3 Way 2 Position Valve: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for 3 way 2 position valve

In the fast-evolving industrial landscape, sourcing the right 3-way 2-position valve can be a daunting challenge for B2B buyers, particularly when navigating the complexities of international markets. These versatile valves play a critical role in controlling fluid and gas flow across various applications, including pneumatic systems, process automation, and machinery control. However, understanding the different types, operational mechanisms, and specific use cases is essential for making informed purchasing decisions.

This comprehensive guide aims to empower international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe—including key markets such as Nigeria and Brazil. We delve into the various designs and functionalities of 3-way 2-position valves, outlining their applications in industries ranging from manufacturing to oil and gas. Additionally, we will cover essential considerations for supplier vetting, cost factors, and environmental compliance to ensure that buyers are equipped with the knowledge necessary to choose the right product for their specific needs.

By providing actionable insights and in-depth analysis, this guide serves as a valuable resource for navigating the global market of 3-way 2-position valves, ultimately enabling buyers to enhance operational efficiency and optimize their procurement processes.

Understanding 3 way 2 position valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Normally Closed (NC) | Closes in the default state, allowing flow when actuated. | Pneumatic systems, single-acting cylinders | Pros: Energy-efficient; Cons: Requires power to open. |

| Normally Open (NO) | Opens in the default state, allowing flow until actuated. | Cooling systems, water flow control | Pros: Simplifies design; Cons: May lead to unintended flow. |

| Bistable | Maintains position without continuous power; pulse-operated. | Automated assembly lines, robotics | Pros: Energy-saving; Cons: Requires a pulse to switch states. |

| Direct-Operated | Uses solenoid directly to control flow; no system pressure needed. | Low-pressure applications, compact systems | Pros: Quick response; Cons: Limited to lower pressures. |

| Indirect-Operated | Requires system pressure to actuate; uses pilot valve. | High-pressure systems, complex applications | Pros: Handles higher pressures; Cons: More complex installation. |

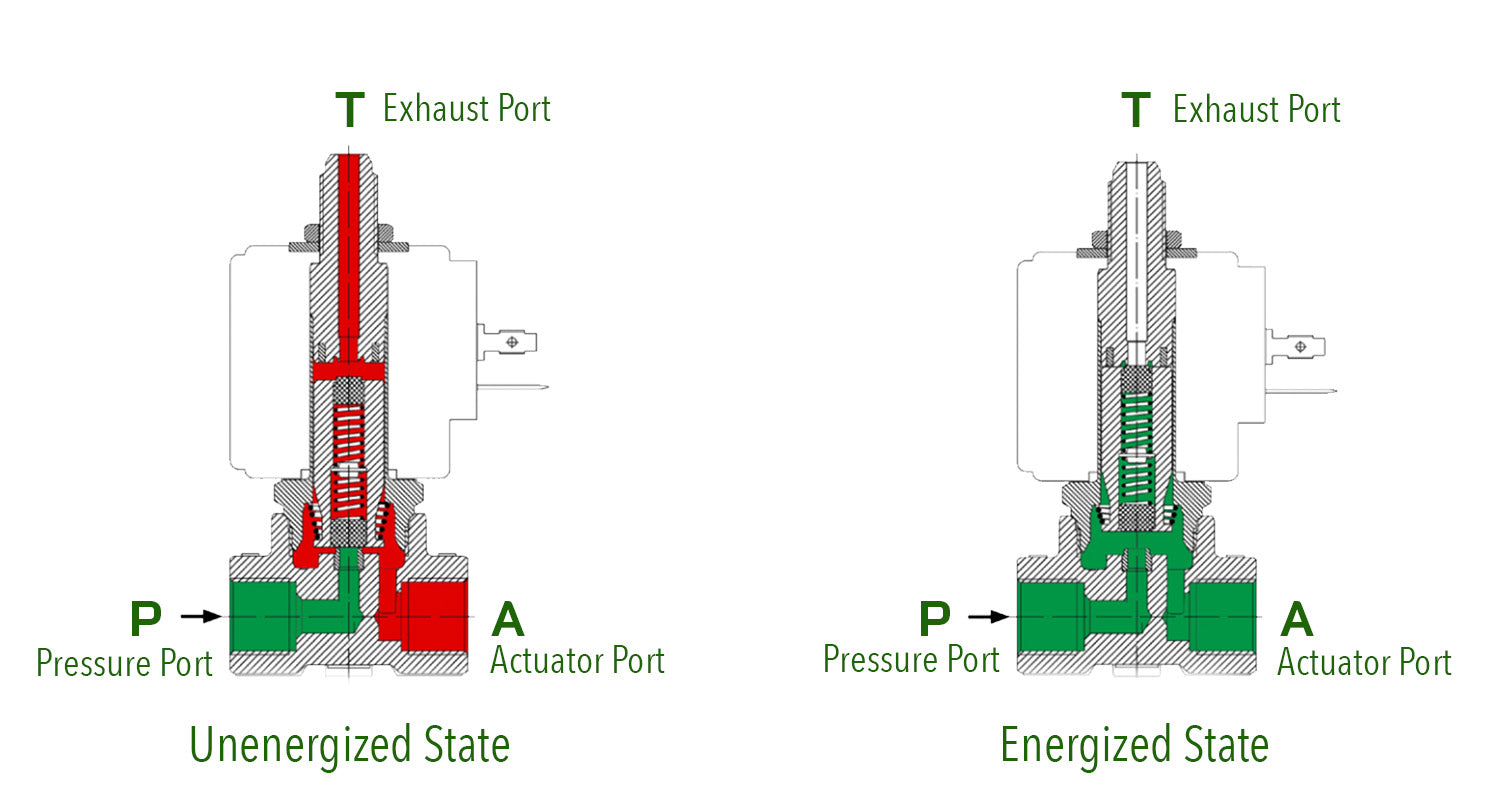

What Are the Characteristics of Normally Closed (NC) 3-Way Valves?

Normally Closed (NC) 3-way valves are designed to remain closed in their default state, enabling flow only when actuated. This design is particularly beneficial in pneumatic systems and applications involving single-acting cylinders, where controlling the flow of air is essential. B2B buyers should consider the energy efficiency of these valves, as they consume power only when the valve is opened. However, it’s important to note that they require continuous power to maintain the open state, which could lead to increased operational costs if not managed properly.

How Do Normally Open (NO) Valves Function in B2B Applications?

