600D Polyester By The Yard: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for 600d polyester by the yard

In the dynamic landscape of global textiles, sourcing high-quality 600d polyester by the yard presents a significant challenge for B2B buyers across diverse markets. With its robust nature and versatility, 600d polyester is favored for a multitude of applications, from durable outdoor gear to fashionable bags. However, navigating the complexities of suppliers, pricing, and product specifications can be daunting, especially for international buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Germany.

This comprehensive guide aims to demystify the global market for 600d polyester by the yard, equipping you with essential insights to make informed purchasing decisions. Within these pages, you will explore various types of 600d polyester fabrics, their applications, and key factors to consider when vetting suppliers. We will delve into pricing strategies, including bulk purchase discounts and cost-effective sourcing options, ensuring you maximize your investment.

By empowering you with the knowledge to navigate this market, this guide serves as a vital resource for businesses aiming to enhance their product offerings while maintaining quality and cost-efficiency. Whether you’re a seasoned buyer or new to the textile industry, understanding the nuances of 600d polyester will position your business for success in an increasingly competitive landscape.

Understanding 600d polyester by the yard Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Coated Solution Dyed Polyester | Water-resistant, UV resistant, durable polyurethane coating | Bags, luggage, outdoor gear | Pros: Excellent durability and colorfastness; Cons: Slightly higher cost due to coating process. |

| Uncoated Polyester | Lightweight, economical, versatile | Apparel, lightweight gear | Pros: Cost-effective; Cons: Less durable and water-resistant compared to coated options. |

| Printed 600D Polyester | Customizable designs, durable water repellent finish | Promotional products, custom gear | Pros: Unique branding opportunities; Cons: Longer lead times for production. |

| Mildew Resistant Polyester | Anti-mildew treatment, suitable for harsh environments | Marine applications, outdoor furniture | Pros: Ideal for damp conditions; Cons: May require specific cleaning methods. |

| Fire Retardant Polyester | Fire-resistant properties, suitable for safety applications | Industrial use, safety gear | Pros: Enhanced safety; Cons: Generally more expensive and may have limited color options. |

What Are the Characteristics of Coated Solution Dyed Polyester?

Coated solution dyed polyester is a premium fabric variant known for its exceptional water and UV resistance. The polyurethane coating on the back provides superior durability, making it ideal for products exposed to harsh outdoor conditions. This type of polyester is frequently used in the manufacturing of bags, luggage, and outdoor gear, where longevity and color retention are essential. B2B buyers should consider the initial higher cost as an investment in long-term performance.

How Does Uncoated Polyester Serve Various Applications?

Uncoated polyester is a lightweight and economical option that caters to a wide range of applications, including apparel and lightweight gear. Its versatility makes it a popular choice among manufacturers looking to balance quality and cost. However, buyers should be aware that uncoated polyester lacks the durability and water resistance of its coated counterparts, making it less suitable for outdoor applications.

