5 Gallon Bucket Side Strainer: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for 5 gallon bucket side strainer

In the dynamic landscape of global trade, sourcing a reliable 5-gallon bucket side strainer can be a daunting challenge for B2B buyers, especially when navigating diverse regional markets. With applications spanning across various industries such as painting, coatings, and food processing, the need for effective filtration solutions is paramount. This guide aims to demystify the complexities associated with sourcing these essential accessories, providing invaluable insights into different types, applications, and technical specifications of 5-gallon bucket side strainers.

As international buyers from Africa, South America, the Middle East, and Europe, such as Brazil and Saudi Arabia, seek to enhance operational efficiency, understanding the nuances of product features and supplier vetting processes becomes crucial. This comprehensive resource delves into critical aspects, including the varying micron ratings, material durability, and compatibility with existing equipment. Additionally, it offers strategic advice on evaluating potential suppliers to ensure quality and reliability.

Equipped with this guide, B2B buyers can make informed purchasing decisions that align with their specific operational needs and regional market demands. The insights provided will empower companies to optimize their procurement processes, reduce downtime, and ultimately enhance their productivity in an increasingly competitive marketplace.

Understanding 5 gallon bucket side strainer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| EZ-Strainer™ Insert | Available in various micron ratings (100-600), fits over pails | Paints, coatings, inks | Pros: Versatile, easy to use; Cons: Limited to specific bucket sizes. |

| Mesh Strainer Bag | Elastic band design, filters to about 250 microns | Food and beverage filtration, chemical processing | Pros: Reusable, cost-effective; Cons: May require hand washing, limited lifespan. |

| Reusable Paint Strainer | Made for stability, eco-friendly, fits standard buckets | Professional painting, DIY projects | Pros: Reduces waste, easy to clean; Cons: Higher initial cost. |

| High-Impact Plastic Strainer | Durable construction, multi-tiered classification capability | Construction, surface prep | Pros: Long-lasting, effective for various materials; Cons: May be bulkier to store. |

| Coarse Strainer | 600 micron rating, ideal for larger debris | Industrial applications, heavy-duty liquids | Pros: Effective for large particles; Cons: Not suitable for fine filtration. |

What Are the Key Features of EZ-Strainer™ Inserts for 5-Gallon Buckets?

EZ-Strainer™ Inserts are designed to sit atop pails or open-head drums, enabling easy pouring while filtering out unwanted debris. Their varying micron ratings (from 100 to 600 microns) cater to different filtration needs, making them ideal for applications involving paints, coatings, and inks. For B2B buyers, the choice of micron rating is crucial, as it directly influences the quality of the final product. While they are versatile and user-friendly, buyers should ensure compatibility with their specific bucket sizes to avoid inefficiencies.

How Do Mesh Strainer Bags Enhance Filtration Processes?

Mesh Strainer Bags feature an elastic band that secures them around the bucket’s rim, providing a snug fit for effective filtering. These bags filter down to approximately 250 microns, making them suitable for food, beverages, and various chemicals. Their reusable nature offers significant cost savings over time. However, buyers should consider the need for hand washing and the potential for reduced lifespan compared to disposable options. This balance of cost and practicality is essential for businesses focused on sustainability.

Why Choose Reusable Paint Strainers for Your Business?

Reusable Paint Strainers are designed for stability and ease of use, fitting securely into standard buckets. They are eco-friendly and reduce waste, making them an attractive option for businesses aiming to minimize environmental impact. Their ability to provide clean and consistent paint applications is particularly beneficial for professional painters and contractors. Although the initial investment may be higher, the long-term savings and reduced environmental footprint can justify the cost for B2B buyers.

What Advantages Do High-Impact Plastic Strainers Offer?

High-Impact Plastic Strainers are built to last, featuring a robust construction that withstands rigorous use in various industrial applications. They allow for multi-tiered classification of materials, which is particularly advantageous in construction and surface preparation contexts. While their durability is a significant advantage, buyers should be aware that their bulkier design may pose storage challenges. Understanding the specific needs of their operations will help businesses choose the right strainer type.

In Which Situations Are Coarse Strainers Most Effective?

Coarse Strainers, with a 600 micron rating, excel at filtering out larger debris from heavy-duty liquids. They are commonly used in industrial settings where the removal of significant particles is necessary. While effective for this purpose, they are not suitable for applications requiring fine filtration. B2B buyers should evaluate their specific filtration needs carefully, balancing the need for coarse filtration with the potential need for additional fine filtration solutions later in the process.

Key Industrial Applications of 5 gallon bucket side strainer

| Industry/Sector | Specific Application of 5 Gallon Bucket Side Strainer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Paint and Coatings | Filtering paint and coatings to remove debris | Ensures a smoother finish and reduces waste, enhancing product quality | Micron rating, durability, and compatibility with various liquids |

| Food and Beverage | Straining liquids in food processing | Maintains product purity and safety, complying with health regulations | Food-grade materials and easy cleaning features |

| Construction and Renovation | Separating particles from concrete or epoxy mixtures | Enhances mixing efficiency and ensures a better final product | Resistance to chemicals and physical wear |

| Chemical Manufacturing | Filtering out impurities from chemical solutions | Improves product consistency and reduces contamination risks | Chemical compatibility and high-performance materials |

| Agriculture and Horticulture | Straining fertilizers and pesticides before application | Maximizes effectiveness and minimizes environmental impact | UV resistance and compatibility with agricultural chemicals |

How is the 5 Gallon Bucket Side Strainer Used in the Paint and Coatings Industry?

