3 Way Solenoid Valve: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for 3 way solenoid valve

In an increasingly interconnected world, sourcing reliable 3-way solenoid valves poses a significant challenge for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. These valves are critical components in fluid control systems, enabling precise management of air, water, and various low-viscosity fluids across a multitude of industries. As industries evolve and demand for automation grows, understanding the myriad types and applications of 3-way solenoid valves becomes essential for informed purchasing decisions.

This comprehensive guide delves into the various types of 3-way solenoid valves, including normally open and normally closed configurations, and explores their applications in sectors such as HVAC, automotive, and chemical processing. By examining supplier vetting processes, cost considerations, and performance metrics, this resource equips B2B buyers with the insights necessary to navigate the complexities of sourcing these critical components.

Ultimately, this guide empowers international buyers to make informed decisions by providing the knowledge required to assess product specifications, compatibility with existing systems, and long-term reliability. With a focus on fostering successful partnerships and streamlining procurement processes, this resource serves as a vital tool for any organization looking to enhance operational efficiency through the effective use of 3-way solenoid valves.

Understanding 3 way solenoid valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 3-Way Normally Closed | Seals off the outlet when de-energized, directing flow from inlet to exhaust. | HVAC systems, chemical processing, automotive | Pros: Reliable for safety; prevents leaks. Cons: Limited flow paths. |

| 3-Way Normally Open | Allows flow from inlet to outlet when de-energized; seals when energized. | Irrigation systems, pneumatic applications | Pros: Simple operation; good for flow control. Cons: Can lead to fluid buildup when improperly used. |

| 3-Way Directional Control | Directs flow between two outlets based on solenoid activation. | Robotics, automation, fluid transfer systems | Pros: Versatile for complex systems; efficient. Cons: Requires careful installation. |

| 3-Way Multipurpose Valve | Configurable for various flow patterns and applications. | Industrial processes, laboratory equipment | Pros: Highly adaptable; can manage multiple media. Cons: More complex; potentially higher cost. |

| Subminiature 3-Way Solenoid Valve | Compact design for tight spaces, low power consumption. | Medical devices, microfluidics | Pros: Space-saving; low energy use. Cons: Limited flow capacity; may not suit high-demand applications. |

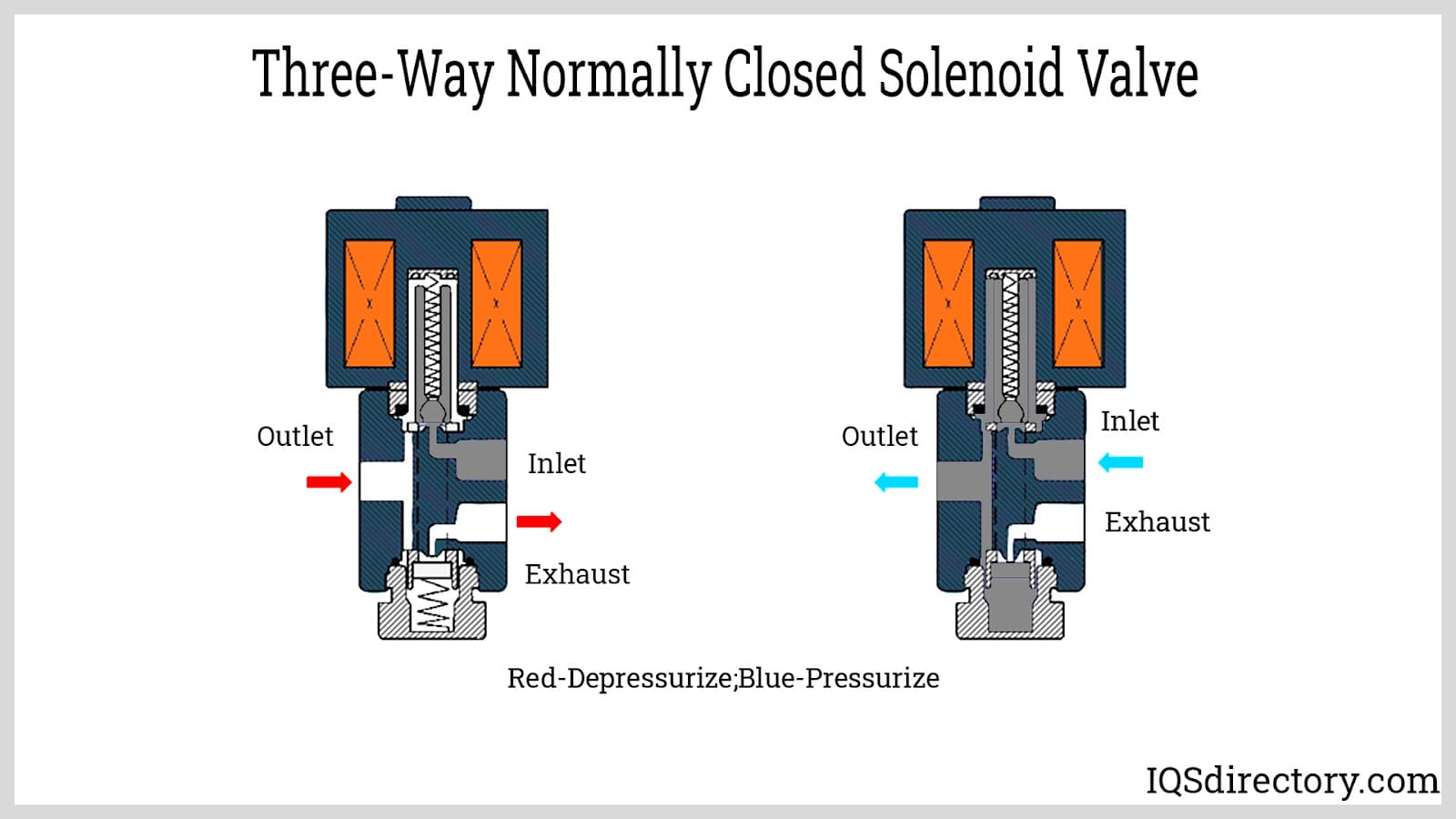

What are the Characteristics of 3-Way Normally Closed Solenoid Valves?

3-way normally closed solenoid valves are designed to be closed when not energized, preventing flow from the inlet to the outlet. This feature is crucial in applications where safety is paramount, such as HVAC systems and chemical processing, where leaks could lead to hazardous situations. B2B buyers should consider the flow capacity and pressure requirements of their systems to ensure compatibility, as these valves can help maintain system integrity by avoiding unwanted fluid escape.

How Do 3-Way Normally Open Solenoid Valves Function?

In contrast to normally closed valves, 3-way normally open solenoid valves allow fluid to flow when de-energized, sealing off the outlet when activated. This design is particularly useful in irrigation and pneumatic applications where consistent flow is necessary. Buyers should evaluate the environmental conditions and media compatibility to select the right materials, as improper choices could lead to premature wear or failure.

What Makes 3-Way Directional Control Solenoid Valves Unique?

3-way directional control solenoid valves offer the ability to direct flow between two outlets based on solenoid activation. This versatility is essential in robotics and automation, where precise control over fluid movement is required. When purchasing, buyers should assess the valve’s response time and cycle life, as these factors significantly impact operational efficiency and reliability in automated systems.

