Safety Latch: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for safety latch

In today’s global marketplace, sourcing reliable safety latches presents a significant challenge for international B2B buyers. As industries increasingly prioritize safety and compliance, understanding the diverse types of safety latches and their applications becomes crucial. This guide aims to demystify the safety latch market by covering various categories, including flipper latches, trigger latches, and heavy-duty options. Additionally, we delve into supplier vetting processes, cost considerations, and best practices for ensuring compliance with international safety standards.

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe—specifically countries like Brazil and Nigeria—this comprehensive resource is designed to empower informed purchasing decisions. With a clear focus on actionable insights, we provide guidance on selecting the right safety latch for specific applications, enabling businesses to enhance their operational safety measures effectively.

Understanding the nuances of safety latches not only helps mitigate risks associated with load disengagement but also fosters compliance with local and international regulations. By leveraging the information within this guide, buyers can navigate the complexities of the global safety latch market, ensuring they choose solutions that meet their unique needs while supporting their business objectives.

Understanding safety latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

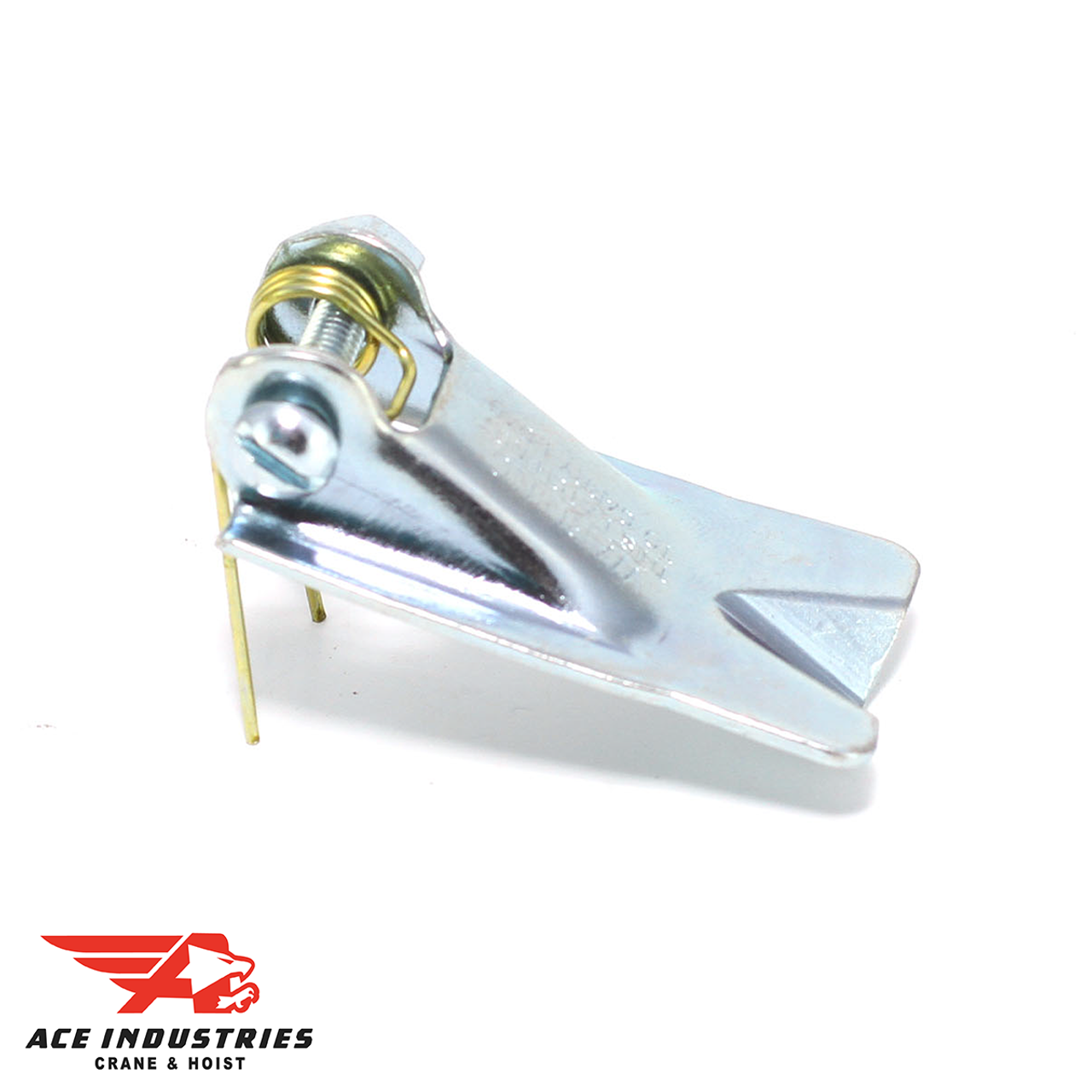

| Flipper Latch | Spring-loaded, pivots over hook opening | General rigging and lifting operations | Pros: Easy to use, prevents accidental disengagement. Cons: May wear out over time. |

| Trigger Latch | Self-locking with a trigger release mechanism | Overhead lifting and crane operations | Pros: Automatic engagement enhances safety. Cons: More complex mechanism can lead to maintenance issues. |

| Heavy-Duty Crane Hook Latch | Reinforced design for high-load applications | Heavy industrial and construction sectors | Pros: High durability for heavy loads. Cons: Higher initial investment. |

| Universal Latch Kit | Adaptable to various hook sizes | Versatile across multiple applications | Pros: Cost-effective and flexible. Cons: May not fit all specific requirements perfectly. |

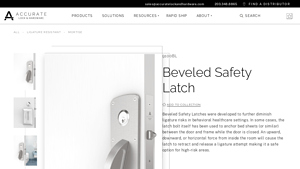

| Beveled Safety Latch | Designed to minimize ligature risks | Healthcare facilities and behavioral settings | Pros: Enhances safety in sensitive environments. Cons: Specialized use limits broader application. |

What are the Characteristics of Flipper Latches and Their B2B Suitability?

