5X115 Rims: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for 5×115 rims

In the competitive landscape of automotive components, sourcing high-quality 5×115 rims can pose significant challenges for B2B buyers, especially those operating across diverse international markets. With vehicles such as the Dodge Charger and Chrysler 300 relying on this specific bolt pattern, the demand for these rims spans continents, from the bustling streets of Brazil to the dynamic markets of Saudi Arabia. This guide aims to equip international buyers with the knowledge necessary to navigate the complexities of sourcing 5×115 rims effectively.

Throughout this comprehensive resource, we will explore various types of 5×115 rims, their applications, and the critical factors to consider when vetting suppliers. Understanding the nuances of rim specifications—including diameter, offset, and finish—is essential for making informed purchasing decisions that align with your business needs. Moreover, we will delve into cost considerations, providing insights into pricing trends and potential financing options available in different regions.

This guide serves as a valuable tool for B2B buyers from Africa, South America, the Middle East, and Europe, empowering them to make strategic sourcing decisions that not only enhance their product offerings but also optimize their supply chain efficiency. By leveraging the insights provided here, you can confidently navigate the global market for 5×115 rims, ensuring that your purchases meet both quality and performance standards essential for customer satisfaction.

Understanding 5×115 rims Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alloy Wheels | Lightweight, corrosion-resistant, various finishes | Performance vehicles, luxury cars | Pros: Enhanced aesthetics, better handling. Cons: Higher cost, potential for damage in rough terrain. |

| Steel Wheels | Durable, typically heavier, more affordable | Commercial vehicles, off-road applications | Pros: Cost-effective, robust for heavy loads. Cons: Heavier, less visually appealing. |

| Forged Wheels | High strength-to-weight ratio, custom designs | High-performance racing, luxury segments | Pros: Lightweight, customizable. Cons: Expensive, may require special handling. |

| Chrome Wheels | Shiny finish, often for aesthetic appeal | Show cars, luxury vehicles | Pros: Eye-catching appearance. Cons: Prone to corrosion, requires regular maintenance. |

| OEM Replacement | Designed to match original specifications | Fleet vehicles, general consumer cars | Pros: Guaranteed fit, reliability. Cons: Limited customization options, may lack unique designs. |

What Are the Characteristics of Alloy Wheels?

Alloy wheels are a popular choice among B2B buyers due to their lightweight construction and aesthetic appeal. Made from a mixture of metals, these wheels often feature various finishes such as matte black, chrome, or polished aluminum. They are particularly suitable for performance and luxury vehicles, providing better handling and improved braking performance. When purchasing alloy wheels, buyers should consider the balance between aesthetics and performance, as well as the specific vehicle requirements to ensure compatibility.

Illustrative image related to 5×115 rims

Why Choose Steel Wheels for Commercial Applications?

Steel wheels are renowned for their durability and cost-effectiveness, making them ideal for commercial vehicles and off-road applications. They are typically heavier than alloy wheels but offer enhanced strength, making them suitable for heavy loads and rough terrains. B2B buyers should evaluate the trade-off between weight and robustness, especially for vehicles that frequently operate in challenging conditions. While they may lack the visual appeal of alloys, their practicality often outweighs aesthetic considerations in commercial settings.

What Are the Benefits of Forged Wheels?

Forged wheels are engineered for high performance, offering a superior strength-to-weight ratio. This makes them a preferred option for racing and high-end luxury cars. B2B buyers interested in these wheels should be aware that they can be more expensive due to the manufacturing process, which allows for custom designs. When considering forged wheels, businesses should focus on the specific performance needs of the vehicles in question, as well as the potential for customization that can enhance brand identity.

How Do Chrome Wheels Enhance Vehicle Aesthetics?

Chrome wheels are primarily chosen for their striking appearance, making them a favored option for show cars and luxury vehicles. Their shiny finish can significantly enhance a vehicle’s aesthetic appeal, attracting attention and interest. However, B2B buyers should consider the maintenance required to keep chrome wheels looking pristine, as they are more prone to corrosion. When purchasing chrome wheels, it’s essential to weigh the visual benefits against the potential for increased upkeep and the environments in which the vehicles will be used.

What Are the Advantages of OEM Replacement Wheels?

OEM (Original Equipment Manufacturer) replacement wheels are designed to match the specifications of the original wheels that come with a vehicle. These wheels are particularly valuable for fleet vehicles and general consumer cars, ensuring a perfect fit and reliable performance. B2B buyers should appreciate the assurance of quality and compatibility that OEM wheels provide, although they may offer limited customization options. For businesses prioritizing reliability and ease of maintenance, OEM replacement wheels represent a practical choice.

Key Industrial Applications of 5×115 rims

| Industry/Sector | Specific Application of 5×115 rims | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of vehicles like Dodge Charger and Chrysler 300 | Enhanced vehicle performance and aesthetic appeal | Ensure compatibility with vehicle models and strict quality standards. |

| Aftermarket Automotive Parts | Custom wheel designs for luxury and performance cars | Increased market competitiveness and customer satisfaction | Focus on unique finishes and designs that appeal to target demographics. |

| Fleet Management | Replacement rims for commercial vehicles | Cost-effective maintenance and enhanced vehicle longevity | Consider bulk purchasing options and logistics for international shipping. |

| Motorsports | Racing vehicles requiring lightweight and durable rims | Improved speed and handling in competitive racing environments | Source from specialized manufacturers with a focus on performance materials. |

| Construction and Heavy Equipment | Rims for utility vehicles and equipment | Enhanced durability for off-road and rugged applications | Evaluate load ratings and strength specifications for heavy-duty use. |

How are 5×115 Rims Used in Automotive Manufacturing?