Why Choose a 3-Way Multipurpose Valve?

Multipurpose valves are designed for flexibility, allowing for various flow configurations depending on the application. This adaptability makes them ideal for industrial processes and laboratory settings where different media may need to be controlled. Buyers should weigh the initial investment against the potential for reduced inventory costs due to the valve’s multifunctionality, as well as consider the complexity of installation and maintenance.

What Advantages Do Subminiature 3-Way Solenoid Valves Offer?

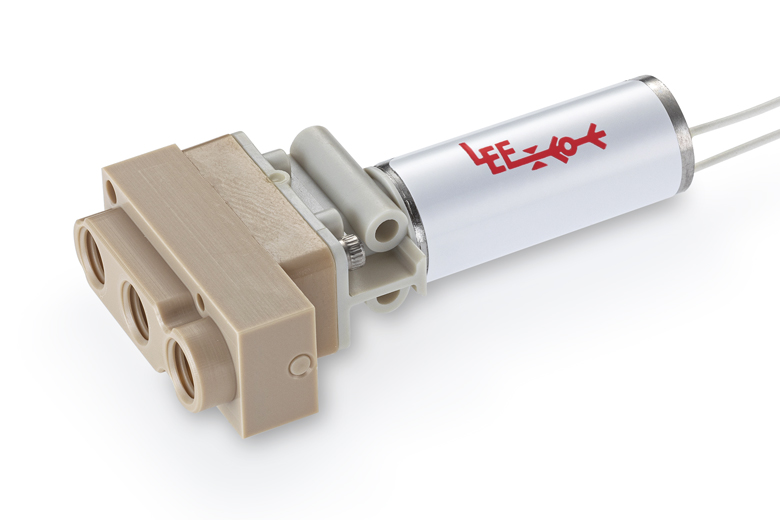

Subminiature 3-way solenoid valves are specifically engineered for applications with space constraints, such as in medical devices or microfluidics. Their low power consumption and compact design make them an attractive option for B2B buyers looking to optimize system performance without sacrificing functionality. However, it is essential to consider their limited flow capacity, which may not be suitable for high-demand applications.

Key Industrial Applications of 3 way solenoid valve

| Industry/Sector | Specific Application of 3 way solenoid valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC | Temperature control in heating and cooling systems | Enhances energy efficiency and comfort | Ensure compatibility with fluid types and pressure ratings |

| Agriculture/Irrigation | Automated irrigation control | Optimizes water usage and crop yield | Evaluate flow rates and environmental conditions |

| Automotive | Coolant flow management in engine systems | Improves engine performance and reliability | Assess thermal and chemical resistance requirements |

| Chemical Processing | Switching between chemical tanks | Ensures safe and accurate chemical handling | Verify compatibility with various chemicals |

| Medical Equipment | Fluid control in diagnostic devices | Increases precision in medical testing and treatment | Check for compliance with health and safety regulations |

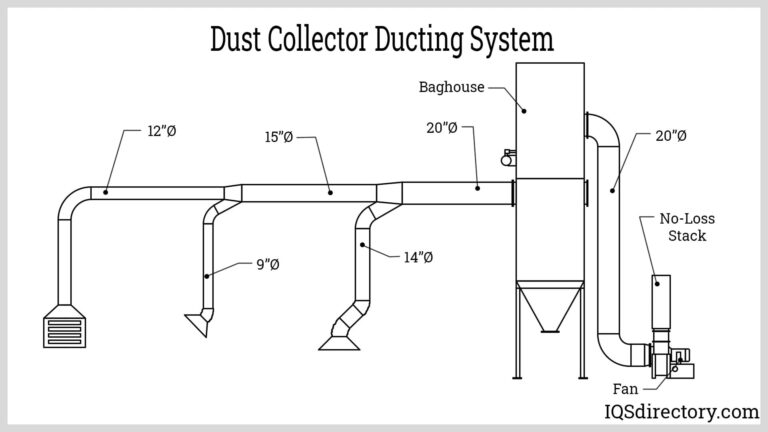

How Are 3 Way Solenoid Valves Used in HVAC Systems?

In HVAC applications, 3 way solenoid valves are critical for controlling the flow of hot and cold water. They enable systems to switch between heating and cooling modes quickly, thereby optimizing energy consumption and maintaining desired indoor temperatures. For international B2B buyers, it is essential to consider the valve’s compatibility with different fluids, pressure ratings, and energy efficiency standards specific to their region, particularly in Europe and the Middle East where regulatory compliance is stringent.

What Role Do 3 Way Solenoid Valves Play in Agriculture?

In agricultural settings, these valves automate irrigation systems, allowing for precise control over water distribution to various crop areas. This not only maximizes water efficiency but also enhances crop yields by ensuring optimal moisture levels. Buyers from South America and Africa should prioritize sourcing valves that can withstand varying environmental conditions and have adjustable flow rates to accommodate different irrigation needs.

How Are 3 Way Solenoid Valves Utilized in the Automotive Industry?

In the automotive sector, 3 way solenoid valves manage coolant flow within engine systems, contributing to improved engine performance and reliability. They facilitate the rapid switching of coolant pathways, which is crucial for maintaining optimal engine temperatures. B2B buyers need to ensure that the valves meet thermal and chemical resistance specifications, especially in high-temperature environments typical of automotive applications in regions like Europe and Vietnam.

Why Are 3 Way Solenoid Valves Important in Chemical Processing?

In chemical processing, these valves are used to switch between various chemical tanks, enabling safe and efficient handling of different substances. They help maintain accurate flow rates and prevent cross-contamination, which is vital for product quality and safety. Buyers in this sector should focus on sourcing valves made from materials compatible with the specific chemicals being processed, as well as those that comply with international safety standards.

How Do 3 Way Solenoid Valves Enhance Medical Equipment Functionality?

In the medical field, 3 way solenoid valves control fluid flow in diagnostic and treatment devices, ensuring precise operation. Their reliability and responsiveness are crucial for accurate medical testing and patient treatment. B2B buyers should prioritize valves that meet stringent health and safety regulations, focusing on those that offer low leakage and high cycle life to ensure long-term performance in critical applications.

3 Common User Pain Points for ‘3 way solenoid valve’ & Their Solutions

Scenario 1: Inconsistent Flow Control in Industrial Applications

The Problem: B2B buyers in industries such as manufacturing or chemical processing often encounter difficulties with inconsistent flow control due to the limitations of their current valve systems. This inconsistency can lead to production delays, increased operational costs, and potential safety hazards. For instance, if a 3-way solenoid valve is unable to effectively switch between different fluids or gases, it can disrupt the intended flow patterns, causing inefficiencies and possibly damaging equipment.

The Solution: To address this issue, buyers should consider investing in high-quality, customizable 3-way solenoid valves designed for specific application requirements. When sourcing these valves, it is crucial to evaluate their compatibility with the media being controlled, including factors such as viscosity, temperature, and pressure ratings. Utilizing a chemical compatibility database can help ensure that the selected valve will perform reliably in the intended application. Additionally, choosing valves with a fast response time and low power consumption can enhance flow control efficiency. Collaborating with manufacturers or suppliers that offer tailored solutions and robust technical support can further mitigate risks associated with inconsistent flow control.