Flipper latches are designed with a spring-loaded mechanism that pivots over the hook opening, providing a secure closure that prevents accidental load disengagement. These latches are commonly used in general rigging and lifting operations, making them suitable for diverse industries. When purchasing flipper latches, buyers should consider the load capacity, material durability, and compatibility with existing hardware to ensure optimal performance.

How Do Trigger Latches Enhance Safety in Overhead Lifting?

Trigger latches feature a self-locking design that engages automatically under load, requiring a manual trigger release for operation. This design is particularly beneficial in overhead lifting and crane operations, where safety is paramount. B2B buyers should focus on the reliability of the locking mechanism and ease of use when selecting trigger latches, as these factors significantly impact operational efficiency and safety compliance.

Why Choose Heavy-Duty Crane Hook Latches for Industrial Applications?

Heavy-duty crane hook latches are specifically engineered to withstand high-load applications, making them ideal for use in heavy industrial and construction settings. Their reinforced design ensures longevity and reliability under strenuous conditions. Buyers in these sectors should evaluate the latch’s load rating and material quality to match their operational demands and minimize downtime due to equipment failure.

What Advantages Do Universal Latch Kits Offer for Diverse Applications?

Universal latch kits are designed to accommodate various hook sizes, providing a versatile solution for businesses that utilize multiple rigging systems. Their adaptability makes them a cost-effective choice for companies looking to streamline their inventory. When purchasing universal latches, buyers should assess the compatibility with their specific hooks and the overall quality to avoid performance issues.

In What Situations are Beveled Safety Latches Most Effective?

Beveled safety latches are engineered to reduce ligature risks, making them particularly valuable in healthcare facilities and behavioral settings. Their unique design enhances safety for vulnerable populations. B2B buyers in these sectors must consider the latch’s effectiveness in reducing risks, alongside compliance with safety regulations, to ensure a secure environment for all users.

Key Industrial Applications of safety latch

| Industry/Sector | Specific Application of Safety Latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Securing lifting equipment during transport | Enhances safety by preventing accidental load drop | Compliance with international safety standards |

| Oil & Gas | Locking valves and equipment in hazardous areas | Reduces risk of leaks and accidents | Material durability and resistance to harsh environments |

| Manufacturing & Warehousing | Ensuring safety on conveyor systems | Minimizes workplace injuries and operational downtime | Compatibility with existing systems and equipment |

| Transportation & Logistics | Securing cargo in transit | Protects goods from damage and loss | Weight capacity and environmental resistance |

| Healthcare | Safety latches on medical equipment cabinets | Prevents unauthorized access and enhances safety | Compliance with healthcare regulations and standards |

How Are Safety Latches Used in the Construction Industry?

In the construction sector, safety latches are crucial for securing lifting equipment, such as hooks and slings, during transport and operation. By preventing accidental disengagement of loads, safety latches enhance overall site safety and compliance with regulations. Buyers in this industry must ensure that the latches meet international safety standards and can withstand the rigors of construction environments, particularly in regions like Africa and South America where conditions can be challenging.

Illustrative image related to safety latch

What Role Do Safety Latches Play in the Oil & Gas Sector?

In the oil and gas industry, safety latches are employed to lock valves and secure equipment in hazardous areas, significantly mitigating the risk of leaks and accidents. These latches must be robust and resistant to corrosive substances, which are prevalent in this sector. For international buyers, sourcing latches that comply with safety and environmental regulations is essential, especially in regions like the Middle East, where operational safety is paramount.

How Are Safety Latches Essential in Manufacturing & Warehousing?

In manufacturing and warehousing environments, safety latches are vital for ensuring the secure operation of conveyor systems. They help prevent workplace injuries by ensuring that moving parts are properly secured, thereby minimizing the risk of accidents. Buyers should consider the compatibility of latches with existing systems and the specific safety certifications required in their regions, such as in Europe, where regulations can be stringent.

Why Are Safety Latches Important in Transportation & Logistics?

Transportation and logistics rely heavily on safety latches to secure cargo during transit, protecting goods from damage and loss. The proper use of latches ensures that loads remain stable and secure throughout the journey, which is critical for maintaining delivery schedules and customer satisfaction. Businesses must focus on the weight capacity and environmental resistance of latches, particularly in regions like Brazil and Nigeria, where transport conditions can vary widely.

What Are the Benefits of Safety Latches in Healthcare Settings?

In healthcare, safety latches are utilized on medical equipment cabinets to prevent unauthorized access and enhance patient safety. They play a critical role in safeguarding sensitive materials and ensuring compliance with healthcare regulations. Buyers in this sector should prioritize latches that meet stringent health and safety standards, particularly in European markets where regulatory compliance is rigorously enforced.

3 Common User Pain Points for ‘safety latch’ & Their Solutions

Scenario 1: Inconsistent Safety Standards Across Regions

The Problem: B2B buyers often face the challenge of varying safety standards for safety latches in different regions. For instance, a company based in Nigeria may find that the specifications for safety latches in local regulations differ significantly from those in Europe or South America. This inconsistency can lead to compliance issues, increased liability, and potential fines if the wrong type of latch is used for specific applications. Buyers may also struggle with ensuring that their products meet international safety standards, which can complicate sourcing and distribution.

The Solution: To navigate these complexities, buyers should prioritize sourcing safety latches from manufacturers who provide comprehensive documentation on compliance with regional safety standards. When evaluating suppliers, look for those who offer a wide range of latch types tailored to different applications, such as flipper latches, trigger latches, and heavy-duty options. Additionally, consider engaging with local regulatory bodies or industry associations to stay informed about the latest compliance requirements. Establishing relationships with reliable suppliers who have experience in your target markets can also help streamline the process of ensuring compliance across borders.

