2005 Honda Odyssey Radiator Outlet Size: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for 2005 honda odyssey radiator outlet size

In the competitive landscape of automotive parts procurement, understanding the specifics of components like the 2005 Honda Odyssey radiator outlet size is crucial for international B2B buyers. Sourcing the right radiator not only ensures optimal vehicle performance but also mitigates the risk of costly repairs and downtime. This guide serves as a comprehensive resource, addressing the various types of radiators available, their applications, and how to effectively vet suppliers.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including countries like Saudi Arabia and Nigeria—face unique challenges when navigating the global market. Factors such as varying quality standards, shipping logistics, and pricing fluctuations can complicate sourcing decisions. This guide empowers you to make informed purchasing choices by offering insights into cost structures, supplier reliability, and product specifications.

By providing detailed information on radiator compatibility, installation considerations, and maintenance best practices, this guide will help you streamline your sourcing process. Whether you are looking to establish long-term supplier relationships or seeking immediate solutions for urgent needs, understanding the nuances of the 2005 Honda Odyssey radiator outlet size will enhance your purchasing strategy and contribute to your overall operational efficiency.

Understanding 2005 honda odyssey radiator outlet size Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Outlet Size | Typically 1.5 inches in diameter; standard OEM design | General replacement parts suppliers | Pros: Widely available, cost-effective. Cons: May lack advanced cooling features. |

| Performance Outlet Size | Larger diameter (up to 2 inches); designed for high flow | Performance parts retailers | Pros: Improves cooling efficiency. Cons: Higher cost, may require modifications. |

| OEM Replacement Size | Exact match to original specifications | Authorized Honda dealerships | Pros: Guaranteed fit and performance. Cons: Often pricier than aftermarket options. |

| Aftermarket Universal Size | Adjustable size options; compatible with various models | Global automotive parts distributors | Pros: Versatile and adaptable. Cons: Quality can vary significantly. |

| Custom Fabricated Size | Tailored to specific performance needs | Specialty automotive shops | Pros: Optimized for unique applications. Cons: Longer lead times and higher costs. |

What Are the Characteristics of Standard Outlet Size Radiators?

Standard outlet size radiators for the 2005 Honda Odyssey typically feature a diameter of 1.5 inches. This size is designed to match the OEM specifications, ensuring compatibility with the vehicle’s cooling system. These radiators are widely available through various suppliers, making them a go-to choice for B2B buyers looking for reliable replacement parts. When considering standard options, buyers should weigh the benefits of cost-effectiveness against the potential limitations in advanced cooling technology.

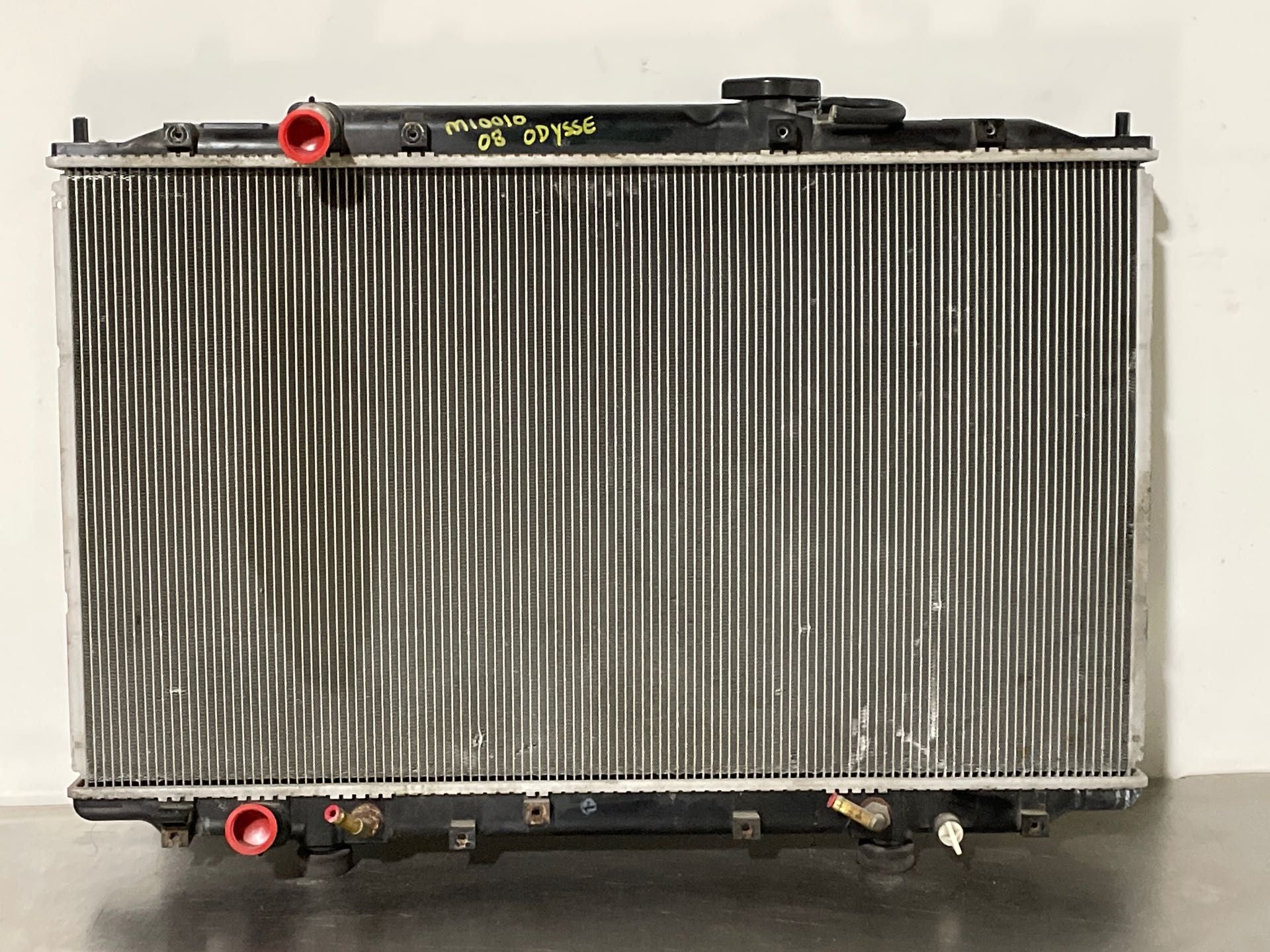

Illustrative image related to 2005 honda odyssey radiator outlet size

How Does Performance Outlet Size Enhance Cooling Efficiency?