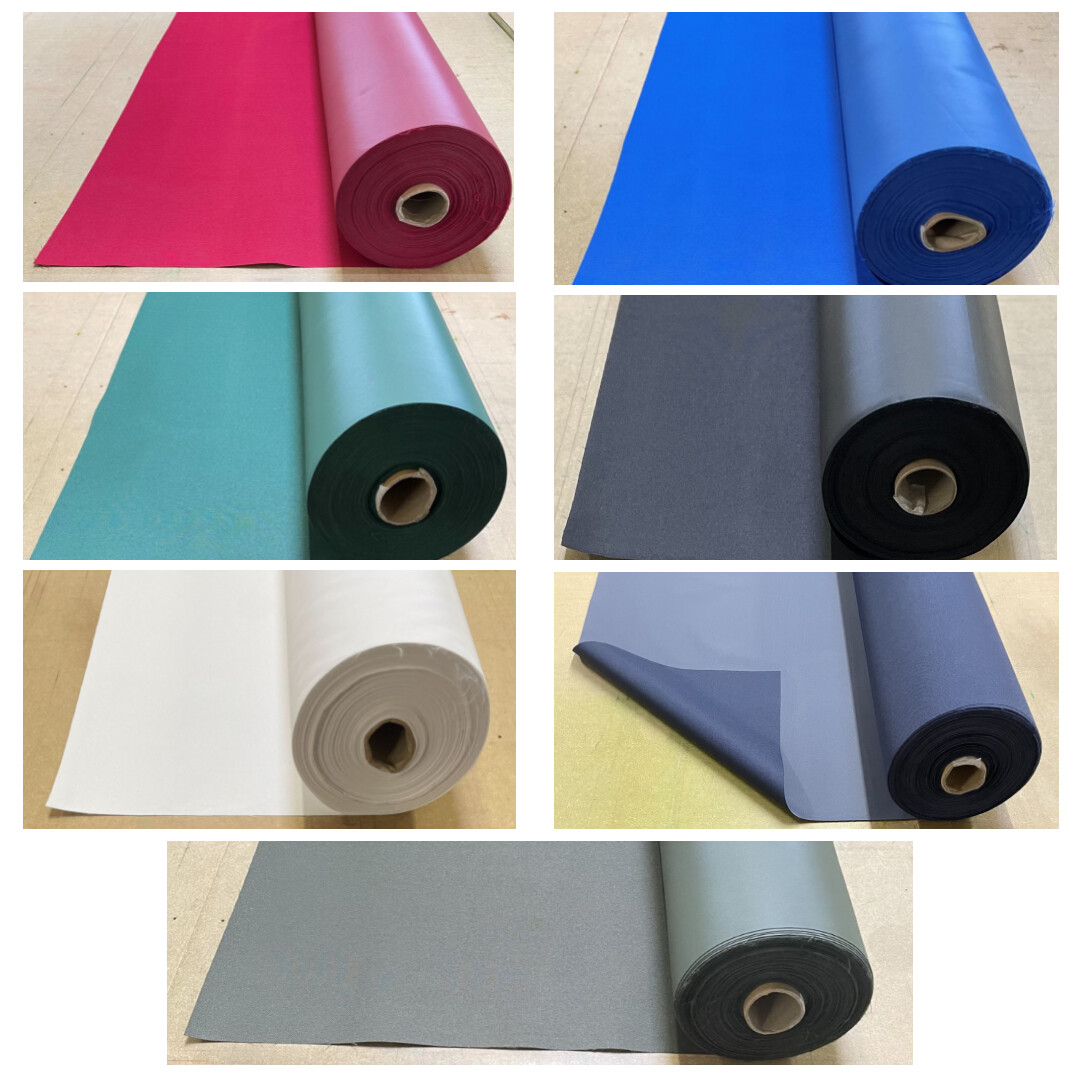

Illustrative image related to 600d polyester by the yard

What Are the Benefits of Printed 600D Polyester?

Printed 600D polyester offers unique branding opportunities through customizable designs while maintaining a durable water-repellent finish. This fabric is particularly appealing for promotional products and custom gear, allowing businesses to stand out in a competitive market. However, B2B buyers should anticipate longer lead times for production, which could impact project timelines.

Why Choose Mildew Resistant Polyester for Harsh Environments?

Mildew resistant polyester is specifically treated to withstand damp and humid conditions, making it an excellent choice for marine applications and outdoor furniture. This fabric type ensures longevity even in challenging environments, but buyers must consider that it may require specific cleaning methods to maintain its properties effectively.

What Should B2B Buyers Know About Fire Retardant Polyester?

Fire retardant polyester is designed for safety applications, providing essential fire-resistant properties. This type of fabric is commonly used in industrial settings and safety gear, where compliance with safety regulations is crucial. While the enhanced safety features are beneficial, B2B buyers should expect higher costs and potentially limited color options, which could impact design choices.

Key Industrial Applications of 600d polyester by the yard

| Industry/Sector | Specific Application of 600d polyester by the yard | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Equipment | Manufacturing tents and awnings | Durable, weather-resistant material for long-lasting products | Ensure UV resistance and waterproofing for outdoor conditions |

| Sports and Recreation | Production of duffel bags and backpacks | Lightweight yet strong fabric suitable for heavy loads | Consider colorfastness and abrasion resistance for longevity |

| Automotive | Seat covers and interior upholstery | Enhances durability and aesthetics of vehicle interiors | Verify compatibility with fire retardant standards |

| Marine Applications | Boat covers and tarpaulins | Provides protection against harsh marine environments | Assess water resistance and mildew resistance for longevity |

| Industrial Packaging | Custom storage bags and protective covers | Cost-effective solution for heavy-duty applications | Evaluate bulk purchasing options for cost savings |

How is 600d Polyester Used in Outdoor Equipment Manufacturing?

In the outdoor equipment sector, 600d polyester is commonly used to manufacture tents and awnings due to its robust durability and weather resistance. This fabric withstands various environmental conditions, making it ideal for outdoor adventures. Buyers should prioritize sourcing materials that offer UV resistance and waterproofing to ensure longevity and performance in harsh conditions, especially for international markets where climate variability can be significant.

Illustrative image related to 600d polyester by the yard

What Role Does 600d Polyester Play in Sports and Recreation?

For the sports and recreation industry, 600d polyester is utilized in the production of duffel bags and backpacks. This mid-weight fabric is strong enough to handle heavy loads while remaining lightweight for ease of transport. B2B buyers should consider factors such as colorfastness and abrasion resistance to guarantee that their products maintain a professional appearance and functionality over time, particularly in regions with high humidity or rigorous use.

How is 600d Polyester Beneficial for Automotive Applications?

In the automotive sector, 600d polyester is often employed for seat covers and interior upholstery. This fabric enhances the durability and aesthetic appeal of vehicle interiors while being easy to clean. International buyers, especially from regions with stringent safety regulations, should ensure that the polyester complies with fire retardant standards to meet local regulations and consumer expectations.

Why is 600d Polyester Important for Marine Applications?

600d polyester is a preferred choice for marine applications, including boat covers and tarpaulins. Its ability to resist water and mildew makes it essential for protecting vessels from the elements. Buyers need to assess the fabric’s water resistance and mildew resistance to ensure it performs well in marine environments, particularly in tropical regions where moisture levels are high.

Illustrative image related to 600d polyester by the yard

How is 600d Polyester Utilized in Industrial Packaging?

In industrial packaging, 600d polyester is used for custom storage bags and protective covers. Its durability provides a cost-effective solution for heavy-duty applications, ensuring that products remain safe during transport and storage. B2B buyers should evaluate bulk purchasing options to maximize cost savings while ensuring that the fabric meets the specific needs of their industry, particularly for businesses operating in diverse geographical regions.

3 Common User Pain Points for ‘600d polyester by the yard’ & Their Solutions

Scenario 1: Ensuring Quality and Consistency in Fabric Orders

The Problem: A B2B buyer sourcing 600D polyester by the yard often faces challenges in ensuring the quality and consistency of the fabric. Variations in dye lots can lead to discrepancies in color and texture, which can be particularly problematic for companies producing products that require uniformity, such as bags or outdoor gear. Additionally, different suppliers may have varying quality standards, making it difficult to maintain a consistent product offering.

