A B2B Buyer’s Guide to Max 80: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for max 80

Navigating the complexities of the global market for MAX 80 products poses significant challenges for international B2B buyers. Whether you are sourcing lightweight steel golf shafts or high-performance electrical fuses, understanding the diverse applications and specifications of MAX 80 items is crucial for making informed purchasing decisions. This guide provides a comprehensive overview of various MAX 80 products, including their technical specifications, intended uses, and optimal supplier vetting strategies.

Buyers from regions such as Africa, South America, the Middle East, and Europe will find actionable insights on cost analysis, quality assurance, and market trends, ensuring that they can effectively navigate this competitive landscape. By equipping you with the knowledge to evaluate product performance, compatibility, and supplier reliability, this guide aims to empower your procurement strategy, ultimately maximizing your investment and operational efficiency.

In an increasingly interconnected world, leveraging this information will not only enhance your purchasing decisions but also position your business for success across multiple markets. Embrace the opportunity to explore the nuances of MAX 80 products and elevate your sourcing strategy today.

Understanding max 80 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| KBS MAX 80 Steel Shaft | Lightweight design, R/S/X flex options, high trajectory, .370″ tip | Golf equipment manufacturing, custom clubs | Pros: Enhances performance for mid-high handicaps; Cons: May require trimming adjustments. |

| Eaton Bussmann MAX-80 | 80A capacity, non-indicating, colored plastic housing | Electrical circuit protection, automotive | Pros: Reliable and durable; Cons: Limited to specific voltage applications. |

| Apollo Acculite 85 | R/S flex, affordable, .370″ tip diameter | Entry-level golf clubs, budget-friendly options | Pros: Cost-effective for beginners; Cons: Lower performance compared to premium shafts. |

| True Temper Command | Versatile R/S flex, suitable for various clubs | Custom club fitting, professional golf equipment | Pros: High-quality materials; Cons: Higher price point than basic options. |

| Bussmann MAX-80 Fuse | 32 Vdc, 1 kAIC, blade end design | Industrial machinery, electrical distribution | Pros: High reliability for critical systems; Cons: Requires proper installation to avoid failures. |

What are the characteristics of KBS MAX 80 Steel Shafts?

The KBS MAX 80 Steel Shaft is specifically designed for mid to high handicap golfers, featuring a lightweight structure that promotes higher trajectories and spin rates. This shaft is available in Regular, Stiff, and X-Stiff flex options, making it versatile for various player preferences. B2B buyers in the golf equipment sector should consider this shaft for custom club manufacturing, as it enhances performance and distance for players looking to improve their game. However, it may require precise trimming, which could complicate the fitting process.

How does the Eaton Bussmann MAX-80 fuse stand out in electrical applications?

The Eaton Bussmann MAX-80 fuse is a non-indicating 80A fuse designed for effective circuit protection in electrical systems. Its colored plastic housing facilitates easy identification, while its robust construction ensures reliability in demanding environments. This product is particularly relevant for B2B buyers in the automotive and industrial sectors, where dependable circuit protection is crucial. However, buyers should note that its application is limited to specific voltage requirements, which may necessitate careful selection.

What makes Apollo Acculite 85 shafts a popular choice for budget-conscious buyers?

The Apollo Acculite 85 Steel Shaft is an economical option for entry-level golf clubs, featuring a .370″ tip diameter and R/S flex. Its affordability makes it an attractive choice for B2B buyers focused on providing budget-friendly golf equipment. While it offers decent performance for beginners, buyers should be aware that it may not deliver the same level of performance as higher-end options, which could impact long-term player development.

In what ways does True Temper Command cater to professional golfers?

True Temper Command shafts are known for their versatility and high-quality materials, suitable for various clubs and player types. These shafts are particularly favored in custom club fitting and professional golf equipment manufacturing. B2B buyers should consider them for their durability and performance enhancements, though the higher price point may be a consideration for budget-sensitive businesses.

Why should Bussmann MAX-80 fuses be prioritized in industrial settings?

The Bussmann MAX-80 fuse is designed for critical electrical distribution systems, offering a 32 Vdc rating and a 1 kAIC capacity. Its blade end design is straightforward to install, making it ideal for industrial machinery and electrical distribution applications. B2B buyers in these sectors should prioritize this fuse for its reliability and effectiveness in protecting sensitive equipment. However, proper installation and adherence to specifications are essential to prevent potential failures.

Key Industrial Applications of max 80

| Industry/Sector | Specific Application of max 80 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Electrical circuit protection using MAX 80 fuses | Ensures safety and reliability in electrical systems | Compliance with local regulations and certifications |

| Construction | Use in power distribution systems | Enhances operational efficiency and safety | Availability of compatible components and local support |

| Automotive | Application in vehicle electrical systems | Reduces risk of electrical failures and improves safety | Quality assurance and performance under different climates |

| Energy Sector | Integration in renewable energy systems | Supports sustainable energy solutions | Understanding of international shipping and tariffs |

| Sports Equipment | Utilization in golf clubs for performance enhancement | Maximizes player performance and satisfaction | Flexibility in customization and trimming options |

How is ‘max 80’ Used in the Manufacturing Sector?

In the manufacturing industry, the MAX 80 fuse is crucial for electrical circuit protection. It safeguards machinery and electrical systems from overloads, ensuring operational safety and reliability. For international buyers, especially in regions like Africa and South America, sourcing these fuses requires attention to local compliance standards and certifications. Manufacturers must ensure that the products meet international quality benchmarks to avoid costly downtimes.