Scenario 2: Difficulties in Finding Replacement Parts

The Problem: Another common pain point for B2B buyers is the difficulty in sourcing replacement parts for safety latches, especially in industries that rely on specific models or brands. For example, a construction company using specialized rigging hardware may experience downtime when a safety latch breaks and cannot find an exact replacement quickly. This situation not only disrupts operations but can also lead to significant financial losses due to project delays.

The Solution: To mitigate this issue, businesses should maintain an inventory of critical replacement parts for safety latches that are frequently used in their operations. Conducting a thorough audit of the latches in use and identifying common failure points can help determine which replacement parts should be stocked. Furthermore, establishing a partnership with a supplier that offers a comprehensive range of latch kits and replacement components can ensure that parts are readily available when needed. Online platforms that allow for easy ordering and quick shipping can also significantly reduce lead times.

Scenario 3: Ensuring Proper Installation and Maintenance

The Problem: Proper installation and ongoing maintenance of safety latches are crucial for ensuring their effectiveness, yet many B2B buyers struggle with this aspect. Inadequate installation can lead to malfunctioning latches, which may compromise safety during lifting or securing loads. Additionally, maintenance schedules may be overlooked, resulting in wear and tear that goes unnoticed until it’s too late. This oversight can not only pose safety risks but also lead to costly repairs and liability issues.

Illustrative image related to safety latch

The Solution: Buyers should invest in training for their staff on the correct installation and maintenance procedures for safety latches. Suppliers that provide educational resources, such as installation manuals, instructional videos, or on-site training, can be invaluable. Regularly scheduled maintenance checks should also be established to inspect latches for signs of wear, ensuring they function correctly. Implementing a maintenance log can help track inspections and repairs, creating a proactive approach to latch management. This not only enhances safety but can also prolong the lifespan of the hardware, ultimately saving costs in the long run.

Strategic Material Selection Guide for safety latch

When selecting materials for safety latches, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in safety latch manufacturing, along with their properties, advantages, disadvantages, and specific considerations for buyers in regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Carbon Steel for Safety Latches?

Carbon steel is a popular choice for safety latches due to its high strength and versatility. It typically has a temperature rating of up to 300°F (149°C) and can withstand considerable pressure, making it suitable for heavy-duty applications. Additionally, carbon steel can be treated with coatings to enhance its corrosion resistance.

Pros: Carbon steel latches are generally cost-effective and durable, making them suitable for a wide range of applications. Their strength is ideal for environments where heavy loads are common.

Cons: However, they are prone to rust and corrosion if not properly coated or maintained, which can limit their lifespan in harsh environments. Manufacturing complexity can increase if additional treatments are required.

Impact on Application: Carbon steel latches are compatible with various media, but their susceptibility to corrosion makes them less suitable for environments with high humidity or exposure to chemicals.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A36 for structural steel and consider the availability of protective coatings that meet local regulations.

How Does Stainless Steel Enhance Safety Latch Performance?

Stainless steel is known for its excellent corrosion resistance, making it ideal for safety latches used in environments prone to moisture or chemicals. With a temperature rating often exceeding 500°F (260°C), stainless steel latches can perform well under extreme conditions.

Pros: The durability and aesthetic appeal of stainless steel make it a preferred choice for applications requiring both functionality and visual appeal. Its resistance to rust ensures a longer lifespan.

Cons: The primary drawback is its higher cost compared to carbon steel. Additionally, while stainless steel is strong, it may not support as heavy a load as some carbon steel alternatives without increasing thickness.

Impact on Application: Stainless steel latches are suitable for food processing, marine, and chemical industries due to their non-reactive nature.

Considerations for International Buyers: Compliance with standards such as ASTM A240 for stainless steel and EN 10088 is crucial. Buyers should also consider the availability of grades suitable for specific applications.

What Role Does Aluminum Play in Safety Latch Applications?

Aluminum is lightweight yet strong, making it an attractive option for safety latches in applications where weight is a critical factor. It typically has a temperature rating of around 400°F (204°C) and offers decent corrosion resistance, especially when anodized.

Pros: The lightweight nature of aluminum latches facilitates easier handling and installation. They are also resistant to corrosion, particularly when treated.

Cons: However, aluminum latches may not be as durable under heavy loads compared to steel alternatives. They can also be more expensive than carbon steel options.

Impact on Application: Aluminum is suitable for applications in the aerospace and automotive industries, where weight savings are essential.

Considerations for International Buyers: Buyers should verify compliance with standards such as ASTM B221 for aluminum extrusions and consider local preferences for specific alloys.

Illustrative image related to safety latch

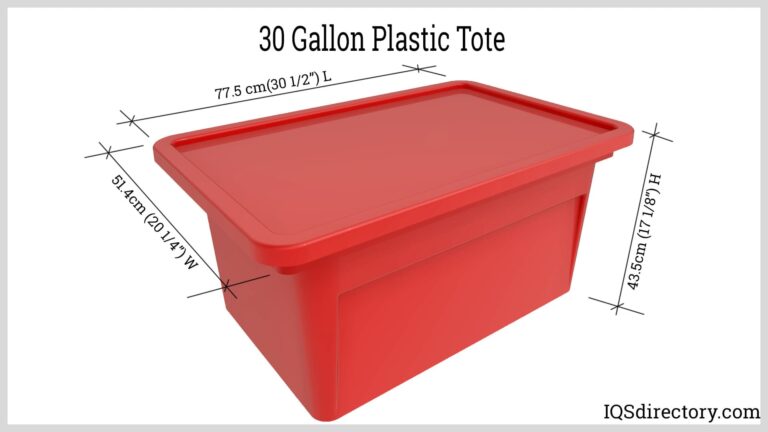

How Does Plastic Compare as a Material for Safety Latches?

