300V Power Cord: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for 300v power cord

In today’s interconnected world, sourcing the right 300V power cord is crucial for businesses looking to ensure operational efficiency and safety. However, international B2B buyers often face challenges such as varying standards, compatibility issues, and the need for reliable suppliers across different regions. This comprehensive guide addresses these challenges head-on, providing insights into the diverse types of 300V power cords available, their applications in various industries, and essential factors to consider when vetting suppliers.

From the durable SJOOW portable cords designed for rugged environments to versatile NEMA power cords suitable for a variety of devices, understanding the specifications and applications of these cords is vital for making informed purchasing decisions. Additionally, the guide delves into cost considerations, enabling buyers to align their budgets with their specific needs, whether they are based in Africa, South America, the Middle East, or Europe, including Germany and Vietnam.

By leveraging the insights and strategies outlined in this guide, B2B buyers will be empowered to navigate the complexities of the global market for 300V power cords. This resource aims to equip you with the knowledge necessary to select high-quality products that meet your operational requirements while fostering long-term partnerships with reputable suppliers.

Understanding 300v power cord Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NEMA 5-15P to Standard ROJ | 3-prong plug, bare end for custom wiring, 10A/300V rating | Custom equipment, electronics manufacturing | Pros: Versatile for custom applications. Cons: Requires expertise for termination. |

| SJOOW Portable Cord | Flexible, weather-resistant, available in multiple gauges | Tools, outdoor machinery, industrial use | Pros: Durable and suitable for harsh environments. Cons: Higher cost for premium variants. |

| IEC320C13 to NEMA 5-15P | Universal compatibility, heavy-duty 14 AWG, molded design | PCs, printers, audio/video equipment | Pros: High durability and compatibility. Cons: Limited to devices requiring specific connectors. |

| SOOW Portable Cord | Heavy-duty, oil-resistant, multiple conductor options | Heavy machinery, construction sites | Pros: Highly durable with various configurations. Cons: Bulkier, may be overkill for lighter applications. |

| SJT Power Cord | Standardized design, SJT rated for indoor use, 10A/300V | Office equipment, consumer electronics | Pros: Cost-effective and widely available. Cons: Limited to indoor applications. |

What Are the Characteristics of NEMA 5-15P to Standard ROJ Power Cords?

The NEMA 5-15P to Standard ROJ power cord is characterized by its three-prong plug and bare end, allowing for custom wiring solutions. This type is particularly useful in environments where specific device configurations are required. B2B buyers should consider the technical expertise needed for safe termination, making it suitable for manufacturers and specialized equipment suppliers.

How Does the SJOOW Portable Cord Stand Out?

The SJOOW portable cord is designed for flexibility and durability, featuring EPDM insulation and a CPE outer jacket that withstands weather conditions, oils, and solvents. With multiple gauge options, it is ideal for powering tools and machinery in both indoor and outdoor settings. B2B buyers looking for robust solutions for construction or industrial applications will find this cord highly suitable, though it may come at a premium price point.

What Makes the IEC320C13 to NEMA 5-15P Cord a Popular Choice?

This power cord offers universal compatibility, making it a versatile choice for a range of devices such as PCs, printers, and audiovisual equipment. Its heavy-duty 14 AWG design ensures durability and longevity. For B2B buyers, this cord is an excellent option for environments requiring reliable power connections, although its use is limited to specific device connectors.

Why Choose SOOW Portable Cords for Heavy Machinery?

SOOW portable cords are designed for heavy-duty applications, with oil-resistant properties and multiple conductor options. Their robust construction makes them suitable for construction sites and industrial machinery. B2B buyers should consider the specific power needs of their applications, as these cords can be bulkier than alternatives but offer unmatched durability.

What Are the Advantages of Using SJT Power Cords?

SJT power cords are a standardized option for indoor use, rated for 10A and 300V. They are cost-effective and widely available, making them a common choice for powering office equipment and consumer electronics. Buyers should note their limitations, as SJT cords are not suitable for outdoor applications, but they provide a reliable solution for everyday business needs.

Key Industrial Applications of 300v power cord

| Industry/Sector | Specific Application of 300v Power Cord | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Power supply for machinery and equipment | Ensures reliable operation of production lines | Compliance with local electrical standards and durability |

| Construction | Temporary power for tools and equipment on-site | Enhances productivity and safety on job sites | Flexibility in lengths and resistance to environmental factors |

| Telecommunications | Powering network equipment and data centers | Supports uninterrupted service and connectivity | Compatibility with various devices and voltage ratings |

| Automotive | Charging stations for electric vehicles | Supports green technology initiatives | Need for weather-resistant and robust insulation |

| Event Management | Power supply for temporary installations | Facilitates seamless operations at events | Custom lengths and quick delivery options |

How is the 300v Power Cord Utilized in Manufacturing?

In the manufacturing sector, 300v power cords are pivotal for powering various machinery and equipment. These cords facilitate the seamless operation of production lines, which is crucial for maintaining output and efficiency. Buyers in this sector need to ensure that the cords meet local electrical standards and possess the durability to withstand the rigors of an industrial environment. For international buyers, especially from regions like Africa and South America, sourcing cords that comply with local regulations can prevent costly downtime and enhance operational safety.

What Role Does the 300v Power Cord Play in Construction?