In the automotive manufacturing sector, 5×115 rims are crucial for vehicles like the Dodge Charger and Chrysler 300. These rims enhance both performance and aesthetics, allowing manufacturers to offer stylish options that appeal to consumers. Buyers need to ensure that the rims meet stringent quality standards and are compatible with specific vehicle models to avoid costly modifications or safety issues.

Illustrative image related to 5×115 rims

What Role Do 5×115 Rims Play in Aftermarket Automotive Parts?

In the aftermarket automotive parts industry, 5×115 rims are often used for custom wheel designs tailored to luxury and performance cars. This application provides businesses with the opportunity to differentiate themselves in a competitive market. Buyers should focus on sourcing unique finishes and designs that resonate with their target demographic, ensuring that they meet the demands of style-conscious consumers.

How are 5×115 Rims Beneficial for Fleet Management?

For fleet management, 5×115 rims serve as replacement options for commercial vehicles, providing a cost-effective solution for ongoing maintenance. These rims contribute to the longevity of the vehicles, minimizing downtime and repair costs. Businesses should consider bulk purchasing options and the logistics of international shipping to optimize their supply chain and ensure timely availability of parts.

Why are 5×115 Rims Important in Motorsports?

In the motorsports industry, 5×115 rims are essential for racing vehicles that require lightweight and durable components. These rims significantly enhance speed and handling, offering a competitive edge on the track. Buyers should prioritize sourcing from specialized manufacturers that focus on performance materials to ensure that the rims can withstand the intense conditions of racing.

How Do 5×115 Rims Support Construction and Heavy Equipment?

In construction and heavy equipment sectors, 5×115 rims are utilized for utility vehicles that operate in rugged environments. These rims need to be highly durable to endure the demands of off-road applications. When sourcing, businesses must evaluate the load ratings and strength specifications to ensure that the rims are suitable for heavy-duty use, thereby reducing the risk of equipment failure.

3 Common User Pain Points for ‘5×115 rims’ & Their Solutions

Scenario 1: Difficulty in Identifying the Correct Fitment for 5×115 Rims

The Problem: B2B buyers often face the challenge of ensuring that the 5×115 rims they are purchasing fit the specific vehicles in their inventory. This is particularly crucial for automotive dealerships and repair shops that depend on precise fitment for customer satisfaction. Misunderstandings can lead to costly returns and lost sales, especially if buyers are unfamiliar with the nuances of bolt patterns, offsets, and rim diameters. With a wide variety of options available, the risk of purchasing incompatible wheels is significant, especially for international buyers who may not have easy access to replacements.

Illustrative image related to 5×115 rims

The Solution: To mitigate this issue, B2B buyers should utilize comprehensive fitment guides and tools available on reputable rim suppliers’ websites. Before making a purchase, buyers should cross-reference the vehicle’s specifications, such as make, model, year, and trim, with the rim’s specifications, ensuring they match the required bolt pattern, diameter, and offset. Engaging with knowledgeable sales representatives can also provide clarity and confidence in the selection process. Additionally, consider investing in software solutions that can help manage inventory and specifications to streamline the selection process and minimize errors.

Scenario 2: Managing Diverse Inventory and Customer Preferences

The Problem: For B2B suppliers and retailers, managing a diverse inventory of 5×115 rims can be daunting. Buyers often have varying preferences regarding style, finish, and performance specifications, which can complicate inventory management. The challenge lies in forecasting demand accurately and ensuring that the right mix of products is available to meet customer needs. This is particularly true in regions with distinct aesthetic preferences, such as the Middle East or Europe, where trends can shift rapidly.

The Solution: Implementing a robust inventory management system that tracks sales patterns and customer preferences can significantly enhance operational efficiency. Suppliers should analyze historical sales data to identify trends related to specific styles and finishes of 5×115 rims that are popular in different markets. Additionally, fostering strong relationships with manufacturers can allow for flexible ordering options, enabling suppliers to respond quickly to changing trends without overcommitting to stock. Offering customization options can also attract customers looking for unique solutions, thereby expanding market reach.

Scenario 3: Navigating Shipping and Logistics Challenges

The Problem: International buyers, particularly those in Africa and South America, often encounter significant logistical hurdles when sourcing 5×115 rims. Issues such as long shipping times, high freight costs, and customs regulations can complicate the procurement process. These logistical challenges can lead to delays in fulfilling customer orders, potentially damaging relationships and causing financial losses.

The Solution: To address these challenges, B2B buyers should partner with experienced logistics providers familiar with international shipping regulations and practices. Utilizing a reliable freight forwarder can streamline the shipping process, ensuring that all necessary documentation is prepared in advance to minimize delays at customs. Buyers can also explore options for bulk purchasing to reduce per-unit shipping costs. Establishing a local distribution center in key markets can further enhance delivery times and reduce logistical complexities. Additionally, transparent communication with suppliers about shipping expectations and timelines can help set realistic delivery dates for customers, improving overall satisfaction.

Strategic Material Selection Guide for 5×115 rims

When selecting materials for 5×115 rims, international B2B buyers must consider various factors, including performance properties, manufacturing complexity, and regional compliance standards. Below, we analyze four common materials used in the production of 5×115 rims: aluminum alloys, steel, magnesium alloys, and carbon fiber.

