1X1 Hardware Cloth: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for 1×1 hardware cloth

As international B2B buyers navigate the complex landscape of sourcing 1×1 hardware cloth, they often encounter challenges related to quality assurance, supplier reliability, and cost-effectiveness. The demand for durable and versatile wire mesh solutions is growing across various sectors, including agriculture, construction, and home improvement. This guide serves as an essential resource for buyers from Africa, South America, the Middle East, and Europe, such as Saudi Arabia and Nigeria, who seek to make informed purchasing decisions in a competitive global market.

In this comprehensive guide, we will explore the diverse types of 1×1 hardware cloth available, including galvanized and vinyl-coated options, and their specific applications in different industries. We will also delve into supplier vetting strategies to help you identify reputable manufacturers and distributors, ensuring that you receive high-quality products that meet your project requirements. Additionally, we will provide insights into cost considerations, allowing you to assess pricing structures effectively and identify bulk purchasing opportunities that can lead to significant savings.

By equipping yourself with the knowledge contained in this guide, you will enhance your procurement strategies, minimize risks, and ultimately secure the best value for your investment in 1×1 hardware cloth. Empower your business with the insights needed to thrive in the global marketplace and make sourcing decisions that align with your operational goals.

Understanding 1×1 hardware cloth Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Galvanized Welded Wire | Hot-dip galvanized for corrosion resistance | Livestock enclosures, garden fencing | Pros: Durable, cost-effective. Cons: Limited aesthetic options. |

| Vinyl Coated Wire | Additional vinyl coating for enhanced protection | Residential and commercial gardens | Pros: Attractive finish, rust-resistant. Cons: Higher cost than galvanized. |

| Heavy-Duty Wire (12 Gauge) | Thicker wire for increased strength and durability | Industrial applications, security fencing | Pros: Highly durable, withstands heavy use. Cons: Heavier and more expensive. |

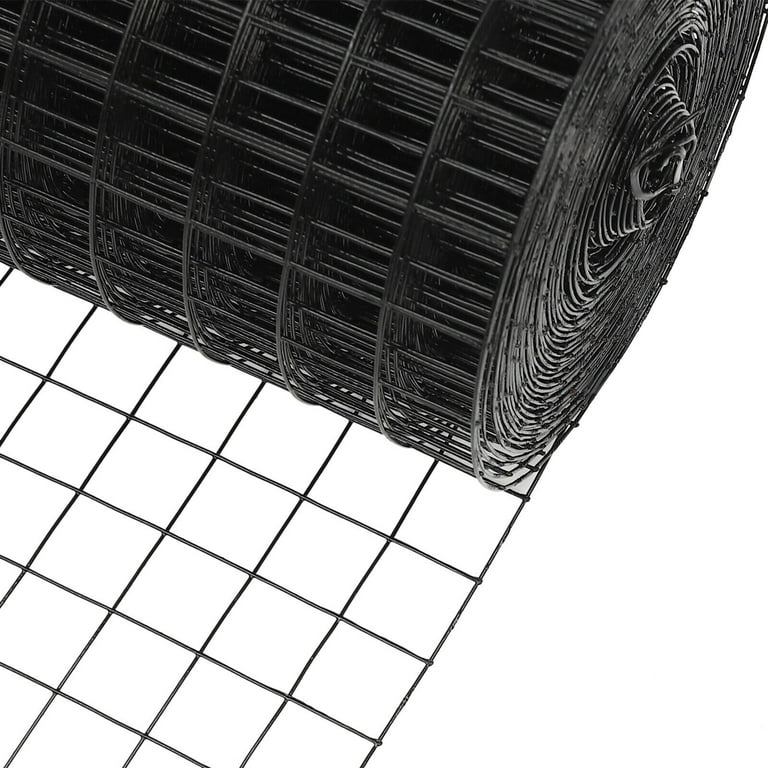

| Black Vinyl Coated Wire | Sleek black finish with corrosion resistance | Urban landscaping, pet enclosures | Pros: Aesthetic appeal, blends well with surroundings. Cons: Prone to fading over time. |

| Custom Mesh Sizes | Tailored mesh openings for specific applications | Specialized agricultural needs | Pros: Versatile for various uses, tailored solutions. Cons: Longer lead times, potentially higher costs. |

What Are the Characteristics of Galvanized Welded Wire?

