8X170 Wheels: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for 8×170 wheels

Navigating the global market for 8×170 wheels presents a unique challenge for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Sourcing the right wheels—whether for heavy-duty trucks or specialized vehicles—requires careful consideration of specifications, quality, and supplier reliability. This guide aims to simplify that process by providing a comprehensive overview of the 8×170 wheel segment, including various types, applications, and critical factors to consider when vetting suppliers.

In today’s competitive landscape, international buyers must make informed purchasing decisions to ensure their investments yield the best performance and value. This guide delves into the intricacies of 8×170 wheels, covering everything from the nuances of bolt patterns and offsets to cost considerations and supplier evaluation techniques. By equipping buyers with actionable insights, we empower them to navigate the complexities of sourcing these essential components with confidence.

Whether you are a distributor in Germany seeking high-performance options or a fleet manager in Saudi Arabia looking for durable solutions, this guide is designed to meet your specific needs. Explore the diverse offerings in the 8×170 wheel market and discover how to enhance your procurement strategy for optimal results.

Understanding 8×170 wheels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cast Aluminum Wheels | Lightweight, cost-effective, various designs | Commercial fleets, light-duty trucks | Pros: Affordable, diverse styles. Cons: Less durable than forged options. |

| Forged Aluminum Wheels | High strength, lightweight, custom designs | Heavy-duty trucks, off-road vehicles | Pros: Superior strength, customizable. Cons: Higher price point. |

| Beadlock Wheels | Enhanced tire security, ideal for off-roading | Off-road racing, rugged terrain vehicles | Pros: Prevents tire slippage, robust design. Cons: Heavier, more complex installation. |

| Steel Wheels | Heavy-duty, high load capacity, cost-effective | Construction vehicles, heavy machinery | Pros: Durable, affordable. Cons: Heavier, limited aesthetic options. |

| Specialty Finish Wheels | Unique coatings and colors, stylish designs | Custom builds, show vehicles | Pros: Aesthetic appeal, customizable. Cons: May require special maintenance. |

What Are the Characteristics of Cast Aluminum Wheels?

Cast aluminum wheels are popular among B2B buyers due to their lightweight and cost-effective nature. These wheels are produced using a casting process, which allows for a variety of designs and finishes. They are ideal for commercial fleets and light-duty trucks, where budget considerations are paramount. Buyers should consider the balance between cost and durability, as cast wheels may not withstand extreme conditions as well as forged options.

How Do Forged Aluminum Wheels Differ from Other Types?

Forged aluminum wheels are crafted from a solid block of aluminum, offering superior strength and performance. They are particularly suited for heavy-duty trucks and off-road vehicles, where load-bearing capacity and durability are critical. While they come at a higher price point, the investment is often justified by their enhanced longevity and customization options. Buyers should assess their specific performance needs against their budget when considering forged wheels.

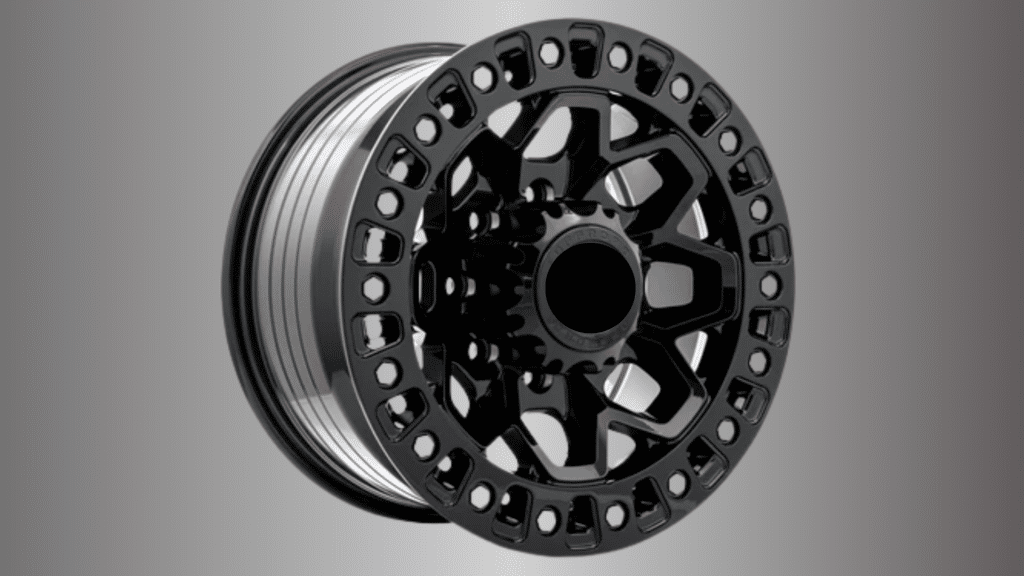

Why Choose Beadlock Wheels for Off-Road Applications?

Beadlock wheels are specifically designed to secure the tire bead against the wheel, making them ideal for off-road racing and rugged terrain vehicles. Their unique construction prevents tire slippage during extreme conditions, providing enhanced safety and performance. However, they tend to be heavier and may require more complex installation. B2B buyers focusing on off-road applications should weigh the benefits of performance against installation complexity.

What Advantages Do Steel Wheels Offer for Heavy Machinery?

Steel wheels are favored for their durability and high load capacity, making them an excellent choice for construction vehicles and heavy machinery. They are typically more affordable than aluminum options, providing a cost-effective solution for businesses operating in demanding environments. However, steel wheels are heavier and may offer fewer aesthetic choices compared to aluminum wheels. Buyers should consider the operational demands of their vehicles when selecting steel wheels.

How Do Specialty Finish Wheels Enhance Vehicle Aesthetics?

Specialty finish wheels come with unique coatings and colors, allowing for a high degree of customization and aesthetic appeal. They are particularly popular among custom builds and show vehicles, where appearance is a significant factor. While these wheels can enhance the visual impact of a vehicle, they may require special maintenance to preserve their finish. B2B buyers should evaluate whether the aesthetic benefits align with their overall vehicle branding and marketing strategies.

Illustrative image related to 8×170 wheels

Key Industrial Applications of 8×170 wheels

| Industry/Sector | Specific Application of 8×170 wheels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Heavy-duty trucks for transporting materials | Enhanced durability and load capacity | Ensure compatibility with vehicle specifications and load ratings. |

| Agriculture | Agricultural machinery and utility vehicles | Improved traction and stability in rough terrains | Consider wheel size and offset for specific machinery requirements. |

| Mining | Off-road vehicles for mineral extraction | Reliable performance in extreme conditions | Focus on high-quality materials to withstand harsh environments. |

| Transportation & Logistics | Fleet vehicles for cargo delivery | Cost-effective maintenance and longevity | Evaluate financing options and bulk purchasing agreements. |

| Automotive Aftermarket | Customization of trucks and SUVs | Enhanced aesthetics and performance | Look for diverse styles and finishes to meet branding needs. |

How Are 8×170 Wheels Used in the Construction Industry?

