A B2B Buyer’s Guide to Cutter Machine Key: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for cutter machine key

In an increasingly interconnected world, sourcing high-quality cutter machine keys presents a significant challenge for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With the diverse range of key-cutting machines available, businesses must navigate the complexities of selecting the right equipment that meets their specific needs, whether for automotive applications, locksmith services, or industrial uses. This comprehensive guide addresses these challenges by detailing the various types of cutter machine keys, their applications, and the importance of vetting suppliers to ensure reliability and quality.

As buyers explore this guide, they will gain insights into the latest advancements in key-cutting technology and the critical factors influencing cost and performance. By understanding the nuances of different machine types and their specifications, businesses can make informed decisions that enhance operational efficiency and customer satisfaction. The guide also emphasizes the importance of supplier partnerships, offering strategies for identifying trustworthy manufacturers and distributors, ultimately leading to smarter purchasing choices.

With this resource, B2B buyers will be equipped to navigate the global market for cutter machine keys effectively, ensuring they find the right solutions that align with their operational goals and market demands.

Understanding cutter machine key Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Key Duplicators | Manual operation, typically lower cost, suitable for basic keys | Locksmith shops, small businesses | Pros: Cost-effective, simple to use. Cons: Slower production rate, limited to basic key types. |

| Automatic Key Cutting Machines | High-speed operation, programmable, can handle complex key shapes | Large locksmith chains, automotive services | Pros: Fast, accurate, versatile. Cons: Higher initial investment, requires maintenance. |

| Electronic Key Cutting Machines | Digital controls, can cut multiple key types including high-security | High-security facilities, automotive locksmiths | Pros: Precision cutting, often includes software updates. Cons: More complex, higher cost. |

| Portable Key Duplicators | Battery-operated, lightweight, designed for on-the-go services | Mobile locksmiths, event services | Pros: Convenient, versatile. Cons: Limited cutting power, may not handle all key types. |

| Tubular Key Cutting Machines | Specifically designed for tubular keys, often used in vending machines | Vending machine services, specialty locksmiths | Pros: Specialized for tubular keys, reliable. Cons: Limited application for non-tubular keys. |

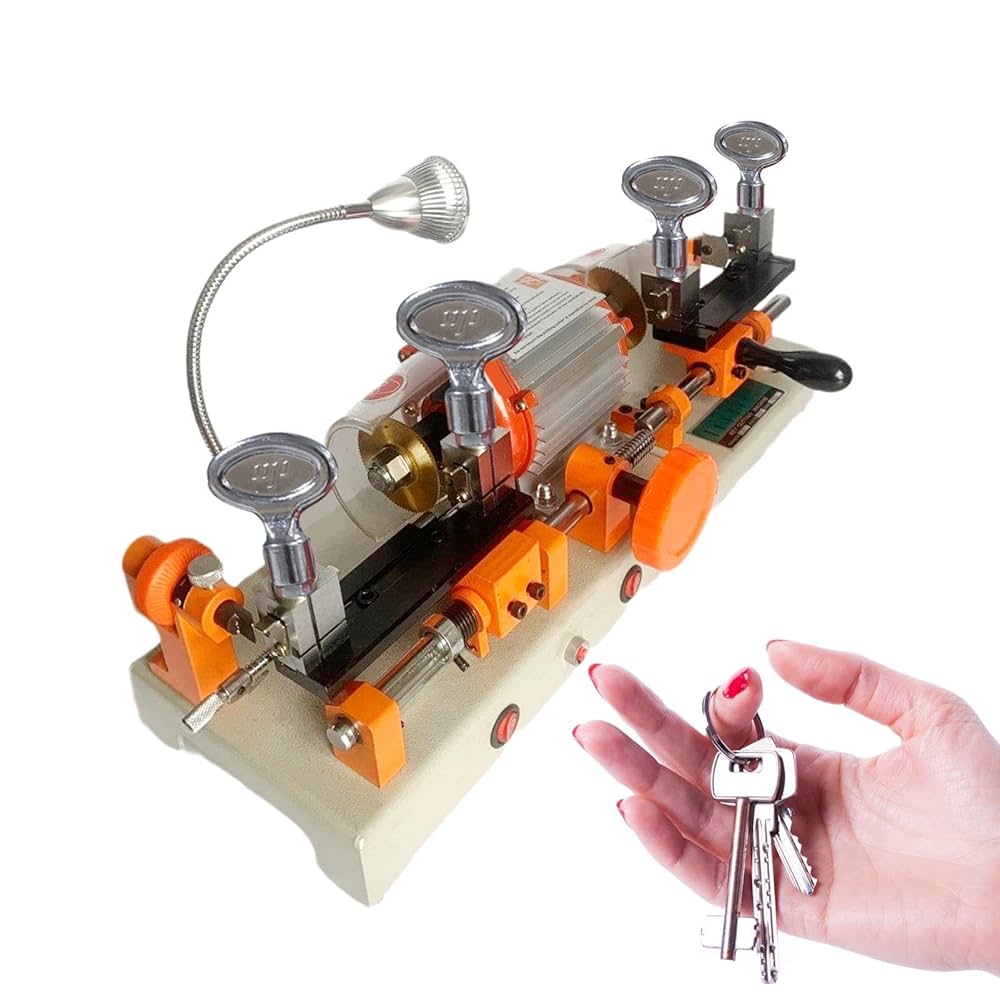

What are the Key Characteristics of Mechanical Key Duplicators?

Mechanical key duplicators are manual devices that allow users to create duplicates of standard keys. They are characterized by their straightforward design, requiring the user to physically operate the machine to cut the key. These machines are ideal for small businesses or locksmith shops that handle basic key types. When considering a purchase, buyers should evaluate the machine’s durability and ease of use, as well as the range of keys it can accommodate.

How Do Automatic Key Cutting Machines Enhance Efficiency?

Automatic key cutting machines are engineered for speed and precision, making them suitable for high-volume operations such as large locksmith chains and automotive services. They feature programmable settings and can handle a variety of key shapes, including complex designs. B2B buyers should consider the machine’s cutting speed, accuracy, and the types of keys it can process. While the upfront investment may be higher, the potential for increased productivity often justifies the cost.

What Advantages Do Electronic Key Cutting Machines Offer?

Electronic key cutting machines combine digital technology with advanced cutting capabilities, enabling them to create duplicates of high-security keys and various key types. They are particularly valuable in settings that require precision, such as high-security facilities and automotive locksmiths. Buyers should assess the machine’s software capabilities and potential for future updates, as well as its overall cost versus the benefits of precision cutting and efficiency.

