: Brass offers good electrical conductivity, making it suitable for applications requiring electrical connections. It also has a natural resistance to corrosion, especially in marine environments.

Cons: Brass can be more expensive than aluminum and may not provide the same level of strength as stainless steel. It is also less suitable for high-load applications.

Impact on Application: Brass is commonly used in applications where electrical conductivity and corrosion resistance are critical, such as in marine and electrical systems.

Considerations for International Buyers: Buyers should check for compliance with standards like ASTM B16 for brass components. In regions like South America, where humidity is high, ensuring the right grade of brass is vital for longevity.

Summary of Material Properties for 12V Linear Actuators

| Material | Typical Use Case for linear actuator 12v | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive, light industrial | Lightweight and cost-effective | Less robust in corrosive environments | Medium |

| Stainless Steel | Heavy-duty industrial applications | Exceptional strength and corrosion resistance | Higher cost and weight | High |

| Plastic Composites | Consumer electronics, automotive | Lightweight and versatile | Limited temperature and load capacity | Low |

| Brass | Electrical fittings, marine applications | Good machinability and corrosion resistance | More expensive and less strong than steel | Medium |

This analysis provides B2B buyers with actionable insights into material selection for 12V linear actuators, enabling informed decisions based on specific application needs and regional considerations.

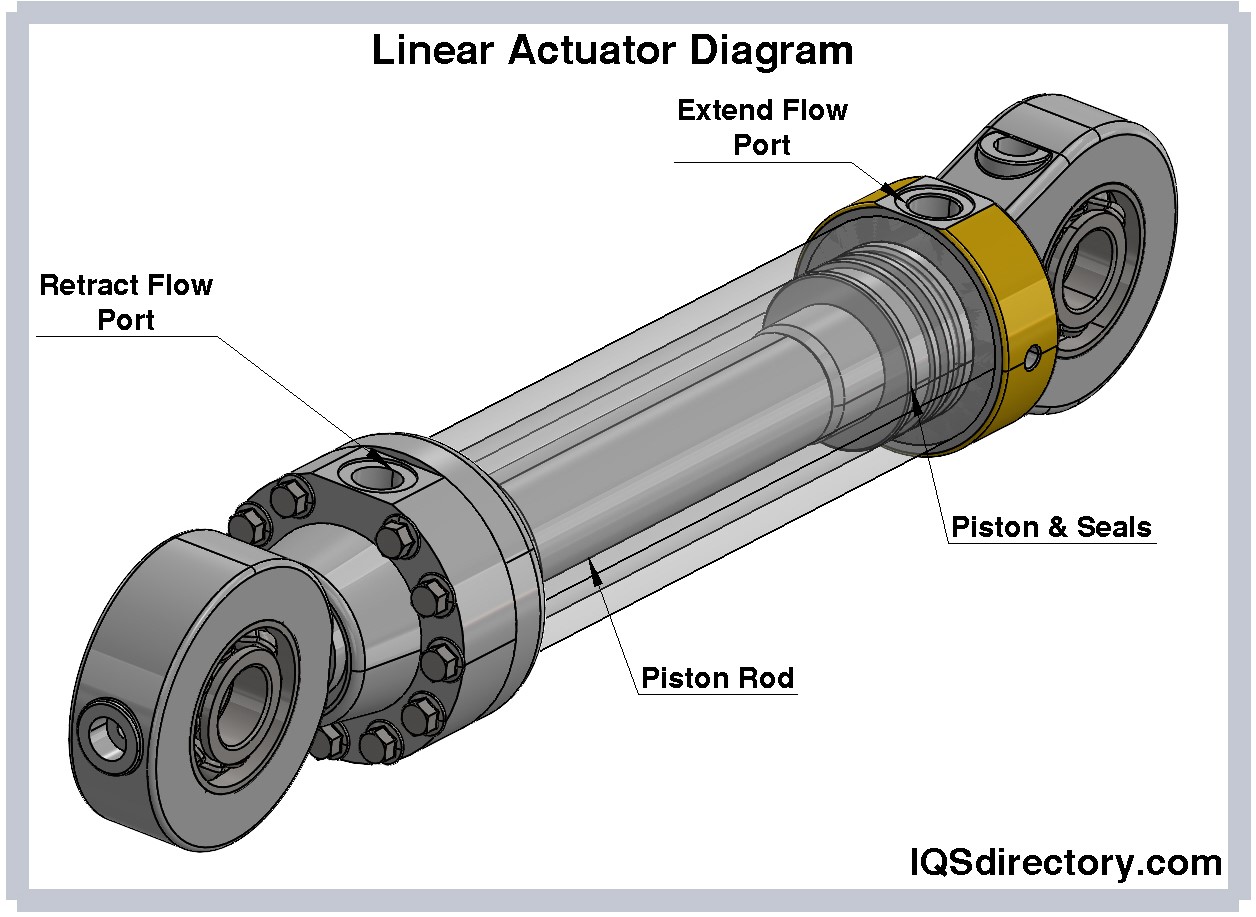

In-depth Look: Manufacturing Processes and Quality Assurance for linear actuator 12v

What Are the Main Stages of Manufacturing 12V Linear Actuators?

The manufacturing process of 12V linear actuators involves several critical stages, each essential for ensuring the final product meets industry standards and customer requirements. Understanding these stages can help B2B buyers in Africa, South America, the Middle East, and Europe make informed decisions when selecting suppliers.

How Is Material Prepared for Linear Actuators?

The first step in the manufacturing process is material preparation, which involves sourcing high-quality raw materials such as aluminum, steel, and various plastics. These materials are chosen for their durability, corrosion resistance, and lightweight properties. Suppliers often conduct rigorous assessments to ensure that materials meet specific standards for tensile strength and fatigue resistance.

Once the materials are sourced, they undergo cutting and shaping processes. Advanced technologies, such as laser cutting and CNC machining, are commonly employed to create precise components. This precision is vital for the actuator’s performance, as even minor deviations can lead to malfunction or reduced efficiency.

What Techniques Are Used in Forming Linear Actuator Components?

After material preparation, the forming stage begins. This involves processes such as extrusion, forging, and molding, depending on the component being manufactured. For instance, the actuator housing may be extruded from aluminum, while internal gears could be molded from high-strength plastic.