Performance outlet size radiators often come with larger diameters, reaching up to 2 inches. This design allows for increased coolant flow, which can significantly enhance the vehicle’s cooling efficiency, especially under heavy loads or high-performance conditions. B2B buyers in the automotive performance sector will find these radiators appealing for their ability to improve engine performance. However, the higher price point and potential need for modifications can be a drawback for some buyers.

Why Choose OEM Replacement Size Radiators?

OEM replacement size radiators are manufactured to the exact specifications of the original parts, ensuring a perfect fit for the 2005 Honda Odyssey. These radiators are typically sold through authorized Honda dealerships, providing peace of mind regarding quality and reliability. For B2B buyers focused on maintaining vehicle integrity and resale value, OEM parts are often the preferred choice despite their higher cost compared to aftermarket options.

What Are the Benefits of Aftermarket Universal Size Radiators?

Aftermarket universal size radiators offer flexibility in terms of compatibility with various vehicle models. These radiators can be adjusted to fit different applications, making them a versatile option for global automotive parts distributors. While they can be more affordable than OEM parts, buyers should be cautious as the quality can vary widely among manufacturers. Ensuring that the radiator meets industry standards is crucial for maintaining vehicle performance.

Illustrative image related to 2005 honda odyssey radiator outlet size

When Should Custom Fabricated Size Radiators Be Considered?

Custom fabricated size radiators are designed for specific performance needs, making them an excellent choice for specialty automotive shops. These radiators are tailored to unique applications, providing optimized performance for high-demand situations. B2B buyers should consider these options when standard or aftermarket solutions do not meet their requirements. However, the longer lead times and increased costs associated with custom fabrication may deter some buyers.

Key Industrial Applications of 2005 honda odyssey radiator outlet size

| Industry/Sector | Specific Application of 2005 Honda Odyssey Radiator Outlet Size | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Replacement of radiators and hoses in Honda Odyssey vehicles | Ensures efficient vehicle cooling, extending engine life | Quality of parts, availability of OEM vs aftermarket options |

| Fleet Management | Maintenance of Honda Odyssey vehicles in transportation fleets | Reduces downtime and maintenance costs through proactive repairs | Bulk purchasing agreements, reliability of suppliers |

| Export and Import Trade | Sourcing of automotive parts for resale in international markets | Expands product offerings and meets diverse customer demands | Compliance with import regulations, shipping logistics |

| Automotive Parts Retail | Retailing of replacement radiators and hoses for Honda Odyssey | Captures market share in the growing demand for Honda parts | Competitive pricing, inventory management, supplier reliability |

| Vehicle Manufacturing | Use in assembly lines for Honda Odyssey production | Streamlines manufacturing processes and quality control | Consistency in part specifications, long-term supplier contracts |

How is the 2005 Honda Odyssey Radiator Outlet Size Utilized in Automotive Repair Shops?

In automotive repair shops, the radiator outlet size of the 2005 Honda Odyssey is crucial for ensuring that replacement radiators and hoses fit properly. This specific measurement prevents leaks and overheating, thereby enhancing vehicle performance. Repair shops must source high-quality parts to guarantee customer satisfaction and vehicle reliability. For international buyers, understanding local regulations regarding parts quality and compatibility is essential, especially in regions like Africa and South America where vehicle standards may differ.

Why is the 2005 Honda Odyssey Radiator Outlet Size Important for Fleet Management?

For fleet management companies operating Honda Odyssey vehicles, the radiator outlet size is integral to maintaining optimal engine temperatures. Regular maintenance of cooling systems can significantly reduce downtime and associated costs. Fleet managers should prioritize sourcing reliable parts to ensure consistency in repairs across multiple vehicles. In regions like the Middle East, where high temperatures can exacerbate cooling issues, having access to quality parts becomes even more critical for operational efficiency.

What Role Does the 2005 Honda Odyssey Radiator Outlet Size Play in Export and Import Trade?

In the export and import trade of automotive parts, the radiator outlet size for the 2005 Honda Odyssey is a key specification for suppliers targeting international markets. Accurate sizing ensures that parts meet the needs of local mechanics and retailers. Importers must navigate compliance with local regulations and standards, particularly in countries like Nigeria and Saudi Arabia. Understanding these requirements can enhance market entry strategies and facilitate smoother transactions.

How Do Automotive Parts Retailers Benefit from the 2005 Honda Odyssey Radiator Outlet Size?

Automotive parts retailers capitalize on the demand for replacement parts for Honda Odyssey vehicles by emphasizing the radiator outlet size in their product offerings. This focus helps them attract customers who are looking for specific fitments. Retailers should consider competitive pricing and the reliability of their suppliers to maintain a steady inventory. In Europe, where vehicle maintenance standards are stringent, having access to OEM parts that match the exact specifications can boost customer loyalty.

What is the Importance of the 2005 Honda Odyssey Radiator Outlet Size in Vehicle Manufacturing?

In vehicle manufacturing, particularly in the assembly of Honda Odysseys, the radiator outlet size is vital for quality control. Manufacturers rely on precise specifications to ensure that all components fit seamlessly, which is essential for overall vehicle performance. Long-term contracts with reliable suppliers are crucial for maintaining consistency in part specifications. This is especially important in European markets, where regulations around vehicle safety and performance are stringent.

