55 Gallon Drum Inches To Gallons Chart: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for 55 gallon drum inches to gallons chart

In the complex landscape of international trade, B2B buyers often grapple with the challenge of accurately converting measurements, particularly when dealing with the ubiquitous 55-gallon drum. Understanding the 55 gallon drum inches to gallons chart is crucial for ensuring that procurement processes are efficient and cost-effective. Whether you are sourcing for industrial applications, logistics, or storage solutions, this guide serves as an essential resource, providing detailed insights into the conversion metrics that govern the use of these standard containers.

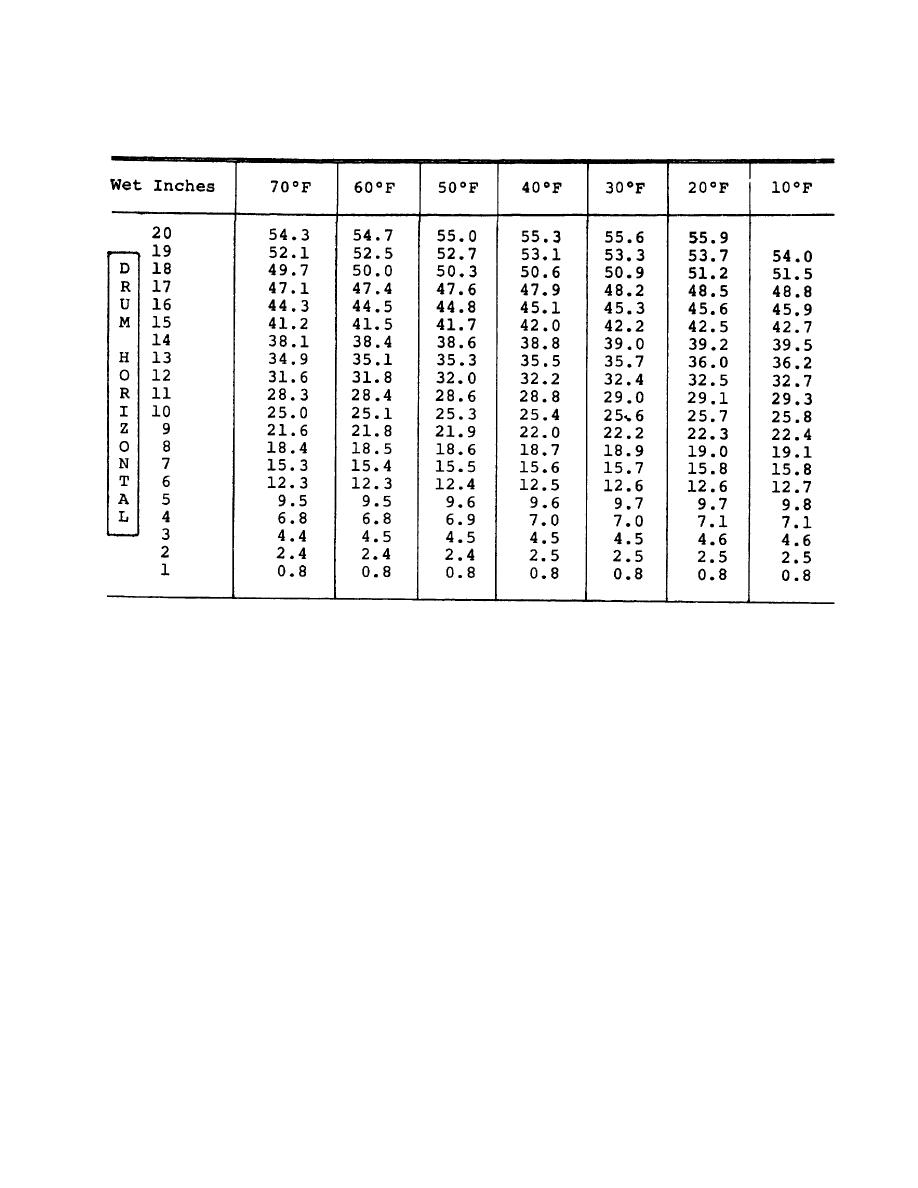

This comprehensive guide delves into various aspects of the 55-gallon drum, including its physical dimensions, weight capacities, and practical applications across diverse industries. We cover critical elements such as supplier vetting processes, cost analysis, and best practices for purchasing in different regions, with a focus on the unique needs of international buyers from Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam.

By equipping decision-makers with the necessary knowledge and tools, this guide empowers B2B buyers to make informed purchasing decisions, ultimately enhancing operational efficiency and reducing costs. Explore the nuanced details of your sourcing strategy and unlock the potential of the 55-gallon drum in your business operations.

Understanding 55 gallon drum inches to gallons chart Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard 55 Gallon Drum Chart | Based on standard dimensions (24″ diameter, 34″ height) | Oil and chemical storage | Pros: Widely used, easy to source. Cons: Limited to standard applications. |

| Custom Height Conversion Chart | Tailored for specific fill heights, varying by contents | Specific industry needs (e.g., chemicals) | Pros: Accurate for specific needs. Cons: Requires precise measurements. |

| Metric Conversion Chart | Provides conversions to liters and other metric units | International shipping and compliance | Pros: Essential for global trade. Cons: May confuse those unfamiliar with metric. |

| Density-Based Conversion Chart | Considers the density of liquids for precise gallon calculation | Liquid measurement in manufacturing | Pros: High accuracy for various liquids. Cons: Complex calculations required. |

| Quick Reference Chart | Simplified versions for fast estimations | Quick assessments in logistics | Pros: Easy to use. Cons: Less accurate than detailed charts. |

What Are the Characteristics of the Standard 55 Gallon Drum Chart?