In construction, 300v power cords are often used to provide temporary power to tools and equipment on-site. This capability enhances productivity and ensures that projects stay on schedule. Construction sites in regions such as the Middle East and Europe may face harsh weather conditions; therefore, cords that are flexible and resistant to environmental factors are essential. Buyers should consider the cord length and gauge, as well as the ability to withstand moisture and physical wear, to ensure safety and reliability.

How is the 300v Power Cord Essential for Telecommunications?

Telecommunications companies utilize 300v power cords to power network equipment and data centers. The reliability of these cords is vital for maintaining uninterrupted service and connectivity, which is critical in today’s digital age. For international buyers, particularly in Europe and developing markets, sourcing cords that are compatible with various devices and meet voltage ratings is crucial for operational efficiency. Ensuring that the cords are robust enough to handle the electrical load without overheating can significantly enhance the longevity of network systems.

In What Ways Does the 300v Power Cord Support the Automotive Industry?

The automotive industry employs 300v power cords primarily for charging stations dedicated to electric vehicles (EVs). These cords are integral to supporting green technology initiatives and enhancing the infrastructure for EVs. Buyers should prioritize cords that are weather-resistant and have robust insulation to ensure safety in outdoor installations. In markets like Africa and South America, where EV adoption is growing, ensuring compliance with local standards and durability against environmental challenges is essential for successful implementation.

How Does the 300v Power Cord Facilitate Event Management?

In event management, 300v power cords are utilized to supply power to temporary installations, such as lighting and sound equipment. This application is crucial for facilitating seamless operations during events and ensuring that all equipment functions correctly. Buyers in this sector should look for cords that can be customized in length to accommodate various setups and that can be delivered quickly to meet tight timelines. The ability to source cords that are durable and easy to handle can significantly impact the success of an event.

3 Common User Pain Points for ‘300v power cord’ & Their Solutions

Scenario 1: Difficulty in Sourcing Compatible 300V Power Cords for Diverse Equipment

The Problem: B2B buyers often face the challenge of sourcing 300V power cords that are compatible with a wide range of equipment, especially when dealing with multiple suppliers and manufacturers. This can lead to confusion regarding specifications, such as wire gauge, amperage ratings, and connector types. Additionally, the lack of standardized compatibility across different countries can complicate procurement, especially for businesses operating in regions like Africa and South America where electrical standards may vary.

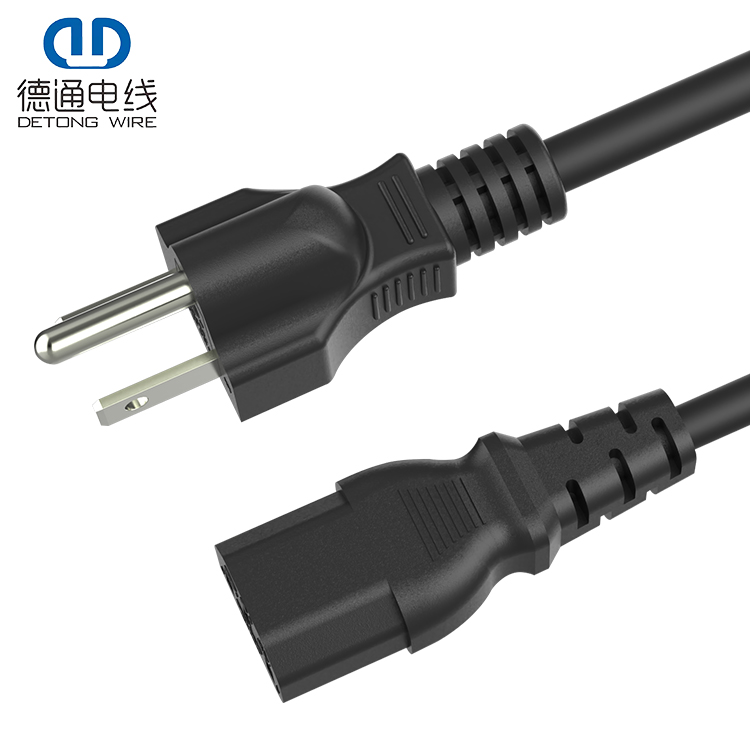

Illustrative image related to 300v power cord

The Solution: To overcome this issue, buyers should develop a comprehensive specification checklist that includes the required wire gauge, amperage, length, and connector types for each piece of equipment. Engaging with manufacturers who offer customizable power cords can also provide tailored solutions that meet specific needs. Establish relationships with suppliers who understand local electrical standards and can provide detailed product information, including certifications and compliance with regional regulations. This proactive approach ensures that the power cords sourced are not only compatible with existing equipment but also meet safety and performance standards.

Scenario 2: Concerns Over Durability and Weather Resistance in Harsh Environments

The Problem: Many industries operate in harsh environments where power cords are exposed to extreme weather conditions, moisture, oils, and UV radiation. Buyers often worry about the durability of standard 300V power cords, which may not withstand such conditions, leading to frequent replacements and increased operational costs. This is particularly relevant for buyers in sectors like construction, agriculture, and outdoor events where equipment is frequently relocated and subjected to the elements.

The Solution: When selecting 300V power cords, opt for those specifically designed for outdoor or industrial use, such as SJOOW or SOOW portable cords, which feature robust insulation and outer jackets that resist moisture, UV light, and chemicals. Additionally, consider cords that are rated for immersion if they may come into contact with water. Establishing a partnership with suppliers who offer cables with warranties for durability can also provide peace of mind. Regularly inspect power cords for signs of wear and replace them proactively to minimize the risk of failure during critical operations.