Galvanized welded wire is a popular choice for B2B buyers seeking cost-effective fencing solutions. The hot-dip galvanization process ensures a robust barrier against corrosion, making it suitable for outdoor applications like livestock enclosures and garden fencing. Its durability often leads to lower maintenance costs, but buyers should note that its utilitarian appearance may not be ideal for decorative purposes.

How Does Vinyl Coated Wire Enhance Durability?

Vinyl coated wire features an additional layer of protective vinyl, which not only enhances its durability but also provides an attractive finish. This type is particularly favored in residential and commercial gardens, where aesthetics are as important as functionality. While it offers superior rust resistance, buyers should consider the higher initial investment compared to galvanized options.

Why Choose Heavy-Duty Wire for Industrial Applications?

Heavy-duty wire, typically available in 12 gauge, is designed for industrial applications requiring maximum strength and resilience. This type is ideal for security fencing and areas with heavy wear, such as construction sites. While it offers unparalleled durability, the trade-offs include increased weight and cost, which should be factored into purchasing decisions.

Illustrative image related to 1×1 hardware cloth

What Are the Benefits of Black Vinyl Coated Wire?

Black vinyl coated wire provides a sleek, modern look while maintaining excellent corrosion resistance. This type is particularly popular in urban landscaping and pet enclosures, where visual appeal is crucial. While it can blend seamlessly into surroundings, buyers should be aware that the color may fade over time, necessitating replacement.

How Can Custom Mesh Sizes Meet Specialized Needs?

Custom mesh sizes allow B2B buyers to tailor their fencing solutions to specific agricultural or industrial needs. This flexibility can be crucial for specialized applications, such as protecting certain crops or securing unique environments. However, buyers should be prepared for longer lead times and potentially higher costs associated with custom orders.

Key Industrial Applications of 1×1 hardware cloth

| Industry/Sector | Specific Application of 1×1 hardware cloth | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Livestock Fencing | Protects animals from predators and keeps them contained | Durability, gauge thickness, and corrosion resistance are critical. |

| Construction | Reinforcement in Concrete and Masonry | Enhances structural integrity and stability | Ensure compliance with local building codes and standards. |

| Horticulture | Garden and Plant Protection | Prevents damage from pests and animals | Consider mesh size and coating for specific plants and environments. |

| Environmental Management | Erosion Control and Drainage Systems | Reduces soil erosion and improves water flow management | Look for UV resistance and material longevity in harsh climates. |

| Home Improvement | Custom Enclosures for Pets and Outdoor Spaces | Provides safety and security for pets and gardens | Custom sizing and ease of installation should be prioritized. |

How Is 1×1 Hardware Cloth Used in Agriculture?

In the agriculture sector, 1×1 hardware cloth is primarily utilized for livestock fencing. Its sturdy construction effectively protects animals from predators while keeping them secure within designated areas. This application is especially vital in regions where wildlife poses a threat. Buyers should focus on the gauge thickness and corrosion resistance of the cloth, ensuring it can withstand harsh weather conditions and maintain its integrity over time. In markets across Africa and South America, where livestock farming is prevalent, sourcing durable materials is essential for long-term cost savings.

What Role Does 1×1 Hardware Cloth Play in Construction?

In the construction industry, 1×1 hardware cloth serves as reinforcement in concrete and masonry applications. It enhances the structural integrity of buildings and pavements, helping to prevent cracking and shifting. For international buyers, particularly in developing regions, compliance with local building codes is crucial. When sourcing, consider the material’s durability and compatibility with various concrete mixes, as these factors significantly impact the final product’s quality and longevity.

