2 Mm Wide Flat Spring: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for 2 mm wide flat spring

In today’s competitive manufacturing landscape, sourcing the right components like a 2 mm wide flat spring can pose significant challenges for international B2B buyers. Understanding the specific applications and material requirements of flat springs is crucial, especially when catering to diverse markets across Africa, South America, the Middle East, and Europe. This guide serves as a comprehensive resource, covering various types of flat springs, their applications, and crucial factors such as supplier vetting and cost considerations.

By delving into the intricacies of flat spring specifications, materials, and manufacturing processes, this guide empowers buyers to make informed decisions that align with their operational needs. Whether you are in Brazil seeking reliable suppliers or in Saudi Arabia exploring custom design options, we provide actionable insights to navigate the complexities of global sourcing.

Additionally, the guide will highlight best practices for evaluating suppliers, ensuring compliance with international standards, and optimizing procurement strategies. With a focus on enhancing your supply chain efficiency, this resource is designed to equip you with the knowledge necessary to confidently procure high-quality flat springs that meet your specific requirements. Unlock the potential of your projects and streamline your sourcing process with our expert guidance on 2 mm wide flat springs.

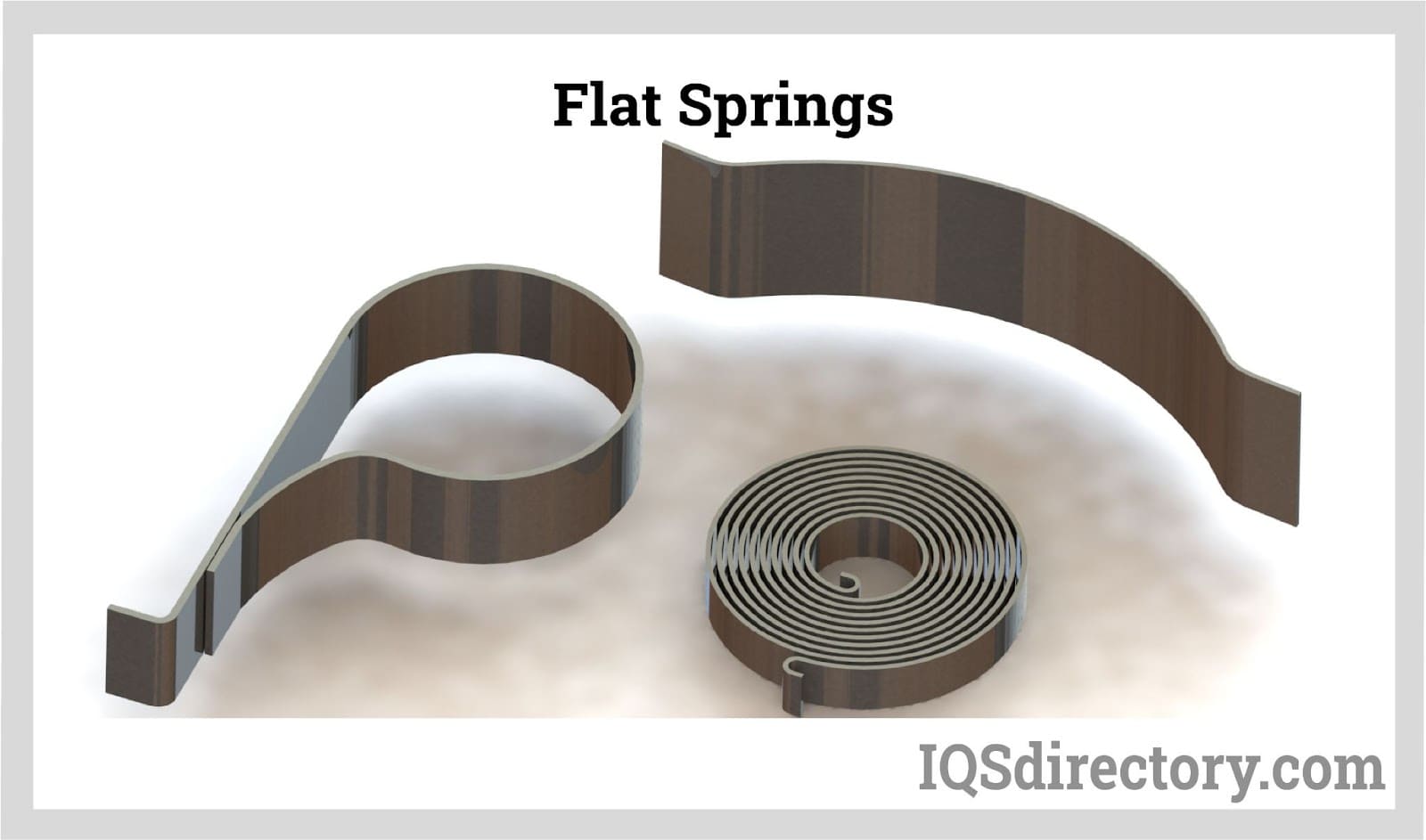

Understanding 2 mm wide flat spring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Belleville Spring | Conical shape allows for compact stacking | Automotive, aerospace, electronics | Pros: Space-efficient, high load capacity. Cons: Sensitive to installation errors. |

| Flat Wound Constant Force Spring | Provides a consistent force over a range of motion | Robotics, medical devices, consumer products | Pros: Smooth operation, customizable lengths. Cons: Limited to applications requiring constant force. |

| Leaf Spring | Multi-layered design for enhanced load distribution | Automotive suspension, industrial machinery | Pros: High durability, effective load management. Cons: Can be bulky, limited flexibility. |

| Disc Washer | Flat disc shape, often used as a washer | Machinery, electronics, automotive | Pros: Simple design, easy installation. Cons: Limited load capacity compared to other types. |

| Clips and Hold-downs | Designed to secure components in place | Electronics, automotive, construction | Pros: Versatile applications, cost-effective. Cons: May require precise dimensions for optimal performance. |

What are the Characteristics of Belleville Springs?