Scenario 3: Managing Inventory and Ensuring Adequate Supply for Projects

The Problem: B2B buyers often struggle with managing inventory levels of 300V power cords, especially when dealing with large projects that require multiple units in varying lengths and specifications. Insufficient inventory can lead to project delays, while overstocking can increase holding costs. This balancing act is crucial for companies operating in fast-paced sectors where electrical components are essential for smooth operations.

The Solution: Implement an inventory management system that tracks usage patterns and forecasts future needs based on project timelines. This can help identify the optimal order quantities and timing for replenishment. Consider establishing agreements with suppliers for bulk purchasing, which can lead to cost savings and ensure a steady supply of power cords. Additionally, maintain a small emergency stock of essential cords to mitigate risks associated with sudden project demands. Regularly reviewing and adjusting inventory practices based on project cycles and usage trends will enhance operational efficiency and reduce costs.

Strategic Material Selection Guide for 300v power cord

What Are the Key Materials Used in 300V Power Cords?

When selecting materials for 300V power cords, several options are commonly used, each with distinct properties and suitability for various applications. This analysis will explore four prevalent materials: PVC, EPDM, TPE, and Neoprene, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

How Does PVC Perform in 300V Power Cords?

Polyvinyl Chloride (PVC) is widely utilized in power cord manufacturing due to its excellent electrical insulation properties and cost-effectiveness. PVC can typically withstand temperatures up to 70°C (158°F) and offers good resistance to abrasion and chemicals, making it suitable for indoor applications.

Pros: PVC is relatively inexpensive and easy to manufacture, which can lower overall production costs. It also provides adequate flexibility for various applications.

Illustrative image related to 300v power cord

Cons: However, PVC is less resistant to extreme temperatures and UV exposure, which can lead to degradation over time, especially in outdoor settings. Additionally, its environmental impact is a concern, as it is not biodegradable.

For international buyers, compliance with standards such as ASTM D3032 for insulation and DIN VDE 0281 for cables is crucial, particularly in regions like Europe where stringent regulations exist.

What Advantages Does EPDM Offer for 300V Power Cords?

Ethylene Propylene Diene Monomer (EPDM) is a synthetic rubber known for its durability and resistance to weathering, ozone, and UV radiation. It can handle temperatures ranging from -40°C to 90°C (-40°F to 194°F), making it suitable for both indoor and outdoor applications.

Pros: EPDM’s robust properties make it ideal for heavy-duty applications, including industrial machinery and outdoor power tools. Its flexibility and resistance to environmental factors enhance its longevity.

Cons: The main drawback of EPDM is its higher production cost compared to PVC, which may impact pricing strategies for B2B buyers. Additionally, its manufacturing process can be more complex, requiring specialized equipment.

International buyers should consider compliance with standards such as UL 62 and IEC 60245, particularly in regions where electrical safety is a priority.

Why Choose TPE for 300V Power Cords?

Thermoplastic Elastomer (TPE) is gaining popularity in power cord applications due to its excellent flexibility and resilience. TPE can withstand temperatures from -40°C to 105°C (-40°F to 221°F) and offers good chemical resistance.

Pros: TPE is lightweight and provides superior flexibility, making it easier to handle and install. It is also recyclable, aligning with growing environmental concerns.

Cons: However, TPE can be more expensive than PVC and EPDM, which may deter cost-sensitive buyers. Additionally, its performance can vary significantly based on the specific formulation used.

International buyers should be aware of the varying standards for TPE across regions, particularly in Europe and Asia, where compliance with RoHS (Restriction of Hazardous Substances) is increasingly important.

Illustrative image related to 300v power cord

What Role Does Neoprene Play in 300V Power Cords?

Neoprene is a synthetic rubber known for its superior resistance to oils, chemicals, and extreme temperatures. It typically operates effectively within a temperature range of -40°C to 90°C (-40°F to 194°F).

Pros: Neoprene’s chemical resistance makes it ideal for applications involving exposure to harsh environments, such as industrial settings or outdoor use. Its durability also contributes to a longer lifespan.

Cons: The primary downside is its higher cost relative to other materials, which may be a concern for budget-conscious buyers. Additionally, the manufacturing process can be more complex, impacting lead times.

International buyers should ensure compliance with relevant standards, such as ASTM D2000, particularly in industries that require stringent material specifications.

Illustrative image related to 300v power cord

Summary Table of Material Selection for 300V Power Cords

| Material | Typical Use Case for 300v power cord | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Indoor applications | Cost-effective and easy to manufacture | Limited UV and temperature resistance | Low |

| EPDM | Outdoor and heavy-duty applications | Excellent weather and UV resistance | Higher production costs | Medium |

| TPE | Flexible and lightweight applications | Superior flexibility and recyclability | Higher cost and variable performance | Medium |

| Neoprene | Harsh industrial environments | Excellent chemical and oil resistance | Higher cost and complex manufacturing | High |

This strategic material selection guide provides valuable insights for B2B buyers in various regions, helping them make informed decisions based on performance, cost, and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 300v power cord

What Are the Main Stages of Manufacturing a 300V Power Cord?

The manufacturing of 300V power cords involves several key stages, each critical to ensuring the final product meets the necessary performance and safety standards.