In the paint and coatings sector, the 5-gallon bucket side strainer is essential for filtering out debris and unwanted particles from liquid products. This ensures that the final application is smooth, free from imperfections, and adheres properly. For international buyers, particularly in markets like Brazil and Saudi Arabia, sourcing strainers with the appropriate micron rating is crucial, as this directly affects the quality of the paint and customer satisfaction.

What Role Does the 5 Gallon Bucket Side Strainer Play in Food and Beverage Processing?

In food and beverage processing, a 5-gallon bucket side strainer is utilized to remove impurities from liquids such as juices, sauces, and other consumables. This application is vital for maintaining product purity, ensuring compliance with health regulations, and enhancing overall safety. Buyers should prioritize food-grade materials and ease of cleaning, particularly when sourcing from suppliers in regions like Africa and the Middle East, where local regulations may vary.

How Does the 5 Gallon Bucket Side Strainer Benefit Construction and Renovation Projects?

The construction and renovation industry uses the 5-gallon bucket side strainer for filtering concrete mixtures and epoxy resins. By removing unwanted particles, the strainer helps achieve a more consistent mix, ultimately improving the quality of the finished product. When sourcing for this application, businesses should consider the strainer’s resistance to chemicals and durability to withstand heavy use in challenging environments.

Why is the 5 Gallon Bucket Side Strainer Important in Chemical Manufacturing?

In chemical manufacturing, the 5-gallon bucket side strainer is crucial for filtering impurities from various chemical solutions. This ensures product consistency and minimizes contamination risks, which is essential for maintaining quality standards. Buyers in this sector should focus on sourcing strainers made from materials compatible with specific chemicals, ensuring they can withstand rigorous processing conditions without degrading.

How is the 5 Gallon Bucket Side Strainer Used in Agriculture and Horticulture?

In agriculture and horticulture, a 5-gallon bucket side strainer is employed to filter fertilizers and pesticides before application. This process maximizes the effectiveness of these products while minimizing environmental impact. When sourcing for this application, buyers should look for strainers that offer UV resistance and compatibility with agricultural chemicals, especially in regions with high sun exposure or varying climate conditions.

3 Common User Pain Points for ‘5 gallon bucket side strainer’ & Their Solutions

Scenario 1: Difficulty in Ensuring Consistent Quality of Filtered Materials

The Problem: B2B buyers often face the challenge of ensuring that the liquids they handle—whether paints, coatings, or industrial fluids—are free from contaminants. A common issue is that the filtering process can lead to inconsistent results, where some batches are clean while others contain particles. This inconsistency not only affects the quality of the final product but can also lead to costly rework and wasted materials, especially in industries such as manufacturing and construction where precision is critical.

The Solution: To address this pain point, buyers should consider investing in high-quality 5-gallon bucket side strainers that feature multiple micron ratings. For instance, selecting strainers with a range from 100 to 600 microns allows businesses to filter out varying sizes of contaminants effectively. Moreover, sourcing strainers that are compatible with specific liquid types—such as those designed for thicker paints or coatings—can enhance filtering efficiency. Implementing a standardized procedure for using these strainers, including regular maintenance and cleaning, will ensure that the strainers remain effective over time. Additionally, conducting periodic quality checks on filtered materials can help identify any inconsistencies early, allowing for timely adjustments.

Scenario 2: Incompatibility with Existing Equipment and Containers

The Problem: Many buyers encounter compatibility issues when trying to use side strainers with their existing 5-gallon buckets or equipment. This can lead to frustrating leaks or spills during the pouring process, which not only wastes valuable materials but also poses safety risks in the workplace. Such situations are particularly common in industries that require frequent transferring of liquids, such as automotive and chemical manufacturing.

The Solution: To mitigate these compatibility issues, it is crucial for buyers to select side strainers that are designed to fit a wide range of standard bucket sizes and types. Buyers should assess the dimensions of their buckets and the specific design of the strainer, ensuring they match for a snug fit. Additionally, considering strainers that come with elastic tops or adjustable features can enhance the fit, preventing spills. It is also advisable to consult with suppliers about custom options if standard solutions do not meet specific requirements. Training staff on how to properly secure and use these strainers can further reduce the risk of spills, enhancing both safety and efficiency.

Scenario 3: Environmental Concerns and Waste Management

The Problem: With increasing regulations around waste management and environmental sustainability, businesses are facing pressure to minimize their waste output, particularly when it comes to disposable filtering materials. Traditional straining solutions often involve single-use products that contribute to landfill waste, which can be both costly and damaging to a company’s environmental reputation.