Why Choose Portable Key Duplicators for On-the-Go Services?

Portable key duplicators are battery-operated and designed for mobile locksmiths and event services. Their lightweight and compact nature allows for easy transport, making them ideal for on-site key cutting. However, they may have limitations in cutting power and the range of key types they can handle. B2B buyers should evaluate the machine’s battery life, cutting capacity, and versatility to ensure it meets their operational needs.

What Makes Tubular Key Cutting Machines Unique?

Tubular key cutting machines are specialized devices designed exclusively for cutting tubular keys, commonly found in vending machines and specialized locks. Their unique design ensures reliable and consistent cuts for tubular keys, making them essential for businesses focusing on this niche. Buyers should consider the machine’s reliability, ease of use, and the specific applications it serves, as its functionality is limited to tubular keys alone.

Key Industrial Applications of cutter machine key

| Industry/Sector | Specific Application of cutter machine key | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Key duplication for vehicles | Ensures quick access to spare keys, reducing downtime for customers | Look for machines that handle diverse key types and support coding systems. |

| Security Services | Creation of master keys for buildings | Enhances security and access control for clients | Seek reliable machines with precision cutting capabilities for high-security keys. |

| Hospitality | Key management for hotels and resorts | Streamlines guest access and improves operational efficiency | Consider machines that can produce various key types and have user-friendly interfaces. |

| Manufacturing | Production of machine keys for equipment | Reduces equipment downtime and operational disruptions | Prioritize durability and compatibility with various cutting techniques. |

| Locksmith Services | Custom key cutting and duplication | Expands service offerings and customer satisfaction | Evaluate machines for versatility and ease of use in different environments. |

How is ‘cutter machine key’ used in the automotive industry, and what challenges does it address?

In the automotive sector, cutter machine keys are essential for duplicating vehicle keys, which often include complex designs and electronic components. Businesses in this industry face challenges such as providing quick turnaround times for customers who may have lost their keys or need duplicates for multiple vehicles. A reliable key-cutting machine can significantly reduce wait times, ensuring that locksmiths can offer immediate service. Buyers should prioritize machines capable of handling various key types, including transponder and laser-cut keys, to meet diverse customer needs effectively.

What role does ‘cutter machine key’ play in security services?

Security services utilize cutter machine keys to create master keys that grant access to different areas within a facility. This application is crucial for maintaining security and controlling access in sensitive environments, such as corporate offices or government buildings. The primary challenge in this sector is ensuring that keys are cut with precision to prevent unauthorized access. Buyers need to focus on sourcing high-quality machines that offer accurate cutting capabilities and support high-security key designs, which are often required in these applications.

How does ‘cutter machine key’ improve operations in the hospitality industry?

In the hospitality industry, cutter machine keys are used for efficient key management in hotels and resorts. This application helps streamline guest access to rooms and facilities, enhancing the overall customer experience. The challenge here lies in managing a large volume of keys while ensuring that they are easily accessible and secure. Businesses should look for key-cutting machines that can produce various key types quickly and have user-friendly interfaces to facilitate ease of use for staff members.

Why is ‘cutter machine key’ critical for manufacturing industries?

Manufacturing industries rely on cutter machine keys to produce machine keys for various equipment. This ensures that operations run smoothly by minimizing equipment downtime due to lost or damaged keys. The main challenge is to have a reliable supply of keys that can withstand the rigors of industrial use. Buyers should consider sourcing machines that offer durability, compatibility with different cutting techniques, and the ability to produce keys in bulk to keep pace with manufacturing demands.

How do locksmith services benefit from ‘cutter machine key’ applications?

Locksmith services depend on cutter machine keys for custom key cutting and duplication, enabling them to meet a wide range of customer requirements. This application allows locksmiths to enhance their service offerings and increase customer satisfaction by providing quick and precise key solutions. The challenge for locksmiths is to operate in environments where various key designs are required. Therefore, sourcing versatile machines that are easy to use and capable of handling different key types is vital for success in this sector.

3 Common User Pain Points for ‘cutter machine key’ & Their Solutions

Scenario 1: Inconsistent Key Quality Leading to Customer Dissatisfaction

The Problem: B2B buyers in the locksmith and security industries often face the challenge of inconsistent key quality when using cutter machines. This inconsistency can stem from using subpar cutting tools or machines that lack precision. For instance, a locksmith may find that keys cut using their current equipment do not fit well in locks, leading to customer complaints and lost business. This scenario is particularly troubling for businesses operating in competitive markets like Europe and South America, where reputation and reliability are crucial for sustaining customer loyalty.

The Solution: To address this issue, it’s essential to invest in high-quality cutter machines and replacement cutters that are specifically designed for the type of keys being duplicated. B2B buyers should prioritize sourcing machines from reputable manufacturers like ILCO or MBA USA that offer precision-engineered solutions. When selecting replacement cutters, ensure they are compatible with your existing machines and suitable for the specific key types you handle, such as automotive or high-security keys. Additionally, establishing a regular maintenance schedule for your machines will help ensure they remain in optimal working condition, further enhancing the quality of the keys produced. This proactive approach not only boosts customer satisfaction but also strengthens your business’s reputation in the long run.

Scenario 2: Limited Range of Key Types and Applications

The Problem: Many businesses face the challenge of limited capabilities with their key cutting machines. This limitation can restrict their ability to serve diverse customer needs, particularly in regions with varying security demands, such as the Middle East and Africa. For example, a locksmith may be equipped only to cut standard keys, leaving them unable to accommodate requests for more complex key types like dimple or laser-cut keys. This can result in lost sales opportunities and customers seeking services elsewhere.

The Solution: To overcome this limitation, B2B buyers should consider investing in versatile key cutting machines that can handle a broader range of key types and applications. Machines like the ILCO Futura Auto or the ILCO Bravo III are designed to accommodate various key styles, including high-security options. Moreover, training staff on the capabilities of these machines can maximize their potential. When purchasing new equipment, buyers should conduct thorough research to identify machines that offer adaptability and the potential for future upgrades. This investment in versatility not only enhances service offerings but also positions your business as a one-stop solution for customers’ key cutting needs.

Scenario 3: High Operational Costs Due to Inefficient Equipment

The Problem: B2B buyers often encounter high operational costs associated with outdated or inefficient key cutting machines. These machines may consume excessive energy, require frequent repairs, or produce a high volume of waste, impacting overall profitability. For instance, a company operating in South America may find that their key cutting processes are taking longer than expected, resulting in increased labor costs and reduced output. This inefficiency can erode profit margins and compromise competitiveness.

