How to Source Pressure Switch High High Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for pressure switch high high

In today’s competitive landscape, navigating the global market for high-pressure switches can present significant challenges for B2B buyers, particularly those sourcing solutions from diverse regions such as Africa, South America, the Middle East, and Europe. High-pressure switches are critical components in various industrial applications, ensuring operational safety and efficiency. However, the complexities surrounding their types, applications, and varying specifications can complicate the procurement process. This comprehensive guide aims to demystify the world of high-pressure switches, offering insights into the different types available, their specific applications across industries, and essential criteria for selecting the right supplier.

International buyers will benefit from our expert advice on vetting suppliers, understanding cost structures, and recognizing the nuances of pressure switch technology. By addressing common pain points such as compatibility with existing systems and regulatory compliance, this guide empowers decision-makers to make informed purchasing choices. Whether you are in Saudi Arabia looking for reliable equipment for oil and gas operations, or in Brazil seeking efficient solutions for agricultural applications, this resource is designed to enhance your understanding and streamline your sourcing process. Equip yourself with the knowledge to navigate the complexities of high-pressure switches and ensure your operations run smoothly and safely.

Understanding pressure switch high high Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Diaphragm Switch | Uses a diaphragm for pressure detection; robust and simple | HVAC systems, water pumps | Pros: High durability; simple design. Cons: Less accurate than electronic switches. |

| Electronic Pressure Switch | Incorporates a pressure transducer for signal output | Industrial automation, oil and gas applications | Pros: High accuracy; longer life span. Cons: More complex and potentially costly. |

| Piston Mechanical Switch | Features a piston mechanism; suited for high-pressure applications | Heavy machinery, hydraulic systems | Pros: Capable of handling high pressures. Cons: Bulkier and may require more maintenance. |

| Adjustable Pressure Switch | Allows for field adjustments to set pressure thresholds | OEM applications, customizable systems | Pros: Flexibility in settings; easy to calibrate. Cons: Potential for user error during adjustments. |

| High Amperage Pressure Switch | Designed to handle high electrical loads | Industrial equipment, power generation systems | Pros: Suitable for high-voltage applications. Cons: Larger footprint and may be more expensive. |

What Are the Characteristics of Mechanical Diaphragm Switches?

Mechanical diaphragm switches utilize a flexible diaphragm that reacts to pressure changes, making them ideal for straightforward applications in HVAC systems and water pumps. Their robust design ensures reliability in various environments, particularly where simplicity is paramount. When purchasing, consider the pressure range, as these switches are typically less precise than their electronic counterparts, making them suitable for less critical applications.

How Do Electronic Pressure Switches Stand Out?

Electronic pressure switches leverage advanced technology, incorporating pressure transducers to provide precise pressure measurements and outputs. Their ability to offer high accuracy and long-term stability makes them indispensable in industrial automation and oil and gas sectors. B2B buyers should evaluate the electronic switch’s compatibility with existing systems and consider potential higher costs compared to mechanical options, which may be justified by the enhanced performance.

What Makes Piston Mechanical Switches Suitable for High-Pressure Applications?

Piston mechanical switches are engineered to handle significant pressure levels, making them the go-to choice for heavy machinery and hydraulic systems. Their robust construction allows them to operate effectively under demanding conditions. Buyers should assess the switch’s specifications to ensure it meets the required pressure ratings and consider the potential maintenance needs due to their mechanical nature.

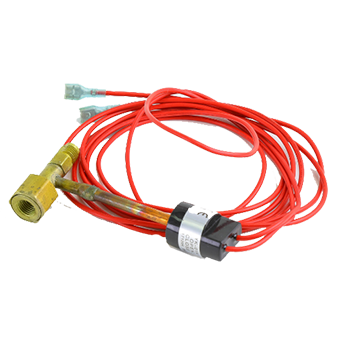

Illustrative image related to pressure switch high high

Why Choose Adjustable Pressure Switches for Custom Applications?

Adjustable pressure switches provide the flexibility to set specific pressure thresholds, making them ideal for OEM applications and systems requiring customization. Their ease of calibration can be a significant advantage, but users must be cautious to avoid errors during adjustments. B2B buyers should prioritize the switch’s range of adjustability and the ease of access for making changes in their operational environments.

What Are the Benefits of High Amperage Pressure Switches?

High amperage pressure switches are specifically designed to manage high electrical loads, making them essential for industrial equipment and power generation systems. Their capability to handle substantial voltage and current makes them vital in high-demand applications. Buyers should consider the switch’s electrical ratings and ensure that it aligns with the power requirements of their systems, keeping in mind that these switches may occupy more space and come at a higher price point.

Key Industrial Applications of pressure switch high high

| Industry/Sector | Specific Application of pressure switch high high | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Monitoring wellhead pressure | Ensures safety and operational efficiency, preventing blowouts and equipment damage. | High-pressure tolerance, corrosion-resistant materials, reliability in harsh environments. |

| HVAC | Chiller and compressor pressure control | Optimizes energy consumption and maintains system integrity, reducing operational costs. | Temperature range compatibility, quick response times, and durability against vibrations. |

| Water Treatment | Reverse osmosis pressure regulation | Enhances water purification efficiency and prolongs equipment lifespan. | Compatibility with various fluids, pressure range specifications, and ease of integration. |

| Manufacturing | Hydraulic system pressure management | Increases productivity by preventing system failures and maintaining optimal pressure levels. | Customizability for specific applications, high durability, and compliance with international standards. |

| Agriculture | Irrigation system pressure control | Ensures consistent water delivery, improving crop yields and resource efficiency. | Resistance to environmental factors, adaptability to varying pressure ranges, and ease of maintenance. |

How is ‘pressure switch high high’ used in the Oil and Gas industry?