Normally Open (NO) valves allow for flow in their default state, closing only when actuated. This characteristic makes them ideal for applications such as cooling systems and water flow control, where a continuous flow is necessary until a specific condition is met. Buyers should weigh the benefits of simplified system designs against the potential for unintended flow when the system is in a default state. Proper application analysis is crucial to avoid operational inefficiencies.

Why Choose Bistable Valves for Automated Systems?

Bistable 3-way valves can maintain their position without the need for continuous power, making them suitable for automated assembly lines and robotics. They operate on a pulse system, requiring a brief signal to switch states. This energy-efficient design is attractive to B2B buyers focused on reducing operational costs. However, the need for a pulse to change states may complicate control systems, necessitating careful planning in system design and implementation.

What Are the Advantages of Direct-Operated Valves?

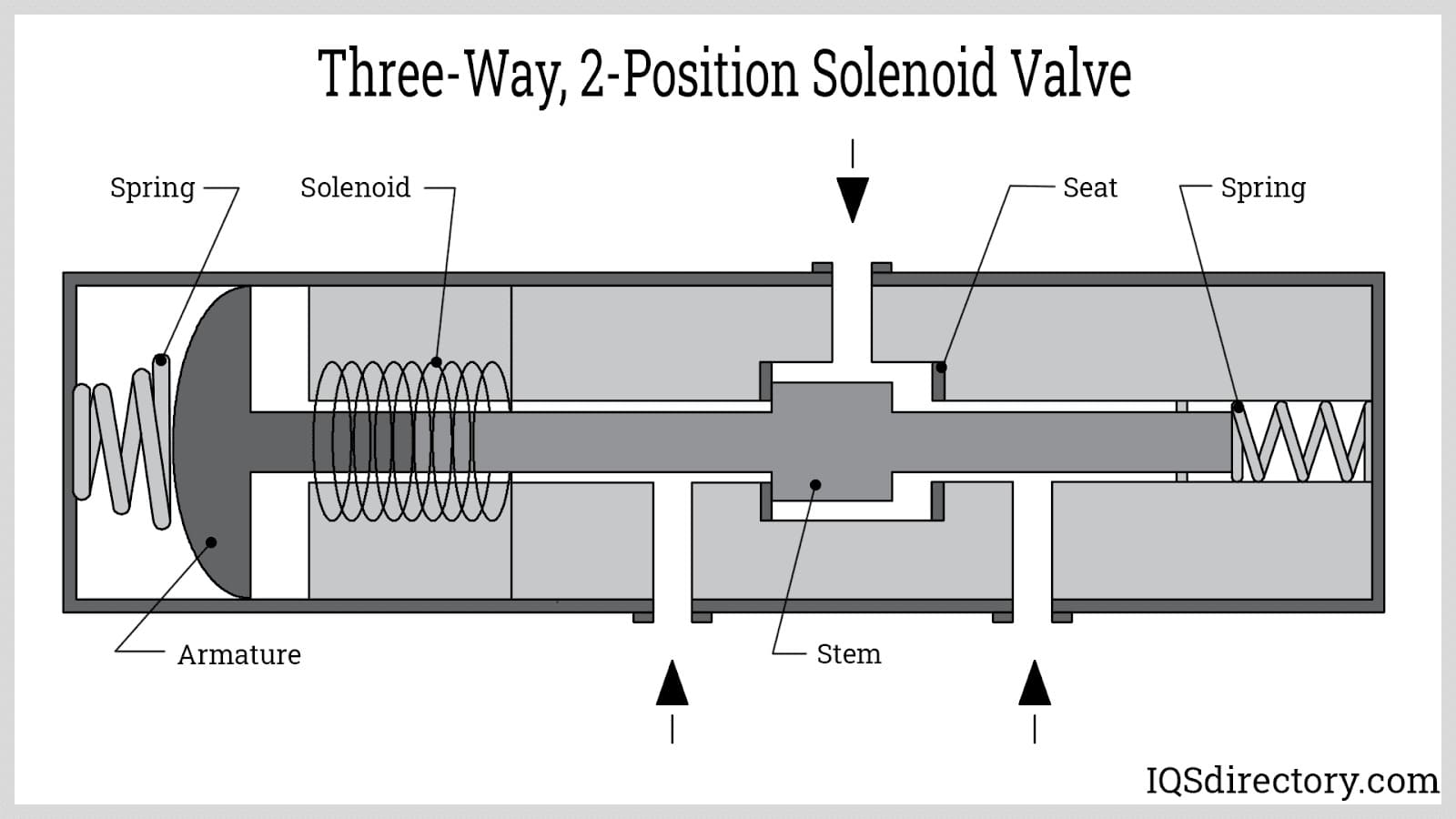

Direct-operated 3-way valves utilize the solenoid directly to control flow, making them ideal for low-pressure applications and compact systems. They offer quick response times, which can enhance system performance in various industrial settings. However, these valves are limited to lower pressure operations, so buyers should ensure compatibility with their specific application requirements. Their simplicity and ease of installation can provide significant advantages in straightforward setups.

How Do Indirect-Operated Valves Compare in Complexity?

Indirect-operated 3-way valves require system pressure to actuate and typically use a pilot valve for operation. This design allows them to handle higher pressures, making them suitable for complex applications in industries such as manufacturing and processing. While they can offer greater versatility, their complexity may lead to higher installation and maintenance costs. B2B buyers should consider the trade-off between performance capability and operational complexity when selecting these valves for their systems.

Key Industrial Applications of 3 way 2 position valve

| Industry/Sector | Specific Application of 3 Way 2 Position Valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Control of pneumatic actuators in assembly lines | Enhances automation, improving efficiency and reducing labor costs | Quality certifications (ISO), compatibility with existing systems, availability of technical support |

| Oil & Gas | Flow control in gas and liquid transfer systems | Ensures safe and efficient operation, minimizing leak risks | Material compatibility (corrosion resistance), pressure ratings, and compliance with industry standards |

| Food & Beverage | Control of liquid ingredients in processing plants | Maintains product quality and safety, ensuring compliance with hygiene standards | FDA compliance, easy cleaning features, and suitability for high temperatures |

| Water Treatment | Regulation of chemical dosing in purification processes | Improves water quality and compliance with environmental regulations | Resistance to chemicals, durability, and reliability in varying temperatures |

| HVAC Systems | Airflow control in heating and cooling systems | Optimizes energy efficiency and comfort levels in buildings | Energy efficiency ratings, adaptability to different HVAC systems, and maintenance requirements |

How Are 3 Way 2 Position Valves Used in Manufacturing?