In the construction sector, 8×170 wheels are primarily utilized on heavy-duty trucks that transport materials and equipment to job sites. These wheels are designed to support significant loads, ensuring safety and reliability. Businesses benefit from the enhanced durability and stability these wheels provide, especially when navigating uneven terrain. International buyers should consider sourcing wheels that meet specific load ratings and vehicle compatibility to avoid costly downtimes.

What Role Do 8×170 Wheels Play in Agriculture?

Agricultural machinery often requires robust wheels capable of providing traction on various terrains. 8×170 wheels are used on tractors and utility vehicles, enabling them to operate efficiently in fields and rugged landscapes. The stability and grip offered by these wheels improve productivity and reduce the risk of accidents. Buyers in regions like Africa and South America should prioritize wheels that are suited for their specific machinery and local conditions.

How Are 8×170 Wheels Essential for Mining Operations?

In the mining industry, 8×170 wheels are essential for off-road vehicles that operate in challenging environments, such as rocky terrains and steep inclines. These wheels are engineered to withstand harsh conditions while ensuring reliable performance. The ability to handle heavy loads and provide stability is crucial for minimizing operational disruptions. Buyers should focus on sourcing high-quality wheels that can endure the rigors of mining activities.

Why Are 8×170 Wheels Important for Transportation and Logistics?

For the transportation and logistics sector, 8×170 wheels are a key component of fleet vehicles used for cargo delivery. These wheels not only enhance the longevity of the vehicles but also contribute to cost-effective maintenance. Businesses benefit from the reduced downtime and increased efficiency that comes with using reliable wheels. When sourcing, international buyers should explore financing options and bulk purchasing agreements to optimize costs.

How Do 8×170 Wheels Enhance Customization in the Automotive Aftermarket?

In the automotive aftermarket, 8×170 wheels are commonly used for customizing trucks and SUVs, allowing businesses to offer unique aesthetics and improved performance. These wheels come in various styles and finishes, catering to diverse consumer preferences. For international buyers, it’s essential to consider the specific branding and design needs of their target market when selecting wheels. Ensuring compatibility with vehicle specifications will help maintain customer satisfaction and loyalty.

3 Common User Pain Points for ‘8×170 wheels’ & Their Solutions

Scenario 1: Difficulty in Identifying the Right Wheel Specifications

The Problem: For many B2B buyers, especially those sourcing for fleets or specialized vehicles, selecting the correct specifications for 8×170 wheels can be a daunting task. With various sizes, offsets, and finishes available, it can be challenging to determine which combination will best suit their vehicles’ performance and aesthetic needs. This confusion can lead to costly mistakes, including purchasing wheels that do not fit properly or do not meet load requirements, ultimately affecting operational efficiency.

The Solution: To effectively navigate this challenge, B2B buyers should implement a systematic approach to specifying wheel requirements. First, they should consult the vehicle’s manual or manufacturer specifications to confirm the correct size, bolt pattern, and load rating for 8×170 wheels. Next, utilizing fitment guides or working closely with fitment specialists can greatly enhance accuracy. Many suppliers offer tools that allow buyers to input their vehicle’s make, model, and year, generating a tailored list of compatible wheels. Additionally, it is wise to engage in conversations with manufacturers about their product lines to understand the nuances of different wheel options, such as the implications of various offsets on vehicle handling and clearance. Establishing a relationship with a reliable supplier who can provide insights and assist with customization can also ensure that the selected wheels meet all operational needs.

Scenario 2: Overcoming Supply Chain Delays and Stock Availability

The Problem: B2B buyers often face significant challenges due to supply chain disruptions, especially in acquiring specific wheel types like 8×170 wheels. Delays in production or shipping can result in extended downtime for vehicles, impacting service delivery and operational timelines. This is particularly critical for businesses that rely on a fleet of vehicles for logistics or transportation services, where each vehicle’s operational readiness is essential for maintaining contracts and customer satisfaction.

Illustrative image related to 8×170 wheels

The Solution: To mitigate supply chain risks, B2B buyers should adopt a proactive purchasing strategy. This includes maintaining an inventory of critical components, including 8×170 wheels, to ensure that replacements are readily available when needed. Establishing relationships with multiple suppliers can also provide alternative sourcing options if one supplier experiences delays. Furthermore, buyers should stay informed about market trends and potential disruptions by subscribing to industry news and updates. Utilizing advanced planning tools or inventory management software can help anticipate needs based on usage patterns, enabling buyers to place orders well in advance. Finally, consider negotiating agreements with suppliers for priority service on orders during peak demand periods, ensuring that your company can maintain its operational capabilities even in challenging supply conditions.

Scenario 3: Navigating Compliance and Quality Standards

The Problem: B2B buyers must also contend with varying compliance and quality standards for wheels across different regions. In markets such as Europe and the Middle East, strict regulations govern vehicle components, and failing to adhere to these can result in penalties or vehicle rejection during inspections. This compliance challenge can be particularly complex for buyers operating internationally, as they must understand the specific requirements for 8×170 wheels in each market.

The Solution: To effectively navigate these compliance hurdles, B2B buyers should conduct thorough research on the relevant regulations in their target markets. This includes familiarizing themselves with standards set by organizations such as the European Union’s ECE regulations or local authorities in Africa and South America. Engaging with suppliers who are knowledgeable about these standards can also be beneficial; they can provide documentation and certifications that prove compliance with quality and safety requirements. Additionally, investing in quality assurance processes, such as pre-purchase inspections or third-party audits of wheel manufacturers, can help ensure that the products meet all necessary standards. Buyers should also stay connected with industry associations that can provide updates on regulatory changes, enabling them to adapt their sourcing strategies promptly. By prioritizing compliance, B2B buyers can reduce the risk of costly disruptions and maintain smooth operations across multiple markets.

Strategic Material Selection Guide for 8×170 wheels

When selecting materials for 8×170 wheels, several key factors come into play, including performance characteristics, cost, and the specific needs of international markets. Here, we analyze four common materials used in the manufacturing of these wheels: aluminum alloy, steel, forged aluminum, and cast aluminum. Each material has its own unique properties that can significantly impact the performance and suitability of the wheels for various applications.

What are the Key Properties of Aluminum Alloy for 8×170 Wheels?

Aluminum alloys are highly favored for their lightweight nature and excellent corrosion resistance. Typically rated for temperatures up to 150°C (302°F), they perform well under moderate pressure conditions. The alloying elements, such as magnesium and silicon, enhance strength and ductility, making them suitable for high-performance applications.

Pros and Cons: The primary advantage of aluminum alloy wheels is their reduced weight, which improves fuel efficiency and handling. However, they can be more expensive than steel and may not withstand extreme impacts as well, making them less suitable for heavy-duty applications.