1. Material Preparation

The first step in the manufacturing process is material preparation. This involves sourcing high-quality raw materials, which typically include copper for the conductors, insulation materials like PVC or EPDM, and protective outer jackets made from durable compounds. Suppliers often conduct quality checks on these materials to ensure they meet industry standards and specifications before they are approved for production.

2. Forming

Once the materials are prepared, the next step is forming the conductors. This process involves drawing the copper into wires of the required gauge, typically ranging from 10 to 18 AWG for 300V applications. The wires are then insulated using materials that comply with safety standards, such as UL or CE ratings. The insulation must be robust enough to withstand environmental factors like moisture, UV exposure, and mechanical wear, ensuring long-term reliability.

3. Assembly

The assembly stage involves combining the insulated conductors with connectors and terminals. This process may vary based on the design requirements, such as whether the cord ends in a NEMA plug or bare wire. Advanced techniques such as automated crimping and soldering are often employed to ensure secure connections. Quality assurance protocols are integrated at this stage to verify that connections are made correctly and securely.

4. Finishing

The final stage of manufacturing is finishing, which includes adding protective coatings, labeling, and packaging. Each cord undergoes a visual inspection to check for defects, such as exposed conductors or insulation flaws. Proper labeling is also crucial, as it provides essential information regarding safety ratings, compliance certifications, and usage instructions.

How Is Quality Assurance Managed in the Production of 300V Power Cords?

Quality assurance (QA) is an essential aspect of the manufacturing process for 300V power cords. It ensures that the products not only comply with international standards but also meet customer expectations.

What Are the Relevant International Standards for 300V Power Cords?

Manufacturers must adhere to various international standards to ensure product safety and reliability. ISO 9001 is one of the most recognized quality management system standards, focusing on continual improvement and customer satisfaction. For electrical products, compliance with standards like CE (Conformité Européenne) and UL (Underwriters Laboratories) is crucial, particularly for markets in Europe and North America. These certifications indicate that the products have been rigorously tested for safety and performance.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early. These include:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they enter production. Suppliers may provide test reports to confirm compliance with specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, random samples are taken to ensure that processes are being followed correctly. This may involve electrical testing of the cords to ensure they meet performance specifications.

-

Final Quality Control (FQC): Before products are shipped, they undergo a final inspection. This includes testing for electrical safety, checking for physical defects, and ensuring that labeling is accurate and compliant with regulations.

What Testing Methods Are Commonly Used for 300V Power Cords?

A range of testing methods is employed to ensure that 300V power cords are safe and reliable. Common testing methods include:

-

Electrical Testing: This involves checking for continuity, insulation resistance, and voltage drop to ensure that the cords can handle their rated voltage and current without failure.

-

Mechanical Testing: Cords are subjected to mechanical stress tests, such as bend, pull, and flex tests, to simulate real-world usage and identify potential points of failure.

-

Environmental Testing: Testing for resistance to UV light, moisture, and extreme temperatures is crucial, especially for cords intended for outdoor use. This ensures that the product can withstand varying environmental conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing practices, quality control measures, and compliance with international standards firsthand. This can be an invaluable tool for building trust and ensuring product quality.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports, including test results and compliance certifications. This documentation provides insight into the supplier’s commitment to quality and their adherence to industry standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control processes. These services can verify compliance with relevant standards and conduct random inspections of finished products.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances when it comes to quality control. Understanding local regulations and standards is crucial, as compliance requirements can vary significantly from one region to another. For instance, cords sold in Europe must meet CE marking requirements, while those sold in the U.S. need to comply with UL standards.

Additionally, buyers should be aware of the logistical challenges that may affect quality, such as shipping conditions and handling. Establishing clear communication with suppliers about expectations and quality standards can help mitigate risks associated with international procurement.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing 300V power cords, ensuring they receive reliable products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘300v power cord’

In this guide, we aim to provide international B2B buyers with a practical checklist for sourcing 300V power cords. By following these steps, you can ensure that your procurement process is efficient, meets technical requirements, and aligns with your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly define your technical specifications. Consider factors such as voltage rating (300V), current capacity, wire gauge (e.g., 14 AWG, 18 AWG), and conductor count. This clarity helps in narrowing down suitable products and avoiding compatibility issues with your equipment.

Illustrative image related to 300v power cord

Step 2: Research Regulatory Compliance

Ensure that the power cords you are considering comply with international safety standards relevant to your region, such as UL, CE, or IEC certifications. Compliance not only guarantees safety but also mitigates risks associated with equipment failure or legal repercussions. Always request documentation to verify these certifications.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to confirm their reliability and reputation. Look for established companies with a strong history in supplying electrical components. Request company profiles, case studies, and references from buyers in similar industries or regions to gauge their reliability and product quality.

- Key Considerations:

- Supplier reviews and ratings

- Industry certifications and awards

Step 4: Assess Product Quality and Durability

Investigate the quality of the 300V power cords. Inquire about the materials used, such as the insulation type and outer jacket, to ensure they can withstand environmental factors like moisture and UV exposure. High-quality cords will reduce long-term costs associated with replacements and failures.

- Specific Features to Look For:

- Resistance to oils and solvents

- Flexibility and ease of handling

Step 5: Request Samples for Testing

Before making a bulk purchase, request samples of the power cords. Testing these samples in real-world applications will allow you to assess their performance, durability, and compatibility with your existing systems. Ensure that the samples meet your defined specifications and quality expectations.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations to secure the best pricing and payment terms. Consider factors such as order volume, lead times, and shipping costs. Establishing favorable terms can significantly impact your overall procurement budget.