Forming techniques must ensure that components are not only robust but also lightweight to maximize efficiency. Key considerations include the actuator’s stroke length, load capacity, and operational environment. For instance, if the actuator is intended for outdoor use, manufacturers may employ techniques that enhance corrosion resistance, such as anodizing aluminum.

How Are Linear Actuators Assembled?

Assembly is a critical stage where all individual components come together. This process often involves both manual and automated techniques. Automated assembly lines equipped with robotics can enhance efficiency, particularly for high-volume production, while manual assembly allows for greater attention to detail for custom orders.

During assembly, components such as motors, gears, and limit switches are integrated. Quality checks are performed at various stages to ensure proper alignment and function. This is crucial as any misalignment can lead to operational failures in the field.

What Finishing Processes Are Applied to Linear Actuators?

Finishing processes enhance the actuator’s appearance and performance. Common techniques include powder coating, painting, and surface treatments to improve corrosion resistance. For actuators that will be exposed to harsh environments, a higher Ingress Protection (IP) rating is often achieved through specialized coatings and sealants.

Additionally, manufacturers may conduct final inspections to ensure that all components meet specifications before the product is packaged for shipment. This stage may involve electrical testing to verify that the actuator operates correctly at the specified voltage.

What Quality Assurance Standards Are Relevant for Linear Actuators?

Quality assurance is paramount in the manufacturing of 12V linear actuators, particularly for B2B buyers seeking reliable performance. International standards like ISO 9001 set the framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

How Are Quality Control Checkpoints Structured?

Quality control (QC) checkpoints are strategically integrated throughout the manufacturing process. The key stages include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival. Suppliers should provide certificates of compliance that demonstrate adherence to relevant standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are performed to monitor critical parameters. This may include dimensional checks and functional tests to ensure that components are being produced to specifications.

-

Final Quality Control (FQC): Once assembly is complete, the final inspection occurs. This includes comprehensive testing of the actuator’s performance, including load capacity, stroke functionality, and electrical testing.

What Testing Methods Are Commonly Used for Quality Assurance?

Manufacturers employ various testing methods to validate the performance and durability of linear actuators. Common tests include:

- Load Testing: Assessing the actuator’s ability to handle specified loads without failure.

- Environmental Testing: Subjecting actuators to extreme temperatures and humidity to evaluate performance in harsh conditions.

- Electrical Testing: Verifying that the actuator operates correctly under specified voltage and current conditions.