Scenario 2: High Maintenance Costs Due to Valve Failures

The Problem: Many B2B buyers face escalating maintenance costs linked to frequent failures of their existing solenoid valves, particularly in environments that demand high durability and reliability. These failures not only lead to increased repair expenses but also result in unscheduled downtimes, which can severely impact productivity and profitability. For instance, in the food processing industry, a malfunctioning valve could halt production lines and compromise product quality.

The Solution: To reduce maintenance costs, buyers should opt for durable 3-way solenoid valves made from high-quality materials such as brass or stainless steel, which are known for their longevity and resistance to corrosion. It is essential to assess the valve’s cycle life and operational conditions, ensuring that the selected valve can withstand the rigors of its intended application. Implementing a preventive maintenance program that includes regular inspections and timely replacements based on wear can also help extend the lifespan of the valves. Additionally, investing in training for maintenance personnel on the proper operation and care of solenoid valves can significantly reduce the likelihood of human error leading to valve failures.

Scenario 3: Complexity in System Integration and Compatibility

The Problem: B2B buyers often struggle with the integration of 3-way solenoid valves into existing systems due to compatibility issues with other components. In particular, mismatched electrical specifications, pressure ratings, or physical dimensions can lead to costly installation challenges and operational inefficiencies. For instance, in HVAC systems, using a valve that does not align with the system’s pressure requirements could result in inadequate temperature control and energy waste.

The Solution: To overcome integration challenges, buyers should conduct a thorough assessment of their existing systems before selecting a 3-way solenoid valve. This involves reviewing the system’s electrical specifications, including voltage and current requirements, as well as understanding the pressure and flow rate needs. When sourcing valves, it is beneficial to work closely with suppliers who offer detailed technical documentation and support, including installation guides and compatibility assessments. Additionally, considering modular valve designs that allow for easy adjustments and replacements can facilitate smoother integration into existing systems. Engaging with experienced engineers during the selection process can provide valuable insights and recommendations, ensuring that the chosen valve enhances the overall system performance.

Strategic Material Selection Guide for 3 way solenoid valve

What Are the Most Common Materials Used in 3-Way Solenoid Valves?

When selecting a 3-way solenoid valve, the choice of material is critical as it directly influences performance, durability, and compatibility with various media. Below, we analyze four common materials used in the construction of these valves, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Brass Perform in 3-Way Solenoid Valves?

Key Properties: Brass is known for its excellent corrosion resistance, particularly in water and air applications. It typically withstands temperatures up to 200°C and pressures around 20 bar, making it suitable for various environments.

Pros & Cons: Brass is durable and has good machinability, which simplifies manufacturing. However, it can be more expensive than other materials like plastic. Additionally, brass is susceptible to dezincification in certain environments, which can lead to premature failure.

Impact on Application: Brass valves are ideal for applications involving water, air, or gas. However, they may not be suitable for aggressive chemicals or high-purity applications due to potential leaching.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as DIN and ASTM for quality assurance, particularly in industries like food processing and HVAC.

What Role Does Stainless Steel Play in 3-Way Solenoid Valves?

Key Properties: Stainless steel offers superior corrosion resistance and can handle extreme temperatures (up to 300°C) and pressures (up to 50 bar). This makes it a preferred choice for harsh environments.