In the oil and gas sector, high-pressure switches are critical for monitoring wellhead pressure. They activate safety measures to prevent blowouts, which can lead to catastrophic failures and environmental disasters. Buyers in this industry should consider switches with high-pressure tolerance and materials resistant to harsh conditions, ensuring reliability and longevity. Given the extreme operating environments often found in oil fields, sourcing switches that can withstand corrosive substances is essential.

What role does ‘pressure switch high high’ play in HVAC systems?

In HVAC applications, high-pressure switches are employed to control the pressure within chillers and compressors. By monitoring and regulating pressure levels, these switches help optimize energy consumption and maintain system integrity, ultimately reducing operational costs. Buyers should prioritize quick response times and compatibility with the temperature ranges specific to their systems. Additionally, durability against vibrations is crucial for maintaining performance in dynamic environments.

How does ‘pressure switch high high’ enhance water treatment processes?

In water treatment facilities, high-pressure switches regulate the pressure in reverse osmosis systems. This regulation is vital for enhancing the efficiency of water purification processes and prolonging the lifespan of pumps and membranes. Buyers should look for switches that can handle various fluids and specific pressure ranges, ensuring seamless integration into existing systems. Moreover, ease of installation and maintenance is a significant consideration for international buyers in this sector.

Why is ‘pressure switch high high’ important in manufacturing?

In manufacturing, high-pressure switches manage hydraulic systems to ensure optimal pressure levels are maintained throughout production processes. This management increases productivity by preventing unexpected system failures that can halt operations. When sourcing these switches, manufacturers should focus on customizability to fit specific application needs and compliance with international safety standards. Durability is also a key factor, as manufacturing environments often involve heavy machinery and rigorous conditions.

How does ‘pressure switch high high’ support agricultural irrigation systems?

High-pressure switches are utilized in agricultural irrigation systems to control water delivery pressure, ensuring crops receive a consistent supply of water. This consistency is essential for improving crop yields and resource efficiency. Buyers should consider switches that can resist environmental factors such as moisture and temperature fluctuations, and those that can adapt to varying pressure requirements. Ease of maintenance is also crucial for farmers looking to minimize downtime and operational costs.

3 Common User Pain Points for ‘pressure switch high high’ & Their Solutions

Scenario 1: Inconsistent Pressure Control in Manufacturing Processes

The Problem: B2B buyers in manufacturing sectors often encounter challenges with maintaining consistent pressure levels in their systems, particularly when using high-high pressure switches. Fluctuating pressure can lead to inefficiencies in production, equipment damage, or even safety hazards. These issues are exacerbated in environments where varying process conditions and materials are used, resulting in unexpected downtime and increased operational costs.

The Solution: To address this issue, buyers should focus on selecting high-high pressure switches that offer adjustable set points and reliable feedback mechanisms. Implementing electronic pressure switches can significantly enhance accuracy and responsiveness compared to mechanical options. These electronic switches can be calibrated to specific operating conditions, allowing for real-time monitoring and adjustments based on system demands. Additionally, working closely with suppliers to understand the specific operational environment—such as the type of fluid, temperature variations, and chemical compatibility—will ensure that the chosen switch meets the necessary durability and performance standards. Regular maintenance checks and calibration of the pressure switches are also crucial for sustaining optimal performance and preventing fluctuations.

Scenario 2: Equipment Failures Due to Incompatible Pressure Switches

The Problem: Many B2B buyers experience equipment failures stemming from the use of incompatible pressure switches within their systems. This can occur when the selected pressure switch does not align with the operational parameters of the machinery, such as pressure range, temperature ratings, or environmental conditions. Incompatible switches can lead to incorrect readings, equipment shutdowns, or even catastrophic failures, causing significant financial loss and reputational damage.

The Solution: To mitigate this risk, it is essential for buyers to thoroughly assess and specify the requirements of their systems before purchasing pressure switches. This involves understanding the full range of operational parameters, including maximum and minimum pressure thresholds, temperature limits, and the nature of the process fluid. Collaborating with experienced suppliers can provide valuable insights into the right type of pressure switch—whether mechanical or electronic—that fits the application. Furthermore, opting for switches that are tested and certified for specific industrial applications can enhance reliability. Implementing a rigorous testing phase for new installations or replacements will help identify potential incompatibilities before they lead to equipment failures.

Scenario 3: Difficulty in Monitoring and Analyzing Pressure Data

The Problem: B2B buyers often struggle with effectively monitoring and analyzing pressure data when using traditional high-high pressure switches. This lack of visibility can hinder decision-making processes and operational improvements. In industries like HVAC or oil and gas, where precise pressure management is critical, the inability to collect and analyze real-time data can lead to inefficient operations and missed opportunities for optimization.

The Solution: To overcome this challenge, buyers should consider integrating smart pressure switches that offer digital outputs and data connectivity options. These advanced switches can communicate with central monitoring systems, providing real-time data analytics and historical trends. By leveraging IoT capabilities, companies can enhance their operational intelligence, enabling proactive maintenance and timely adjustments to process parameters. Additionally, investing in software solutions that interpret and visualize pressure data will empower teams to make informed decisions quickly. Training staff on data interpretation and the importance of pressure management will further enhance the overall effectiveness of pressure control strategies.