Impact on Application: Aluminum alloy wheels are ideal for vehicles requiring high performance and aesthetic appeal. They are compatible with a variety of media and environments, but care should be taken in regions with high saline exposure, as this can lead to corrosion.

International Considerations: Buyers from Europe, particularly Germany, may prefer aluminum wheels that meet DIN standards for safety and performance. In regions like the Middle East, where high temperatures are common, selecting alloys with higher heat resistance can be critical.

Illustrative image related to 8×170 wheels

How Does Steel Compare as a Material for 8×170 Wheels?

Steel wheels are known for their exceptional durability and strength, making them a popular choice for heavy-duty applications. With a temperature rating of approximately 200°C (392°F), they can handle higher stress levels without deformation. Steel also offers good resistance to wear and tear.

Pros and Cons: The main advantage of steel wheels is their cost-effectiveness and ability to withstand harsh conditions. However, they are heavier than aluminum, which can negatively impact fuel efficiency and performance. Additionally, steel is more susceptible to rust if not properly coated.

Impact on Application: Steel wheels are suitable for off-road vehicles and trucks that require robustness. They can handle rough terrains and heavy loads but may not be the best choice for performance-oriented applications.

International Considerations: Compliance with ASTM standards is crucial for steel wheels, especially in North America. Buyers in South America and Africa may prioritize cost over weight, making steel a favorable option.

Why Choose Forged Aluminum for 8×170 Wheels?

Forged aluminum wheels are manufactured through a process that compresses aluminum under high pressure, resulting in a denser and stronger product. They typically have a temperature rating similar to that of standard aluminum alloys but exhibit superior strength-to-weight ratios.

Illustrative image related to 8×170 wheels

Pros and Cons: The key advantage of forged aluminum is its high strength and lightweight properties, making it ideal for performance vehicles. However, the manufacturing process is more complex and costly, which can limit market accessibility for budget-conscious buyers.

Impact on Application: Forged wheels are particularly beneficial for racing and high-performance vehicles where weight savings and strength are paramount. They are less prone to cracking under stress compared to cast wheels.

International Considerations: Forged aluminum wheels may need to meet stricter safety and performance standards in regions like Europe, where regulatory compliance is critical. Buyers should also consider the availability of forged options in their local markets.

What are the Benefits of Cast Aluminum for 8×170 Wheels?

Cast aluminum wheels are produced by pouring molten aluminum into molds, resulting in a variety of designs and finishes. They are generally less expensive than forged wheels and can be made in larger quantities.

Illustrative image related to 8×170 wheels

Pros and Cons: The primary advantage of cast aluminum is its cost-effectiveness and design versatility. However, cast wheels can be heavier and less durable than forged options, making them more suitable for standard vehicles rather than high-performance applications.

Impact on Application: Cast aluminum wheels are suitable for everyday vehicles and light trucks. They provide a good balance of performance and aesthetics but may not perform well under extreme conditions.

International Considerations: Compliance with international standards such as JIS is important for cast aluminum wheels. Buyers in regions with diverse climates should consider the potential for corrosion and choose finishes that enhance durability.

Illustrative image related to 8×170 wheels

Summary Table of Material Selection for 8×170 Wheels

| Material | Typical Use Case for 8×170 wheels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy | High-performance vehicles and trucks | Lightweight and corrosion-resistant | Higher cost and less impact resistance | Medium |

| Steel | Heavy-duty trucks and off-road vehicles | Durable and cost-effective | Heavier and prone to rust | Low |

| Forged Aluminum | Racing and high-performance applications | Superior strength-to-weight ratio | Complex manufacturing and higher cost | High |

| Cast Aluminum | Everyday vehicles and light trucks | Cost-effective and versatile design | Heavier and less durable | Medium |

This analysis provides a comprehensive overview of the materials commonly used for 8×170 wheels, aiding B2B buyers in making informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for 8×170 wheels

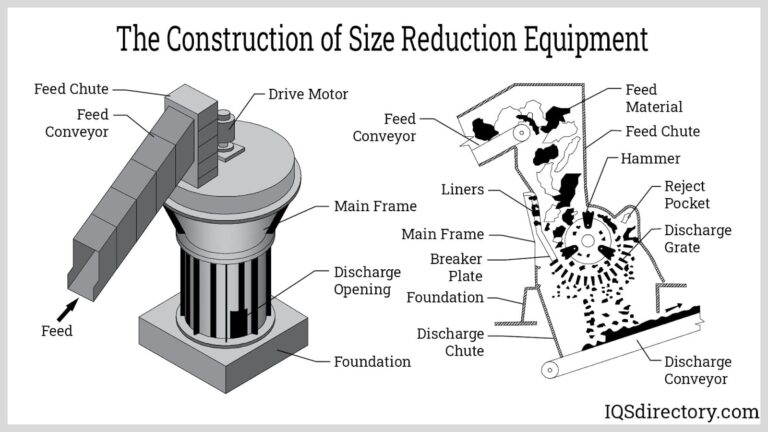

What Are the Key Stages in the Manufacturing Process of 8×170 Wheels?

The manufacturing process for 8×170 wheels involves several critical stages that ensure the final product meets the required specifications for performance and durability. Understanding these stages is crucial for B2B buyers who are sourcing wheels for commercial or industrial applications.

Material Preparation: What Materials Are Used?

The first step in manufacturing 8×170 wheels is material preparation. Typically, manufacturers utilize aluminum or steel, with aluminum being favored for its lightweight properties and aesthetic appeal. For steel wheels, high-strength steel is often chosen for its durability and cost-effectiveness. The materials undergo rigorous quality checks before production begins, including chemical composition analysis and mechanical property assessments to ensure they meet industry standards.

How Are 8×170 Wheels Formed?

Once the materials are prepared, the next stage involves forming the wheel. This can be accomplished through various techniques such as casting or forging.

Illustrative image related to 8×170 wheels

-

Casting: In this process, molten metal is poured into a mold that shapes the wheel. This method allows for complex designs and is generally more cost-effective for large-scale production.

-

Forging: This technique involves shaping the wheel by applying pressure to the metal at high temperatures, resulting in a stronger and more durable product. Forged wheels are often preferred for high-performance applications due to their superior strength-to-weight ratio.

After forming, the wheels undergo machining to achieve precise dimensions, including the bolt pattern, which in this case is 8×170.

What Finishing Processes Are Applied to 8×170 Wheels?

The finishing stage includes several processes that enhance the wheel’s aesthetic appeal and protect it from environmental factors. Common finishing techniques include:

-

Powder Coating: This is a popular method that involves applying a dry powder that is then cured under heat, resulting in a durable and attractive finish.

-

Anodizing: This electrochemical process adds a protective layer to aluminum wheels, improving corrosion resistance and surface hardness.