What Role Does ‘max 80’ Play in Construction Projects?

In construction, MAX 80 fuses are integrated into power distribution systems, providing a reliable means of protecting electrical circuits from faults. This application enhances operational efficiency by minimizing the risk of electrical failures that can lead to project delays. Buyers should consider the availability of compatible components and local technical support to ensure seamless integration into existing systems.

How is ‘max 80’ Essential in Automotive Applications?

The automotive industry utilizes MAX 80 fuses within vehicle electrical systems to minimize the risk of electrical failures. These fuses are designed to handle high currents, which is vital for the safety of modern vehicles equipped with complex electronic systems. Buyers in Europe, for instance, must prioritize quality assurance and ensure that these components can withstand diverse climatic conditions, enhancing vehicle reliability.

Why is ‘max 80’ Important for Renewable Energy Systems?

In the energy sector, particularly in renewable energy projects, the MAX 80 fuse plays a significant role in protecting electrical circuits from overloads. This application supports sustainable energy solutions by ensuring the safe operation of solar panels and wind turbines. International buyers should be aware of shipping regulations and tariffs that may affect the import of these components, ensuring they budget accordingly.

How Does ‘max 80’ Enhance Performance in Sports Equipment?

In the sports equipment sector, particularly in golf, the MAX 80 shaft is engineered to enhance player performance by providing a lightweight, high-trajectory option for mid-high handicap players. This application allows athletes to maximize their game while enjoying improved distance and control. Buyers should look for customization options and understand the trimming process to ensure the shafts meet their specific requirements.

3 Common User Pain Points for ‘max 80’ & Their Solutions

Scenario 1: Sourcing Quality MAX 80 Components for Diverse Markets

The Problem: B2B buyers often struggle with sourcing high-quality MAX 80 products that meet their specific needs, particularly in diverse international markets. Issues arise when local suppliers lack the necessary inventory or product specifications to cater to unique requirements, leading to delays and increased costs. Buyers may also face challenges verifying the authenticity and quality of the components, risking their operational efficiency and customer satisfaction.

The Solution: To navigate this sourcing challenge, buyers should establish relationships with reputable manufacturers and distributors who specialize in MAX 80 components. Conduct thorough research to identify suppliers with a proven track record in quality assurance and customer service. Utilize platforms such as industry-specific trade shows, online marketplaces, or B2B networks to connect with trusted vendors. When communicating with suppliers, clearly specify product requirements, such as compliance standards and delivery timelines, to ensure alignment. Additionally, consider requesting samples or conducting quality audits before placing large orders to mitigate risks associated with subpar products.

Scenario 2: Understanding Technical Specifications for Optimal Performance

The Problem: Many B2B buyers lack the technical expertise to fully understand the specifications of MAX 80 products, which can lead to improper application and performance issues. For instance, misunderstanding the differences between R/S/X flex options in golf shafts or the implications of tip diameters can result in purchasing products that do not fit their intended use, ultimately affecting performance and increasing costs due to returns or replacements.

The Solution: To overcome this knowledge gap, buyers should invest time in educating themselves about the technical specifications of MAX 80 products. Resources such as manufacturer websites, product datasheets, and industry webinars can provide valuable insights. Additionally, engaging with technical support teams from suppliers can clarify any doubts regarding product features and applications. For golf shafts, for example, understanding the benefits of each flex option can guide buyers in selecting the right fit for their clientele. Developing a standard checklist of technical specifications for each product type can also aid in making informed purchasing decisions.

Scenario 3: Managing Inventory and Supply Chain Disruptions

The Problem: B2B buyers frequently face challenges in managing inventory levels for MAX 80 products, particularly in the face of supply chain disruptions. Global events, such as political instability or pandemics, can lead to unexpected delays in shipments, causing stockouts that negatively impact business operations and customer trust.

The Solution: To effectively manage inventory and mitigate risks associated with supply chain disruptions, buyers should adopt a proactive inventory management strategy. This includes maintaining buffer stock levels of essential MAX 80 products based on demand forecasts and historical sales data. Establishing multi-supplier relationships can also provide alternatives in case one supplier faces delays. Implementing inventory management software can enhance visibility across the supply chain, allowing for real-time tracking of stock levels and shipment statuses. Finally, regular communication with suppliers about their production capabilities and any potential risks can help buyers adjust their strategies in advance, ensuring they remain prepared for unforeseen circumstances.

Strategic Material Selection Guide for max 80

What Are the Key Properties of Common Materials for MAX 80 Applications?

When selecting materials for MAX 80 applications, it is crucial to understand the properties that influence product performance. Here, we analyze four common materials: steel, aluminum, copper, and plastic composites, focusing on their suitability for various applications.

How Does Steel Perform in MAX 80 Applications?

Steel, particularly carbon and stainless varieties, is widely used in MAX 80 applications due to its impressive strength and durability. Key properties include high tensile strength, resistance to deformation under stress, and a temperature rating that can withstand extreme conditions. Steel’s corrosion resistance varies; stainless steel offers superior protection against environmental factors, making it ideal for outdoor applications.

Pros: Steel is highly durable, cost-effective for large-scale production, and offers excellent mechanical properties. It is suitable for high-load applications and can be easily sourced globally.