How Is 1×1 Hardware Cloth Beneficial in Horticulture?

Horticulturists frequently use 1×1 hardware cloth for garden and plant protection. It acts as a barrier against pests and animals, safeguarding crops from potential damage. This application is vital in regions where agricultural pests are prevalent. Buyers should evaluate the mesh size to ensure it meets the specific needs of their plants and consider additional coatings for enhanced durability. In markets like the Middle East, where extreme weather can affect plant health, sourcing UV-resistant options can provide added value.

In What Ways Does 1×1 Hardware Cloth Aid in Environmental Management?

1×1 hardware cloth is an effective solution for erosion control and drainage systems in environmental management. It helps stabilize soil and prevent erosion, particularly in areas prone to heavy rainfall or flooding. Businesses looking to implement these systems should prioritize sourcing materials that offer UV resistance and longevity, especially in climates with extreme weather conditions. This is particularly relevant for projects in regions like Africa and South America, where environmental sustainability is increasingly important.

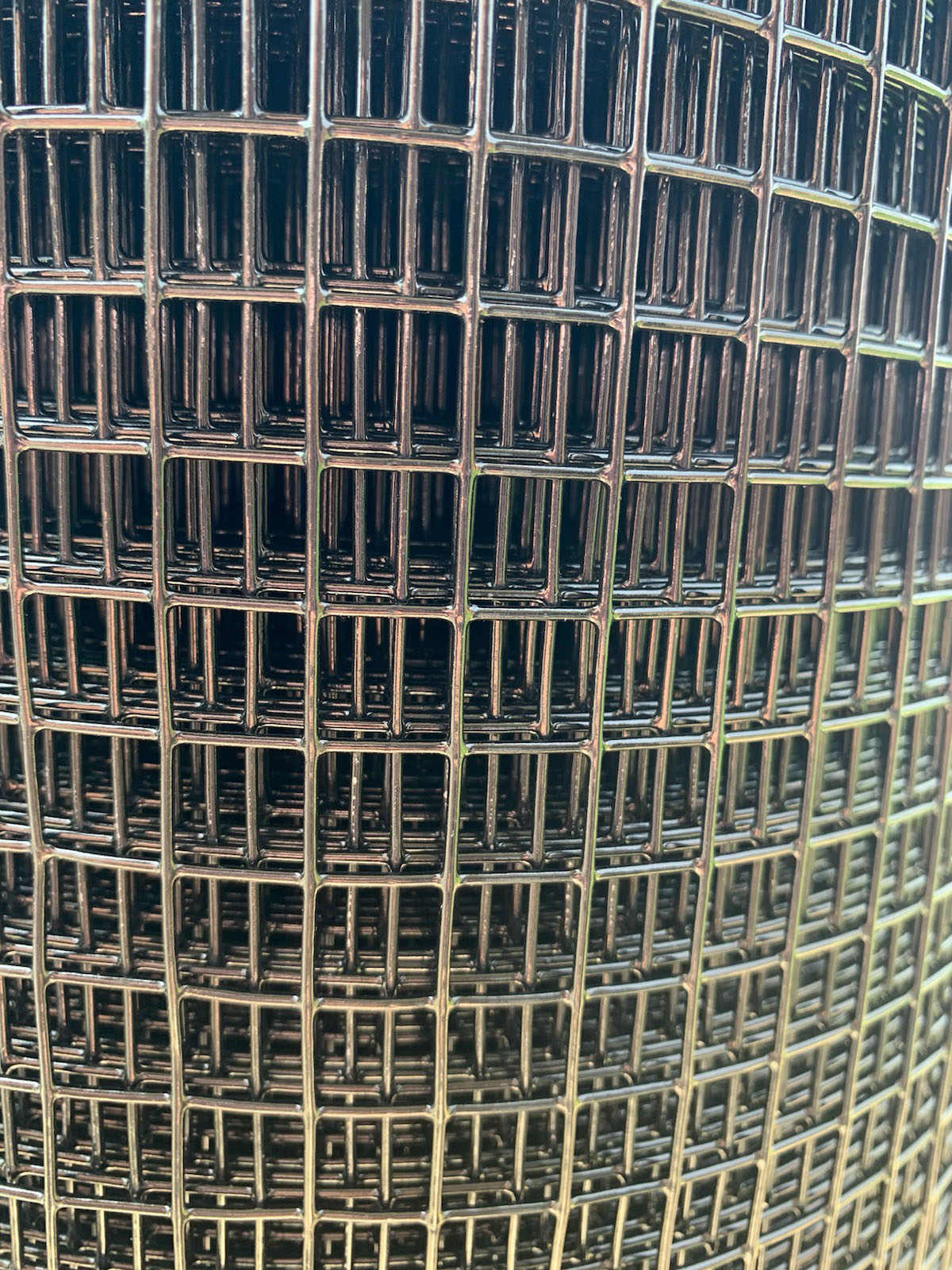

Illustrative image related to 1×1 hardware cloth

How Does 1×1 Hardware Cloth Enhance Home Improvement Projects?

In the home improvement sector, 1×1 hardware cloth is commonly used for creating custom enclosures for pets and outdoor spaces. This application provides safety and security, making it an attractive option for homeowners. When sourcing for this purpose, buyers should focus on custom sizing options and ease of installation. In European markets, where DIY culture is strong, providing ready-to-install solutions can significantly enhance the product’s appeal.

3 Common User Pain Points for ‘1×1 hardware cloth’ & Their Solutions

Scenario 1: Difficulty in Sourcing Durable 1×1 Hardware Cloth

The Problem: B2B buyers, especially those operating in regions with harsh environmental conditions, often face challenges in sourcing hardware cloth that can withstand extreme weather, pests, and other forms of wear and tear. For instance, a construction firm in Saudi Arabia might struggle to find a supplier that offers galvanized or vinyl-coated options that are not only cost-effective but also durable enough for long-term use in fencing and gardening applications. The risk of investing in subpar materials can lead to increased costs due to replacements and repairs.