Plastic safety latches are increasingly used in applications requiring lightweight and corrosion-resistant solutions. They can typically withstand temperatures up to 200°F (93°C) and are resistant to many chemicals.

Pros: The primary advantage of plastic latches is their resistance to corrosion and low weight, making them easy to install and maintain. They are also cost-effective for low-load applications.

Cons: However, plastic latches may not be suitable for high-stress applications due to lower strength compared to metal alternatives. They can also degrade under UV exposure unless specifically treated.

Impact on Application: Plastic latches are ideal for indoor applications or environments where exposure to moisture and chemicals is minimal.

Considerations for International Buyers: Compliance with safety standards, such as ASTM D638 for tensile properties of plastics, is essential. Buyers should also consider the impact of temperature and UV exposure on the material’s longevity.

Summary Table of Material Selection for Safety Latches

| Material | Typical Use Case for Safety Latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Heavy-duty applications | Cost-effective and durable | Prone to rust without proper coating | Low |

| Stainless Steel | Food processing, marine | Excellent corrosion resistance | Higher cost compared to carbon steel | High |

| Aluminum | Aerospace, automotive | Lightweight and easy to handle | Less durable under heavy loads | Medium |

| Plastic | Indoor applications | Corrosion-resistant and cost-effective | Not suitable for high-stress applications | Low |

This guide should assist international B2B buyers in making informed decisions regarding material selection for safety latches, ensuring compliance with local standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for safety latch

What Are the Key Stages in the Manufacturing Process of Safety Latches?

The manufacturing of safety latches involves several critical stages, each ensuring that the final product meets safety and performance standards.

-

Material Preparation: The initial stage involves selecting high-quality materials, typically steel or stainless steel, to ensure strength and durability. Suppliers must verify the material’s grade and specifications to comply with industry standards. This stage may include processes like cutting and pre-forming, where raw materials are processed into manageable sizes for further shaping.

-

Forming: This stage utilizes techniques such as forging, casting, or machining to create the basic shape of the latch. Forging is particularly favored for its ability to produce strong, resilient components. For instance, hot forging can enhance the material’s grain structure, resulting in improved toughness. CNC machining may also be employed for precision components, ensuring that each latch fits perfectly with its intended application.

-

Assembly: Once formed, the components are assembled. This may involve welding or riveting to create a complete latch system. In some cases, additional features such as spring mechanisms or locking systems are integrated during this stage. Careful attention to detail is crucial, as any misalignment can compromise the latch’s effectiveness.

-

Finishing: The final stage involves surface treatments to enhance corrosion resistance and aesthetics. Processes like galvanizing, powder coating, or anodizing can be employed. This not only prolongs the latch’s lifespan but also complies with specific industry standards regarding corrosion resistance, especially for applications in harsh environments.

How Is Quality Assurance Implemented in Safety Latch Manufacturing?

Quality assurance (QA) is a cornerstone of safety latch manufacturing, ensuring that products meet the required standards and specifications.

-

What International Standards Should Buyers Be Aware Of?

Key international standards such as ISO 9001 for quality management systems are essential for manufacturers aiming to demonstrate their commitment to quality. Additionally, specific industry standards, like the CE marking in Europe or API specifications for oil and gas applications, can be critical indicators of compliance for safety latches. -

What Are the QC Checkpoints During Production?

Quality control (QC) checkpoints are integrated throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials for compliance with specifications before production begins.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections ensure that processes are adhered to, and any deviations are addressed immediately.

– Final Quality Control (FQC): This final inspection verifies that the finished latches meet all specifications and safety standards before shipment. -

What Testing Methods Are Commonly Used?

Common testing methods include tensile strength tests, fatigue tests, and corrosion resistance tests. These assessments help determine if the latches can withstand the operational stresses they will encounter in real-world applications. Additionally, functional testing ensures that the latches operate as intended under various conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, especially from regions like Africa, South America, and the Middle East, verifying a supplier’s quality control processes is vital to ensure product reliability.

-

Conducting Audits: Buyers should consider conducting on-site audits of potential suppliers. This allows for a firsthand evaluation of manufacturing processes, quality control measures, and overall operational standards.

-

Requesting Quality Reports: Suppliers should be able to provide detailed quality reports, including results from various testing methods and compliance certifications. This documentation serves as evidence of the supplier’s commitment to maintaining high-quality standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These inspections can be particularly valuable for buyers unfamiliar with local regulations and standards.

What Are the Nuances of Quality Control for International B2B Buyers?

Understanding the nuances of quality control in international trade is crucial for buyers. Different regions may have varying safety standards and regulations, which can affect compliance.

-

Regional Standards Compliance: Buyers must be aware of the specific quality and safety standards that apply to their region. For instance, products sold in the European market must comply with CE marking regulations, while those in North America may require adherence to ANSI standards.

-

Cultural Considerations: Different cultures may influence how quality control is perceived and implemented. For instance, some regions may prioritize cost over quality, while others may have stringent adherence to quality protocols. Understanding these cultural nuances can aid buyers in selecting the right suppliers.

-

Logistical Challenges: Transporting safety latches across borders can introduce additional quality control challenges. Buyers should ensure that suppliers have robust packaging and shipping processes to prevent damage during transit, which can compromise the integrity of the latches.

Conclusion: How to Ensure Quality and Compliance in Safety Latch Procurement

In summary, B2B buyers looking to procure safety latches must navigate a complex landscape of manufacturing processes and quality assurance measures. By understanding the key stages of production, the importance of quality control, and how to effectively verify supplier compliance, buyers can make informed decisions that enhance safety and performance in their operations. Prioritizing these factors not only mitigates risks but also fosters long-term partnerships with reliable suppliers, ultimately contributing to the success of their business endeavors.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘safety latch’

In today’s competitive marketplace, sourcing safety latches efficiently is essential for ensuring operational safety and compliance. This guide offers a systematic approach to help B2B buyers navigate the procurement process, ensuring they select the right products and suppliers for their needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s critical to establish your specific requirements for safety latches. Consider factors such as load capacity, materials (e.g., stainless steel, carbon steel), and the intended application (e.g., rigging, door safety). Clearly defining these specifications will help you communicate effectively with potential suppliers and ensure you receive products that meet your operational needs.