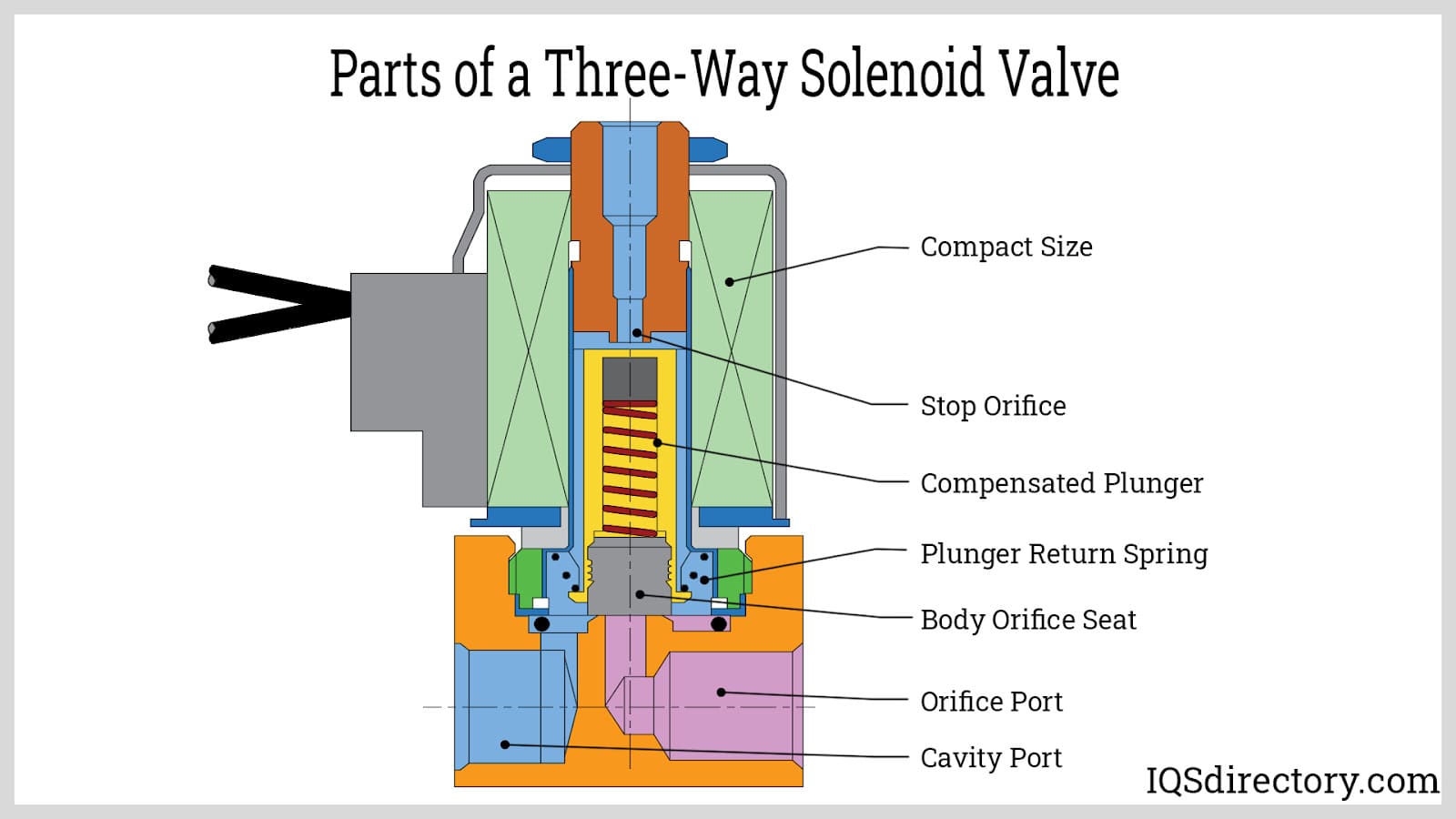

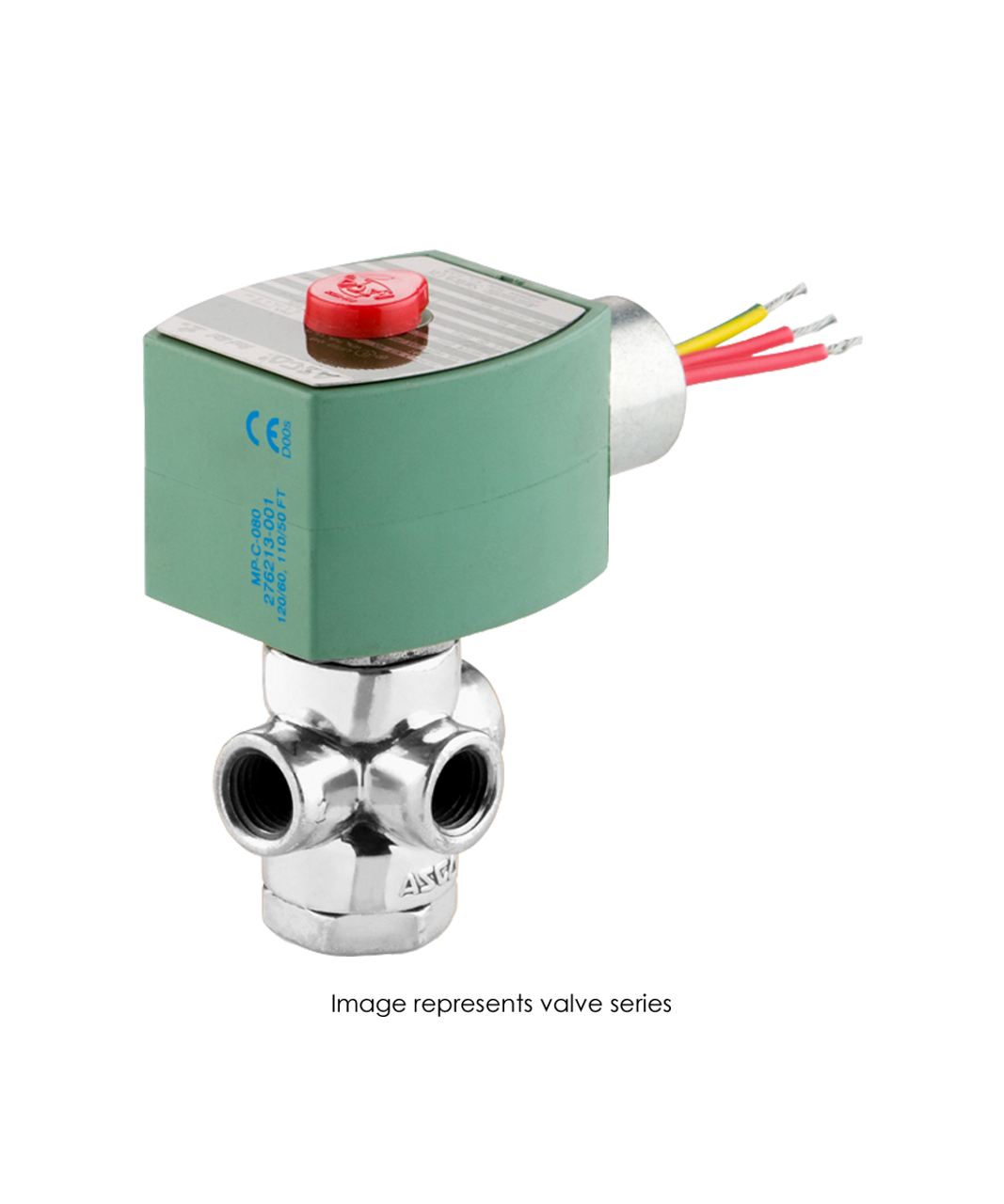

Illustrative image related to 3 way solenoid valve

Pros & Cons: The durability of stainless steel is unmatched, ensuring a long service life. However, it is heavier and more costly than brass or plastic, which may affect shipping and installation costs.

Impact on Application: Stainless steel is suitable for applications involving aggressive chemicals, steam, or high-pressure systems. It is often used in the pharmaceutical and food industries due to its hygienic properties.

Considerations for International Buyers: Compliance with international standards such as ISO and FDA is crucial for buyers in the medical and food sectors, particularly in Europe and North America.

How Do Plastics Compare for 3-Way Solenoid Valves?

Key Properties: Common plastics like PVC and PTFE are lightweight and offer good chemical resistance. They typically operate within a temperature range of -20°C to 80°C and can handle pressures up to 10 bar.

Pros & Cons: Plastics are generally less expensive and easier to manufacture, allowing for cost-effective solutions. However, they may not perform well under high temperatures or pressures, limiting their application scope.

Impact on Application: Plastic valves are ideal for low-pressure applications and are commonly used in irrigation and chemical processing. They are not suitable for high-temperature steam applications.

Considerations for International Buyers: Buyers should check for compliance with environmental regulations, especially in regions like Africa and South America, where regulations may vary significantly.

What About Aluminum in 3-Way Solenoid Valves?

Key Properties: Aluminum is lightweight and offers good corrosion resistance, with operational limits typically around 150°C and pressures up to 30 bar.

Pros & Cons: Aluminum is cost-effective and easy to machine, making it a popular choice for manufacturers. However, it is less durable than stainless steel and may corrode in certain environments, such as saltwater.

Impact on Application: Aluminum valves are suitable for air and water applications but may not be ideal for corrosive environments or high-pressure systems.

Considerations for International Buyers: Buyers in regions with high humidity or salt exposure, such as coastal areas in South America, should consider the potential for corrosion and ensure that the aluminum used is anodized or treated.

Summary Table of Material Selection for 3-Way Solenoid Valves

| Material | Typical Use Case for 3 Way Solenoid Valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Water, air, gas applications | Good corrosion resistance | Susceptible to dezincification | Medium |

| Stainless Steel | Aggressive chemicals, high-pressure systems | Superior durability and hygiene | Higher cost and weight | High |

| Plastic | Irrigation, chemical processing | Cost-effective and lightweight | Limited temperature/pressure range | Low |

| Aluminum | Air, water applications | Lightweight and easy to machine | Less durable in corrosive environments | Medium |

This guide serves as a comprehensive overview for B2B buyers looking to select the most suitable materials for their 3-way solenoid valve applications, ensuring optimal performance and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 way solenoid valve

What Are the Key Stages in the Manufacturing Process of 3-Way Solenoid Valves?

The manufacturing of 3-way solenoid valves involves several critical stages that ensure the final product meets high standards of quality and functionality. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Commonly Used?

The first step in the manufacturing process is the selection and preparation of materials. Common materials for 3-way solenoid valves include brass, stainless steel, and various plastics, depending on the application requirements such as pressure tolerance and chemical compatibility. The materials are sourced from certified suppliers to ensure quality and consistency. Each batch undergoes inspection to verify material specifications, ensuring they meet the necessary standards.

How Are 3-Way Solenoid Valves Formed?