Strategic Material Selection Guide for pressure switch high high

What Are the Key Materials for High-Pressure Switches?

When selecting materials for high-pressure switches, it is crucial to consider factors such as temperature and pressure ratings, corrosion resistance, and compatibility with the media being monitored. Below, we analyze four common materials used in high-pressure switch construction, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Stainless Steel Perform in High-Pressure Switch Applications?

Key Properties: Stainless steel is renowned for its excellent corrosion resistance and high strength, making it suitable for harsh environments. It typically withstands temperatures up to 400°C (752°F) and pressures exceeding 10,000 psi, depending on the specific grade.

Pros & Cons: The durability of stainless steel offers a long lifespan, reducing the need for frequent replacements. However, it is more expensive than other materials and can be challenging to machine, which may increase manufacturing complexity.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive fluids, making it ideal for chemical processing and oil & gas applications.

Considerations for International Buyers: Buyers from regions like the Middle East and Europe must ensure compliance with standards such as ASTM A276 for stainless steel grades. Additionally, the availability of specific grades may vary by region, impacting lead times.

What Role Does Brass Play in High-Pressure Switches?

Key Properties: Brass offers good corrosion resistance and can handle moderate temperatures (up to 200°C or 392°F) and pressures (generally up to 3,000 psi).

Pros & Cons: Brass is easier to machine than stainless steel, leading to lower manufacturing costs. However, it is less durable under extreme conditions and may corrode when exposed to certain chemicals, limiting its application scope.

Impact on Application: Brass is commonly used in HVAC systems and low-pressure applications. Its compatibility with water and air makes it a popular choice for residential and commercial pressure switches.

Considerations for International Buyers: Buyers should check for compliance with local standards like JIS H3250 for brass materials. In South America, the availability of specific brass alloys may affect sourcing.

How Does Polymer Material Benefit High-Pressure Switch Design?

Key Properties: Polymers, such as PEEK (Polyether Ether Ketone), exhibit excellent chemical resistance and can operate effectively at temperatures up to 260°C (500°F) and pressures around 5,000 psi.

Pros & Cons: The lightweight nature of polymers can reduce overall device weight, making them suitable for portable applications. However, they may not be as durable as metals in high-stress environments and can be more expensive.

Impact on Application: Polymers are ideal for applications involving aggressive chemicals, such as in the pharmaceutical or food processing industries.

Considerations for International Buyers: Compliance with food safety standards (e.g., FDA regulations) is essential for buyers in Europe and North America. Additionally, sourcing polymers may be limited in some African markets.

What Advantages Does Aluminum Bring to High-Pressure Switches?

Key Properties: Aluminum is lightweight and offers good corrosion resistance, with temperature ratings up to 150°C (302°F) and pressure ratings typically around 2,500 psi.

Illustrative image related to pressure switch high high

Pros & Cons: The low cost and ease of machining make aluminum a popular choice for mass production. However, it is less suitable for high-temperature and high-pressure applications compared to stainless steel or brass.

Impact on Application: Aluminum is often used in automotive and HVAC applications where weight savings are critical.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as DIN 17615 for aluminum alloys. In regions like Africa, sourcing aluminum components may be more accessible than other materials.

Summary Table of Material Selection for High-Pressure Switches

| Material | Typical Use Case for pressure switch high high | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing, oil & gas | Excellent corrosion resistance | High cost, difficult to machine | High |

| Brass | HVAC systems, low-pressure applications | Lower manufacturing costs | Limited durability in extreme conditions | Medium |

| Polymer | Pharmaceutical, food processing | Lightweight, excellent chemical resistance | Less durable under stress | High |

| Aluminum | Automotive, HVAC applications | Cost-effective, easy to machine | Not suitable for high pressure/temperature | Low |

This guide provides a comprehensive overview of the strategic material selection for high-pressure switches, helping international B2B buyers make informed decisions based on their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for pressure switch high high

What Are the Main Stages of Manufacturing High-Pressure Switches?

The manufacturing process for high-pressure switches involves several critical stages, each ensuring that the final product meets stringent performance and reliability standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used in High-Pressure Switches?

High-pressure switches are typically constructed from materials that can withstand extreme conditions, including high pressures and temperatures. Common materials include stainless steel for durability, brass for conductivity, and specialized polymers for seals and diaphragms. Before manufacturing, these materials undergo rigorous inspection to ensure they meet industry specifications. This initial step is crucial as the quality of raw materials directly affects the performance and lifespan of the switches.

How Is the Forming Process Conducted for High-Pressure Switches?

The forming process involves shaping the prepared materials into the required components of the pressure switch. Techniques such as stamping, machining, and molding are commonly employed. For instance, diaphragms may be stamped from sheet metal or molded from polymers, while housings are often machined to precise specifications. Precision in this stage is vital, as any inaccuracies can lead to malfunction or failure under pressure.

What Assembly Techniques Are Used in High-Pressure Switch Production?

Once the components are formed, they are assembled into a complete high-pressure switch. This assembly can be manual or automated, depending on the manufacturer’s capabilities and the complexity of the design. Key assembly techniques include:

- Mechanical Assembly: Components such as springs, levers, and electrical contacts are assembled using specialized tools to ensure proper function.