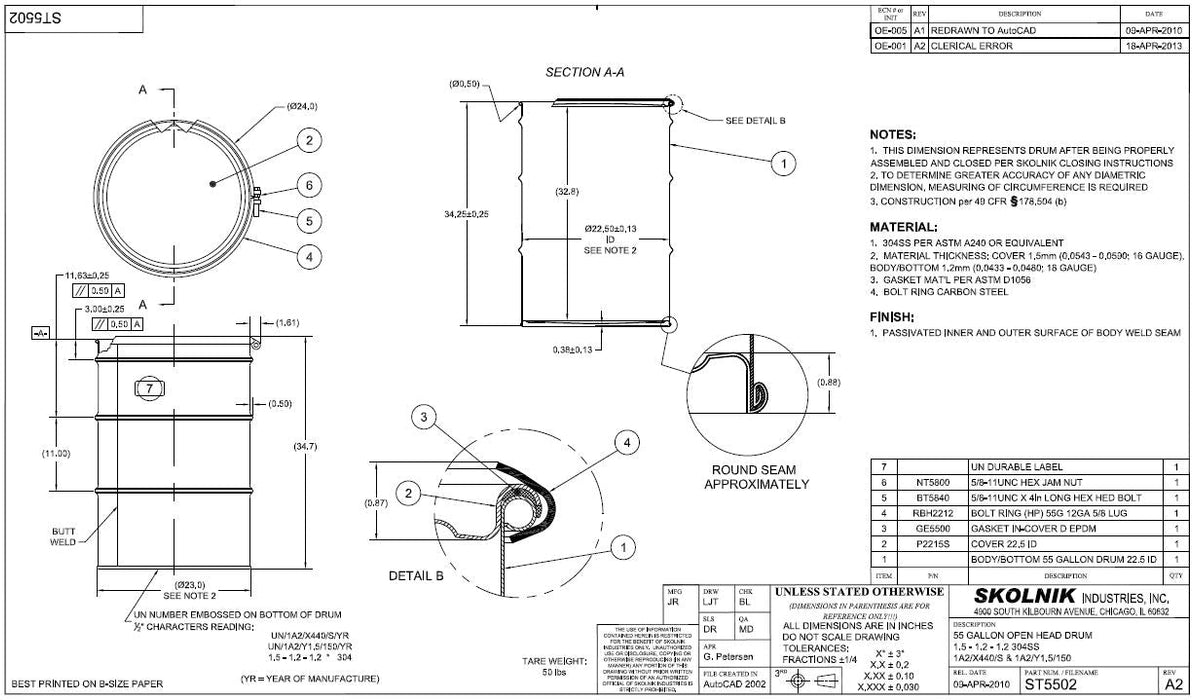

The Standard 55 Gallon Drum Chart is designed based on the standard dimensions of a 55-gallon drum, typically measuring 24 inches in diameter and 34 inches in height. This chart provides a straightforward conversion of inches of liquid height to gallons, making it easy for businesses to estimate the volume of liquid stored. It is commonly used across various industries, particularly for oil and chemical storage, where standardization is essential. Buyers appreciate its widespread availability and ease of use, although its limitations arise when dealing with non-standard drum sizes.

How Does the Custom Height Conversion Chart Work?

The Custom Height Conversion Chart caters to businesses that require precise measurements based on specific fill heights. This chart is beneficial in scenarios where the original fill height of the drum is known, allowing for more accurate calculations of remaining gallons. Industries dealing with hazardous materials or specialized liquids often rely on this type of chart to ensure compliance and safety. Buyers should be mindful that while this chart offers accuracy, it necessitates careful measurement and understanding of the contents to avoid miscalculations.

Why Is the Metric Conversion Chart Important for B2B Transactions?

The Metric Conversion Chart is essential for international B2B transactions, especially for companies exporting or importing products across regions that use metric measurements. This chart converts gallons to liters, facilitating compliance with local regulations and standards. It is particularly valuable for industries operating in Africa, South America, and Europe, where metric units are standard. While it enhances global trade efficiency, buyers may find it challenging if they are not accustomed to metric conversions, necessitating additional training or resources.

What Makes the Density-Based Conversion Chart Unique?

The Density-Based Conversion Chart considers the density of the liquid being measured, providing a tailored approach to gallon calculations. This is particularly useful in industries where the liquid’s density varies significantly, such as in chemical manufacturing or food production. By taking density into account, businesses can achieve high accuracy in their inventory and logistics management. However, the complexity of calculations may require specialized knowledge or software, making it less accessible for some buyers.

How Can the Quick Reference Chart Benefit B2B Operations?

The Quick Reference Chart offers a simplified approach for businesses needing fast estimations of liquid volumes. This chart is particularly useful in logistics and shipping, where quick decisions are often necessary. While it provides a user-friendly interface for quick calculations, it may sacrifice some accuracy compared to more detailed charts. Buyers should consider the trade-off between speed and precision when selecting this type of chart for their operations.

Key Industrial Applications of 55 gallon drum inches to gallons chart

| Industry/Sector | Specific Application of 55 gallon drum inches to gallons chart | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Accurate measurement of oil levels in storage tanks | Ensures optimal inventory management and reduces waste | Consider local regulations on oil storage and transportation |

| Chemical Manufacturing | Precise dosing of chemicals for production processes | Enhances production efficiency and safety in handling hazardous materials | Ensure compliance with safety standards and compatibility of materials |

| Agriculture | Bulk storage and measurement of fertilizers or pesticides | Facilitates better crop management and cost control | Verify the chemical compatibility of drums with stored substances |

| Food & Beverage | Storage and portioning of liquid ingredients | Maintains quality control and consistency in production | Check for food-grade certifications and appropriate sealing options |

| Waste Management | Measurement of waste levels for disposal logistics | Optimizes waste collection schedules and reduces operational costs | Assess local waste disposal regulations and environmental compliance |

How is the ’55 Gallon Drum Inches to Gallons Chart’ Used in the Oil & Gas Industry?

In the oil and gas sector, the ’55 gallon drum inches to gallons chart’ is crucial for accurately measuring oil levels in storage tanks. Each inch of liquid corresponds to a specific volume, allowing businesses to monitor inventory precisely. This measurement is essential for optimizing supply chain operations, preventing overfills, and ensuring compliance with safety regulations. International buyers, particularly from regions like Africa and the Middle East, must also consider local regulations regarding oil storage and transportation.

What Role Does the ‘Inches to Gallons Chart’ Play in Chemical Manufacturing?

Chemical manufacturers rely on the ‘inches to gallons chart’ to ensure precise dosing of various chemicals during production. By knowing the volume of chemicals stored in 55-gallon drums, companies can enhance their production efficiency and maintain safety standards when handling hazardous materials. This is particularly important for international buyers in South America and Europe, who must ensure that their sourcing aligns with strict safety regulations and compatibility requirements of the materials involved.

How is the Chart Utilized in Agriculture for Fertilizers and Pesticides?

In agriculture, the ’55 gallon drum inches to gallons chart’ is used for bulk storage and measurement of fertilizers and pesticides. Accurate volume measurement allows for better crop management and cost control, as farmers can adjust application rates based on precise quantities available. Buyers from regions like Africa and South America should verify the chemical compatibility of the drums with the substances they plan to store, ensuring safe handling and effective use.

How Does the Chart Benefit Food & Beverage Production?

For the food and beverage industry, the ‘inches to gallons chart’ assists in the storage and portioning of liquid ingredients. By providing accurate volume measurements, it helps maintain quality control and consistency in production, which are vital for consumer trust and regulatory compliance. International buyers, especially from Europe and the Middle East, should check for food-grade certifications and appropriate sealing options to ensure the safety of their products.

Why is the ‘Inches to Gallons Chart’ Important for Waste Management?

In waste management, the ’55 gallon drum inches to gallons chart’ is essential for measuring waste levels in drums to optimize disposal logistics. Accurate volume measurements enable companies to schedule waste collection efficiently, reducing operational costs and minimizing environmental impact. International buyers must assess local waste disposal regulations and ensure compliance with environmental standards when sourcing drums for waste management applications.