In manufacturing, 3 way 2 position valves are integral for controlling pneumatic actuators on assembly lines. They enable precise control of air flow to single-acting cylinders, facilitating the automation of various processes such as material handling and packaging. By enhancing automation, these valves help reduce labor costs and improve overall efficiency. Buyers in this sector should prioritize valves that meet quality certifications and ensure compatibility with existing systems to avoid costly downtimes.

What Role Do 3 Way 2 Position Valves Play in Oil & Gas?

In the oil and gas industry, 3 way 2 position valves are essential for managing the flow of both gas and liquid in transfer systems. These valves help ensure safe operations by preventing leaks and allowing for quick shut-off during emergencies. The ability to control flow precisely contributes to operational efficiency and safety. When sourcing these valves, businesses must consider material compatibility to resist corrosion, adherence to pressure ratings, and compliance with stringent industry standards.

How Are 3 Way 2 Position Valves Utilized in Food & Beverage Processing?

In the food and beverage sector, 3 way 2 position valves are utilized for controlling the flow of liquid ingredients during processing. Their role is critical in maintaining product quality and ensuring compliance with hygiene standards. By allowing for quick changes in flow direction, these valves facilitate smooth operations in bottling, mixing, and ingredient dosing. Buyers should focus on valves that are FDA compliant and designed for easy cleaning, as well as those that can withstand high temperatures typical in food processing.

Why Are 3 Way 2 Position Valves Important in Water Treatment?

In water treatment facilities, 3 way 2 position valves regulate the dosing of chemicals used for purification processes. Their precise control contributes to improved water quality and helps facilities comply with environmental regulations. These valves ensure that the correct amounts of chemicals are administered, thus preventing overuse and reducing operational costs. When sourcing valves for this application, buyers should prioritize durability against chemicals and reliability under varying temperature conditions.

How Do 3 Way 2 Position Valves Enhance HVAC Systems?

In HVAC systems, 3 way 2 position valves are crucial for controlling air flow in heating and cooling applications. They help optimize energy efficiency and maintain comfortable indoor environments by directing air as needed. Efficient control of air flow leads to significant energy savings and improved user comfort. Buyers should consider energy efficiency ratings and the adaptability of these valves to different HVAC systems, as well as their maintenance requirements to ensure long-term performance.

3 Common User Pain Points for ‘3 way 2 position valve’ & Their Solutions

Scenario 1: Inconsistent Flow Control Leads to Process Downtime

The Problem:

Many B2B buyers, particularly in manufacturing and processing industries, face challenges with inconsistent flow control when using 3-way 2-position valves. This inconsistency can lead to unplanned downtime, as machinery may not operate optimally if the valve fails to redirect or stop the flow of air, gas, or liquid as intended. For instance, in a pneumatic system controlling a single-acting cylinder, a malfunctioning valve might cause the cylinder to stop unexpectedly, halting the entire production line and leading to lost revenue and increased operational costs.

The Solution:

To mitigate this issue, buyers should prioritize sourcing high-quality 3-way 2-position valves designed for durability and reliability. Look for valves with robust construction materials that can withstand the specific pressures and temperatures of your application. Additionally, implementing routine maintenance schedules can ensure that valves are functioning correctly. Users should regularly inspect the valves for wear and tear, check for leaks, and ensure that the actuation mechanism is clean and free from obstructions. Investing in valves with clear operating indicators can also help operators quickly assess the valve’s status, reducing response time in case of failures.

Scenario 2: Difficulty in Integration with Existing Systems

The Problem:

Another common pain point arises when buyers struggle to integrate new 3-way 2-position valves into their existing pneumatic or hydraulic systems. This is often due to compatibility issues with existing fittings, control systems, or actuators. For example, a company in South America may find that the new valves they ordered do not match the specifications of their legacy equipment, resulting in delays and increased costs as they seek adapters or entirely new systems.

The Solution:

To ensure seamless integration, buyers should conduct thorough compatibility assessments before purchasing. This involves checking the specifications of both the existing systems and the new valves, such as port sizes, pressure ratings, and actuator types. It can be beneficial to consult with suppliers who can provide detailed technical information and support. Additionally, consider choosing valves that adhere to international standards, which can enhance compatibility across different manufacturers and systems. Utilizing a modular approach to valve selection can also facilitate easier upgrades in the future, allowing for more straightforward integration without extensive system overhauls.

Scenario 3: Uncertainty About Valve Specifications and Applications

The Problem:

B2B buyers often express confusion regarding the appropriate specifications and applications for 3-way 2-position valves. With various options available—such as normally closed, normally open, and bistable designs—buyers may struggle to determine the right valve for their specific needs. This uncertainty can lead to suboptimal purchasing decisions, where the chosen valve may not perform efficiently or could even damage the system it is meant to control.

The Solution:

To navigate these complexities, buyers should invest time in understanding the operating principles and applications of different valve types. It is advisable to create a detailed requirements checklist based on the specific application, including factors such as fluid type, pressure, temperature, and flow rate. Engaging with knowledgeable suppliers who offer expert consultation can also provide insights tailored to unique operational needs. Furthermore, buyers can benefit from case studies or application notes that illustrate how similar industries successfully implemented specific valve types. By prioritizing education and consultation, buyers can make informed decisions that enhance system performance and reliability.

Strategic Material Selection Guide for 3 way 2 position valve

What Materials Are Commonly Used for 3 Way 2 Position Valves?

When selecting materials for 3 way 2 position valves, it is essential to consider the specific application requirements, including the media being controlled, environmental factors, and compliance with international standards. Below, we analyze four common materials used in the construction of these valves: brass, stainless steel, plastic, and aluminum.

How Does Brass Perform in 3 Way 2 Position Valves?

Brass is a popular choice for 3 way 2 position valves due to its excellent machinability and good corrosion resistance, particularly in water and air applications. It typically has a temperature rating of up to 150°C and can handle moderate pressure levels, making it suitable for various industrial applications.

Pros: Brass valves are relatively inexpensive and easy to manufacture, which can reduce overall costs. Their durability in non-corrosive environments ensures a long service life.

Cons: However, brass is susceptible to dezincification in aggressive environments, which can lead to premature failure. Additionally, it may not be ideal for high-temperature or high-pressure applications.

Impact on Application: Brass is compatible with water, air, and some oils, but it is not recommended for aggressive chemicals or high-purity applications.

Considerations for International Buyers: Brass valves must comply with standards such as ASTM B283 or equivalent local standards. Buyers in regions like Africa and South America should ensure that the brass used is of high quality to avoid issues with corrosion.