These tests help ensure that the actuators will perform reliably in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for mitigating risk. Here are some actionable steps:

-

Conduct Audits: Buyers should consider conducting onsite audits of potential suppliers. This allows them to assess manufacturing processes, quality control practices, and overall operational capabilities.

-

Request Quality Reports: Suppliers should be willing to provide detailed quality reports that outline their QC processes, testing results, and compliance with international standards.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the manufacturing process and final products. This is particularly important for buyers who cannot physically visit the manufacturing site.

-

Evaluate Certifications: Buyers should look for suppliers with relevant certifications, such as ISO 9001 and CE marking. These certifications indicate adherence to quality management standards and regulatory compliance.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers must also navigate additional nuances in quality control. For instance, understanding regional compliance standards is crucial. In the Middle East, for example, compliance with GSO standards may be required, while in Europe, CE marking is critical for market entry.

Moreover, language barriers and cultural differences can impact communication regarding quality standards. It’s advisable for buyers to establish clear communication channels and documentation practices to ensure that all quality expectations are understood and met.

By understanding the intricacies of manufacturing processes and quality assurance, B2B buyers can make informed decisions when selecting suppliers for 12V linear actuators, ensuring that they receive high-quality products that meet their operational requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘linear actuator 12v’

This guide serves as a practical checklist for B2B buyers seeking to procure 12V linear actuators. With the increasing demand for automation across various industries, understanding the sourcing process can enhance decision-making and ensure the selection of the right actuator for your specific needs.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for your linear actuator. Consider factors such as stroke length, force output, and voltage. Understanding these parameters helps narrow down options and ensures compatibility with your application.

– Stroke Length: Determine the distance the actuator needs to travel.

– Force Output: Assess the load the actuator must handle.

Illustrative image related to linear actuator 12v

Step 2: Research Market Trends and Applications

Stay informed about the latest trends in linear actuator technology and applications relevant to your industry. This knowledge can help you identify innovative features that may enhance your project’s efficiency or performance.

– Industry Needs: Different sectors may require varying specifications, such as waterproofing for agricultural applications or high load capacities for industrial use.

– Emerging Technologies: Look for advancements like smart actuators with integrated feedback systems.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers before making a commitment. Request detailed company profiles, case studies, and references from similar industries or regions to gauge their reliability and performance.

– Supplier Reputation: Investigate the supplier’s history, customer feedback, and industry standing.

– Product Range: Ensure the supplier offers a variety of models to meet diverse needs.

Step 4: Verify Supplier Certifications

Confirm that suppliers possess necessary certifications and adhere to international standards. This step is vital for ensuring product quality and compliance with safety regulations.

– Quality Assurance: Look for ISO certifications or industry-specific standards.

– Test Reports: Request documentation that proves the actuator has been tested for performance and durability.

Step 5: Request Samples for Testing

Before finalizing your order, request samples to evaluate the actuators’ performance in real-world conditions. Testing samples can reveal any discrepancies between specifications and actual performance.

– Performance Testing: Assess the actuator’s functionality, noise levels, and responsiveness.

– Compatibility Checks: Ensure that the actuator integrates seamlessly with your existing systems.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier and tested the products, engage in negotiations regarding pricing, delivery timelines, and payment terms. This step can lead to cost savings and a more favorable purchasing agreement.

– Bulk Discounts: Inquire about discounts for larger orders to optimize your budget.

– Payment Flexibility: Discuss potential payment plans that suit your financial strategy.

Step 7: Establish Ongoing Support and Communication

After procurement, maintain communication with your supplier for ongoing support. Establishing a reliable line of communication can facilitate troubleshooting, future orders, and any necessary adjustments.

– Customer Support: Verify the availability of technical support and warranty services.

– Feedback Mechanisms: Provide feedback on product performance to help the supplier improve their offerings.

By following this checklist, B2B buyers can confidently navigate the procurement process for 12V linear actuators, ensuring they select the best solutions for their applications while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for linear actuator 12v Sourcing

What Are the Key Cost Components for Sourcing 12V Linear Actuators?

When sourcing 12V linear actuators, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

Illustrative image related to linear actuator 12v

-

Materials: The type and quality of materials used significantly affect the cost. Premium actuators made from corrosion-resistant materials or those with higher IP ratings typically command higher prices. Common materials include aluminum and stainless steel, known for their durability.