The Solution: To tackle this issue, B2B buyers should consider investing in reusable 5-gallon bucket side strainers made from durable materials that can withstand multiple uses and cleaning processes. For example, options made from stainless steel mesh or high-grade nylon are not only effective but also eco-friendly. Buyers can create a systematic cleaning and reuse protocol for these strainers, ensuring they are properly maintained to extend their lifespan. Furthermore, partnering with suppliers who provide take-back programs or recycling options for disposable strainers can significantly reduce overall waste. By adopting these sustainable practices, businesses can enhance their environmental credentials while also potentially reducing costs associated with purchasing new filtering products regularly.

Strategic Material Selection Guide for 5 gallon bucket side strainer

What Are the Key Materials for 5 Gallon Bucket Side Strainers?

When selecting materials for 5-gallon bucket side strainers, it is essential to consider the specific applications and environments in which these strainers will be used. Below are analyses of four common materials used in the manufacturing of these strainers, along with their properties, advantages, disadvantages, and considerations for international buyers.

1. High-Impact Plastic

Key Properties: High-impact plastic is lightweight, resistant to many chemicals, and can withstand a wide range of temperatures. It typically has a temperature rating of up to 80°C (176°F) and is resistant to moisture and UV light.

Pros & Cons: This material is cost-effective and easy to mold into various shapes, making it suitable for mass production. However, while it offers good durability, it may not withstand extreme temperatures or heavy mechanical stress as well as metals.

Impact on Application: High-impact plastic is compatible with most liquids, including paints, solvents, and oils. However, it may not be suitable for applications involving high-pressure systems.

Considerations for International Buyers: Buyers from regions with stringent environmental regulations should ensure that the plastic used is compliant with local standards, such as REACH in Europe. Additionally, understanding the local waste management practices for plastic disposal can be important.

Illustrative image related to 5 gallon bucket side strainer

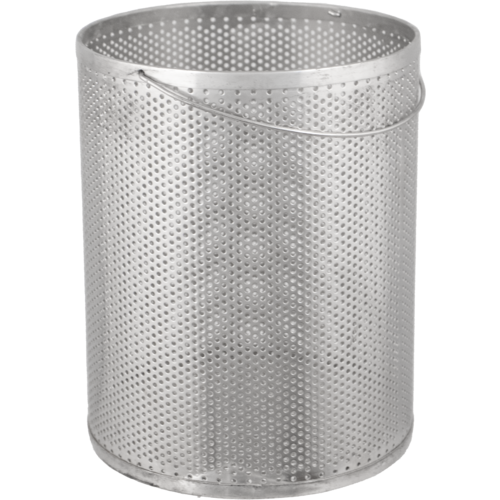

2. Stainless Steel Mesh

Key Properties: Stainless steel mesh is known for its high strength, corrosion resistance, and ability to withstand high temperatures (up to 500°C or 932°F). It is also non-reactive, making it suitable for various chemical applications.

Pros & Cons: The durability and longevity of stainless steel make it a preferred choice for heavy-duty applications. However, it is more expensive than plastic options and can be heavier, which may affect shipping costs.

Impact on Application: Stainless steel mesh is ideal for filtering applications involving aggressive chemicals or high temperatures. It is often used in industrial settings where the strainers must endure rigorous use.

Considerations for International Buyers: Buyers should verify that the stainless steel used meets international standards such as ASTM A240 for corrosion resistance. Additionally, understanding local sourcing options for stainless steel can help manage costs.

3. Nylon Mesh

Key Properties: Nylon mesh is flexible, lightweight, and offers good chemical resistance. It typically operates effectively at temperatures up to 120°C (248°F) and provides excellent filtration capabilities.

Pros & Cons: Its flexibility allows for easy installation and removal, making it user-friendly. However, nylon may not be as durable as metal options and can degrade under prolonged exposure to UV light or extreme temperatures.

Impact on Application: Nylon mesh is suitable for applications involving water-based solutions, paints, and coatings. It is less effective for high-temperature or aggressive chemical applications.

Illustrative image related to 5 gallon bucket side strainer

Considerations for International Buyers: Compliance with food safety standards is crucial if the strainers are used in food-related applications. Buyers should also consider the environmental impact of nylon disposal in their regions.

4. Polyester Fabric

Key Properties: Polyester fabric is durable, resistant to moisture, and can handle temperatures up to 150°C (302°F). It is often used in applications requiring a lightweight and flexible strainer.

Pros & Cons: The fabric’s flexibility makes it easy to fit onto various bucket sizes. However, it may not be as robust as metal options and can be prone to tearing under heavy use.

Impact on Application: Polyester fabric is effective for filtering paints and coatings but may not hold up well in high-pressure or high-temperature applications.

Considerations for International Buyers: Buyers should ensure that the polyester used meets local environmental regulations, especially in regions with strict textile waste management policies.

Summary Table

| Material | Typical Use Case for 5 Gallon Bucket Side Strainer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Impact Plastic | General-purpose liquid filtration | Cost-effective and lightweight | Limited temperature and pressure resistance | Low |

| Stainless Steel Mesh | Industrial applications with aggressive chemicals | High durability and corrosion resistance | Higher cost and weight | High |

| Nylon Mesh | Water-based solutions and paints | Flexible and easy to install | Less durable under UV and high temperatures | Medium |

| Polyester Fabric | Paint and coating filtration | Lightweight and flexible | Prone to tearing under heavy use | Medium |

This guide provides B2B buyers with insights into the materials used for 5-gallon bucket side strainers, helping them make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 5 gallon bucket side strainer

What Are the Key Stages in the Manufacturing Process of a 5 Gallon Bucket Side Strainer?