3 Common User Pain Points for ‘2005 honda odyssey radiator outlet size’ & Their Solutions

Scenario 1: Sourcing Compatible Radiators for the 2005 Honda Odyssey

The Problem:

B2B buyers often struggle to find radiators that precisely fit the 2005 Honda Odyssey, especially when dealing with international suppliers. In regions like Africa and South America, where aftermarket parts may not be standardized, it can be difficult to ensure compatibility. Buyers might encounter issues with dimensions, outlet sizes, and features like integrated oil coolers, leading to costly returns and delays in their operations.

Illustrative image related to 2005 honda odyssey radiator outlet size

The Solution:

To overcome sourcing challenges, B2B buyers should begin by consulting detailed specifications for the radiator outlet size and overall dimensions of the 2005 Honda Odyssey radiator. Utilizing platforms like AutoZone can provide accurate part numbers and sizes, allowing buyers to cross-reference with their suppliers. When engaging with suppliers, ensure to communicate the exact part number (e.g., Duralast Radiator B2806) and dimensions (450 x 768 x 26 mm) to confirm compatibility. Establishing relationships with reputable distributors who understand the nuances of the market can also facilitate smoother transactions and better quality assurance.

Scenario 2: Ensuring Proper Installation of Radiator Hoses

The Problem:

Another prevalent pain point for B2B buyers is the installation of radiator hoses that connect to the radiator outlet. Many mechanics, particularly in regions with a high demand for vehicle maintenance, may find themselves unsure about the correct hose sizes or the best practices for installation. Incorrect hose fittings can lead to leaks or overheating, which not only compromises vehicle performance but also impacts customer satisfaction.

The Solution:

To mitigate installation issues, buyers should invest in comprehensive training for their mechanics on the specifics of the 2005 Honda Odyssey radiator outlet size and hose specifications. Providing access to instructional materials, such as detailed video tutorials or step-by-step guides, can enhance the knowledge base of the team. Furthermore, sourcing hoses that are specifically designed for the 2005 Honda Odyssey can prevent compatibility issues. Encourage mechanics to replace both upper and lower hoses simultaneously when changing the radiator to streamline the process and ensure optimal performance.

Scenario 3: Managing Preventive Maintenance for Radiator Systems

The Problem:

Preventive maintenance is critical for the longevity of the radiator system in the 2005 Honda Odyssey. However, B2B buyers often find it challenging to keep track of maintenance schedules and the necessary components that need regular checks, such as hoses, coolant levels, and overall radiator health. Ignoring these factors can lead to premature radiator failure, which can be particularly costly in terms of repairs and downtime.

The Solution:

Implementing a robust preventive maintenance program can greatly enhance the reliability of the radiator systems. Buyers should establish a maintenance checklist that includes regular inspections of the radiator and its components, particularly focusing on the hoses’ condition and coolant quality. Advise buyers to use high-quality, OEM-recommended coolant, and to change it every 10 years, as per manufacturer recommendations. Additionally, leveraging technology such as inventory management software can help track maintenance schedules and remind buyers when components need inspection or replacement. By prioritizing preventive maintenance, businesses can significantly reduce the risk of unexpected failures and enhance overall vehicle reliability.

Strategic Material Selection Guide for 2005 honda odyssey radiator outlet size

What Materials Are Commonly Used for the 2005 Honda Odyssey Radiator Outlet Size?

When selecting materials for the radiator outlet of the 2005 Honda Odyssey, it is essential to consider several factors such as thermal performance, corrosion resistance, and compatibility with automotive fluids. Here, we analyze four common materials: aluminum, plastic, brass, and stainless steel.

How Does Aluminum Perform in Radiator Outlet Applications?

Aluminum is widely used in automotive applications due to its excellent thermal conductivity and lightweight nature. It can withstand high temperatures and pressures, making it suitable for radiator outlets. Aluminum also exhibits good corrosion resistance, particularly when anodized, which enhances its lifespan in coolant systems.

Pros: Aluminum is durable, lightweight, and cost-effective. Its excellent heat dissipation properties contribute to efficient engine cooling.

Cons: While aluminum is generally resistant to corrosion, it can be susceptible to galvanic corrosion when in contact with dissimilar metals. Additionally, it may require more complex manufacturing processes, particularly if intricate designs are needed.

Illustrative image related to 2005 honda odyssey radiator outlet size

Impact on Application: Aluminum is compatible with most automotive coolants, but care must be taken to avoid mixing it with incompatible metals.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local automotive standards. Aluminum components must meet ASTM or JIS specifications for quality assurance.

Why Choose Plastic for Radiator Outlet Components?

Plastic, specifically engineered thermoplastics, is increasingly used for radiator outlets due to its lightweight and cost-effective nature. It offers good resistance to corrosion and can handle moderate temperature ranges.

Pros: Plastic is inexpensive and can be molded into complex shapes, allowing for innovative designs. It is also resistant to many chemicals found in automotive fluids.

Cons: Plastic may not withstand high temperatures as well as metals, leading to potential deformation or failure under extreme conditions. Its longevity may also be less than that of metal alternatives.

Impact on Application: Compatibility with specific coolant types is crucial, as some plastics may degrade when exposed to certain chemicals.

Considerations for International Buyers: Buyers should be aware of the varying quality of plastics in different markets. Ensuring compliance with international standards like DIN can mitigate risks associated with subpar materials.

What Are the Benefits of Using Brass in Radiator Outlets?

Brass is another material option known for its excellent corrosion resistance and durability. It can withstand high temperatures and pressures, making it suitable for radiator applications.

Pros: Brass is highly resistant to corrosion and has good thermal conductivity. Its mechanical strength makes it a reliable choice for high-stress applications.

Illustrative image related to 2005 honda odyssey radiator outlet size

Cons: Brass is heavier than aluminum and plastic, which may be a consideration for weight-sensitive applications. It is also more expensive than some alternatives.

Impact on Application: Brass is compatible with most automotive fluids, providing a reliable option for long-term use.

Considerations for International Buyers: Compliance with ASTM standards is essential, particularly in regions like Europe where quality assurance is critical. Brass components should be sourced from reputable suppliers to ensure quality.

How Does Stainless Steel Compare for Radiator Outlets?