The Solution: To overcome these challenges, buyers should establish strong relationships with reliable suppliers who can provide detailed product specifications and samples before placing bulk orders. Implementing a system for regular quality checks upon receipt of materials is crucial. Buyers should also consider ordering sufficient fabric in one go to minimize color lot variation. For instance, when placing an order, specify that you require a consistent dye lot and request a certification of quality. Additionally, maintaining an inventory of swatches from previous orders can aid in ensuring future orders match. By doing this, buyers can assure their end customers of the quality and consistency they expect.

Scenario 2: Managing Pricing Fluctuations and Bulk Orders

The Problem: Buyers in regions like Africa or South America may encounter significant pricing fluctuations when purchasing 600D polyester by the yard. This can be exacerbated by currency exchange rates and varying import tariffs, impacting their overall budget. Furthermore, smaller companies might struggle to meet minimum order quantities set by suppliers, which can lead to excess inventory or increased costs.

The Solution: One effective strategy is to negotiate bulk purchase agreements with suppliers, which can secure more stable pricing. Buyers should also explore forming purchasing cooperatives with other businesses in similar industries to collectively meet minimum order quantities, thus benefiting from bulk pricing without excess inventory risks. Additionally, it’s advisable to keep abreast of market trends and establish contracts that lock in prices for a set period. This approach not only mitigates the risk of price hikes but also allows for better financial planning. Buyers should also consider sourcing locally when possible, as this can reduce shipping costs and tariffs, thus stabilizing overall expenses.

Illustrative image related to 600d polyester by the yard

Scenario 3: Understanding the Technical Specifications of 600D Polyester

The Problem: Many B2B buyers may not fully understand the technical specifications of 600D polyester, such as its weight, coating types, and weather resistance. This knowledge gap can lead to purchasing materials that do not meet the specific requirements for their intended applications, resulting in product failures or unsatisfied customers. For instance, a company may mistakenly use an uncoated version for outdoor products, leading to rapid wear and customer complaints.

The Solution: To address this, buyers should invest time in education regarding fabric specifications and their implications for product performance. Attending industry webinars, workshops, or trade shows can provide valuable insights into the different types of 600D polyester and their best uses. Moreover, requesting comprehensive technical datasheets from suppliers can clarify the properties of the fabric, including its water resistance, UV stability, and weight. Additionally, engaging with suppliers for expert consultations can help determine the right type of 600D polyester for specific applications, ensuring that the purchased fabric aligns with product requirements. This proactive approach not only enhances product quality but also fosters long-term supplier relationships based on mutual understanding and trust.

Strategic Material Selection Guide for 600d polyester by the yard

What Are the Key Properties of 600d Polyester Fabrics?

600d polyester fabrics are characterized by their durability and versatility, making them suitable for a variety of applications. The “600d” refers to the denier, a unit of measurement that indicates the fabric’s thickness and strength. Key properties include a medium weight of approximately 6.2 oz/sq yd, which provides a balance between sturdiness and flexibility. Additionally, many variants come with a polyurethane coating that enhances water resistance and durability against UV rays, making them ideal for outdoor use.

What Are the Advantages and Disadvantages of 600d Polyester?

Pros:

– Durability: 600d polyester is known for its high tensile strength, making it resistant to wear and tear. This is particularly beneficial for products exposed to harsh conditions, such as outdoor gear and luggage.

– Water Resistance: The polyurethane coating provides excellent water repellency, which is essential for applications like boat covers and outdoor furniture.

– Cost-Effectiveness: Compared to other high-performance fabrics, 600d polyester is relatively affordable, making it an attractive option for bulk purchases.

Illustrative image related to 600d polyester by the yard

Cons:

– Breathability: While water-resistant, 600d polyester is not breathable, which may limit its use in applications requiring ventilation.

– Fire Resistance: Most 600d polyester fabrics are not fire retardant, which can be a limitation in specific industrial applications.

– Color Fastness: Although solution-dyed variants offer good UV resistance, color fading can occur over time, particularly in extreme sunlight.

How Does 600d Polyester Impact Specific Applications?

The application of 600d polyester varies significantly based on its properties. For instance, its robust nature makes it suitable for manufacturing bags, outdoor gear, and covers. The water-resistant quality is particularly advantageous for products used in wet conditions, such as raincoats and tarps. However, the lack of breathability may restrict its use in clothing designed for high-intensity activities.

What Should International B2B Buyers Consider When Sourcing 600d Polyester?

When sourcing 600d polyester, international buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider compliance with local standards such as ASTM, DIN, or JIS. Buyers should also be aware of the specific environmental conditions in their region, such as humidity and UV exposure, which may affect the performance of the fabric. Additionally, understanding the supply chain logistics and potential tariffs can impact overall costs and delivery timelines.

Illustrative image related to 600d polyester by the yard

Summary Table of 600d Polyester Materials

| Material | Typical Use Case for 600d Polyester by the Yard | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Coated Solution Dyed Polyester | Outdoor gear, bags, covers | Excellent water resistance and UV protection | Limited breathability | Medium |

| Uncoated Polyester | Basic applications, indoor use | Lower cost, lightweight | Less durable and water-resistant | Low |

| Printed 600d Polyester | Custom gear, fashion items | Customization options available | Potential for color fading | Medium |

| Heavyweight 600d Polyester | Industrial applications, heavy-duty bags | High tensile strength | Heavier weight may limit usability | High |

This strategic material selection guide provides essential insights for B2B buyers looking to source 600d polyester by the yard, ensuring they make informed decisions based on their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 600d polyester by the yard

What Are the Key Stages in the Manufacturing Process of 600D Polyester by the Yard?