-

Polishing: For those seeking a high-shine appearance, polishing is employed to achieve a reflective surface.

Each finishing method has its advantages, and the choice often depends on the intended use of the wheel and customer preferences.

Illustrative image related to 8×170 wheels

What Quality Assurance Measures Are in Place for 8×170 Wheels?

Quality assurance (QA) is a critical component of the manufacturing process, especially for B2B buyers who require reliability and safety in their products. Various international and industry-specific standards guide these processes.

Which International Standards Apply to Wheel Manufacturing?

Manufacturers of 8×170 wheels often adhere to international standards such as ISO 9001, which outlines criteria for an effective quality management system. Compliance with these standards assures buyers of consistent quality and continuous improvement in manufacturing processes.

Additionally, certain products may require certifications such as CE marking for compliance with European safety regulations or API specifications for wheels used in specific industrial applications.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early. Key QC checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During production, regular inspections are conducted to monitor processes and detect any deviations from quality standards.

-

Final Quality Control (FQC): After the wheels are completed, a final inspection checks for dimensional accuracy, surface finish, and overall quality before the products are shipped.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, must ensure that their suppliers maintain high-quality standards. Here are several ways to verify a supplier’s QC measures:

Illustrative image related to 8×170 wheels

What Documentation Should Buyers Request?

Buyers should request documentation that outlines the supplier’s quality management practices, including:

-

Quality Assurance Manuals: These documents provide insight into the supplier’s QA processes and adherence to international standards.

-

Inspection Reports: Detailed reports from IQC, IPQC, and FQC stages should be available for review.

-

Certification Copies: Certifications such as ISO 9001 or CE should be provided to confirm compliance with quality standards.

How Can Third-Party Inspections Enhance Buyer Confidence?

Engaging third-party inspection agencies can significantly enhance buyer confidence. These agencies conduct independent assessments of the supplier’s manufacturing processes and product quality, providing an unbiased evaluation. Buyers should consider incorporating these inspections into their procurement process, especially for high-value purchases.

What Are the Quality Control Nuances for International Buyers?

When sourcing 8×170 wheels from international suppliers, buyers must be aware of regional differences in quality standards and regulations.

-

Understanding Regional Certifications: Different countries may have specific certifications that are recognized locally but not internationally. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Logistical Considerations: Quality control doesn’t end at the factory. Buyers should consider the logistics of shipping and handling, as improper transport can compromise product integrity. Ensuring that suppliers have robust logistics strategies in place is crucial.

-

Cultural Sensitivity in Communication: Effective communication is key to successful international transactions. Understanding cultural nuances can facilitate better negotiations and clearer expectations regarding quality standards.

Conclusion: Ensuring Quality in 8×170 Wheel Manufacturing

For B2B buyers, a comprehensive understanding of the manufacturing processes and quality assurance measures for 8×170 wheels is essential. By focusing on material preparation, forming techniques, and finishing processes, along with rigorous quality control checkpoints, buyers can make informed decisions that ensure they receive high-quality products that meet their specific needs. Engaging with suppliers who adhere to international standards and providing transparent documentation enhances trust and reduces risks in the procurement process.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘8×170 wheels’

In the competitive landscape of automotive parts sourcing, particularly for 8×170 wheels, having a systematic approach is essential for making informed procurement decisions. This checklist is designed to guide international B2B buyers through the sourcing process, ensuring that you find the right products at the right price while minimizing risks.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Identify critical attributes such as diameter, width, offset, and load rating that align with your vehicle’s requirements. This clarity will help streamline your search and ensure compatibility with your fleet or client needs.

- Diameter: Common sizes for 8×170 wheels range from 16” to 24”.

- Offset: Understand how offset impacts handling and aesthetics to meet performance standards.

Step 2: Conduct Market Research

Gather data on current market trends, pricing, and available styles for 8×170 wheels. Knowing the average price range and variations in styles will empower you to negotiate better deals with suppliers.

Illustrative image related to 8×170 wheels

- Price Variations: Recognize that prices can vary significantly based on brand, material (cast vs. forged), and finish.

- Style Trends: Be aware of popular styles and finishes to cater to your clients’ preferences.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, a thorough evaluation is crucial. Request company profiles, product samples, and references from previous clients in your industry. This ensures that the supplier is credible and capable of meeting your needs.

- Supplier Credentials: Look for certifications such as ISO standards that indicate quality management systems.

- Customer Feedback: Seek testimonials or case studies that demonstrate the supplier’s reliability and product performance.

Step 4: Verify Compliance with International Standards

Ensure that the wheels comply with international safety and quality standards, particularly if you are sourcing for regions with specific regulations, such as Europe or South America.

- Regulatory Compliance: Familiarize yourself with local regulations regarding automotive parts to avoid legal complications.

- Quality Assurance: Request documentation that confirms adherence to safety standards, such as ISO or SAE certifications.

Step 5: Negotiate Terms and Conditions

Once you identify potential suppliers, negotiate the terms of purchase, including payment methods, delivery timelines, and return policies. Clear agreements will mitigate risks and ensure smooth transactions.

Illustrative image related to 8×170 wheels

- Payment Options: Explore financing options that can ease cash flow, especially for bulk purchases.

- Delivery Terms: Discuss shipping options, costs, and lead times to prevent unexpected delays.

Step 6: Request Samples or Prototype Testing

Before finalizing your order, request samples or arrange for prototype testing. This step allows you to assess the quality and fit of the wheels firsthand, ensuring they meet your specifications.

- Quality Control: Inspect samples for material quality, finish, and workmanship.

- Fitment Testing: Ensure compatibility with your vehicles through physical testing or consultation with fitment specialists.

Step 7: Establish a Long-term Relationship with Suppliers

Building a long-term relationship with reliable suppliers can lead to better pricing, priority service, and exclusive product access. Maintain open communication and provide feedback to foster collaboration.

- Feedback Loop: Share your experiences to help suppliers improve their offerings.

- Future Opportunities: Discuss potential future needs and how the supplier can accommodate them.

By following this checklist, B2B buyers can navigate the complexities of sourcing 8×170 wheels effectively, ensuring a successful procurement process that meets both quality and operational requirements.

Comprehensive Cost and Pricing Analysis for 8×170 wheels Sourcing

In the competitive landscape of sourcing 8×170 wheels, understanding the cost structure and pricing dynamics is crucial for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis outlines the key cost components, price influencers, and strategic tips for buyers looking to optimize their purchasing decisions.

What Are the Key Cost Components for 8×170 Wheels?

The cost structure for 8×170 wheels comprises several essential components:

-

Materials: The choice of materials significantly impacts pricing. Common materials include aluminum and steel, with aluminum wheels typically being more expensive due to their lighter weight and enhanced performance characteristics. Higher-grade alloys or specialized finishes can further increase material costs.