3 Common User Pain Points for ’55 gallon drum inches to gallons chart’ & Their Solutions

Scenario 1: Miscalculating Liquid Volume Can Lead to Costly Errors

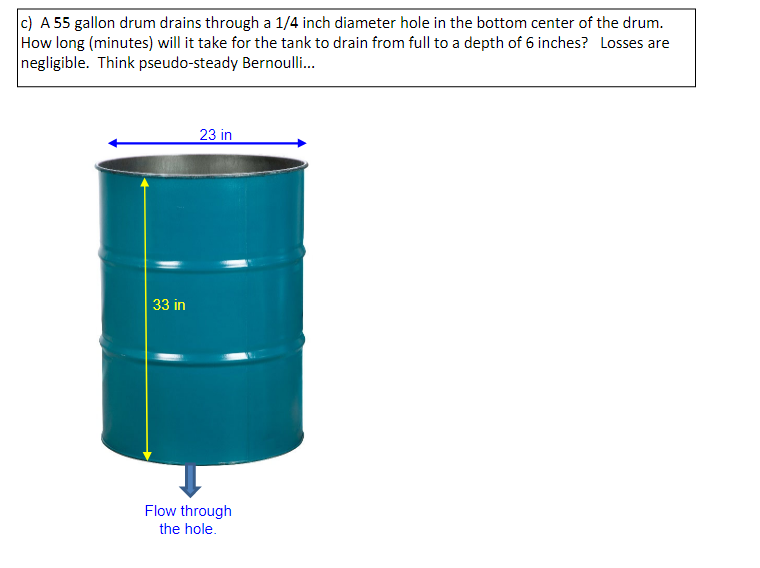

The Problem: For many international buyers, accurately converting the height of liquid in a 55-gallon drum to gallons is crucial for inventory management and cost estimation. Miscalculating this volume can lead to over-ordering or under-utilizing materials, ultimately affecting project budgets and timelines. For instance, a manufacturer in Nigeria might need to know exactly how many gallons of oil remain in a drum to fulfill an urgent order. If they rely on inaccurate calculations, they risk production delays and potential loss of client trust.

Illustrative image related to 55 gallon drum inches to gallons chart

The Solution: To avoid such costly errors, B2B buyers should always refer to a reliable ’55 gallon drum inches to gallons chart’ that provides precise measurements. It is advisable to use a standardized conversion factor, which generally estimates that each inch of height in a 55-gallon drum equates to approximately 1.59 gallons. Buyers can enhance accuracy by measuring the liquid level and applying the conversion directly from the chart. For critical operations, consider maintaining a physical copy of the chart in storage areas and digital copies in operational software. Regular training sessions can also be instituted to ensure that staff are well-versed in using these charts effectively, thereby minimizing the risks of miscalculation.

Scenario 2: Inconsistent Drum Sizes Across Suppliers

The Problem: A common issue faced by B2B buyers is the inconsistency in drum sizes across different suppliers. A buyer in Vietnam may find that a supplier provides a 55-gallon drum that varies slightly in height or diameter, affecting the volume calculations. Such discrepancies can lead to confusion when trying to convert measurements into usable quantities, particularly when dealing with bulk orders or specialized materials.

The Solution: To mitigate this issue, B2B buyers should always verify the specific dimensions of the drums they intend to purchase before relying on any conversion charts. It is essential to establish relationships with reputable suppliers who provide detailed specifications, including height and diameter measurements. Additionally, using a universal conversion chart that lists various drum sizes and their corresponding gallon capacities can help standardize calculations. Implementing a quality assurance process that includes regular checks on drum specifications can also ensure that the drums meet the necessary standards, thereby improving consistency in inventory management.

Illustrative image related to 55 gallon drum inches to gallons chart

Scenario 3: Difficulty in Communicating Measurements Across Teams

The Problem: In multi-national operations, particularly in regions like South America or the Middle East, teams often face challenges in communicating measurements across different languages and units of measure. A logistics coordinator may struggle to convey how many gallons are left in a drum if their team members are accustomed to different measurement systems. This can lead to confusion in operations and potential delays in material handling.

The Solution: To streamline communication, B2B buyers should implement a standardized measurement system across all teams and provide multilingual training on using the ’55 gallon drum inches to gallons chart’. Digital tools and apps that can convert measurements in real time can be particularly beneficial. Additionally, visual aids such as bilingual charts or infographics can help bridge the language gap. Regular meetings to discuss measurement protocols and updates can foster a culture of clarity and ensure that all team members are on the same page. This proactive approach will help to minimize misunderstandings and improve operational efficiency across diverse teams.

Strategic Material Selection Guide for 55 gallon drum inches to gallons chart

What Are the Key Properties of Steel Drums for 55 Gallon Applications?

Steel is the most commonly used material for 55-gallon drums, particularly in industrial applications. Its key properties include high strength, durability, and excellent resistance to impact and puncture. Steel drums typically have a temperature rating that can withstand a wide range of conditions, making them suitable for storing various liquids, including hazardous materials. However, they are susceptible to corrosion, especially when exposed to moisture or corrosive substances.

Pros and Cons: The primary advantages of steel drums include their robustness and ability to contain a wide variety of media, including chemicals and oils. They are generally more cost-effective than other materials like stainless steel or plastic. On the downside, they can be heavy and may require additional handling equipment. Corrosion resistance can be enhanced with coatings, but this adds to manufacturing complexity and cost.

Impact on Application: Steel drums are ideal for storing petroleum products, chemicals, and food-grade materials when properly treated. International buyers should consider compliance with standards such as ASTM for quality assurance. In regions like Africa and South America, where environmental factors may accelerate corrosion, selecting coated or lined steel drums can be crucial.