The Solution: To address sourcing issues, buyers should prioritize suppliers that specialize in heavy-duty, galvanized, or vinyl-coated 1×1 hardware cloth. Conduct thorough research on suppliers by reviewing their certifications, production methods, and customer feedback. It’s essential to request samples to assess the material’s strength and durability firsthand. Additionally, consider establishing a relationship with local distributors who understand regional conditions and can provide tailored solutions. Utilizing bulk purchasing options can also yield significant savings and ensure a consistent supply of high-quality materials for ongoing projects.

Scenario 2: Installation Challenges with 1×1 Hardware Cloth

The Problem: Many buyers encounter difficulties during the installation of 1×1 hardware cloth, particularly when it comes to ensuring a secure and effective fit for their intended applications, such as livestock enclosures or garden fencing. Inexperienced teams may struggle with proper tensioning and attachment methods, leading to sagging or insecure fencing that does not serve its purpose. This can be especially problematic for businesses in agricultural sectors where security and durability are paramount.

Illustrative image related to 1×1 hardware cloth

The Solution: To overcome installation challenges, it is crucial to invest in comprehensive training for teams responsible for the setup. Suppliers often provide installation guides or videos that demonstrate best practices. Buyers should also consider employing professional contractors who have experience with hardware cloth installations. Key tips include using appropriate fasteners, ensuring the mesh is taut during installation, and applying a protective coating to prevent rust, particularly in humid environments. Furthermore, utilizing tools such as tensioning devices can enhance the installation process and ensure a long-lasting structure.

Scenario 3: Misunderstanding Specifications for 1×1 Hardware Cloth

The Problem: A common pain point for B2B buyers is the misunderstanding of specifications related to wire gauge and mesh size, which can lead to inappropriate selections for specific applications. For example, a buyer from a construction company in Nigeria might mistakenly choose a lower gauge mesh thinking it will suffice for securing a high-traffic area, only to find it bends or breaks under pressure. This miscalculation not only results in additional costs but also delays project timelines.