Forming is a crucial stage where raw materials are shaped into the components of the solenoid valve. Techniques such as machining, molding, and stamping are commonly employed. Machining processes like CNC (Computer Numerical Control) machining are used to create precise valve bodies and components. Molding techniques may be utilized for plastic components, ensuring a high level of detail and minimizing waste. During this stage, dimensional checks are performed to ensure components meet design specifications.

What Does the Assembly Process Involve?

The assembly of a 3-way solenoid valve involves integrating various components, including the solenoid coil, valve body, and seals. This process requires skilled labor and precise techniques to ensure that each component fits perfectly. Automated assembly systems are often employed to enhance efficiency and reduce human error. Quality checks are conducted at this stage to ensure that the assembly is correct and that there are no visible defects.

What Finishing Techniques Are Applied?

Finishing processes enhance the valve’s functionality and appearance. Techniques like surface treatment, coating, and marking are used to provide corrosion resistance, improve aesthetics, and ensure clear identification of the product. For instance, anodizing or plating can be applied to metal components to prevent rust and wear. Additionally, proper cleaning is essential to remove any contaminants from the manufacturing process before the final inspection.

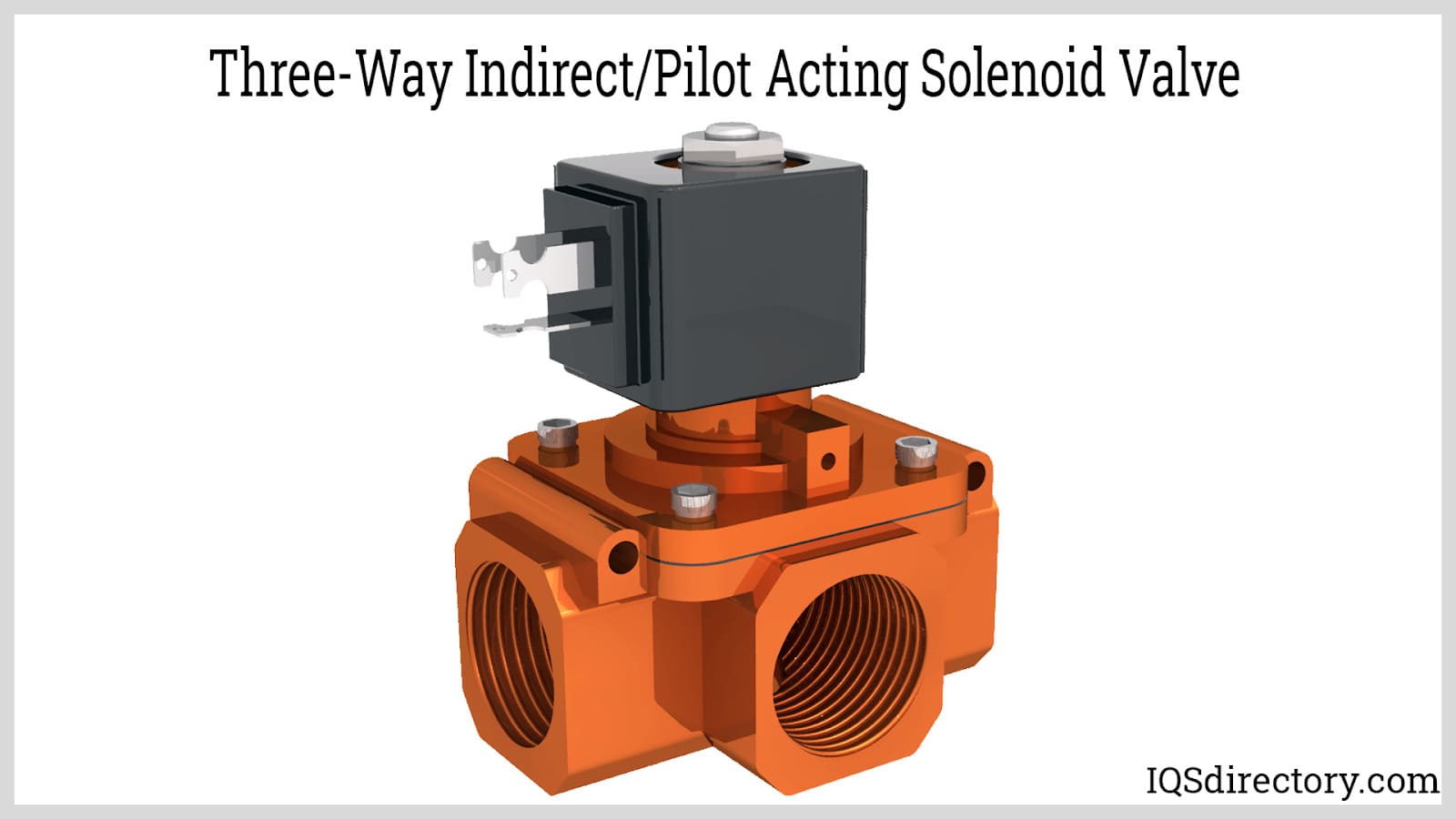

Illustrative image related to 3 way solenoid valve

How Is Quality Assurance Implemented in 3-Way Solenoid Valve Manufacturing?

Quality assurance (QA) is a fundamental aspect of the manufacturing process that guarantees the reliability and safety of 3-way solenoid valves. Compliance with international standards such as ISO 9001 is crucial, along with industry-specific certifications like CE and API.

What International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is a widely recognized standard that outlines criteria for a quality management system. Compliance with ISO 9001 indicates that the manufacturer consistently provides products that meet customer and regulatory requirements. Additionally, CE marking is essential for products sold in the European market, confirming that the product complies with health, safety, and environmental protection standards. For industries such as oil and gas, adherence to API standards is vital to ensure product reliability under extreme conditions.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process. These checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process help identify defects early. This may involve measuring critical dimensions and conducting functional tests.

- Final Quality Control (FQC): Once assembly is complete, a thorough inspection is conducted. This may include pressure testing, electrical testing, and performance evaluations to verify that the valves operate as intended.

What Testing Methods Are Commonly Used?

Several testing methods are employed to assess the performance and reliability of 3-way solenoid valves. Common testing techniques include:

- Pressure Testing: Ensures that the valve can withstand specified pressures without leaking.

- Electrical Testing: Confirms that the solenoid coil operates correctly, including resistance and response time checks.

- Functional Testing: Involves operating the valve under simulated conditions to ensure it performs as expected.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control measures of a supplier is crucial. There are several ways to conduct this verification:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed quality assurance reports from suppliers, including documentation of compliance with international standards. Regular audits can provide insights into the supplier’s manufacturing processes and quality control systems. Buyers may also consider third-party inspections to validate the supplier’s claims about quality and compliance.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control and certification. For instance, products must often comply with local regulations in addition to international standards. This can vary significantly between regions, necessitating thorough research and possibly consultation with local experts to ensure compliance.

Moreover, some regions may require additional certifications or testing, which can impact supply chain logistics and costs. Establishing clear communication with suppliers regarding these requirements is essential for successful international transactions.

Conclusion: Ensuring Quality in Your Supply Chain

The manufacturing processes and quality assurance measures for 3-way solenoid valves are critical factors for B2B buyers. By understanding these processes and verifying the quality control practices of suppliers, businesses can ensure they source reliable and compliant products that meet their operational needs. Investing time in due diligence on manufacturing and quality assurance not only mitigates risks but also fosters long-term partnerships with suppliers that prioritize excellence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 way solenoid valve’

When sourcing a 3-way solenoid valve, a systematic approach is essential to ensure you select the right product for your specific application. This checklist will guide you through the critical steps to streamline your procurement process and make informed decisions.