The manufacturing of 600D polyester fabric involves several critical stages, each contributing to the fabric’s durability, performance, and suitability for various applications. Understanding these stages is essential for B2B buyers looking for quality products.

-

Material Preparation

The process begins with the selection of raw materials, primarily polyester fibers. The quality of these fibers can significantly impact the final product. Manufacturers typically use high-tenacity polyester to ensure strength and durability. The fibers are then processed to remove impurities and prepare them for spinning. -

Forming

Once the polyester fibers are prepared, they undergo spinning to create yarn. The spinning process can vary, with techniques such as ring spinning or open-end spinning being common. The yarn is then woven into a fabric using a plain weave method, which is essential for achieving the characteristic 600D (denier) strength. This step ensures that the fabric has the required weight and texture. -

Coating

Many 600D polyester fabrics undergo a coating process, typically involving a polyurethane layer. This coating enhances the fabric’s water resistance and durability. The application of a Durable Water Repellent (DWR) finish further improves the fabric’s performance in outdoor conditions, making it suitable for applications like bags, covers, and outdoor gear. -

Finishing

After coating, the fabric goes through various finishing processes. These may include heat setting, which stabilizes the fabric dimensions and improves its performance. Additional treatments may be applied to enhance colorfastness and UV resistance, ensuring longevity in outdoor applications. -

Quality Control

Before the fabric is rolled and packaged, it undergoes stringent quality control checks to ensure it meets industry standards. This includes visual inspections for defects, testing for strength and durability, and verifying that the fabric meets specific weight and width requirements.

How Is Quality Assurance Implemented in the Production of 600D Polyester?

Quality assurance (QA) is a vital aspect of manufacturing 600D polyester fabric, ensuring that the final product meets both international and industry-specific standards. For B2B buyers, understanding these QA processes can help in selecting reliable suppliers.

-

International Standards Compliance

Manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards indicates that the supplier has established processes to consistently deliver quality products. Additionally, specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply, depending on the intended use of the fabric. -

Quality Control Checkpoints

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers verify that the polyester fibers meet specified quality standards before processing begins.

– In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to monitor the production process. This includes checking the spinning, weaving, and coating stages to ensure compliance with quality specifications.

– Final Quality Control (FQC): Once the fabric is finished, it undergoes a final inspection to ensure it meets all requirements, including weight, width, and performance characteristics. This step is crucial for identifying any defects before the product is shipped. -

Common Testing Methods

Various testing methods are employed to assess the fabric’s performance characteristics. These include tensile strength tests, water resistance tests, and UV resistance tests. B2B buyers should inquire about the specific tests performed and the results to verify the quality of the fabric.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, ensuring supplier quality is paramount. Here are actionable steps to verify the quality control processes of potential suppliers.

-

Conduct Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This can include on-site visits to observe production practices and quality checks in action. B2B buyers should develop a checklist based on industry standards to guide these audits. -

Request Quality Control Reports

Suppliers should be willing to provide detailed quality control reports, including results from various tests and inspections. These reports can serve as documentation of the supplier’s commitment to quality assurance and compliance with international standards. -

Engage Third-Party Inspection Services

For added assurance, B2B buyers can engage third-party inspection services to assess the quality of the fabric before shipment. These independent inspections can validate the supplier’s quality claims and provide an unbiased evaluation of the product.

What Are the Quality Control Nuances for International B2B Buyers?

International trade can introduce complexities in quality assurance, particularly for buyers from diverse regions. Here are some nuances to consider:

Illustrative image related to 600d polyester by the yard

-

Understanding Regional Standards

Different regions may have varying standards and regulations governing textile products. Buyers should familiarize themselves with the standards applicable in their market, such as REACH regulations in Europe or specific import regulations in African countries. -

Language and Communication Barriers

Effective communication is critical in ensuring that quality expectations are clearly conveyed. B2B buyers should consider partnering with suppliers who have experience working with international clients and can provide documentation in the buyer’s preferred language. -

Cultural Differences in Business Practices

Business practices can vary significantly across regions. Understanding these cultural differences can help in establishing effective partnerships with suppliers. For instance, some regions may prioritize personal relationships in business dealings, while others may focus on contractual obligations.

Conclusion

The manufacturing processes and quality assurance mechanisms for 600D polyester by the yard are vital components that B2B buyers must understand. By comprehending the manufacturing stages, quality control checkpoints, and verification methods, buyers can make informed decisions when sourcing this versatile fabric. As international trade continues to grow, prioritizing quality assurance will ensure successful partnerships and high-quality products for various applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘600d polyester by the yard’

To successfully procure 600d polyester by the yard, it is essential to follow a systematic approach. This guide offers a step-by-step checklist that will help B2B buyers navigate the complexities of sourcing this versatile fabric, ensuring they meet their project requirements effectively.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your project’s technical requirements. Consider factors such as weight, width, color, coating, and any specific performance attributes like UV resistance or water repellency. Having these specifications will help you identify suitable products that meet your needs and avoid costly mistakes later.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to compile a list of potential suppliers. Look for companies that specialize in fabrics, particularly those with a strong reputation in the market for 600d polyester. Utilize online platforms, trade shows, and industry publications to gather insights and reviews about suppliers’ reliability and product quality.

Illustrative image related to 600d polyester by the yard

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess relevant certifications and adhere to quality standards. Certifications such as ISO 9001 indicate a commitment to quality management systems, while environmental certifications can reflect sustainable practices. These credentials can enhance your confidence in the supplier’s ability to deliver high-quality products consistently.