The manufacturing process for a 5-gallon bucket side strainer involves several critical stages, each designed to ensure the final product meets both performance and quality standards. The typical stages include:

Material Preparation

The first step in manufacturing involves selecting high-quality materials. Common materials for side strainers include food-grade nylon, stainless steel mesh, and high-impact plastics. These materials are chosen for their durability and resistance to chemicals, which is crucial for applications involving paints, coatings, and other liquids. The materials undergo a rigorous inspection to ensure they meet the required specifications before proceeding to the next stage.

Forming Techniques

After material preparation, the forming process takes place. This can involve various techniques such as injection molding for plastic components or stamping for metal parts. For instance, stainless steel mesh may be cut and shaped to fit the required dimensions of the strainer. Advanced forming techniques ensure that the strainers have the necessary strength and fit snugly over standard 5-gallon buckets, which is essential for optimal performance.

Illustrative image related to 5 gallon bucket side strainer

Assembly Process

Once the components are formed, they are assembled. This stage may involve attaching handles, ensuring the mesh is secured, and adding any other necessary fittings. Automated assembly lines are often used to enhance efficiency, although some aspects may require skilled labor to ensure precision. Quality checks during assembly are crucial to identify any defects or misalignments early in the process.

Finishing Touches

The finishing stage includes surface treatments and coatings that enhance the product’s performance and longevity. For plastic strainers, this may involve UV stabilization to prevent degradation from sunlight exposure. Stainless steel components might receive a passivation treatment to enhance corrosion resistance. Additionally, each strainer is cleaned and packaged according to industry standards, ready for distribution.

How Is Quality Assurance Integrated into the Manufacturing of 5 Gallon Bucket Side Strainers?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final products meet both international standards and customer expectations. Here’s how QA is typically structured for 5-gallon bucket side strainers:

What Are the Relevant International Standards?

Manufacturers often adhere to international quality standards such as ISO 9001, which emphasizes a quality management system that consistently provides products that meet customer and regulatory requirements. Depending on the target market, additional certifications like CE marking for European markets or API standards for specific industrial applications may also be required. These certifications signify that the products have undergone rigorous testing and meet safety and environmental regulations.

What Are the Key Quality Control Checkpoints?

Quality control is typically structured around several key checkpoints:

-

Incoming Quality Control (IQC): Materials are inspected upon arrival to verify compliance with specifications. This includes checking the integrity and safety of raw materials before they enter the production line.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor the production process. This might involve measuring the dimensions of components, testing the strength of welds, and ensuring that the assembly is performed correctly.

-

Final Quality Control (FQC): Once the strainers are fully assembled, a final inspection is carried out. This includes functional testing to ensure that the strainers perform as intended, such as filtering effectiveness and structural integrity.

What Testing Methods Are Commonly Used for Quality Assurance?

Manufacturers employ various testing methods to ensure the quality and reliability of the strainers:

-

Mechanical Testing: This assesses the strength and durability of materials, ensuring that they can withstand typical use scenarios without failure.

-

Filtration Efficiency Testing: This involves pouring liquids with known particle sizes through the strainer to measure its effectiveness in removing unwanted debris.

-

Chemical Resistance Testing: For applications involving paints or solvents, strainers must be tested for their resistance to chemical degradation.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers seeking to ensure quality in their procurement processes should consider several approaches:

-

Supplier Audits: Conducting on-site audits of suppliers provides insight into their manufacturing processes and quality control practices. This allows buyers to assess compliance with international standards and best practices.

-

Requesting Quality Assurance Reports: Suppliers should be willing to provide documentation of their quality assurance processes, including test results and certification details.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality management system and product quality.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is essential:

-

Cultural and Regulatory Differences: Different regions may have varying expectations regarding quality and safety standards. Understanding local regulations is crucial for compliance and can influence purchasing decisions.

-

Logistics and Supply Chain Considerations: Quality control processes may vary based on logistical challenges. Buyers should ensure that their suppliers have robust systems in place to maintain quality throughout the supply chain.

-

Long-Term Partnerships: Building long-term relationships with suppliers can enhance trust and facilitate better communication regarding quality concerns and product improvements.

In conclusion, the manufacturing and quality assurance processes for 5-gallon bucket side strainers are critical to ensuring a reliable product that meets the diverse needs of international B2B buyers. By understanding these processes and implementing thorough verification methods, buyers can significantly mitigate risks and enhance their procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘5 gallon bucket side strainer’

To successfully procure a 5-gallon bucket side strainer, B2B buyers need a structured approach to ensure they select the best product for their needs. This guide provides a step-by-step checklist that will help you navigate the sourcing process efficiently.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for the side strainer. This includes the micron rating (e.g., 100 to 600 microns) and materials (e.g., stainless steel mesh or food-grade nylon). Defining these parameters ensures that the strainer meets your operational needs, particularly in filtering out specific contaminants from liquids like paints, coatings, or food products.