Cons: The primary downside is its weight, which can be a disadvantage in applications where lightweight materials are preferable. Additionally, steel may require additional coatings to enhance corrosion resistance, increasing manufacturing complexity.

Impact on Application: Steel is compatible with various media, including water, oil, and gases, making it versatile. However, buyers should consider the specific environmental conditions to select the appropriate type of steel.

What Advantages Does Aluminum Offer for MAX 80?

Aluminum is another common material used in MAX 80 applications, known for its lightweight nature and excellent corrosion resistance. It has a lower density compared to steel, making it suitable for applications where weight is a critical factor. Aluminum’s thermal and electrical conductivity also makes it a preferred choice in electrical applications.

Pros: The lightweight nature of aluminum reduces shipping costs and makes handling easier. It is also resistant to corrosion without the need for additional coatings, which simplifies manufacturing processes.

Cons: The main limitation is its lower strength compared to steel, which may restrict its use in high-load applications. Aluminum can also be more expensive than steel, impacting overall project budgets.

Impact on Application: Aluminum is particularly well-suited for applications exposed to moisture or corrosive environments, such as marine or chemical industries. B2B buyers should ensure compliance with relevant standards, such as ASTM B221 for extruded aluminum.

Why Choose Copper for MAX 80 Applications?

Copper is renowned for its excellent electrical and thermal conductivity, making it a prime candidate for electrical components in MAX 80 applications. Its key properties include high ductility, resistance to corrosion, and antimicrobial properties, which can be beneficial in specific applications.

Pros: Copper’s superior conductivity makes it ideal for electrical applications, ensuring efficient energy transfer. Its antimicrobial properties also make it suitable for healthcare-related applications.

Cons: The primary drawback is its cost, as copper is generally more expensive than both steel and aluminum. Additionally, copper is heavier, which can be a disadvantage in applications where weight savings are crucial.

Impact on Application: Copper is compatible with various media, including water and gases, but its cost may limit its use in large-scale applications. Buyers should consider the long-term benefits of using copper against its initial investment.

How Do Plastic Composites Compare for MAX 80?

Plastic composites are increasingly utilized in MAX 80 applications due to their lightweight and corrosion-resistant properties. They can be engineered to meet specific performance requirements, including temperature and pressure ratings.

Pros: The primary advantages of plastic composites include their resistance to corrosion, lightweight nature, and flexibility in design. They can be molded into complex shapes, allowing for innovative designs.

Cons: However, plastic composites may not offer the same level of strength and durability as metals, which can limit their use in high-stress applications. Additionally, they may have higher manufacturing costs depending on the complexity of the design.

Impact on Application: Plastic composites are suitable for applications in corrosive environments, such as chemical processing. Buyers should verify compliance with international standards, such as ISO 9001, to ensure quality and reliability.

Summary Table of Material Selection for MAX 80

| Material | Typical Use Case for MAX 80 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, tools | High durability and strength | Heavier weight, potential corrosion issues | Medium |

| Aluminum | Lightweight frames, electrical parts | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium to High |

| Copper | Electrical wiring, thermal applications | Excellent conductivity and antimicrobial properties | Higher cost and weight | High |

| Plastic Composites | Chemical tanks, lightweight parts | Corrosion resistance and design flexibility | Lower strength compared to metals | Medium to High |

This guide serves as a comprehensive resource for international B2B buyers looking to make informed material selections for MAX 80 applications, considering performance, cost, and compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for max 80

What Are the Key Stages in the Manufacturing Process of MAX 80 Products?

The manufacturing process for MAX 80 products, particularly steel shafts, involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential in ensuring that the final product meets the performance and quality standards expected by B2B buyers.

-

Material Preparation: The process begins with the selection of high-quality steel, which is crucial for the durability and performance of the MAX 80 shafts. The steel is sourced from reputable suppliers and undergoes rigorous testing to ensure it meets specified mechanical properties. After sourcing, the steel is cut to size and prepped for further processing.

-

Forming: This stage involves shaping the steel into the desired shaft form. Techniques such as cold drawing or hot forging may be employed, depending on the required specifications and properties of the shaft. The forming process is carefully controlled to maintain the desired dimensions and tolerances, which are critical for performance.

-

Assembly: In the case of multi-component products, assembly is the next step. For MAX 80 shafts, this may involve attaching specific components or features that enhance performance, such as grips or tips. Each component is meticulously aligned and secured to ensure optimal functionality.

-

Finishing: The final stage involves finishing processes such as polishing and coating. A chrome finish is typically applied to enhance the aesthetic appeal and protect against corrosion. This stage also includes any necessary trimming, where shafts are cut to specific lengths based on customer requirements.

How Is Quality Assurance Implemented in MAX 80 Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of MAX 80 products, ensuring that every item produced meets international and industry-specific standards. The QA process includes several checkpoints and testing methods.

-

International Standards: Compliance with international standards such as ISO 9001 is crucial for manufacturers. This certification indicates that the company has implemented a quality management system that consistently provides products that meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE (for European markets) or API (for oil and gas applications) may also apply.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards. Any non-conforming materials are rejected or returned.

– In-Process Quality Control (IPQC): During the manufacturing process, periodic inspections are conducted to monitor the production process. This ensures that any deviations from quality standards are detected and corrected in real-time.