- Electrical Assembly: For electronic pressure switches, integrating the pressure transducer and necessary wiring is crucial. This stage often requires adherence to strict electrical standards to ensure safety and functionality.

- Sealing and Calibration: After assembly, the switches are sealed to prevent contamination and calibrated to ensure they operate within specified parameters.

What Finishing Processes Are Important for High-Pressure Switches?

The finishing stage adds final touches to the high-pressure switches, enhancing both functionality and aesthetic appeal. This may include surface treatments such as anodizing or plating to improve corrosion resistance. Additionally, final quality checks are conducted to ensure that each switch meets the necessary specifications before it is packaged for distribution.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is a critical component in the manufacturing of high-pressure switches. Buyers should look for manufacturers who adhere to internationally recognized standards such as ISO 9001, which ensures a consistent quality management system. Additionally, certifications relevant to specific industries, such as CE marking for European markets and API certification for oil and gas applications, should be verified.

How Are Quality Control Checkpoints Implemented During Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process to ensure that every switch produced meets both internal and external quality standards. Key checkpoints include:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for compliance with specifications before they enter the production line. This step helps prevent defective materials from affecting the final product.

-

In-Process Quality Control (IPQC): During manufacturing, various checks are performed at critical stages to monitor process parameters and ensure consistency. This includes dimensional checks and functional tests on components as they are produced.

-

Final Quality Control (FQC): After assembly, each high-pressure switch undergoes rigorous testing to ensure it meets operational specifications. This may involve pressure testing, electrical continuity checks, and environmental testing to simulate real-world conditions.

What Testing Methods Are Commonly Used for High-Pressure Switches?

Testing methods play a crucial role in quality assurance for high-pressure switches. Common testing techniques include:

-

Pressure Testing: This method evaluates the switch’s ability to function accurately under specified pressure conditions. It ensures that the switch activates and deactivates at the correct thresholds.

-

Electrical Testing: For electronic switches, electrical tests verify that the switch operates correctly and that all electrical connections are secure.

-

Environmental Testing: This simulates the conditions the switch will face in its intended application, including temperature extremes, humidity, and exposure to corrosive substances.

How Can B2B Buyers Verify Supplier Quality Control Processes?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider the following approaches:

-

Audits: Regular audits of manufacturing facilities can provide insights into the supplier’s adherence to quality standards and their manufacturing processes. Buyers should request audit reports as part of their due diligence.

-

Quality Reports: Suppliers should provide detailed quality reports that document the results of their QC processes, including test results and compliance certifications.

-

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of verification, ensuring that products meet the required standards before shipment.

What Are the QC and Certification Nuances for International Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific QC and certification requirements that may vary by region. Understanding local regulations and standards is crucial for compliance and avoiding potential issues with product acceptance.

-

Regional Certifications: Buyers should verify that the high-pressure switches meet local standards, such as GOST in Russia, INMETRO in Brazil, or SANS in South Africa.

-

Documentation: Ensure that the supplier provides all necessary documentation, including certificates of compliance and product specifications, to facilitate smooth customs processes and regulatory compliance.

By understanding these manufacturing and quality assurance processes, B2B buyers can make informed decisions when sourcing high-pressure switches, ensuring they partner with reputable manufacturers that deliver reliable and high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pressure switch high high’

In the competitive landscape of industrial procurement, sourcing the right pressure switch high high is crucial for operational efficiency and safety. This guide offers a structured approach to help B2B buyers navigate the complexities of selecting and purchasing high-pressure switches, ensuring informed decisions that align with specific requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of an effective sourcing strategy. Identify the operating pressure range, temperature tolerance, and environmental conditions that the pressure switch will face. Consider the type of pressure switch—mechanical or electronic—based on the precision and reliability required for your application.

Illustrative image related to pressure switch high high

- Pressure Range: Ensure the selected switch can handle the maximum expected pressure without failure.

- Environmental Factors: Evaluate whether the switch will be exposed to corrosive substances or extreme temperatures.

Step 2: Research Market Options

Investigate various manufacturers and suppliers to understand the range of available pressure switches. Look for companies with a solid reputation in producing high-quality products that meet international standards.

- Industry Reviews: Seek feedback from existing customers and industry forums to gauge reliability and performance.

- Product Variety: Ensure that suppliers offer a range of models to fit different applications, from HVAC systems to industrial machinery.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct thorough evaluations. Request detailed company profiles, product catalogs, and references from businesses in similar industries or regions.

- Certifications and Compliance: Confirm that suppliers adhere to international quality standards (e.g., ISO certifications) and safety regulations relevant to your industry.

- Case Studies: Review past projects to assess the supplier’s experience with high-pressure applications.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the pressure switches for testing. This step allows you to evaluate the product’s performance under your specific operational conditions.

Illustrative image related to pressure switch high high

- Testing Criteria: Assess the switches for responsiveness, durability, and accuracy under simulated pressure conditions.

- Documentation: Ensure you receive technical documentation that outlines the switch’s specifications and operational limits.

Step 5: Negotiate Pricing and Terms

Engage in negotiations to secure favorable pricing and terms. Consider not only the unit price but also warranty periods, return policies, and after-sales support.

- Volume Discounts: If purchasing in bulk, inquire about pricing structures that can offer significant savings.

- Service Agreements: Discuss the possibility of maintenance services or extended warranties to safeguard your investment.