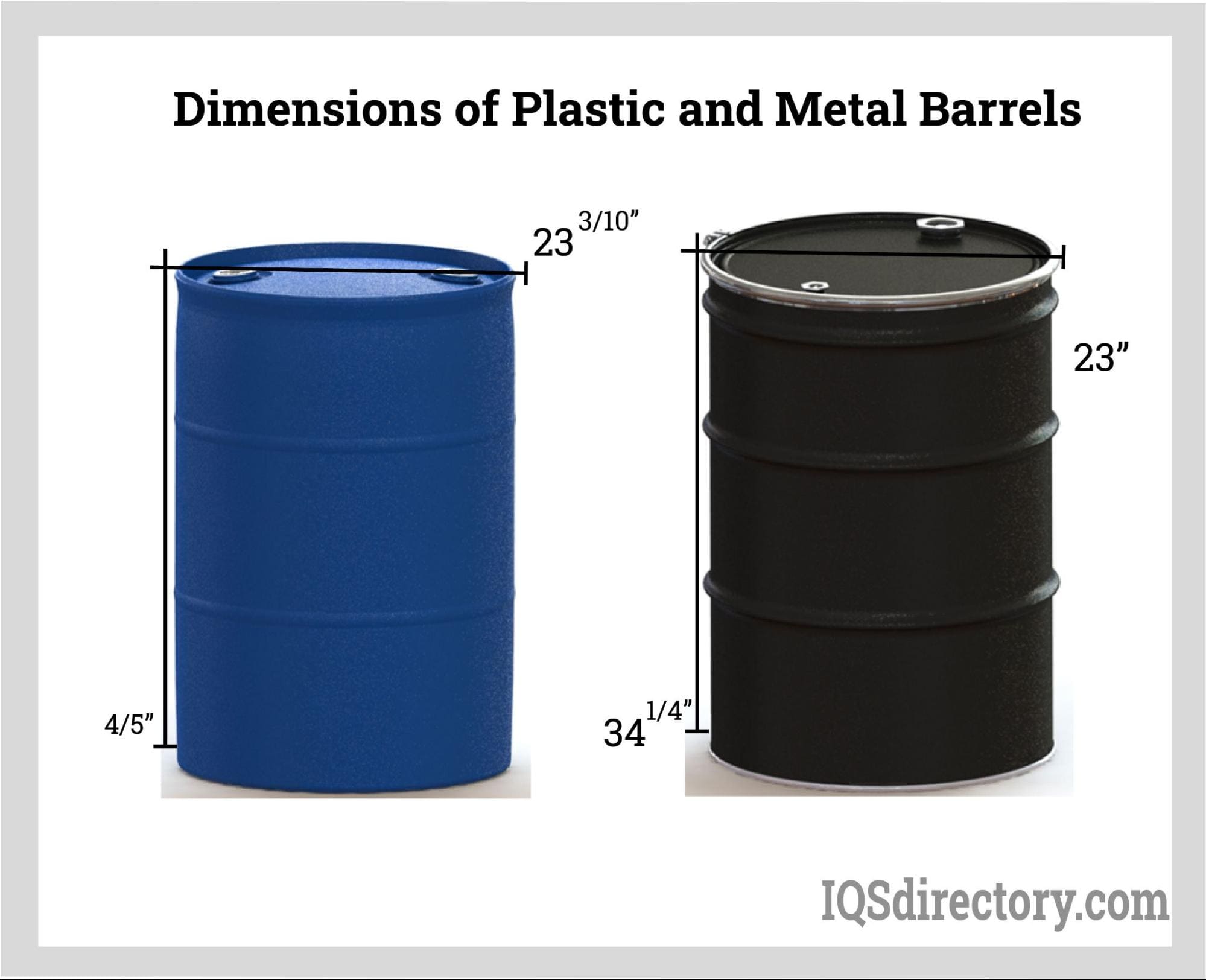

How Does Plastic Compare to Steel for 55 Gallon Drums?

Plastic drums, often made from high-density polyethylene (HDPE), offer a lightweight alternative to steel. They are resistant to corrosion and chemicals, making them suitable for storing aggressive substances. Plastic drums typically have a lower temperature rating compared to steel, which may limit their use in high-temperature applications.

Pros and Cons: The primary advantages of plastic drums include their resistance to rust and corrosion, lightweight nature, and lower cost compared to steel. However, they may not withstand high pressures or impacts as effectively as steel drums. Additionally, they can be more susceptible to UV degradation if not properly treated.

Impact on Application: Plastic drums are commonly used for storing food products, chemicals, and non-hazardous liquids. For international buyers, ensuring compliance with food safety standards (like FDA regulations) is essential, especially in regions with strict import regulations.

What Are the Benefits of Using Stainless Steel Drums?

Stainless steel drums are known for their exceptional durability and resistance to corrosion, making them suitable for a variety of applications, including food and pharmaceutical storage. They can withstand a wide range of temperatures and pressures, which enhances their versatility.

Illustrative image related to 55 gallon drum inches to gallons chart

Pros and Cons: The key advantage of stainless steel drums is their long lifespan and ability to maintain product integrity. They are easy to clean and sterilize, which is crucial in industries like food and pharmaceuticals. However, they come at a higher cost compared to both steel and plastic, and their manufacturing process can be more complex.

Impact on Application: Stainless steel drums are ideal for high-value applications where purity and cleanliness are paramount. International buyers should be aware of compliance with standards such as ASTM and ISO, particularly in regions with stringent quality requirements like Europe.

What Should Buyers Consider When Choosing Fiber Drums?

Fiber drums, often made from composite materials, are lightweight and recyclable. They are suitable for dry goods and non-hazardous materials. Their temperature and pressure ratings are generally lower than those of metal drums, which may limit their use.

Pros and Cons: Fiber drums are cost-effective and environmentally friendly, appealing to businesses looking to reduce their carbon footprint. However, they lack the strength and durability of metal drums and are not suitable for liquids or hazardous materials.

Impact on Application: Fiber drums are commonly used for packaging and shipping dry goods, such as powders and granules. International buyers should consider local regulations regarding packaging materials, especially in regions with strict environmental policies.

Summary Table of Material Selection for 55 Gallon Drums

| Material | Typical Use Case for 55 gallon drum inches to gallons chart | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Storing chemicals, oils, and hazardous materials | High strength and durability | Susceptible to corrosion | Med |

| Plastic | Storing food products and non-hazardous liquids | Corrosion resistant and lightweight | Limited high-temperature use | Low |

| Stainless Steel | Food and pharmaceutical storage | Exceptional durability and purity | Higher cost and complex mfg | High |

| Fiber | Packaging dry goods and non-hazardous materials | Cost-effective and recyclable | Not suitable for liquids | Low |

This comprehensive analysis provides actionable insights for B2B buyers, enabling informed decisions regarding the selection of materials for 55-gallon drums based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 55 gallon drum inches to gallons chart

What Are the Key Stages in the Manufacturing Process of 55 Gallon Drums?

The manufacturing process for 55-gallon drums involves several critical stages to ensure the final product meets industry standards and customer requirements. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The manufacturing process begins with selecting high-quality raw materials, typically steel or plastic. For steel drums, the metal is rolled into sheets and cut to size. For plastic drums, resin pellets are prepared. This stage is crucial as the quality of the raw materials directly impacts the durability and functionality of the drums.

-

Forming: During the forming stage, the prepared sheets of steel or molded plastic are shaped into cylindrical forms. For steel drums, this involves processes like deep drawing and welding. In the case of plastic drums, blow molding or injection molding techniques are employed. These methods ensure the drums achieve the required dimensions and structural integrity.

-

Assembly: After forming, components such as tops, bottoms, and bungs are assembled. This stage may involve welding for steel drums or thermal sealing for plastic variants. Proper assembly is vital to prevent leaks and ensure that the drum can withstand transportation and storage stresses.