What are the Key Properties of Aluminum Alloys for 5×115 Rims?

Aluminum alloys are widely favored for their lightweight nature and excellent corrosion resistance. They typically have a temperature rating of up to 150°C and can withstand moderate pressure, making them suitable for various driving conditions. Aluminum rims can be anodized for enhanced surface protection, which is particularly beneficial in regions with high humidity or saline environments, such as coastal areas in South America and Africa.

Pros and Cons: The primary advantage of aluminum alloys is their weight-to-strength ratio, which improves vehicle performance and fuel efficiency. However, they can be more expensive than steel options and may require specialized manufacturing processes, which could increase lead times. Additionally, aluminum rims may not be as durable in extreme off-road conditions compared to steel.

How Does Steel Compare as a Material for 5×115 Rims?

Steel is another common material for rims, known for its robustness and cost-effectiveness. It has a high tensile strength and can withstand higher temperatures (up to 200°C) and pressures compared to aluminum. Steel rims are generally less prone to bending under heavy loads, making them suitable for heavy-duty applications.

Pros and Cons: The main advantage of steel rims is their durability and lower cost, making them an attractive option for budget-conscious buyers. However, they are heavier than aluminum, which can negatively impact fuel efficiency. Steel is also more susceptible to rust if not properly coated, which is a significant consideration for buyers in humid climates.

What Advantages Do Magnesium Alloys Offer for 5×115 Rims?

Magnesium alloys are known for their exceptional strength-to-weight ratio, making them a premium choice for high-performance vehicles. They can handle high temperatures and pressures, typically rated up to 150°C, and offer good corrosion resistance when treated properly.

Pros and Cons: Magnesium rims are lighter than aluminum and steel, enhancing vehicle performance. However, they are more expensive and can be challenging to manufacture due to their reactivity during processing. Additionally, magnesium requires careful handling to prevent corrosion, which may be a concern in regions with high moisture levels.

Illustrative image related to 5×115 rims

Are Carbon Fiber Rims a Viable Option for 5×115 Applications?

Carbon fiber rims are gaining traction in the automotive industry due to their incredible strength and lightweight properties. They can withstand high temperatures and pressures, making them suitable for racing and high-performance applications. Carbon fiber is also highly resistant to corrosion and fatigue.

Pros and Cons: The primary advantage of carbon fiber rims is their unmatched weight savings, which significantly boosts performance. However, they are the most expensive option and require specialized manufacturing techniques, which can lead to longer production times. Furthermore, carbon fiber rims may not be suitable for all driving conditions, particularly in rugged terrains.

Summary Table of Material Selection for 5×115 Rims

| Material | Typical Use Case for 5×115 rims | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Standard passenger vehicles | Lightweight and corrosion-resistant | Higher cost and less durable in off-road conditions | Medium |

| Steel | Heavy-duty and budget vehicles | Cost-effective and durable | Heavier, prone to rust | Low |

| Magnesium Alloys | High-performance vehicles | Superior strength-to-weight ratio | Expensive and complex to manufacture | High |

| Carbon Fiber | Racing and high-performance applications | Unmatched weight savings | Very high cost and limited suitability for rugged use | High |

This material selection guide provides critical insights for B2B buyers in diverse regions, ensuring they can make informed decisions based on performance requirements, cost considerations, and local market conditions.

Illustrative image related to 5×115 rims

In-depth Look: Manufacturing Processes and Quality Assurance for 5×115 rims

What Are the Main Stages of Manufacturing 5×115 Rims?

The manufacturing of 5×115 rims involves several critical stages that ensure the final product meets both performance and aesthetic standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with the selection of high-quality raw materials, typically aluminum alloys or steel, chosen for their strength-to-weight ratio and corrosion resistance. These materials undergo rigorous inspection to ensure they meet specified standards. The raw materials are then cut into the required dimensions for further processing.

Forming Techniques

Forming is a crucial step where the prepared materials are shaped into the desired rim structure. Common techniques include casting, forging, and machining. In casting, molten metal is poured into molds to create the rim shape, while forging involves compressing the material under high pressure to enhance its strength. Machining follows, where precision tools shape the rim to exact specifications, including the bolt pattern and offset.

Assembly Process

After forming, the rims are assembled, which may involve the integration of additional components such as valve stems and hub-centric rings. This step is vital for ensuring proper fitment on vehicles. Automated systems often assist in this process to enhance efficiency and consistency.

Finishing Touches

The finishing stage includes surface treatments such as anodizing, powder coating, or polishing. These treatments not only enhance the aesthetic appeal of the rims but also provide an additional layer of protection against environmental factors. Quality checks are performed at every stage to ensure that the rims meet the required specifications before they are packaged for shipment.

Illustrative image related to 5×115 rims

How is Quality Assurance Implemented in Rim Manufacturing?

Quality assurance (QA) in the manufacturing of 5×115 rims is essential for maintaining safety, performance, and customer satisfaction. Various international and industry-specific standards guide these QA processes.

International Standards for Quality Control

One of the primary international standards for quality management is ISO 9001. Compliance with ISO 9001 indicates that a manufacturer has implemented a quality management system that continuously improves processes, products, and services. This is critical for B2B buyers who want to ensure the reliability of their suppliers.