Belleville springs feature a unique conical shape that allows for stacking, enabling them to handle high loads in a compact form. This design makes them particularly suitable for applications in automotive and aerospace sectors where space is at a premium. When considering a Belleville spring, B2B buyers should evaluate the load requirements and installation conditions, as improper installation can lead to performance issues.

Illustrative image related to 2 mm wide flat spring

How Do Flat Wound Constant Force Springs Work?

Flat wound constant force springs are engineered to deliver a consistent force throughout their extension range, making them ideal for applications such as robotics and medical devices. Their ability to be customized in length allows for flexibility in design. B2B buyers should consider the specific force requirements and the operational environment, as these springs are best suited for applications that demand smooth, continuous motion.

What Makes Leaf Springs a Popular Choice?

Leaf springs consist of multiple layers of material, which distribute loads effectively, making them a staple in automotive suspensions and industrial machinery. Their robust design offers exceptional durability and load-bearing capabilities. Buyers in the B2B market should assess their space constraints and flexibility needs, as leaf springs can be bulkier than other spring types, potentially impacting design and installation.

In What Scenarios are Disc Washers Used?

Disc washers are flat springs designed primarily for use as washers in various machinery and electronic applications. Their straightforward design allows for easy installation and they can help distribute loads evenly. Buyers should consider the load capacity and specific application requirements, as disc washers may not provide the same level of performance under heavy loads as more robust spring types.

Why Choose Clips and Hold-downs?

Clips and hold-downs are versatile flat springs used to secure components in place across various industries, including electronics and construction. Their cost-effectiveness and adaptability make them a popular choice for manufacturers. When purchasing, B2B buyers should pay attention to the precise dimensions and material properties, as the effectiveness of these components relies heavily on accurate sizing for optimal performance.

Key Industrial Applications of 2 mm wide flat spring

| Industry/Sector | Specific Application of 2 mm wide flat spring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Seat belt retraction mechanisms | Enhances safety and compliance with regulations | Material durability, tensile strength, and corrosion resistance. |

| Electronics | Electrical contacts in circuit boards | Reliable connectivity and performance | Conductivity, temperature tolerance, and form factor. |

| Aerospace | Control surfaces in small aircraft | Lightweight yet strong components | Precision manufacturing, weight specifications, and certifications. |

| Medical Devices | Components in diagnostic equipment | Ensures accuracy and reliability in critical tasks | Biocompatibility, regulatory compliance, and custom design needs. |

| Consumer Appliances | Hinge mechanisms in compact devices | Space-saving designs and improved functionality | Custom shapes, load capacity, and aesthetic considerations. |

How Is the 2 mm Wide Flat Spring Used in Automotive Applications?

In the automotive sector, 2 mm wide flat springs are critical components in seat belt retraction mechanisms. These springs ensure that seat belts retract smoothly and securely, enhancing passenger safety. With stringent regulations in place, manufacturers require springs that meet high durability and compliance standards. When sourcing, businesses must consider the spring’s material properties, such as tensile strength and corrosion resistance, to ensure long-lasting performance in various environmental conditions.

What Role Does the 2 mm Wide Flat Spring Play in Electronics?

In the electronics industry, 2 mm wide flat springs are commonly used as electrical contacts on circuit boards. Their design allows for reliable connectivity in compact spaces, which is essential for the functionality of modern electronic devices. Buyers in this sector must prioritize sourcing springs that offer excellent conductivity and can withstand temperature fluctuations. Additionally, ensuring the right form factor is crucial for compatibility with existing electronic designs.

How Are 2 mm Wide Flat Springs Utilized in Aerospace?

The aerospace industry employs 2 mm wide flat springs in control surfaces of small aircraft, where weight and strength are paramount. These springs contribute to the precise operation of flaps and rudders, enhancing flight stability and control. For international buyers, particularly in regions like the Middle East and Europe, sourcing these springs involves strict adherence to aerospace standards and certifications. Precision manufacturing capabilities are also essential to meet the specific weight and performance requirements.

In What Ways Are 2 mm Wide Flat Springs Important for Medical Devices?

In medical devices, 2 mm wide flat springs are integral to various diagnostic equipment, ensuring accurate and reliable operation. These springs help maintain the necessary tension and functionality in equipment that requires precision, such as imaging devices. Buyers must consider biocompatibility and regulatory compliance when sourcing these components, as they often come into contact with sensitive medical environments. Custom design capabilities can also be a significant advantage in this sector.

How Do Consumer Appliances Benefit from 2 mm Wide Flat Springs?

In consumer appliances, 2 mm wide flat springs are often used in hinge mechanisms of compact devices, such as laptops and kitchen gadgets. These springs enable smooth opening and closing actions, contributing to user convenience and product longevity. When sourcing, businesses should focus on custom shapes and load capacities to fit specific appliance designs. Additionally, aesthetic considerations may play a role, particularly in consumer-facing products, making it essential for suppliers to offer a range of design options.

3 Common User Pain Points for ‘2 mm wide flat spring’ & Their Solutions

Scenario 1: Challenges with Sourcing Quality 2 mm Wide Flat Springs

The Problem: B2B buyers often struggle to find reliable suppliers who can provide high-quality 2 mm wide flat springs that meet their specific requirements. This challenge is exacerbated in regions with less established supply chains, such as parts of Africa and South America, where local options may be limited. Buyers frequently encounter issues like inconsistent material quality, inadequate specifications, and lack of responsiveness from suppliers, leading to delays in production and increased costs.

The Solution: To overcome sourcing challenges, B2B buyers should prioritize establishing relationships with manufacturers who have a proven track record in flat spring production. Conducting thorough research on potential suppliers is crucial; look for certifications such as ISO 9001 and compliance with international standards like REACH and RoHS. Request samples and conduct material testing to ensure the springs meet the required mechanical properties and dimensions. Additionally, leveraging platforms that connect buyers with global suppliers can help broaden sourcing options and improve the chances of finding reliable partners. Establishing clear communication regarding specifications and delivery timelines can also mitigate risks associated with sourcing.