Step 4: Request Samples for Quality Assessment

Always request fabric samples before making bulk purchases. This allows you to assess the material’s texture, weight, and durability firsthand. Ensure the samples represent the specific color and coating you intend to order, as dye lots can vary. This step is vital to confirm that the fabric will perform as needed in your applications.

Step 5: Compare Pricing and Payment Terms

Once you have a shortlist of suppliers and have evaluated their samples, compare pricing structures and payment terms. Look for bulk discounts, shipping costs, and any additional fees. Establishing clear payment terms upfront can prevent misunderstandings later in the procurement process and help with cash flow management.

Illustrative image related to 600d polyester by the yard

Step 6: Confirm Lead Times and Shipping Logistics

Discuss lead times for production and shipping with your selected supplier. Understanding how long it will take to receive your order is crucial for planning your project timeline. Inquire about shipping methods, costs, and whether they can accommodate your specific delivery requirements, especially if you are sourcing internationally.

Step 7: Establish a Communication Plan

Set up a clear communication plan with your supplier to ensure ongoing dialogue throughout the sourcing process. Regular updates on order status, potential delays, and any issues that arise can foster a stronger working relationship. Effective communication helps mitigate risks and ensures that both parties are aligned on expectations.

By following these steps, B2B buyers can make informed decisions when sourcing 600d polyester by the yard, ensuring that they find the right fabric for their projects while fostering successful supplier relationships.

Comprehensive Cost and Pricing Analysis for 600d polyester by the yard Sourcing

What Are the Key Cost Components for Sourcing 600D Polyester by the Yard?

When sourcing 600D polyester by the yard, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The base cost of the fabric itself typically ranges from $3.50 to $22.00 per linear yard, depending on factors such as coating (polyurethane or other finishes), color, and whether the fabric is solution-dyed. Fabrics with additional features like fire retardancy or higher durability may command higher prices.

-

Labor: Labor costs can vary significantly based on the region and the manufacturing processes employed. Countries with lower labor costs may offer more competitive pricing, but this can also affect quality.

-

Manufacturing Overhead: This includes expenses related to running the manufacturing facilities, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing practices can help keep overhead low, thus influencing the final price.

-

Tooling: If custom designs or patterns are required, tooling costs will be incurred for setup and production. This is especially relevant for buyers looking for unique prints or specifications.

-

Quality Control (QC): Rigorous QC processes ensure that the fabric meets specific standards. Higher QC standards can lead to increased costs, but they also provide assurance of product quality.

-

Logistics: Shipping and handling costs are critical, particularly for international buyers. Factors such as distance, shipping method, and customs duties can significantly impact the total cost.

-

Supplier Margin: Each supplier will have a different margin based on their business model, market positioning, and value-added services. Understanding these margins can help buyers negotiate better pricing.

How Do Price Influencers Affect the Cost of 600D Polyester?

Several factors influence the pricing of 600D polyester, including order volume, specifications, material quality, and supplier reliability.

Illustrative image related to 600d polyester by the yard

-

Volume/MOQ: Many suppliers offer discounts for bulk purchases or minimum order quantities (MOQ). For instance, ordering 20 yards or more might yield a 22% discount, while ordering a full roll could provide even more savings.

-

Specifications and Customization: Custom features, such as specific colors, patterns, or coatings, can lead to higher prices. Buyers should assess whether these customizations are essential for their projects to avoid unnecessary costs.

-

Materials and Quality Certifications: Fabrics with certifications (e.g., UV resistance, water repellency) generally cost more. Buyers should weigh the benefits of these certifications against their project requirements.

-

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers with a track record of quality may charge a premium, but they often provide better service and assurance.

-

Incoterms: Understanding shipping terms is crucial for international buyers. Different Incoterms can influence total landed costs, affecting pricing negotiations.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing 600D Polyester?

-

Negotiation: Always negotiate prices, especially when placing large orders. Suppliers may have wiggle room in their pricing and may be willing to offer discounts for loyalty or long-term contracts.

-

Total Cost of Ownership: Consider the total cost of ownership rather than just the purchase price. This includes shipping, potential wastage, and the cost of any additional treatments or coatings required.

-

Research and Compare Suppliers: Conduct thorough research on multiple suppliers to compare pricing, quality, and service. This not only aids in finding the best deal but also provides leverage during negotiations.

-

Be Aware of Pricing Nuances for International Transactions: International buyers should be mindful of currency fluctuations, tariffs, and import duties, which can alter the effective price of the fabric.

-

Stay Informed About Market Trends: Prices can fluctuate based on global supply chain issues, demand spikes, or changes in raw material costs. Staying informed can help buyers make timely purchasing decisions.

In conclusion, understanding the intricate cost components and price influencers associated with sourcing 600D polyester by the yard allows buyers to optimize their purchasing strategies and enhance overall cost-efficiency.

Alternatives Analysis: Comparing 600d polyester by the yard With Other Solutions

When evaluating fabric options for various applications, it is essential for B2B buyers to consider not only the primary choice, such as 600D polyester by the yard, but also viable alternatives that may offer different advantages based on specific project requirements. This analysis highlights two notable alternatives: nylon fabric and PVC-coated polyester. Each option has its unique attributes that can cater to diverse needs across industries.

| Comparison Aspect | 600D Polyester By The Yard | Nylon Fabric | PVC-Coated Polyester |

|---|---|---|---|

| Performance | Water-resistant, durable, UV resistant | High tensile strength, lightweight | Excellent water and chemical resistance |

| Cost | Moderate ($10 – $12 per yard) | Higher ($15 – $20 per yard) | Moderate ($12 – $15 per yard) |

| Ease of Implementation | Easy to cut and sew, widely available | Slightly more challenging due to slipperiness | Requires special handling due to coating |

| Maintenance | Low maintenance, machine washable | Requires careful washing to maintain integrity | Easy to clean, but can be prone to scratches |

| Best Use Case | Bags, outdoor gear, upholstery | Apparel, outdoor gear, and accessories | Tarps, covers, and industrial applications |

What Are the Advantages and Disadvantages of Nylon Fabric as an Alternative to 600D Polyester?