-

Labor: Labor costs encompass the wages of skilled workers involved in manufacturing, assembly, and quality control. Regions with higher labor costs can influence the final price of the actuator.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead, potentially lowering prices for buyers.

-

Tooling: Initial tooling costs for custom or specialized actuators can be substantial. These costs are often amortized over larger production runs, making it crucial for buyers to consider their volume needs.

-

Quality Control (QC): Ensuring that products meet safety and performance standards incurs costs. Suppliers with rigorous QC processes may charge more, but this often results in fewer defects and lower long-term costs for buyers.

-

Logistics: Shipping and handling costs vary based on the origin of the product, shipping method, and destination. International buyers should be aware of potential customs duties and tariffs that can increase overall expenses.

-

Margin: Suppliers typically include a profit margin in their pricing. This can vary significantly based on market conditions, competition, and perceived value of the product.

How Do Price Influencers Affect the Cost of 12V Linear Actuators?

Several factors can influence the pricing of 12V linear actuators:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often leads to discounts. Suppliers may offer better pricing tiers based on order volume, so negotiating for larger quantities can yield significant savings.

-

Specifications and Customization: Customized actuators designed for specific applications may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Actuators made from higher-grade materials or those with certifications (such as ISO or IP ratings) typically come at a premium. Buyers should assess whether these features are essential for their applications.

-

Supplier Factors: The reputation, reliability, and geographic location of suppliers play a critical role in pricing. Established suppliers with a strong track record may charge more but offer better customer service and support.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) related to shipping can help buyers anticipate additional costs. Terms like FOB (Free On Board) or CIF (Cost, Insurance, Freight) can affect the total landed cost of the product.

What Are Some Effective Buyer Tips for Negotiating Prices on 12V Linear Actuators?

International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, should consider several strategies to enhance their sourcing experience:

-

Negotiate Prices: Don’t hesitate to negotiate with suppliers. Highlighting potential bulk purchases or long-term partnerships can incentivize suppliers to offer better pricing.

-

Focus on Cost-Efficiency: Look beyond the initial purchase price. Consider the Total Cost of Ownership (TCO), which includes maintenance, energy consumption, and potential downtime costs.

-

Understand Pricing Nuances: Be aware of regional pricing differences. Factors such as local demand, currency fluctuations, and logistics can affect costs. Understanding these nuances can help in making informed purchasing decisions.

-

Conduct Market Research: Comparative shopping is essential. Evaluate multiple suppliers, their offerings, and pricing structures to ensure you’re getting the best deal.

-

Plan for International Shipping: Factor in potential delays and additional costs associated with international shipping. Working with suppliers who have experience in your region can mitigate risks.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on supplier, order specifics, and market conditions. Always consult suppliers directly for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing linear actuator 12v With Other Solutions

Exploring Alternatives to Linear Actuator 12V: A Comparative Analysis

When evaluating solutions for motion control in various applications, it’s essential to consider different technologies beyond the standard linear actuator 12V. While linear actuators offer specific advantages, alternatives may provide unique benefits that could be better suited for particular needs. This analysis compares linear actuators with pneumatic actuators and electric motors, highlighting performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Linear Actuator 12V | Pneumatic Actuator | Electric Motor |

|---|---|---|---|

| Performance | Smooth, precise motion; force range 35-400 lbs | High speed; variable force depending on air pressure | Continuous rotation; high torque available |

| Cost | Moderate initial cost ($150-$500) | Lower upfront cost but high operational cost | Varies widely based on specifications; can be cost-effective |

| Ease of Implementation | Simple integration with electronic systems | Requires air compressor and plumbing | Requires more complex electrical setup |

| Maintenance | Low maintenance; durable design | Regular maintenance needed for compressor | Generally low maintenance but depends on application |

| Best Use Case | Robotics, automation, medical devices | Industrial automation, packaging, and assembly | Conveyor systems, fans, pumps |

In-Depth Analysis of Alternatives

Pneumatic Actuators

Pneumatic actuators utilize compressed air to produce motion. They are known for their high speed and ability to generate significant force, making them ideal for applications requiring rapid actuation. However, they necessitate a source of compressed air, which can lead to higher operational costs over time. Additionally, their performance can be affected by air quality and pressure fluctuations. Pneumatic actuators excel in industries like packaging and assembly, where speed is crucial, but they may lack the precision that some applications demand.