Step 7: Plan for After-Sales Support

Lastly, evaluate the after-sales support offered by the supplier. Reliable technical support and warranty options are crucial for addressing any issues that may arise post-purchase. Confirm that the supplier is willing to provide assistance in case of product malfunctions or inquiries regarding installation.

By following this checklist, B2B buyers can streamline their procurement process for 300V power cords, ensuring that they select the right products and establish solid supplier relationships.

Comprehensive Cost and Pricing Analysis for 300v power cord Sourcing

What Are the Key Cost Components in Sourcing 300V Power Cords?

Understanding the cost structure of 300V power cords is essential for B2B buyers to make informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly affects pricing. High-quality copper conductors, insulation materials (such as EPDM or PVC), and durable outer jackets contribute to the overall cost. For instance, cords with thicker wire gauges (e.g., 10 AWG versus 18 AWG) tend to be more expensive due to the higher material requirements.

-

Labor: The labor costs associated with manufacturing power cords vary based on the complexity of the assembly process and the skill level of the workforce. Automated production lines may reduce labor costs, but custom orders requiring manual assembly can increase expenses.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, rent, and administrative expenses. Efficient operations can mitigate these costs, but they will still be a factor in the final pricing.

-

Tooling: Custom tooling for specialized power cords can add significant upfront costs. If a buyer requires unique specifications or designs, they should be prepared for additional charges that may not be present in standard products.

-

Quality Control (QC): Ensuring compliance with international standards (such as UL or CE certifications) incurs costs related to testing and quality assurance processes. Suppliers that prioritize QC may have higher prices, reflecting their commitment to delivering reliable products.

-

Logistics: Shipping and handling costs can vary widely based on the origin of the product, shipping methods, and destination. International buyers should consider these costs in their total pricing analysis, particularly when sourcing from regions with significant distance or logistical challenges.

-

Margin: Suppliers typically add a margin to cover their operating costs and ensure profitability. Understanding the market dynamics can help buyers negotiate better prices by recognizing where margins can be adjusted.

How Do Price Influencers Affect 300V Power Cord Costs?

Several factors influence the pricing of 300V power cords, which B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit prices. Buyers should assess their needs and consider negotiating for bulk pricing, especially if they anticipate regular purchases.

-

Specifications and Customization: Custom specifications or unique features will increase costs. Buyers should weigh the necessity of customization against the potential price increase and consider standard options where possible.

-

Quality and Certifications: Products that meet stringent quality standards typically come with higher price tags. Buyers should evaluate whether the additional cost aligns with their operational requirements and safety standards.

-

Supplier Factors: The supplier’s reputation, production capacity, and geographic location can impact pricing. Established suppliers with a track record of reliability may charge more but offer peace of mind and consistency in quality.

-

Incoterms: International buyers must understand Incoterms, as they define responsibilities for shipping, risk, and costs. Choosing the right terms can influence the final price significantly.

What Are Some Effective Buyer Tips for Negotiating 300V Power Cord Prices?

To achieve cost-efficiency in sourcing 300V power cords, consider the following strategies:

-

Negotiate for Better Pricing: Leverage your purchasing volume to negotiate discounts. Suppliers may be willing to adjust prices for larger orders or long-term contracts.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as durability, reliability, and maintenance costs to determine the true value of the product over its lifespan.

-

Be Aware of Pricing Nuances for International Buyers: Currency fluctuations, tariffs, and import duties can affect overall costs. Buyers from regions like Africa or South America should factor in these elements when budgeting for purchases.

-

Request Quotes from Multiple Suppliers: Obtaining multiple quotes can provide insight into market rates and help identify competitive pricing. Use this information to strengthen your negotiating position.

-

Understand Local Market Dynamics: Pricing can vary significantly based on local demand and supply conditions. Buyers should stay informed about market trends in their specific regions to make well-timed purchasing decisions.

In conclusion, understanding the cost structure, price influencers, and effective negotiation strategies is vital for international B2B buyers when sourcing 300V power cords. By applying these insights, buyers can achieve better pricing and ensure their sourcing decisions align with their operational needs.

Alternatives Analysis: Comparing 300v power cord With Other Solutions

Introduction to Power Solutions Alternatives

In the realm of electrical applications, selecting the right power solution is critical for ensuring efficiency, safety, and cost-effectiveness. While the 300V power cord is a popular choice for various industrial and commercial applications, there are alternative options available that may better suit specific needs. This analysis compares the 300V power cord with two viable alternatives: the SJOOW portable cord and the 14 AWG premium universal power cord. Each solution has distinct characteristics that can influence purchasing decisions for B2B buyers.

Comparison Table

| Comparison Aspect | 300V Power Cord | SJOOW Portable Cord | 14 AWG Premium Universal Power Cord |

|---|---|---|---|

| Performance | Supports up to 10A at 300V | Supports higher current ratings (up to 30A) | Supports up to 15A at 125V |

| Cost | Generally low cost per unit | Higher initial investment per foot | Moderate cost, competitive for premium quality |

| Ease of Implementation | Easy to install with bare ends | Requires professional termination for best performance | Plug-and-play design, user-friendly |

| Maintenance | Minimal maintenance required | Durable but requires inspection over time | Low maintenance, but check for wear periodically |

| Best Use Case | Custom applications needing flexibility | Heavy-duty applications in harsh environments | General-purpose use across various devices |

Detailed Breakdown of Alternatives

What are the Benefits and Drawbacks of the SJOOW Portable Cord?