Industry-Specific Certifications

In addition to ISO standards, rim manufacturers may also pursue certifications like CE marking in Europe and API (American Petroleum Institute) specifications for specific applications. These certifications ensure that products meet regulatory requirements and industry benchmarks.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integral to the manufacturing process, ensuring that any potential defects are identified and rectified early. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to verify that they meet predefined specifications. Materials that do not meet these standards are rejected or reprocessed.

-

In-Process Quality Control (IPQC): During manufacturing, various parameters such as dimensions, weight, and material properties are monitored. This ensures that any deviations from the desired specifications are caught in real-time.

-

Final Quality Control (FQC): Before shipping, rims undergo a final inspection to check for defects in aesthetics and functionality. This includes visual inspections, dimensional checks, and performance tests such as load testing to ensure they can withstand operational conditions.

What Testing Methods Are Commonly Used in Rim Quality Assurance?

Several testing methods are employed to ensure the quality and safety of 5×115 rims. These include:

-

Tensile Testing: This method evaluates the strength and ductility of the rim material. It helps manufacturers understand how the material will perform under stress.

-

Fatigue Testing: Rims are subjected to repeated stress cycles to simulate real-world conditions. This testing helps to predict the lifespan of the rims under various driving conditions.

-

Visual Inspection: A thorough visual inspection is conducted to identify surface imperfections, such as scratches or irregularities that could affect performance.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to ensure their suppliers maintain rigorous quality control standards. Here are some strategies:

Illustrative image related to 5×115 rims

-

Supplier Audits: Conducting regular audits of suppliers can help verify compliance with quality standards. This includes reviewing manufacturing processes, quality control measures, and certification documentation.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports that outline their QA processes, inspection results, and any corrective actions taken for defects.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These firms can conduct random inspections and verify that products meet the required specifications before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, face unique challenges when it comes to quality control. Understanding these nuances can help in making informed purchasing decisions:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers should familiarize themselves with local regulations regarding vehicle parts to ensure that the rims comply with safety standards.

-

Cultural Differences: Communication styles and business practices can vary significantly across cultures. Building strong relationships with suppliers can lead to better quality assurance and more responsive service.

-

Logistical Considerations: Shipping products internationally can introduce risks such as damage during transit. B2B buyers should ensure that suppliers have robust packaging and handling procedures in place.

In conclusion, the manufacturing and quality assurance processes for 5×115 rims are complex and multifaceted. By understanding these processes, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that prioritize quality and safety.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘5×115 rims’

The following guide serves as a practical checklist for B2B buyers interested in sourcing 5×115 rims. This step-by-step approach will help you navigate the procurement process efficiently and ensure you make informed decisions.

Step 1: Define Your Technical Specifications

Begin by determining the exact specifications you need for the 5×115 rims. This includes diameter, width, offset, and finish. Knowing these details will not only streamline your search but also ensure compatibility with the vehicles you are targeting. For example, if you are looking for rims suitable for high-performance vehicles, consider specifications that enhance durability and aesthetics.

Step 2: Research Market Demand and Trends

Investigate the current market demand for 5×115 rims in your target regions, such as Africa, South America, the Middle East, and Europe. Understanding trends, such as popular styles or finishes, will help you align your sourcing strategy with buyer preferences. This knowledge can also inform your marketing efforts and pricing strategies.

Illustrative image related to 5×115 rims

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Look for reputable manufacturers or distributors with proven experience in the automotive industry. Request company profiles, case studies, and references from buyers in a similar industry or region. This due diligence will help you avoid potential pitfalls associated with unreliable suppliers.

- Check certifications: Ensure that potential suppliers hold relevant certifications, such as ISO or quality management standards, to guarantee product reliability.

- Assess production capabilities: Understand their production capacity and lead times to ensure they can meet your demand.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted potential suppliers, request samples of the rims you are considering. Evaluating the quality of the rims firsthand is essential, as it allows you to assess factors like finish, weight, and overall durability. This step can prevent costly mistakes in bulk orders.

Step 5: Negotiate Pricing and Payment Terms

Engage in negotiations with your chosen suppliers to secure favorable pricing and payment terms. Consider factors such as bulk order discounts and financing options that can enhance your cash flow. Clear communication about payment terms is vital to avoid misunderstandings down the line.

- Explore financing options: Look for suppliers that offer flexible financing solutions, which can facilitate larger orders without straining your budget.

- Understand total costs: Be aware of shipping, customs, and any additional fees that may apply to ensure your final costs align with your budget.

Step 6: Confirm Shipping and Logistics Arrangements

Coordinate with your supplier to establish efficient shipping and logistics arrangements. Ensure that the supplier can provide reliable shipping options to your desired locations, especially if you are sourcing from international markets.

- Track delivery timelines: Confirm estimated delivery times and any tracking options available to monitor your shipment.

- Evaluate logistics partners: Assess the supplier’s logistics partners to ensure they have a good reputation for timely and safe delivery.

Step 7: Establish a Communication Plan

Finally, set up a communication plan with your supplier to ensure ongoing support and transparency. Regular check-ins can help address any concerns that arise during the order process and build a strong working relationship.

Illustrative image related to 5×115 rims

- Designate points of contact: Establish clear lines of communication with designated contacts on both sides to streamline information exchange.

- Schedule regular updates: Agree on a schedule for updates regarding order status and any potential changes in market conditions.

By following this practical sourcing checklist, B2B buyers can effectively navigate the complexities of procuring 5×115 rims, ensuring a successful and efficient purchasing process.