Electric Motors

Electric motors convert electrical energy into mechanical energy, providing continuous rotational motion. They are versatile and can be used in various applications, from small fans to large industrial machines. The cost of electric motors varies widely, with some high-torque models offering excellent value for heavy-duty applications. However, integrating electric motors often requires a more complex electrical setup and control system. They are best suited for applications like conveyor systems and pumps, where continuous motion is essential. Maintenance is generally low, but it can depend on the specific use case and environmental conditions.

Illustrative image related to linear actuator 12v

Making an Informed Decision for Your Application

Choosing the right motion control solution ultimately depends on your specific application requirements. If precision and compactness are paramount, a linear actuator 12V is often the best choice, especially in environments where space is limited and reliability is critical. Conversely, if speed and force are your primary concerns, pneumatic actuators may offer the performance you need at a lower initial cost, albeit with higher ongoing expenses. Electric motors can serve well in applications requiring continuous motion but may require more complex integration.

By carefully evaluating the performance characteristics, costs, and maintenance needs of each solution, B2B buyers can make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for linear actuator 12v

What Are the Key Technical Properties of a 12V Linear Actuator?

When selecting a 12V linear actuator for industrial applications, understanding its technical properties is vital for ensuring that the component meets specific operational requirements. Here are some essential specifications to consider:

1. Force Rating (Load Capacity)

The force rating indicates the maximum load the actuator can handle, typically measured in pounds (lbs). Common ratings for 12V linear actuators range from 20 lbs to over 3000 lbs. For B2B buyers, selecting an actuator with the appropriate force rating is crucial to ensure it can perform the intended task without failure, thereby minimizing downtime and maintenance costs.

2. Stroke Length

The stroke length defines how far the actuator can extend or retract, usually measured in inches. Stroke lengths for 12V actuators can vary from as little as 1 inch to over 40 inches. Understanding the required stroke length is essential for proper fit in specific applications, such as robotics, automotive, or medical equipment, ensuring that the actuator can fully execute its intended motion.

3. Duty Cycle

The duty cycle refers to the amount of time an actuator can operate continuously before needing a rest period. It is expressed as a percentage, with higher percentages indicating longer operational times. For businesses, knowing the duty cycle is important for planning operational efficiency and ensuring the actuator can sustain the required workload without overheating or failing.

4. Ingress Protection (IP) Rating

The IP rating measures the actuator’s resistance to dust and water ingress. For example, an IP68 rating indicates the actuator is dust-tight and can withstand immersion in water beyond 1 meter. This is particularly significant for industries operating in harsh environments, such as agriculture or outdoor applications, where durability and reliability are critical.

5. Power Supply Voltage

For 12V linear actuators, the voltage must match the operational specifications of the equipment. Using an incompatible power supply can lead to performance issues or damage. B2B buyers should ensure that their existing systems can accommodate the voltage requirements of the actuator, especially when integrating with other components.

What Are Common Trade Terms in the Linear Actuator Industry?

Understanding industry jargon is essential for effective communication and decision-making in B2B transactions. Here are some common terms associated with 12V linear actuators:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of linear actuators, knowing whether a supplier is an OEM can help buyers assess product quality and reliability, as OEMs often adhere to strict manufacturing standards.

Illustrative image related to linear actuator 12v

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For businesses, understanding MOQ is crucial for budgeting and inventory management. Suppliers often set MOQs to ensure production efficiency, so buyers must negotiate effectively to meet their needs without overcommitting.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For B2B buyers, issuing an RFQ helps in gathering competitive bids from multiple suppliers, facilitating informed decision-making based on price, delivery timelines, and service levels.

4. Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms published by the International Chamber of Commerce that outline the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping logistics, costs, and risk management, ensuring smoother international trade operations.

5. Customization

Customization refers to the ability to modify a product to meet specific requirements. In the linear actuator market, many manufacturers offer customizable options for stroke lengths, force ratings, and additional features. For businesses, customization can enhance product performance and fit, making it a critical consideration for unique applications.

By understanding these technical properties and trade terminology, B2B buyers can make informed decisions when procuring 12V linear actuators, ensuring they select the right products for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the linear actuator 12v Sector

What Are the Key Trends and Dynamics in the Global Linear Actuator 12V Market?