Stainless steel is known for its exceptional corrosion resistance and durability, making it a premium choice for radiator outlets. It can withstand high temperatures and pressures, making it suitable for demanding applications.

Pros: Stainless steel offers superior strength and longevity. Its resistance to corrosion ensures a longer lifespan, reducing the need for frequent replacements.

Cons: The primary drawback of stainless steel is its cost, which is typically higher than aluminum or plastic. Additionally, its weight can be a concern in applications where weight savings are critical.

Impact on Application: Stainless steel is compatible with a wide range of automotive fluids, ensuring reliable performance in various conditions.

Considerations for International Buyers: Buyers should ensure that stainless steel components meet international standards, such as ASTM or JIS, to guarantee quality and performance.

Illustrative image related to 2005 honda odyssey radiator outlet size

Summary Table of Material Selection for 2005 Honda Odyssey Radiator Outlet Size

| Material | Typical Use Case for 2005 Honda Odyssey Radiator Outlet Size | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Radiator outlet fittings and components | Lightweight and excellent thermal conductivity | Susceptible to galvanic corrosion | Medium |

| Plastic | Molded components for radiator outlets | Cost-effective and versatile | Limited temperature resistance | Low |

| Brass | High-stress applications in radiator systems | Excellent corrosion resistance | Heavier and more expensive | High |

| Stainless Steel | Premium radiator outlet components | Superior strength and longevity | Higher cost and weight | High |

This comprehensive analysis of material options for the 2005 Honda Odyssey radiator outlet provides valuable insights for international B2B buyers, enabling informed decisions that align with performance requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 2005 honda odyssey radiator outlet size

What Are the Key Manufacturing Processes for the 2005 Honda Odyssey Radiator Outlet Size?

The manufacturing of the radiator outlet for the 2005 Honda Odyssey involves several critical stages, each designed to ensure the final product meets the necessary performance and durability standards. Here’s a breakdown of the main stages in the manufacturing process:

Material Preparation: What Materials Are Used and How Are They Prepared?

The primary materials used for radiator outlets are typically aluminum or high-grade plastic. Aluminum is favored for its lightweight and thermal conductivity, while plastic may be used in specific designs for its resistance to corrosion and lower cost.

During material preparation, raw materials undergo various processes, such as:

- Cleaning: This involves removing any surface contaminants that could affect the bonding or finishing processes.

- Alloying (for aluminum): Aluminum may be alloyed with other metals to enhance its strength and performance characteristics.

- Thermal Treatment: Some materials are subjected to heat treatment to improve their mechanical properties before proceeding to forming.

Forming: How Is the Radiator Outlet Shaped?

The forming stage is where the material is shaped into the desired outlet configuration. This can involve several techniques:

Illustrative image related to 2005 honda odyssey radiator outlet size

- Extrusion: For aluminum, this technique is commonly used to create a continuous profile. The aluminum is forced through a die to form the desired shape.

- Injection Molding: For plastic components, molten plastic is injected into a mold to form the outlet shape. This process allows for high precision and repeatability.

- Stamping and Bending: Additional processes may be employed to create flanges or other features necessary for fitting the outlet into the radiator assembly.

Assembly: How Are Components Joined Together?

Once individual components are formed, they undergo an assembly process. This may include:

- Joining Techniques: Methods such as welding (for aluminum) or adhesive bonding (for plastic) are employed to connect different parts of the outlet.

- Integration with Additional Components: The outlet may include fittings for hoses or connections to the radiator, necessitating careful alignment and securing to ensure a leak-proof assembly.

Finishing: What Final Treatments Are Applied?

Finishing processes enhance the durability and aesthetic of the radiator outlet. Common techniques include:

- Surface Coating: Anodizing for aluminum or protective coatings for plastic components may be applied to prevent corrosion and wear.

- Quality Inspection: Each finished component undergoes thorough inspection to ensure it meets design specifications and quality standards.

What Quality Assurance Measures Are in Place for Radiator Outlets?

Quality assurance is paramount in the manufacturing of radiator outlets, especially given their critical role in vehicle cooling systems. Here’s an overview of relevant standards and practices:

What International Standards Should B2B Buyers Consider?

B2B buyers should look for suppliers who comply with international quality standards such as:

- ISO 9001: This standard outlines a framework for a quality management system and emphasizes continual improvement and customer satisfaction.

- CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: Relevant for components that may interact with fluids, ensuring compatibility and safety.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are essential for maintaining product integrity. Common checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify and rectify any deviations from standards.

- Final Quality Control (FQC): A thorough inspection of finished products before they are dispatched to customers.

What Testing Methods Are Commonly Used for Radiator Outlets?

Testing methods are crucial for verifying the performance and reliability of radiator outlets. Typical testing methods include:

- Pressure Testing: Ensures the outlet can withstand the pressure of the cooling system without leaking.

- Thermal Cycling Tests: Evaluates how the material responds to temperature fluctuations, simulating real-world conditions.

- Visual Inspections: Checking for surface defects, proper dimensions, and overall assembly integrity.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, it is essential to establish a robust verification process for supplier quality control.

Illustrative image related to 2005 honda odyssey radiator outlet size

What Steps Should Buyers Take to Assess Supplier Quality?

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, quality control processes, and adherence to standards.

- Requesting Quality Reports: Suppliers should be able to provide documentation demonstrating compliance with quality standards, including test results and inspection reports.

- Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of the supplier’s quality control measures.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, buyers should be aware of specific nuances:

- Cultural Differences: Understanding local practices and communication styles can impact the effectiveness of quality control discussions.

- Regulatory Compliance: Different regions may have varying regulations affecting product standards; ensuring compliance is critical for market entry.

- Logistics and Supply Chain Considerations: Quality can be affected by transport conditions; hence, buyers should consider logistics partners with quality assurance protocols.