Step 1: Define Your Technical Specifications

Before engaging suppliers, clearly outline your technical requirements. Consider factors such as flow rate, pressure, temperature range, and the specific media (liquid, gas, or vacuum) the valve will control. Documenting these specifications helps in narrowing down options and ensures compatibility with your system.

- Flow Rate: Determine the necessary flow capacity to avoid bottlenecks in your application.

- Pressure and Temperature: Check the maximum operating conditions to prevent valve failure.

Step 2: Research Different Valve Types

Familiarize yourself with the various types of 3-way solenoid valves available, such as normally closed, normally open, and directional control valves. Each type serves different purposes and operates differently, so understanding these variations can significantly impact your selection.

- Normally Closed vs. Normally Open: Know when to use each type based on your system’s requirements.

- Directional Control: Essential for applications needing precise flow direction management.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers to ensure reliability and quality. Look for companies with a proven track record in manufacturing 3-way solenoid valves, and request company profiles, case studies, and customer references.

- Reputation: Check online reviews and industry feedback to gauge supplier reliability.

- Experience: Opt for suppliers with experience in your industry, as they will better understand your specific needs.

Step 4: Verify Certifications and Compliance

Ensure that the suppliers’ products meet relevant industry standards and certifications, such as ISO or CE. Compliance with these standards is crucial for safety and performance, especially in industries like automotive, medical, and food processing.

- Quality Assurance: Confirm if the supplier has robust quality control processes in place.

- Regulatory Compliance: Check if the valves comply with local regulations in your target market.

Step 5: Request Samples for Testing

Before making a bulk order, request samples to evaluate the valve’s performance in your specific application. Testing samples allows you to assess functionality, response time, and compatibility with your system.

- Performance Testing: Conduct tests under actual operating conditions to verify reliability.

- Compatibility Check: Ensure the valve integrates seamlessly with existing systems.

Step 6: Compare Pricing and Terms

Once you have shortlisted suppliers, compare pricing, payment terms, and delivery timelines. While cost is a critical factor, consider the total value, including warranty and after-sales support.

Illustrative image related to 3 way solenoid valve

- Total Cost of Ownership: Factor in maintenance costs and expected lifespan.

- Payment Flexibility: Look for suppliers offering favorable payment terms to ease cash flow.

Step 7: Establish a Long-term Relationship

After selecting a supplier, focus on building a long-term partnership. Regular communication can help address future needs and foster collaboration on new projects.

- Feedback Loop: Share performance feedback to help suppliers improve their offerings.

- Future Needs: Discuss potential future requirements to ensure the supplier can accommodate growth.

By following this checklist, you can navigate the procurement process for 3-way solenoid valves with confidence, ensuring that you make informed decisions that align with your operational needs.

Comprehensive Cost and Pricing Analysis for 3 way solenoid valve Sourcing

What Are the Key Cost Components of 3 Way Solenoid Valves?

When sourcing 3 way solenoid valves, understanding the cost structure is essential for making informed purchasing decisions. The main cost components include:

-

Materials: The quality and type of materials significantly impact the overall cost. Common materials for 3 way solenoid valves include brass, stainless steel, and various plastics. The choice of material affects not only the initial price but also the valve’s durability and suitability for specific applications.

-

Labor: Labor costs encompass wages for workers involved in manufacturing, assembly, and testing processes. Skilled labor may be required for more complex valves or custom designs, which can increase overall costs.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient production processes can help reduce overhead, thus lowering the price.

-

Tooling: Custom tooling for specific designs or high-volume production runs can require significant upfront investment. This cost is amortized over the production volume, impacting unit pricing.

-

Quality Control (QC): Rigorous testing and quality assurance processes ensure product reliability and compliance with industry standards. These QC measures can add to the overall cost but are crucial for maintaining high-quality standards.

-

Logistics: Transportation, warehousing, and handling costs contribute to the total cost of the valve. Shipping methods and distances, especially for international buyers, can affect pricing.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure profitability. This margin can vary based on market conditions and competition.

What Factors Influence the Pricing of 3 Way Solenoid Valves?

Pricing for 3 way solenoid valves can be influenced by several factors, including:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes typically lead to lower per-unit costs due to economies of scale. Buyers should consider their immediate and future needs to negotiate better pricing.

-

Specifications and Customization: Custom features or specifications (e.g., unique materials, sizes, or functionalities) can lead to increased costs. Standardized valves are usually more cost-effective.

-

Materials: As previously mentioned, the choice of materials significantly affects pricing. Higher-grade materials may lead to increased durability but also higher initial costs.

-

Quality and Certifications: Valves that meet specific industry certifications (like ISO, API, etc.) may come at a premium due to the additional testing and compliance costs.

-

Supplier Factors: The reputation, location, and reliability of suppliers can influence pricing. Established suppliers may offer better quality assurance but at a higher price point.

-

Incoterms: Understanding delivery terms is crucial for international buyers. Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact total landed costs, including shipping and insurance.

What Tips Can Buyers Use to Negotiate Better Prices for 3 Way Solenoid Valves?

To optimize purchasing costs, buyers should consider the following strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing, especially for larger orders. Don’t hesitate to ask for discounts or better terms based on order volume.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, energy efficiency, and lifespan to assess the true cost of the valve over its operational life.

-

Research Market Trends: Stay informed about market trends and price fluctuations. Understanding seasonal demands can help in timing purchases for better pricing.

-

Consider Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, sourcing from local suppliers can reduce shipping costs and lead times, potentially lowering overall expenses.

-

Be Aware of Pricing Nuances: International buyers should factor in currency fluctuations, tariffs, and import duties that can affect pricing. Clear communication with suppliers regarding these factors is essential.

Disclaimer

The pricing information provided in this analysis is indicative and can vary based on multiple factors, including market conditions, supplier negotiations, and specific buyer requirements. It is advisable to conduct thorough research and obtain multiple quotes before making purchasing decisions.

Illustrative image related to 3 way solenoid valve

Alternatives Analysis: Comparing 3 way solenoid valve With Other Solutions

Introduction: Understanding Alternatives in Valve Solutions

In the realm of fluid control systems, selecting the right valve technology is crucial for optimizing performance and efficiency. While the 3-way solenoid valve is a popular choice due to its versatility and reliability, various alternatives can also meet specific operational needs. This analysis will explore viable alternative solutions, comparing their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | 3 Way Solenoid Valve | Pneumatic Actuated Valve | Manual Ball Valve |

|---|---|---|---|

| Performance | High-speed actuation, responsive | Moderate speed, responsive | Slow actuation, dependent on manual force |

| Cost | Moderate initial investment | Higher initial investment | Low initial investment |

| Ease of Implementation | Easy installation and integration | Moderate complexity | Simple installation |

| Maintenance | Low maintenance, durable | Moderate maintenance required | Low maintenance |

| Best Use Case | Automated systems, HVAC, irrigation | Large-scale industrial applications | Applications requiring manual control |

Detailed Breakdown of Alternatives

Pneumatic Actuated Valve

Pneumatic actuated valves use compressed air to control flow. They are effective for larger systems where high flow rates and pressure control are necessary. While these valves offer rapid actuation, they often require more complex installation and setup compared to 3-way solenoid valves. The initial investment is higher due to the need for air supply systems and controls. However, for industries such as manufacturing and processing, where automation and speed are critical, pneumatic valves can provide significant advantages.