The linear actuator market is witnessing significant growth driven by advancements in automation, increasing demand for precision control, and the expanding application of these devices across various industries. B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking 12V linear actuators for applications ranging from manufacturing automation to renewable energy solutions, such as solar tracking systems. The compact design of 12V actuators allows for their integration in space-constrained environments, making them a preferred choice for diverse projects.

Emerging trends indicate a shift towards smart technologies, with a growing demand for actuators equipped with feedback systems that enhance operational efficiency and reliability. As industries evolve, the need for high-performance actuators capable of withstanding harsh conditions, such as high humidity or dust, is becoming critical. Consequently, manufacturers are focusing on developing products with higher IP ratings and corrosion resistance, appealing to international buyers who require durability in challenging environments.

Illustrative image related to linear actuator 12v

Another notable trend is the rising significance of bulk purchasing. International buyers are increasingly favoring suppliers who offer tiered pricing structures, allowing for cost savings on large orders. This dynamic not only fosters long-term partnerships but also encourages buyers to explore custom actuator solutions tailored to specific operational needs, enhancing overall project efficiency.

How Are Sustainability and Ethical Sourcing Impacting the Linear Actuator 12V Market?

As environmental concerns gain prominence globally, B2B buyers are prioritizing sustainability in their sourcing strategies. The linear actuator market is no exception; manufacturers are increasingly adopting eco-friendly practices and materials to minimize their environmental impact. The use of sustainable manufacturing processes, such as reducing waste and energy consumption, is becoming a key differentiator for suppliers.

Buyers are also on the lookout for products that come with certifications indicating compliance with environmental standards. Green certifications, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), are vital in assuring buyers that the products meet strict environmental guidelines. This trend towards ethical sourcing is not only beneficial for the planet but also enhances brand reputation and customer loyalty among environmentally conscious consumers.

Furthermore, as global regulations tighten around waste and emissions, B2B buyers in regions like Europe and North America are increasingly demanding transparency in supply chains. Suppliers who can demonstrate their commitment to sustainable practices, including responsible sourcing of raw materials and adherence to ethical labor standards, will likely gain a competitive edge in the marketplace.

How Has the Linear Actuator 12V Market Evolved Over Time?

The linear actuator market has undergone significant evolution since its inception. Initially dominated by hydraulic and pneumatic systems, the industry has shifted towards electric solutions, particularly 12V actuators, due to their efficiency and reduced maintenance requirements. Early models were limited in terms of power and functionality, but advancements in technology have led to the development of high-performance actuators that can handle substantial loads while maintaining compact designs.

The introduction of smart technologies has further transformed the landscape, enabling actuators to provide feedback and integrate seamlessly with automation systems. This evolution has opened new avenues for applications across various sectors, including automotive, aerospace, and renewable energy. As the demand for automation continues to rise, the linear actuator market is poised for ongoing growth, driven by innovation and the increasing need for reliable, efficient motion control solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of linear actuator 12v

-

How do I choose the right linear actuator for my application?

Selecting the correct linear actuator involves considering several factors including stroke length, force requirements, and environmental conditions. Start by determining the load that the actuator must move and the distance it needs to travel. Also, assess the operating environment—if it’s exposed to dust or moisture, look for actuators with appropriate IP ratings. Finally, consider the power supply; for a 12V actuator, ensure your system can provide adequate voltage and current. Consulting with manufacturers or using online calculators can help streamline this process. -

What are the benefits of using a 12V linear actuator in my project?

12V linear actuators offer several advantages, including compact size and ease of integration into various systems. They are often lighter and less expensive than higher voltage options, making them ideal for smaller projects or applications with limited space. Additionally, 12V systems are widely available and compatible with standard power supplies, enhancing flexibility for international buyers. Their versatility makes them suitable for automation tasks in diverse industries, such as robotics, healthcare, and manufacturing. -

What should I consider when vetting suppliers for linear actuators?

When vetting suppliers, look for established manufacturers with a proven track record in delivering high-quality linear actuators. Check for certifications that ensure product quality and adherence to international standards. Evaluate their customer service and support capabilities, especially regarding warranty and after-sales services. Request samples or references from previous clients to assess reliability. Additionally, inquire about their logistics capabilities, including shipping times and handling for international orders to regions like Africa, South America, and the Middle East. -

What is the typical minimum order quantity (MOQ) for linear actuators?