– Final Quality Control (FQC): After the product is completed, it undergoes final inspections and tests. This may include dimensional checks, functional testing, and visual inspections to ensure the product is free from defects. -

Common Testing Methods: Various testing methods are utilized to assess the mechanical properties and performance of MAX 80 products. Common tests include tensile strength testing, impact resistance testing, and fatigue testing. These evaluations provide critical data on how the products will perform in real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential to ensure product reliability. Here are effective strategies for buyers:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes and quality management systems. During an audit, buyers can assess compliance with international standards and identify any potential quality issues.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality reports that outline testing methods, results, and compliance with relevant standards. These documents provide transparency and assurance regarding the product quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. These services can verify compliance with industry standards and provide additional assurance of product quality.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control for international transactions is crucial for B2B buyers. Here are some key considerations:

-

Regulatory Compliance: Different regions have varying regulations regarding product safety and quality. Buyers must ensure that their suppliers comply with the regulations relevant to their target markets, such as CE marking for the European Union or specific certifications for African or South American markets.

-

Cultural and Communication Barriers: Buyers should be aware of potential cultural differences that may impact communication and expectations regarding quality. Establishing clear communication channels and expectations upfront can mitigate misunderstandings.

-

Supply Chain Transparency: Ensuring transparency throughout the supply chain can enhance trust and reliability. Buyers should inquire about the sourcing of materials and the traceability of components used in the manufacturing process.

-

Long-term Partnerships: Building long-term relationships with suppliers can lead to improved quality over time. Engaging in collaborative quality improvement initiatives can benefit both parties and lead to enhanced product offerings.

By understanding the manufacturing processes and quality assurance mechanisms for MAX 80 products, B2B buyers can make informed decisions and establish partnerships that prioritize quality and performance. This knowledge is essential for navigating the complexities of international procurement, ensuring that the products meet the high standards required in competitive markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘max 80’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure ‘max 80’ products, specifically focusing on the KBS MAX 80 steel shafts and related items. Ensuring a systematic approach to sourcing can enhance the quality of your procurement decisions, reduce risks, and ultimately lead to better product performance and customer satisfaction.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical specifications you require from the ‘max 80’ product. This includes determining the type of product, dimensions, weight, and material characteristics. Establishing precise specifications helps in identifying suitable suppliers and ensures that the products meet your operational needs.

- Consider factors such as flex type (Regular, Stiff, X-Stiff) and diameter (.370″) when specifying shafts.

- Keep in mind the intended use and performance requirements, such as trajectory and spin rate.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in ‘max 80’ products. Look for companies with a proven track record in your industry and region. Understanding their market reputation can save you time and resources in the long run.

- Utilize online directories, industry forums, and trade shows to gather a list of potential suppliers.

- Pay attention to reviews and ratings from other B2B buyers to gauge supplier reliability.

Step 3: Evaluate Supplier Certifications and Compliance

Before moving forward, verify that potential suppliers hold necessary certifications and comply with industry standards. This ensures product quality and safety, which is crucial for maintaining your brand’s reputation.

- Request documentation for certifications such as ISO or other relevant industry standards.

- Confirm that the products meet regional compliance requirements, especially if you are sourcing internationally.

Step 4: Request Product Samples

Once you have narrowed down your list of suppliers, request product samples to evaluate quality firsthand. Testing samples can provide insights into how well the products meet your specifications and performance expectations.

- Assess the materials, craftsmanship, and overall feel of the samples.

- Consider how the samples perform under conditions similar to your intended use.

Step 5: Negotiate Terms and Pricing

Engage in discussions with your selected suppliers regarding pricing, payment terms, and delivery schedules. Effective negotiation can lead to favorable terms that benefit both parties.

- Be clear about your budget constraints while seeking the best value for your investment.

- Consider bulk purchase discounts or long-term partnership agreements to enhance cost-effectiveness.

Step 6: Conduct a Risk Assessment

Perform a risk assessment to identify any potential challenges associated with your chosen supplier. This includes evaluating factors such as lead times, shipping reliability, and potential language barriers in international sourcing.

- Analyze the supplier’s history of delivery performance and customer service responsiveness.

- Consider geopolitical factors that may affect supply chain stability, especially for international suppliers.

Step 7: Establish a Communication Plan

Finally, establish a clear communication plan with your supplier to ensure ongoing collaboration and transparency. Effective communication can prevent misunderstandings and foster a positive working relationship.

- Set up regular check-ins to discuss order status, address concerns, and provide feedback.

- Utilize project management tools to streamline communication and documentation sharing.

By following this structured checklist, B2B buyers can ensure a more effective and efficient procurement process for ‘max 80’ products, ultimately maximizing their investment and supporting their business goals.

Comprehensive Cost and Pricing Analysis for max 80 Sourcing

What Are the Key Cost Components in Sourcing ‘max 80’ Products?

Understanding the cost structure of ‘max 80’ products, such as the KBS MAX 80 steel shafts or similar components, is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly influences the cost. For example, high-quality steel or specialized alloys can raise the base price. It’s essential to evaluate the material specifications to determine if they align with your performance needs and budget.

-

Labor: Labor costs vary by region and the complexity of manufacturing processes. Skilled labor may be necessary for precision engineering, especially in high-end products, which can increase overall costs.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment maintenance. Understanding the supplier’s operational efficiency can provide insights into potential cost savings.