Manual Ball Valve

Manual ball valves are simple devices that control flow by rotating a ball within the valve body. They are easy to install and maintain, making them a cost-effective solution for smaller systems or applications where manual operation is feasible. However, they lack the speed and automation of solenoid valves and require operator intervention to open or close. As such, manual ball valves are best suited for applications where precise control is less critical, such as in water supply lines or non-critical service lines.

Illustrative image related to 3 way solenoid valve

Conclusion: How to Choose the Right Valve Solution for Your Needs

When selecting a valve for your application, consider the specific operational requirements, including the need for automation, flow rates, and maintenance capabilities. The 3-way solenoid valve excels in automated environments due to its rapid response and minimal maintenance. In contrast, pneumatic actuated valves are better suited for large-scale operations requiring higher flow rates, while manual ball valves offer a cost-effective solution for simpler applications. By evaluating these factors, B2B buyers can make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for 3 way solenoid valve

When considering the procurement of 3-way solenoid valves, understanding key technical properties and industry-specific terminology is crucial for making informed decisions. This section outlines essential specifications and common jargon to help B2B buyers navigate their purchasing process effectively.

What Are the Essential Technical Properties of a 3-Way Solenoid Valve?

-

Material Grade

The construction material of a 3-way solenoid valve, such as brass, stainless steel, or plastic, significantly impacts its durability, corrosion resistance, and suitability for specific applications. For instance, stainless steel valves are ideal for chemical processing due to their resistance to corrosive substances, while brass valves are commonly used in water and air applications. Selecting the appropriate material can enhance the valve’s lifespan and reliability in harsh environments. -

Operating Pressure

This specification indicates the maximum pressure at which the valve can operate effectively. Operating pressure typically ranges from vacuum conditions up to 100 psi or more, depending on the valve design. Understanding the pressure requirements of your system ensures that the selected valve will function optimally without risking leaks or failures, which could lead to costly downtime. -

Flow Rate (Cv Value)

The flow rate, often represented by the Cv (flow coefficient) value, measures the valve’s capacity to allow fluid flow. A higher Cv indicates a greater flow capacity, which is essential for applications requiring rapid fluid transfer, such as HVAC systems. B2B buyers must match the Cv value to their system’s flow requirements to maintain efficiency and performance. -

Response Time

This metric refers to the time it takes for the valve to open or close after being energized. Typically measured in milliseconds, a shorter response time is critical in applications where quick control is necessary, such as in automation and process control. Buyers should consider their operational needs to determine the appropriate response time for their applications. -

Leakage Rate

The leakage rate indicates the amount of fluid that may escape when the valve is in a closed position. A lower leakage rate is preferable, especially in sensitive applications, as it minimizes waste and maintains system integrity. Buyers should assess the leakage standards of potential valves to ensure compliance with industry regulations and operational efficiency. -

Electrical Specifications

This encompasses the voltage and current requirements for the solenoid’s operation. Common specifications include options for AC or DC power. Understanding the electrical demands is crucial for integration into existing systems and ensuring compatibility with control panels.

What Are Common Trade Terms Related to 3-Way Solenoid Valves?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. For B2B buyers, sourcing valves from reputable OEMs ensures quality and reliability, as these manufacturers are typically held to strict production standards. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell in a single order. Understanding the MOQ is vital for budget planning and inventory management, especially for smaller businesses that may not require large quantities. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and other details for specific products. Issuing an RFQ allows buyers to compare offers and negotiate terms, ensuring they receive the best value for their investment. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for managing shipping costs and liabilities, particularly for buyers sourcing valves from overseas suppliers. -

Lead Time

Lead time refers to the time required from placing an order to receiving the product. Understanding lead times helps B2B buyers plan their projects and manage inventory effectively, ensuring they have the necessary components when needed.

By grasping these technical properties and terminology, B2B buyers can make more informed decisions regarding the procurement of 3-way solenoid valves, ultimately optimizing their operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the 3 way solenoid valve Sector

What Are the Key Market Dynamics Affecting 3 Way Solenoid Valve Sourcing?

The global market for 3-way solenoid valves is experiencing robust growth, driven by increasing demand across various sectors including automotive, HVAC, medical equipment, and food processing. Key trends influencing this market include the shift toward automation and smart technologies. As industries prioritize efficiency and precision, the integration of advanced control systems utilizing 3-way solenoid valves is becoming commonplace. Furthermore, the rising emphasis on energy efficiency has led manufacturers to innovate and produce valves that require less power while maintaining performance.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate a complex landscape of suppliers and manufacturers. The focus on digital transformation is reshaping sourcing practices; businesses are increasingly leveraging online platforms for procurement, which enhances transparency and streamlines the purchasing process. Additionally, global supply chain disruptions have prompted buyers to seek local suppliers or alternative sourcing strategies to mitigate risks associated with long lead times and fluctuating costs.

Illustrative image related to 3 way solenoid valve

How Can Sustainability and Ethical Sourcing Impact Your Choice of 3 Way Solenoid Valves?

The environmental impact of manufacturing and sourcing 3-way solenoid valves is a growing concern among B2B buyers. The production processes often involve materials and chemicals that can be detrimental to the environment. As such, there is an increasing demand for suppliers who prioritize sustainability. Ethical sourcing practices are becoming essential, with buyers seeking manufacturers that adhere to environmentally friendly practices and contribute positively to their communities.

Green certifications, such as ISO 14001 for environmental management, can serve as indicators of a supplier’s commitment to sustainability. Additionally, the use of recyclable materials and eco-friendly manufacturing processes is gaining traction. Buyers should consider suppliers who offer products that not only meet operational requirements but also align with their corporate sustainability goals. By choosing ethically sourced products, companies can enhance their brand reputation and appeal to a growing demographic of environmentally conscious consumers.

What Is the Historical Context of 3 Way Solenoid Valves in B2B Markets?

The development of solenoid valves dates back to the early 19th century, evolving significantly alongside advancements in electrical engineering. Initially, these valves were primarily used in industrial applications, but their versatility soon led to adoption in diverse sectors such as automotive and medical technology. The introduction of 3-way solenoid valves allowed for more complex control of fluid dynamics, enabling applications that require the regulation of multiple flow paths.

Illustrative image related to 3 way solenoid valve

Over the decades, innovations in materials and manufacturing processes have improved the performance and reliability of these valves. Modern 3-way solenoid valves now offer enhanced energy efficiency, faster response times, and greater durability, catering to the needs of a rapidly changing global market. As industries continue to evolve, the importance of these valves in controlling fluid dynamics remains pivotal, underscoring their significance in contemporary B2B procurement strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of 3 way solenoid valve

-

How do I select the right 3-way solenoid valve for my application?