-

Finishing: The final stage includes surface treatments such as painting, coating, or polishing. For steel drums, protective coatings are often applied to prevent rust and corrosion. For plastic drums, UV inhibitors may be added to protect against sun damage. This stage enhances the aesthetic appeal of the drum and extends its lifespan.

How Is Quality Assurance Implemented in the Production of 55 Gallon Drums?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the drums produced meet international standards and customer expectations. Various international and industry-specific standards guide the QA process, including ISO 9001, which outlines the requirements for a quality management system.

-

Relevant International Standards: Compliance with ISO 9001 ensures that manufacturers adopt a systematic approach to quality management, focusing on continuous improvement. Additionally, certifications such as CE mark and API (American Petroleum Institute) standards are essential for drums used in specific industries, particularly those involving hazardous materials.

-

Quality Control Checkpoints: The quality assurance process typically includes several checkpoints:

– Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During the manufacturing process, operators conduct regular inspections to monitor quality and identify any deviations from standards.

– Final Quality Control (FQC): Before shipping, finished drums undergo a thorough inspection to verify that they meet all specifications and safety standards. -

Common Testing Methods: Manufacturers utilize various testing methods to ensure the integrity of the drums. These may include pressure testing, leak testing, and physical inspections for structural integrity. Non-destructive testing (NDT) methods can also be employed to assess the quality of welded seams without damaging the drum.

What Are the Best Practices for B2B Buyers to Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some best practices:

Illustrative image related to 55 gallon drum inches to gallons chart

-

Conduct Supplier Audits: One of the most effective ways to ensure quality is through supplier audits. These audits assess the supplier’s manufacturing processes, quality management systems, and compliance with international standards. Buyers should establish clear audit criteria and conduct regular assessments.

-

Request Quality Control Reports: Buyers should ask suppliers for detailed quality control reports that outline testing methods, results, and compliance with relevant standards. This documentation provides transparency and assurance of the supplier’s commitment to quality.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. Independent inspectors can verify that the drums meet specified standards and can provide certificates of conformity.

-

Understand QC Certification Nuances: Different regions may have varying standards and certifications. Buyers should familiarize themselves with the specific requirements applicable in their regions, such as CE marking in Europe or API certifications for oil and gas applications. Understanding these nuances ensures that the products meet local regulations and industry standards.

-

Evaluate Supplier Reputation and Experience: Researching the supplier’s history and reputation in the industry can provide insights into their quality control practices. Engaging with other businesses that have worked with the supplier can also yield valuable feedback.

How Do Manufacturing and Quality Assurance Practices Affect B2B Buyer Decisions?

The manufacturing and quality assurance practices employed by suppliers significantly impact B2B buyer decisions. Buyers prioritize suppliers that demonstrate a commitment to quality, reliability, and compliance with international standards. A well-documented quality assurance process not only ensures product safety and performance but also builds trust and credibility with buyers.

Moreover, effective communication regarding quality standards, testing methods, and compliance can enhance supplier relationships. Suppliers that are transparent about their processes and willing to accommodate buyer requirements are more likely to secure long-term partnerships.

In summary, understanding the manufacturing processes and quality assurance practices of 55-gallon drum suppliers is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions that align with their operational needs and compliance requirements, ultimately leading to successful procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ’55 gallon drum inches to gallons chart’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure a reliable ’55 gallon drum inches to gallons chart.’ Understanding the conversion from inches to gallons is essential for accurate inventory management, logistics planning, and ensuring compliance with industry standards. This checklist will help you navigate the sourcing process effectively, ensuring you get the most accurate and useful information for your operational needs.

Step 1: Define Your Technical Specifications

Clearly outline your requirements related to the 55-gallon drum dimensions and the conversion needs. Knowing the specifics, such as the height of the drum and the type of liquid it will contain, will help in selecting the right conversion chart. This ensures that any calculations you perform will be based on accurate data tailored to your applications.

Illustrative image related to 55 gallon drum inches to gallons chart

Step 2: Research Conversion Standards

Familiarize yourself with standard conversion rates for a 55-gallon drum. Typically, one inch of liquid height in a 55-gallon drum corresponds to approximately 1.59 gallons. Understanding these metrics will allow you to assess the reliability of the charts you encounter and avoid errors in your calculations.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it is crucial to thoroughly vet them. Request company profiles, case studies, and references from buyers in similar industries or regions. This due diligence will ensure you are dealing with reputable suppliers who can provide accurate and reliable conversion charts.

Step 4: Verify Chart Accuracy and Quality

Examine the accuracy of the inches to gallons chart you plan to use. Look for charts that have been validated by industry standards or come with endorsements from credible sources. Ensure that the chart includes clear instructions and is easy to interpret, as this will save time and reduce errors in your calculations.

Step 5: Check for Customization Options

Inquire if the supplier offers customization of the conversion chart to meet your specific needs. Custom charts can include additional metrics or formats that align better with your operational requirements. Having a tailored chart can improve efficiency and accuracy in your processes.

Step 6: Assess Support and Documentation

Review the level of customer support and documentation provided by the supplier. A supplier who offers comprehensive user guides, FAQs, and responsive customer service can be invaluable, particularly when you encounter unique situations or require clarification on the chart’s use.

Illustrative image related to 55 gallon drum inches to gallons chart

Step 7: Compare Pricing and Terms

Finally, compare pricing among different suppliers while considering the quality and reliability of the charts. Analyze the terms of purchase, including return policies, warranties, and potential discounts for bulk orders. This step ensures that you not only get a fair price but also a product that meets your needs effectively.

By following this checklist, B2B buyers can confidently procure a ’55 gallon drum inches to gallons chart’ that meets their operational requirements while ensuring accuracy and reliability.

Comprehensive Cost and Pricing Analysis for 55 gallon drum inches to gallons chart Sourcing

What Are the Key Cost Components in Sourcing a 55 Gallon Drum Inches to Gallons Chart?

When considering the sourcing of a 55-gallon drum inches to gallons chart, several cost components come into play. Understanding these components is crucial for B2B buyers to accurately assess total expenses.

-

Materials: The primary material for these charts is typically durable paper or plastic, with variations in quality affecting the cost. Higher-quality materials may provide better longevity and usability, particularly in industrial environments where exposure to moisture and chemicals is common.

-

Labor: Labor costs encompass the design and production stages. Skilled labor may be required for detailed graphics and accurate measurements, which can increase the overall cost.

-

Manufacturing Overhead: This includes costs associated with the production facility, utilities, and equipment depreciation. Efficient operations can help mitigate these costs, impacting the final price.

-

Tooling: If custom designs or sizes are requested, tooling costs can be significant. This expense should be factored into the overall pricing, especially for unique specifications.

-

Quality Control (QC): Ensuring accuracy in measurements is essential. Rigorous quality control processes may add to the cost but are necessary to maintain product integrity and customer satisfaction.