Step 2: Research Regulatory Standards

Understanding the relevant safety and regulatory standards in your region is crucial. Different markets, such as Europe or South America, may have specific compliance requirements for safety latches. Familiarize yourself with these standards, as they will influence both your product selection and supplier assessment.

- Key Standards to Consider:

- ISO standards for rigging hardware.

- Local safety regulations that apply to your industry.

Step 3: Identify Potential Suppliers

Compile a list of suppliers who specialize in safety latches and related hardware. Look for manufacturers and distributors with a solid reputation in your target markets, including Africa, South America, and the Middle East. Utilize industry directories, trade shows, and online marketplaces to discover potential partners.

- Supplier Characteristics to Evaluate:

- Years of experience in the industry.

- Reviews and testimonials from previous clients.

Step 4: Request Product Samples

Once you have shortlisted suppliers, request samples of the safety latches you are considering. This step allows you to assess the quality, durability, and functionality of the products firsthand. Testing samples can also help ensure that the latches meet your defined specifications and regulatory standards.

Step 5: Evaluate Supplier Certifications

Before finalizing any supplier, verify their certifications and compliance with international quality standards. Certifications such as ISO 9001 can indicate that a supplier adheres to strict quality management practices. This step is vital for ensuring that you are sourcing products that are safe and reliable.

- Important Certifications to Look For:

- ISO certifications relevant to manufacturing.

- Compliance with regional safety standards.

Step 6: Negotiate Terms and Conditions

Once you have chosen a supplier, engage in negotiations regarding pricing, delivery timelines, and payment terms. Clearly outline expectations regarding product quality and after-sales support. Effective negotiation can lead to better pricing structures and more favorable terms, ensuring a mutually beneficial partnership.

Step 7: Establish a Long-Term Relationship

After successful procurement, focus on building a long-term relationship with your supplier. Regular communication, feedback, and performance evaluations will help ensure that your ongoing needs are met and that any issues can be resolved promptly. A strong partnership can lead to better service and potential cost savings over time.

By following these steps, B2B buyers can streamline their sourcing process for safety latches, ensuring they select the right products and establish reliable supplier relationships essential for operational success.

Comprehensive Cost and Pricing Analysis for safety latch Sourcing

What Are the Key Cost Components in Sourcing Safety Latches?

When sourcing safety latches, international B2B buyers must understand the various cost components that influence the final pricing. These include:

Illustrative image related to safety latch

-

Materials: The choice of materials significantly impacts costs. Common materials such as carbon steel and stainless steel are prevalent. Stainless steel typically commands a higher price due to its corrosion resistance and durability, making it a preferred choice in demanding environments.

-

Labor: Labor costs can vary based on the manufacturing location. Countries with higher labor costs may produce latches at a premium, while regions with lower labor costs can offer more competitive pricing. The complexity of the latch design can also influence labor costs.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and other operational expenses that contribute to the production process. Efficient production facilities often pass on savings to buyers.

-

Tooling: Initial tooling costs can be substantial, especially for customized or specialized latches. Buyers should consider whether they require off-the-shelf products or bespoke solutions, as this will affect the upfront investment.

-

Quality Control (QC): Ensuring that safety latches meet industry standards and regulations is crucial. Enhanced QC processes can increase costs but are essential for compliance and safety assurance.

-

Logistics: Transportation costs can fluctuate based on distance, shipping method, and logistics provider. For international buyers, understanding the nuances of shipping costs, including duties and tariffs, is vital.

-

Margin: Suppliers typically add a margin to cover their expenses and profit. This margin can vary based on the supplier’s market position, brand reputation, and product demand.

How Do Price Influencers Affect Safety Latch Costs?

Several factors can influence the pricing of safety latches:

-

Volume/MOQ: Larger order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQ) that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom latches designed for specific applications may incur higher costs due to unique material or manufacturing requirements. Standard products are generally more affordable.

-

Quality and Certifications: Products that meet higher safety and quality standards typically carry a premium price. Certifications can serve as a mark of quality but can also add to the cost.

-

Supplier Factors: The supplier’s reputation, reliability, and service offerings can impact price. Established suppliers may charge more but offer better quality assurance and customer support.

-

Incoterms: Understanding international shipping terms is essential for cost management. Different Incoterms define responsibilities for shipping costs and risks, which can influence the overall price.

What Buyer Tips Can Help Optimize Costs in Sourcing Safety Latches?

To maximize cost efficiency and value when sourcing safety latches, buyers should consider the following tips:

-

Negotiate Wisely: Engage in discussions with suppliers about pricing, especially for larger orders. Leverage volume commitments to negotiate better terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider ongoing costs such as maintenance, replacement, and potential downtime. Investing in higher-quality latches may reduce long-term expenses.

-

Understand Pricing Nuances for International Markets: For buyers in regions like Africa, South America, the Middle East, and Europe, be aware of currency fluctuations, local tariffs, and import taxes that can impact overall costs.

-

Research Multiple Suppliers: Compare prices and offerings from various suppliers to identify the best value. Look for suppliers that provide transparent pricing and detailed product specifications.

-

Stay Informed About Market Trends: Keep abreast of changes in material costs, labor rates, and industry standards that may affect pricing. This knowledge can help you make informed purchasing decisions.

Disclaimer

The prices and cost factors mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence before finalizing any procurement decisions.

