2 Pump Hydraulic Setup Diagram Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for 2 pump hydraulic setup diagram

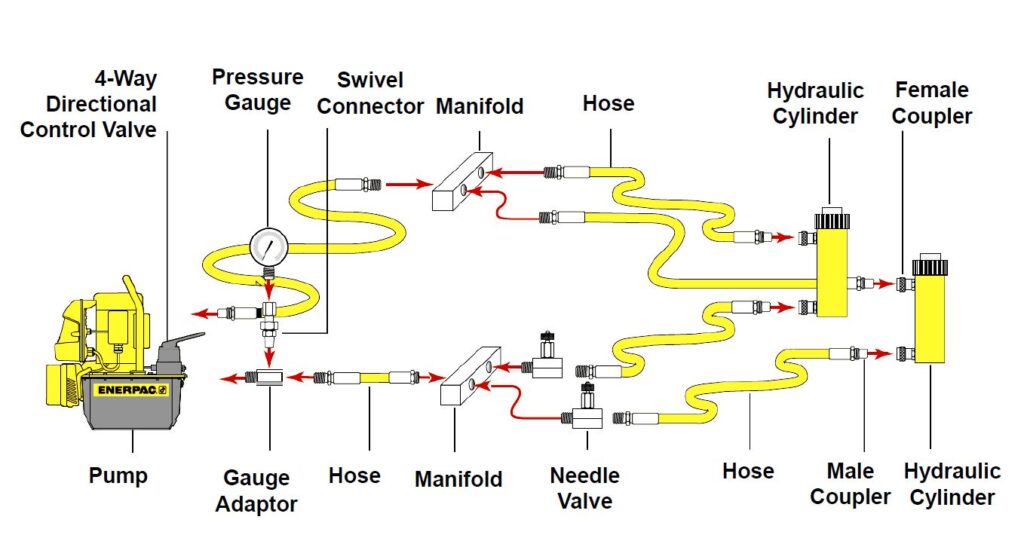

In the competitive landscape of hydraulic systems, understanding the intricacies of a 2 pump hydraulic setup diagram is crucial for B2B buyers looking to enhance operational efficiency and performance. With diverse applications ranging from automotive to industrial machinery, sourcing the right hydraulic setup can pose significant challenges. This guide aims to demystify the complexities of hydraulic systems by providing a comprehensive analysis of various types of 2 pump setups, their applications, and essential components.

International buyers from regions such as Africa, South America, the Middle East, and Europe, including markets like Nigeria and Vietnam, will find invaluable insights into supplier vetting processes, cost considerations, and best practices for implementation. By equipping decision-makers with the knowledge to differentiate between various hydraulic kits and understand their specifications, this guide empowers informed purchasing decisions.

Furthermore, we delve into installation best practices, maintenance tips, and troubleshooting advice, ensuring that businesses can maximize the lifespan and performance of their hydraulic systems. As you navigate the global market for hydraulic solutions, this guide serves as your essential resource for achieving operational excellence and staying ahead of the competition.

Understanding 2 pump hydraulic setup diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

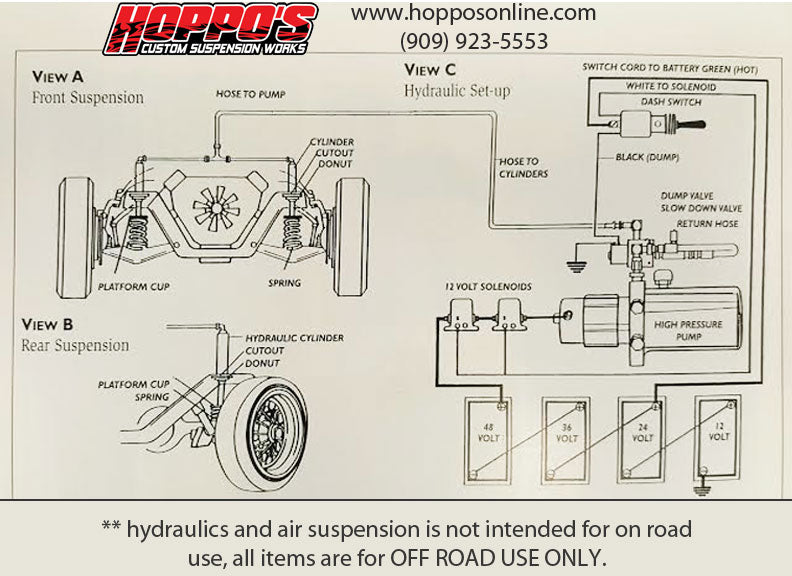

| Front/Back/Side/Side Kit | Two pumps, four dumps, multiple solenoids, versatile switch options. | Automotive customization, lowriders. | Pros: High versatility; Cons: Complex installation. |

| 2 Pump CCE Kit | Enhanced power, chrome fittings, designed for performance. | Competitive automotive events. | Pros: High performance; Cons: Higher cost. |

| 2 Pump Mini Truck Kit | Compact design, ideal for smaller vehicles. | Smaller vehicles, urban applications. | Pros: Space-efficient; Cons: Limited power. |

| 2 Pump Raw Whammy Kit | Focused on extreme performance, includes specialized components. | High-performance customization. | Pros: Maximum lift; Cons: Requires expert installation. |

| 2 Pump 3 Dump Setup | Specific control over each dump, adaptable wiring options. | Versatile applications in customization. | Pros: Customizable; Cons: Wiring complexity. |

What are the Key Characteristics of a Front/Back/Side/Side Kit?

The Front/Back/Side/Side Kit is characterized by its two pumps and four dumps, which allow for comprehensive control over vehicle elevation and movement. This setup is particularly beneficial for lowriders and automotive enthusiasts who require nuanced control for various stunts and display purposes. B2B buyers should consider the complexity of installation and maintenance, which may necessitate professional assistance.

How Does the 2 Pump CCE Kit Enhance Performance?

The 2 Pump CCE Kit is designed for those seeking enhanced power and performance in their hydraulic systems. Featuring chrome fittings and robust components, this kit is ideal for competitive automotive events where performance is crucial. Buyers should be aware that while this kit offers superior capabilities, it often comes at a higher price point, which may affect budget considerations.

What Makes the 2 Pump Mini Truck Kit Ideal for Smaller Vehicles?

The 2 Pump Mini Truck Kit is tailored for compact vehicles, making it an excellent choice for urban applications where space is at a premium. This kit retains essential functionalities while offering a more compact design, making it appealing to businesses focusing on smaller automotive modifications. However, its limited power output may not suit all applications, so buyers should evaluate their specific needs carefully.

Why Choose the 2 Pump Raw Whammy Kit for Extreme Performance?

The 2 Pump Raw Whammy Kit is engineered for those who demand extreme performance from their hydraulic systems. It includes specialized components that enhance lifting capabilities and overall performance. B2B buyers must consider that this setup typically requires expert installation, which could lead to additional costs and logistics.

How Can the 2 Pump 3 Dump Setup Provide Customization?

The 2 Pump 3 Dump Setup allows users to control each dump individually, offering flexibility for various customization needs. This setup is particularly suited for businesses that focus on unique automotive modifications. However, the complexity of wiring can be a drawback, making it essential for buyers to either possess technical skills or seek professional help for installation.