To choose the appropriate 3-way solenoid valve, consider factors such as flow rate, pressure, temperature requirements, and the type of media being controlled (liquid, gas, or vacuum). It’s crucial to assess the compatibility of the valve materials with the media, especially in chemical processing applications. Review manufacturer specifications and consult with technical experts or use chemical compatibility databases for informed decisions. Additionally, evaluate the installation requirements and maintenance needs to ensure seamless integration into your system. -

What is the best type of 3-way solenoid valve for HVAC applications?

For HVAC systems, a normally closed 3-way solenoid valve is often recommended, as it effectively manages the flow of hot and cold water to maintain desired temperatures. These valves allow for quick switching between supply lines, enhancing energy efficiency and temperature control. Ensure that the selected valve can handle the pressure and temperature specifications of your HVAC system, and consider models with a fast response time for optimal performance. -

What are the typical minimum order quantities (MOQs) for 3-way solenoid valves?

Minimum order quantities for 3-way solenoid valves can vary significantly depending on the manufacturer and the specific model. Generally, MOQs may range from 10 to 100 units, especially for standard models. However, for customized valves, manufacturers might have higher MOQs due to the additional resources required for production. It’s advisable to communicate directly with suppliers to negotiate MOQs based on your specific needs and budget. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms for international purchases of 3-way solenoid valves can vary widely. Many suppliers may offer terms such as net 30, 60, or 90 days, contingent upon your creditworthiness and the relationship established with the supplier. Some manufacturers may require upfront payment or a deposit, especially for custom orders. It’s essential to clarify payment terms during negotiations to avoid any misunderstandings and ensure smooth transaction processes. -

How can I ensure the quality of the 3-way solenoid valves I purchase?

To ensure the quality of your 3-way solenoid valves, request certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, inquire about the supplier’s quality assurance processes, including testing procedures and warranty policies. Request samples when possible to assess performance and durability before committing to larger orders. Engaging in supplier audits or seeking references from other customers can also help gauge the reliability of your supplier. -

What are the logistics considerations when importing 3-way solenoid valves?

Logistics plays a crucial role in the timely delivery of 3-way solenoid valves. Factors to consider include shipping methods (air freight vs. sea freight), customs clearance processes, and potential tariffs or import duties. Collaborate with a freight forwarder experienced in handling industrial components to navigate these challenges effectively. Additionally, ensure that your supplier provides accurate documentation, such as commercial invoices and packing lists, to facilitate smooth customs clearance. -

Can I customize a 3-way solenoid valve for specific applications?

Yes, many manufacturers offer customization options for 3-way solenoid valves to meet specific application requirements. Customizations can include variations in size, materials, pressure ratings, and electrical specifications. It is advisable to discuss your exact needs with the supplier’s engineering team to explore available options and understand any implications on lead times and costs. Ensure that any modifications are documented to maintain clarity throughout the production process. -

What industries commonly use 3-way solenoid valves?

3-way solenoid valves are widely used across various industries, including HVAC, automotive, food processing, chemical processing, and medical applications. Their versatility allows for effective control of fluid and gas flow in systems requiring precision. In automotive settings, they manage coolant and air flow, while in food processing, they help regulate ingredients. Understanding the specific applications within your industry can assist in selecting the most suitable valve type for your needs.

Top 8 3 Way Solenoid Valve Manufacturers & Suppliers List

1. Electric Solenoid Valves – 3 Way Solenoid Valves

Domain: electricsolenoidvalves.com

Registered: 2013 (12 years)

Introduction: 3 Way Solenoid Valves are used for controlling the flow of water, air, vacuum, or other low viscosity fluids. They feature three ports: an inlet port, an outlet port, and an exhaust port. The valves are actuated by a solenoid that moves a plunger to open and close the valve. The exhaust port vents or releases pressure or fluid, preventing unwanted buildup. Key advantages include flexibility in con…

2. McMaster – Three-Way Solenoid Valves

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Three-Way Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Emerson – Three-Way Solenoid Valves

Domain: emerson.com

Registered: 1995 (30 years)

Introduction: This company, Emerson – Three-Way Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Reddit – 3-Way Solenoid Valve

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 3-way solenoid valve: solves soupy puck, portafilter sneezing, and dripping after stopping brew; drawbacks include potential blockage, being an electrical failure point, and requiring maintenance like back-flushing or valve cleaning. Non-solenoid designs lack meaningful pressure control, which is important for espresso, but may save on manufacturing costs.

5. Humphrey – Direct Solenoid 3 Way Pneumatic Valve

Domain: humphrey-products.com

Registered: 2000 (25 years)

Introduction: {“Model”:”31087RCVAI12VDC”,”Series”:”310″,”Type”:”Direct Solenoid 3 way Pneumatic Valve”,”Dimensions (HxWxD)”:”2.38 x 0.75 x 1.25 in”,”Piping Type”:”Inline, Direct”,”Piping Port Size”:”1/8 NPSF”,”Number of Ports”:”3 ports”,”Number of Positions”:”2 positions”,”Voltage”:”12VDC”,”Pressure Range”:”0-125 psi”,”Flow (SCFM @ 100 psig)”:”11″,”Flow (LPM @ 6.9 bar)”:”311″,”Orifice Size”:”0.097 in (2.47 mm)”…

6. AGBind – 3-Way Normally Closed Solenoid Valves

Domain: agbind.com

Registered: 2018 (7 years)

Introduction: 3-Way Normally Closed Solenoid Valves allow for maximum passage of media with multiple orifice size options. Applications include air, water, steam, compressed air, and food and beverage. Features include no minimum pressure required, mountable in any position, and a wide variety of seal material options. Part Number: Series, Body Material options include Brass, PVC, Stainless Steel, Lead Free Bra…

7. Tameson – 3-Way Solenoid Valves

Domain: tameson.com

Registered: 2015 (10 years)

Introduction: 3-way solenoid valves direct flow between three ports, enabling complex control scenarios such as mixing, diverting, or alternating flow paths. They can be normally closed (NC), normally open (NO), or universal. Suitable applications include fluid control systems, cylinder control, HVAC systems, vacuum applications, medical devices, and pilot valves. Selection criteria include media type and mater…

8. Anderson Bolds – Three-Way Solenoid Valves

Domain: anderson-bolds.com

Registered: 1996 (29 years)

Introduction: This company, Anderson Bolds – Three-Way Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for 3 way solenoid valve

As international B2B buyers navigate the complexities of sourcing 3-way solenoid valves, understanding the strategic advantages of these components becomes paramount. The flexibility, reliability, and efficiency of 3-way solenoid valves make them indispensable across diverse applications, from automotive to chemical processing. By focusing on strategic sourcing, businesses can secure high-quality products that meet their specific operational requirements while optimizing costs.

In the evolving global marketplace, fostering strong relationships with suppliers is critical. Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize suppliers who offer not only competitive pricing but also comprehensive support and expertise in valve selection. Leveraging resources like chemical compatibility databases and consulting with industry experts can significantly enhance decision-making processes.

Looking ahead, the demand for advanced solenoid valve solutions will likely grow, driven by innovations in automation and fluid control technologies. To stay ahead of the curve, international buyers are encouraged to engage with trusted suppliers and explore customizable options that align with their operational needs. By taking proactive steps in sourcing, businesses can ensure they are well-equipped to meet future challenges in their respective industries.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.