Nylon fabric is known for its exceptional tensile strength, making it a preferred option for applications requiring durability and resistance to wear and tear. It is lightweight, which can be a significant advantage in products like apparel and outdoor gear where weight is a factor. However, nylon can be more expensive than 600D polyester, typically ranging from $15 to $20 per yard. Additionally, its slippery nature can complicate sewing and handling, which may increase production time and costs.

Illustrative image related to 600d polyester by the yard

How Does PVC-Coated Polyester Compare to 600D Polyester?

PVC-coated polyester offers superior water and chemical resistance, making it an excellent choice for industrial applications such as tarps and covers. Its robust nature allows it to withstand harsh environmental conditions, which is beneficial for outdoor use. The cost of PVC-coated polyester is generally moderate, falling between $12 and $15 per yard. However, it requires special handling due to its coating, which can make it more difficult to sew than 600D polyester. While maintenance is relatively easy, the material is prone to scratches, which can affect its appearance over time.

How Can B2B Buyers Choose the Right Fabric Solution for Their Needs?

When selecting the right fabric, B2B buyers should consider the specific requirements of their projects, including performance needs, budget constraints, and the intended application. If durability and weight are critical, nylon may be the optimal choice despite its higher cost. Conversely, for projects requiring water resistance and chemical durability, PVC-coated polyester could be more suitable. For general purposes, especially in bags and outdoor gear, 600D polyester remains a strong contender due to its balance of performance, cost, and ease of use. Ultimately, understanding the unique attributes of each fabric will empower buyers to make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for 600d polyester by the yard

What Are the Key Technical Properties of 600D Polyester by the Yard?

Understanding the technical properties of 600D polyester is crucial for B2B buyers, especially when making purchasing decisions for products like bags, covers, and outdoor gear. Here are some essential specifications:

-

Denier (D)

Denier is a unit of measurement that indicates the thickness of the fiber used in the fabric. A 600D polyester indicates a medium weight fabric that is robust yet flexible. For B2B buyers, denier affects the durability and application of the fabric. Higher denier fabrics are typically stronger and more suitable for heavy-duty applications. -

Weight (Oz/Sq Yd)

The weight of 600D polyester usually ranges around 6 to 10 ounces per square yard. This weight provides a balance between sturdiness and ease of handling. Buyers should consider weight based on the end-use of the product; heavier weights are generally better for items that will face wear and tear, such as luggage or outdoor gear. -

Coating Type

Many 600D polyester fabrics come with a polyurethane coating, which adds water resistance and durability. This feature is particularly important for outdoor applications where moisture exposure is a concern. Understanding the coating type can help buyers select the right fabric for their specific needs, ensuring product longevity. -

Fabric Width

Typically, 600D polyester is available in widths ranging from 58 to 60 inches. The width affects the yield of fabric per linear yard, which can influence cost-effectiveness for large projects. Buyers should consider the width when calculating material needs for manufacturing processes to minimize waste. -

Color Fastness and UV Resistance

Solution-dyed polyester fabrics offer superior UV resistance, which is vital for outdoor products that will be exposed to sunlight. Additionally, color fastness ensures that the fabric maintains its hue over time, which is essential for aesthetic purposes in consumer products. Buyers focused on outdoor or decorative applications should prioritize these properties. -

Fire Retardancy

While many 600D polyester fabrics are not inherently fire retardant, some manufacturers offer treated options. This property is crucial for buyers in industries where fire safety is a regulatory requirement, such as in tents or camping gear.

What Are the Common Trade Terms Associated with 600D Polyester?

Familiarity with industry terminology can facilitate smoother transactions and negotiations. Here are key trade terms relevant to 600D polyester:

Illustrative image related to 600d polyester by the yard

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers looking to source materials for branded products. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers to consider as it affects inventory management and cash flow. Knowing the MOQ helps in planning purchases effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For 600D polyester, an RFQ can help buyers compare costs and secure favorable terms, ensuring they get the best deal for their needs. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, covering aspects such as shipping costs and risk. Understanding Incoterms is essential for B2B buyers engaged in cross-border transactions, particularly when sourcing materials from diverse regions. -

Lead Time

This refers to the time taken from placing an order to the delivery of the product. Knowing the lead time for 600D polyester is crucial for buyers to manage production schedules and meet customer demands. -

Certification Standards

These are industry-specific benchmarks that materials must meet to ensure quality and safety. Buyers should be aware of relevant certification standards for 600D polyester to ensure compliance with regulations and to maintain product integrity.

By understanding these properties and terms, B2B buyers can make informed decisions when sourcing 600D polyester, ultimately leading to better product quality and business outcomes.

Navigating Market Dynamics and Sourcing Trends in the 600d polyester by the yard Sector

What Are the Current Market Dynamics and Key Trends in the 600D Polyester Sector?

The 600D polyester market is experiencing a robust growth trajectory, driven by increasing demand in various sectors, including outdoor apparel, luggage, and industrial applications. The fabric’s durability, water resistance, and versatility make it a preferred choice for manufacturers catering to both consumer and commercial markets. Particularly in regions like Africa, South America, the Middle East, and Europe, the rise in outdoor activities and tourism is pushing the demand for high-quality, resilient fabrics. Additionally, the growing trend toward customization in product offerings is prompting suppliers to innovate in terms of colors, patterns, and finishes.