-

Tooling: Custom tooling for unique designs or specifications can be a significant upfront cost. Buyers should weigh the benefits of customization against the investment required for tooling.

-

Quality Control (QC): Robust QC processes ensure product reliability but can add to the cost. Certifications and compliance with international standards may also be reflected in the pricing.

-

Logistics: Shipping and handling costs can vary widely based on the Incoterms used, the shipping distance, and the chosen logistics provider. Buyers should consider total shipping costs when calculating the overall expenditure.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market rate for similar products can help in negotiating better deals.

How Do Price Influencers Affect Sourcing Decisions for ‘max 80’ Products?

Several factors can influence the pricing of ‘max 80’ products, which buyers should consider:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Larger orders often lead to volume discounts, making it more economical for businesses with high demand.

-

Specifications and Customization: Custom specifications can drive up costs. Buyers should assess whether the additional features justify the increased price or if standard options suffice.

-

Materials and Quality Certifications: Products made from superior materials or those that meet specific quality certifications will typically cost more. Investing in higher-quality products can lead to better performance and lower maintenance costs in the long run.

-

Supplier Factors: The supplier’s reputation, production capacity, and reliability can influence pricing. Engaging with established suppliers may provide assurance of quality but could come at a premium.

-

Incoterms: The choice of Incoterms affects the distribution of shipping costs and responsibilities. Understanding these terms can help buyers optimize their logistics costs.

What Are Effective Buyer Tips for Cost-Efficiency in ‘max 80’ Sourcing?

To maximize cost-efficiency when sourcing ‘max 80’ products, consider these tips:

-

Negotiation Strategies: Always be prepared to negotiate pricing and terms. Understanding the supplier’s cost structure can provide leverage during discussions.

-

Total Cost of Ownership (TCO): Evaluate the total cost of ownership, including acquisition, operation, and disposal costs. Sometimes, a higher initial investment can lead to lower long-term costs due to durability and performance.

-

Pricing Nuances for International Buyers: B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and import tariffs that can affect final costs. Conducting thorough market research can help mitigate these risks.

-

Supplier Diversification: Engaging multiple suppliers can foster competition, potentially lowering prices and improving service quality.

-

Regular Market Analysis: Stay updated on market trends and pricing shifts to ensure that you are getting the best value for your investment.

Disclaimer on Indicative Prices

The prices mentioned for ‘max 80’ products are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always confirm current pricing directly with suppliers to ensure accuracy.

Alternatives Analysis: Comparing max 80 With Other Solutions

Understanding the Importance of Alternative Solutions in the B2B Space

In today’s competitive landscape, understanding the alternatives to any product or solution is crucial for B2B buyers. This is particularly relevant when evaluating the KBS MAX 80 shaft, a lightweight option designed for mid to high handicap golfers seeking improved performance from their irons. By comparing it to other viable alternatives, businesses can make informed decisions that align with their unique requirements, budget, and operational capabilities.

Comparison Table

| Comparison Aspect | Max 80 | Apollo Acculite 85 | True Temper Command |

|---|---|---|---|

| Performance | High trajectory and spin | Moderate trajectory, lower spin | Balanced performance across various shots |

| Cost | $34.95 | $12.99 | $10.99 |

| Ease of Implementation | Requires trimming; moderate | Simple installation | Easy installation |

| Maintenance | Low maintenance | Low maintenance | Low maintenance |

| Best Use Case | Ideal for mid-high handicaps | Budget-conscious players | Versatile for all skill levels |

What Are the Benefits and Drawbacks of Apollo Acculite 85?

The Apollo Acculite 85 is a cost-effective alternative to the KBS MAX 80, priced at just $12.99. This shaft is designed for budget-conscious players who still want a decent level of performance. However, it offers a moderate trajectory and lower spin rates compared to the MAX 80. This may limit its effectiveness for golfers looking to maximize distance and control. Its simple installation process makes it a convenient option, but it may not satisfy advanced players seeking specialized performance enhancements.

How Does True Temper Command Compare?

True Temper Command shafts are another viable alternative, priced at $10.99. They provide balanced performance across various shots, making them versatile for all skill levels. Their easy installation process is an added advantage for users looking for quick implementation. However, while they are cost-effective and practical, they may lack the high trajectory and spin rates offered by the KBS MAX 80. This could be a drawback for players aiming for specific shot dynamics.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting a golf shaft like the KBS MAX 80 or its alternatives, B2B buyers should consider their specific needs and circumstances. If budget constraints are a primary concern, options like the Apollo Acculite 85 or True Temper Command provide cost savings while still delivering acceptable performance. However, for those who prioritize high trajectory and spin for mid to high handicap players, the KBS MAX 80 may be the superior choice despite its higher price point. Ultimately, the decision should align with the buyer’s performance requirements, budget, and ease of use, ensuring the best possible outcome for their golfing experience.

Essential Technical Properties and Trade Terminology for max 80

What Are the Key Technical Properties of MAX 80 Products?

Understanding the technical properties of MAX 80 products is essential for B2B buyers looking to make informed purchasing decisions. Here are some critical specifications that define the MAX 80 steel shafts and fuses:

-

Material Grade: The MAX 80 steel shafts are often made from high-grade steel, ensuring durability and performance. Material grade impacts the strength and flexibility of the shaft, which is crucial for golfers seeking enhanced distance and control in their game. For fuses, the material used can affect conductivity and heat resistance, which are vital for safe electrical applications.