Step 2: Research Market Trends and Supplier Options

Conduct thorough market research to identify current trends and leading suppliers of 5-gallon bucket strainers. Look into suppliers that specialize in your industry, as they may offer tailored solutions. Utilize platforms like trade shows, industry publications, and online marketplaces to gather insights on supplier reputation and product offerings.

Illustrative image related to 5 gallon bucket side strainer

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their experience with the specific type of strainers you require, and ensure they can provide proof of quality standards and certifications relevant to your region.

Step 4: Verify Product Quality and Compliance

Ensure that the strainers meet international quality standards and comply with any local regulations, especially if they will come into contact with food or hazardous materials. Request samples to assess the product’s durability, filtration efficiency, and ease of use. Pay attention to user reviews or testimonials that highlight the strainers’ performance in real-world applications.

Step 5: Negotiate Pricing and Terms

Once you have identified potential suppliers, initiate negotiations on pricing and payment terms. Consider bulk purchasing discounts and inquire about shipping costs, lead times, and return policies. Having a clear understanding of total costs will help you make a financially sound decision.

Illustrative image related to 5 gallon bucket side strainer

Step 6: Establish Communication and Support Channels

Before finalizing your order, ensure that the supplier has robust communication and support channels. This is vital for addressing any concerns post-purchase, such as product issues or restocking needs. A reliable supplier should provide timely responses and support throughout the partnership.

Step 7: Plan for Long-Term Collaboration

Consider the potential for long-term collaboration with suppliers who meet your criteria. Establishing a strong relationship can lead to better pricing, priority service, and access to new products. Regularly communicate your needs and feedback to foster a mutually beneficial partnership.

By following this checklist, B2B buyers can effectively navigate the procurement process for 5-gallon bucket side strainers, ensuring they select the best products and suppliers for their operational needs.

Comprehensive Cost and Pricing Analysis for 5 gallon bucket side strainer Sourcing

When sourcing 5-gallon bucket side strainers, understanding the intricate cost structure is vital for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Various cost components contribute to the final price, and being aware of these can help buyers make informed decisions.

Illustrative image related to 5 gallon bucket side strainer

What Are the Key Cost Components for 5 Gallon Bucket Side Strainers?

-

Materials: The primary materials used in manufacturing strainers include high-impact plastics and stainless steel mesh. These materials not only determine the durability and effectiveness of the strainers but also influence the cost significantly. For instance, higher-quality materials may lead to increased upfront costs but can reduce long-term expenses due to lower replacement rates.

-

Labor: Labor costs vary depending on the manufacturing location. Regions with lower wage rates may offer significant savings, but this should be weighed against potential quality concerns. Skilled labor is necessary for precise assembly, especially for customized or high-quality products.

-

Manufacturing Overhead: This includes costs related to the factory’s operation, such as utilities, rent, and administrative expenses. Efficient production processes can help minimize these costs, which can then be reflected in competitive pricing.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. Buyers should consider whether the supplier has the capability to produce the required strainers without incurring excessive tooling expenses, as this can impact overall pricing.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the strainers meet required specifications and standards. While this adds to the cost, it is crucial for maintaining product reliability, especially in demanding applications.

-

Logistics: Shipping costs and delivery times can vary significantly based on the supplier’s location and the chosen shipping method. Understanding Incoterms is essential for determining who bears the risk and cost during transportation, which can affect the final price.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on the supplier’s business model, market demand, and competition.

What Influences Pricing for 5 Gallon Bucket Side Strainers?

Several factors can affect the pricing structure for these products:

- Volume/MOQ: Bulk orders often lead to discounted pricing. Buyers should negotiate minimum order quantities (MOQ) to optimize costs.

- Specifications/Customization: Custom designs or specific features may lead to higher costs. Buyers should assess the necessity of these customizations against their budget.

- Material Quality and Certifications: Strainers that meet specific industry certifications or use premium materials will typically cost more. Buyers should evaluate the importance of these factors based on their application.

- Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more but offer better quality assurance.

How Can Buyers Negotiate Better Prices for Strainers?

-

Leverage Volume Discounts: When possible, consolidate orders to meet higher volume thresholds, which can lead to more favorable pricing.

-

Understand Total Cost of Ownership (TCO): Consider not just the purchase price but also the longevity and efficiency of the strainers. A higher initial investment may yield lower operational costs over time.

-

Explore Multiple Suppliers: Comparing quotes from various suppliers can help in negotiating better terms and identifying the best value.

-

Consider Local Suppliers: For buyers in Africa, South America, and the Middle East, sourcing from local suppliers may reduce shipping costs and lead times, providing a competitive edge.

-

Engage in Transparent Communication: Building a good relationship with suppliers can lead to better negotiation outcomes. Discussing long-term partnerships may encourage suppliers to offer more favorable terms.

What Should International Buyers Keep in Mind?

International buyers should be aware of pricing nuances due to exchange rates, import duties, and local market conditions. Additionally, understanding regional regulations and certifications can prevent unforeseen costs during the sourcing process.

Disclaimer: The prices mentioned in various sources are indicative and can fluctuate based on market conditions and supplier negotiations. Always consult multiple sources and verify pricing before making purchasing decisions.