Emerging technologies in sourcing, such as digital printing and automation in manufacturing, are reshaping the landscape. Companies are increasingly adopting e-commerce platforms for efficient procurement processes, allowing for direct interaction with manufacturers and suppliers. This shift is particularly beneficial for international buyers, as it streamlines logistics and reduces lead times. Furthermore, the emphasis on transparency in the supply chain is leading to better practices in sourcing and quality assurance, enabling buyers to make informed decisions.

How Is Sustainability Influencing the Sourcing of 600D Polyester Fabrics?

Sustainability is becoming a crucial consideration for B2B buyers in the 600D polyester sector. The environmental impact of synthetic fabrics has prompted a shift toward more sustainable practices, including the use of recycled materials and eco-friendly manufacturing processes. Buyers are increasingly seeking suppliers who prioritize ethical sourcing and can provide certifications that validate their commitment to sustainability.

The importance of ethical supply chains cannot be overstated. B2B buyers are not only looking for high-quality products but also for suppliers who demonstrate social responsibility, fair labor practices, and reduced carbon footprints. Certifications such as Global Recycled Standard (GRS) and OEKO-TEX® ensure that the materials used in production meet rigorous environmental and safety standards. By partnering with suppliers who adhere to these principles, businesses can enhance their brand reputation and appeal to a growing consumer base that values sustainability.

Illustrative image related to 600d polyester by the yard

How Has the 600D Polyester Fabric Market Evolved Over Time?

The evolution of the 600D polyester fabric market can be traced back to the increasing demand for durable and versatile materials in the late 20th century. Originally developed for military applications due to its strength and resilience, 600D polyester has since found its way into various industries, including outdoor gear, automotive upholstery, and fashion. The introduction of solution-dyed technology has further enhanced its appeal, providing improved UV resistance and colorfastness.

Today, the market is characterized by a diverse range of offerings, including coated and uncoated varieties, each tailored to specific applications. This evolution reflects broader trends in consumer preferences for high-performance materials that can withstand harsh conditions while also being aesthetically pleasing. As the market continues to adapt to changing demands, international buyers are well-positioned to leverage these innovations to meet their specific needs.

Frequently Asked Questions (FAQs) for B2B Buyers of 600d polyester by the yard

-

1. How do I choose the right 600D polyester for my project?

Selecting the right 600D polyester involves considering factors such as the fabric’s weight, coating, and intended use. For outdoor applications, opt for solution-dyed polyester with a durable water repellent (DWR) finish, which enhances sun resistance and longevity. Assess the fabric’s thickness and weight; a heavier fabric (around 10 oz) is ideal for items like luggage or outdoor gear, while lighter options may suffice for less demanding applications. Always request samples to evaluate the fabric’s texture, color fastness, and overall suitability for your specific needs. -

2. What are the common applications for 600D polyester by the yard?

600D polyester is highly versatile and suitable for various applications. It is commonly used in the production of bags, such as duffel and sport bags, due to its durability and resistance to wear. The fabric is also ideal for outdoor gear, covers, and upholstery, owing to its water-resistant properties. Additionally, it can be utilized in manufacturing tent materials, tarps, and boat covers, making it a preferred choice across industries that require robust and weather-resistant materials. -

3. What are the key factors to consider when vetting suppliers for 600D polyester?

When vetting suppliers, prioritize their reputation, product quality, and reliability. Check for certifications that demonstrate compliance with international standards, such as ISO certifications. Assess their production capacity and lead times to ensure they can meet your demands. Request references or testimonials from other B2B clients to gauge their service levels. Additionally, inquire about their policies on quality assurance, returns, and customer support to ensure a positive purchasing experience. -

4. What are typical minimum order quantities (MOQs) for 600D polyester?

Minimum order quantities for 600D polyester can vary significantly based on the supplier and the specific fabric type. Generally, MOQs can range from as low as 10 yards for smaller suppliers to 50 yards or more for bulk manufacturers. It’s advisable to negotiate MOQs with suppliers, especially if you require customization or specific colors. Some suppliers may offer discounts for larger orders, making it beneficial to plan your purchase accordingly to optimize costs. -

5. What payment terms should I expect when sourcing 600D polyester internationally?

Payment terms can vary widely among suppliers but typically involve a deposit of 30% to 50% upfront, with the balance due upon shipment or delivery. Some suppliers may offer payment via letter of credit, especially for larger orders, providing additional security for both parties. Always clarify payment methods accepted, such as bank transfers or PayPal, and ensure you have a clear agreement on currency exchange rates if dealing internationally. Understanding these terms upfront can help avoid potential disputes. -

6. How do I ensure quality assurance when purchasing 600D polyester?

To ensure quality assurance, request detailed specifications and samples before finalizing your order. Consider implementing a quality control process that includes inspections at various stages of production. Many suppliers offer third-party inspection services to verify fabric quality, color accuracy, and weight consistency. Additionally, familiarize yourself with the fabric’s warranty policies and return options, as these can provide recourse if the product does not meet your expectations. -

7. What logistics considerations should I keep in mind when importing 600D polyester?

Logistics considerations include shipping methods, import duties, and customs regulations. Choose between air freight for faster delivery or sea freight for cost-effectiveness, depending on your urgency and budget. Research import tariffs and regulations in your country to avoid unexpected fees. Collaborating with a freight forwarder can simplify the shipping process, ensuring compliance with all legal requirements and facilitating smooth customs clearance. -

8. How can I customize 600D polyester for my specific needs?

Customization options for 600D polyester often include color selection, coating types, and printing designs. Many suppliers offer custom dyeing services, allowing you to choose from a wide range of colors. Additionally, inquire about printed patterns or logos, which can enhance branding for your products. Discuss your requirements with the supplier to understand their capabilities and any minimum quantities required for custom orders. Always request samples of custom designs to ensure they meet your quality standards before proceeding with larger orders.