Alternatives Analysis: Comparing safety latch With Other Solutions

Exploring Alternatives to Safety Latch Solutions

When considering safety mechanisms for securing loads or protecting access points, it’s essential to evaluate various solutions beyond traditional safety latches. Alternatives may offer distinct advantages or drawbacks depending on the application, environment, and specific safety requirements of your operations. This section will compare safety latches with two viable alternatives: Self-Locking Hooks and Magnetic Safety Locks.

| Comparison Aspect | Safety Latch | Self-Locking Hooks | Magnetic Safety Locks |

|---|---|---|---|

| Performance | High reliability in securing loads; prevents accidental disengagement. | Automatically engages under load; highly secure. | Strong hold; quick release when needed, but can fail if power is lost. |

| Cost | Generally low to moderate; cost-effective for bulk purchases. | Moderate; depends on brand and load capacity. | Higher initial investment for installation and equipment. |

| Ease of Implementation | Simple installation; requires minimal training. | Typically straightforward but may need specific fitting. | Requires professional installation for optimal effectiveness. |

| Maintenance | Low; periodic inspections recommended for wear and tear. | Low; minimal maintenance needed, just regular checks. | Moderate; regular checks necessary to ensure magnetic integrity and power supply. |

| Best Use Case | Ideal for rigging and lifting applications where safety is paramount. | Best for heavy lifting where automatic engagement is beneficial. | Suitable for access control where quick release and secure locking are needed. |

Understanding Self-Locking Hooks: Advantages and Disadvantages

Self-locking hooks are designed to engage automatically when a load is applied, providing an extra layer of security. These hooks are particularly advantageous in environments where safety is critical, such as construction or industrial settings. Their automatic engagement reduces the risk of human error, making them ideal for high-stakes lifting operations. However, they can be more expensive than traditional safety latches, and if not properly fitted, may not perform optimally.

Evaluating Magnetic Safety Locks: Pros and Cons

Magnetic safety locks utilize a powerful magnet to secure doors or access points. They are favored in environments that require quick access while maintaining security, such as hospitals or sensitive facilities. One of their main benefits is the ease of access they provide when needed; however, they can be vulnerable in power outages, as their locking mechanism relies on an electrical source. Additionally, the installation process may require professional assistance, adding to initial costs.

Conclusion: Selecting the Right Safety Solution for Your Needs

Choosing the right safety mechanism depends largely on your specific operational needs, budget, and safety requirements. Safety latches are an excellent choice for traditional rigging applications, offering reliability and cost-effectiveness. In contrast, self-locking hooks and magnetic safety locks may provide enhanced security and convenience in specialized environments. By carefully evaluating these alternatives based on performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions that enhance safety and operational efficiency in their organizations.

Essential Technical Properties and Trade Terminology for safety latch

What Are the Key Technical Properties of Safety Latches?

Understanding the technical specifications of safety latches is crucial for ensuring product reliability and compliance with industry standards. Here are several essential properties that B2B buyers should consider:

-

Material Grade

Safety latches are typically made from materials like carbon steel, stainless steel, or alloy steel. The material grade affects strength, durability, and resistance to corrosion. For example, stainless steel latches are preferable in marine environments due to their resistance to rust, while carbon steel latches may be more cost-effective for less corrosive settings. -

Load Capacity

This specification indicates the maximum weight a safety latch can securely hold. Load capacity is critical in applications where safety is paramount, such as rigging and lifting operations. Buyers should ensure that the latch’s load capacity meets or exceeds the requirements of their specific application to prevent accidents and equipment failures. -

Tolerance Levels

Tolerance refers to the acceptable deviation in dimensions during manufacturing. Tight tolerances are essential for ensuring that safety latches fit perfectly with their corresponding hardware, which is vital for maintaining safety standards. Latches with poor tolerance may lead to misalignment, increasing the risk of failure. -

Finish and Coating

The finish or coating on a safety latch can affect its resistance to wear and corrosion. Options such as powder coating or galvanization can enhance durability, particularly in harsh environments. B2B buyers should assess the environmental conditions of their application to select the appropriate finish that offers long-term performance. -

Certification Standards

Many safety latches are manufactured in compliance with industry standards such as ASTM, OSHA, or ISO. Certification ensures that the product meets specific safety and quality benchmarks. Buyers should look for latches that have the necessary certifications to guarantee reliability and legal compliance in their operations. -

Design Type

Different types of latches, such as flipper, trigger, or heavy-duty latches, are designed for specific applications. Understanding the differences can help buyers select the right latch for their needs, ensuring optimal performance and safety.

What Are Common Trade Terms Related to Safety Latches?

Navigating the terminology in the safety latch market can be challenging. Here are some common trade terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for inventory management and financial planning, especially for businesses looking to maintain a steady supply of safety latches. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. Buyers should prepare detailed RFQs to ensure they receive accurate pricing and terms, facilitating better negotiation and procurement processes. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and manage shipping risks effectively. -

Lead Time

Lead time is the amount of time from placing an order to receiving the product. Understanding lead times can help businesses plan their operations and avoid delays in project timelines. -

After-Sales Support

This term refers to the services provided by suppliers after a product has been purchased, including installation, maintenance, and troubleshooting. Robust after-sales support can significantly enhance the overall value of a supplier relationship.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing safety latches, ultimately enhancing their operational efficiency and safety standards.

Navigating Market Dynamics and Sourcing Trends in the safety latch Sector

What Are the Key Trends Driving the Safety Latch Market?

The safety latch market is witnessing robust growth, driven by several global trends. Increasing safety regulations across industries such as construction, manufacturing, and logistics are compelling businesses to adopt high-quality safety latch solutions. In regions like Africa and South America, rapid industrialization and urbanization are leading to heightened demand for reliable safety equipment. Additionally, the rise of e-commerce and online procurement platforms is changing how businesses source safety latches, allowing for more competitive pricing and wider selection.