Alternatives Analysis: Comparing 5 gallon bucket side strainer With Other Solutions

Introduction: Understanding Alternative Solutions for Straining

In industrial and manufacturing settings, efficient straining solutions are crucial for maintaining product quality and operational efficiency. While the 5-gallon bucket side strainer is a popular choice due to its versatility and ease of use, various alternatives exist that may better suit specific applications. This section analyzes several viable alternatives, providing B2B buyers with a clear perspective on the best options available in the market.

Illustrative image related to 5 gallon bucket side strainer

Comparison Table: Evaluating 5 Gallon Bucket Side Strainer Against Alternatives

| Comparison Aspect | 5 Gallon Bucket Side Strainer | EZ-Strainer™ Insert | Mesh Strainer Bag |

|---|---|---|---|

| Performance | High filtration efficiency; removes large particles effectively | Variable micron ratings (100-600); good for liquid products | Filters down to 250 microns; suitable for bottling |

| Cost | Moderate ($35) | Low ($4.23 – $5.26 per unit) | Very low ($0.79 per bag) |

| Ease of Implementation | Fits standard buckets; easy to use | Designed for quick use; fits various containers | Simple to use; elastic band holds it in place |

| Maintenance | Minimal; reusable | Single-use or limited reuse | Single-use or washable (hand wash only) |

| Best Use Case | Ideal for paints, coatings, and larger debris | Great for inks, paints, and silicone | Perfect for food products and bottling processes |

Detailed Breakdown of Alternatives

EZ-Strainer™ Insert:

The EZ-Strainer™ Insert is a practical alternative for those looking to filter liquids effectively. With micron ratings ranging from 100 to 600, it caters to various filtration needs, making it suitable for applications such as paint and coatings. The insert’s design allows it to fit snugly over a range of containers, providing convenience and ease of use. However, while it is cost-effective, its single-use nature may lead to increased costs over time if used frequently.

Mesh Strainer Bag:

The mesh strainer bag is an affordable solution that fits directly into a 5-gallon bucket, supported by an elastic band. It filters down to 250 microns, making it suitable for applications like bottling and food processing. The low cost per bag makes it an attractive option for businesses looking to minimize expenses. However, it is primarily a single-use product and requires hand washing for reuse, which may not be ideal for high-volume operations.

Conclusion: Choosing the Right Straining Solution for Your Needs

Selecting the appropriate straining solution involves considering various factors, including performance, cost, and application requirements. The 5-gallon bucket side strainer offers robust performance for larger debris, while alternatives like the EZ-Strainer™ Insert and mesh strainer bag provide flexibility and cost savings. B2B buyers should evaluate their specific needs, including the types of materials being strained and the frequency of use, to make an informed decision. By aligning the right product with operational requirements, businesses can enhance efficiency and maintain product integrity in their processes.

Essential Technical Properties and Trade Terminology for 5 gallon bucket side strainer

What Are the Essential Technical Properties of a 5 Gallon Bucket Side Strainer?

When selecting a 5-gallon bucket side strainer, several technical properties should be considered to ensure optimal performance and suitability for specific applications. Here are some critical specifications:

Illustrative image related to 5 gallon bucket side strainer

-

Material Composition

Most side strainers are constructed from high-impact plastics or stainless steel mesh. High-impact plastic provides durability and resistance to chemical exposure, while stainless steel mesh offers superior filtration and longevity. Understanding material composition is vital for B2B buyers as it directly impacts the strainer’s effectiveness and lifespan, particularly in industries dealing with aggressive chemicals or heavy-duty applications. -

Micron Rating

The micron rating indicates the size of particles that can be filtered out, typically ranging from 100 to 600 microns. A lower micron rating (e.g., 100 microns) is ideal for applications requiring fine filtration, such as paint or coatings, whereas a higher rating (e.g., 600 microns) may suffice for less critical applications. This property is crucial for ensuring product quality and consistency, particularly in manufacturing processes where contaminants can lead to defects. -

Compatibility and Fit

Compatibility with standard 5-gallon buckets is essential. Strainers should fit securely over the rim to prevent spillage during use. Many designs feature tabs or handles to enhance stability. Ensuring that the strainer fits various bucket types is important for international buyers who may source buckets from different manufacturers. -

Load Capacity

Load capacity refers to the amount of material the strainer can handle without compromising its integrity. This property is particularly significant in high-volume operations where efficiency and reliability are paramount. Buyers should evaluate load capacity based on their specific application needs to avoid operational disruptions. -

Reusable vs. Disposable

Some strainers are designed for single-use, while others are reusable and can withstand multiple cleaning cycles. Reusable options can be more cost-effective over time, especially for businesses with high demand. Understanding the lifecycle of the product is essential for budget management and sustainability practices. -

Temperature Resistance

For applications involving heated materials (like certain paints or coatings), temperature resistance is a key property. Strainers must withstand specific temperature ranges without degrading. Buyers should assess their operational temperatures to ensure the selected strainer meets their requirements.

What Common Trade Terms Should Buyers Know When Purchasing 5 Gallon Bucket Side Strainers?