-

Logistics: Shipping costs vary based on the destination, especially for international shipments. Factors such as shipping mode (air vs. sea), packaging, and import duties can significantly influence the total logistics costs.

-

Margin: Suppliers typically add a markup to cover their costs and generate profit. Understanding the expected margins in your specific market can help in negotiating better pricing.

How Do Price Influencers Affect the Cost of 55 Gallon Drum Charts?

Several key price influencers can impact the sourcing costs of a 55-gallon drum inches to gallons chart:

-

Volume/MOQ: Larger orders often result in reduced per-unit costs due to economies of scale. Establishing a minimum order quantity (MOQ) can be beneficial for both parties.

-

Specifications and Customization: Custom charts with specific measurements or branding will typically incur additional costs. Buyers should evaluate whether the customization adds enough value to justify the extra expense.

-

Materials and Quality Certifications: High-quality materials or certified products (e.g., ISO-certified) may command higher prices. Buyers should weigh the importance of certification against their budget constraints.

-

Supplier Factors: The supplier’s reputation, reliability, and location can affect pricing. Established suppliers may offer better quality assurance but at a premium.

-

Incoterms: Understanding the shipping terms (Incoterms) is vital for pricing. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can influence total costs, particularly in international transactions.

What Buyer Tips Can Help Negotiate Better Pricing?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, can benefit from several strategic tips:

-

Negotiation: Always negotiate prices, especially for bulk orders. Suppliers may have flexibility in pricing, particularly if they value your business for future orders.

-

Cost-Efficiency: Consider the total cost of ownership, which includes not just the purchase price but also logistics, storage, and potential waste. A slightly higher upfront cost may lead to lower long-term expenses.

-

Understand Pricing Nuances: Be aware of local market conditions and currency fluctuations that may affect pricing. This knowledge can empower buyers during negotiations.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and priority service. Regular communication and feedback can foster loyalty.

-

Research and Compare: Conduct thorough market research and compare quotes from multiple suppliers. This helps in identifying fair market prices and may provide leverage in negotiations.

By understanding these cost structures and price influencers, B2B buyers can make informed decisions when sourcing a 55-gallon drum inches to gallons chart, ultimately optimizing their procurement process and enhancing their operational efficiency.

Alternatives Analysis: Comparing 55 gallon drum inches to gallons chart With Other Solutions

Exploring Alternatives to the 55 Gallon Drum Inches to Gallons Chart

In the realm of industrial storage and liquid measurement, the 55-gallon drum inches to gallons chart is a widely accepted tool. However, there are alternative solutions that can also assist businesses in achieving accurate liquid measurements. This analysis compares the 55-gallon drum inches to gallons chart against two viable alternatives: digital liquid measurement devices and volumetric flow meters. Each solution offers unique benefits and drawbacks, making it essential for B2B buyers to consider their specific needs when choosing the most appropriate method.

| Comparison Aspect | 55 Gallon Drum Inches To Gallons Chart | Digital Liquid Measurement Devices | Volumetric Flow Meters |

|---|---|---|---|

| Performance | Accurate for standard measurements | Highly accurate, real-time data | Accurate over time, continuous |

| Cost | Low-cost, requires no investment | Moderate to high initial cost | High initial investment |

| Ease of Implementation | Simple and straightforward | Requires training for use | Installation needed |

| Maintenance | Minimal, no maintenance required | Regular calibration needed | Routine maintenance required |

| Best Use Case | Small to medium liquid storage | Large-scale operations, precision | Continuous monitoring of flow |

Understanding Digital Liquid Measurement Devices

Digital liquid measurement devices provide a modern approach to measuring liquid levels. They offer real-time data through sensors and digital displays, allowing for precise monitoring. One of the main advantages is their accuracy; they can measure liquid levels continuously and provide instant feedback. However, these devices often come with a moderate to high initial cost, which may not be feasible for smaller businesses. Additionally, they require some training to operate effectively, and regular calibration is necessary to maintain accuracy. Thus, while they are excellent for large-scale operations, smaller enterprises might find them less suitable.

Evaluating Volumetric Flow Meters

Volumetric flow meters are another alternative that facilitates continuous measurement of liquid flow, making them ideal for operations requiring constant monitoring. They are particularly useful in processes where liquid needs to be measured as it flows through pipes. These devices are known for their reliability and ability to provide accurate measurements over time. However, they require a significant initial investment and ongoing maintenance to ensure optimal performance. Installation can also be complex, necessitating skilled personnel for setup. As a result, while volumetric flow meters are advantageous for large operations, smaller businesses may struggle to justify the costs and complexity.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting the most appropriate solution for liquid measurement, B2B buyers should consider their specific operational requirements, budget constraints, and the scale of their operations. The 55-gallon drum inches to gallons chart remains a cost-effective and straightforward option for small to medium-sized enterprises that require basic liquid measurement capabilities. In contrast, digital liquid measurement devices and volumetric flow meters offer advanced features and accuracy suitable for larger operations, albeit at a higher cost and complexity. Ultimately, the right choice will depend on the buyer’s unique needs, available resources, and the specific applications they aim to support.

Essential Technical Properties and Trade Terminology for 55 gallon drum inches to gallons chart

What are the Essential Technical Properties of a 55 Gallon Drum?

When dealing with 55-gallon drums, understanding critical specifications is vital for ensuring compatibility, safety, and operational efficiency. Here are key technical properties to consider:

-

Material Grade:

The most common materials used for 55-gallon drums include steel, plastic, and fiberglass. Steel drums are known for their durability and resistance to punctures and corrosion, making them suitable for hazardous materials. Plastic drums are lighter and resistant to a wider range of chemicals, while fiberglass drums are often used for transporting corrosive substances. Selecting the right material impacts both the safety of the contents and the longevity of the drum. -

Dimensions:

A standard 55-gallon drum typically has a height of 34 inches and a diameter of 24 inches. These dimensions are crucial for storage and transportation logistics. Understanding the physical dimensions helps in planning warehouse space and ensures compatibility with handling equipment such as forklifts and pallet jacks. -

Weight Capacity:

The weight capacity of a 55-gallon drum varies significantly based on the contents. For example, a drum filled with water can weigh around 460 pounds, while different liquids or materials may change this figure. Knowing the weight capacity is essential for compliance with transportation regulations and for ensuring that handling equipment can safely manage the load. -

Volume Tolerance:

While a 55-gallon drum is designed to hold 55 gallons, actual usable volume may vary due to headspace required for thermal expansion and contraction. Understanding this tolerance is critical for accurately calculating how much product can be safely stored or transported, particularly in regions with fluctuating temperatures. -

Bung Size:

Most 55-gallon drums feature a standard bung size of 2 inches for both filling and venting. This specification is important when selecting pumps or fittings for transferring liquids. Ensuring compatibility with bungs can save time and reduce operational interruptions. -

Compatibility with Contents:

Each material used in a 55-gallon drum has specific compatibility ratings with various chemicals. It is essential to ensure that the drum material can safely contain the intended contents to prevent leaks or chemical reactions, which could lead to hazardous situations.