Scenario 2: Difficulty in Customization for Specific Applications

The Problem: Many B2B buyers require customized 2 mm wide flat springs for unique applications, such as in automotive or electronic devices. However, they often face difficulties in collaborating with manufacturers to achieve the desired design specifications. Misunderstandings about material properties, spring configurations, and load requirements can result in prototypes that fail to meet performance expectations, leading to wasted time and resources.

The Solution: To ensure successful customization, buyers should engage in collaborative design processes with manufacturers who offer CAD-assisted product design. Providing detailed specifications, including load requirements, environmental conditions, and intended applications, can help manufacturers create a prototype that meets the buyer’s needs. Utilizing engineering resources from the supplier, such as design simulations and material recommendations, can further refine the product. Regular check-ins during the design and production phases can help identify potential issues early, allowing for adjustments before mass production begins.

Scenario 3: Managing Inventory and Lead Times Effectively

The Problem: Buyers often encounter challenges with managing inventory levels and lead times when sourcing 2 mm wide flat springs. Inconsistent demand or unexpected production delays can lead to stock shortages, which disrupts manufacturing processes and affects overall business operations. This issue is particularly pressing for companies that rely on just-in-time (JIT) manufacturing practices.

The Solution: To effectively manage inventory and lead times, B2B buyers should implement a proactive inventory management strategy. Establishing a minimum order quantity with suppliers can ensure a consistent supply of 2 mm wide flat springs, while also negotiating favorable lead times to accommodate production schedules. Utilizing inventory management software can provide real-time insights into stock levels and help forecast demand more accurately. Additionally, maintaining a strategic partnership with suppliers can allow for quicker response times and flexibility during unexpected demand surges. Regularly reviewing and adjusting inventory strategies based on market trends and production cycles will also help mitigate risks associated with supply chain disruptions.

Strategic Material Selection Guide for 2 mm wide flat spring

What Are the Key Properties of Different Materials for 2 mm Wide Flat Springs?

When selecting materials for 2 mm wide flat springs, it’s crucial to consider their mechanical properties, manufacturing complexity, and suitability for specific applications. Here, we analyze four common materials used in the production of flat springs: carbon steel, stainless steel, brass, and phosphor bronze.

How Does Carbon Steel Perform in Flat Spring Applications?

Carbon steel is a popular choice for flat springs due to its excellent tensile strength and durability. It typically offers a high yield strength, making it suitable for applications requiring significant load-bearing capabilities. However, carbon steel is prone to corrosion, which can limit its use in environments with moisture or corrosive substances.

Pros: High strength, cost-effective, and readily available.

Cons: Susceptible to rust and corrosion, requiring protective coatings for certain applications.

Impact on Application: Ideal for indoor applications or environments where exposure to moisture is minimal.

Considerations for International Buyers: Compliance with ASTM standards is common, and buyers should be aware of the need for protective coatings in humid climates, especially in regions like Brazil and parts of Africa.

What Advantages Does Stainless Steel Offer for Flat Springs?

Stainless steel, particularly grades like 301 and 304, is favored for its corrosion resistance and aesthetic appeal. This material maintains its strength at elevated temperatures and is suitable for a variety of applications, including those exposed to harsh environments.

Pros: Excellent corrosion resistance, high strength-to-weight ratio, and good formability.

Cons: Higher cost compared to carbon steel and may require specialized manufacturing processes.

Impact on Application: Suitable for outdoor applications, food processing, and medical devices where hygiene is critical.

Considerations for International Buyers: Buyers should ensure compliance with RoHS and REACH regulations, particularly in Europe and the Middle East, where environmental regulations are stringent.

Why Choose Brass for Flat Springs?

Brass is another viable option for flat springs, known for its good electrical conductivity and corrosion resistance. It is particularly effective in applications requiring non-sparking materials, making it suitable for electrical contacts and components in explosive environments.

Pros: Good corrosion resistance, excellent machinability, and non-sparking properties.

Cons: Lower tensile strength compared to steel options and can be more expensive.

Impact on Application: Ideal for electrical and electronic applications, especially in environments where static discharge is a concern.

Considerations for International Buyers: Compliance with specific industry standards may be necessary, particularly for electrical applications in regions like Saudi Arabia and Europe.