Navigating the B2B landscape involves familiarizing oneself with industry jargon. Here are some common terms related to purchasing 5-gallon bucket side strainers:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that may be marketed by another company. Understanding OEM relationships can help buyers identify quality standards and compatibility with existing equipment. -

MOQ (Minimum Order Quantity)

This term indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management, especially for companies looking to scale their operations. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. Understanding how to properly submit an RFQ can streamline the procurement process, allowing businesses to compare options efficiently. -

Incoterms (International Commercial Terms)

These are predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Familiarity with Incoterms helps in understanding shipping responsibilities, costs, and risks involved in transactions, which is crucial for international buyers. -

Lead Time

Lead time refers to the duration from placing an order to receiving the product. It is important for supply chain planning, and understanding lead times can help businesses maintain their production schedules without delays. -

Certification Standards

Many products, including side strainers, may need to comply with industry-specific certification standards, such as ISO or ANSI. Awareness of these standards is important for ensuring product reliability and compliance with regulatory requirements.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the most suitable 5-gallon bucket side strainer for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the 5 gallon bucket side strainer Sector

What Are the Current Market Trends Impacting the 5 Gallon Bucket Side Strainer Sector?

The 5-gallon bucket side strainer market is experiencing robust growth driven by a global increase in DIY projects and industrial applications that require reliable filtration solutions. Key trends influencing this sector include the rising demand for efficient liquid handling across various industries, such as paints, coatings, and chemicals. As businesses strive for operational efficiency, they are increasingly sourcing products that enhance productivity and reduce waste. Furthermore, advancements in materials and manufacturing techniques are leading to the development of more durable and versatile strainers that can cater to specific filtration needs, such as varying micron ratings from 100 to 600 microns.

International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are also increasingly looking for suppliers that can offer customization and quick turnaround times. The ability to adapt products to meet local market needs, such as specific material compatibility or unique sizing requirements, is becoming a key differentiator for suppliers. Additionally, the shift toward e-commerce platforms for B2B transactions is altering the sourcing landscape, making it easier for buyers to compare products and suppliers globally, thus driving competition and innovation.

How Is Sustainability and Ethical Sourcing Shaping the 5 Gallon Bucket Side Strainer Market?

Sustainability and ethical sourcing have become paramount concerns for businesses worldwide, including those in the 5-gallon bucket side strainer market. Environmental impact assessments are increasingly influencing procurement decisions, with buyers prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint. This includes using recyclable materials and eco-friendly manufacturing processes.

The adoption of green certifications is also gaining traction, as buyers seek assurance that the products they source are not only effective but also environmentally responsible. For instance, suppliers that utilize biodegradable or recyclable materials in their strainer production are more likely to capture the attention of environmentally-conscious buyers.

Moreover, the trend toward circular economy practices is prompting businesses to seek products that can be reused or repurposed, reducing waste in the supply chain. This shift is driving innovation, with manufacturers developing reusable mesh strainers that offer cost-effective solutions for businesses while promoting sustainability.

What Is the Historical Context of the 5 Gallon Bucket Side Strainer Sector?

Historically, the concept of using strainers in bucket applications dates back several decades, primarily in industrial settings where the need for filtration during liquid handling was critical. Early designs were rudimentary, often consisting of simple mesh or fabric materials that lacked durability and efficiency. However, as industries evolved and the demand for cleaner, particle-free liquids increased, so too did the complexity and functionality of these strainers.

Illustrative image related to 5 gallon bucket side strainer

The introduction of advanced materials, such as high-impact plastics and stainless steel, has significantly improved the performance and lifespan of bucket strainers. Over time, the market has expanded beyond industrial applications to include DIY enthusiasts and small businesses, creating a diverse range of products tailored to different user needs. Today, the focus on quality, sustainability, and customization continues to drive the evolution of the 5-gallon bucket side strainer sector, making it an essential component in various applications worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of 5 gallon bucket side strainer

-

How do I choose the right micron rating for a 5-gallon bucket side strainer?

Choosing the right micron rating for a side strainer depends on the specific application and the type of materials you are filtering. For instance, if you are working with paints or coatings, a finer micron rating (around 100-200 microns) is ideal to capture small debris. Conversely, for thicker materials or those with larger particulates, a coarser rating (600 microns or more) may suffice. Always consider the viscosity and nature of the liquid being filtered to ensure optimal performance and efficiency in your operations. -

What is the best type of 5-gallon bucket side strainer for industrial use?

For industrial applications, a durable strainer made of high-impact plastic with stainless steel mesh is recommended. These materials ensure longevity and resistance to corrosion, making them suitable for heavy-duty use. Additionally, consider strainers that can accommodate various mesh grades for multi-tiered filtration, which allows for enhanced versatility in filtering different types of liquids. Always verify that the strainer fits securely on standard 5-gallon buckets to prevent spills during use. -

What are the key factors to consider when vetting suppliers for 5-gallon bucket side strainers?

When vetting suppliers, prioritize their reputation, certifications, and experience in the industry. Look for suppliers with positive customer reviews and a track record of delivering quality products. Assess their production capabilities, including customization options, minimum order quantities (MOQ), and lead times. Additionally, inquire about their quality assurance processes and whether they provide samples before placing larger orders. A reliable supplier should also have transparent communication and support for international shipping logistics. -

What are the typical payment terms for international B2B transactions involving 5-gallon bucket strainers?