What are Common Trade Terms Related to 55 Gallon Drums?

Familiarity with industry jargon can streamline communication and facilitate smoother transactions. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer):

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. When purchasing drums, understanding whether you are dealing with an OEM can affect pricing, quality, and warranty considerations. -

MOQ (Minimum Order Quantity):

MOQ specifies the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for inventory management and cost calculations, especially for international buyers who may need to factor shipping costs into their total expenditure. -

RFQ (Request for Quotation):

An RFQ is a document sent to suppliers requesting a price quote for specific goods or services. This is particularly relevant when sourcing 55-gallon drums, as it allows buyers to compare prices and terms from multiple suppliers effectively. -

Incoterms (International Commercial Terms):

These are a set of pre-defined commercial terms published by the International Chamber of Commerce (ICC) related to international commercial law. Familiarity with Incoterms can clarify responsibilities regarding shipping, insurance, and tariffs, which is especially important for international transactions involving 55-gallon drums. -

Lead Time:

Lead time refers to the amount of time it takes from placing an order until it is delivered. Understanding lead times is vital for planning inventory and ensuring that production schedules remain on track, especially in industries where timely delivery is critical. -

Hazmat (Hazardous Materials):

This term refers to substances that pose a risk to health, property, or the environment. When dealing with 55-gallon drums, particularly in industrial settings, understanding hazmat regulations ensures compliance and safety in storage and transportation.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding the procurement and management of 55-gallon drums, enhancing operational efficiency and compliance in their respective industries.

Navigating Market Dynamics and Sourcing Trends in the 55 gallon drum inches to gallons chart Sector

What Are the Key Drivers in the 55 Gallon Drum Market?

The global market for 55-gallon drums is being influenced by several key drivers, making it essential for international B2B buyers to stay informed. First, the growth in industrial manufacturing across regions such as Africa, South America, and the Middle East is driving demand for reliable storage solutions. As industries scale, the need for standardized containers that can efficiently store and transport liquids and bulk materials becomes critical. Additionally, with the rise of e-commerce and the logistics sector, companies require packaging that meets regulatory standards while ensuring product integrity during transit.

Emerging technologies such as IoT and data analytics are also reshaping the sourcing landscape. Smart drums equipped with sensors can monitor contents and provide real-time data on inventory levels, enhancing supply chain efficiency. Furthermore, the increasing adoption of automation in warehousing and distribution centers is streamlining the handling of 55-gallon drums, reducing labor costs, and improving accuracy in stock management. For international buyers, keeping an eye on these technological advancements can lead to more informed purchasing decisions and optimized operational processes.

Illustrative image related to 55 gallon drum inches to gallons chart

How Is Sustainability Influencing B2B Sourcing of 55 Gallon Drums?

Sustainability is becoming a cornerstone of B2B sourcing strategies, particularly in the context of 55-gallon drums. Companies are increasingly aware of their environmental footprint and the importance of ethical sourcing. This shift is prompting buyers to seek suppliers that adhere to sustainable practices, such as using recycled materials or implementing eco-friendly manufacturing processes.

The demand for ‘green’ certifications is also on the rise. Drums produced from sustainable materials or those that have undergone environmentally responsible production methods can enhance a company’s reputation and appeal to eco-conscious consumers. Additionally, the circular economy model is gaining traction, encouraging the reuse and recycling of 55-gallon drums to minimize waste. B2B buyers should prioritize partnerships with suppliers who can demonstrate their commitment to sustainability, as this not only aligns with corporate social responsibility goals but can also lead to long-term cost savings.

What Is the Historical Context of 55 Gallon Drums in B2B?

The 55-gallon drum has a rich history that dates back to the early 20th century, initially developed for the storage and transportation of oil. Over the decades, its design and material composition have evolved to meet the changing needs of various industries. Today, these drums are commonly used for a wide range of applications, from chemical storage to food processing, reflecting their versatility and reliability.

As global trade expanded, the standardization of the 55-gallon drum facilitated easier logistics and handling across borders. This historical context underscores the drum’s significance in the B2B sector, as it remains a vital component in supply chains worldwide. Understanding the evolution of this container can help international buyers appreciate its enduring value and influence on current market dynamics.

In conclusion, navigating the complexities of the 55-gallon drum market requires a keen awareness of market drivers, sustainability trends, and historical significance. By staying informed, B2B buyers can make strategic sourcing decisions that not only meet their operational needs but also align with broader environmental and ethical goals.

Illustrative image related to 55 gallon drum inches to gallons chart

Frequently Asked Questions (FAQs) for B2B Buyers of 55 gallon drum inches to gallons chart

-

1. How do I convert inches of liquid height in a 55-gallon drum to gallons?

To convert the height of liquid in inches to gallons in a 55-gallon drum, you can use the approximation that each inch of height corresponds to about 1.59 gallons. Therefore, measure the liquid height in inches and multiply by 1.59 to determine the volume in gallons. For example, if the liquid height is 10 inches, the calculation would be 10 inches x 1.59 gallons/inch = approximately 15.9 gallons. -

2. What is the best method for sourcing 55-gallon drums internationally?

When sourcing 55-gallon drums internationally, prioritize suppliers with a proven track record and good reputation. Research potential vendors through trade platforms, industry forums, or recommendations from business contacts. Verify their certifications and compliance with international standards. Additionally, consider requesting samples to assess quality before placing larger orders. Engaging with local trade associations may also provide insights into reliable suppliers in specific regions. -

3. How can I ensure the quality of 55-gallon drums before purchasing?

To ensure quality, request detailed specifications and certifications from the supplier, such as ISO standards or material safety data sheets. Conduct a factory audit if feasible, or seek third-party inspection services to evaluate the drums before shipment. Additionally, consider obtaining samples for testing, focusing on aspects like durability, material integrity, and compatibility with the intended contents. Quality assurance measures are crucial, especially when dealing with hazardous materials. -

4. What are the typical minimum order quantities (MOQs) for 55-gallon drums?

Minimum order quantities for 55-gallon drums can vary widely based on the supplier and the type of drum. Generally, MOQs range from 50 to 500 units for standard orders. Customization requests, such as specific coatings or markings, may require higher MOQs. Always clarify MOQs with potential suppliers during negotiations to ensure they align with your purchasing needs and capacity. -

5. What payment terms should I expect when ordering 55-gallon drums?

Payment terms for ordering 55-gallon drums typically include options like upfront payment, partial payment upon order confirmation, and the balance before shipping. It’s essential to negotiate terms that suit your cash flow, considering factors like order size and supplier reliability. Many suppliers may also accept letters of credit or trade finance options, especially for larger international orders. Always ensure that payment methods are secure and documented. -