Emerging technologies are reshaping the safety latch sector, particularly with the integration of smart technology. Intelligent safety latches equipped with IoT capabilities are gaining traction, providing real-time monitoring and alerts to enhance operational safety. For international buyers, particularly in Europe and the Middle East, understanding these technological advancements can offer significant competitive advantages. Moreover, the trend towards customization is becoming prevalent, as businesses seek tailored solutions to meet specific safety requirements.

How Does Sustainability Influence Sourcing Decisions in the Safety Latch Sector?

Sustainability is increasingly becoming a central consideration for B2B buyers in the safety latch sector. The environmental impact of manufacturing processes and the sourcing of materials are under scrutiny, leading companies to prioritize suppliers who demonstrate a commitment to sustainable practices. This shift is not only regulatory-driven but also aligned with the growing consumer demand for eco-friendly products.

Illustrative image related to safety latch

Ethical sourcing is paramount, particularly as international supply chains face pressures from various stakeholders. Buyers are encouraged to seek suppliers who can provide transparency in their operations, showcasing adherence to ethical labor practices and sustainable material sourcing. Certifications such as ISO 14001 for environmental management and compliance with EU regulations can serve as benchmarks for responsible sourcing.

Incorporating ‘green’ materials in safety latch production, such as recycled metals and sustainable coatings, can also enhance a company’s marketability. For B2B buyers, aligning procurement strategies with sustainability goals can lead to improved brand reputation and customer loyalty.

What Is the Historical Context of Safety Latches in B2B Markets?

The evolution of safety latches can be traced back to the early days of industrialization when the need for secure and reliable fastening mechanisms became critical. Initially, safety latches were rudimentary, primarily made from basic metals and designed for specific applications. Over the decades, advancements in materials science and engineering led to the development of more sophisticated latches, including those made from high-strength alloys and corrosion-resistant materials.

The latter half of the 20th century saw a significant shift towards standardization and safety compliance, driven by regulatory frameworks that emphasized worker safety. This period marked the introduction of innovative designs such as trigger and flipper latches, which improved operational safety in rigging and lifting applications. Today, the focus has expanded beyond functionality to include aesthetics, customization, and sustainability, reflecting the dynamic needs of the modern B2B landscape.

Illustrative image related to safety latch

Overall, understanding these historical developments can provide valuable insights for international buyers looking to navigate the complexities of the safety latch market. By recognizing the trajectory of safety latch innovations, businesses can better anticipate future trends and align their sourcing strategies accordingly.

Frequently Asked Questions (FAQs) for B2B Buyers of safety latch

-

1. How do I choose the right safety latch for my application?

Choosing the right safety latch depends on several factors including the load capacity, the type of rigging or lifting operation, and the specific safety requirements of your industry. For high-load applications, consider heavy-duty latches designed for crane operations. If your operation involves frequent load engagement and disengagement, trigger latches or flipper latches may be most suitable. Additionally, ensure that the latch meets international safety standards relevant to your region, such as ISO or ANSI certifications, to guarantee reliability and compliance. -

2. What are the key features to look for in a safety latch?

When sourcing safety latches, key features to consider include durability, material (such as carbon or stainless steel), and the mechanism type (flipper, trigger, or heavy-duty). Look for latches that offer corrosion resistance, especially if used in harsh environments. Additionally, consider the ease of installation and maintenance, as well as whether the latch provides secure engagement under load to prevent accidental release. Lastly, ensure that the latch has been tested and certified according to relevant safety standards. -

3. How can I vet suppliers of safety latches internationally?

To vet suppliers of safety latches, start by checking their certifications and compliance with international standards such as ISO 9001 for quality management. Request references from other B2B buyers and assess their reputation in the industry. It’s also beneficial to review their product range to ensure they offer the specific types of latches you need. Finally, consider visiting their facilities if possible or using third-party inspection services to verify their manufacturing processes and quality assurance practices. -

4. What are the typical minimum order quantities (MOQ) for safety latches?

Minimum order quantities (MOQ) for safety latches can vary significantly by supplier and product type. Generally, MOQs can range from as low as 50 units for standard products to several hundred for custom or specialized latches. When negotiating with suppliers, inquire about the possibility of smaller orders, especially for initial trials or to meet specific project needs. Many suppliers are willing to accommodate flexible MOQs for long-term partnerships or larger subsequent orders. -

5. What payment terms should I expect when purchasing safety latches internationally?

Payment terms for international purchases of safety latches typically vary by supplier and can include options such as upfront payment, partial payment, or payment upon delivery. Common terms include 30% deposit with the order and the balance before shipment. It’s crucial to establish clear payment terms before finalizing any agreement to avoid misunderstandings. Consider using secure payment methods like letters of credit or escrow services to protect your investment in case of disputes. -

6. How do I ensure quality assurance for safety latches?

To ensure quality assurance for safety latches, request detailed product specifications and test reports from suppliers. Look for suppliers who adhere to recognized quality management systems, such as ISO certifications. Implement a quality control process that includes receiving inspections upon delivery and periodic audits of supplier practices. Additionally, consider sourcing samples for testing before placing larger orders to assess the latch’s performance and suitability for your application. -

7. What logistics considerations should I keep in mind when sourcing safety latches?

When sourcing safety latches, logistics considerations include shipping methods, lead times, and customs regulations in your country. Assess the supplier’s shipping capabilities and reliability to ensure timely delivery. Understand the import duties and taxes applicable to your region to avoid unexpected costs. It’s also beneficial to establish a clear communication channel with your supplier to track shipments and address any potential delays proactively. -

8. Are there customization options available for safety latches?

Yes, many suppliers offer customization options for safety latches to meet specific application needs. Customization can include variations in size, load capacity, materials, and latch mechanisms. When discussing customization, provide detailed specifications and requirements to the supplier. Keep in mind that custom orders may have longer lead times and higher MOQs, so plan accordingly to accommodate your project timelines.