Key Industrial Applications of 2 pump hydraulic setup diagram

| Industry/Sector | Specific Application of 2 pump hydraulic setup diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Heavy equipment operation, such as excavators and cranes | Enhanced lifting and maneuverability, leading to increased efficiency on job sites | Durability of components, compatibility with existing machinery, and local support services |

| Automotive | Lowrider and custom vehicle hydraulic systems | Customization and improved vehicle performance, attracting niche markets | Availability of specialized kits, ease of installation, and compliance with local regulations |

| Agriculture | Fertilizer and pesticide spraying systems | Improved crop yield through efficient application methods | Resistance to harsh environmental conditions and ease of maintenance |

| Marine and Maritime | Boat lifting and docking systems | Safety and efficiency in handling heavy marine equipment | Corrosion resistance, adaptability to various boat sizes, and service availability in coastal regions |

| Mining and Resource Extraction | Load handling and transportation systems | Increased productivity and safety in transporting materials | Strength of hydraulic components, sourcing from reputable suppliers, and compliance with safety standards |

How is the 2 Pump Hydraulic Setup Diagram Used in Construction?

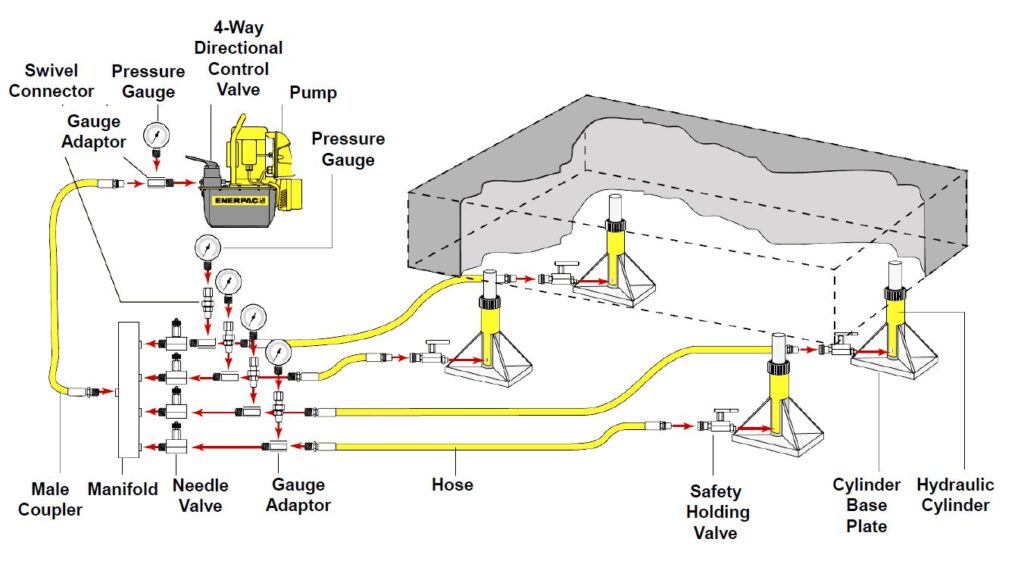

In the construction industry, the 2 pump hydraulic setup diagram is pivotal for operating heavy machinery like excavators and cranes. These systems allow for precise control over lifting and lowering operations, enhancing overall efficiency on job sites. For international buyers, especially in Africa and South America, sourcing durable hydraulic components that can withstand challenging conditions is crucial. Additionally, compatibility with existing machinery is a key consideration, as well as the availability of local support services to ensure minimal downtime.

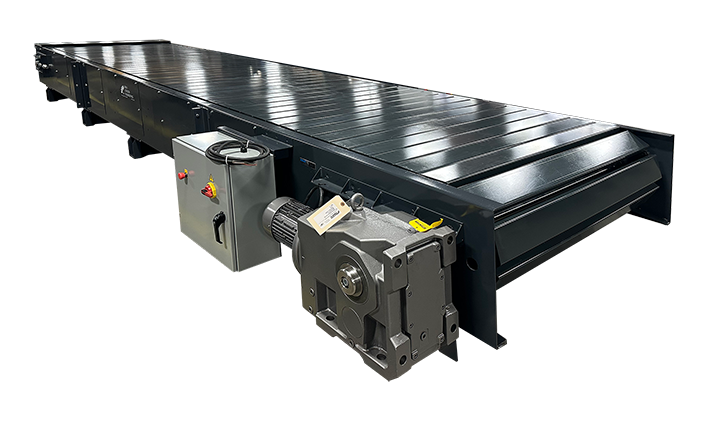

Illustrative image related to 2 pump hydraulic setup diagram

What Role Does the 2 Pump Hydraulic Setup Play in Automotive Customization?

The automotive sector utilizes the 2 pump hydraulic setup diagram primarily for lowrider and custom vehicle applications. This setup enables enthusiasts to achieve desired ride heights and performance characteristics, thus catering to a niche market. Buyers in Europe and the Middle East should focus on sourcing specialized kits that offer ease of installation and compliance with local automotive regulations. The ability to customize vehicles not only enhances aesthetics but also boosts performance, making it an attractive proposition for businesses in this sector.

How is the 2 Pump Hydraulic Setup Beneficial in Agriculture?

In agriculture, the 2 pump hydraulic setup diagram facilitates the operation of spraying systems for fertilizers and pesticides. This application ensures precise and efficient distribution of agricultural chemicals, ultimately leading to improved crop yields. Buyers from regions like Africa and South America must consider the resistance of hydraulic components to harsh environmental conditions, as well as the ease of maintenance to ensure longevity and reliability in the field.

What Advantages Does the 2 Pump Hydraulic Setup Offer in Marine Applications?

The marine and maritime industries utilize the 2 pump hydraulic setup diagram for boat lifting and docking systems. These setups enhance safety and efficiency in handling heavy marine equipment, which is critical in busy ports and marinas. When sourcing these systems, businesses should prioritize components that are corrosion-resistant and adaptable to various boat sizes. Additionally, having access to service providers in coastal regions is essential for maintaining equipment functionality.

How Does the 2 Pump Hydraulic Setup Improve Mining Operations?

In the mining and resource extraction sectors, the 2 pump hydraulic setup diagram is integral for load handling and transportation systems. This setup increases productivity and safety when transporting heavy materials across challenging terrains. Buyers should focus on the strength and durability of hydraulic components, ensuring they can withstand the rigors of mining operations. Sourcing from reputable suppliers who comply with safety standards is also vital for international buyers looking to enhance operational efficiency.