Conclusion: Ensuring Quality in the Manufacturing of 2005 Honda Odyssey Radiator Outlet Size

Understanding the manufacturing processes and quality assurance measures for the 2005 Honda Odyssey radiator outlet is crucial for B2B buyers. By leveraging international standards, implementing rigorous quality control checkpoints, and actively engaging in supplier verification, businesses can ensure they source high-quality components that meet their performance needs. This proactive approach not only enhances product reliability but also fosters long-term partnerships with suppliers across diverse global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2005 honda odyssey radiator outlet size’

To effectively source the radiator outlet size for a 2005 Honda Odyssey, international B2B buyers need a structured approach that ensures they obtain the correct parts while mitigating risks associated with procurement. This checklist provides essential steps to guide buyers through the sourcing process.

Step 1: Define Your Technical Specifications

Understanding the exact specifications of the radiator outlet size is crucial. The 2005 Honda Odyssey typically has a radiator outlet size that must match the OEM standards for optimal performance. Refer to technical manuals or manufacturer specifications to ensure you have the correct dimensions and compatibility details.

Illustrative image related to 2005 honda odyssey radiator outlet size

Step 2: Research Reliable Suppliers

Identify suppliers that specialize in automotive parts, particularly those with a focus on Honda components. Reliable suppliers will often have a robust online presence, customer reviews, and testimonials. Look for those who have a history of supplying parts to businesses in your region, as they will be more familiar with local market conditions.

- Check for Product Availability: Ensure the supplier has the specific radiator outlet size in stock.

- Assess Lead Times: Understand the expected delivery times to avoid disruptions in your operations.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Request company profiles, case studies, and references from other businesses in similar industries. This process not only helps you verify credibility but also ensures that the supplier can meet your quality and service expectations.

- Request Certifications: Ensure suppliers have necessary certifications, such as ISO, that indicate adherence to quality standards.

- Look for Warranty Offers: A supplier that offers warranties on parts shows confidence in their products.

Step 4: Request Samples and Specifications

Before placing a bulk order, request samples of the radiator outlet size. This allows you to physically verify the quality and compatibility with your existing systems. Examine the materials used and ensure they meet your durability standards.

- Inspect for Quality: Look for any signs of defects or inconsistencies in the sample.

- Confirm Specifications: Make sure the sample matches the technical specifications you defined in Step 1.

Step 5: Negotiate Terms and Pricing

Once you have identified a reliable supplier and confirmed product quality, enter negotiations regarding pricing and terms. Discuss bulk order discounts, payment terms, and shipping costs to ensure you are getting the best deal.

Illustrative image related to 2005 honda odyssey radiator outlet size

- Consider Total Cost of Ownership: Factor in shipping, duties, and potential tariffs, especially when dealing with international suppliers.

- Clarify Return Policies: Ensure you understand the return and exchange policies in case the parts do not meet your expectations.

Step 6: Finalize Purchase and Place Order

After successful negotiations, finalize your order. Ensure that all specifications, quantities, and prices are clearly documented in the purchase order. Double-check all details to prevent any discrepancies that could lead to delays or additional costs.

Step 7: Monitor Delivery and Quality Control

After placing the order, monitor the delivery process closely. Upon receipt, conduct a quality check to confirm that the parts match your specifications and are free from defects.

- Document Any Issues: If discrepancies arise, document them immediately and contact the supplier for resolution.

- Provide Feedback: Share your experience with the supplier, as this can help improve their service and assist other buyers in the future.

By following this checklist, B2B buyers can streamline their procurement process for the 2005 Honda Odyssey radiator outlet size, ensuring a reliable supply chain and reducing the risk of errors.

Comprehensive Cost and Pricing Analysis for 2005 honda odyssey radiator outlet size Sourcing

What Are the Key Cost Components for Sourcing a 2005 Honda Odyssey Radiator Outlet?

When sourcing components like the radiator outlet for a 2005 Honda Odyssey, understanding the cost structure is essential for informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

-

Materials: The radiator outlet is typically made from durable materials such as aluminum or plastic. The choice of material can significantly influence the cost, with aluminum often being more expensive due to its superior heat dissipation properties.

-

Labor: Labor costs can vary depending on the region and complexity of the manufacturing process. In countries with lower labor costs, such as some parts of South America and Africa, sourcing may provide a cost advantage.

-

Manufacturing Overhead: This includes costs associated with factory maintenance, utilities, and indirect labor. Efficient manufacturing processes can reduce these overhead costs, which can be passed on to buyers.

-

Tooling: Initial tooling costs for specialized molds or machinery can be significant, especially for custom or low-volume parts. These costs are often amortized over the production run, affecting unit pricing.

-

Quality Control (QC): Ensuring that parts meet specifications is vital, especially for critical components like radiator outlets. Effective QC processes can add to the cost but are essential for minimizing returns and warranty claims.

-

Logistics: Shipping costs can vary significantly based on the origin of the product and the destination. Incoterms play a crucial role in defining who bears the shipping costs and risks.

-

Margin: Supplier margins can fluctuate based on competition, demand, and market conditions. Understanding the market landscape can help buyers negotiate better pricing.

How Do Price Influencers Impact the Cost of Radiator Outlets?

Several factors can influence the pricing of radiator outlets, particularly for international B2B buyers.

Illustrative image related to 2005 honda odyssey radiator outlet size

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes can lead to discounts. Suppliers often offer tiered pricing, incentivizing larger purchases which can significantly reduce the per-unit cost.

-

Specifications and Customization: Custom specifications can increase costs due to the need for specialized tooling and additional QC measures. Buyers should weigh the benefits of customization against the potential for higher costs.

-

Materials: As mentioned, the choice of materials can affect pricing. Buyers should consider the total cost of ownership, including potential savings from using higher-quality materials that last longer and require fewer replacements.

-

Quality and Certifications: Parts that meet specific industry certifications or quality standards may come at a premium. However, investing in certified products can reduce risks associated with failures or recalls.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Established suppliers may charge more but offer better guarantees and support.

-

Incoterms: Understanding Incoterms is crucial for international buyers. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can impact overall costs.

What Buyer Tips Can Help in Negotiating Costs for Radiator Outlets?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to better pricing and terms.