The SJOOW portable cord is designed for heavy-duty applications, making it ideal for powering tools and equipment in both indoor and outdoor settings. Its EPDM insulation and CPE outer jacket provide excellent resistance to oils, moisture, and UV exposure, which is crucial for environments with harsh conditions. However, this durability comes at a higher cost, making it less budget-friendly for projects with tight financial constraints. Additionally, while the SJOOW cord can handle higher current loads, it often requires professional installation, which can add to overall project costs.

How Does the 14 AWG Premium Universal Power Cord Compare?

The 14 AWG premium universal power cord is another strong alternative, particularly for users needing a versatile solution. This cord is compatible with a variety of devices, including PCs and printers, due to its molded design and straightforward plug-and-play functionality. Its moderate cost makes it an attractive option for businesses looking to stock up on essential power supplies without overspending. However, it has a lower voltage rating (125V) compared to the 300V power cord, limiting its use in high-power applications. Additionally, while it is durable, it may not withstand extreme conditions as well as the SJOOW cord.

Conclusion: How to Choose the Right Power Solution for Your Needs

When selecting the appropriate power solution, B2B buyers must consider several factors, including performance requirements, budget constraints, and specific application needs. The 300V power cord is ideal for custom applications requiring flexibility, while the SJOOW portable cord excels in harsh environments with higher power demands. Meanwhile, the 14 AWG premium universal power cord serves well for general use in less demanding settings. By weighing these aspects, businesses can make informed decisions that align with their operational goals and ensure reliable power delivery for their equipment.

Essential Technical Properties and Trade Terminology for 300v power cord

What Are the Key Technical Properties of a 300V Power Cord?

When selecting a 300V power cord, understanding its technical specifications is crucial for ensuring safety, compatibility, and performance in various applications. Below are critical specifications that every B2B buyer should consider:

-

Voltage Rating

The voltage rating indicates the maximum voltage the cord can handle safely. For a 300V power cord, this specification ensures that the cord can be used in applications requiring up to 300 volts. Using a cord with an inadequate voltage rating can lead to overheating, insulation failure, and potential electrical hazards. -

Current Rating (Amperage)

This rating specifies the maximum current the cord can carry without overheating. For example, a 10A rating means the cord can safely handle up to 10 Amperes of current. Choosing a cord with the appropriate amperage rating is vital for the safe operation of equipment and can prevent electrical fires. -

Wire Gauge (AWG)

The American Wire Gauge (AWG) indicates the diameter of the wire used in the cord. Lower AWG numbers represent thicker wires, which can carry more current. For instance, an 18 AWG wire can handle up to 10 Amps, while a 14 AWG wire can handle up to 15 Amps. Selecting the right gauge affects both the performance and durability of the cord. -

Insulation Material

The type of insulation material impacts the cord’s resistance to environmental factors. Common materials include PVC, EPDM, and CPE, each offering varying levels of protection against moisture, UV radiation, and chemicals. A durable insulation material is essential for outdoor applications or environments where the cord may be exposed to harsh conditions. -

Length

The length of the power cord is another critical specification, as it determines the distance between the power source and the device. Common lengths include 6 feet, 10 feet, and longer custom lengths. Selecting the right length can minimize voltage drop and ensure that devices are conveniently located. -

Connector Type

The type of connectors on either end of the cord (e.g., NEMA 5-15P, IEC320C13) dictates compatibility with devices and power sources. Understanding connector types is vital for ensuring that the power cord will work with the intended equipment, reducing the risk of mismatches.

What Are Common Trade Terms Associated with 300V Power Cords?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B space. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of power cords, an OEM may produce specialized cords tailored for specific devices, ensuring compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory costs and ensure they are ordering a sufficient quantity to meet demand without overstocking. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products. For power cords, submitting an RFQ can help buyers obtain competitive pricing and understand the supplier’s capabilities and lead times. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Key terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) clarify who is responsible for shipping costs, insurance, and risk during transit, which is vital for effective supply chain management. -

UL Listed

This designation indicates that a product has been tested and meets specific safety standards set by Underwriters Laboratories. For power cords, UL listing is essential for ensuring compliance with safety regulations, providing assurance to buyers regarding the quality and safety of the product. -

SJT Rating

This refers to a type of thermoplastic jacket used for flexible cords. An SJT rating signifies that the cord is suitable for both indoor and outdoor use, offering protection against moisture and mechanical wear. Understanding these ratings helps buyers select cords that meet their specific application needs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 300V power cords, ensuring they meet their operational requirements while maintaining safety and reliability.

Navigating Market Dynamics and Sourcing Trends in the 300v power cord Sector

What Are the Current Market Dynamics and Key Trends in the 300V Power Cord Sector?

The global market for 300V power cords is witnessing significant growth, driven by the increasing demand for reliable electrical connectivity in various industries, including manufacturing, construction, and consumer electronics. The surge in automation and the ongoing industrial revolution are propelling the need for durable power solutions. Key trends include a shift towards customizable power cords that cater to specific applications, particularly for international B2B buyers in Africa, South America, the Middle East, and Europe. Customization allows companies to meet unique regional requirements, enhancing compatibility and safety standards in diverse markets.