Comprehensive Cost and Pricing Analysis for 5×115 rims Sourcing

What Are the Key Cost Components in Sourcing 5×115 Rims?

Understanding the cost structure for sourcing 5×115 rims is crucial for B2B buyers looking to optimize their procurement processes. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly impacts pricing. Common materials for rims include aluminum and steel, with aluminum generally being more expensive due to its lightweight and corrosion-resistant properties. The quality of the alloy used can also affect performance and durability.

-

Labor: Labor costs can vary based on the region of manufacturing. Countries with lower labor costs may offer competitive pricing, but it’s essential to consider the trade-off in quality and craftsmanship.

-

Manufacturing Overhead: This encompasses expenses related to the production facility, utilities, and equipment maintenance. Efficient operations can minimize overhead costs, which can subsequently lower the final price of the rims.

-

Tooling: The initial investment in molds and machinery for producing specific rim designs can be substantial. However, this cost is often amortized over large production runs, making it critical to assess minimum order quantities (MOQs) to maximize cost efficiency.

-

Quality Control (QC): Rigorous QC processes are essential to ensure product safety and reliability. While this may add to the cost, it is a necessary investment to avoid costly returns and reputational damage.

-

Logistics: Shipping and handling costs can vary widely depending on the destination and Incoterms. International buyers should factor in customs duties, taxes, and potential delays, which can impact overall costs.

-

Margin: Suppliers typically add a margin to cover their expenses and profit. Understanding the market dynamics can help buyers negotiate better terms.

How Do Price Influencers Affect the Cost of 5×115 Rims?

Several factors influence the pricing of 5×115 rims, particularly for international buyers from regions such as Africa, South America, the Middle East, and Europe.

-

Volume/MOQ: Larger orders generally result in lower per-unit costs. Establishing a clear understanding of the MOQ with suppliers can lead to significant cost savings.

-

Specifications and Customization: Custom designs or specific finishes may incur additional charges. Buyers should evaluate whether the added cost aligns with their market demands.

-

Materials and Quality Certifications: Higher-quality materials or certifications (such as ISO standards) may increase upfront costs but can lead to lower total cost of ownership (TCO) through enhanced durability and reduced failure rates.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may command higher prices, but the assurance of consistent quality can justify the investment.

-

Incoterms: Understanding the responsibilities outlined in Incoterms is crucial for cost management. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the costs of shipping and insurance, impacting the overall pricing structure.

What Are Effective Buyer Tips for Sourcing 5×115 Rims Internationally?

B2B buyers should adopt strategic approaches when sourcing 5×115 rims to enhance cost-efficiency and negotiation outcomes.

-

Negotiation Strategies: Be prepared to negotiate terms, including pricing, payment terms, and delivery schedules. Establishing a long-term partnership with suppliers can also yield better pricing and service.

-

Cost-Efficiency Considerations: Look beyond the initial purchase price. Evaluating the total cost of ownership, including maintenance and potential replacement costs, can guide more informed purchasing decisions.

-

Pricing Nuances for International Buyers: International buyers should be aware of currency fluctuations, geopolitical risks, and varying import regulations. These factors can significantly affect the final cost and should be considered during the sourcing process.

-

Local Market Research: Understanding local market conditions in your target region can provide insights into pricing trends and competitive offerings, enabling better negotiation leverage.

In conclusion, a comprehensive understanding of the cost structure and pricing influencers for 5×115 rims will empower B2B buyers to make informed decisions, ultimately leading to better procurement strategies and improved profitability.

Alternatives Analysis: Comparing 5×115 rims With Other Solutions

Exploring Alternative Solutions for 5×115 Rims

When evaluating wheel options, B2B buyers often consider various alternatives to the standard 5×115 rims. These alternatives can offer different advantages depending on the specific requirements of the vehicle, budget, and performance needs. Below, we compare 5×115 rims with two viable alternatives: 5×120 rims and wheel adapters.

| Comparison Aspect | 5×115 Rims | 5×120 Rims | Wheel Adapters |

|---|---|---|---|

| Performance | Designed for specific vehicles; optimal fit and handling. | Generally offers a wider selection; may require modifications for fit. | Allows fitment of various wheels; can alter handling dynamics. |

| Cost | Mid-range pricing, depending on brand and finish. | Often slightly more expensive due to wider selection. | Inexpensive compared to buying new rims; costs vary by quality. |

| Ease of Implementation | Direct fit for compatible vehicles; minimal installation hassle. | May require additional modifications to fit correctly. | Simple to install but requires accurate measurement for safety. |

| Maintenance | Low maintenance; regular inspections recommended. | Similar low maintenance; depends on quality. | May require periodic checks for integrity and fitment. |

| Best Use Case | Ideal for vehicles like Dodge, Chrysler, and certain GM models. | Suitable for vehicles with a wider range of aftermarket options. | Best for custom builds or vehicles needing specific fitment solutions. |

Analyzing the Alternatives to 5×115 Rims

5×120 Rims

5×120 rims are another popular option, especially for vehicles that can accommodate this bolt pattern, such as BMWs and some GM models. The primary advantage of 5×120 rims is the broader selection available in the aftermarket. This allows buyers to choose from a variety of styles, sizes, and finishes. However, the downside is that they may require modifications to fit vehicles originally designed for 5×115 rims, which can increase installation costs and time. Additionally, using the wrong bolt pattern can negatively impact vehicle handling and safety.