3 Common User Pain Points for ‘2 pump hydraulic setup diagram’ & Their Solutions

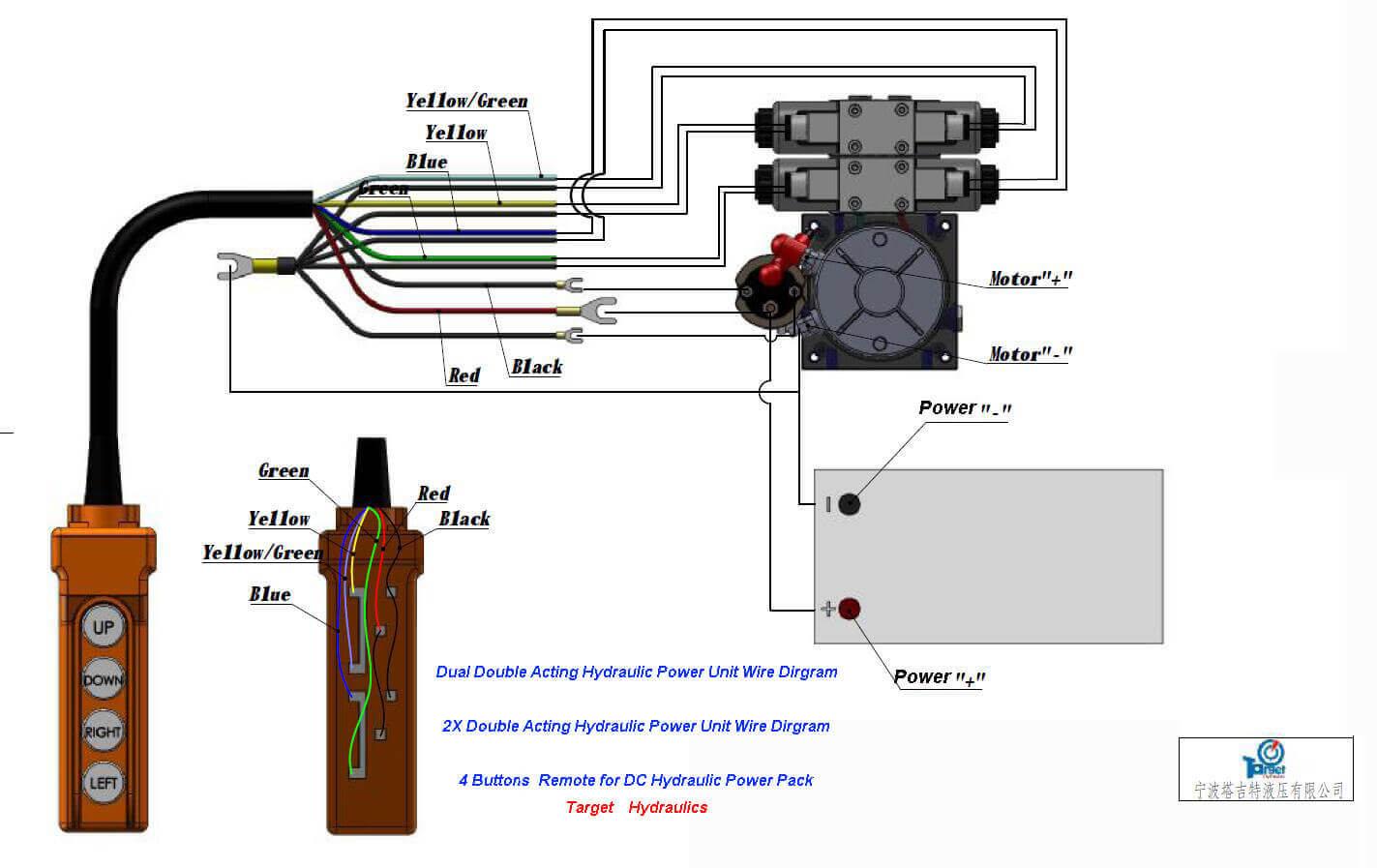

Scenario 1: Difficulty in Wiring the 2 Pump Hydraulic System

The Problem: Many B2B buyers encounter challenges when wiring their 2 pump hydraulic systems. This often stems from a lack of clear diagrams or instructions tailored to their specific setup, which can lead to improper connections, malfunctioning equipment, or even safety hazards. As buyers from diverse regions, such as Africa and South America, may not have easy access to local support or resources, they often feel overwhelmed when faced with the intricate wiring required for their hydraulic systems.

The Solution: To address wiring challenges, buyers should seek detailed wiring diagrams that correspond with their specific configurations, such as 2 pumps and 4 dumps. Engaging with reputable suppliers who provide comprehensive installation manuals and diagrams can significantly ease the process. Additionally, buyers can benefit from online forums and communities dedicated to hydraulic systems, where they can exchange tips and solutions. For a practical approach, consider organizing a workshop or training session with experienced technicians to walk through the wiring process. This hands-on experience can build confidence and ensure that the setup is executed correctly.

Scenario 2: Incompatibility with Existing Equipment

The Problem: B2B buyers often face the issue of incompatibility between their existing hydraulic components and new 2 pump hydraulic kits. This is particularly prevalent in regions where equipment standards may vary, leading to mismatched fittings, hoses, or solenoids. The frustration of investing in a new system only to discover it does not integrate well with their current setup can result in costly delays and operational inefficiencies.

The Solution: To mitigate compatibility issues, buyers should conduct thorough assessments of their existing hydraulic systems before purchasing new components. This includes checking specifications such as hose sizes, fitting types, and pressure ratings. It’s advisable to work with suppliers who offer customizable kits or modular components that can be tailored to fit existing equipment. Furthermore, requesting technical support or consultation from suppliers can provide clarity on whether a specific 2 pump kit will integrate seamlessly with current setups. Establishing a relationship with a knowledgeable supplier can also facilitate smoother future upgrades or replacements.

Scenario 3: Installation Challenges and Lack of Professional Support

The Problem: A common pain point for international buyers is the lack of professional installation support for 2 pump hydraulic systems. In many regions, particularly in emerging markets, skilled technicians may be scarce, and buyers might struggle with DIY installations. This can lead to improper setups that not only affect performance but also pose safety risks.

The Solution: To overcome installation challenges, buyers should prioritize sourcing hydraulic kits that come with clear, comprehensive installation instructions and diagrams. When possible, they should also consider hiring local hydraulic professionals or technicians who have experience with similar setups. Engaging in partnerships with local technical schools or training centers can also be beneficial, as these institutions often seek real-world projects for their students. For buyers in remote areas, investing in virtual training sessions with experts can provide valuable insights and support, helping them to successfully install and maintain their 2 pump hydraulic systems with confidence.

Strategic Material Selection Guide for 2 pump hydraulic setup diagram

What Are the Key Materials for a 2 Pump Hydraulic Setup?

When selecting materials for a 2 pump hydraulic setup, it is essential to consider their properties, suitability, and compliance with international standards. The following analysis covers four common materials used in hydraulic systems, focusing on their performance characteristics, pros and cons, and implications for international buyers.

Steel: The Backbone of Hydraulic Systems

Steel is a widely used material in hydraulic setups due to its excellent strength and durability. It typically has high temperature and pressure ratings, making it suitable for demanding applications. Steel is also resistant to deformation under load, which is critical for maintaining system integrity.

Illustrative image related to 2 pump hydraulic setup diagram

Pros: Steel offers high tensile strength and is relatively cost-effective compared to other materials. It is readily available and can be easily fabricated into various shapes.

Cons: Steel is susceptible to corrosion if not properly treated, which can lead to system failures over time. Additionally, its weight can be a disadvantage in mobile applications.

Impact on Application: Steel is compatible with a wide range of hydraulic fluids but may require protective coatings in corrosive environments.

Considerations for International Buyers: Compliance with standards such as ASTM A36 or DIN 17100 is essential. Buyers in regions like Africa and South America should ensure that local suppliers can provide certified steel products.