Payment terms can vary by supplier and region but commonly include options like net 30, net 60, or payment upon shipment. Some suppliers may require a deposit upfront, especially for custom orders. Utilizing secure payment methods such as letters of credit or escrow services can protect both parties in international transactions. It’s essential to discuss and agree upon payment terms before finalizing the order to avoid any misunderstandings later. -

How can I ensure the quality of 5-gallon bucket side strainers during international shipping?

To ensure quality during shipping, request that suppliers provide detailed quality assurance documentation, including inspection reports and certifications. Consider arranging for third-party inspections before shipment, particularly for bulk orders. Additionally, using robust packaging can prevent damage during transit. Ensure that your supplier has a clear return policy in case any defects are identified upon receipt. Regular communication throughout the shipping process can also help address any potential issues proactively. -

What customization options are available for 5-gallon bucket side strainers?

Many suppliers offer customization options, including different micron ratings, sizes, and materials based on specific industry needs. You can request features such as elastic tops for better fitting or color coding for easy identification in multi-product environments. Some manufacturers may also provide branding options, allowing your company logo to be printed on the strainers. Discuss your requirements with potential suppliers to explore the best options available for your applications. -

What logistics considerations should I keep in mind when importing 5-gallon bucket strainers?

When importing, consider logistics factors such as shipping methods, tariffs, and local regulations that may affect delivery times and costs. Evaluate the total landed cost, which includes product price, shipping, customs duties, and taxes. Choose a reliable freight forwarder familiar with your destination country to navigate potential challenges. It’s also wise to plan for potential delays in customs clearance, especially during peak shipping seasons. -

Are there eco-friendly options for 5-gallon bucket side strainers?

Yes, many manufacturers now offer eco-friendly strainer options made from biodegradable or recyclable materials. Look for products that promote reusability, reducing the need for disposable alternatives. Some strainers are designed for easy cleaning and can be reused multiple times, which is beneficial for both the environment and your operational costs. Inquire with suppliers about their sustainable practices and product lines to ensure you are sourcing environmentally friendly solutions.

Top 4 5 Gallon Bucket Side Strainer Manufacturers & Suppliers List

1. The Cary Company – 400 Micron Medium EZ-Strainer™ Insert

Domain: thecarycompany.com

Registered: 1999 (26 years)

Introduction: This company, The Cary Company – 400 Micron Medium EZ-Strainer™ Insert, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Hillco – 5 Gallon Mesh Strainer Bag

Domain: hillco.buzz

Registered: 2024 (1 years)

Introduction: 5 Gallon Mesh Strainer Bag, Regular price: $0.79, Filters to about 250 microns, Made from food-grade nylon mesh, Fits neatly into a 5 gallon pail with an elastic band to hold it in place, Can be used once or washed for a few more uses (hand wash only, not dishwasher safe). Customer reviews indicate 83% positive feedback.

3. Runyon Surface Prep – 5 Gallon Bucket Strainer

Domain: runyonsurfaceprep.com

Registered: 2011 (14 years)

Introduction: {“name”: “5 Gallon Bucket Strainer”, “price”: “$35.00”, “sku”: “31881”, “weight”: “3 lbs”, “description”: “Save time and improve your recovery with this 5 gallon bucket strainer. This strainer can be used for sizing material down before processing through a Hippo Mixer. Stack various mesh grades together for multi-tiered classification! It also conveniently fits over the top of most 5-gallon bucke…

4. US Plastic – 100 Micron Ultra Fine EZ-Strainers™

Domain: usplastic.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “100 Micron (0.003925\”) Ultra Fine EZ-Strainers™ for 5 Gallon Containers”, “Item Number”: “10879”, “Price”: “$5.79 /Each”, “Bulk Pricing”: {“25+”: “$5.5005 /Each”, “50+”: “$5.211 /Each”, “150+”: “$4.9215 /Each”}, “Material”: “High molecular weight HDPE”, “Type”: “Strainer”, “Weight”: “0.155 lbs”, “Dimensions”: {“Inner Diameter”: “10.675\” (+0.25\”/-0\”)”, “Outer Diameter”: “11.75…

Strategic Sourcing Conclusion and Outlook for 5 gallon bucket side strainer

In the competitive landscape of industrial supply, effective strategic sourcing of 5-gallon bucket side strainers can significantly enhance operational efficiency and product quality. These strainers serve crucial functions in filtering contaminants from paints, coatings, and other liquids, ensuring that only the highest quality materials are used. By selecting strainers tailored to specific micron ratings and applications, businesses can optimize their processes, reduce waste, and ultimately save costs.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize partnerships with reliable suppliers who can provide customized solutions and ensure consistent product availability. Understanding the nuances of different strainer types—whether disposable or reusable—will empower organizations to make informed decisions that align with their operational needs and sustainability goals.

Looking ahead, as industries continue to innovate and evolve, the demand for high-quality filtration solutions will only increase. Now is the time to invest in robust sourcing strategies that not only meet current requirements but also anticipate future needs. Engage with trusted manufacturers and distributors to secure your supply chain and enhance your competitive edge.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to 5 gallon bucket side strainer