Additionally, there is a growing emphasis on multi-conductor cables, such as SJOOW and SOOW types, which provide enhanced durability and flexibility for portable applications. Buyers are increasingly seeking cords that can withstand harsh environmental conditions, making weather-resistant materials essential. Emerging technologies, such as IoT-enabled devices, are also influencing sourcing decisions as manufacturers look for innovative power solutions that facilitate connectivity and monitoring.

Furthermore, the rise of e-commerce platforms has transformed how B2B buyers source power cords, enabling easier access to a global supply chain. This shift allows buyers to compare products, prices, and suppliers from different regions, making it crucial for manufacturers to optimize their online presence and offer competitive pricing.

How Can Sustainability and Ethical Sourcing Impact B2B Purchasing Decisions in the 300V Power Cord Market?

Sustainability is becoming a critical factor in B2B purchasing decisions, particularly in the 300V power cord sector. Buyers are increasingly aware of the environmental impact associated with the production and disposal of electrical components. Companies are now prioritizing suppliers who adopt eco-friendly practices, including the use of recyclable materials and sustainable manufacturing processes.

Ethical sourcing is not just a trend; it’s a necessity for businesses aiming to enhance their corporate social responsibility (CSR) image. Buyers are looking for suppliers who can provide certifications that verify the use of ‘green’ materials and responsible sourcing practices. These certifications may include RoHS compliance, which restricts hazardous substances, and ISO 14001, which focuses on effective environmental management systems.

Additionally, as regulations around environmental standards tighten globally, particularly in Europe and North America, international buyers from emerging markets must ensure their suppliers adhere to these standards. This not only mitigates risks associated with non-compliance but also fosters long-term relationships with environmentally conscious manufacturers. By choosing sustainable options, companies can not only reduce their carbon footprint but also appeal to a growing demographic of eco-aware consumers.

How Has the 300V Power Cord Sector Evolved Over Time to Meet B2B Needs?

The evolution of the 300V power cord sector has been marked by significant technological advancements and changing consumer demands. Initially, power cords were primarily designed for basic functionality, with limited options in terms of length, gauge, and materials. However, as industries have become more specialized, the need for diverse and tailored solutions has emerged.

In recent decades, the introduction of multi-conductor cables has transformed the landscape, allowing for more efficient power distribution and improved safety. Manufacturers have increasingly focused on developing cords that are not only durable but also resistant to environmental factors such as moisture, UV exposure, and chemical exposure. This shift has enabled the use of 300V power cords in various applications, from industrial machinery to consumer electronics.

Moreover, the globalization of supply chains has facilitated the availability of high-quality power cords across different regions, catering to the specific needs of international B2B buyers. As a result, the sector continues to adapt to technological innovations and sustainability demands, ensuring that manufacturers can meet the evolving requirements of their clientele. This ongoing evolution underscores the importance of staying informed about market trends and sourcing strategies in the 300V power cord sector.

Frequently Asked Questions (FAQs) for B2B Buyers of 300v power cord

-

How do I ensure the quality of the 300V power cords I purchase?

To ensure the quality of 300V power cords, it is essential to work with reputable suppliers who adhere to international safety and quality standards. Request certifications such as UL, CE, or IEC to verify compliance. Conducting factory audits or quality assurance checks can also be beneficial. Additionally, consider requesting samples before placing a bulk order to assess the product’s durability and performance. -

What are the key specifications I should look for in a 300V power cord?

When sourcing a 300V power cord, key specifications to consider include wire gauge (AWG), current rating (in amperes), voltage rating, insulation material, and length. The wire gauge affects the cable’s capacity to handle power loads, while insulation materials like EPDM or PVC determine durability and resistance to environmental factors. Ensure that the cord meets the requirements of your application, including flexibility and temperature ratings. -

What is the typical minimum order quantity (MOQ) for 300V power cords?

The minimum order quantity for 300V power cords varies by supplier, but it often ranges from 100 to 500 units. Larger manufacturers may offer lower MOQs, while smaller or specialized suppliers might require higher quantities. It’s advisable to discuss your specific needs with suppliers to see if they can accommodate smaller orders or provide flexible terms based on your purchasing strategy. -

Can I customize the length and specifications of the 300V power cords?

Yes, many suppliers offer customization options for 300V power cords, including varying lengths, wire gauges, and connector types. Customization can help meet specific application requirements or compliance standards in your region. When discussing customization with suppliers, be clear about your needs and any relevant certifications to ensure that the final product aligns with your specifications. -

What payment terms should I expect when sourcing 300V power cords internationally?

Payment terms can vary widely depending on the supplier and your relationship with them. Common terms include a 30% deposit upfront, with the balance due before shipment, or net 30 to net 60 days after delivery. It’s crucial to negotiate favorable terms that suit your cash flow situation while ensuring that the supplier feels secure in the transaction. Always use secure payment methods to protect your investment. -

How can I effectively vet suppliers of 300V power cords?

Vetting suppliers involves several steps: check their business credentials, seek references from past clients, and evaluate their production capabilities and certifications. Request samples and assess their communication responsiveness. Online reviews and industry reputation can also provide insights into reliability. Consider using third-party verification services to ensure that suppliers meet quality and compliance standards. -

What logistics considerations should I keep in mind for international shipping of 300V power cords?