Wheel Adapters

Wheel adapters provide a flexible solution for those looking to fit different bolt patterns. By using adapters, buyers can install wheels with a 5×120 pattern on vehicles that originally require 5×115 rims. This option is often more cost-effective than purchasing new rims. However, the trade-off is that adapters can alter the vehicle’s handling dynamics and may require regular checks to ensure they remain secure. Furthermore, not all adapters are created equal; quality varies significantly, and inferior products can lead to safety issues.

Illustrative image related to 5×115 rims

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate wheel solution, B2B buyers must consider the specific needs of their vehicles, budget constraints, and performance expectations. While 5×115 rims provide a tailored fit for specific models, alternatives like 5×120 rims and wheel adapters offer flexibility for different applications. Ultimately, the decision should be based on compatibility, desired aesthetics, and the long-term value of the investment. By carefully weighing the pros and cons of each option, buyers can ensure they make an informed choice that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for 5×115 rims

What Are the Key Technical Properties of 5×115 Rims?

When evaluating 5×115 rims for procurement, understanding critical technical specifications is vital for ensuring product compatibility and performance. Here are some essential properties to consider:

-

Material Grade

Rims are typically manufactured from materials such as aluminum alloy or steel. Aluminum alloys are lightweight and provide better fuel efficiency, while steel rims are more durable and often less expensive. Selecting the right material grade is essential to balance performance, cost, and weight—factors that directly influence vehicle handling and fuel economy. -

Offset

The offset of a rim refers to the distance from the wheel’s mounting surface to the centerline of the wheel. A positive offset means the mounting surface is closer to the outside edge of the wheel, while a negative offset indicates it’s closer to the vehicle. Understanding the offset is crucial for ensuring proper fitment and avoiding issues such as tire rubbing or clearance problems. -

Load Rating

This specification indicates the maximum weight a rim can support safely. Load ratings are particularly important for B2B buyers dealing with commercial vehicles or heavy-duty applications. Ensuring that the rims meet or exceed the load requirements of the vehicle helps prevent failures that could lead to costly downtime and safety hazards. -

Diameter and Width

The diameter (measured in inches) and width (measured in inches) of the rim impact tire selection and overall vehicle performance. A wider rim can provide better handling and stability, while the diameter must align with the vehicle’s specifications. These dimensions are crucial for compatibility with tires and overall aesthetics. -

Backspacing

Backspacing is the distance from the mounting surface to the back edge of the wheel. This measurement is essential for ensuring that the wheel does not interfere with the brake components or suspension parts. Proper backspacing is vital for maintaining the vehicle’s handling characteristics and safety. -

Finish

The surface finish of a rim affects both aesthetics and durability. Common finishes include chrome, matte black, and painted options, each offering different levels of protection against corrosion and wear. Selecting the right finish can enhance the product’s marketability, particularly in regions where aesthetics play a significant role in consumer purchasing decisions.

What Are Common Trade Terms Used in the 5×115 Rim Industry?

Familiarity with industry-specific terminology can enhance communication and facilitate smoother transactions. Here are some common trade terms relevant to 5×115 rims:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the vehicle manufacturer. For buyers, choosing OEM rims can guarantee compatibility and quality, particularly for replacement parts. Understanding the difference between OEM and aftermarket products can aid in making informed purchasing decisions. -

MOQ (Minimum Order Quantity)

MOQ specifies the least number of units a supplier is willing to sell in a single order. For B2B buyers, knowing the MOQ is essential for budgeting and inventory planning. Negotiating favorable MOQs can lead to cost savings and better supply chain efficiency. -

RFQ (Request for Quotation)

An RFQ is a formal request for suppliers to provide pricing and terms for specific products. Issuing an RFQ can help buyers compare offers from multiple vendors, ensuring they receive the best value for their purchases. -

Incoterms

These are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for determining who is responsible for shipping costs, insurance, and risk during transportation, which can significantly impact the total landed cost of the rims. -

Fitment Guarantee

A fitment guarantee assures buyers that the rims will fit their specified vehicles without modifications. This assurance is vital for B2B buyers to mitigate the risks associated with returns and exchanges, ensuring customer satisfaction and efficient inventory management. -

Load Index

The load index is a numerical code that indicates the maximum load a tire can support at a specified pressure. This term is essential for ensuring that the selected rims can accommodate the tires’ load index, which directly impacts vehicle safety and performance.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing 5×115 rims, ultimately leading to better product selection and enhanced customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the 5×115 rims Sector

What are the Key Market Dynamics and Trends Influencing the 5×115 Rims Sector?

The global market for 5×115 rims is being driven by a resurgence in automotive customization and performance enhancements. As international markets in Africa, South America, the Middle East, and Europe expand, there is an increasing demand for personalized vehicle aesthetics and improved functionality. Notably, regions such as Brazil and Saudi Arabia are experiencing growth in automotive aftermarket activities, fueled by a younger demographic that prioritizes style and performance in vehicles.

Emerging technologies in e-commerce and logistics are transforming how B2B buyers source rims. Online marketplaces now offer a plethora of options, complete with detailed specifications, customer reviews, and price comparisons. This shift towards digital sourcing is not only streamlining purchasing processes but also providing buyers with greater transparency and choice. Additionally, the rise of AI-driven recommendation systems is enhancing user experiences, allowing buyers to find the perfect 5×115 rims tailored to their vehicle needs more efficiently.