Step 6: Finalize Your Purchase Order

After selecting a supplier and agreeing on terms, finalize the purchase order. Ensure that all specifications, delivery timelines, and payment terms are clearly outlined in the contract.

- Confirmation of Specifications: Double-check that the order reflects the correct model, quantities, and specifications.

- Logistics Planning: Coordinate with the supplier regarding shipping and delivery, especially if you are sourcing internationally.

Step 7: Monitor Installation and Performance

Upon receipt of the pressure switches, closely monitor their installation and performance in the field. Regular checks can identify any potential issues early, ensuring that the switches operate effectively within the desired parameters.

- Feedback Loop: Encourage feedback from operators regarding the performance of the switches to inform future purchasing decisions.

- Preventative Maintenance: Establish a maintenance schedule to prolong the life of the switches and maintain system efficiency.

By following this structured checklist, B2B buyers can confidently navigate the sourcing process for high-pressure switches, ensuring they select products that meet their operational needs while maximizing value.

Comprehensive Cost and Pricing Analysis for pressure switch high high Sourcing

What Are the Key Cost Components in Sourcing High-Pressure Switches?

When sourcing high-pressure switches, several cost components come into play. These include materials, labor, manufacturing overhead, tooling, quality control, logistics, and supplier margins.

Illustrative image related to pressure switch high high

-

Materials: The choice of materials directly affects the cost. High-quality materials that can withstand extreme pressures and environmental conditions will naturally be more expensive. Common materials include stainless steel and specialized plastics, which offer durability and resistance to corrosion.

-

Labor: Labor costs vary depending on the manufacturing location. Regions with higher wage standards, such as parts of Europe, may incur higher labor costs compared to regions in Africa or South America.

-

Manufacturing Overhead: This encompasses costs related to utilities, equipment maintenance, and facility operations. Efficient manufacturing processes can help reduce overhead costs, benefiting the overall pricing structure.

-

Tooling: The initial investment in tooling is significant, especially for custom designs. Buyers should consider whether the tooling costs are amortized over a larger production run, as this can reduce the per-unit price.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the products meet specified standards. While this may add to the upfront costs, it reduces the risk of defects and enhances the product’s reliability.

-

Logistics: Transportation and shipping costs can vary widely based on the distance from the manufacturer to the buyer, as well as the chosen shipping method. International shipping may involve additional customs duties and tariffs.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the industry standard margins can help buyers negotiate better terms.

How Do Price Influencers Affect High-Pressure Switch Sourcing?

Several factors can influence the pricing of high-pressure switches, especially for international buyers.

-

Volume/MOQ (Minimum Order Quantity): Larger orders usually lead to lower per-unit costs due to economies of scale. Buyers should negotiate the MOQ to align with their purchasing capacity.

-

Specifications and Customization: Custom features, such as specialized connectors or specific pressure ratings, can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Material Quality and Certifications: High-quality materials often come with certifications that guarantee performance and safety. While these may increase initial costs, they can lead to lower total costs over time due to reduced failure rates.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers may charge more, but they often provide better quality assurance and customer service.

-

Incoterms: Understanding the terms of delivery is crucial. Incoterms dictate the responsibilities of buyers and sellers in shipping, insurance, and duties, affecting overall cost calculations.

What Tips Can Help Buyers Optimize Costs When Sourcing High-Pressure Switches?

To maximize cost-efficiency in sourcing high-pressure switches, international buyers should consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Suppliers may be willing to offer discounts or favorable payment terms to secure a bulk order.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, operational efficiency, and potential downtime. Selecting high-quality switches may incur a higher upfront cost but lead to lower TCO.

-

Understand Regional Pricing Nuances: Different regions may have distinct pricing structures influenced by local market conditions, labor costs, and material availability. For instance, sourcing from a supplier in Brazil may be more cost-effective for South American buyers due to reduced shipping costs.

-

Research and Compare Suppliers: Take time to compare multiple suppliers, considering not just price but also quality, lead times, and customer support.

Disclaimer on Indicative Prices

Prices for high-pressure switches can fluctuate based on market conditions, supplier negotiations, and specific project requirements. Buyers should conduct thorough market research and obtain multiple quotes to ensure they receive the best value for their investment.

Alternatives Analysis: Comparing pressure switch high high With Other Solutions

In the landscape of industrial automation and control systems, pressure switches play a pivotal role in ensuring operational safety and efficiency. However, several alternative solutions exist that can achieve similar goals, each offering unique advantages and disadvantages. This analysis compares the ‘Pressure Switch High High’ against two viable alternatives: electronic pressure transducers and mechanical pressure gauges.

Illustrative image related to pressure switch high high

| Comparison Aspect | Pressure Switch High High | Electronic Pressure Transducer | Mechanical Pressure Gauge |

|---|---|---|---|

| Performance | Reliable for high-pressure applications with setpoint activation | High accuracy and continuous output for dynamic pressure monitoring | Simple and robust, suitable for static pressure measurements |

| Cost | Moderate initial investment, potential for long-term savings through efficiency | Higher upfront costs but can reduce operational costs through precision | Low-cost option, but limited in functionality |

| Ease of Implementation | Requires calibration and setup based on application needs | Installation may be complex, requiring integration with electronic systems | Easy to install; minimal training needed |

| Maintenance | Low maintenance; periodic checks recommended | Low maintenance; requires calibration checks for accuracy | Regular maintenance needed to ensure accuracy |

| Best Use Case | Ideal for safety-critical applications where pressure thresholds must be monitored | Best for applications requiring real-time data and precision | Suitable for basic pressure monitoring in non-critical applications |

What Are the Pros and Cons of Using Electronic Pressure Transducers?