Illustrative image related to 3 way 2 position valve

Why Choose Stainless Steel for 3 Way 2 Position Valves?

Stainless steel is another excellent material for 3 way 2 position valves, known for its superior corrosion resistance and strength. It can withstand high temperatures (up to 300°C) and pressures, making it suitable for a wide range of applications, including chemical processing and food industries.

Pros: The durability and longevity of stainless steel valves make them a reliable choice for critical applications. They are also easy to clean, which is essential in hygienic environments.

Cons: The primary drawback is the higher cost compared to brass and plastic. Additionally, stainless steel valves can be more challenging to machine, potentially increasing manufacturing complexity.

Impact on Application: Stainless steel is compatible with a wide variety of media, including aggressive chemicals, steam, and high-pressure gases.

Considerations for International Buyers: Compliance with standards such as ASTM A351 or EN 1.4401 is crucial. Buyers in Europe and the Middle East may prefer stainless steel due to its reputation for quality and reliability.

Illustrative image related to 3 way 2 position valve

What Are the Benefits of Using Plastic in 3 Way 2 Position Valves?

Plastic valves, typically made from materials such as PVC, CPVC, or polypropylene, are lightweight and resistant to corrosion, making them ideal for applications involving aggressive chemicals or corrosive environments.

Pros: Plastic valves are generally less expensive and easier to install than metal valves. They also offer excellent chemical resistance, which is critical in many industrial applications.

Cons: However, plastic valves may have lower pressure and temperature ratings compared to metal options, limiting their use in high-stress applications. They can also be less durable over time, especially in high-temperature environments.

Impact on Application: Plastic valves are suitable for water, acids, and other corrosive media but may not be ideal for high-temperature or high-pressure applications.

Considerations for International Buyers: Buyers should ensure that plastic materials meet relevant standards such as ASTM D1784. In regions like Africa and South America, where chemical processing is prevalent, plastic valves may be highly sought after.

How Does Aluminum Compare for 3 Way 2 Position Valves?

Aluminum is a lightweight material that offers good corrosion resistance and strength, making it a viable option for 3 way 2 position valves in various applications.

Pros: Aluminum valves are easy to manufacture and can be anodized for enhanced corrosion resistance. They also provide a good balance between weight and strength.

Cons: However, aluminum is not as durable as stainless steel and may corrode in certain environments, especially when exposed to saltwater or high humidity.

Impact on Application: Aluminum valves are suitable for air and water applications but may not be ideal for aggressive chemicals.

Considerations for International Buyers: Compliance with standards such as ASTM B221 is essential. Buyers in regions with high humidity, like parts of Africa and the Middle East, should consider the environmental impact on aluminum valves.

Summary Table of Material Selection for 3 Way 2 Position Valves

| Material | Typical Use Case for 3 way 2 position valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Water and air applications | Cost-effective and durable | Susceptible to dezincification | Low |

| Stainless Steel | Chemical processing, food industry | High corrosion resistance | Higher cost and machining complexity | High |

| Plastic | Aggressive chemicals, low-pressure systems | Lightweight and cost-effective | Lower pressure/temperature ratings | Med |

| Aluminum | Air and water applications | Lightweight and easy to manufacture | Less durable in harsh environments | Med |

This strategic material selection guide provides valuable insights for international B2B buyers, aiding in the decision-making process for selecting the most suitable material for 3 way 2 position valves.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 way 2 position valve

What Are the Main Stages of Manufacturing a 3 Way 2 Position Valve?

The manufacturing process of a 3-way 2-position valve involves several critical stages that ensure the final product meets the required specifications for performance and reliability. Understanding these stages can help B2B buyers assess the capabilities of potential suppliers.

Material Preparation for 3 Way 2 Position Valves

The first stage in manufacturing involves selecting the appropriate materials. Common materials include brass, stainless steel, and plastics, each chosen based on the application requirements such as pressure ratings and environmental conditions. Raw materials are often sourced from certified suppliers to ensure quality and consistency.

Once materials are selected, they undergo various preparations, including cutting and machining to create specific shapes and sizes. This stage may also involve heat treatment processes to enhance material properties like strength and durability.

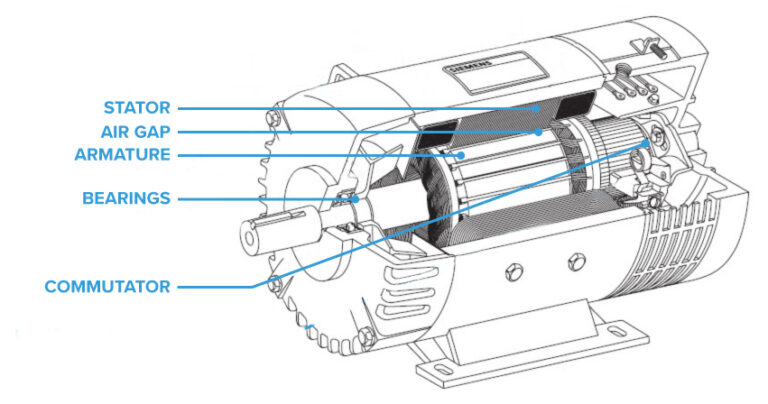

How Are 3 Way 2 Position Valves Formed?

The forming process typically includes techniques such as machining, casting, or forging, depending on the design and material. Machining is the most common method, where CNC (Computer Numerical Control) machines precisely cut and shape the valve components, ensuring high tolerances.

For valves made from metal, casting may be employed, where molten metal is poured into molds to form the valve body. Forging can also be used for high-strength applications, where metal is shaped under high pressure. Each of these methods has its advantages and is chosen based on cost, volume, and performance requirements.

What Are the Key Steps in the Assembly of 3 Way 2 Position Valves?

After the individual components are formed, the assembly stage begins. This involves combining the valve body, spool, actuator, and other parts into a complete unit. The assembly process often includes:

- Insertion of Internal Components: The spool and other internal mechanisms are placed into the valve body.

- Sealing: O-rings and gaskets are added to prevent leaks and ensure proper sealing.

- Final Assembly: The valve is closed and secured, often using screws or other fasteners.

Automation plays a significant role in this stage, with robotic systems enhancing precision and reducing assembly time. However, manual checks are often necessary to ensure the correct assembly, particularly in complex valve designs.

What Finishing Processes Are Used for 3 Way 2 Position Valves?

The finishing stage enhances the valve’s aesthetic and functional qualities. This may involve surface treatments such as polishing, anodizing, or coating to improve corrosion resistance and wear performance. These processes also help in achieving the desired finish that can withstand harsh operational environments.