6. How do I handle logistics for shipping 55-gallon drums internationally?

Logistics for shipping 55-gallon drums internationally involves careful planning. Engage a freight forwarder experienced in handling hazardous or bulky goods. Ensure compliance with international shipping regulations, including proper labeling and documentation for customs clearance. Additionally, choose appropriate shipping methods, such as container shipping for larger quantities, and confirm that the drums are securely packed to prevent damage during transit. -

7. What customization options are available for 55-gallon drums?

Customization options for 55-gallon drums can include specific colors, coatings, and printing for branding or identification purposes. Some suppliers offer options for different types of lids or bungs, as well as modifications for specific applications, such as food-grade materials or corrosion-resistant coatings. Discuss your requirements with potential suppliers to explore available customization options that meet your operational needs. -

8. How can I verify the compliance of 55-gallon drums with international standards?

To verify compliance with international standards, request relevant certifications from the supplier, such as UN certification for hazardous materials or ISO standards for quality management. Conduct due diligence by checking the supplier’s history and reputation in the industry. Additionally, consult with local regulatory bodies or industry associations to ensure that the drums meet the necessary safety and quality standards for your specific market.

Top 8 55 Gallon Drum Inches To Gallons Chart Manufacturers & Suppliers List

1. Convert-Me – Inches to Gallons Conversion

Domain: convert-me.com

Registered: 2000 (25 years)

Introduction: Inches to gallons conversion for a standard 55 gallon drum. 1.72 gallons per inch based on a fill height of 32 inches. Alternative estimate of 1.7 gallons per inch. Other conversions mentioned include 1.56 gallons per inch for a 19.25×19.25×29.5 drum.

2. Fluid-Bag – 55 Gallon Drum Specifications

Domain: fluid-bag.com

Registered: 1998 (27 years)

Introduction: 55 gallon drum dimensions: 24 inches (61 cm) in diameter, 34 inches (86 cm) in height; capacity: approximately 208.2 liters; empty weight: 38 to 42 pounds (17 to 19 kg); full weight with water: 460 to 500 pounds (209 to 227 kg); full weight with oil: around 440 pounds (200 kg); can hold 350 to 400 pounds (159 to 181 kg) of corn. Common applications include industrial settings, storage, and various…

3. Boat Manuals – 55-Gal Drum Gauging Guide

Domain: boatmanuals.tpub.com

Registered: 1998 (27 years)

Introduction: Table D-7 GAUGING CONTENTS OF 55-GAL. DRUMS; TB-55-1900-201-45-1 Guide to Army Watercraft Survey Inspections Repair Procedures and Repair Specifications Preparation Manual; Useful for general inventory purposes; Measurement method: ordinary yardstick inserted through the bung; Measurement noted in ‘Wet Inches’ column; Gallons of liquid found opposite ‘Wet Inches’ under corresponding temperature; C…

4. Kyles Converter – Drum to Gallons Conversion Tool

Domain: kylesconverter.com

Registered: 2009 (16 years)

Introduction: Drums (55 US Gal) to Gallons (U.S. Dry) conversion tool. 1 Drum (55 US gal) = 55 US fluid gallons. 1 Drum = 0.20819764812 cubic meters. 1 Gallon (U.S. dry) = 1/8 bu (US lvl). Conversion examples: 1 Drum = 47.2652 Gallons (U.S. Dry), 10 Drums = 472.6519 Gallons (U.S. Dry), 100 Drums = 4726.5185 Gallons (U.S. Dry). Metric sizes may be 200, 205, or 208 liters. Reverse conversion available.

5. Answers – 55-Gallon Drum Capacity

Domain: answers.com

Registered: 1996 (29 years)

Introduction: A 55-gallon drum has a total capacity of 55 gallons. It measures approximately 35.5 inches in height. The calculation for gallons per inch is about 1.56 gallons per inch. The approximate measurements for various gallon levels are: 10 gallons = 6.5 inches, 20 gallons = 12.8 inches, 30 gallons = 19.2 inches, 40 gallons = 25.6 inches, 50 gallons = 32 inches, and 55 gallons = 35.5 inches. Additionally…

6. Adams Petro – Heating Oil Tank Chart

Domain: adamspetro.com

Registered: 2008 (17 years)

Introduction: Tank Chart for Measuring Residential Heating Oil: Capacity options include 275H (flat), 275V (upright), 500, 550, and 1000 gallons. Dimensions vary by tank type: 275H is 27×44 inches, 275V is 44×27 inches, and others are 48 inches in diameter with varying lengths (60 to 130 inches). The chart provides the amount of heating oil in gallons based on the tank’s height in inches, ranging from 7 to 550 …

7. Red Power Magazine – 55 Gallon Drums

Domain: redpowermagazine.com

Registered: 2000 (25 years)

Introduction: 55 gallon drums are standardized cylindrical containers primarily made of steel, designed to replace wooden barrels that were previously used in the oil industry. The standard size of 55 gallons was established due to several factors, including the dimensions of existing 42-gallon wooden barrels, engineering considerations for strength and safety, and manufacturing efficiencies that minimize scrap…

8. ConvertUnits – Drum to Gallon Converter

Domain: convertunits.com

Registered: 2006 (19 years)

Introduction: Convert drum [US, petroleum] to gallon [US, liquid]. 1 drum is equal to 55 gallons. Quick conversion chart: 1 drum = 55 gallons, 2 drum = 110 gallons, 3 drum = 165 gallons, 4 drum = 220 gallons, 5 drum = 275 gallons, 6 drum = 330 gallons, 7 drum = 385 gallons, 8 drum = 440 gallons, 9 drum = 495 gallons, 10 drum = 550 gallons. The SI derived unit for volume is the cubic meter: 1 cubic meter = 4.803…

Strategic Sourcing Conclusion and Outlook for 55 gallon drum inches to gallons chart

In the realm of industrial packaging, understanding the conversion of inches to gallons in 55-gallon drums is crucial for optimizing storage and logistics. This guide has highlighted that each inch of liquid height in a standard 55-gallon drum typically equates to approximately 1.59 gallons. For B2B buyers, particularly those in emerging markets across Africa, South America, the Middle East, and Europe, leveraging accurate measurement conversions can lead to better inventory management and cost savings.

Strategic sourcing is essential in this context, as it enables companies to procure the right drums that meet their specific needs while ensuring compliance with local regulations. By choosing suppliers who understand the regional nuances, buyers can enhance their operational efficiency and build resilient supply chains.

Looking ahead, the demand for 55-gallon drums is expected to grow, driven by increased industrial activities and the need for safe storage solutions. International buyers should actively seek partnerships with reputable manufacturers and distributors to secure high-quality drums that align with their operational requirements. By making informed purchasing decisions today, businesses can position themselves for success in the evolving global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.