-

Tip Diameter: The tip diameter for the MAX 80 steel shafts is typically .370 inches. This specification is vital for compatibility with various clubs. A precise tip diameter ensures proper fit and performance, enabling the shaft to perform optimally with the club head.

-

Weight: The MAX 80 steel shaft weighs approximately 111 grams. Weight affects swing speed and control; lighter shafts can increase swing speed, while heavier shafts may offer more control. B2B buyers must consider the weight in relation to the target user’s skill level and playing style.

-

Flexibility (Flex): Available in Regular, Stiff, and X-Stiff options, the flex of the shaft is tailored to different player abilities. Flexibility impacts the trajectory and spin of the ball, making it a critical factor for performance. Choosing the right flex can significantly affect a player’s game, making it essential for buyers to understand their customer’s needs.

-

Length: The standard length of the MAX 80 shaft is around 43 inches. Length influences leverage and control during swings. Buyers should evaluate the preferred club length for their target markets to ensure optimal performance.

-

Finish: The chrome finish on the MAX 80 shafts not only provides aesthetic appeal but also offers corrosion resistance. This property is important for maintaining the integrity of the product over time, especially in humid or wet conditions.

What Are the Common Trade Terms Associated with MAX 80?

Navigating the B2B landscape requires familiarity with specific trade terminology. Here are some common terms related to MAX 80 products:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for B2B buyers when sourcing components for their products.

-

MOQ (Minimum Order Quantity): MOQ denotes the minimum quantity a supplier is willing to sell. Knowing the MOQ helps buyers plan their inventory and manage costs effectively, ensuring they do not overcommit to unnecessary stock.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing information for specific products. This process is essential for buyers to compare costs and negotiate terms, ensuring they receive the best deal.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, risk management, and cost allocation.

-

Lead Time: This term indicates the time required from placing an order to delivery. Understanding lead times is crucial for inventory management and ensuring timely product availability.

-

Certification: Many MAX 80 products, particularly electrical components, may require compliance with specific industry standards or certifications. Certifications ensure that products meet safety and quality requirements, which is vital for B2B buyers to ensure reliability and compliance in their operations.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategies and foster stronger supplier relationships. Understanding these elements not only aids in decision-making but also aligns product offerings with market demands.

Navigating Market Dynamics and Sourcing Trends in the max 80 Sector

What Are the Current Market Dynamics and Key Trends Influencing the Max 80 Sector?

The Max 80 sector, particularly in the context of golf equipment and electrical components, is experiencing notable shifts driven by technological advancements and changing consumer preferences. Global drivers include a growing emphasis on performance enhancement in sports equipment, such as lightweight golf shafts designed for mid-high handicap players. This trend is complemented by the increasing popularity of custom-fitted equipment, where B2B buyers seek specific specifications to meet regional player needs, especially in emerging markets like Africa and South America.

In the electrical components arena, the demand for high-performance fuses, such as the Bussmann series MAX-80, reflects a broader trend toward reliability and safety in electrical systems. Buyers are increasingly focusing on suppliers that offer innovative solutions to power management challenges, particularly in regions undergoing rapid industrialization.

Emerging technologies, such as digital platforms for sourcing and supply chain management, are also reshaping how international B2B buyers engage with suppliers. Businesses are leveraging data analytics for better inventory management and demand forecasting, enhancing their ability to respond to market fluctuations swiftly.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in the Max 80 Sector?

Sustainability is becoming a pivotal consideration for B2B buyers in the Max 80 sector. The environmental impact of manufacturing processes, particularly in the production of golf shafts and electrical components, necessitates a focus on reducing carbon footprints and waste. Buyers should prioritize suppliers that demonstrate a commitment to sustainable practices, such as using recycled materials or implementing energy-efficient production methods.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers for adherence to labor standards and environmental regulations. Certifications such as ISO 14001 for environmental management or Fair Trade can serve as indicators of a supplier’s commitment to ethical practices.

In the context of the Max 80 products, utilizing ‘green’ materials not only meets regulatory requirements but also appeals to environmentally conscious consumers. As markets in Europe and North America push for more sustainable options, B2B buyers sourcing from these regions should be proactive in seeking suppliers who align with these values.

What Has Been the Evolution of the Max 80 Sector Over Time?

The Max 80 sector has evolved significantly, transitioning from traditional manufacturing practices to a more innovative and technology-driven landscape. Initially dominated by standard specifications and mass production, the focus has shifted towards customization and performance optimization, particularly in golf equipment. This evolution mirrors broader trends in consumer demand for personalized products that enhance user experience.

In the electrical components segment, advancements in materials science have enabled the development of more efficient and reliable products, such as the MAX-80 fuse. As industries evolve, the Max 80 sector continues to adapt, ensuring that it meets the diverse needs of international B2B buyers, particularly those in emerging markets looking for quality and performance.

In summary, understanding these dynamics will empower B2B buyers to make informed sourcing decisions that not only enhance their product offerings but also align with global sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of max 80

-

How do I choose the right MAX 80 product for my needs?

To select the appropriate MAX 80 product, first identify your specific requirements, such as performance characteristics and application context. For example, if you’re sourcing iron shafts for mid-high handicap players, the KBS MAX 80 Steel, known for its lightweight design and high trajectory, may be ideal. Conduct thorough research on the specifications, including flex options and materials, and consult with your suppliers to ensure alignment with your performance goals. -

What are the key specifications to consider when sourcing MAX 80 products?