-

Labor: Labor costs vary based on the manufacturing location and the complexity of the wheel design. Regions with lower labor costs may offer more competitive pricing, but this can also lead to quality concerns.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help keep these costs lower.

-

Tooling: The initial investment in tooling for custom or specialized wheel designs can be significant. Buyers should consider whether they need standard or custom specifications, as this will affect the upfront costs.

-

Quality Control (QC): Implementing stringent QC processes ensures that the wheels meet safety and performance standards. However, robust QC measures can add to the overall cost.

-

Logistics: Shipping costs are a major factor, especially for international buyers. Factors such as distance, shipping method, and customs duties can significantly influence total costs.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the market rates for similar products can help buyers gauge if they are being charged fairly.

How Do Price Influencers Affect 8×170 Wheel Sourcing?

Several factors can influence the pricing of 8×170 wheels:

-

Volume/MOQ: Purchasing in bulk can lead to lower per-unit costs. Suppliers often have minimum order quantities (MOQs), and exceeding these can unlock better pricing structures.

-

Specifications and Customization: Custom designs or specific requirements (like unique offsets or finishes) can increase costs. Buyers should balance their needs against the potential price increase.

-

Materials and Quality Certifications: Wheels that meet higher quality standards or certifications will generally command a premium price. It’s vital to assess whether these certifications are necessary for your market.

-

Supplier Factors: The supplier’s reputation, production capacity, and reliability can also impact pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding Incoterms can help buyers determine who bears the cost and risk during shipping. This knowledge can prevent unexpected charges and facilitate smoother transactions.

What Are the Best Practices for Negotiating Prices on 8×170 Wheels?

B2B buyers should consider the following strategies to optimize their purchasing process:

-

Negotiate with Multiple Suppliers: Engaging with several suppliers can create competition, leading to better pricing. Always request quotes and compare them based on similar specifications.

-

Focus on Total Cost of Ownership (TCO): When evaluating prices, consider not just the upfront cost but also the long-term costs associated with maintenance, durability, and performance. This perspective can lead to more informed purchasing decisions.

-

Understand Pricing Nuances in International Markets: Buyers from regions like Africa and South America may face additional challenges such as tariffs, currency fluctuations, and varying local demand. Being aware of these factors can aid in more effective negotiations.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better terms, discounts, and flexibility in future transactions.

Conclusion

Sourcing 8×170 wheels involves navigating a complex web of costs and pricing factors. By understanding the cost components, recognizing the influencers on pricing, and employing strategic negotiation tactics, B2B buyers can achieve favorable outcomes in their purchasing endeavors. As market conditions and supplier dynamics evolve, staying informed and adaptable will be key to successful sourcing.

Disclaimer: Prices referenced in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always confirm current pricing with suppliers directly.

Alternatives Analysis: Comparing 8×170 wheels With Other Solutions

Introduction: Exploring Alternatives to 8×170 Wheels

When considering wheel options for vehicles with an 8×170 bolt pattern, it’s essential to evaluate alternatives that might offer similar benefits or improved performance. While 8×170 wheels are popular for specific vehicle models, such as the Ford F250 and F350, various other wheel configurations and technologies can also meet the needs of international B2B buyers. This analysis compares 8×170 wheels with two viable alternatives: 8×165.1 wheels and forged wheels, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | 8×170 Wheels | 8×165.1 Wheels | Forged Wheels |

|---|---|---|---|

| Performance | Excellent load capacity | Good load capacity | Superior strength and weight-saving |

| Cost | Moderate ($300 – $1,200/set) | Generally lower ($250 – $1,000/set) | Higher ($1,000 – $3,000/set) |

| Ease of Implementation | Direct fit for specific models | Requires adapters for some vehicles | Direct fit but needs expert installation |

| Maintenance | Standard upkeep | Similar upkeep | Minimal due to durability |

| Best Use Case | Heavy-duty trucks | Light to medium-duty vehicles | Performance and racing applications |

Detailed Breakdown of Alternatives

8×165.1 Wheels: A Cost-Effective Option

8×165.1 wheels serve as a solid alternative, particularly for light to medium-duty vehicles. They typically come at a lower cost compared to 8×170 wheels, making them attractive for budget-conscious buyers. However, they may require adapters for vehicles originally designed for 8×170 wheels, which could complicate installation. While they offer good load capacity, they may not provide the same performance benefits as 8×170 wheels in heavy-duty applications. Therefore, they are best suited for vehicles that don’t require extensive load-bearing capabilities.

Forged Wheels: High Performance and Durability

Forged wheels are recognized for their superior strength and lightweight characteristics, making them ideal for performance vehicles and racing applications. Although they come at a higher price point, the investment can pay off through improved handling and reduced wear on vehicle components. Forged wheels typically have a longer lifespan, which can reduce overall maintenance costs. However, they may require expert installation, particularly if custom modifications are necessary for fitment. This makes them a less straightforward option for buyers seeking a simple, direct replacement.

Illustrative image related to 8×170 wheels

Conclusion: Choosing the Right Wheel Solution for Your Needs

In selecting the most appropriate wheel solution, B2B buyers should consider the specific requirements of their vehicles, including load capacity, intended use, and budget constraints. While 8×170 wheels are excellent for heavy-duty applications, alternatives like 8×165.1 wheels can provide cost savings for lighter vehicles, and forged wheels offer unmatched performance for racing enthusiasts. Ultimately, the decision should align with the operational needs and financial considerations of the business, ensuring optimal performance and cost-effectiveness in the long run.