The MOQ for linear actuators can vary significantly among suppliers, often ranging from 10 to 100 units. Factors influencing MOQ include the type of actuator, customization options, and the supplier’s production capabilities. For international buyers, negotiating MOQs can be possible, especially if you are looking to establish a long-term relationship. Always clarify the MOQ during discussions to ensure it aligns with your project needs and budget. -

Can I customize a linear actuator to meet specific project requirements?

Yes, many manufacturers offer customization options for linear actuators, including modifications in stroke length, force capacity, and design features. Customization can also extend to the inclusion of feedback systems or specific connectors. When discussing your needs, provide detailed specifications and any unique requirements to the supplier. Be aware that custom orders may have longer lead times and higher costs, so plan accordingly. -

What payment terms should I expect when sourcing linear actuators internationally?

Payment terms can vary widely depending on the supplier and the nature of your order. Common options include upfront payments, partial payments, or payment upon delivery. It’s essential to discuss and agree on terms early in the negotiation process. For larger orders, suppliers may offer credit terms or discounts for early payment. Always ensure that payment methods are secure and that you understand the implications of currency exchange rates, especially when dealing with international transactions. -

How can I ensure quality assurance (QA) for my linear actuators?

To ensure QA, request detailed product specifications, including testing methods and standards used by the supplier. Inquire about the quality control processes in place during manufacturing, such as inspections and performance testing. Many reputable suppliers provide certifications that validate their products meet international standards. Consider conducting third-party inspections or audits if you are ordering in large quantities, particularly for critical applications. -

What logistics considerations should I keep in mind when importing linear actuators?

Logistics is crucial when importing linear actuators. First, understand the shipping methods available, as they can affect costs and delivery times. Ensure that the supplier provides proper documentation for customs clearance, including invoices and certificates of origin. Be aware of import duties and taxes applicable in your country, as these can impact your overall budget. Finally, choose a reliable freight forwarder experienced in handling industrial equipment to mitigate potential shipping delays or complications.

Top 10 Linear Actuator 12V Manufacturers & Suppliers List

1. Firgelli – Premium Linear Actuators

Domain: firgelliauto.com

Registered: 2004 (21 years)

Introduction: Premium linear actuators available in 12v or 24v with stroke lengths ranging from 1″ to 30″. Features include enhanced corrosion resistance, higher IP rating for water and dust resistance, and built-in limit switches for automatic stopping. Force options range from 35 to 400 lbs. Various models include Super Duty Actuators (220–450 lbs, 2–40 inches), Utility Linear Actuator (110–330 lbs, 2–12 inch…

2. Progressive Automations – Mini Industrial Actuator

Domain: progressiveautomations.com

Registered: 2008 (17 years)

Introduction: Industrial Linear Actuators – Progressive Automations

Key Product Details:

1. **Mini Industrial Actuator – Optional Feedback**

– Model: PA-09

– Voltage: 12 VDC, 24 VDC

– Stroke: 2-40 inch

– Force: 330 lbs

– Price: $163.99 USD

2. **Water-resistant Linear Actuator IP66 – Optional Feedback**

– Model: PA-10

– Voltage: 12 VDC, 24 VDC

– Stroke: 2-36 inch

…

3. GlideForce – DC Linear Actuators

Domain: surpluscenter.com

Registered: 1996 (29 years)

Introduction: DC Linear Actuators available from brands like GlideForce and Progressive Motions. Key specifications include load ratings ranging from up to 199 lbs to 1000 lbs and voltages of 12 Volt DC and 24 Volt DC. Stroke lengths vary from 1.97″ to 27.375″ and include options with sensors and limit switches. Prices range from approximately $14.95 to $447.90.

4. Thomson – Electric Actuators

Domain: thomsonlinear.com

Registered: 2008 (17 years)

Introduction: Thomson electric actuators offer a range of features and specifications:

– Stroke lengths: 1 to 40 inches (25 to 1000 mm)

– Dynamic load ratings: 25 to 3596 lbs. (100 N to 16 kN)

– Speeds: 0.2 to 2.0 in/sec (5 to 50 mm/sec)

– Voltage options: 12 VDC, 24 VDC, 36 VDC, 90 VDC, 115 VAC, 230 VAC, 400 VAC

– Duty cycle: minimum of 25%

– Ingress Protection (IP) ratings: IP65, IP66, IP67, IP69K

– Fe…

5. LINAK – 12V Linear Actuators

Domain: linak-us.com

Registered: 1997 (28 years)

Introduction: 12V Linear Actuators: LA12, LA14, LA20, LA23, LA33, LA36, LA37.