Additionally, labels and markings are often applied during this stage, ensuring compliance with regulatory standards and aiding in traceability.

Illustrative image related to 3 way 2 position valve

How Is Quality Assurance Conducted for 3 Way 2 Position Valves?

Quality assurance (QA) is paramount in the manufacturing of 3-way 2-position valves, ensuring that they meet international and industry-specific standards. For B2B buyers, understanding these QA processes is essential for assessing supplier reliability.

What Are the Relevant International Standards for Quality Control?

ISO 9001 is a globally recognized standard for quality management systems, ensuring that manufacturers maintain consistent quality throughout the production process. Compliance with this standard is often a prerequisite for suppliers in international markets.

In addition to ISO 9001, specific industry standards may apply, such as CE marking for products sold in Europe, which indicates conformity with health, safety, and environmental protection standards. For sectors like oil and gas, API (American Petroleum Institute) standards may also be relevant.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are integral to the manufacturing process of 3-way 2-position valves. These typically include:

- Incoming Quality Control (IQC): Inspecting raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitoring production processes to catch defects early, using statistical process control (SPC) methods.

- Final Quality Control (FQC): Conducting thorough inspections and tests on the finished product to verify performance and compliance with specifications.

Common testing methods include pressure testing, leak testing, and functional testing to ensure the valve operates correctly under various conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability and compliance. Here are some strategies to consider:

What Steps Can Buyers Take to Audit Supplier Quality Control?

- Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing processes and quality control systems. This can help identify any potential gaps in compliance with international standards.

- Requesting Quality Reports: Suppliers should be able to provide detailed quality control reports, including data from IQC, IPQC, and FQC processes. Reviewing these reports can help verify their adherence to quality standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These services can perform checks at various stages of production, ensuring that the final product meets agreed specifications.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must be aware of the nuances in quality control and certification that may vary by region. For example, compliance with local regulations and standards is critical in markets like the European Union, where CE marking is mandatory.

Additionally, understanding cultural and operational differences in quality assurance practices can enhance communication and collaboration with suppliers from different regions. This knowledge can also help buyers navigate potential challenges related to quality, delivery, and compliance in international trade.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for 3-way 2-position valves empowers B2B buyers to make informed decisions when selecting suppliers. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control, businesses can ensure they source reliable and high-performing valves for their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 way 2 position valve’

Introduction

This guide aims to provide B2B buyers with a comprehensive checklist for sourcing 3-way 2-position valves. These valves are essential components in various pneumatic systems, and understanding how to procure them effectively can enhance operational efficiency and reliability in your applications. Follow these steps to ensure you select the right valve for your needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly define your technical requirements. Consider the specific application for which the valve will be used, including factors such as fluid type (liquid or gas), pressure ratings, and temperature ranges. This clarity will help you filter potential suppliers and ensure compatibility with your existing systems.

- Identify flow direction: Determine whether you need normally open (NO) or normally closed (NC) configurations based on your operational needs.

- Check actuator requirements: Understand whether you require direct or indirect actuation, which impacts the valve’s response time and energy consumption.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers that specialize in 3-way 2-position valves. Look for manufacturers with a solid reputation in the industry and experience in your specific application area.

- Utilize industry directories: Leverage online platforms and trade associations to compile a list of credible suppliers.

- Read reviews and testimonials: Seek feedback from other B2B buyers to gauge supplier reliability and product performance.

Step 3: Evaluate Potential Suppliers

Once you have a shortlist, it’s crucial to vet each supplier thoroughly. Request detailed company profiles, product catalogs, and case studies to assess their expertise and product offerings.

- Ask for references: Contact other businesses in your industry to learn about their experiences with the suppliers.

- Check for certifications: Ensure the suppliers hold relevant industry certifications (e.g., ISO, ATEX) to guarantee product quality and compliance with international standards.

Step 4: Request Quotes and Compare Pricing

Engage with your shortlisted suppliers to obtain detailed quotes for the valves you need. Pricing can vary significantly based on specifications, materials, and supplier reputation.

- Consider total cost of ownership: Look beyond the initial price and evaluate factors such as maintenance costs, warranty terms, and expected lifespan.

- Negotiate terms: Don’t hesitate to discuss bulk order discounts or payment terms that align with your budget constraints.

Step 5: Assess Lead Times and Delivery Options

Understanding lead times is crucial for effective project planning. Ensure that the suppliers can meet your timeline requirements without compromising quality.

- Inquire about production schedules: Ask suppliers how they manage lead times and their capacity for urgent orders.

- Evaluate shipping options: Consider the logistics involved in delivery, especially if sourcing from international suppliers, to avoid unexpected delays.

Step 6: Review After-Sales Support and Warranty Policies

Before finalizing your purchase, assess the after-sales support offered by the supplier. Strong customer service can significantly impact your experience post-purchase.

- Check warranty conditions: Ensure the warranty covers manufacturing defects and understand the process for claiming warranty support.

- Assess technical support availability: Determine if the supplier provides technical assistance for installation and troubleshooting to minimize downtime.

Step 7: Finalize the Order and Document Everything

Once you have selected a supplier, finalize the order by confirming all specifications, pricing, and delivery details in writing. Documentation is critical for future reference and to ensure all parties are aligned.

- Keep records of communications: Document every interaction with the supplier, including quotes, agreements, and delivery schedules.

- Verify order confirmations: Ensure that the supplier acknowledges and confirms your order to prevent any misunderstandings.

Following this checklist will streamline your procurement process, ensuring you select the best 3-way 2-position valves for your operational needs while establishing a reliable supplier relationship.

Comprehensive Cost and Pricing Analysis for 3 way 2 position valve Sourcing

Understanding the cost structure and pricing dynamics of 3-way 2-position valves is crucial for international B2B buyers, especially in emerging markets like Africa, South America, the Middle East, and Europe. This guide will explore the various cost components, price influencers, and offer actionable tips for buyers to enhance their sourcing strategies.

Illustrative image related to 3 way 2 position valve

What Are the Key Cost Components in 3-Way 2-Position Valve Manufacturing?

The cost structure for 3-way 2-position valves encompasses several critical components:

-

Materials: The primary materials used in manufacturing these valves include brass, stainless steel, and various plastics, depending on the application. The choice of material significantly impacts both the cost and durability of the valves.