Essential Technical Properties and Trade Terminology for 8×170 wheels

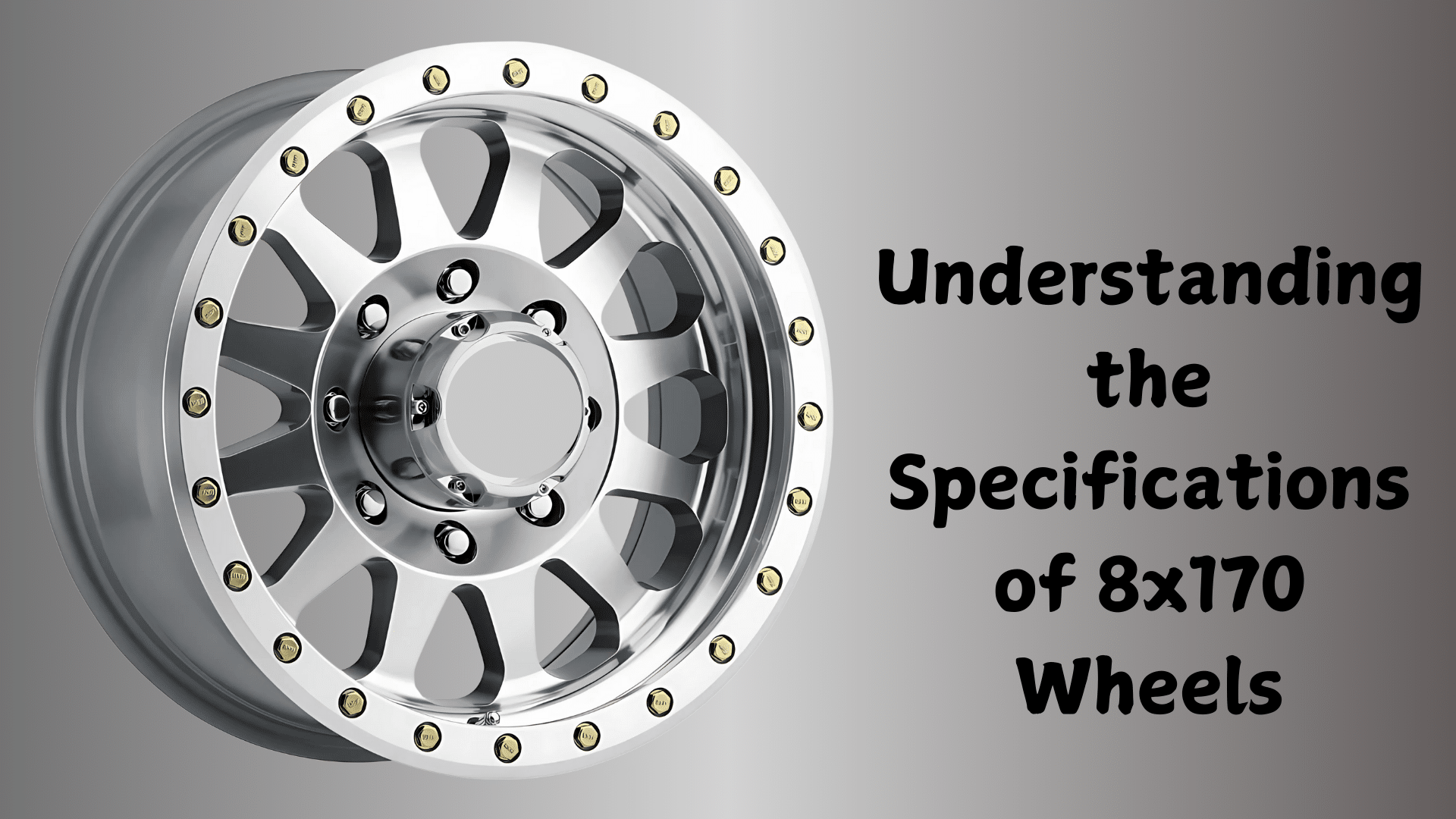

What Are the Key Technical Properties of 8×170 Wheels?

When sourcing 8×170 wheels, understanding the following technical properties is essential for making informed purchasing decisions. Each specification plays a critical role in ensuring compatibility, performance, and durability for vehicles, particularly in demanding environments.

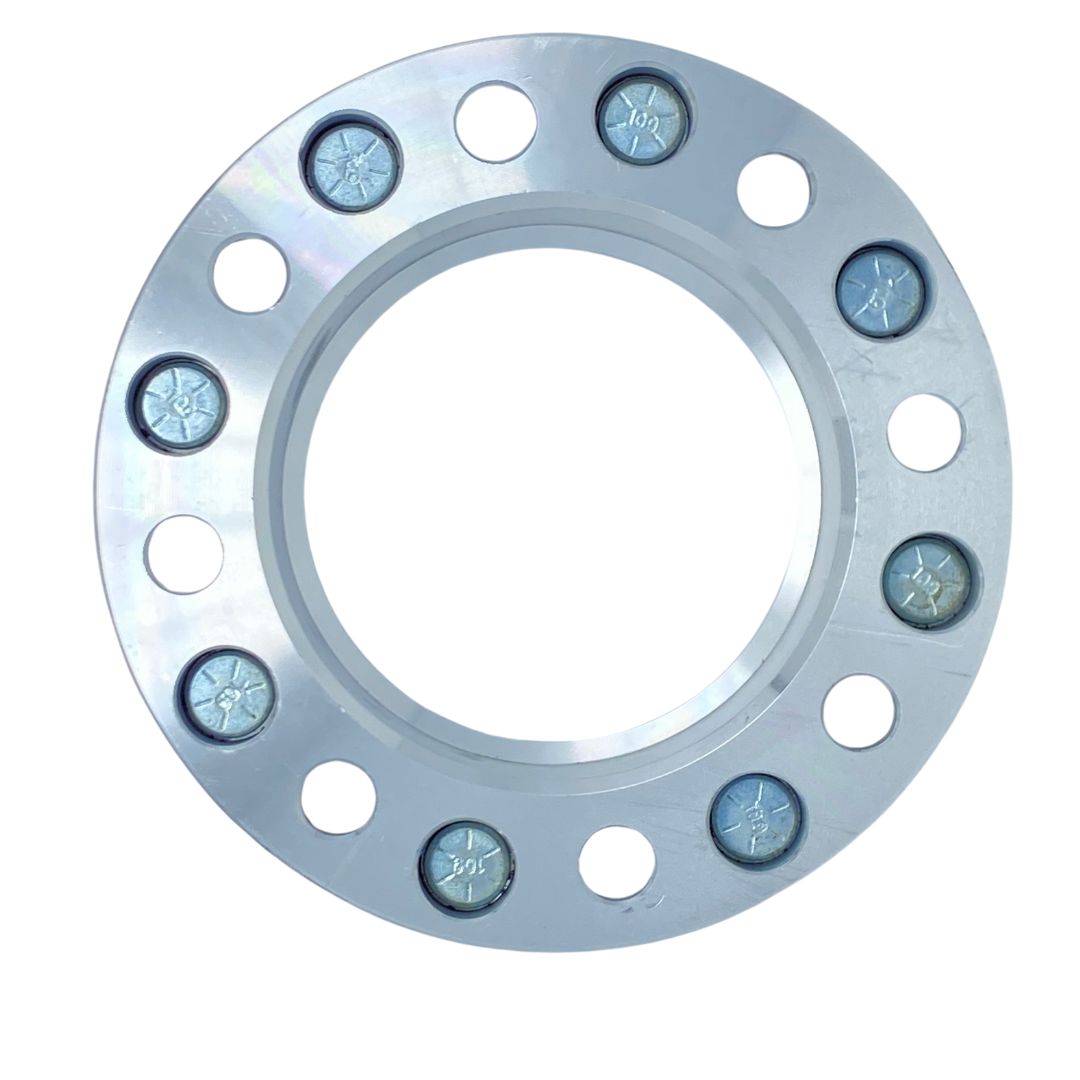

1. Bolt Pattern (8×170)

The bolt pattern is a crucial specification, indicating the number of bolts (8) and the distance (170 mm) between them. It ensures that the wheels fit securely onto the vehicle’s hub. For buyers, verifying the bolt pattern against their vehicle’s specifications is essential to avoid compatibility issues, which can lead to safety risks and additional costs.