-

Negotiation: Always approach negotiations with a clear understanding of your requirements and the market landscape. Leverage your purchasing volume and long-term partnership potential to negotiate better deals.

-

Cost-Efficiency: Evaluate the total cost of ownership rather than just the purchase price. Consider factors like maintenance, longevity, and warranty when assessing the value of a radiator outlet.

-

Pricing Nuances for International Buyers: Be mindful of currency fluctuations, tariffs, and import duties that can affect the final cost. Building relationships with suppliers who understand your market can also yield better terms.

-

Research and Compare: Use multiple sources to gather pricing data and quality information. This can provide leverage during negotiations and help identify the best value suppliers.

By understanding the cost structure, price influencers, and negotiation strategies, B2B buyers can make more informed purchasing decisions when sourcing radiator outlets for the 2005 Honda Odyssey. This comprehensive approach can lead to improved profitability and operational efficiency.

Alternatives Analysis: Comparing 2005 honda odyssey radiator outlet size With Other Solutions

Exploring Alternatives for the 2005 Honda Odyssey Radiator Outlet Size

In the automotive industry, particularly for B2B buyers focusing on vehicle maintenance and parts procurement, understanding the available alternatives to specific components is essential. This section compares the radiator outlet size of the 2005 Honda Odyssey with alternative solutions that serve similar cooling needs, providing insights into their performance, cost, and usability.

Comparison Table

| Comparison Aspect | 2005 Honda Odyssey Radiator Outlet Size | Aluminum Radiators | Aftermarket Plastic Radiators |

|---|---|---|---|

| Performance | Efficient cooling; OEM design | Excellent heat dissipation | Adequate cooling, but may vary |

| Cost | Moderate ($217 – $331) | Higher initial investment | Lower cost ($150 – $250) |

| Ease of Implementation | Designed for direct fit; minimal adjustments required | Requires some modifications | Direct fit; easy installation |

| Maintenance | Low; OEM reliability | Low; durable, but can corrode | Higher; prone to wear and tear |

| Best Use Case | Replacement in Honda Odyssey vehicles | Performance upgrades or racing | Budget-friendly repairs |

Detailed Breakdown of Alternatives

Aluminum Radiators

Aluminum radiators are known for their superior heat dissipation and lightweight properties. They offer better performance than standard OEM radiators, making them an excellent choice for high-performance applications or vehicles subjected to extreme conditions. However, they generally come at a higher cost, which could be a consideration for B2B buyers focused on budget constraints. Installation might require some modifications, especially if the radiator is not designed specifically for the vehicle model.

Illustrative image related to 2005 honda odyssey radiator outlet size

Aftermarket Plastic Radiators

Aftermarket plastic radiators provide a cost-effective solution for replacing the original components. They are significantly cheaper than aluminum options, making them attractive for budget-conscious buyers. However, the performance may not match that of the OEM aluminum or even the standard Honda radiator, and longevity could be an issue, as they may wear out faster under heavy use. These radiators are designed for direct fit, ensuring ease of installation, which is beneficial for quick repairs.

Conclusion

When choosing the right solution for the 2005 Honda Odyssey radiator outlet size, B2B buyers should carefully consider their specific needs and priorities. If performance and reliability are paramount, investing in the original or an aluminum radiator may be the best choice. Conversely, for those focused on cost savings and quick fixes, aftermarket plastic radiators can provide a viable alternative, albeit with potential trade-offs in durability and efficiency. Ultimately, understanding the unique requirements of the vehicle and the environment it operates in will guide buyers toward the most appropriate solution.

Essential Technical Properties and Trade Terminology for 2005 honda odyssey radiator outlet size

What Are the Key Technical Properties of the 2005 Honda Odyssey Radiator Outlet Size?

When sourcing components like the radiator outlet for the 2005 Honda Odyssey, understanding specific technical properties is essential for ensuring compatibility and performance. Below are critical specifications that international B2B buyers should consider:

1. Material Grade

The radiator outlet is typically made from high-grade aluminum or plastic composites. Aluminum offers excellent thermal conductivity and resistance to corrosion, while plastic variants are lightweight and resistant to wear. Selecting the right material is crucial for durability and performance, particularly in varying climates prevalent in markets like Africa and the Middle East.

2. Outlet Diameter

The outlet diameter is a critical measurement, often specified in millimeters. For the 2005 Honda Odyssey, the outlet diameter is approximately 32 mm. This specification is vital to ensure proper fitment with hoses and other cooling system components. Incorrect sizing can lead to coolant leaks or overheating, which could severely impact vehicle performance.

3. Pressure Rating

Radiators operate under specific pressure conditions to maintain optimal coolant flow. The pressure rating typically ranges between 15-20 psi for a standard radiator. Knowing this rating helps buyers assess the radiator’s ability to withstand pressure fluctuations, which can be common in regions with extreme temperature variations.

4. Connector Type

The connector type, whether it be a slip fit or threaded, is essential for ensuring a secure connection with hoses. For the 2005 Honda Odyssey, understanding the connector type helps prevent leaks and ensures that the cooling system operates efficiently. This is especially important for buyers who may be dealing with varying hose types across different regions.

Illustrative image related to 2005 honda odyssey radiator outlet size

5. Heat Exchange Capacity

Heat exchange capacity refers to the radiator’s ability to dissipate heat, which is critical for engine performance. A radiator designed for the 2005 Honda Odyssey typically has a heat exchange capacity rated at approximately 1,500-2,000 BTU per hour. This specification is crucial for buyers looking to maintain optimal engine temperatures, particularly in warmer climates.

6. Compatibility with Internal Components

Understanding whether the radiator outlet is compatible with internal components like oil or transmission coolers is essential. Some models may feature integrated cooling systems that can enhance overall vehicle efficiency. Knowing the compatibility can assist buyers in making informed decisions about comprehensive cooling solutions.

What Are Common Trade Terms Related to the 2005 Honda Odyssey Radiator Outlet?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are several key terms relevant to the radiator outlet:

1. OEM (Original Equipment Manufacturer)

This term refers to parts made by the original manufacturer of the vehicle. OEM parts are often preferred for their guaranteed compatibility and quality, essential for maintaining the reliability of vehicles like the Honda Odyssey.

2. MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units a supplier is willing to sell. Understanding MOQ is critical for buyers, especially when planning inventory for markets with varying demand patterns.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and availability for specific products. Crafting a detailed RFQ can streamline the procurement process and help buyers secure competitive pricing.

4. Incoterms

These are international commercial terms that define the responsibilities of buyers and sellers in shipping transactions. Familiarity with Incoterms helps in understanding shipping costs, risks, and the transfer of ownership.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Knowing lead times is crucial for inventory management and ensuring that replacement parts are available when needed.

6. Aftermarket Parts

Aftermarket parts are components made by companies other than the original manufacturer. While they can be less expensive, buyers must ensure they meet quality standards to avoid issues with fit and performance.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing radiator outlets for the 2005 Honda Odyssey, ensuring compatibility and reliability in their automotive supply chains.

Navigating Market Dynamics and Sourcing Trends in the 2005 honda odyssey radiator outlet size Sector

What Are the Current Market Dynamics Influencing the 2005 Honda Odyssey Radiator Outlet Size Sector?

The market for the 2005 Honda Odyssey radiator outlet size is experiencing significant shifts driven by various global factors. One of the primary drivers is the increasing demand for reliable automotive components across emerging markets, particularly in regions like Africa, South America, the Middle East, and Europe. As vehicle ownership rises in these areas, so does the need for high-quality replacement parts. B2B buyers are particularly focused on sourcing durable and efficient radiators and their components, given the harsh driving conditions often encountered in these regions.

Illustrative image related to 2005 honda odyssey radiator outlet size

Emerging B2B technologies are reshaping sourcing strategies, with platforms that facilitate direct connections between manufacturers and buyers becoming more prevalent. Digital supply chain management tools and advanced analytics are enabling international buyers to streamline procurement processes, allowing for better forecasting and inventory management. Additionally, the trend towards just-in-time (JIT) inventory systems helps minimize carrying costs and reduce waste, appealing to cost-conscious buyers.

Moreover, the competitive landscape is evolving, with suppliers emphasizing quality assurance and certification to meet the rising standards of international buyers. As a result, B2B buyers must be vigilant in evaluating suppliers based on their product specifications, including dimensions and compatibility of the radiator outlet size. Furthermore, the shift towards e-commerce platforms has simplified the sourcing process, enabling buyers to access a broader range of products and suppliers with ease.

How Is Sustainability and Ethical Sourcing Impacting the B2B Landscape for Radiator Components?

Sustainability is increasingly becoming a critical consideration in the sourcing of automotive components, including those for the 2005 Honda Odyssey. The environmental impact of manufacturing processes and the lifecycle of automotive parts are drawing more scrutiny from B2B buyers. As global awareness of environmental issues rises, buyers are prioritizing suppliers who demonstrate a commitment to sustainable practices.

Illustrative image related to 2005 honda odyssey radiator outlet size

Ethical sourcing is also gaining traction, with companies striving to ensure their supply chains are free from exploitation and environmental harm. B2B buyers are looking for partners that hold certifications such as ISO 14001 for environmental management or those that use recyclable materials in their products. This not only helps reduce the carbon footprint but also enhances the buyer’s brand reputation in an increasingly eco-conscious market.

Furthermore, suppliers are responding to this demand by investing in greener technologies and materials. For instance, the use of recycled aluminum in radiator production can significantly reduce energy consumption and emissions. Buyers should actively seek out suppliers who can provide transparency regarding their sourcing practices and environmental impact, ensuring that their procurement choices align with their corporate social responsibility goals.

What Historical Factors Have Shaped the Current B2B Landscape for Radiator Sourcing?

The evolution of the radiator market for vehicles like the 2005 Honda Odyssey can be traced back to significant advancements in automotive technology and manufacturing processes over the past few decades. Initially, radiators were primarily made from brass and copper, which offered excellent thermal conductivity but were costly and heavy. As manufacturers sought to reduce costs and improve efficiency, aluminum became the material of choice due to its lightweight properties and resistance to corrosion.

The introduction of computerized manufacturing processes and precision engineering has further enhanced the quality and reliability of radiator components. This shift has allowed for tighter tolerances and better performance, which is critical for modern vehicles that demand higher efficiency and durability. The globalization of the supply chain has also played a pivotal role, enabling international buyers to access a broader range of products and suppliers, thereby increasing competition and driving innovation in the market.

Today, the focus on quality, sustainability, and ethical sourcing continues to evolve, shaping the decisions of B2B buyers in the automotive parts sector. Understanding these historical trends is essential for navigating the current landscape and making informed sourcing decisions.

Illustrative image related to 2005 honda odyssey radiator outlet size

Frequently Asked Questions (FAQs) for B2B Buyers of 2005 honda odyssey radiator outlet size

-

How do I determine the radiator outlet size for a 2005 Honda Odyssey?

To find the radiator outlet size for a 2005 Honda Odyssey, it’s essential to consult technical specifications provided by manufacturers or detailed service manuals. Typically, this model features a 1.5-inch outlet size, but verifying with a reliable supplier or parts distributor is advisable to ensure compatibility. Additionally, checking online databases or automotive forums can provide insights from other users who have sourced similar parts. Accurate measurements can help avoid costly mistakes when purchasing or replacing components. -

What is the best replacement radiator for a 2005 Honda Odyssey?

When sourcing a replacement radiator for a 2005 Honda Odyssey, consider options like the Duralast Radiator B2806, known for its durability and performance. The Nissens Radiator 69477 is another excellent choice, boasting a solid reputation among users for fit and longevity. Evaluate factors such as internal engine oil cooler compatibility and customer reviews to ensure you select a radiator that meets both performance standards and your budget. Always confirm specifications with the supplier to match your vehicle’s requirements. -

What are the common issues with the radiator in a 2005 Honda Odyssey?