Aluminum: Lightweight and Corrosion-Resistant

Aluminum is increasingly popular in hydraulic applications due to its lightweight nature and inherent corrosion resistance. It is particularly beneficial in applications where weight reduction is critical, such as in automotive or aerospace industries.

Pros: Aluminum’s low density makes it easier to handle and install, reducing overall system weight. It also has good thermal conductivity, which can be advantageous in heat dissipation.

Cons: While aluminum has decent strength, it is not as strong as steel, which may limit its use in high-pressure applications. Additionally, it can be more expensive than steel.

Illustrative image related to 2 pump hydraulic setup diagram

Impact on Application: Aluminum is compatible with many hydraulic fluids but may not be suitable for high-temperature applications without special treatments.

Considerations for International Buyers: Buyers should look for compliance with standards such as ASTM B221 or JIS H4000. In regions like the Middle East, where high temperatures are common, ensuring aluminum’s suitability for specific applications is crucial.

Plastic Composites: Versatile and Cost-Effective

Plastic composites, such as polyamide or polyethylene, are gaining traction in hydraulic systems due to their versatility and resistance to corrosion. These materials are often used in components like hoses and fittings.

Illustrative image related to 2 pump hydraulic setup diagram

Pros: Plastic composites are lightweight and resistant to many chemicals, making them ideal for various hydraulic fluids. They are also less expensive than metals, providing a cost-effective solution.

Cons: These materials typically have lower pressure ratings compared to metals, which may limit their use in high-pressure systems. They can also be less durable in extreme temperature conditions.

Impact on Application: Plastic composites are suitable for low to moderate-pressure applications and are compatible with a wide range of hydraulic fluids.

Considerations for International Buyers: Compliance with standards such as ASTM D638 or ISO 527 is essential for ensuring product quality. Buyers in Europe should also consider EU regulations regarding material safety.

Stainless Steel: The Premium Choice for Corrosion Resistance

Stainless steel combines the strength of steel with enhanced corrosion resistance, making it ideal for hydraulic applications exposed to harsh environments. It is often used in high-end systems where reliability is paramount.

Pros: Stainless steel offers excellent durability and resistance to corrosion, making it suitable for use in various environments, including marine applications.

Cons: The main drawback is the higher cost compared to regular steel and aluminum. Additionally, stainless steel can be more challenging to machine and fabricate.

Impact on Application: Stainless steel is compatible with a wide range of hydraulic fluids and can withstand high pressures and temperatures.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A312 or DIN 17440. In regions like Africa and South America, where corrosive environments may be prevalent, investing in stainless steel can lead to long-term savings.

Summary Table of Material Selection

| Material | Typical Use Case for 2 Pump Hydraulic Setup Diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, cylinders | High strength and cost-effective | Susceptible to corrosion | Medium |

| Aluminum | Lightweight applications, automotive systems | Lightweight and corrosion-resistant | Lower strength than steel | High |

| Plastic Composites | Hoses and fittings | Versatile and cost-effective | Lower pressure ratings | Low |

| Stainless Steel | High-end, corrosive environments | Excellent corrosion resistance | Higher cost and machining complexity | High |

This guide serves as a strategic resource for B2B buyers looking to make informed decisions regarding material selection for their hydraulic systems, ensuring compatibility, compliance, and performance in diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for 2 pump hydraulic setup diagram

What are the Main Stages in the Manufacturing Process of a 2 Pump Hydraulic Setup?

The manufacturing process for a 2 pump hydraulic setup involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring that the final product meets both performance and quality standards, making it essential for B2B buyers to understand these processes.

Material Preparation: Sourcing Quality Components

The first step in the manufacturing process is the sourcing and preparation of materials. High-quality raw materials such as steel, aluminum, and various polymers are essential for the durability and efficiency of hydraulic components. Suppliers often undergo a rigorous selection process to ensure that materials meet industry standards. For instance, chrome finishes are commonly applied to pumps and fittings to enhance corrosion resistance and aesthetics.

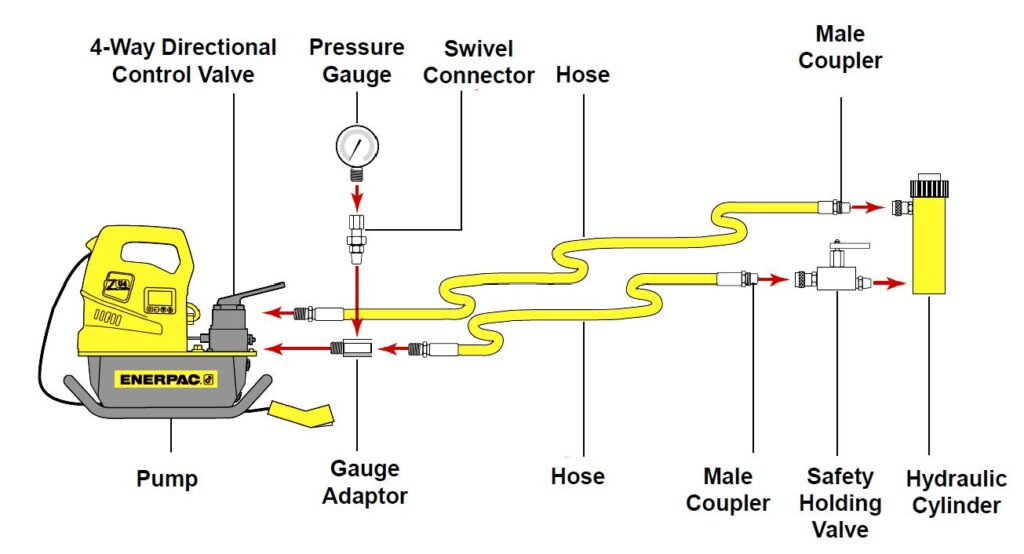

Illustrative image related to 2 pump hydraulic setup diagram

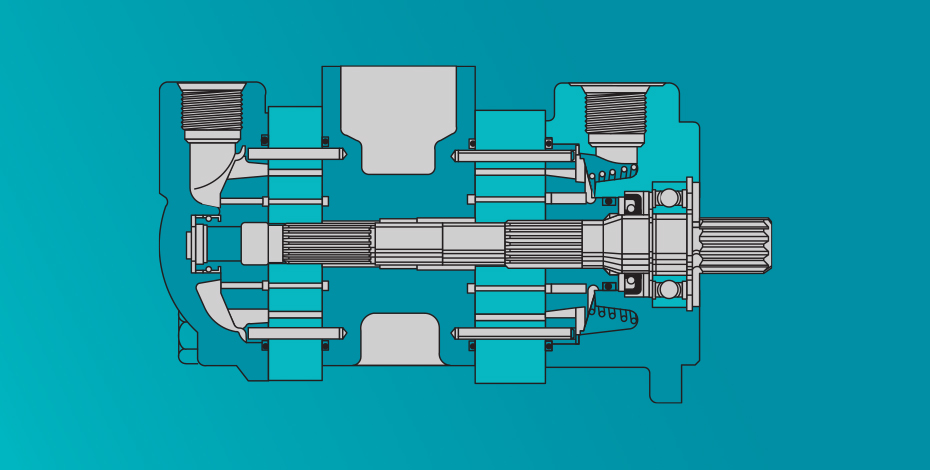

Forming: Precision Engineering Techniques

Once materials are prepared, forming techniques such as machining, stamping, and welding come into play. These processes require precision engineering to create components that fit together seamlessly. Advanced CNC (Computer Numerical Control) machines are typically used for machining, allowing for high accuracy in producing pump bodies and cylinders. Additionally, forming techniques such as extrusion may be employed for producing hoses and other fluid conveyance components.