The Solution: To mitigate these costs, businesses should evaluate their current key cutting equipment and consider investing in modern, energy-efficient machines that offer improved performance and lower operational costs. Machines with automated features, such as the ILCO Speed series, can enhance productivity while minimizing waste. Additionally, implementing a robust training program for staff on the optimal use of equipment can further reduce costs by ensuring machines operate at peak efficiency. Establishing partnerships with suppliers who provide ongoing technical support can also help maintain equipment performance, prolonging its lifespan and reducing the frequency of costly repairs. This strategic investment not only improves the bottom line but also enhances operational efficiency, allowing businesses to allocate resources more effectively.

Strategic Material Selection Guide for cutter machine key

What Are the Best Materials for Cutter Machine Keys?

When selecting materials for cutter machine keys, it is essential to consider their properties, advantages, and limitations. The choice of material can significantly impact the performance, durability, and cost-effectiveness of the keys. Below, we analyze four common materials used in the manufacturing of cutter machine keys.

How Does Steel Perform as a Material for Cutter Machine Keys?

Steel is a widely used material for cutter machine keys due to its excellent strength and durability. It typically exhibits high tensile strength and can withstand significant pressure and wear. Steel keys can also be heat-treated to enhance their hardness, making them suitable for high-performance applications.

Pros: Steel is relatively cost-effective and readily available. Its durability ensures a long lifespan, reducing the need for frequent replacements.

Cons: On the downside, steel is prone to corrosion if not adequately protected, which can limit its use in humid or corrosive environments. Additionally, the manufacturing process can be complex, requiring precise machining.

Impact on Application: Steel keys are compatible with various media, including metals and plastics, making them versatile for different cutting tasks. However, international buyers should ensure compliance with standards like ASTM A36 for structural steel.

What Advantages Do Carbide Materials Offer for Cutter Machine Keys?

Carbide is known for its exceptional hardness and wear resistance, making it ideal for high-precision cutter machine keys. It can withstand high temperatures and pressures, which is crucial for applications involving tough materials.

Pros: The primary advantage of carbide is its longevity; it maintains sharpness longer than steel, resulting in fewer tool changes and increased productivity.

Cons: The main limitation is its higher cost compared to steel. Additionally, carbide is more brittle, which can lead to chipping under certain conditions.

Impact on Application: Carbide is suitable for cutting harder materials, such as stainless steel or high-strength alloys. Buyers in regions with stringent quality standards, such as Germany, should look for compliance with ISO 9001 for manufacturing processes.

Why Consider Aluminum for Cutter Machine Keys?

Aluminum is a lightweight alternative that offers good corrosion resistance and is easy to machine. It is often used for applications where weight reduction is essential, such as in portable key-cutting machines.

Pros: Aluminum’s lightweight nature makes it easier to handle and transport. It also has good thermal conductivity, which can be beneficial in applications requiring heat dissipation.

Cons: However, aluminum is not as strong as steel or carbide, which may limit its use in heavy-duty applications. It can also be more expensive than steel, depending on the alloy.

Impact on Application: Aluminum keys are suitable for less demanding cutting tasks and are often preferred in environments where corrosion is a concern. Buyers should be aware of the relevant standards, such as ASTM B221 for aluminum alloys.

What Role Does Plastic Play in Cutter Machine Key Manufacturing?

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are increasingly being used for cutter machine keys. They offer good chemical resistance and are lightweight.