2. Offset

Offset refers to the distance from the wheel’s centerline to the mounting surface. It can be positive, negative, or zero, affecting the vehicle’s handling, suspension geometry, and tire clearance. Selecting the correct offset is vital to maintain proper alignment and avoid premature tire wear. B2B buyers should consult with fitment specialists to determine the optimal offset for their specific vehicle applications.

3. Load Rating

The load rating indicates the maximum weight a wheel can safely support. It is expressed in pounds or kilograms and is critical for ensuring that the wheel can handle the demands of heavy-duty applications, such as those found in commercial vehicles or off-road environments. Buyers must match the load rating to their vehicle’s requirements to prevent wheel failure and ensure operational safety.

4. Material Composition

Wheels are typically made from materials like aluminum alloy or steel. Aluminum wheels are lighter and often preferred for performance, while steel wheels offer higher durability and resistance to impacts. Understanding the material composition helps buyers assess the trade-offs between weight, strength, and cost, ultimately influencing their purchasing decision.

5. Diameter and Width

Wheel diameter (measured in inches) and width are critical specifications that influence tire selection and overall vehicle performance. Common sizes for 8×170 wheels range from 16” to 24”. Buyers need to ensure that the diameter and width align with their vehicle’s requirements and intended use, whether for on-road or off-road applications.

Illustrative image related to 8×170 wheels

6. Center Bore

The center bore is the hole at the back of the wheel that fits over the hub of the vehicle. It is essential for ensuring proper fitment and alignment. A mismatch can lead to vibrations and unsafe driving conditions. Buyers should verify that the center bore matches their vehicle’s specifications or consider using hub-centric rings for proper fitment.

What Are Common Trade Terms Related to 8×170 Wheels?

Understanding industry jargon can significantly enhance communication and facilitate smoother transactions in the B2B marketplace. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the vehicle’s original manufacturer. When sourcing wheels, OEM products are often preferred for their guaranteed compatibility and quality. Buyers should consider whether they require OEM wheels or if aftermarket options meet their needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers, as it affects inventory levels and cash flow. Understanding MOQ helps businesses plan their purchases effectively, particularly when entering new markets or launching new products.

3. RFQ (Request for Quotation)

An RFQ is a formal process through which buyers solicit pricing and terms from suppliers. Submitting an RFQ allows buyers to compare offers and negotiate better terms. It is an essential step for ensuring competitive pricing, particularly in bulk orders.

Illustrative image related to 8×170 wheels

4. Incoterms

Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms is vital for B2B transactions, as they clarify who bears the risk and costs associated with shipping, insurance, and customs. Understanding Incoterms helps prevent disputes and ensures smooth logistics.

5. Fitment Guarantee

A fitment guarantee assures buyers that the wheels will fit their specific vehicle model without modification. This assurance is crucial for buyers, especially those purchasing in bulk, as it reduces the risk of returns and ensures customer satisfaction.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 8×170 wheels, ensuring they meet the demands of their specific applications while optimizing costs and operational efficiency.

Illustrative image related to 8×170 wheels

Navigating Market Dynamics and Sourcing Trends in the 8×170 wheels Sector

What Are the Current Market Dynamics and Key Trends Affecting the 8×170 Wheels Sector?

The global market for 8×170 wheels is experiencing significant growth, driven by the increasing demand for heavy-duty vehicles, particularly in sectors such as construction, agriculture, and transportation. This surge is particularly evident in emerging markets across Africa, South America, and the Middle East, where infrastructure development is on the rise. The expansion of e-commerce and the need for logistics solutions are also propelling the demand for vehicles equipped with robust wheel systems like those featuring the 8×170 bolt pattern, predominantly found in Ford F250 and F350 models.

In terms of technology, B2B buyers are increasingly leveraging online platforms for sourcing wheels, benefiting from enhanced transparency and a broader selection. Innovations such as 3D printing for prototypes and advanced inventory management systems are streamlining the sourcing process, allowing buyers to respond quickly to market demands. Additionally, the integration of AI-driven analytics is empowering suppliers to forecast trends and optimize their product offerings based on real-time data.

Another trend is the growing preference for customizability, as buyers seek wheels that not only meet functional requirements but also align with brand aesthetics. Color finishes, offsets, and wheel sizes from 16” to 26” are becoming critical factors in purchasing decisions. This shift calls for suppliers to remain agile and responsive to diverse buyer needs, particularly in regions where vehicle personalization is a significant market driver.

How Is Sustainability and Ethical Sourcing Influencing the 8×170 Wheels Industry?

Sustainability is emerging as a key consideration for B2B buyers in the 8×170 wheels market. The environmental impact of manufacturing processes, particularly in metal casting and forging, is under scrutiny. Suppliers are increasingly adopting eco-friendly practices, such as using recycled materials and reducing carbon footprints in production. This shift not only meets regulatory requirements but also caters to a growing segment of buyers who prioritize sustainability in their purchasing decisions.

Illustrative image related to 8×170 wheels

Ethical sourcing is gaining traction, with buyers favoring suppliers who demonstrate transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and Fair Trade are becoming essential for companies looking to establish credibility in the marketplace. For instance, manufacturers who can certify that their aluminum sourcing is responsible and free from conflict minerals are likely to gain a competitive edge.

Furthermore, the use of ‘green’ materials, such as eco-friendly coatings and sustainable packaging, is being promoted by suppliers to appeal to environmentally conscious buyers. As the global focus on climate change and sustainability intensifies, B2B buyers in the 8×170 wheels sector will increasingly seek partnerships with manufacturers who align with these values, shaping future procurement strategies.

What Is the Evolution and Historical Context of 8×170 Wheels in the B2B Marketplace?

The 8×170 wheel pattern has its roots in the late 1990s, primarily designed to accommodate heavy-duty trucks like the Ford F250 and F350. Initially, the market was limited to a few manufacturers, but as demand grew, so did the diversity of styles and materials available.

Illustrative image related to 8×170 wheels

In the early 2000s, the rise of customization trends led to an influx of aftermarket suppliers, expanding the options for buyers in terms of design and functionality. Over the past decade, technological advancements in manufacturing processes have allowed for more precise engineering and innovative designs, catering to an increasingly discerning customer base.

Today, the 8×170 wheel market stands as a testament to the balance between performance and aesthetics, with manufacturers now offering a wide range of finishes, offsets, and sizes. This evolution reflects broader trends within the automotive industry, where personalization and performance are paramount, providing B2B buyers with a wealth of choices to meet their specific needs.