When planning logistics for international shipping, consider factors such as shipping costs, lead times, and customs regulations in both the exporting and importing countries. Choose a reliable freight forwarder experienced in handling electrical components. Ensure that all documentation, including invoices and packing lists, is accurate and complete to avoid delays at customs. Also, assess the shipping options available, including air freight for urgent needs or sea freight for cost-effective bulk orders. -

What are the common applications for 300V power cords in different industries?

300V power cords are widely used in various industries, including manufacturing, construction, and telecommunications. They are commonly employed to power tools, machinery, and portable devices. In commercial settings, these cords are often utilized for connecting computers, printers, and audio-visual equipment. Understanding the specific applications in your industry can guide you in selecting the right cord specifications to meet your operational needs.

Top 6 300V Power Cord Manufacturers & Suppliers List

1. CableWholesale – NEMA 5-15P to ROJ Power Cord

Domain: cablewholesale.com

Registered: 1999 (26 years)

Introduction: {‘part_number’: ’10W1-10206′, ‘type’: ‘NEMA 5-15P to Standard ROJ Power Cord’, ‘length’: ‘6 feet’, ‘color’: ‘Black’, ‘wire_gauge’: ’18 AWG’, ‘amp_rating’: ’10A’, ‘volt_rating’: ‘300V’, ‘weight’: ‘0.33 lbs’, ‘end_1’: ‘NEMA 5-15P Power Plug’, ‘end_2’: ‘Bare end’, ‘warranty’: ‘Lifetime’, ‘price’: ‘$5.81’, ‘quantity_discount’: {’50’: ‘$5.23’, ‘100’: ‘$4.84’, ‘250’: ‘$4.46’, ‘500’: ‘CALL’}, ‘availabili…

2. Remington Industries – SJOOW 3-Conductor Portable Cord

Domain: remingtonindustries.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “SJOOW 3-Conductor Portable Cord”, “Voltage Rating”: “300 V”, “Current Ratings”: {“10 AWG”: “30 A”, “12 AWG”: “25 A”, “14 AWG”: “18 A”, “16 AWG”: “13 A”, “18 AWG”: “10 A”}, “Temperature Rating”: “90°C (194°F)”, “Insulation Material”: “EPDM”, “Conductor Material”: “Bare Copper”, “Outer Jacket Material”: “CPE”, “Number of Conductors”: “3”, “Wire Sizes Available”: [“10 AWG”, “12 AWG”…

3. CablesToGo – 6ft Premium Universal Power Cord

Domain: cablestogo.com

Registered: 1995 (30 years)

Introduction: {“length”:”6ft (1.8m)”,”gauge”:”14 AWG”,”type”:”Premium Universal Power Cord”,”connector_1″:”NEMA 5-15P”,”connector_2″:”IEC320C13″,”compliance”:”TAA Compliant”}

4. Reddit – Electrical Components

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The original cord is rated for 300V. The replacement plug purchased is rated for 15A and 125V.

5. Dell – Docking Station Adapter with Power Cable

Domain: doityourself.com

Registered: 1995 (30 years)

Introduction: Dell docking station adapter DP/N 03XYY8; 3-foot power cable; plug end: STC 5D, STARGAZER, 7A 125V, E352372; outlet end: STA10, STARGAZER, 7A 125V, E352372; cord specifications: E239360 (UL) SPT-2 3/C ISAWG(0.824 mm²) 60°C 300V VW-1 252445 CSA SPT-2 3/C ISAWG(0.824 mm²) 60°C 300V FT2 ZHONGLI SCI-TECH GROUP; needs a compatible cable 9- or 10-ft long; voltage ratings: 7A 125V on ends, 300V on cord.

6. Wire and Cable Your Way – SJOOW Cable (300V)

Domain: wireandcableyourway.com

Registered: 2015 (10 years)

Introduction: {“product_name”:”SJOOW Cable (300V)”,”description”:”Multiconductor power cables suitable for 300 volt applications requiring flexibility and durability, such as portable tools, equipment, appliances, and small motors.”,”features”:{“oil_resistant”:”Yes”,”water_resistant”:”Yes”},”available_sizes”:[{“gauge”:”18/2″,”od_inches”:0.285,”ampacity”:10,”price_per_foot”:0.43},{“gauge”:”18/3″,”od_inches”:0.30…

Strategic Sourcing Conclusion and Outlook for 300v power cord

In the dynamic landscape of power solutions, the 300V power cord stands out as a critical component for various applications across industries. Buyers must prioritize strategic sourcing to ensure they select high-quality, reliable cords that meet their operational needs. Key considerations include understanding the specifications such as gauge, conductor material, and insulation types, which directly impact performance, durability, and safety.

Moreover, leveraging supplier relationships can enhance procurement efficiency and lead to cost savings, particularly in bulk purchases. It’s essential to assess suppliers based on their capacity to provide customized solutions, ensuring compatibility with specific machinery and equipment, especially in regions with unique power requirements.

Looking ahead, international B2B buyers from Africa, South America, the Middle East, and Europe should embrace the evolving trends in power cord manufacturing, including innovations in materials and environmental considerations. As global demand for energy-efficient solutions grows, aligning sourcing strategies with these trends will be vital. Take proactive steps today to secure partnerships that position your business for success in the competitive power solutions market.

Illustrative image related to 300v power cord

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.