Electronic pressure transducers provide a continuous output signal that is useful for real-time monitoring of pressure levels. They offer high accuracy and can be integrated into complex control systems, making them suitable for industries like oil and gas, pharmaceuticals, and manufacturing. However, they come with a higher initial investment and may require more complex installation procedures. Moreover, while they have low maintenance needs, calibration checks are essential to ensure continued accuracy over time.

How Do Mechanical Pressure Gauges Compare?

Mechanical pressure gauges are straightforward devices that measure pressure through the deformation of a sensing element. They are cost-effective and easy to install, making them an attractive option for businesses with limited budgets or those that require simple pressure readings. However, they may not provide the same level of accuracy as electronic solutions and are generally limited to static pressure applications. Regular maintenance is also necessary to ensure the gauge remains accurate, which could lead to higher long-term costs if not managed properly.

Conclusion: How Should B2B Buyers Choose the Right Solution for Their Needs?

When selecting between a pressure switch high high and its alternatives, B2B buyers should carefully evaluate their specific operational requirements, budget constraints, and the complexity of their systems. If safety and high-pressure threshold monitoring are paramount, a pressure switch high high remains an excellent choice. Conversely, for applications demanding precise and continuous pressure readings, electronic pressure transducers may be more suitable despite their higher costs. For basic applications with budget constraints, mechanical pressure gauges can serve effectively, provided that buyers are prepared for regular maintenance. Ultimately, the right choice hinges on aligning the solution’s capabilities with the operational goals and constraints of the organization.

Illustrative image related to pressure switch high high

Essential Technical Properties and Trade Terminology for pressure switch high high

What Are the Essential Technical Properties of a High-Pressure Switch?

When selecting a high-pressure switch, understanding its technical specifications is vital for ensuring compatibility with your application. Here are several critical properties to consider:

1. Pressure Range

The pressure range defines the limits within which the switch can operate effectively. For high-pressure switches, this typically ranges from several hundred to several thousand psi. Knowing the pressure range is crucial for ensuring the switch will function correctly under the specific conditions of your system, preventing failures or malfunctions.

2. Material Grade

The material used in the construction of the pressure switch significantly impacts its durability and performance. Common materials include stainless steel and brass, which offer resistance to corrosion and high temperatures. Selecting the right material is essential for applications involving aggressive fluids or extreme environments, as it affects the switch’s longevity and reliability.

3. Electrical Ratings

Electrical ratings indicate the maximum voltage and current the switch can handle. This specification is critical for ensuring that the switch can safely operate within your electrical system without the risk of failure. Understanding electrical ratings helps prevent potential hazards, such as short circuits or equipment damage, which can arise from using an improperly rated switch.

4. Setpoint Adjustment

This refers to the ability to customize the activation point of the pressure switch. Some models feature adjustable setpoints, allowing users to modify the pressure thresholds as needed. This flexibility can be particularly beneficial for applications with varying operational requirements, providing greater control over system performance.

5. Response Time

The response time indicates how quickly the pressure switch can react to changes in pressure. A faster response time is often necessary for applications that require immediate action to prevent system overloads or failures. Understanding this property is vital for industries where precision and timing are critical, such as in hydraulic systems or safety applications.

6. Operating Temperature Range

This specification defines the range of temperatures within which the pressure switch can operate effectively. It is essential to select a switch that can withstand the temperature extremes of your application, as high or low temperatures can compromise the switch’s functionality and lifespan.

What Are Common Trade Terms Related to High-Pressure Switches?

Understanding industry terminology is crucial for effective communication and decision-making in B2B transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, recognizing OEM components ensures compatibility and quality assurance, as these parts are often designed to meet specific industry standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budget planning and inventory management, especially for businesses that may not require large volumes but want to ensure supply continuity.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting a price quotation for specific goods or services. Utilizing RFQs can streamline the procurement process, enabling buyers to compare prices and terms from multiple suppliers effectively.

4. Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is critical for managing logistics and understanding cost implications in cross-border transactions.

5. NPT (National Pipe Taper)

NPT refers to a standard for threaded pipes and fittings commonly used in the United States. Knowing whether a pressure switch has NPT threads is essential for ensuring proper connections and preventing leaks in piping systems.

Illustrative image related to pressure switch high high

6. Calibration

Calibration is the process of adjusting the precision of a measuring instrument. For pressure switches, regular calibration ensures accurate pressure readings, which is crucial for maintaining system integrity and performance.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing high-pressure switches, ensuring they select the right products for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the pressure switch high high Sector

What Are the Key Market Dynamics Influencing the Pressure Switch High High Sector?

The pressure switch high high sector is currently witnessing significant transformations driven by a combination of technological advancements and evolving customer demands. A notable global driver is the increasing industrial automation across various sectors, particularly in oil and gas, HVAC, and manufacturing. These industries require robust and precise pressure management systems to ensure operational efficiency and safety. For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging trends such as the rise of smart sensors and IoT-enabled pressure switches are shaping the market landscape. These innovations allow for real-time monitoring and data analysis, enhancing predictive maintenance capabilities. Buyers are increasingly looking for suppliers that offer integrated solutions, combining mechanical and electronic pressure switches to optimize performance. Additionally, the demand for custom solutions tailored to specific application needs is on the rise, prompting manufacturers to enhance their product offerings.