-

Labor: Labor costs vary by region and manufacturing practices. In regions with higher labor costs, such as Europe, the overall production cost can increase. Conversely, sourcing from countries with lower labor costs might offer savings but could raise concerns about quality control.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Efficient manufacturing processes can help minimize these overheads, contributing to lower overall pricing.

-

Tooling: The initial investment in molds and machinery is a significant cost factor, especially for custom or high-volume orders. Tooling costs can be amortized over larger production runs, making it essential for buyers to consider minimum order quantities (MOQs).

-

Quality Control (QC): Rigorous QC processes ensure that valves meet industry standards and certifications. While this adds to the cost, it is essential for maintaining reliability and safety in applications.

-

Logistics: Transportation costs can vary significantly based on the distance, mode of transport, and chosen Incoterms. Buyers should evaluate logistics costs as part of the total cost of ownership.

-

Margin: Suppliers typically apply a markup to cover their costs and generate profit. This margin can vary based on market demand, competition, and the supplier’s pricing strategy.

What Influences the Pricing of 3-Way 2-Position Valves?

Several factors influence the pricing of 3-way 2-position valves:

-

Volume/MOQ: Larger orders often result in discounts due to economies of scale. Buyers should negotiate MOQs that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom designs or specific performance requirements can increase costs. Buyers should be clear about their specifications to avoid unexpected pricing changes.

-

Material Quality and Certifications: Valves that require specific certifications (e.g., ISO, ATEX) may have higher costs due to the additional testing and compliance measures involved.

-

Supplier Factors: The supplier’s reputation, reliability, and service levels can impact pricing. Established suppliers may charge a premium for their proven quality and support.

-

Incoterms: The agreed-upon Incoterms can affect the final price. Buyers should understand the implications of terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) on their total costs.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

-

Negotiate Wisely: Leverage your purchasing power by negotiating terms that benefit both parties. Establish long-term relationships with suppliers for better pricing and service.

-

Focus on Total Cost of Ownership (TCO): Instead of solely considering the purchase price, evaluate the TCO, which includes maintenance, logistics, and potential downtime costs. A higher upfront cost may lead to lower long-term expenses.

-

Understand Pricing Nuances in International Markets: Different regions have varying pricing strategies influenced by local demand, currency fluctuations, and economic conditions. Buyers from Africa, South America, and the Middle East should be aware of these factors when making purchasing decisions.

-

Research Suppliers Thoroughly: Assess multiple suppliers for quality, price, and reliability. Request samples and conduct due diligence to ensure they meet your standards.

-

Stay Updated on Market Trends: Being aware of changes in material costs, technological advancements, and market dynamics can help buyers make informed purchasing decisions.

Conclusion

Sourcing 3-way 2-position valves involves navigating a complex landscape of costs and pricing influences. By understanding the cost components, leveraging negotiation strategies, and focusing on total cost of ownership, international B2B buyers can make more informed decisions that enhance their operational efficiency and profitability. As always, prices may vary based on specific requirements and market conditions, so it is advisable to request quotes tailored to your needs.

Alternatives Analysis: Comparing 3 way 2 position valve With Other Solutions

In the quest for effective fluid control solutions, businesses often explore various technologies beyond the conventional 3-way 2-position valve. Understanding the alternatives available can help B2B buyers make informed decisions tailored to their specific operational needs.

| Comparison Aspect | 3 Way 2 Position Valve | Alternative 1: 2 Way Valve | Alternative 2: 5 Way Valve |

|---|---|---|---|

| Performance | Controls flow direction between three ports; suitable for simple tasks. | Provides on/off control for two ports; simpler design for straightforward applications. | Controls flow in double-acting cylinders; can manage multiple outputs and inputs. |

| Cost | Moderate cost; offers good value for versatility. | Generally lower cost; ideal for basic applications. | Higher initial investment; suitable for complex systems. |

| Ease of Implementation | Requires proper setup for pneumatic systems; versatile in application. | Easy to install; minimal configuration needed. | More complex installation; requires a good understanding of pneumatic systems. |

| Maintenance | Moderate maintenance; seals may need regular checking. | Low maintenance; fewer components to service. | Higher maintenance due to more components and potential for failure points. |

| Best Use Case | Ideal for applications needing flow direction control (e.g., pneumatic actuators). | Best for simple on/off control in low-demand applications (e.g., water flow). | Optimal for systems requiring precise control over double-acting cylinders (e.g., robotics). |

What Are the Benefits and Drawbacks of Using a 2-Way Valve as an Alternative?

The 2-way valve is a popular alternative, primarily due to its simplicity and cost-effectiveness. It features two ports, allowing for straightforward on/off control of fluid flow. This makes it an excellent choice for applications where complex control is unnecessary. However, its limitations include the inability to manage flow direction or exhaust, making it unsuitable for more intricate systems that require versatile control.

How Does a 5-Way Valve Compare as an Alternative Solution?

The 5-way valve expands on the capabilities of the 3-way valve by controlling the flow in double-acting pneumatic cylinders. It allows for the management of multiple inputs and outputs, making it ideal for sophisticated machinery and automation processes. However, the complexity of installation and higher costs can be a drawback for businesses that do not require such advanced functionalities. Maintenance may also be more intensive due to the additional components involved.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting a valve solution, B2B buyers should carefully consider their specific application requirements, budget constraints, and maintenance capabilities. The 3-way 2-position valve offers a balanced approach, suitable for many applications needing flow direction control. However, for simpler tasks, a 2-way valve may suffice, while more complex systems might benefit from the versatility of a 5-way valve. By evaluating these alternatives in terms of performance, cost, ease of implementation, and maintenance, businesses can make informed decisions that enhance operational efficiency and effectiveness.

Essential Technical Properties and Trade Terminology for 3 way 2 position valve

What Are the Essential Technical Properties of a 3-Way 2-Position Valve?