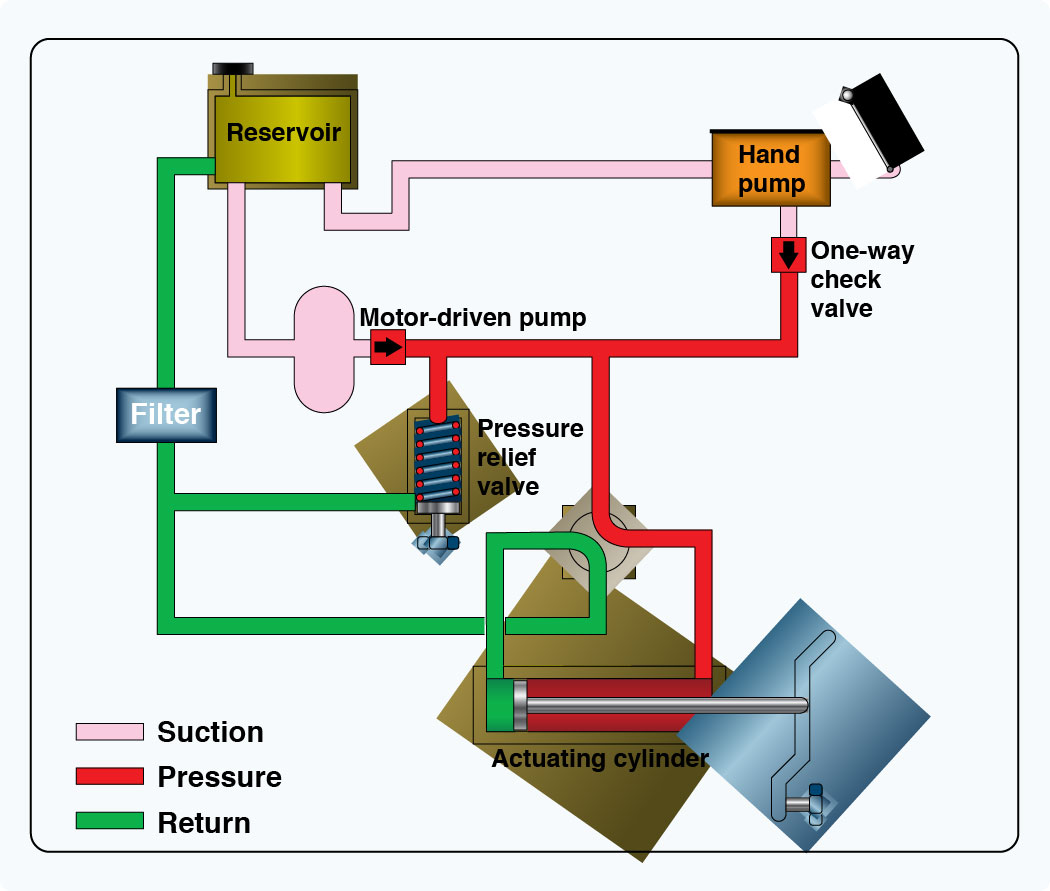

Assembly: Ensuring Functional Integrity

The assembly stage is where individual components are brought together to create the complete hydraulic system. This process involves carefully installing pumps, solenoids, cylinders, and control switches according to specific diagrams and engineering specifications. Skilled technicians ensure that all parts are aligned correctly and securely fastened to prevent leaks and failures. The assembly process may also include the installation of safety features, such as pressure relief valves, to enhance operational safety.

Finishing: Quality Control and Aesthetic Touches

Finishing involves the application of coatings, such as powder coating or anodizing, which serve both functional and aesthetic purposes. These coatings protect against wear and environmental factors, ensuring the longevity of the hydraulic setup. Quality checks are conducted during this stage to verify that all parts meet the required specifications and standards.

How is Quality Assurance Implemented in the Manufacturing of Hydraulic Systems?

Quality assurance (QA) is a critical component of manufacturing, especially in the hydraulic industry, where performance and safety are paramount. Implementing an effective QA system involves adherence to both international standards and industry-specific certifications.

What International Standards Are Relevant for Hydraulic Manufacturing?

International standards such as ISO 9001 provide a framework for quality management systems. Compliance with these standards ensures that manufacturers establish processes for continuous improvement, customer satisfaction, and effective resource management. Additionally, industry-specific certifications like CE marking in Europe and API standards in North America add credibility and demonstrate compliance with safety and performance requirements.

What are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral to the manufacturing process and typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify that they meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are performed to ensure that components are being produced to the required specifications.

- Final Quality Control (FQC): Before products are shipped, a comprehensive inspection is conducted, including functional testing to ensure the hydraulic system operates as intended.

What Common Testing Methods are Used in Hydraulic System Manufacturing?

Testing methods for hydraulic systems include pressure testing, leak testing, and performance testing under various conditions. Pressure tests assess the ability of components to withstand operational stresses, while leak tests ensure that all connections are secure. Performance tests simulate real-world conditions to evaluate the system’s efficiency and responsiveness.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must conduct due diligence when selecting suppliers to ensure that their quality control processes meet international standards. Here are several methods to verify supplier QC:

What are the Best Practices for Auditing Suppliers?

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control practices. These audits should focus on reviewing quality management systems, production processes, and compliance with relevant standards. Buyers may also request documentation of previous audits or certifications to gain insight into the supplier’s quality assurance processes.

How Can Buyers Access Quality Control Reports?

Requesting quality control reports from suppliers can provide transparency into their manufacturing practices. These reports should detail the results of various tests and inspections conducted during production. Buyers should look for consistency in these reports and any corrective actions taken in response to non-conformities.

What Role Does Third-Party Inspection Play in Quality Assurance?

Engaging third-party inspection services can add an additional layer of confidence for B2B buyers. Independent inspectors can conduct audits and tests to verify that the supplier’s products meet the agreed-upon specifications and international standards. This is particularly valuable for buyers operating in regions where local quality assurance practices may vary.

What are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must be aware of the nuances that may affect quality control. Factors such as local regulations, import/export standards, and cultural differences in manufacturing practices can influence the quality assurance process. Buyers should familiarize themselves with the specific requirements of their respective regions and ensure that their suppliers can comply with these standards.

In summary, understanding the manufacturing processes and quality assurance measures for a 2 pump hydraulic setup is crucial for B2B buyers. By focusing on these areas, buyers can make informed decisions that ensure they are sourcing high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2 pump hydraulic setup diagram’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure a 2 pump hydraulic setup diagram. Understanding the intricacies of hydraulic systems is essential for ensuring optimal performance and reliability in various applications, particularly in sectors like automotive, industrial machinery, and construction. By following these steps, buyers can effectively source high-quality hydraulic solutions tailored to their specific needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for the hydraulic setup. This includes the type of pumps, cylinder specifications, and the number of solenoids needed. A well-defined specification helps in communicating your needs effectively to suppliers, ensuring they can provide the right solutions.