Moreover, sustainability is becoming a crucial factor in sourcing decisions. Buyers are increasingly looking for suppliers that demonstrate eco-friendly practices, such as using recycled materials and minimizing waste during manufacturing. This trend is particularly pronounced in Europe, where stringent regulations around environmental impact are influencing purchasing behavior.

How is Sustainability Influencing Sourcing Decisions for 5×115 Rims?

In the context of 5×115 rims, sustainability encompasses both environmental impact and ethical sourcing practices. The production of rims can involve significant carbon emissions, particularly when considering the raw materials and energy consumed during manufacturing. Therefore, international B2B buyers are prioritizing suppliers that actively pursue sustainable practices, such as using low-impact materials and energy-efficient processes.

Illustrative image related to 5×115 rims

Ethical supply chains are also gaining prominence. Buyers are increasingly aware of the social implications of their sourcing decisions, including labor practices and community impacts in manufacturing countries. Suppliers that can demonstrate commitment to ethical sourcing, potentially through certifications like Fair Trade or ISO 14001 for environmental management, are more likely to attract business from conscientious buyers.

Additionally, the use of “green” materials, such as recycled aluminum or eco-friendly coatings, is becoming a selling point for suppliers. B2B buyers are not only looking for high-quality products but also for those that align with their corporate sustainability goals. This trend is reshaping the competitive landscape, as companies that can effectively communicate their sustainability efforts stand to gain a significant advantage in the market.

What is the Historical Evolution of the 5×115 Rims Market?

The 5×115 rims sector has evolved significantly since its inception, paralleling advancements in automotive technology and design preferences. Initially, rims were primarily functional, focusing on durability and performance. However, as consumer preferences shifted towards personalization and aesthetic appeal in the late 20th century, manufacturers began to innovate with designs, finishes, and materials.

In the early 2000s, the rise of online retail transformed the landscape, making it easier for consumers and businesses alike to access a wider range of options. This digital transformation has continued, with many suppliers now leveraging advanced technologies to enhance the buying experience, streamline logistics, and ensure fitment accuracy. The historical trajectory of the 5×115 rims market reflects broader trends in automotive customization and global sourcing, illustrating how industry dynamics continuously adapt to changing consumer demands and technological advancements.

Overall, understanding these market dynamics, sustainability considerations, and historical trends is crucial for B2B buyers looking to navigate the complexities of sourcing 5×115 rims effectively.

Illustrative image related to 5×115 rims

Frequently Asked Questions (FAQs) for B2B Buyers of 5×115 rims

-

How do I determine the right 5×115 rims for my vehicle?

To find the correct 5×115 rims for your vehicle, start by confirming your vehicle’s specifications, including the make, model, and year. Utilize online fitment tools available on various supplier websites, which allow you to input your vehicle details and show compatible rim options. Additionally, consider factors such as diameter, width, offset, and load rating to ensure the rims meet both aesthetic and functional requirements. Always check for fitment guarantees to avoid costly mistakes. -

What are the most popular applications for 5×115 rims?

5×115 rims are commonly used in vehicles such as the Dodge Charger, Chrysler 300, and various models from Buick and Cadillac. These rims are particularly suited for performance vehicles, offering enhanced handling and aesthetics. When sourcing rims, consider the specific models prevalent in your target market, such as Brazil or Saudi Arabia, to ensure you meet local demand effectively. -

What customization options are available for 5×115 rims?

Customization options for 5×115 rims can include various finishes (e.g., matte black, chrome, or gloss), sizes, and designs. Many suppliers offer bespoke services, allowing you to specify unique colors or patterns tailored to your brand’s identity. Discuss these options with manufacturers early in the procurement process to understand minimum order quantities and lead times associated with custom designs. -

What is the typical minimum order quantity (MOQ) for 5×115 rims?

The MOQ for 5×115 rims can vary significantly by supplier, typically ranging from 4 to 100 units depending on the manufacturer and type of rim. For bulk orders, suppliers often provide better pricing and terms. Be sure to negotiate MOQs that align with your inventory strategy, especially if you’re targeting specific markets with varying demand levels. -

What payment terms should I expect when sourcing 5×115 rims internationally?

Payment terms for international orders of 5×115 rims can include options like upfront payment, deposits, or net payment terms (e.g., net 30, 60, or 90 days). Discuss these terms upfront to ensure they align with your financial strategy and cash flow needs. Be aware that different suppliers may have varying policies based on their country of operation and local regulations. -

How can I vet suppliers for 5×115 rims to ensure quality?

To vet suppliers effectively, consider their industry experience, client testimonials, and certifications. Request samples of the rims to assess quality firsthand. Additionally, conduct background checks and seek references from other businesses that have sourced products from them. Using platforms that provide supplier ratings and reviews can also aid in selecting reliable partners. -

What logistics considerations should I keep in mind when importing 5×115 rims?

When importing 5×115 rims, consider shipping methods, costs, and timelines. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Be aware of customs regulations in your destination country, including import duties and taxes, which can affect total costs. Partner with logistics providers experienced in automotive parts to streamline the process. -

How do I ensure quality assurance (QA) for my 5×115 rim orders?

To implement effective QA measures, establish clear specifications and standards with your suppliers before production begins. Request periodic quality checks during the manufacturing process and consider on-site inspections if feasible. Additionally, insist on third-party quality certifications and conduct random sampling upon receipt of goods to ensure they meet your expectations and compliance standards.