Frequently Asked Questions (FAQs) for B2B Buyers of 8×170 wheels

-

1. How do I determine the right 8×170 wheels for my vehicle?

To select the appropriate 8×170 wheels, start by identifying your vehicle’s specifications, including make, model, and year. Most commonly, vehicles like the Ford F250 and F350 from 1999 onward utilize this bolt pattern. Utilize online fitment guides provided by suppliers to match your vehicle with compatible wheel sizes, widths, and offsets. Always confirm details with a fitment specialist to ensure optimal compatibility and performance. -

2. What is the best material for 8×170 wheels in terms of durability?

When selecting wheels, forged aluminum is often considered the best option for durability and performance due to its superior strength-to-weight ratio. Cast aluminum wheels are also popular and generally more affordable, but they may not withstand extreme conditions as well as forged wheels. Consider your application—heavy-duty use may warrant investing in forged wheels, while lighter applications could suffice with cast options. -

3. What customization options are available for 8×170 wheels?

Customization options for 8×170 wheels can vary widely among manufacturers. Common customizations include selecting specific diameters, widths, offsets, and finishes such as matte, gloss, or chrome. Some suppliers also offer bespoke designs or the ability to incorporate branding elements. Communicating your specific needs to suppliers can help facilitate the design process and ensure that the wheels meet your requirements. -

4. What are the minimum order quantities (MOQs) for 8×170 wheels when sourcing internationally?

Minimum order quantities for 8×170 wheels can vary significantly based on the manufacturer and your location. Typically, MOQs range from 4 to 100 wheels, depending on the supplier’s capabilities and production processes. It’s advisable to discuss your needs directly with potential suppliers, as some may offer flexibility on MOQs for first-time orders or larger contracts. -

5. How can I vet suppliers when sourcing 8×170 wheels?

To effectively vet suppliers, start by researching their reputation within the industry. Look for reviews, testimonials, and case studies from previous clients. Request samples to assess product quality and confirm compliance with international standards. Additionally, verify their certifications, production capabilities, and customer service responsiveness. Building relationships with suppliers who understand your market can also lead to more successful partnerships. -

6. What payment terms should I negotiate when sourcing 8×170 wheels?

When negotiating payment terms, consider options that balance your cash flow needs with supplier requirements. Common terms include net 30, net 60, or even upfront payments for custom orders. It’s essential to discuss and clarify terms such as deposits, milestones, and payment methods (e.g., wire transfers, letters of credit). Establishing clear terms can help avoid misunderstandings and ensure smooth transactions. -

7. What quality assurance measures should I expect from suppliers of 8×170 wheels?

Reputable suppliers should have robust quality assurance (QA) protocols in place, including material inspections, dimensional checks, and performance testing. Inquire about their QA certifications and whether they conduct third-party inspections. Suppliers should also provide warranties or guarantees on their products, ensuring that any defects or issues are addressed promptly. Establishing these expectations upfront can help safeguard your investment. -

8. How do logistics and shipping impact the sourcing of 8×170 wheels?

Logistics and shipping are critical components of the sourcing process. Consider factors such as shipping costs, delivery times, and customs regulations when planning your order. Opt for suppliers who offer fast and reliable shipping options, and inquire about their handling of potential delays or damages during transit. Understanding the logistics involved can help you better manage inventory and meet customer demands effectively.

Top 6 8X170 Wheels Manufacturers & Suppliers List

1. Discounted Wheel Warehouse – 8×170 Bolt Pattern Wheels

Domain: discountedwheelwarehouse.com

Introduction: 8×170 Bolt Pattern Wheels and Rims available in multiple sizes (17″, 18″, 20″, 22″, 24″) and finishes (chrome, matte black, satin black, unique milled and machined variants). Suitable for commercial trucks and SUVs including Ford Super Duty, Dodge Ram, Chevrolet, and GMC Sierra series. Discounted Wheel Warehouse offers a wide selection of styles.

2. eBay – 8×170 Car and Truck Wheels

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 8×170 Car and Truck Wheels for sale on eBay. Related searches include 8×170 Wheels and Tires, 8×170 Rims, 8×170 Steel Wheels, and various rim diameters and widths. Categories include other wheel and tire parts, tire pressure monitoring sensors, and wheel accessories. The listing features a variety of options with a bolt pattern of 8×170.

3. BB Wheels – 8×170 Bolt Pattern Wheels

Domain: bbwheelsonline.com

Registered: 2012 (13 years)

Introduction: 8×170 Bolt Pattern Wheels | Free Shipping To Lower 48 States | Financing all Credit Types | Contact: 320-333-2155 | Text: 507-432-2127

4. Facebook – 8×170 Wheels For Sale/Trade

Domain: facebook.com

Introduction: 8×170 Wheels For Sale/Trade

5. Alcoa – 22.5×8.25 High Polished Wheels

Domain: buytruckwheels.com

Registered: 2008 (17 years)

Introduction: Ford Light Truck Wheels – tagged “8 on 170mm” – Free Shipping on All Orders! Popular Products include: 1. Alcoa Wheels 22.5×8.25 Alcoa High Polished Both Sides 10x285mm – Price: $329.00, SKU: ULA187. 2. Northstar 19.5×6.00 Northstar Mirror Polished Both Sides 2012-2018 Dodge Ram 3500 DRW 8×6.5″ 6 Wheel Direct Bolt Kit – Price: $2,199.00, SKU: 495600-NorthstarM14. 3. Northstar 22.5 Black Aluminum H…

6. The Wheel Shop – 8X170 Wheels

Domain: thewheelshop.ca

Registered: 2019 (6 years)

Introduction: 8X170 WHEELS available at The Wheel Shop CA INC. Free shipping on orders over $350 for most Canadian provinces. Current promotion: 6% OFF with coupon “WHEEL6”. Hassle-free returns within 90 days. The collection includes various lug patterns such as 8×165.1 mm, 8×180 mm, 8×200 mm, and 8×210 mm. The site also offers a wide range of wheels including alloy, steel, and replica options, as well as tires…

Strategic Sourcing Conclusion and Outlook for 8×170 wheels

In navigating the complex landscape of sourcing 8×170 wheels, international buyers must prioritize strategic sourcing to maximize value and ensure the best fit for their specific needs. Understanding the diverse options available, from forged to cast wheels, allows businesses to tailor their purchases based on performance requirements and budget constraints. Establishing relationships with reliable suppliers who offer competitive pricing, efficient shipping, and comprehensive customer support will enhance procurement strategies.

As demand for 8×170 wheels continues to grow in regions such as Africa, South America, the Middle East, and Europe, particularly in markets like Germany and Saudi Arabia, buyers should leverage their purchasing power to negotiate favorable terms. Emphasizing quality and durability in wheel selection not only supports long-term operational efficiency but also strengthens brand reputation.

Looking ahead, the market for 8×170 wheels is poised for innovation and expansion. Buyers are encouraged to explore emerging technologies and sustainable manufacturing practices that may offer additional benefits. Engage with suppliers proactively and capitalize on the opportunities that arise in this dynamic sector to secure a competitive edge.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.