When sourcing MAX 80 products, consider specifications like weight, tip diameter, flex options (Regular, Stiff, X-Stiff), and length. For instance, the KBS MAX 80 shaft has a weight of 111g and a .370″ tip diameter, which influences its performance. Additionally, assess the finish and quality of materials, as these factors directly impact durability and user satisfaction. Ensure that the product meets relevant standards for your region. -

How can I verify the credibility of a supplier for MAX 80 products?

To verify a supplier’s credibility, start by checking their industry reputation through online reviews and testimonials. Request references from previous clients and assess their experience in international trade, particularly with businesses in your region. Additionally, examine their compliance with international quality standards and certifications. A reliable supplier should be transparent about their sourcing processes, manufacturing capabilities, and provide detailed product information. -

What are the minimum order quantities (MOQ) for MAX 80 products?

Minimum order quantities (MOQ) for MAX 80 products can vary significantly between suppliers and product types. Typically, for specialized items like golf shafts or electrical components, MOQs might range from 50 to 500 units. Always clarify MOQs during initial discussions to avoid potential complications in your procurement process. Some suppliers may offer flexibility based on your specific needs or long-term partnership agreements. -

What payment terms should I expect when sourcing MAX 80 products internationally?

Payment terms for international B2B transactions can vary widely, but common practices include payment in advance, letters of credit, or net 30/60 terms. It’s crucial to discuss and agree upon payment methods with your supplier early in negotiations. Understanding the currency exchange rates and potential transaction fees is also essential to avoid unexpected costs. Always ensure that the payment terms are documented in your contract for clarity and protection. -

How do I ensure quality assurance for MAX 80 products?

To ensure quality assurance, request detailed product specifications and certifications from your supplier. Conduct factory audits if possible, or utilize third-party inspection services to verify product quality before shipment. Establish clear quality standards in your contracts and specify penalties for non-compliance. Regular communication with your supplier regarding quality expectations can also help maintain high standards throughout the production process. -

What logistics considerations should I keep in mind when importing MAX 80 products?

Logistics considerations for importing MAX 80 products include understanding shipping options, lead times, and customs regulations. Assess whether air freight or sea freight is more suitable based on urgency and cost-effectiveness. Ensure you are aware of any tariffs or import duties applicable to your products in your country. Collaborating with a reliable logistics partner can help streamline the import process and mitigate potential delays. -

How can I customize MAX 80 products to fit my specific requirements?

Customization options for MAX 80 products may include alterations in length, flex, and finishing options. When discussing customization with your supplier, provide detailed specifications and any necessary design files. Be prepared for potential minimum order quantities for customized items. Additionally, inquire about lead times for custom orders and request samples if possible, to ensure the final product meets your expectations before full-scale production.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Max 80 Manufacturers & Suppliers List