Illustrative image related to 2 mm wide flat spring

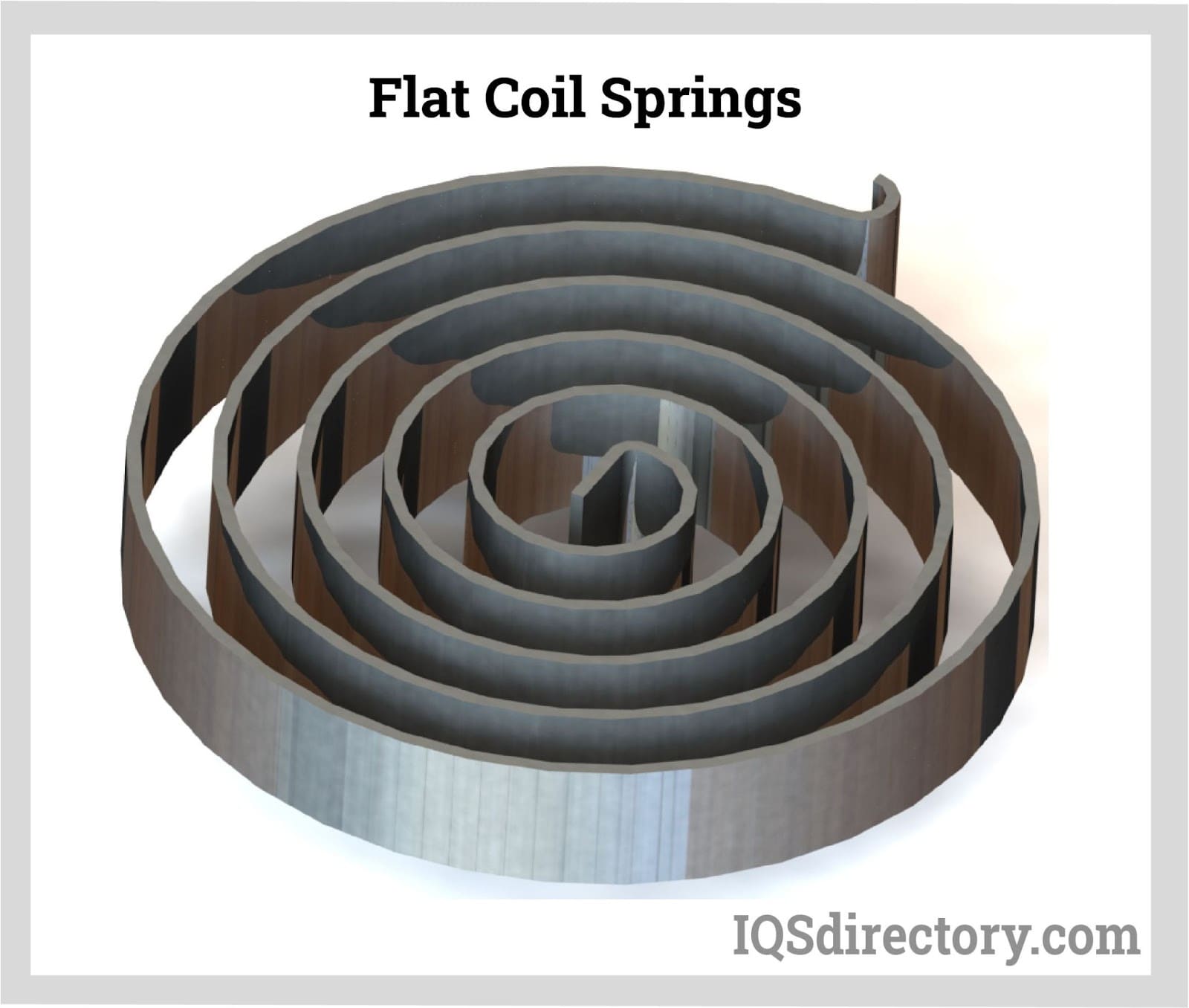

What Role Does Phosphor Bronze Play in Flat Spring Manufacturing?

Phosphor bronze is a copper alloy that combines strength with excellent corrosion resistance. It is particularly valued for its fatigue resistance and ability to maintain elasticity over time, making it suitable for precision applications.

Pros: High fatigue resistance, good corrosion resistance, and excellent electrical conductivity.

Cons: More expensive than carbon steel and may require specialized manufacturing techniques.

Impact on Application: Ideal for applications in the electronics and automotive industries, where durability and performance are critical.

Considerations for International Buyers: Buyers should check for compliance with ASTM and JIS standards, particularly in high-tech industries across Europe and Asia.

Summary Table of Material Selection for 2 mm Wide Flat Springs

| Material | Typical Use Case for 2 mm wide flat spring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General industrial applications | High strength and cost-effective | Susceptible to corrosion | Low |

| Stainless Steel | Outdoor and medical applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Electrical contacts and non-sparking needs | Good conductivity and corrosion resistance | Lower tensile strength | Medium |

| Phosphor Bronze | Precision applications in electronics | High fatigue resistance | More expensive and specialized manufacturing | High |

This strategic material selection guide provides B2B buyers with valuable insights into the properties, advantages, and limitations of various materials for 2 mm wide flat springs, aiding informed decision-making tailored to specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 2 mm wide flat spring

What Are the Key Manufacturing Processes for 2 mm Wide Flat Springs?

The manufacturing of 2 mm wide flat springs is a precise and multi-stage process that ensures the springs meet the stringent requirements of various applications. The main stages include material preparation, forming, assembly, and finishing. Each stage employs specific techniques to guarantee the quality and performance of the final product.

How Is Material Prepared for 2 mm Wide Flat Springs?

Material preparation is the foundational step in the manufacturing process. Typically, flat springs are made from high-quality materials such as carbon steel, stainless steel, or specialized alloys like beryllium copper. The choice of material affects the spring’s strength, flexibility, and corrosion resistance.

- Material Selection: B2B buyers should specify the desired properties, such as tensile strength and corrosion resistance, based on their application needs.

- Cutting: The raw material is cut into strips of the required width (2 mm) and thickness. Precision in this step is crucial to minimize waste and ensure uniformity.

- Heat Treatment: Depending on the material, heat treatment processes such as quenching or annealing may be applied to enhance the mechanical properties of the flat spring.

What Techniques Are Used in the Forming Process?

Forming is where the flat spring takes its functional shape. This stage is critical, as it determines the spring’s performance characteristics.

- Fourslide and Power Pressing: These advanced techniques allow for the intricate shaping of springs. Fourslide machines can create complex geometries and features, making them ideal for custom designs.

- Hand Forming: For smaller production runs or custom pieces, hand forming can be employed. Skilled technicians shape the springs manually, ensuring attention to detail.

- Progressive Die Stamping: This method is efficient for high-volume production, allowing for rapid and consistent shaping of the flat springs through a series of dies.

How Does Assembly Fit into the Manufacturing of Flat Springs?

While many flat springs may not require assembly, certain designs do involve the incorporation of additional components.

- Integration with Other Parts: Flat springs can be assembled with clips, washers, or other hardware to create a complete assembly. This is particularly common in applications where the spring plays a role in a larger mechanical system.

- Welding and Joining: In some cases, welding or other joining techniques may be used to secure components, requiring precision to maintain the integrity of the spring.

What Finishing Processes Are Essential for 2 mm Wide Flat Springs?

Finishing processes enhance the performance and appearance of flat springs.

- Surface Treatment: Processes such as coating, plating, or anodizing improve corrosion resistance. B2B buyers should consider the environmental conditions where the springs will be used to select the appropriate finish.