- Considerations:

- Pump capacity and performance ratings

- Compatibility with existing systems and components

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in hydraulic systems. Look for companies with a proven track record in manufacturing or supplying hydraulic components. Supplier credibility is vital to ensure quality and reliability in your hydraulic setup.

Illustrative image related to 2 pump hydraulic setup diagram

- Key Actions:

- Review online resources and industry forums for recommendations

- Check for certifications and industry affiliations

Step 3: Evaluate Supplier Experience and Expertise

Assess the experience and technical expertise of potential suppliers. Established suppliers often have a wealth of knowledge and can provide insights into the best practices for hydraulic setups. This expertise can be invaluable in troubleshooting and optimizing system performance.

- Focus Areas:

- Years in business and specialization in hydraulic systems

- Client testimonials and case studies showcasing successful projects

Step 4: Request Detailed Product Specifications

Once potential suppliers are identified, request detailed product specifications for their hydraulic kits. This should include diagrams, component lists, and assembly instructions. Understanding the components involved will aid in assessing whether the setup meets your operational requirements.

- What to Look For:

- Compatibility with your technical specifications

- Availability of assembly and installation support

Step 5: Compare Pricing and Value

Pricing is a critical factor in the procurement process, but it shouldn’t be the sole determinant. Compare the total cost of ownership, including installation and maintenance services, along with the initial purchase price. A slightly higher upfront cost can be justified if it leads to better performance and lower maintenance needs over time.

Illustrative image related to 2 pump hydraulic setup diagram

- Considerations:

- Warranty and after-sales service

- Availability of replacement parts and support

Step 6: Verify Supplier Certifications and Compliance

Ensure that potential suppliers adhere to industry standards and regulations. Certifications can indicate the quality and safety of their products, which is particularly important in hydraulic systems due to the pressures involved. Compliance with international standards can also ease importation processes.

- Key Certifications:

- ISO 9001 for quality management

- CE marking for compliance in Europe

Step 7: Finalize Contract Terms and Conditions

Before finalizing any agreements, review the contract terms carefully. Ensure that all aspects of the purchase, including delivery timelines, payment terms, and warranty conditions, are clearly defined. A well-structured contract minimizes the risk of misunderstandings and ensures a smoother procurement process.

- Key Contract Elements:

- Delivery schedules and penalties for delays

- Clear return and refund policies

By following this checklist, B2B buyers can navigate the complexities of sourcing a 2 pump hydraulic setup diagram effectively, ensuring they select the right components for their operational needs.

Comprehensive Cost and Pricing Analysis for 2 pump hydraulic setup diagram Sourcing

What Are the Key Cost Components in Sourcing a 2 Pump Hydraulic Setup?

When evaluating the costs associated with sourcing a 2 pump hydraulic setup, several critical components must be taken into account. These include:

-

Materials: The primary materials for a hydraulic setup consist of pumps, motors, cylinders, hoses, fittings, and solenoids. The choice of materials can significantly affect the overall cost. For instance, high-quality chrome components may incur a premium but can enhance durability and performance.

-

Labor: Labor costs encompass assembly, installation, and any necessary customizations. Depending on the complexity of the hydraulic system and the expertise required, labor costs can vary significantly.

-

Manufacturing Overhead: This includes costs related to production facilities, equipment maintenance, utilities, and administrative expenses. Effective management of overhead can lead to more competitive pricing.

-

Tooling: Specialized tools and equipment are often required for the production of hydraulic components. The initial investment in tooling can be substantial but is essential for maintaining quality and efficiency in production.

-

Quality Control (QC): Ensuring that each component meets safety and performance standards is crucial. QC processes may involve testing and certification, which can add to the overall cost but are necessary to minimize the risk of failures.

-

Logistics: Transportation and warehousing costs must be factored in, especially for international shipments. These costs can vary based on the mode of transport and the distance from the supplier to the buyer.

-

Margin: Suppliers typically mark up their prices to cover operational costs and generate profit. Understanding the margin can help buyers gauge whether the price is competitive.

How Do Price Influencers Impact the Sourcing of 2 Pump Hydraulic Setups?

Several factors can influence the pricing of hydraulic setups, particularly for international buyers:

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Larger orders often result in lower per-unit costs due to economies of scale.

-

Specifications and Customization: Custom specifications can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials: The type of materials selected can significantly impact the price. For example, opting for standard materials versus high-performance materials can lead to substantial cost differences.

-

Quality and Certifications: Products that meet international quality standards or have specific certifications may come at a premium. However, investing in certified products can reduce risks associated with quality failures.

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge more due to their proven track record, while newer or less reputable suppliers may offer lower prices but potentially at the cost of quality.

-

Incoterms: Understanding the terms of trade, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for international buyers. These terms dictate who is responsible for shipping costs and risk during transit.

What Are Effective Buyer Tips for Sourcing 2 Pump Hydraulic Setups Internationally?

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiate: Always engage in negotiations to obtain better pricing. Suppliers may have room to adjust prices, especially for larger orders or long-term contracts.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential downtime. A higher upfront investment may lead to lower long-term costs.

-

Understand Pricing Nuances: Be aware that prices may vary significantly based on regional market dynamics. Research local suppliers and compare prices to ensure you’re getting a competitive deal.

-

Focus on Quality Over Price: It may be tempting to choose the lowest price, but quality should not be compromised. Investing in reliable components can prevent costly repairs and replacements down the line.

-

Stay Informed on Market Trends: Regularly review industry trends and pricing updates to make informed purchasing decisions. This knowledge can empower negotiations and help anticipate price fluctuations.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always request detailed quotes from multiple suppliers to ensure you are making the most informed decision.

Alternatives Analysis: Comparing 2 pump hydraulic setup diagram With Other Solutions

When considering hydraulic systems for various applications, it’s crucial to evaluate alternatives to the traditional two-pump hydraulic setup diagram. Each solution offers unique benefits and drawbacks depending on the specific requirements of your operation. This analysis provides a comparative look at the two-pump setup alongside other viable options, enabling informed decision-making for B2B buyers.

| Comparison Aspect | 2 Pump Hydraulic Setup Diagram | Alternative 1: 3 Pump Hydraulic System | Alternative 2: Electric Actuation Systems |

|---|---|---|---|

| Performance | Moderate lifting power, good for small to medium loads | Higher lifting capacity, allows for complex maneuvers | Variable speed and precise control, ideal for lighter applications |

| Cost | Generally lower initial investment (approx. $1,600 – $1,900) | Higher upfront cost due to additional pump (approx. $2,500+) | Mid-range cost (approx. $1,500 – $3,000) depending on specifications |

| Ease of Implementation | Requires mechanical knowledge for setup and wiring | More complex wiring and setup; requires expertise | Easier to install; often comes with user-friendly controls |

| Maintenance | Moderate, needs regular checks on pumps and seals | Higher maintenance due to more components | Generally lower maintenance; fewer moving parts |

| Best Use Case | Ideal for lowriders and light-duty applications | Best for performance-driven setups needing significant lift | Suitable for applications requiring precision, such as robotics or light machinery |

What Are the Pros and Cons of a 3 Pump Hydraulic System?

The three-pump hydraulic system enhances performance significantly by allowing independent control of multiple dumps. This setup is particularly advantageous for applications requiring intricate maneuvers, such as in competitive lowriding or heavy-duty lifting. However, the complexity of wiring and higher costs may deter some users, especially those with limited technical expertise or budget constraints. Overall, this solution is best for those who prioritize performance and can invest in the necessary installation and maintenance.