Another key market dynamic is the growing emphasis on local sourcing and supply chain resilience. Geopolitical factors and the recent disruptions caused by the pandemic have pushed buyers to reconsider their sourcing strategies. Buyers are now focusing on suppliers that can demonstrate reliability and flexibility, particularly those operating within their regions.

How Is Sustainability and Ethical Sourcing Shaping the Pressure Switch High High Sector?

Sustainability and ethical sourcing have become integral to the pressure switch high high sector, as businesses increasingly recognize the environmental impact of their operations. The production of pressure switches involves materials that can have a significant ecological footprint, including metals and plastics. Therefore, international B2B buyers are increasingly prioritizing suppliers who utilize sustainable manufacturing processes and materials.

The importance of ethical supply chains cannot be overstated. Buyers are now seeking manufacturers who adhere to responsible sourcing practices, ensuring that materials are sourced from suppliers who respect labor rights and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and certifications related to sustainable materials are becoming essential criteria for supplier selection.

Furthermore, the adoption of ‘green’ materials, such as biodegradable plastics and recyclable metals, is gaining traction. B2B buyers should look for suppliers who can demonstrate their commitment to sustainability through transparent practices and certifications. This focus not only addresses regulatory requirements but also aligns with the corporate social responsibility goals of many organizations.

What Is the Brief Evolution of Pressure Switch Technology?

The evolution of pressure switch technology dates back to the early 20th century, when mechanical pressure switches were first developed. These devices utilized simple mechanical components such as diaphragms and springs to activate electrical contacts at predetermined pressure levels. Over the decades, advancements in materials science and engineering led to the development of more robust and reliable mechanical switches.

The introduction of electronic pressure switches in the late 20th century marked a significant turning point. These devices offered enhanced accuracy, quicker response times, and the ability to handle complex monitoring tasks. As industrial applications became more sophisticated, the integration of digital technologies allowed for features like remote monitoring and data logging, further elevating the functionality of pressure switches.

Today, the sector is witnessing a convergence of mechanical and electronic technologies, with hybrid solutions emerging to meet diverse industry needs. This evolution reflects a broader trend towards automation and smart manufacturing, positioning pressure switches as critical components in modern industrial systems. International B2B buyers must keep abreast of these developments to leverage the best available technologies for their operations.

Frequently Asked Questions (FAQs) for B2B Buyers of pressure switch high high

-

How do I solve issues with pressure switch performance?

To address performance issues with a high-pressure switch, first, ensure that the switch is compatible with the process fluid and pressure range. Regular maintenance checks, including cleaning and inspecting the diaphragm or piston for wear, can prevent malfunction. If the switch is not triggering correctly, verify the setpoint adjustments and electrical connections. Additionally, ensure that the installation meets manufacturer specifications, as improper installation can lead to performance problems. If issues persist, consider consulting with a technical expert or supplier for further diagnostics. -

What is the best type of pressure switch for high-pressure applications?

For high-pressure applications, mechanical piston pressure switches are often the best choice due to their robustness and ability to handle high voltages and amperages. They provide reliable switching action under significant pressure variations. Electronic pressure switches can also be suitable for applications requiring greater accuracy and longevity, as they can offer advanced features like digital readouts and programmable settings. Ultimately, the choice depends on the specific requirements of your application, including the pressure range and environmental conditions. -

What factors should I consider when sourcing high-pressure switches internationally?

When sourcing high-pressure switches internationally, consider factors such as the supplier’s reputation, compliance with international quality standards, and the availability of technical support. Verify the supplier’s experience in your specific industry and their ability to provide customized solutions if needed. Additionally, evaluate logistics aspects, including shipping times, tariffs, and local regulations that may affect delivery. Requesting samples before placing bulk orders can also ensure product quality and compatibility with your systems. -

What are typical minimum order quantities (MOQ) for pressure switches?

Minimum order quantities (MOQ) for pressure switches can vary significantly depending on the manufacturer and the specific product line. Generally, MOQs can range from 10 to 100 units for standard products, while custom designs may require higher quantities. It’s advisable to discuss your specific needs with potential suppliers, as some may offer flexibility on MOQs for first-time buyers or larger contracts. Understanding the MOQ can help you manage inventory and cash flow effectively. -

What payment terms are commonly offered by suppliers of pressure switches?

Payment terms for high-pressure switches typically include options such as net 30, net 60, or payment in advance. Some suppliers may offer discounts for upfront payments or larger orders. International transactions may involve additional considerations, such as currency exchange rates and banking fees. It’s crucial to clarify payment terms early in the negotiation process to avoid misunderstandings and ensure smooth transactions. Establishing a good relationship with your supplier can also lead to more favorable terms in the future. -

How can I ensure quality assurance (QA) for pressure switches?

To ensure quality assurance for pressure switches, request certifications from suppliers that verify compliance with international standards, such as ISO 9001. Conducting regular audits of the supplier’s manufacturing processes and quality control measures can further enhance product reliability. Additionally, consider implementing a testing protocol upon receipt of the switches to verify performance against specifications. Engaging in open communication with your supplier about QA processes can foster trust and improve product quality over time. -

What are the logistics considerations when importing pressure switches?