- Deburring and Polishing: These processes remove sharp edges and enhance the aesthetic quality of the springs, which can be crucial in consumer-facing applications.

- Quality Inspection: Before the springs are packaged, they undergo rigorous inspections to ensure they meet specified tolerances and quality standards.

What Are the Quality Assurance Standards for Flat Springs?

Quality assurance (QA) is a critical component of the manufacturing process for flat springs. International standards such as ISO 9001, along with industry-specific certifications like CE or API, play an essential role in ensuring product reliability and safety.

Which International Standards Should B2B Buyers Consider?

- ISO 9001: This globally recognized standard focuses on quality management systems and is essential for ensuring consistent quality in manufacturing.

- CE Marking: Important for products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Certification: For flat springs used in the oil and gas industry, API certification ensures adherence to industry standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, processes are monitored to catch defects early. Techniques such as statistical process control (SPC) may be used.

- Final Quality Control (FQC): The final inspection ensures that the finished products meet all specifications before shipping.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly in international markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential.

- Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices.

- Requesting Quality Reports: Suppliers should be willing to share quality reports and certifications, which can include results from internal inspections and third-party testing.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures.

What Are the Unique Quality Control Nuances for International B2B Buyers?

When sourcing flat springs from international suppliers, B2B buyers should be aware of specific nuances that may affect quality assurance:

- Regulatory Compliance: Different regions may have varying regulations regarding materials and manufacturing processes. Understanding these is vital for compliance.

- Cultural Differences: Approaches to quality and manufacturing standards can differ across regions, which may impact the reliability of the products.

- Logistics and Supply Chain: Considerations regarding shipping, customs, and local regulations can affect lead times and quality. Establishing clear communication channels with suppliers can help mitigate these risks.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions, ensuring they receive high-quality 2 mm wide flat springs suitable for their specific applications.

Illustrative image related to 2 mm wide flat spring

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2 mm wide flat spring’

Introduction

When sourcing a 2 mm wide flat spring, a structured approach can streamline the procurement process and ensure you meet your specific application needs. This checklist will guide international B2B buyers through essential steps to effectively identify, evaluate, and secure the right flat spring for their projects.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first crucial step. Consider the application for which the flat spring will be used, including load capacity, deflection, and environmental conditions.

- Material Selection: Determine whether you need stainless steel for corrosion resistance or high carbon steel for strength.

- Dimensions: Ensure the spring’s thickness and width align with your design specifications.

Step 2: Research Potential Suppliers

Identifying reputable suppliers is essential for successful procurement. Conduct thorough research to find manufacturers that specialize in flat springs.

- Industry Experience: Look for suppliers with a proven track record in your specific industry.

- Geographical Considerations: Consider suppliers located in regions that align with your logistical needs to minimize shipping costs and lead times.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s crucial to vet suppliers thoroughly. Assess their manufacturing capabilities to ensure they can meet your specifications.

- Production Techniques: Inquire about the manufacturing methods they use, such as fourslide, powerpress, or hand-forming.

- Quality Control: Verify if they have robust quality assurance processes, including certifications like ISO 9001.

Step 4: Request Samples and Prototypes

Requesting samples or prototypes can help validate the supplier’s capabilities and the quality of their products.

- Test for Fit and Function: Ensure the samples meet your design specifications and perform as required in your application.

- Feedback Loop: Use this opportunity to provide feedback on any adjustments needed before placing a larger order.

Step 5: Check Compliance and Certifications

Ensure that your supplier complies with relevant industry standards and regulations. This is particularly important when sourcing internationally.

- Regulatory Compliance: Confirm adherence to standards such as RoHS and REACH, especially if your application is in electronics or automotive sectors.

- Certifications: Look for additional certifications that may be relevant to your specific industry.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, it’s time to negotiate the terms of your contract.

- Pricing Structure: Discuss pricing, including bulk order discounts and payment terms.

- Delivery Timelines: Establish clear expectations for lead times and shipping methods to avoid delays.

Step 7: Establish a Communication Plan

Effective communication is vital throughout the sourcing process. Establish a plan for regular updates and feedback.

- Point of Contact: Designate a primary contact for both parties to streamline communication.

- Progress Updates: Schedule regular check-ins to monitor the production process and address any potential issues early.

By following these steps, B2B buyers can efficiently navigate the sourcing process for 2 mm wide flat springs, ensuring they select the right product to meet their specific needs while fostering strong supplier relationships.

Illustrative image related to 2 mm wide flat spring

Comprehensive Cost and Pricing Analysis for 2 mm wide flat spring Sourcing

What Are the Key Cost Components for Sourcing 2 mm Wide Flat Springs?

When sourcing 2 mm wide flat springs, understanding the cost structure is vital for making informed purchasing decisions. The primary components of the cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the cost of flat springs. Common materials include carbon steel, stainless steel, and specialty alloys, each with varying price points. For instance, stainless steel tends to be more expensive due to its corrosion resistance and durability.

-

Labor: Labor costs can vary based on the complexity of the spring design and the manufacturing processes employed. Automated production may lower labor costs, whereas custom, hand-crafted springs can significantly increase labor expenses.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and maintenance of machinery. Efficient manufacturing processes can help reduce overhead costs, thereby impacting the overall price of the springs.

-

Tooling: Tooling costs involve the expenses associated with creating the dies and molds necessary for producing flat springs. Custom designs may require more specialized tooling, which can add to the initial cost.

-

Quality Control: Ensuring that flat springs meet specific standards requires investment in quality control processes. Compliance with certifications like ISO, RoHS, or REACH can also influence costs, as suppliers may need to implement additional testing and documentation procedures.

-

Logistics: Shipping and handling costs are critical to consider, especially for international buyers. Factors such as distance, mode of transport, and the Incoterms selected can significantly affect logistics costs.

-

Margin: Finally, suppliers will include a profit margin in their pricing. This can vary based on market demand, supplier reputation, and the competitive landscape.