How Does Electric Actuation Compare to Hydraulic Systems?

Electric actuation systems offer precise control and variable speed, making them suitable for applications that demand accuracy over raw power. They are often easier to install due to simpler wiring and fewer components, which can be a major advantage for less experienced users. However, electric systems may not provide the same lifting capacity as hydraulic solutions, especially in heavy-duty scenarios. Therefore, while they present a modern alternative, they are best suited for lighter applications where precision is critical.

Conclusion: How Should B2B Buyers Choose the Right Hydraulic Solution?

Selecting the right hydraulic system depends on your specific application requirements, budget, and technical capabilities. For buyers focused on performance and maneuverability, the three-pump hydraulic system may be the best choice, despite its higher cost and complexity. Conversely, if ease of installation and maintenance is a priority, electric actuation systems present a viable alternative. Ultimately, understanding your operational needs and the environments in which these systems will be deployed is key to making an informed decision that aligns with your business objectives.

Essential Technical Properties and Trade Terminology for 2 pump hydraulic setup diagram

What Are the Key Technical Properties of a 2 Pump Hydraulic Setup?

Understanding the essential technical properties of a 2 pump hydraulic setup is critical for B2B buyers looking to invest in hydraulic systems. Here are some key specifications:

-

Pump Type and Capacity

The type of pump, such as gear or piston, significantly affects the system’s efficiency and performance. Capacity is typically measured in gallons per minute (GPM) or liters per minute (LPM). Selecting the right pump type ensures optimal performance for specific applications, especially in high-demand industries like construction or automotive. -

Pressure Rating

This specification indicates the maximum pressure the hydraulic system can safely handle, usually measured in pounds per square inch (PSI) or bar. A higher pressure rating allows for more powerful operation, which is essential for applications requiring heavy lifting or precise control. Buyers must ensure that the pressure rating matches their operational needs to prevent system failures. -

Material Grade

The quality of materials used in hydraulic components, such as aluminum or high-strength steel, influences durability and resistance to wear and tear. High-grade materials can withstand harsh environments and reduce maintenance costs over time. Understanding material specifications helps buyers select products that offer longevity and reliability. -

Hose Specifications

Hydraulic hoses must meet specific standards regarding diameter, pressure rating, and temperature tolerance. This ensures compatibility and safety within the hydraulic system. Correct hose specifications prevent leaks and failures, which can lead to costly downtime and repairs. -

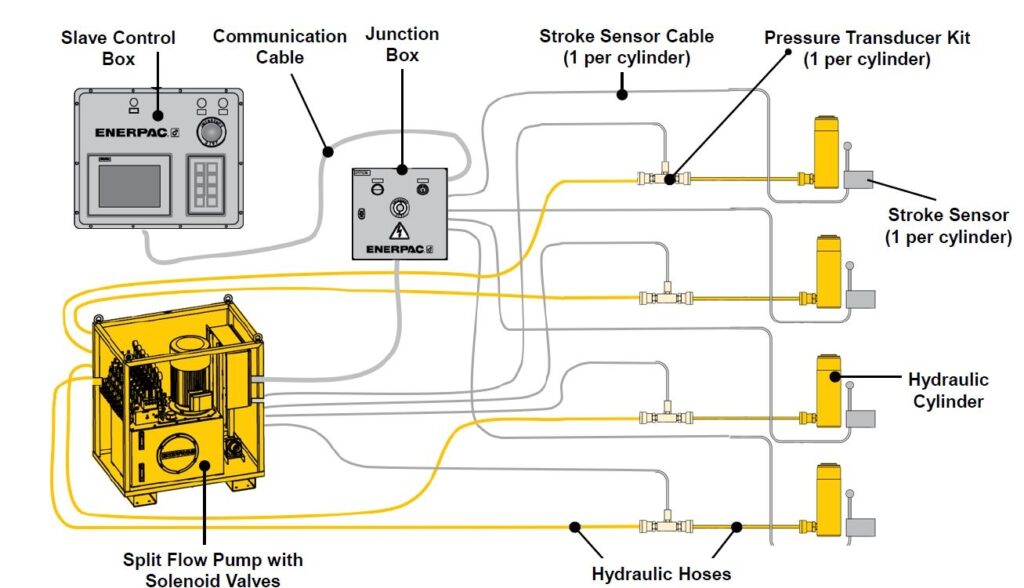

Solenoid Count and Type

The number and type of solenoids in the system dictate the control capabilities of the hydraulic setup. Solenoids are crucial for directing fluid flow and controlling the operation of pumps and cylinders. A well-designed solenoid arrangement enhances operational efficiency and responsiveness. -

Installation Requirements

These specifications detail the necessary components and configurations for assembling the hydraulic system. Understanding installation requirements, including wiring and plumbing needs, is vital for ensuring a smooth integration into existing systems.

What Common Trade Terms Should B2B Buyers Know?

Familiarity with industry-specific terminology is essential for effective communication and negotiation in the hydraulic sector. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s end product. Understanding OEM relationships can help buyers identify reliable suppliers and ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

This is the smallest amount of product a supplier is willing to sell. Knowing the MOQ is critical for budget planning and inventory management, especially for international buyers who may face higher shipping costs for smaller orders. -

RFQ (Request for Quotation)

An RFQ is a formal request to suppliers for pricing on specific products or services. This process enables buyers to compare costs and terms from multiple suppliers, fostering competitive pricing and better procurement decisions. -

Incoterms

Short for International Commercial Terms, Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers manage shipping costs, risks, and delivery timelines effectively. -

Hydraulic Cylinder

A hydraulic cylinder converts hydraulic energy into linear mechanical energy. Recognizing the role of hydraulic cylinders in a 2 pump setup is essential for selecting the right components that meet operational demands. -

Flow Rate

This term refers to the volume of fluid that moves through the hydraulic system over a specific period. Flow rate is critical for determining the speed and efficiency of hydraulic operations, affecting overall system performance.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 2 pump hydraulic systems that meet their operational needs and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the 2 pump hydraulic setup diagram Sector

What Are the Current Market Dynamics in the 2 Pump Hydraulic Setup Sector?

The market for 2 pump hydraulic setups is experiencing robust growth, driven by increasing demand in various industries, including automotive, construction, and agriculture. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are actively seeking efficient hydraulic solutions to enhance performance and productivity. The rise in lowriding culture, especially in urban settings, has further fueled interest in hydraulic setups, particularly for customizing vehicles. Additionally, the advent of advanced technologies like IoT and automation is reshaping sourcing trends, enabling more efficient inventory management and predictive maintenance.

Emerging trends indicate a shift toward modular hydraulic systems, which allow for easy upgrades and scalability. Buyers are increasingly favoring suppliers that offer comprehensive kits, such as those including chrome pumps and motors, along with essential components like solenoids and hoses. This trend is particularly significant for businesses looking to streamline their operations while minimizing downtime. Furthermore, as industries evolve, there is a growing emphasis on sourcing high-quality, durable components that can withstand rigorous use, ensuring long-term reliability.

How Is Sustainability and Ethical Sourcing Addressed in the 2 Pump Hydraulic Sector?