When considering a 3-way 2-position valve for your operations, understanding its technical specifications is crucial for ensuring optimal performance and compatibility with your systems. Here are several key properties to consider:

-

Material Grade

The material of the valve significantly affects its durability and suitability for different environments. Common materials include brass, stainless steel, and plastic. Brass is often used for general applications, while stainless steel is preferred in corrosive environments or where hygiene is paramount, such as in food processing. Selecting the right material ensures longevity and reliability, reducing maintenance costs. -

Port Size

Port size determines the flow capacity of the valve. Common port sizes range from 1/8 inch to 1 inch, affecting the volume of fluid or gas that can pass through. For B2B buyers, understanding port size is essential for matching the valve to existing piping systems, ensuring efficiency, and preventing bottlenecks in fluid transfer. -

Operating Pressure Range

Each valve has a specified operating pressure range, indicating the maximum and minimum pressures it can handle safely. Typical ranges can be from 0 to 10 bar, but some valves can withstand higher pressures. Knowing this range is vital for selecting a valve that can operate effectively within the parameters of your system without risking failure. -

Actuation Method

The valve can be actuated either electrically (via a solenoid) or pneumatically. Solenoid-actuated valves are often faster and easier to control, making them suitable for automated systems. Understanding the actuation method helps in integrating the valve into your existing control systems and ensures that it meets your operational needs. -

Response Time

The response time refers to how quickly the valve can open or close after receiving a signal. This is especially critical in applications requiring precise flow control, such as in manufacturing processes. A shorter response time can enhance system efficiency and improve overall productivity. -

Temperature Rating

Each valve is rated for specific temperature ranges, which can affect its performance and lifespan. Valves designed for high-temperature applications (e.g., over 100°C) require materials that can withstand thermal stress. For industries in extreme climates, knowing the temperature rating ensures safety and functionality.

What Are Common Trade Terms Related to 3-Way 2-Position Valves?

In the B2B landscape, familiarity with industry terminology is essential for effective communication and negotiation. Here are several common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking for quality assurance in components and systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers, as it can affect purchasing decisions and inventory management. Knowing the MOQ helps in budgeting and planning procurement strategies. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products or services. This process is vital for obtaining competitive pricing and ensuring that suppliers understand the buyer’s needs. -

Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in a transaction. Familiarity with Incoterms can help buyers manage shipping, insurance, and risk, ensuring clarity in international purchases. -

Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead times is essential for inventory management and production planning, especially in industries with tight schedules. -

Certification Standards

Certification standards, such as ISO or CE marking, indicate that a product meets specific safety and quality criteria. For B2B buyers, these certifications can provide assurance of product reliability and compliance with regulatory requirements.

Incorporating this knowledge into your purchasing strategy will help ensure that you select the right 3-way 2-position valve for your specific applications and operational needs, while also facilitating smoother transactions in the B2B marketplace.

Navigating Market Dynamics and Sourcing Trends in the 3 way 2 position valve Sector

What Are the Key Market Dynamics and Trends Affecting 3 Way 2 Position Valves Globally?

The market for 3-way 2-position valves is experiencing significant growth, driven by the increasing demand for automation in various industries including manufacturing, oil and gas, and food processing. The rise of Industry 4.0 has led to a surge in the adoption of smart technologies, which are integral for optimizing operations and enhancing efficiency. In regions like Africa and South America, where industrial growth is on the rise, the demand for pneumatic systems, including 3-way valves, is expected to accelerate as companies seek to modernize their infrastructure.

Emerging trends in B2B sourcing are leaning towards digital platforms for procurement, enabling international buyers to easily compare products and suppliers. The proliferation of IoT (Internet of Things) technology is also influencing the design and functionality of 3-way valves, as manufacturers are now integrating sensors and data analytics capabilities into their products. Furthermore, the focus on interoperability among devices is prompting suppliers to provide compatible components that can seamlessly work together, enhancing system efficiency.

In the Middle East and Europe, regulatory standards are shaping the market, with stringent guidelines on safety and performance pushing manufacturers to innovate continuously. Buyers in these regions are increasingly looking for suppliers that can demonstrate compliance with these standards while offering competitive pricing and reliable delivery timelines.

How Is Sustainability Influencing the Sourcing of 3 Way 2 Position Valves?

Sustainability is becoming a crucial factor in the sourcing strategies of B2B buyers, particularly for 3-way 2-position valves. The environmental impact of manufacturing processes is under scrutiny, and companies are increasingly prioritizing suppliers that practice ethical sourcing and reduce their carbon footprint. This shift is prompting valve manufacturers to adopt greener materials and production techniques, such as using recyclable components and minimizing waste.

Ethical supply chains are essential for maintaining brand reputation and meeting consumer demands for sustainable practices. Buyers are now seeking suppliers that can provide transparency in their sourcing processes and demonstrate adherence to international sustainability certifications, such as ISO 14001. These certifications indicate a commitment to environmental management and sustainable practices, making them attractive to B2B buyers looking to align with eco-friendly initiatives.

Illustrative image related to 3 way 2 position valve

Moreover, the incorporation of green technologies in the design of 3-way valves is gaining traction. For instance, manufacturers are exploring the use of low-energy solenoids and advanced materials that reduce energy consumption and enhance the longevity of products. By prioritizing sustainability and ethical sourcing, B2B buyers can not only meet regulatory requirements but also contribute positively to the environment and appeal to a growing base of eco-conscious consumers.

What Is the Evolution of 3 Way 2 Position Valves in the B2B Market?

The evolution of 3-way 2-position valves can be traced back to the early days of industrial automation, where basic mechanical systems were predominant. Initially, these valves were manually operated, limiting their application in complex processes. However, as industries embraced automation, the introduction of pneumatic and electric actuation revolutionized valve functionality, allowing for precise control and integration into automated systems.

With advancements in materials science, manufacturers began producing valves that offered enhanced durability and resistance to corrosive environments, making them suitable for a wider range of applications. The digital transformation of the industry has further accelerated innovation, with manufacturers now integrating smart technology into valve designs to enable real-time monitoring and data analytics.

Today, 3-way 2-position valves are not only critical components in pneumatic systems but also play a vital role in the broader context of automation and process control. Their evolution reflects the industry’s shift towards greater efficiency, sustainability, and adaptability, positioning them as essential tools for B2B buyers seeking to optimize their operations in an increasingly competitive global market.

Frequently Asked Questions (FAQs) for B2B Buyers of 3 way 2 position valve

-

How do I choose the right 3-way 2-position valve for my application?

Selecting the right 3-way 2-position valve involves understanding the specific requirements of your application, such as the type of media (liquid or gas), pressure ratings, and temperature ranges. Consider whether you need a normally closed or normally open valve based on how you want the flow to be managed. Additionally, review the valve’s compatibility with your existing systems, and assess the materials used in the valve construction for durability, especially in corrosive environments. -

What is the difference between a normally closed and normally open 3-way valve?

A normally closed (NC) 3-way valve remains closed when not actuated, preventing flow from the inlet to the outlet until activated. Conversely, a normally open (NO) valve allows flow in its default state and only stops flow when actuated. Understanding this distinction is crucial for ensuring the valve fits your operational needs, particularly in applications involving pneumatic or hydraulic systems. -

What are the common applications for 3-way 2-position valves in industrial settings?