What Factors Influence Pricing for 2 mm Wide Flat Springs?

Several factors can influence the pricing of flat springs, making it essential for buyers to understand these nuances.

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize their pricing.

-

Specifications and Customization: Custom designs or specific material requirements can significantly increase costs. Buyers should clearly define their specifications to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials and the presence of certifications can lead to increased prices. Buyers should weigh the benefits of quality against their budget constraints.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can impact pricing. Established suppliers with advanced manufacturing processes may offer better quality but at a premium price.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They dictate who is responsible for shipping, insurance, and tariffs, which can greatly affect total costs.

What Are the Best Practices for Negotiating Costs and Ensuring Cost Efficiency?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency.

-

Conduct Market Research: Understanding market prices and alternative suppliers can provide leverage during negotiations. This knowledge helps in assessing whether a quoted price is competitive.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also logistics, maintenance, and potential replacement costs over the product’s lifecycle. A lower upfront cost may not always equate to a better deal.

-

Build Long-Term Relationships: Establishing a strong relationship with suppliers can lead to better pricing, priority service, and tailored solutions. Loyalty can result in discounts and favorable terms.

-

Request Quotes from Multiple Suppliers: Obtaining multiple quotes allows buyers to compare prices and terms effectively. This practice ensures that buyers are aware of the market range for flat springs.

-

Be Clear on Specifications: Providing detailed specifications can minimize miscommunication and the risk of additional costs due to changes or rework.

Conclusion

While the cost of 2 mm wide flat springs can vary widely based on numerous factors, a comprehensive understanding of the cost structure and pricing influencers can empower buyers to make informed decisions. By leveraging negotiation strategies and focusing on total cost considerations, B2B buyers can optimize their sourcing processes, ensuring both quality and cost-effectiveness in their purchases.

Disclaimer: Prices mentioned in this analysis are indicative and may vary based on market conditions and specific supplier quotes.

Alternatives Analysis: Comparing 2 mm wide flat spring With Other Solutions

Exploring Alternatives to the 2 mm Wide Flat Spring

In the realm of mechanical components, the choice of spring technology is pivotal for achieving desired performance in various applications. The 2 mm wide flat spring is a versatile option, but there are several alternative solutions that can also meet specific requirements. This section will explore these alternatives in detail, offering insights to help B2B buyers make informed decisions.

| Comparison Aspect | 2 Mm Wide Flat Spring | Alternative 1: Compression Spring | Alternative 2: Tension Spring |

|---|---|---|---|

| Performance | Excellent for limited space and unique mounting needs | High load capacity and durability | Effective for applications requiring pulling force |

| Cost | Moderate, varies by material | Generally lower cost for mass production | Comparable to flat springs, cost-effective for high volumes |

| Ease of Implementation | Requires specific design considerations | Easy to install, widely available | Simple installation, but requires anchoring points |

| Maintenance | Low, minimal wear under proper usage | Low, can last a long time if not overstressed | Low, but may require periodic checks on anchoring |

| Best Use Case | Electrical contacts, clips, shims | Automotive applications, machinery | Textile and industrial applications requiring pulling |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of Compression Springs?

Compression springs are widely used in various industries due to their high load capacity and durability. They are generally less expensive to produce, especially in bulk, making them an attractive option for cost-sensitive projects. However, they often require more space than flat springs, which may limit their applicability in compact designs. Their installation is straightforward, but they must be carefully selected to avoid overstressing, which can lead to premature failure.

How Do Tension Springs Compare to Flat Springs?

Tension springs are ideal for applications that require a pulling force. They are commonly used in textiles and various industrial machinery, providing reliable performance in dynamic environments. Their cost is similar to that of flat springs, especially when sourced in bulk. Installation is simple, but tension springs require secure anchoring points, which may complicate their use in certain applications. Additionally, they need to be monitored to ensure the anchoring remains intact, adding a minimal maintenance requirement.

Illustrative image related to 2 mm wide flat spring

Making the Right Choice: Which Spring Solution Is Best for Your Application?

When selecting a spring solution, B2B buyers should consider the specific requirements of their applications, including space constraints, load requirements, and installation complexities. The 2 mm wide flat spring excels in compact spaces and unique mounting scenarios, making it an excellent choice for specialized applications. However, if cost and ease of installation are primary concerns, compression springs may be preferable. Conversely, for applications requiring consistent pulling force, tension springs may be the most effective solution.

Ultimately, understanding the unique advantages and limitations of each option will empower buyers to select the best spring technology tailored to their operational needs, ensuring optimal performance and cost efficiency.

Essential Technical Properties and Trade Terminology for 2 mm wide flat spring

What Are the Key Technical Properties of a 2 mm Wide Flat Spring?

1. Material Grade

The choice of material significantly impacts the performance and durability of a 2 mm wide flat spring. Common materials include high carbon steel, stainless steel, brass, and phosphor bronze. Each material offers distinct properties such as corrosion resistance, tensile strength, and flexibility. For instance, stainless steel is preferred in environments exposed to moisture due to its excellent corrosion resistance, making it ideal for applications in the automotive and aerospace industries.

2. Strip Thickness

The thickness of the flat spring strip is crucial for its load-bearing capacity and overall functionality. Typically, the thickness ranges from 0.08 mm to 3.18 mm. A thicker strip can withstand greater forces, while a thinner strip may offer more flexibility. Understanding the required strip thickness allows buyers to ensure that the spring meets the specific demands of their application, preventing premature failure.

3. Tolerance Levels

Tolerance refers to the permissible limits of variation in dimensions. For a 2 mm wide flat spring, maintaining tight tolerances is essential for ensuring proper fit and function in assemblies. A common tolerance might be ±0.1 mm. Accurate tolerances are vital in industries such as electronics, where precision affects performance and safety. Buyers should specify tolerance requirements in their orders to guarantee that the springs will integrate seamlessly into their products.