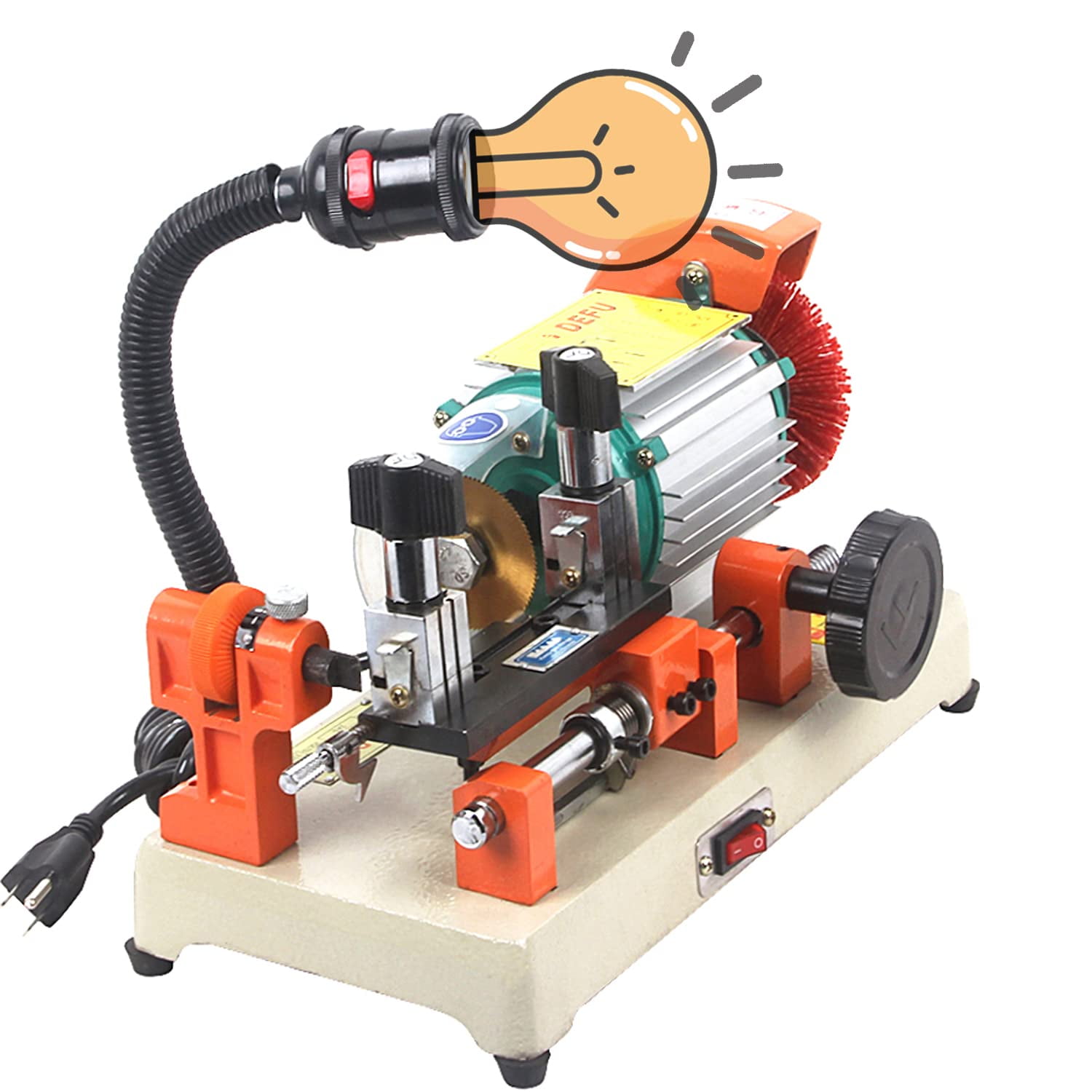

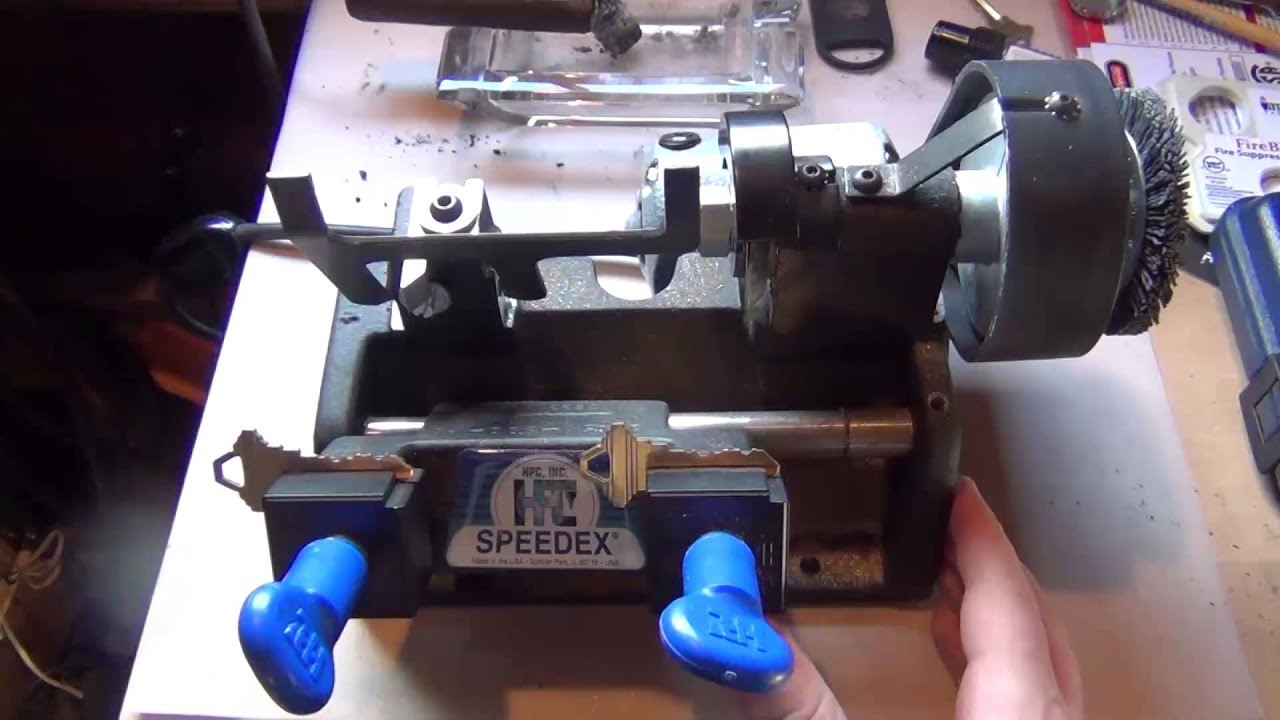

Illustrative image related to cutter machine key

Pros: The primary advantage of plastic is its resistance to corrosion and chemicals, making it suitable for various environments. Additionally, plastic keys can be manufactured at a lower cost.

Cons: The downside is that plastic is generally less durable than metals, which may lead to a shorter lifespan in high-wear applications. It may also not perform well under high temperatures.

Impact on Application: Plastic keys are best suited for light-duty applications or specific environments where metal keys would corrode. Buyers should ensure that the plastic meets relevant standards, such as ASTM D638 for tensile properties.

Summary Table of Material Selection for Cutter Machine Keys

| Material | Typical Use Case for cutter machine key | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General-purpose cutting tasks | Cost-effective and durable | Prone to corrosion | Low |

| Carbide | High-precision cutting applications | Exceptional hardness and longevity | Higher cost and brittleness | High |

| Aluminum | Lightweight, portable applications | Good corrosion resistance and machinability | Less strength compared to steel | Medium |

| Plastic | Light-duty and chemical-resistant tasks | Corrosion resistant and low cost | Less durable under high wear | Low |

This strategic material selection guide provides B2B buyers with insights into the properties, advantages, and limitations of various materials used in cutter machine keys, ensuring they make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cutter machine key

What Are the Key Stages in the Manufacturing Process of Cutter Machine Keys?

The manufacturing process of cutter machine keys involves several critical stages that ensure the final product meets the necessary specifications for precision and durability. Understanding these stages can help B2B buyers assess the reliability of suppliers.

Material Preparation: What Materials Are Used for Cutter Machine Keys?

The initial stage of manufacturing begins with the selection of high-quality materials. Common materials include stainless steel, high-speed steel, and specialized alloys that provide strength and wear resistance. These materials are sourced from reputable suppliers who comply with international quality standards. Proper handling and storage are crucial to prevent contamination or degradation prior to processing.

Forming: How Are Cutter Machine Keys Shaped?

In the forming stage, the raw materials undergo various shaping techniques. These may include:

- CNC Machining: This method allows for high precision in cutting the raw material into the desired shape. CNC machines operate using computer-aided design (CAD) files, ensuring consistent quality across multiple units.

- Grinding: After initial shaping, grinding processes refine the dimensions and surface finish of the keys. This step is vital for achieving the required tolerances and surface smoothness that impact performance.

Assembly: What Is Involved in Assembling Cutter Machine Keys?

For more complex cutter machine keys that may have additional components (like electronic features or interchangeable blades), the assembly stage is crucial. This process typically involves:

- Component Integration: Different parts are carefully assembled, ensuring that all mechanical and electronic elements fit together seamlessly.

- Calibration: For machines with electronic components, calibration is essential to ensure accurate operation. This may involve setting parameters according to manufacturer specifications.