Top 8 600D Polyester By The Yard Manufacturers & Suppliers List

1. Big Duck Canvas – 600D Polyester Fabric

Domain: bigduckcanvas.com

Registered: 2011 (14 years)

Introduction: 600D Polyester Fabric, Coated Fabric, 600×600 Denier, Water repellent, Abrasion resistant, TPU coated for flexibility and softness, Solution-dyed for lasting color, Common uses include backpacks, boat covers, and awnings, Available for purchase by the yard or in wholesale rolls, Price range approximately $11.20 to $11.95 per yard, No minimum purchase required.

2. Rockywoods – 600 Denier Coated Polyester Fabric – Lilac

Domain: rockywoods.com

Registered: 1998 (27 years)

Introduction: 600 Denier coated Solution Dyed Polyester Fabric – Lilac (Sold per Yard)

3. Seattle Fabrics – 600×300 Denier Polyester Fabric

Domain: seattlefabrics.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “600×300 Denier Polyester Fabric | PVC Polyester Fabric by the Yard”, “Price”: “$8.95/linear yard”, “Part Number”: “FP600X300”, “Width”: “58 inches”, “Weight”: “10 oz. per square yard”, “Material”: “PVC backed 600 x 300 Denier Polyester”, “Backing”: “0.55mm vinyl embossed backing”, “Availability”: “Sold by the yard in .25, .5, .75 yard increments, .5 yard minimum”, “Colors Availab…

4. Dutchware Gear – 600D Polyester Printed Fabric

Domain: dutchwaregear.com

Registered: 2012 (13 years)

Introduction: 600D Polyester Printed fabric with a polyurethane back coating and durable water repellent finish. Versatile and commonly used for luggage, sport and duffel bags, and outdoor gear. Sold by the linear yard. Width: 59/60″; Weight per sq yard: 8 +/- 0.50 oz/sqyd; Denier: 600; Plain Weave; 100% Polyester; Coating: DWR, UC Spray Rating 90. Available in various patterns including Bacon, Banana, Buffalo-…

5. Canvas Etc. – 600 Denier Polyester Fabric

Domain: canvasetc.com

Registered: 2005 (20 years)

Introduction: This company, Canvas Etc. – 600 Denier Polyester Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. MMI Textiles – 600D Polyester

Domain: mmitextiles.com

Registered: 2001 (24 years)

Introduction: {“product_name”: “600D Polyester”, “colors”: [“black”, “white”, “dark brown”, “charcoal”, “orange”, “navy”, “red”, “regatta”, “gray”, “stone”, “tan”, “#f8f102”, “dark green”, “brindle”], “common_uses”: [“awnings & canopies”, “banners”, “tents”, “flags”, “pop-up tents”, “gazebos”, “outdoor and indoor cushions”, “duffle bags”, “sporting equipment bags”, “boat covers”], “specifications”: {“fiber”: “P…

7. GABOATS – 600D 8.4 oz Polyester Fabric

Domain: gaboats.com

Registered: 2002 (23 years)

Introduction: {“name”: “600D 8.4 oz Polyester Fabric”, “weight”: “8.4 oz”, “width”: “68 inches”, “length”: “up to 7 yards”, “price”: “$17.00”, “description”: “600D 8.4 oz polyester heat shrink material used to cover boats.”, “ordering_info”: “Available by the linear yard – up to 7-yards per order. For longer lengths or multiple rolls, contact us directly before ordering.”}

8. Sewing Supply Depot – 600D Water Resistant PU Coated Polyester Fabric

Domain: sewingsupplydepot.com

Registered: 2011 (14 years)

Introduction: {“Product Name”: “600D Water Resistant PU Coated Polyester Fabric (By the Yard)”, “Price”: “$9.47”, “Suitable For”: “Lighter backpacks and smaller duffel bags”, “Material”: “600 x 600 Denier Polyurethane coated Polyester”, “Width”: “60 inches”, “Weight”: “250gsm / 7.5oz”, “Available Colors”: [“Black”, “Orange”, “Royal”, “Navy”, “Dark Gray”, “Forest Green”, “Red”], “SKU”: “CRDR600-Black”, “Vendor”:…

Strategic Sourcing Conclusion and Outlook for 600d polyester by the yard

In the dynamic landscape of fabric procurement, 600D polyester by the yard emerges as a robust option for international B2B buyers. Its durability, water resistance, and UV protection make it suitable for a variety of applications, from outdoor gear to luggage manufacturing. The strategic sourcing of this material allows businesses to enhance product quality while ensuring cost-effectiveness.

By capitalizing on bulk purchasing discounts and reliable suppliers, companies can optimize their supply chains and mitigate risks associated with fluctuating material prices. Additionally, the ability to customize colors and patterns offers a competitive edge in markets such as Africa, South America, the Middle East, and Europe, where consumer preferences can vary widely.

Illustrative image related to 600d polyester by the yard

As we look to the future, it is crucial for buyers to establish strong relationships with suppliers who can provide consistent quality and innovation. Embracing a proactive sourcing strategy will not only improve product offerings but also position businesses favorably in a competitive marketplace. Now is the time to explore the possibilities that 600D polyester can offer—connect with trusted suppliers today to secure your competitive advantage.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.