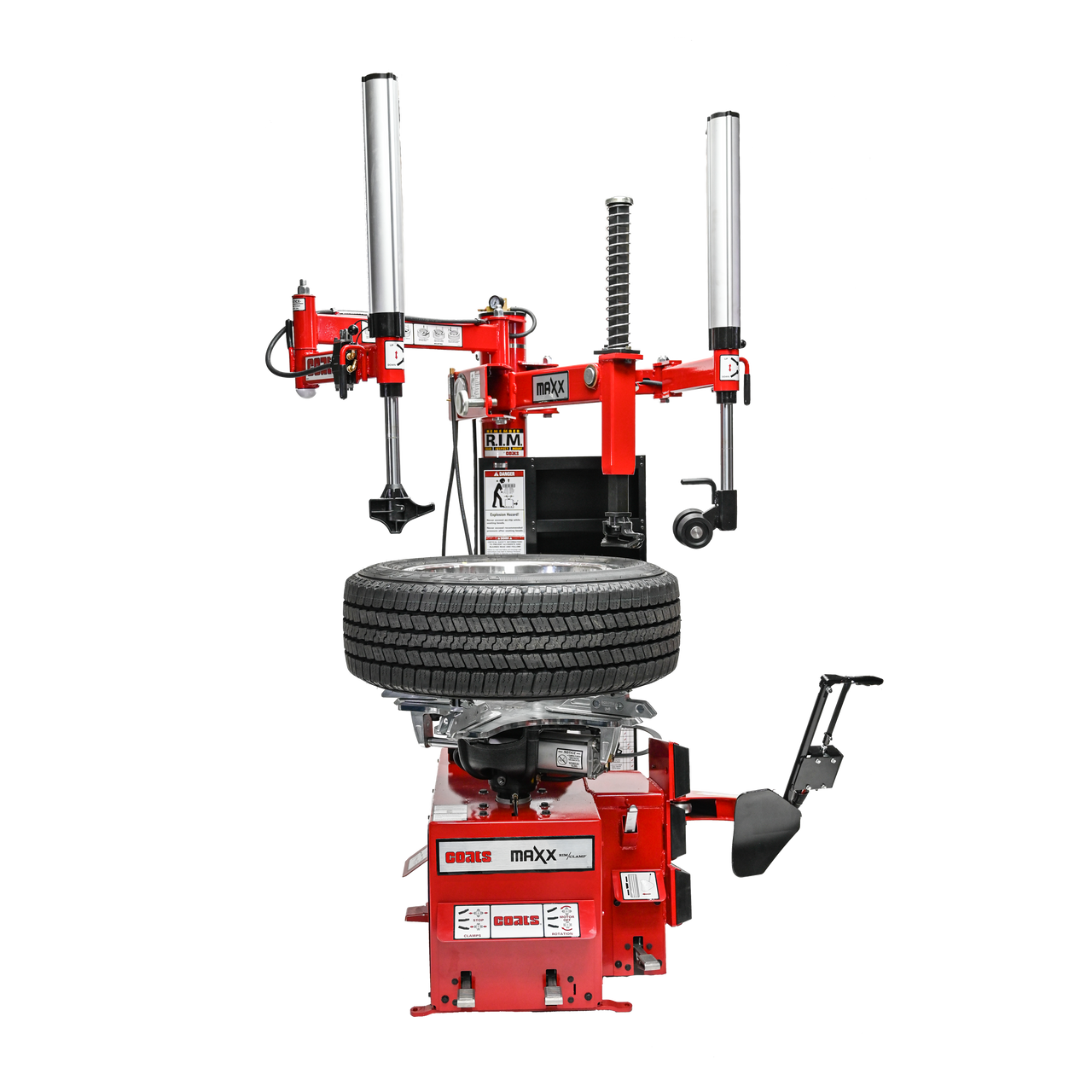

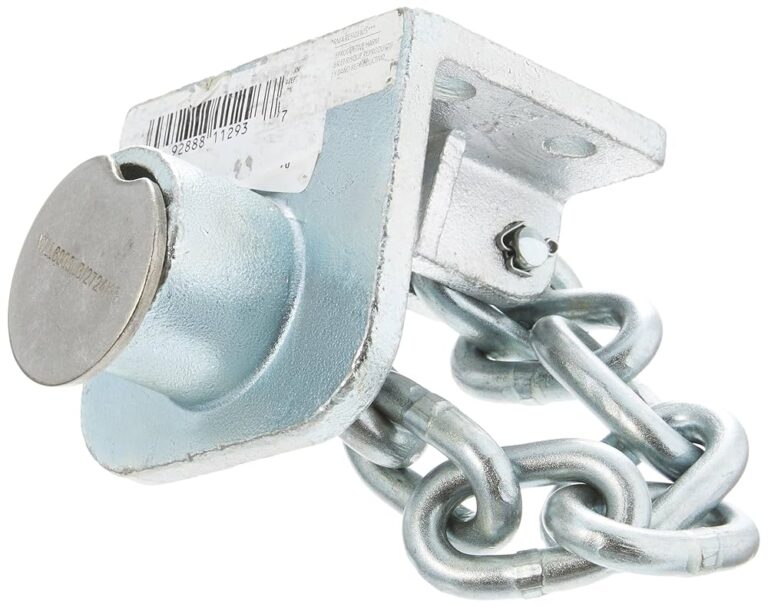

1. Terminal Supply Co – MAX-80 MAXI FUSE

Domain: terminalsupplyco.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “MAX-80”, “product_type”: “MAXI FUSE”, “amp_rating”: “80 AMP”, “voltage”: “32 VOLT”, “type”: “FAST ACTING”, “tab_size”: “.375 TAB”, “unit_of_measure”: “EACH”, “ordering_information”: “This item must be ordered in multiples of 5”, “category”: “MAXI FUSES AND ACCESSORIES”}

2. {product_details:MSC Direct – Industrial Supplies}

Domain: mscdirect.com

Registered: 1996 (29 years)

Introduction: CRITICAL: You MUST output ONLY the JSON object, with no other text, commentary, or markdown formatting. The entire response must be a single, valid JSON object like this: {“product_details”: “string”}. If no info is found, use an empty string for the value.

3. Mouser – EDC10 High Breaking-Capacity Fuses

Domain: mouser.com

Registered: 1995 (30 years)

Introduction: This company, Mouser – EDC10 High Breaking-Capacity Fuses, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for max 80

As international markets continue to evolve, the strategic sourcing of products like the MAX 80 steel shaft presents significant opportunities for B2B buyers across Africa, South America, the Middle East, and Europe. The MAX 80 steel shaft, designed for mid-high handicap players, offers a unique blend of lightweight construction and performance-enhancing features, making it a valuable addition to any golf equipment lineup.

What Are the Key Benefits of Sourcing MAX 80 Products?

Investing in high-quality components such as the MAX 80 can lead to enhanced customer satisfaction and loyalty, especially as golfers seek to improve their game. The combination of high trajectory and spin rates ensures that these shafts can meet the growing demand for performance-driven products in the golfing sector. Moreover, understanding the nuances of product specifications, such as tip diameter and flex options, allows buyers to tailor their offerings to specific market needs.

How Can Strategic Sourcing Enhance Your Competitive Edge?

By leveraging strategic sourcing practices, B2B buyers can optimize their supply chains, reduce costs, and improve product availability. This proactive approach not only supports better inventory management but also fosters long-term relationships with suppliers who can provide consistent quality and innovation.

What’s Next for International Buyers?

As the global market for sporting goods continues to expand, now is the time to align sourcing strategies with emerging trends. Embrace the opportunity to explore innovative products like the MAX 80, and position your business for sustained growth. Engage with trusted suppliers today to maximize your competitive edge and meet the diverse needs of your clientele.