When importing pressure switches, consider logistics factors such as shipping methods, delivery times, and customs regulations in your country. Evaluate whether air freight or sea freight is more suitable based on urgency and cost. Ensure that the supplier provides the necessary documentation for customs clearance, including invoices and certificates of origin. Working with experienced logistics partners can help navigate potential challenges and ensure timely delivery of your products. -

Can I customize pressure switches to meet specific application needs?

Yes, many manufacturers offer customization options for pressure switches to meet specific application requirements. Customizations may include adjustments to pressure ranges, materials for wetted parts, electrical ratings, and mounting configurations. When discussing customization, provide detailed specifications and performance criteria to ensure the final product aligns with your needs. Engaging with suppliers early in the design process can facilitate smoother development and production timelines.

Top 7 Pressure Switch High High Manufacturers & Suppliers List

1. Paquin – High Pressure Switches

Domain: paquin.com

Registered: 1996 (29 years)

Introduction: High Pressure Switches include various models designed for industrial and commercial applications. Key products are: 1. BPA-BPF Diaphragm High Pressure Mechanical Switch – durable and reliable pressure monitoring solution. 2. EPA/EPF Series Mechanical Diaphragm Low/Medium/High Pressure Switch – widely used by OEMs for production volume requirements. 3. PBPA/PBPF Series Piston Mechanical High Press…

2. Reddit – Importance of Pressure Switches in Condenser Units

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around the importance of pressure switches in a condenser unit, specifically the low and high pressure switches. The high pressure switch prevents the compressor from running under high pressure, which can cause damage, while the low pressure switch protects against low refrigerant charge, which can lead to overheating. A manual reset high pressure switch is recommended to …

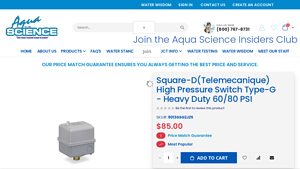

3. Aqua Science – Square-D High Pressure Switch Type-G

Domain: aquascience.net

Registered: 1999 (26 years)

Introduction: Square-D Heavy Duty High Pressure Switch Type-G 60/80 PSI

4. LiquaGen – High Pressure Switch 1/4 Push Connect

Domain: liquagen.com

Registered: 2014 (11 years)

Introduction: {“name”:”High Pressure Switch 1/4\” Push Connect”,”regular_price”:”$14.50″,”sale_price”:”$9.99″,”sku”:”PMP-HPS”,”description”:”LiquaGen pressure switch serves the purpose of automatically stopping the pump when it detects an increase in pressure resulting from the filling of your holding container. It is commonly activated by a float valve or pressurized storage tank. To ensure proper functionalit…

5. Aquatec – High Pressure Switches

Domain: airwaterice.com

Registered: 1999 (26 years)

Introduction: Aquatec High Pressure Switches

– Regular price: $24.95 for 1/4″ High Pressure switch, $29.95 for 3/8″ High Pressure switch

– Fitting Sizes: 1/4″ and 3/8″

– High Pressure Shut-off Switch for Aquatec series Booster Pumps

– 60/40 cut off / cut on

– Designed to turn off the pump when the desired pressure is achieved

– Requires a simple Allen wrench for adjustments

– Weight: 0.25 pounds

– Available opt…

6. Potter Signal – Auto-Test Pressure Switch

Domain: pottersignal.com

Registered: 1998 (27 years)

Introduction: Pressure Switches include the Auto-Test Pressure Switch (ATPS), which automates testing of fire sprinkler system pressures for faster, safer, and more accurate inspections. Other products include: PS10 Series Pressure Type Waterflow Switch, PS15 Low/High Supervisory Pressure Switch (15 psi), PS25 Low/High Supervisory Pressure Switch (25 psi), PS40 Series Low/High Supervisory Pressure Switch (40 ps…

7. Nason – High Pressure Switches

Domain: nasonptc.com

Registered: 1997 (28 years)

Introduction: {‘product_type’: ‘High Pressure Switches’, ‘features’: [‘No-creep design’, ‘Snap-action electrical device’, ‘Activated by elastomer diaphragm or piston’, ‘Maintains contacts open or closed until set point is reached’, ‘Snaps over center to a new state at set point’, ‘Remains in new state until pressure lowers’, ‘Operational life of over one million cycles’, ‘UL, CSA, and military approved’, ‘Wide …

Strategic Sourcing Conclusion and Outlook for pressure switch high high

In navigating the complexities of sourcing high-pressure switches, international B2B buyers must prioritize quality, reliability, and compatibility with specific applications. Understanding the distinctions between mechanical and electronic pressure switches, along with their respective advantages, is crucial for making informed decisions. Additionally, evaluating the operational environment—including factors like temperature, process fluid, and pressure range—ensures optimal performance and longevity of the equipment.

Strategic sourcing of high-pressure switches not only enhances operational efficiency but also mitigates risks associated with equipment failure. By partnering with reputable manufacturers and suppliers, businesses can secure components that meet rigorous industry standards, thereby safeguarding their investments.

Illustrative image related to pressure switch high high

Looking ahead, the demand for advanced pressure management solutions is expected to grow, driven by technological advancements and increasing automation across various sectors. Now is the time for international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, to leverage this opportunity. Engaging with suppliers who can provide tailored solutions will position your business for success in an evolving market landscape. Explore partnerships today to ensure you are equipped for tomorrow’s challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.