Finishing: What Are the Final Touches Applied to Cutter Machine Keys?

The finishing stage enhances both the aesthetic and functional properties of the keys. This includes:

- Surface Treatment: Techniques such as plating, anodizing, or coating may be applied to improve corrosion resistance and durability.

- Quality Inspection: Prior to packaging, each key undergoes thorough inspection to confirm that it meets predefined quality criteria.

What Quality Assurance Practices Are Essential for Cutter Machine Keys?

Quality assurance (QA) is integral to ensuring that cutter machine keys function effectively and reliably. B2B buyers should be aware of the standards and practices that govern quality assurance in this industry.

Which International Standards Should B2B Buyers Look For?

Many manufacturers adhere to international standards to ensure product quality. Key standards include:

- ISO 9001: This standard emphasizes a quality management system that enhances customer satisfaction through effective processes and continuous improvement.

- CE Marking: Required in Europe, CE marking indicates that the product meets EU safety, health, and environmental protection standards.

In addition to these, industry-specific certifications (such as API for oil and gas applications) may also be relevant depending on the intended use of the cutter machine keys.

What Are the Critical QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are essential at various stages of production to identify defects early. These include:

Illustrative image related to cutter machine key

- Incoming Quality Control (IQC): This initial checkpoint evaluates the quality of raw materials before they enter the manufacturing process. Suppliers should provide certificates of analysis (CoA) to verify material quality.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor the production process and ensure adherence to specifications.

- Final Quality Control (FQC): The final inspection includes testing the finished products against quality benchmarks, confirming that they meet all requirements before shipment.

What Testing Methods Are Commonly Used in Quality Assurance?

Several testing methods are utilized to validate the quality of cutter machine keys:

- Dimensional Inspection: Measuring the dimensions of the keys using precision tools to ensure they match specifications.

- Material Testing: Conducting hardness tests, tensile tests, and fatigue tests to assess the material properties.

- Functional Testing: Testing the keys in real-world conditions to verify their performance in actual cutting scenarios.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control measures of their suppliers:

- Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices.

- Quality Reports: Requesting detailed quality reports that outline inspection results, testing methodologies, and compliance with standards can help assess supplier reliability.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control systems.

What Are the Quality Control Nuances for International B2B Buyers?

For buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is critical:

- Local Regulations: Familiarity with local regulations and standards can help ensure compliance and avoid potential legal issues.

- Cultural Considerations: Building relationships with suppliers from different cultural backgrounds may require understanding their business practices and communication styles.

- Logistics and Supply Chain: Quality assurance extends beyond manufacturing to include logistics. Buyers should ensure that transportation methods do not compromise product integrity.

By understanding the manufacturing processes and quality assurance practices surrounding cutter machine keys, B2B buyers can make informed decisions and choose reliable suppliers that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cutter machine key’

In the competitive landscape of key cutting and locksmithing, sourcing the right cutter machine key is crucial for ensuring efficiency and precision in your operations. This guide provides a structured approach for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, to effectively procure high-quality cutter machine keys.

1. Identify Your Key Cutting Needs

Understanding your specific requirements is the first step in sourcing a cutter machine key. Consider the types of keys you will be cutting—standard, high-security, or automotive keys—and the volume of work you expect. This information will guide you in selecting a machine that can handle your workload and the key types efficiently.

2. Define Your Technical Specifications

Once you have a clear understanding of your needs, outline the technical specifications required for the cutter machine key. Pay attention to aspects such as:

– Cutting precision: Ensure the machine can deliver accurate cuts to avoid rework.

– Compatibility: Check that the machine is compatible with your existing key cutting equipment.

3. Research Potential Suppliers

Thoroughly researching potential suppliers is essential for making informed decisions. Look for suppliers with a solid reputation in the industry, preferably those who specialize in key cutting machines. Use these criteria to evaluate suppliers:

– Industry experience: Seek out suppliers with a proven track record.

– Customer reviews: Look for testimonials or case studies from businesses similar to yours.

4. Verify Supplier Certifications

Before proceeding with any purchase, ensure that the suppliers hold relevant certifications. Certifications can indicate compliance with international standards and quality assurance. Key certifications to look for include:

– ISO 9001: This demonstrates a commitment to quality management.

– Local compliance: Ensure they meet regional regulations in your target market.

5. Request Product Samples

To assess the quality of the cutter machine key, request samples before making a bulk purchase. Evaluate the samples based on:

– Material quality: Check the durability and performance of the key.

– Cutting efficiency: Test the key on different types of locks to ensure it meets your expectations.

6. Negotiate Terms and Pricing

Engage in negotiations to secure the best deal possible. Be clear about your budget while also considering the long-term value of the machine. Important factors to discuss include:

– Volume discounts: Inquire about discounts for bulk purchases.

– Warranty and support: Ensure there is a robust warranty and customer support post-purchase.

Illustrative image related to cutter machine key

7. Finalize the Purchase and Plan for Delivery

Once you have settled on a supplier and agreed on terms, finalize your order. Pay close attention to the logistics of delivery, especially if you are importing the machine. Consider:

– Shipping options: Look for reliable shipping methods that suit your timeline.

– Customs regulations: Ensure compliance with your local customs to avoid delays.

By following these steps, you will be well-equipped to source cutter machine keys effectively, ensuring that your business operations run smoothly and efficiently.

Comprehensive Cost and Pricing Analysis for cutter machine key Sourcing

Understanding the cost structure and pricing dynamics of cutter machines is essential for international B2B buyers seeking to make informed purchasing decisions. This analysis delves into the key components of costs, factors influencing pricing, and strategic buyer tips specifically tailored for markets in Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Cutter Machine Sourcing?

When evaluating cutter machines, several cost components contribute to the overall price.

-

Materials: The quality and type of materials used in manufacturing cutter machines significantly impact costs. High-grade steel, advanced electronics, and durable components can lead to higher upfront costs but may reduce maintenance and replacement expenses over time.

-

Labor: Labor costs vary by region and can affect the final pricing. In countries with higher wages, such as Germany, labor costs will be a more significant portion of the total price compared to regions with lower wage structures.

-

Manufacturing Overhead: This includes costs related to facility operations, utilities, and administrative expenses. Efficient manufacturing processes can help lower these costs, thereby impacting the pricing structure positively.

-

Tooling: The need for specialized tools for production can add to the initial investment. Suppliers who have optimized their tooling processes may offer more competitive pricing.