4. Spring Rate

The spring rate measures how much load is needed to compress or extend the spring by a certain distance, typically expressed in N/mm (Newtons per millimeter). This property is crucial for determining how a spring will behave under load. A higher spring rate indicates a stiffer spring, while a lower rate suggests more flexibility. Buyers must consider the spring rate to ensure that the spring performs as required in its intended application, whether in automotive parts or electronic devices.

5. Finish and Coating

The surface finish of a flat spring can affect its performance and longevity. Options include polished, galvanized, or coated finishes to enhance corrosion resistance. For applications exposed to harsh environments, coatings like zinc or nickel plating may be necessary. Buyers should assess the environmental conditions the spring will face and specify the appropriate finish to prevent degradation and extend service life.

Illustrative image related to 2 mm wide flat spring

What Are Common Trade Terms Related to 2 mm Wide Flat Springs?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of flat springs, an OEM might require custom specifications to fit their product lines. Understanding OEM requirements is essential for suppliers to ensure compatibility and maintain strong business relationships.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For flat springs, this could be influenced by production costs and setup time. Buyers should be aware of MOQ requirements as it affects purchasing decisions and inventory management, especially in low-volume applications.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. For a 2 mm wide flat spring, an RFQ should include detailed specifications, including material, dimensions, and tolerances. This process is critical for obtaining competitive pricing and ensuring that suppliers understand the buyer’s needs.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. They clarify who bears the costs and risks associated with the shipment of goods. Understanding Incoterms is vital for B2B transactions involving flat springs, as they can affect pricing and delivery timelines.

5. Custom Spring Design

This term refers to the process of creating springs tailored to specific application requirements. Buyers looking for unique spring functionalities must engage with manufacturers that offer custom design services. This collaboration ensures that the final product meets exact specifications, leading to improved performance in their applications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 2 mm wide flat springs, ensuring they select the right solutions for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the 2 mm wide flat spring Sector

What Are the Current Market Dynamics and Key Trends for 2 mm Wide Flat Springs?

The global market for 2 mm wide flat springs is experiencing significant growth, driven by the increasing demand for compact and efficient components across various industries, including automotive, electronics, and medical devices. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are focusing on sourcing flat springs that offer versatility in design and material specifications. Notably, the trend towards custom solutions is gaining traction, with manufacturers leveraging advanced CAD design capabilities to create bespoke products that meet specific client requirements.

Additionally, the integration of Industry 4.0 technologies is reshaping sourcing dynamics. B2B buyers are increasingly looking for suppliers who utilize automation, data analytics, and IoT-enabled manufacturing processes to enhance production efficiency and quality control. This technological adoption not only streamlines operations but also allows for rapid prototyping and shorter lead times, which are crucial for companies needing quick turnaround times in fast-paced markets. Furthermore, the growth of e-commerce platforms for industrial components is enabling buyers to access a wider range of suppliers, fostering competition and driving down prices.

How Are Sustainability and Ethical Sourcing Affecting the 2 mm Wide Flat Spring Sector?

Sustainability has become a focal point in the B2B sector, and the sourcing of 2 mm wide flat springs is no exception. Buyers are increasingly concerned about the environmental impact of their procurement choices, prompting a shift towards ethical sourcing practices. This involves selecting suppliers who prioritize sustainability in their manufacturing processes, such as using recycled materials and implementing energy-efficient production techniques.

Moreover, certifications like ISO 14001 for environmental management and adherence to RoHS and REACH regulations are becoming critical factors in supplier selection. These certifications indicate a commitment to reducing environmental footprints and ensuring compliance with international standards. B2B buyers should actively seek suppliers who demonstrate transparency in their supply chains and are willing to provide documentation that verifies their sustainable practices. By prioritizing ethical sourcing, companies not only comply with regulatory requirements but also enhance their brand reputation among environmentally-conscious consumers.

What Is the Historical Context Behind the Development of Flat Springs?

The evolution of flat springs dates back to the early industrial era, where their simple yet effective design made them integral to various mechanical systems. Initially crafted from basic materials like carbon steel, advancements in metallurgy and manufacturing processes have significantly enhanced their performance and durability. The introduction of stainless steel and specialized alloys has allowed for improved resistance to corrosion and fatigue, expanding their applications in high-demand sectors such as automotive and aerospace.

As technology progressed, the manufacturing of flat springs transitioned from manual processes to automated systems, allowing for higher precision and scalability. This evolution has facilitated the customization of flat springs, enabling manufacturers to meet the specific needs of diverse industries. Today, flat springs are not only a staple in traditional applications but are also increasingly utilized in innovative technologies, reflecting their adaptability and relevance in contemporary manufacturing landscapes.

Frequently Asked Questions (FAQs) for B2B Buyers of 2 mm wide flat spring

-

1. How do I solve sourcing issues for 2 mm wide flat springs?

To effectively solve sourcing issues for 2 mm wide flat springs, first, identify reliable suppliers through industry networks or trade shows. Evaluate potential suppliers based on their manufacturing capabilities, quality certifications (such as ISO 9001), and compliance with international standards like RoHS and REACH. It’s also essential to request samples and conduct quality assessments. Establishing a strong communication channel with suppliers can help clarify technical specifications and lead times, ensuring your sourcing strategy aligns with production schedules. -

2. What is the best material for 2 mm wide flat springs in automotive applications?

For automotive applications, high carbon steel or stainless steel is often the best choice for 2 mm wide flat springs due to their superior strength and corrosion resistance. High carbon steel offers excellent tensile strength, making it suitable for demanding environments, while stainless steel provides enhanced durability against rust and wear. When selecting the material, consider the specific application requirements, such as load capacity and environmental exposure, to ensure optimal performance and longevity. -

3. How can I customize my 2 mm wide flat springs for specific applications?

Customization of 2 mm wide flat springs is achievable by working closely with your supplier’s engineering team. Provide detailed specifications, including dimensions, load requirements, and environmental conditions. Many manufacturers offer CAD-assisted design services, enabling you to visualize your spring design before production. Discuss material options and any specific features, such as notches or bends, to tailor the spring to your application needs. Always request prototypes to validate the design before full-scale production. -