– LA12: Max load: 750 N, Max speed: 40 mm/s.

– LA14: Max load: 750 N, Max speed: 45 mm/s, Stroke length: 19-130 mm.

– LA20: Max load: 2,500 N, Max speed: 8.9 mm/s.

– LA23: Max load: 2,500 N, Max speed: 22.0 mm/s, IPX6.

– LA33: Max load: 5,000 N, Max speed: 70 mm/s, Stroke length: 100-600 mm.

– LA36: Max load: 6,800 N, Max speed:…

6. TiMOTION – High Speed Electric Linear Actuators

Domain: timotion.com

Registered: 2004 (21 years)

Introduction: High Speed 12V DC Electric Linear Actuators (Electric Cylinders) from TiMOTION are designed for various applications across multiple industries. Key details include:

– Voltage Options: 12V, 24V, 36V, 48V DC; 110V and 220V AC.

– Protection Levels: Customizable waterproof and dustproof ratings, including IP42, IP54, IP66, IP66W, and IP69K.

– Styles: Various styles available, including Inline Driv…

7. Windy Nation – Linear Actuator 12V 225 lbs

Domain: windynation.com

Registered: 2008 (17 years)

Introduction: Linear Actuator: 12-Volt, 225 lbs capacity; includes mounting brackets. Optional accessories: AC to 12 VDC power supply, wireless remote control, and DPDT switch. Available stroke lengths: 2, 4, 6, 8, 12, 16, 20, 30 inches. Regular price: $105.99. SKU: LIN-ACTK-2PR. Free shipping on all products. Quick snap locking connectors for easy installation.

8. Actuonix – 12V Linear Actuators

Domain: actuonix.com

Registered: 2016 (9 years)

Introduction: 12V linear actuators designed for automotive, robotics, and electronic applications. Features include:

– Power Source: Requires a 12V power supply.

– Energy Conversion: Electric motor converts electrical energy to mechanical energy.

– Transmission Mechanism: Rotational motion converted to linear motion via lead screw assembly and customizable gearbox.

– Control System: Varies from simple on/of…

9. eBay – 12V Linear Actuators

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 12V Linear Actuators available in various stroke lengths: 600mm (24 in), 500mm (20 in), 450mm (18 in), 400mm (16 in), 300mm (12 in), 250mm (10 in), 200mm (8 in), 150mm (6 in), 100mm (4 in), 50mm (2 in).

10. Pushcart – Heavy Duty Linear Actuator

Domain: shop.mypushcart.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “Linear Actuator – Heavy Duty 12 Volt 2 Stroke”, “SKU”: “LAD-B2”, “Price”: “$49.99”, “Regular Price”: “$89.95”, “Shipping”: “FREE 2-DAY SHIPPING ON ALL REMOTE START SYSTEMS”, “Return Policy”: “30 DAY RETURN POLICY”, “Technical Support”: “FREE EXPERT TECHNICAL SUPPORT MONDAY – FRIDAY 9AM – 5PM (MST)”, “Specifications”: {“Travel Speed”: “0.472 inches/sec (12 mm/sec) at 50% load”, “D…

Strategic Sourcing Conclusion and Outlook for linear actuator 12v

As the demand for efficient and reliable motion solutions continues to grow globally, strategic sourcing of 12V linear actuators presents a significant opportunity for international buyers. The versatility, compact design, and high performance of these actuators make them ideal for a variety of applications across diverse industries, from manufacturing to automation. Key factors such as force capacity, stroke length, and environmental protection ratings should guide procurement decisions, ensuring that the chosen actuator meets specific operational requirements.

Investing in premium linear actuators can enhance product durability and efficiency, ultimately reducing long-term operational costs. Furthermore, leveraging suppliers that offer custom solutions and robust customer support will ensure that businesses can adapt to evolving market needs and technological advancements.

Looking ahead, international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, should actively engage with suppliers to explore the latest innovations and optimize their sourcing strategies. By prioritizing quality and reliability, organizations can position themselves for success in an increasingly competitive landscape. Now is the time to capitalize on these advancements—connect with trusted manufacturers and distributors to secure the best solutions for your operational needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.