-

Quality Control (QC): Rigorous QC processes ensure that machines meet specific standards, which can increase costs but also enhance product reliability and customer satisfaction.

-

Logistics: Shipping and handling costs, including customs duties and taxes, play a crucial role, particularly for international buyers. Understanding local logistics can help mitigate unexpected expenses.

-

Margin: Supplier margins can vary widely. It is essential to understand the market positioning of suppliers to gauge whether their pricing reflects fair profit margins or inflated costs.

What Influences Pricing for Cutter Machines?

Several factors influence the pricing of cutter machines beyond just the cost components:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often lead to discounts, making it crucial for buyers to assess their purchasing needs accurately.

-

Specifications and Customization: Custom features or specifications can significantly increase costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Quality and Certifications: Machines with industry certifications or those built to higher quality standards may command premium pricing, but they often provide better reliability and lower total cost of ownership.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may offer better warranties and support, justifying higher prices.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) used in the transaction is vital. These terms dictate who bears the costs and risks during shipping, which can affect the final price.

How Can Buyers Negotiate and Improve Cost Efficiency?

For international B2B buyers, especially in diverse markets, strategic negotiation and planning can lead to significant cost savings:

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and terms over time.

-

Explore Total Cost of Ownership: Rather than focusing solely on the initial purchase price, consider the total cost of ownership, which includes maintenance, repairs, and operational efficiencies.

-

Stay Informed About Market Trends: Keeping abreast of changes in material costs, labor trends, and technological advancements can provide leverage in negotiations.

-

Consider Local Suppliers: Where possible, sourcing from local suppliers can reduce shipping costs and lead times, improving overall efficiency.

What Should Buyers Keep in Mind Regarding Pricing Nuances?

Buyers should be aware of the pricing nuances specific to their regions. For instance, currency fluctuations can affect costs for international purchases. Additionally, understanding local market dynamics, such as demand fluctuations and competition, can help buyers make more informed decisions.

Disclaimer on Indicative Prices

Prices for cutter machines can fluctuate based on market conditions, supplier negotiations, and changes in material costs. Therefore, it is advisable for buyers to conduct thorough research and obtain updated quotes directly from suppliers to ensure accurate budgeting.

Alternatives Analysis: Comparing cutter machine key With Other Solutions

Exploring Alternatives to Cutter Machine Key Solutions

In the competitive landscape of key cutting and duplication, it’s crucial for businesses to evaluate various solutions that can meet their operational needs. While cutter machine keys are a popular choice due to their efficiency and precision, alternative methods and technologies can also provide effective solutions. This section compares cutter machine keys against two viable alternatives: manual key cutting and laser key cutting systems.

Comparison Table

| Comparison Aspect | Cutter Machine Key | Manual Key Cutting | Laser Key Cutting System |

|---|---|---|---|

| Performance | High precision and speed | Moderate precision, slower process | Extremely high precision, rapid |

| Cost | Moderate initial investment | Low initial cost, but labor-intensive | High upfront cost, lower long-term costs |

| Ease of Implementation | Requires some training | Simple to use, minimal training | Requires advanced training and setup |

| Maintenance | Regular maintenance needed | Minimal maintenance | Regular calibration and upkeep |

| Best Use Case | High-volume duplication, automotive | Low-volume, custom keys | High-security applications, complex key types |

Detailed Breakdown of Alternatives

Manual Key Cutting

Manual key cutting involves the use of handheld tools to create duplicates. This method is often favored by smaller locksmith shops or in situations where the demand for key duplication is low.

Pros:

– Cost-effective: The initial investment is minimal, making it accessible for new businesses.

– Flexibility: Ideal for custom jobs or unique key designs that may not be compatible with automated machines.

Cons:

– Labor-intensive: Requires more time and effort, especially for high-volume tasks.

– Inconsistent quality: The precision of cuts can vary significantly depending on the operator’s skill level.

Laser Key Cutting System

Laser key cutting systems utilize advanced technology to cut keys with unparalleled precision. These systems are increasingly popular in industries that require high-security solutions or complex key designs.

Pros:

– Precision: Capable of producing intricate cuts that are often required for high-security keys.

– Speed: Faster than manual methods, allowing for quick turnaround times on larger orders.

Cons:

– High cost: The initial investment and maintenance can be significant, making it less accessible for small operations.

– Training requirements: Operators need specialized training to effectively use and maintain the equipment, which can be a barrier for some businesses.

Conclusion: How to Choose the Right Solution for Your Business Needs

When selecting the most suitable key cutting solution, B2B buyers must consider their specific operational needs, volume of key duplication, and budget constraints. Cutter machine keys offer a balanced approach for businesses needing efficiency and precision in high-volume environments. However, for those who prioritize flexibility and cost, manual cutting may be sufficient. Conversely, organizations focused on high-security solutions may find that investing in laser cutting technology is worthwhile in the long run. Ultimately, evaluating the unique demands of your business will guide you in making the right choice that aligns with your operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for cutter machine key

What Are the Essential Technical Properties of Cutter Machine Keys?

When sourcing cutter machine keys, understanding their critical specifications is essential for ensuring compatibility and performance. Here are some key properties to consider:

1. Material Grade

The material grade of a cutter machine key significantly impacts its durability and cutting efficiency. Common materials include high-speed steel (HSS) and carbide. HSS provides a good balance of toughness and wear resistance, while carbide offers superior hardness and longevity. For B2B buyers, selecting the right material grade is crucial to minimize downtime and maintenance costs.

2. Tolerance

Tolerance refers to the allowable deviation in dimensions during manufacturing. In the context of cutter machine keys, tight tolerances ensure a precise fit in key cutting machines, leading to accurate cuts. A tolerance of ±0.01mm is often standard for professional-grade equipment. Understanding tolerance specifications can help businesses maintain quality control and reduce errors in key duplication.

3. Cutting Angle

The cutting angle affects the sharpness and efficiency of the key cutter. Different key types, such as edge-cut or dimple keys, require specific cutting angles for optimal performance. A typical cutting angle ranges from 30 to 45 degrees. B2B purchasers must ensure that the cutting angle matches the intended application to achieve high-quality key duplication.

4. Cutter Diameter

Cutter diameter is a critical specification that determines the size of the key cuts. Standard diameters range from 2mm to 10mm, depending on the machine and key type. Choosing the correct diameter is vital for achieving the desired key profile and ensuring the cutter’s compatibility with the machine.