Sustainability has become a pivotal concern in the hydraulic equipment sector. B2B buyers are increasingly aware of the environmental impact of their purchases, making ethical sourcing a critical factor in decision-making. Suppliers are now under pressure to provide products that not only meet performance standards but also adhere to sustainable practices. This includes using environmentally friendly materials and manufacturing processes that reduce waste and energy consumption.

The importance of certification cannot be overstated; buyers are gravitating toward suppliers with ‘green’ certifications that demonstrate a commitment to sustainability. Certifications such as ISO 14001 for environmental management systems indicate that a supplier is dedicated to minimizing environmental impact. Moreover, the use of recyclable materials in hydraulic components, such as hoses and fittings, is gaining traction, as businesses aim to reduce their carbon footprint. By prioritizing ethical supply chains, international buyers can enhance their brand image and align with the growing global demand for sustainable practices.

What Is the Evolution of the 2 Pump Hydraulic Setup Industry?

The evolution of the 2 pump hydraulic setup industry can be traced back to the early innovations in hydraulic technology. Initially used in industrial applications, hydraulic systems gained popularity in automotive customization during the late 20th century, particularly within the lowrider community. As consumer demand for personalized vehicles grew, manufacturers began developing specialized kits that made it easier for enthusiasts to install and modify their setups.

Over the years, advancements in materials and technology have led to the development of more efficient and powerful hydraulic systems. Today, suppliers offer a variety of configurations, from basic setups to complex systems capable of precise control over multiple hydraulic functions. The introduction of digital controls and automation has further revolutionized the industry, allowing for enhanced user experiences and operational efficiencies. This historical context is crucial for B2B buyers, as it highlights the industry’s adaptability and commitment to innovation, ensuring they invest in products that meet current and future demands.

Frequently Asked Questions (FAQs) for B2B Buyers of 2 pump hydraulic setup diagram

-

How do I troubleshoot a hydraulic pump that isn’t functioning properly?

To troubleshoot a hydraulic pump, start by checking the power supply and ensuring that all electrical connections are secure. Inspect the hydraulic fluid levels and look for any leaks in the hoses or connections. If the pump is making unusual noises, it could indicate internal damage or wear. Review the wiring diagram specific to your setup to verify that all components are correctly connected. If issues persist, consulting with a professional technician or the pump manufacturer may be necessary to avoid further damage. -

What is the best configuration for a 2 pump hydraulic system?

The best configuration for a 2 pump hydraulic system largely depends on the intended application. For applications requiring high performance, a setup featuring two pumps with dedicated circuits for front and rear control is ideal. This allows for independent operation and better control over the hydraulic functions. Ensure that the system includes appropriate solenoids and switches for efficient operation. Assessing your specific requirements and consulting with experienced suppliers can help determine the most effective configuration. -

What factors should I consider when selecting a supplier for hydraulic components?

When selecting a supplier, evaluate their experience and reputation in the hydraulic industry. Look for suppliers who offer a range of products and customization options to meet your specific needs. Additionally, assess their quality assurance processes and certifications to ensure compliance with international standards. It’s crucial to check references and reviews from other clients, especially those in your region, to gauge reliability and service quality. -

What are the typical minimum order quantities (MOQs) for hydraulic components?

Minimum order quantities (MOQs) for hydraulic components can vary significantly among suppliers. Generally, MOQs may range from a single unit for small orders to several dozen for bulk purchases, especially in international transactions. It’s important to discuss your specific requirements with potential suppliers to negotiate MOQs that align with your purchasing capabilities while ensuring you receive competitive pricing. -

How can I ensure quality assurance for hydraulic systems in international trade?

To ensure quality assurance, work with suppliers who provide detailed product specifications and certifications. Request samples before placing large orders to verify quality. Establish clear quality control measures, such as inspections during production and upon delivery. Additionally, consider using third-party inspection services to assess the products before shipment, especially when sourcing from overseas manufacturers. -

What payment terms should I expect when sourcing hydraulic components internationally?

Payment terms can vary based on the supplier’s policies and the nature of your relationship. Common terms include advance payment, partial payment upfront with the balance upon delivery, or net payment terms allowing a set period post-delivery for payment. It’s advisable to clarify payment methods (e.g., wire transfer, credit terms) and ensure that they align with your financial processes to avoid misunderstandings. -

What logistics considerations should I keep in mind when importing hydraulic systems?

When importing hydraulic systems, consider shipping methods, customs regulations, and potential tariffs or duties. Ensure that your supplier can provide necessary documentation, such as certificates of origin and compliance. Work with a logistics partner experienced in international shipping to navigate customs clearance efficiently. Additionally, plan for lead times that account for production and shipping delays to align with your project timelines. -

Can I customize a 2 pump hydraulic setup according to my specific needs?

Yes, many suppliers offer customization options for 2 pump hydraulic setups. You can specify the components, such as pump sizes, cylinder types, and switch configurations based on your application. Discuss your requirements with the supplier to ensure that they can accommodate your needs. Custom setups may involve additional costs and lead times, so it’s beneficial to plan accordingly to meet your project deadlines.

Top 3 2 Pump Hydraulic Setup Diagram Manufacturers & Suppliers List

1. Hoppos – 2 Pump Kit

Domain: hopposonline.com

Registered: 2009 (16 years)

Introduction: 2 Pump Kit (Front/Back/Side/Side) – Retail Price: $1,875.00 – SKU: 2PFBSSHYD – Includes: 2 Chrome Pumps, 2 Chrome Motors, 2 Pairs of Cylinders, 2 Pairs of Shallow Cups, 2 Pairs of Donuts, 4 Dumps, 6 Solenoids, 17′ Ft of Switch Cord, 4 6 Prong Switches with Panel, 1 Complete Fitting Kit with Slo-Downs, 1 Complete #6 JIC Hose Kit. Options available for Motor type, Gear size, Block type, Cylinder siz…

2. Pinterest – Electric Pump Diagrams

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: This company, Pinterest – Electric Pump Diagrams, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Lay It Low – 2 Pump, 4 Dump Hydraulic System

Domain: layitlow.com

Registered: 2001 (24 years)

Introduction: 2 pump, 4 dump hydraulic system with 4 solenoids; requires rewiring for 3 switches: one for front up and down, one for rear up and down, and one for pancake up and down.

Strategic Sourcing Conclusion and Outlook for 2 pump hydraulic setup diagram

In conclusion, the strategic sourcing of a 2 pump hydraulic setup presents a unique opportunity for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Understanding the various components, such as pumps, motors, and solenoids, as well as their applications, allows businesses to optimize performance while ensuring cost-efficiency. By sourcing quality hydraulic kits and components, companies can enhance their operational capabilities, whether in construction, automotive, or manufacturing sectors.

Furthermore, maintaining a focus on quality and compatibility is crucial, as it can significantly impact system performance and longevity. Buyers should leverage local suppliers and manufacturers when possible to reduce lead times and support regional economies. As the demand for hydraulic systems grows, staying informed about the latest technologies and innovations will be essential for maintaining a competitive edge.

As you consider your sourcing strategies, engage with reputable suppliers and explore diverse options to ensure your business is well-equipped to meet future challenges. The right investment in hydraulic technology can drive efficiency and productivity, paving the way for sustained growth and success in your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.