4. What are the minimum order quantities (MOQs) for 2 mm wide flat springs?

Minimum order quantities for 2 mm wide flat springs can vary significantly between suppliers. Some manufacturers may offer flexible MOQs for custom orders, while others may have strict minimums based on production capabilities. It’s advisable to inquire directly with potential suppliers about their MOQs and any associated pricing tiers. If your volume is lower than the MOQ, consider partnering with other businesses to consolidate orders, which can also help reduce shipping costs. -

5. What payment terms should I expect when sourcing internationally?

When sourcing 2 mm wide flat springs internationally, payment terms can differ widely based on supplier policies and your negotiation leverage. Common terms include upfront deposits (typically 30% to 50%) with the balance payable upon delivery or a Letter of Credit (LC) for larger orders. Ensure to clarify payment methods accepted, such as bank transfers or credit terms, and be aware of any potential currency exchange implications. Establishing clear payment terms upfront can help mitigate financial risks. -

6. How do I ensure quality assurance for my flat spring orders?

To ensure quality assurance for your 2 mm wide flat spring orders, establish a robust QA process with your supplier. Request documentation of their quality management systems and certifications, such as ISO 9001. Implement regular inspections and audits during production, and consider third-party inspections for large orders. Additionally, demand first-article inspections (FAIs) and material certification for compliance with specified standards to ensure that the springs meet your technical requirements. -

7. What logistics considerations should I keep in mind when importing flat springs?

When importing 2 mm wide flat springs, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose between air freight for speed or sea freight for cost-effectiveness based on your urgency. Ensure that your supplier provides proper documentation for customs clearance, including invoices and packing lists. Familiarize yourself with import duties and taxes applicable in your country to avoid unexpected costs. Collaborating with a reliable freight forwarder can streamline the shipping process. -

8. How can I vet suppliers of 2 mm wide flat springs effectively?

To effectively vet suppliers of 2 mm wide flat springs, start by researching their company history and reputation in the industry. Look for reviews and testimonials from other B2B buyers. Request references from previous clients to gauge their experience with the supplier. Evaluate their manufacturing capabilities, quality control processes, and compliance with international standards. Conduct a factory visit if possible, or utilize third-party services to assess their production facilities and practices.

Top 6 2 Mm Wide Flat Spring Manufacturers & Suppliers List

1. McMaster – 2mm Springs

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – 2mm Springs, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Lee Spring – Custom Flat Springs

Domain: leespring.com

Registered: 1996 (29 years)

Introduction: Flat springs made of flat strip steel for applications with limited space or as part of mounting assemblies. Customizable in shape, size, design, and materials. Common uses include electrical contacts, leaf springs, cantilever applications, disc washers, hold-downs, clips, and shims. Stock options include Belleville disc springs (300 Series Stainless Steel, 51CrV4 spring steel) and flat wound Cons…

3. MP Jet – Compression Spring Wire 0.2 Dia 2 mm Set

Domain: mpjet.com

Registered: 2001 (24 years)

Introduction: Compression spring wire 0.2 dia 2 mm – set

4. Springwire – High Carbon Steel Flat Spring Wire

Domain: springwire.net

Registered: 2010 (15 years)

Introduction: {‘High_Carbon_Steel_Flat_Spring_Wire’: {‘Size’: ‘T 300mm x W 800mm’, ‘Commodity’: ‘Finished Hard rolled flat wire (ungalvinized)’, ‘Usage’: ‘High tensile cord reel in seat belt of automobile’, ‘Specification’: {‘C’: ‘0.680~0.720% (0.711%)’, ‘Si’: ‘0.120~0.250% (0.180%)’, ‘Mn’: ‘0.450~0.700% (0.453%)’, ‘P’: ‘0~0.030% (0.009%)’, ‘S’: ‘0~0.030% (0.009%)’}, ‘Dimension’: {‘T1’: ‘0.290~0.310mm (0.300mm)…

5. MISUMI – Flat Springs

Domain: us.misumi-ec.com

Registered: 2007 (18 years)

Introduction: Flat Springs – One Point, Two Point, Straight Shape; Part Number: Please configure to get your Part Number; Length: Specified in 1mm increments up to 300mm; Features: Standard plate thickness and width, hole processing, one-point bending, two-point bending; Clean processed version available; Caution: Straight Type prone to plastic deformation due to low elasticity.

6. APS – Flat Leaf Springs

Domain: aps-ct.com

Registered: 1999 (26 years)

Introduction: Flat Leaf Springs manufactured in the USA. Thickness ranges from .003″ (.076 mm) to .125″ (3.175 mm) and widths up to 12″ (304.8 mm). Types include beryllium copper springs, small leaf springs, and custom flat springs. Suitable for aerospace, naval, automotive industries, and more. Manufacturing methods include fourslide, multi-slide, and power press, with a focus on reducing scrap costs. Common m…

Strategic Sourcing Conclusion and Outlook for 2 mm wide flat spring

In conclusion, the strategic sourcing of 2 mm wide flat springs presents a significant opportunity for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. The versatility and adaptability of flat springs make them essential components across various industries, from automotive to electronics. By leveraging local suppliers and manufacturers who offer customization options and rapid delivery, businesses can enhance their operational efficiency and product innovation.

Investing in strategic sourcing not only ensures the availability of high-quality materials but also fosters long-term partnerships that can lead to cost savings and improved supply chain resilience. As the demand for specialized flat springs grows, international buyers should prioritize collaboration with experienced manufacturers who can provide tailored solutions and adhere to global compliance standards.

Looking ahead, the market for flat springs is poised for growth, driven by advancements in technology and increasing application areas. Now is the time to engage with suppliers and explore how optimized sourcing strategies can elevate your business performance. Take the next step in your sourcing journey and connect with industry leaders to secure your supply chain advantage.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.