Top 7 5X115 Rims Manufacturers & Suppliers List

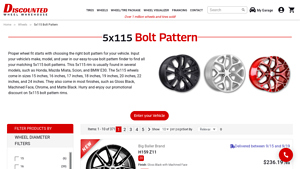

1. Discounted Wheel Warehouse – 5×115 Bolt Pattern Wheels

Domain: discountedwheelwarehouse.com

Registered: 2002 (23 years)

Introduction: 5×115 Bolt Pattern Wheels and Rims available in sizes: 15, 16, 17, 18, 19, 20, 22, and 24 inches. Finishes include Gloss Black, Machined Face, Chrome, and Matte Black. Suitable for vehicles like Honda, Mazda Miata, Scion, and BMW E30. Promotional discounts available.

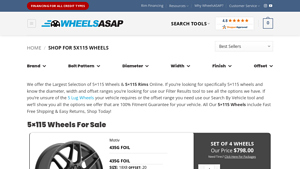

2. Wheels ASAP – 5×115 Wheels & Rims

Domain: wheelsasap.com

Registered: 2017 (8 years)

Introduction: Key Product Details:

– Product Type: 5×115 Wheels & Rims

– Total Products Available: 152

– Brands: American Racing, Asanti, Black DUB, Foose, Konig, Kraze, Maxxim, Mazzi, Motegi, Motiv, Motiv Offroad, Niche, OE Creations, Petrol, Platinum, Ridler, TSW, US MAG

– Bolt Pattern: 5×115

– Available Diameters: 16, 17, 18, 19, 20, 22, 24, 26

– Available Widths: 7, 7.5, 8, 8.5, 9, 9.5, 10, 10.5, 11, 12

– F…

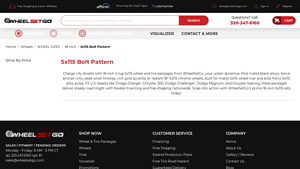

3. WheelsetGo – 18 Inch Muscle Wheel & Tire Packages

Domain: wheelsetgo.com

Registered: 2021 (4 years)

Introduction: 18 Inch 5×115 Muscle Wheel & Tire Packages, Free Shipping to Lower 48 States, Financing All Credit Types, Available finishes: matte black alloys, bronze rims, silver finishes, gold accents, chrome wheels, Fits vehicles: Dodge Charger, Chrysler 300, Dodge Challenger, Dodge Magnum, Chrysler Sebring.

4. eBay – 5×115 Wheel & Tire Packages

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 5×115 Car & Truck Wheel & Tire Packages available for sale on eBay. Wheel diameters include 18, 19, 20, 22, and 24 inches. Related searches include 5×115 rims and tires, 5×115 wheels, and various other bolt patterns. Package quantities range from 1 to 8. Categories include other wheel and tire parts such as tire pressure monitoring sensors, valve stems, and wheel accessories.

5. BB Wheels – 5×115 Bolt Pattern Wheels

Domain: bbwheelsonline.com

Registered: 2012 (13 years)

Introduction: 5×115 Bolt Pattern Wheels | Free Shipping To Lower 48 States | Financing available for all credit types | Contact: 320-333-2155 | Text: 507-432-2127

6. Reddit – Wheel Bolt Pattern Compatibility

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around the compatibility of wheel bolt patterns, specifically 5×115 and 5×114.3. The user is considering using 5×114.3 rims on a 2005 Impala, which has a 5×115 bolt pattern. They seek personal experiences regarding ride quality when using rims with a slightly different bolt pattern. The difference is 0.7mm, which some users argue is negligible, while others caution against …

7. 5×115 Bolt Pattern – Key Vehicle Models

Domain: wheel-size.com

Registered: 2012 (13 years)

Introduction: 5×115 Bolt Pattern: Common to BAIC, Buick, Cadillac, Chevrolet, Chrysler, Daewoo, and Dodge vehicles. Notable models include:

– BAIC: Senova X65 (2015-2021)

– Buick: Allure (2005-2009), Cascada (2016-2019), Encore (2020-2026), Regal (1987-2026)

– Cadillac: ATS (2013-2019), CTS (2002-2007), DeVille (1985-2005)

– Chevrolet: Alero (1999-2004), Equinox (2005-2009, 2017-2026), Malibu (2016-2025)

-…

Strategic Sourcing Conclusion and Outlook for 5×115 rims

In the evolving landscape of automotive parts procurement, strategic sourcing of 5×115 rims stands as a critical component for B2B buyers across Africa, South America, the Middle East, and Europe. By leveraging a diverse range of suppliers, businesses can access a vast selection of high-quality wheels tailored to fit popular models such as the Chrysler 300 and Dodge Charger. This allows for a more competitive edge in fulfilling customer demands while ensuring cost-efficiency.

The strategic sourcing process not only enhances product availability but also fosters relationships with manufacturers who provide innovative designs and finishes, meeting the growing aesthetic preferences of consumers. As market trends shift toward personalization, the ability to offer unique rim designs—such as matte black or chrome finishes—can significantly influence purchasing decisions.

Looking ahead, international buyers are encouraged to adopt a proactive sourcing approach. By engaging with reliable suppliers and exploring flexible financing options, businesses can better position themselves to capitalize on emerging market opportunities. Now is the time to optimize your procurement strategy and elevate your offerings in the competitive automotive market. Embrace the future of sourcing 5×115 rims and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to 5×115 rims

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.