5. Shank Design

The shank design of a cutter influences how it fits into the key cutting machine. Common designs include cylindrical and hexagonal shanks. A well-designed shank ensures secure attachment and stability during operation, which is essential for consistent cutting performance. Understanding shank design helps B2B buyers select cutters that will integrate seamlessly with their existing equipment.

Illustrative image related to cutter machine key

What Are Common Trade Terms Related to Cutter Machine Keys?

Familiarity with industry terminology can enhance communication and negotiation with suppliers. Here are several important trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the cutter machine key industry, OEM parts are often preferred for their guaranteed compatibility and quality. B2B buyers should seek OEM products to ensure reliable performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budget management and inventory planning. Suppliers often set MOQs to ensure profitability, so buyers should negotiate terms that align with their needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers for specific products or services. In the context of cutter machine keys, an RFQ can help businesses compare pricing and terms from multiple suppliers, facilitating informed purchasing decisions.

Illustrative image related to cutter machine key

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is critical for B2B buyers to understand shipping costs, risk, and responsibilities in cross-border transactions.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. It is a crucial factor for businesses that rely on timely access to cutter machine keys for operations. Understanding lead times helps buyers manage inventory and production schedules effectively.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing cutter machine keys, ultimately enhancing their operational efficiency and competitiveness in the market.

Illustrative image related to cutter machine key

Navigating Market Dynamics and Sourcing Trends in the cutter machine key Sector

What Are the Key Market Dynamics and Trends Impacting the Cutter Machine Key Sector?

The global market for cutter machines is witnessing significant transformations driven by advancements in technology, increased automation, and the growing need for precision in key duplication. International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly seeking high-quality, reliable cutter machines that can meet the demands of diverse applications, from automotive to residential locksmithing. The rise of e-commerce platforms has further facilitated access to a broader range of products, allowing businesses to source equipment from various manufacturers worldwide.

A prominent trend in the cutter machine sector is the shift toward automated and semi-automated solutions. These machines not only enhance efficiency but also reduce the potential for human error, which is crucial in precision tasks like key cutting. Additionally, the integration of digital technology, such as cloud-based software for inventory management and operational analytics, is becoming commonplace, allowing businesses to streamline their operations and improve decision-making processes.

Furthermore, sustainability is shaping buyer preferences. As businesses become more conscious of their environmental footprint, they are inclined to source machines from manufacturers who prioritize sustainable practices. The demand for machines that utilize eco-friendly materials and energy-efficient technologies is on the rise, aligning with global efforts to combat climate change.

How Important Is Sustainability and Ethical Sourcing in the Cutter Machine Key Sector?

Sustainability and ethical sourcing are increasingly relevant in the cutter machine key sector, influencing purchasing decisions among B2B buyers. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Buyers are now more inclined to partner with suppliers who demonstrate a commitment to reducing their carbon footprint through sustainable practices, such as using recyclable materials and adopting cleaner production methods.

Moreover, ethical sourcing practices that ensure fair labor conditions and transparency within the supply chain are paramount. Buyers are keen to collaborate with manufacturers who comply with international labor standards and provide certifications that attest to their ethical sourcing practices. This not only fosters trust but also enhances brand reputation, a critical factor in today’s competitive marketplace.

The incorporation of green certifications—such as ISO 14001 for environmental management systems—can serve as a significant differentiator for suppliers. Buyers are likely to favor products that are certified as eco-friendly, as this aligns with their corporate social responsibility goals and enhances their market positioning.

What Is the Historical Context of Cutter Machine Key Development in the B2B Market?

The evolution of cutter machines can be traced back to the early 20th century when manual key duplication methods dominated the market. The introduction of electric key-cutting machines in the mid-20th century marked a significant advancement, enabling locksmiths to produce keys with greater speed and accuracy. As technology progressed, the development of automated and semi-automated machines became prevalent, allowing for even higher precision and efficiency.

In recent years, the integration of digital technologies and software solutions has revolutionized the cutter machine sector. Modern machines now offer features such as programmable cutting paths, automatic key measurement, and cloud connectivity for seamless operation. This evolution not only reflects the changing needs of the market but also illustrates the ongoing commitment to enhancing productivity and accuracy within the locksmithing industry.

As international B2B buyers navigate the complexities of sourcing cutter machines, understanding these historical trends, current market dynamics, and sustainability considerations will be vital for making informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of cutter machine key

-

How do I solve key duplication issues with my cutter machine?

To resolve key duplication problems, first ensure that your cutter machine is properly calibrated and maintained. Regularly inspect the cutting blades for wear and replace them as needed to maintain precision. Additionally, use high-quality key blanks that match the specifications of the original keys to avoid discrepancies. If issues persist, consult the manufacturer for troubleshooting tips or consider training for your staff to enhance their skills in operating the equipment efficiently. -

What is the best key-cutting machine for automotive keys?

The best key-cutting machine for automotive keys often depends on your specific needs, such as the types of keys you frequently duplicate. For high-volume operations, machines like the ILCO Futura Auto or the Futura Pro are excellent choices due to their advanced features and ability to handle various key types, including laser and dimple keys. Always assess the machine’s compatibility with the automotive keys in your region and consider any necessary software updates for efficient operation. -

What should I consider when sourcing cutter machines internationally?

When sourcing cutter machines internationally, consider factors such as supplier reliability, product certifications, and compliance with local regulations. Investigate the supplier’s track record and seek out reviews or testimonials from other B2B buyers. Additionally, evaluate the support services they offer, including training, warranty, and after-sales service. It’s essential to understand the logistics involved, including shipping costs, customs duties, and potential delays, to ensure a smooth procurement process. -

How do I vet suppliers for cutter machines?

To vet suppliers effectively, start by researching their reputation in the industry. Look for certifications and affiliations with recognized organizations. Request references and case studies from previous clients to gauge their reliability and service quality. Conduct due diligence by checking their financial stability and compliance with international trade regulations. Engaging in direct communication can also provide insights into their customer service approach and willingness to accommodate specific needs. -

What are the common payment terms for international B2B transactions?

Common payment terms in international B2B transactions include advance payment, letters of credit, and payment upon delivery. Depending on the relationship with the supplier, you might negotiate for partial payments at different stages of the order process. Always clarify the payment methods accepted (e.g., bank transfer, PayPal) and ensure that any fees related to currency exchange or transaction processing are understood upfront. Establishing clear payment terms helps mitigate financial risks. -

What is the minimum order quantity (MOQ) for cutter machines?