Common issues with the 2005 Honda Odyssey radiator include coolant leaks, blockages, and corrosion. Over time, wear and tear can lead to degradation of materials, causing leaks or reduced cooling efficiency. Regular maintenance, including coolant changes and inspections for cracks or signs of wear, can prevent these issues. If you notice overheating or fluid loss, it’s crucial to address these problems promptly to avoid more severe engine damage. -

How can I vet suppliers for Honda Odyssey radiator parts?

To vet suppliers for Honda Odyssey radiator parts, start by checking their industry reputation and customer reviews. Look for suppliers that specialize in automotive parts and have a proven track record in international shipping. Verify certifications and quality assurance processes to ensure they meet international standards. Additionally, request samples or detailed specifications before placing bulk orders to assess product quality firsthand. -

What are typical payment terms in B2B transactions for automotive parts?

Payment terms in B2B transactions for automotive parts can vary widely, but common practices include net 30 or net 60 days after invoice. Some suppliers may require a deposit upfront, especially for large orders or customized parts. It’s essential to establish clear payment terms in the contract, including any penalties for late payments. Using secure payment methods, such as letters of credit or escrow services, can also help mitigate risks in international transactions. -

What is the minimum order quantity (MOQ) for radiator parts?

Minimum order quantities (MOQs) for radiator parts can vary by supplier, often depending on production capabilities and inventory levels. Generally, MOQs for automotive parts range from 50 to 100 units, but some suppliers may offer lower quantities for first-time buyers or sample orders. Discuss your specific needs with potential suppliers to negotiate terms that work for both parties, especially if you are exploring bulk purchases for resale. -

How do I handle logistics and shipping for radiator orders?

When managing logistics and shipping for radiator orders, choose a reliable freight forwarder familiar with international trade regulations. Ensure that all necessary documentation, such as invoices and customs forms, is prepared accurately to avoid delays at customs. Consider shipping options that balance cost and delivery time, such as sea freight for larger orders or air freight for urgent shipments. Always track shipments closely and maintain communication with suppliers to address any potential issues proactively. -

What quality assurance measures should I expect from suppliers?

Expect suppliers to implement rigorous quality assurance measures, including regular inspections and testing of radiator parts. Inquire about certifications, such as ISO 9001, which indicate adherence to international quality standards. Suppliers should provide documentation of testing procedures, such as pressure tests and leak tests, to ensure product reliability. Establish clear quality expectations in your contract, and consider conducting your inspections if sourcing significant quantities or high-value items.

Top 5 2005 Honda Odyssey Radiator Outlet Size Manufacturers & Suppliers List

1. Honda – Radiator & Components

Domain: honda.oempartsonline.com

Registered: 2015 (10 years)

Introduction: Radiator & Components for 2005 Honda Odyssey | OEM Parts Online Orders Typically Ship in 2-4 Business Days Depending on Inventory. Due to Global Shortages, Some Parts Are On Backorder. Vehicle: 2005 Honda Odyssey LX 3.5L V6 – Gas. Categories: Cooling System, Radiator & Components.

2. Tru-Cool – LPD 4452 Transmission Oil Cooler

Domain: odyclub.com

Registered: 2001 (24 years)

Introduction: Tru-Cool LPD 4452 Transmission Oil Cooler; Dimensions: 5″ wide, 11″ high, .” thick; Rated GVW: 14,500; Rated BTU capacity: 9,800; Includes approximately 4 feet of ATF hose, couplers, (4) hose clamps, miscellaneous hardware; Mounting brackets included; Recommended: Honda ATF (do not substitute); Installation requires standard mechanic’s tools.

3. Honda – Genuine OEM Radiators & Hoses

Domain: hondapartsconnection.com

Registered: 2017 (8 years)

Introduction: This company, Honda – Genuine OEM Radiators & Hoses, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Dayco – Radiator Hoses

Domain: shop.advanceautoparts.com

Registered: 1997 (28 years)

Introduction: 2005 Honda Odyssey Radiator Hoses – High-quality radiator hoses for optimal performance. Options include By-Pass Hoses and Coolant Hoses. Top-rated brands like Dayco with prices starting at $7.99. Average price around $20.45, ranging from $7.99 to $25.99. Popular choices include Curved Radiator Hoses made of EPDM Rubber, 22.5″ Long, 1.22″ Diameter starting at $17.99. Dayco Radiator Hose (Part No.G…

5. Honda – Lower Radiator Coolant Hose

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”:”For 2005-2006 Honda Odyssey 3.5L Lower Radiator Coolant Hose”,”condition”:”New”,”price”:”$36.19″,”shipping”:”Free 2-4 day delivery”,”quantity_available”:3,”item_number”:”205094380312″,”molded”:”Yes”,”payment_options”:”4 interest-free payments of $9.05 available with Klarna”,”warranty”:”1-year accident protection plan from Allstate for $5.99″}

Strategic Sourcing Conclusion and Outlook for 2005 honda odyssey radiator outlet size

How Can Strategic Sourcing Enhance Your Procurement of 2005 Honda Odyssey Radiators?

In the competitive landscape of automotive parts sourcing, understanding the specific requirements, such as the radiator outlet size for the 2005 Honda Odyssey, is crucial for international buyers. This knowledge not only ensures compatibility but also facilitates better inventory management and cost efficiency. Strategic sourcing empowers businesses to optimize their procurement processes by fostering relationships with reliable suppliers who can provide high-quality parts at competitive prices.

Additionally, incorporating preventive maintenance insights can significantly enhance the longevity of the vehicles serviced. For instance, regularly replacing radiator hoses and coolant can prevent costly repairs and downtime, underscoring the importance of quality parts. By prioritizing these factors, buyers can enhance customer satisfaction and reduce operational risks.

As you navigate the global marketplace, particularly in regions like Africa, South America, the Middle East, and Europe, consider leveraging strategic sourcing to build resilient supply chains. Engaging with trusted suppliers and investing in quality components will position your business for long-term success. Take action today to ensure that your procurement strategies align with industry best practices, paving the way for growth and sustainability in your automotive parts business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.