Top 9 Safety Latch Manufacturers & Suppliers List

1. Rigging Warehouse – Key Latch Kit Products

Domain: riggingwarehouse.com

Registered: 2006 (19 years)

Introduction: Key product details for Latch Kits include: 1. AMH Replacement Latch Kits for various tonnage alloy hooks (1 Ton to 5.4 Ton) with specific model numbers (e.g., 336-ALK010 for 1 Ton Alloy Swivel Hook). 2. Cartec Latch Kits for specific roundsling hooks (e.g., CKS08 for CJ026 Purple Roundsling Hook). 3. Crosby Replacement Latch Kits for various sizes of Grade 80 Chain Hooks and Grade 8 Sling Hooks, …

2. Safety 1st – Cabinet & Drawer Latches

Domain: safety1st.com

Registered: 1995 (30 years)

Introduction: Safety 1st Cabinet & Drawer Latches – White (14 Pack)\nItem #: 483900924\nPrice: $4.99\nPack Size: 14 latches\nFeatures: \n- Helps babyproof your home\n- Wide, easy-grip surface for quick access for parents\n- Latches remain out of sight for both children and visitors\n- Simple, quick installation (Philips head screwdriver required)\n- Designed for sturdy use, suitable for clever toddlers.

3. Campbell Chain and Fittings – Latch Kits

Domain: campbellchainandfittings.com

Registered: 2014 (11 years)

Introduction: Latch Kits available for various hook sizes including: 2-22 (1/4″), 3-23 (5/16″), 4-24, 5-25 (3/8″), 6-26, 7-27, 8-28 (7/16″), 10-30, 11-31 (5/8″). Replacement Latch Kits are also offered, including a universal option for sizes 2-22 (1/4″) and 4-24.

4. McMaster – Safety Hook Latches

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Safety Hook Latches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Shiffle Equip – Door Security Latches

Domain: shifflerequip.com

Registered: 1997 (28 years)

Introduction: Door Safety Latches Products:

1. Door Security Latch, Includes Cable Lock & Holsters – fits Double Door without Mullion, 12″W x 4″D SL 4150 – $92.55

2. Door Security Latch, Includes Holster – fits Double Door without Mullion, 12″W x 4″D SL 4100 – $80.00

3. Door Security Latch – fits Double Door without Mullion, 24-1/2″W x 3-3/4″D SL 2100 – $75.60

4. Cable lock for Security Latch SL-5000 – $14.55

5…

6. Brixon – Safety Latches

Domain: brixon.com

Registered: 1998 (27 years)

Introduction: Safety Latches by Release Force: 3.9 lbs. – 17 lbs., 10 lbs. – 45 lbs., 43 lbs. – 180 lbs., 58 lbs. – 285 lbs. Materials: Stainless Steel, Cast Iron, Cast Aluminum, Cast Steel, Sparkproof Brass, Sparkproof Aluminum. Applications: Industrial Processing, Medical, Food & Beverage, Dust Collectors, Agriculture, Woodworking, Military, Aviation, Energy Storage, Industrial Coating. Features: Manual mecha…

7. LiftSupply – Latch Kits

Domain: liftsupply.com

Registered: 2006 (19 years)

Introduction: LATCH KIT – LiftSupply offers various latch kits including:

1. S-4320 Latch Repair Kit – Heavy duty stamped latch interlock with hook tip, high cycle long life spring, can be made into a positive locking hook. Price: $11.69.

2. CM Latch Repair Kit – For use with swivel, rigging, and shank hooks, zinc construction, easy to install. Price: $10.67.

3. SS-4055 Latch Kits – Crosby® stainless steel con…

8. Bishop Lifting – Latch Kits for Rigging Hooks

Domain: lifting.com

Registered: 1996 (29 years)

Introduction: Latch Kits for Rigging Hooks from Bishop Lifting. Includes various models such as Cartec CKSLX, Cartec CKSX, CM HA 1000 Clevis Sling Hook, CM HA 1000 Eye Sling Hook, Crosby PL Heavy-Duty, Crosby S-4088, Crosby S-4316, Crosby S-4320, Crosby SS-4055, Gunnebo RDBK, Gunnebo RDEKN, Gunnebo RDGKN / OKN, Gunnebo RDOBK / GBK, Gunnebo RDSKN / OKN, Gunnebo RDUKN, Johnson J-Latch, Pewag ELD, and Pewag SFG.

9. Accurate Lock – 9100BL Beveled Safety Latch

Domain: accuratelockandhardware.com

Registered: 2006 (19 years)

Introduction: 9100BL Beveled Safety Latch – Designed to reduce ligature risks in behavioral healthcare settings. The latch retracts under upward, downward, or horizontal force, preventing ligature attempts. Ligature Resistant and ADA Compliant. Compatible with Accurate 9100 Grade 1 Mortise Locks. Meets BHMA 156.34 Ligature Resistant Trim Standard. Features a bevel on top and bottom to minimize ligature points. …

Strategic Sourcing Conclusion and Outlook for safety latch

In conclusion, strategic sourcing of safety latches is essential for optimizing operational efficiency and ensuring compliance with safety standards across various industries. By focusing on high-quality latch kits from reputable suppliers, businesses can minimize risks associated with load disengagement and enhance the overall safety of their operations. Key considerations include evaluating the durability of materials, compatibility with existing equipment, and adherence to international safety regulations.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to enhance their supply chains, it is crucial to establish reliable partnerships with manufacturers and distributors who offer comprehensive product ranges, including specialized latch kits for diverse applications. This approach not only supports cost-effective procurement but also fosters innovation through access to the latest technologies in safety solutions.

Illustrative image related to safety latch

Looking ahead, the demand for robust and reliable safety latches will continue to grow as industries evolve. Buyers are encouraged to proactively engage with suppliers to explore tailored solutions that meet their specific needs, ensuring a competitive edge in their respective markets. Prioritize safety and efficiency today to build a resilient future for your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.