Minimum order quantities (MOQs) for cutter machines vary by supplier and product type. Some manufacturers may have a low MOQ for standard models, while custom or specialized machines might require a higher MOQ due to production costs. When negotiating with suppliers, inquire about their flexibility in MOQs, especially if you’re just starting out or testing the market. Understanding MOQ is crucial for inventory management and budget planning. -

How can I ensure quality assurance (QA) for my cutter machines?

To ensure quality assurance for your cutter machines, establish clear specifications and performance standards before placing an order. Request samples or demonstrations to evaluate the machine’s capabilities firsthand. Verify that the supplier adheres to quality management standards, such as ISO certifications. Additionally, consider implementing a QA process that includes regular inspections and maintenance checks once the machines are in operation to sustain their performance over time. -

What logistics considerations should I keep in mind when importing cutter machines?

When importing cutter machines, logistics considerations include selecting a reliable freight forwarder, understanding customs regulations, and planning for potential delays. Ensure that the shipping method aligns with your timeline and budget, whether by air or sea. Familiarize yourself with import duties and taxes that may apply, and prepare all necessary documentation to facilitate customs clearance. Effective logistics planning can prevent unexpected costs and ensure timely delivery of your equipment.

Top 7 Cutter Machine Key Manufacturers & Suppliers List

1. LockPicks – Key Cutting Machines

Domain: lockpicks.com

Registered: 1997 (28 years)

Introduction: Key Cutting Machines available at LockPicks.com include various types such as Automatic Key Duplicators, Manual Key Duplicators, and Semi-Automatic Key Duplicators. Notable brands include WENXING, JMA, PRO-LOK, SILCA, and HPC. Prices range from $495.04 to $10,250.00, with specific models like the WENXING W288E Automatic Key Machine priced at $749.00, JMA NOMAD Key Duplicating Machine at $497.37, a…

2. UHS Hardware – 30-Day Returns

Domain: uhs-hardware.com

Registered: 2016 (9 years)

Introduction: This company, UHS Hardware – 30-Day Returns, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. ILCO – Key-Cutting Machines & Accessories

Domain: locksmithkeyless.com

Registered: 2015 (10 years)

Introduction: ILCO Key-Cutting Machines & Accessories, high-quality locksmith equipment, precision and accuracy in key cutting, suitable for businesses and professionals, free shipping on eligible orders over $99, zero interest financing for 12 months, same day shipping until 5PM EST.

4. REXA – USA Cutter

Domain: mbausa.com

Registered: 1996 (29 years)

Introduction: {“products”:[{“name”:”USA – REXA CUTTER – 4.4 MM”,”msrp”:”$108.77″,”description”:”Swiss-made replacement cutter for all standard Börkey key machines sold in the U.S. Fits 954 Rexa 3 machines (1987 on), Compact Pro machines, and 994 Rexa 2000 machines.”},{“name”:”FLAT STEEL CUTTER CONVERSION KIT”,”brand”:”HPC Locksmith Tools”,”msrp”:”$67.91″,”description”:”Optional cutter kit for HPC 9160MC Premier…

5. HPC – Mini Speedex Key Duplicator

Domain: clksupplies.com

Registered: 2004 (21 years)

Introduction: [{“name”:”HPC Mini Speedex Key Duplicator”,”price”:”$495.04″,”description”:”Lightweight, industrial-grade duplicator, one of the most accurate.”},{“name”:”Ilco Flash 008 Key Machine 120V”,”price”:”$779.20″,”description”:”Easily duplicates most edge cut cylinder, cruciform, large bow and long blade keys.”},{“name”:”Nomad Key Machine by JMA -110V”,”price”:”$497.37″,”description”:”Compact design for …

6. Triton – Key Cutting Machine

Domain: bannersolutions.com

Registered: 1997 (28 years)

Introduction: This company, Triton – Key Cutting Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

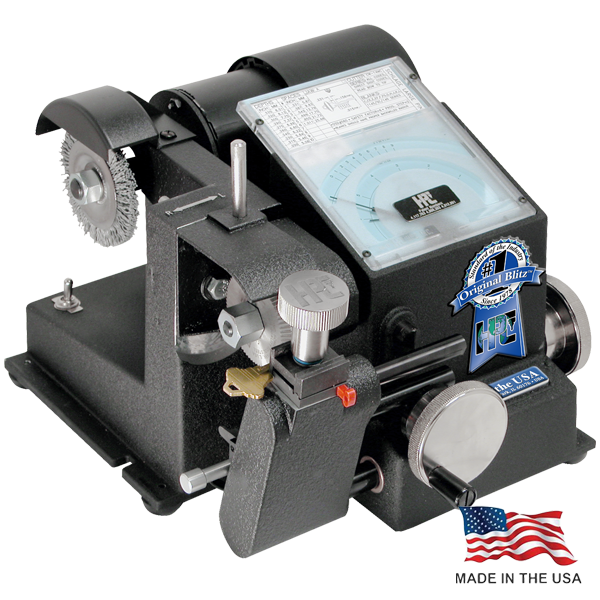

7. HPC – Blitz™ Key Cutting Machine

Domain: commercialdoorhardwaresupply.com

Registered: 2016 (9 years)

Introduction: {“products”:[{“name”:”HPC Blitz™ Key Cutting Machine”,”price”:”$5,469.50″,”model”:”1200CMB, 1200CMB240V, 1200CMBACDC”,”description”:”The Original Blitz™ Machine, standard of the industry since 1978, cuts virtually all standard pin and disc tumbler keys and many specialty keys. Features a code card system for easy key cutting and optional adapters for various key types.”,”specifications”:{“CMB Spec…

Strategic Sourcing Conclusion and Outlook for cutter machine key

In conclusion, strategic sourcing for cutter machine keys is essential for international B2B buyers looking to enhance operational efficiency and maintain competitive advantage. By selecting high-quality machines and reliable suppliers, businesses can ensure precision in key duplication and replacement, which is vital in sectors ranging from locksmithing to automotive services. The variety of machines available—from manual to fully automatic options—offers flexibility to meet specific business needs, while the integration of advanced technology, such as battery-powered and portable solutions, caters to a growing demand for versatility.

As the market evolves, it is crucial for buyers in Africa, South America, the Middle East, and Europe to stay informed about the latest innovations and trends in key-cutting technology. Collaborating with reputable distributors ensures not only access to high-quality products but also ongoing technical support that enhances operational capabilities.

Illustrative image related to cutter machine key

Looking ahead, now is the time for businesses to reassess their sourcing strategies and invest in cutting-edge solutions that will drive growth and efficiency. By leveraging the insights from this guide, buyers can position themselves advantageously in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.