3-way 2-position valves are widely used in applications such as pneumatic actuation, fluid control, pressure release, and blow-off systems. They are integral in managing flow direction in single-acting cylinders and in vacuum operations. Their versatility allows them to be utilized in various sectors, including manufacturing, food processing, and chemical industries, ensuring efficient process control and automation. -

How can I vet potential suppliers for 3-way 2-position valves?

When vetting suppliers, consider their industry experience, product certifications, and customer reviews. Request samples to evaluate product quality and reliability. It’s also beneficial to inquire about their manufacturing processes, lead times, and support services. Establishing clear communication regarding your technical requirements and expectations can help ensure that the supplier can meet your needs effectively. -

What customization options are available for 3-way 2-position valves?

Many manufacturers offer customization options for 3-way 2-position valves, including specific port sizes, materials, and sealing types. You can also request modifications for environmental resistance, such as corrosion-proof coatings or high-temperature materials. Discussing your unique application needs with the supplier can lead to tailored solutions that enhance performance and longevity in your systems. -

What is the typical minimum order quantity (MOQ) for 3-way 2-position valves?

Minimum order quantities for 3-way 2-position valves can vary significantly between manufacturers. Generally, MOQs may range from 10 to 100 units, depending on the complexity and customization of the valves. For bulk orders, you might negotiate better terms. Always confirm the MOQ with the supplier to align with your inventory and project requirements. -

What payment terms should I expect when sourcing valves internationally?

Payment terms can differ by supplier and region, but common practices include advance payment, partial payment upon order confirmation, and the balance upon shipment. Consider using secure payment methods like letters of credit or escrow services for large orders. It’s also advisable to clarify currency exchange rates and any applicable taxes or tariffs that may affect the total cost. -

What logistics considerations should I be aware of when importing valves?

When importing 3-way 2-position valves, consider shipping methods, customs clearance, and potential tariffs. Work with logistics providers who have experience in your target markets, as they can help navigate regulations and ensure timely delivery. Additionally, ensure proper documentation is prepared, including invoices, packing lists, and certificates of origin, to facilitate smooth customs processing.

Top 6 3 Way 2 Position Valve Manufacturers & Suppliers List

1. Emerson – Three-Way Solenoid Valves

Domain: emerson.com

Registered: 1995 (30 years)

Introduction: This company, Emerson – Three-Way Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Electric Solenoid Valves – 3 Way, 2 Position 3V310-10

Domain: electricsolenoidvalves.com

Registered: 2013 (12 years)

Introduction: {“SKU”:”3V310-10″,”Valve Type”:”3 Way, 2 Position”,”Suitable Media”:”Clean Air (40 Micron Filter)”,”Operation Type”:”Single Solenoid, Air Return”,”Port Size”:”3/8\” Female NPT, Body Ported”,”Flow Rate”:”CV=1.68″,”Response Time”:”Less than 0.05 Seconds”,”Body Material”:”Aluminum Alloy”,”Seal Material”:”NBR O-Ring”,”Power”:”AC: 4.0VA / DC: 3.0 Watts”,”Insolation Class”:”Class F”,”Enclosure Rating”:”…

3. Universal Power Conversion – 2 Position 3 Way Pneumatic Valve

Domain: universalpowerconversion.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “2 Position 3 Way Single Air Pilot Spring Return Pneumatic Valve”, “Part Number”: “3A31008NCT”, “Package Quantity”: 1, “Package Price”: “$33.17”, “Price Each”: “$33.17”, “Total Price”: “$33.17”, “Lead Time”: “5-7 Weeks”, “Specifications”: {“Type”: “2/3 Way”, “Actuator”: “Single Air Pilot”, “Thread”: “1/4 NPT”, “Acting”: “NC”}}

4. Humphrey – Direct Solenoid 3-Way Pneumatic Valve

Domain: humphrey-products.com

Registered: 2000 (25 years)

Introduction: {“Model”:”E193378024VDC”,”Type”:”Direct Solenoid 3-way Pneumatic Valve”,”Made in”:”USA”,”Voltage”:”24VDC”,”Piping Type”:”Inline, Direct”,”Piping Port Size”:”Rc1/4″,”Number of Ports”:”3 ports”,”Number of Positions”:”2 positions”,”Coil Entry Orientation”:”Standard, over Port 2″,”Size (in)”:”HxWxD 3.77 x 0.75 x 1.5″,”Type of Operation”:”Direct Acting”,”Flow – SCFM @ 100 psig”:”38″,”Flow – LPM @ 6.9 b…

5. U.S. Solid – 1/4 3 Way 2 Position Pneumatic Electric Solenoid Valve

Domain: ussolid.com

Registered: 2010 (15 years)

Introduction: {“name”: “U.S. Solid 1/4″ 3 Way 2 Position Pneumatic Electric Solenoid Valve”, “voltage”: “DC 12 V”, “type”: “3 Way 2 Position”, “size”: “1/4″”}

6. Pneumadyne – 3-Way 2-Position Valves

Domain: pneumadyne.com

Registered: 1995 (30 years)

Introduction: Product Name: 3-Way 2-Position Valves

Material: Solid aluminum body, stainless steel toggle

Input/Output Ports: 1/8 NPT (F)

Flow Rate: 41 scfm at 125 psi

Operating Pressure: 0 to 125 psi

Exhaust Port: Non-threaded, allows exhaust flow to atmosphere

Actuation Types: Detented and momentary toggle actuation

Mounting Options: Panel or surface mount

Heavy Duty Toggle: Available for extreme environments…

Strategic Sourcing Conclusion and Outlook for 3 way 2 position valve

In conclusion, the strategic sourcing of 3-way 2-position valves is essential for optimizing operational efficiency across various industries, particularly in regions like Africa, South America, the Middle East, and Europe. These valves play a critical role in managing fluid dynamics, making them invaluable for applications ranging from pneumatic systems to process automation. By understanding the diverse functionalities and benefits of these valves, international B2B buyers can make informed decisions that enhance productivity and reduce costs.

Investing in high-quality 3-way valves not only supports reliable performance but also aligns with environmental considerations, ensuring compliance with industry standards. As the demand for automation and efficient fluid control systems continues to rise, sourcing from reputable manufacturers will become increasingly important.

We encourage buyers to explore partnerships with established suppliers who can provide tailored solutions to meet specific operational needs. Embrace the future of industrial automation by prioritizing strategic sourcing of 3-way 2-position valves, and position your business for success in an evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.