The Solution: To mitigate issues stemming from specification misunderstandings, it is imperative for buyers to familiarize themselves with the different wire gauges and their corresponding strengths. Engaging with suppliers who can provide expert guidance on material selection based on specific use cases is essential. For instance, a 16-gauge wire is typically suitable for general fencing, while a 12-gauge wire may be necessary for high-stress applications. Additionally, buyers should ensure they understand the implications of mesh size on the intended use, such as preventing small animal intrusion or maintaining structural integrity. Implementing a checklist during the procurement process can help ensure all necessary specifications are met before making a purchase.

Strategic Material Selection Guide for 1×1 hardware cloth

What Are the Key Materials for 1×1 Hardware Cloth?

When selecting 1×1 hardware cloth for various applications, the choice of material plays a crucial role in determining performance, durability, and suitability for specific environments. Here, we explore four common materials used in the manufacturing of 1×1 hardware cloth: galvanized steel, stainless steel, vinyl-coated wire, and hot-dipped galvanized wire.

How Does Galvanized Steel Perform in 1×1 Hardware Cloth Applications?

Galvanized steel is a popular choice for hardware cloth due to its excellent corrosion resistance and strength. The galvanization process involves coating the steel with a layer of zinc, which protects it from rust and degradation, particularly in outdoor applications. This material typically withstands temperatures up to 300°F and is suitable for medium-pressure environments.

Pros: Galvanized steel is relatively cost-effective, durable, and easy to install. It is ideal for agricultural applications, such as fencing for livestock and garden enclosures.

Cons: While it offers good corrosion resistance, it may not perform well in highly acidic or alkaline environments. Over time, the zinc coating can wear off, leading to rust if not maintained.

Illustrative image related to 1×1 hardware cloth

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards for galvanized materials, such as ASTM A653. The availability of galvanized steel may vary, so sourcing from reputable suppliers is essential.

What Advantages Does Stainless Steel Offer for 1×1 Hardware Cloth?

Stainless steel hardware cloth is another robust option, known for its superior corrosion resistance and strength. It is particularly effective in high-temperature environments, withstanding temperatures exceeding 1000°F without losing structural integrity.

Pros: Stainless steel is highly durable and resistant to rust, making it suitable for coastal and humid environments. Its aesthetic appeal also makes it a preferred choice for decorative applications.

Cons: The primary drawback is its higher cost compared to galvanized steel. Additionally, its manufacturing process can be more complex, potentially leading to longer lead times.

Considerations for International Buyers: Buyers in the Middle East and Europe should be aware of compliance with standards such as EN 10088 for stainless steel. The material’s availability may be influenced by local manufacturing capabilities.

Illustrative image related to 1×1 hardware cloth

How Does Vinyl-Coated Wire Enhance 1×1 Hardware Cloth?

Vinyl-coated wire is a versatile option that combines the strength of steel with a protective vinyl layer. This coating enhances corrosion resistance and provides an attractive finish, making it suitable for both agricultural and residential applications.

Pros: The vinyl coating offers excellent protection against rust, UV rays, and physical wear. It is also available in various colors, allowing for aesthetic customization.

Cons: The vinyl coating can be prone to chipping or peeling, which may expose the underlying wire to corrosion. Additionally, the cost is generally higher than that of standard galvanized wire.

Considerations for International Buyers: Buyers should check for compliance with local standards regarding coatings, such as ASTM D3359 for adhesion testing. Availability may vary based on regional manufacturing practices.

What Are the Benefits of Hot-Dipped Galvanized Wire for 1×1 Hardware Cloth?

Hot-dipped galvanized wire undergoes a more robust galvanization process than standard galvanized wire, resulting in a thicker zinc coating. This enhances its corrosion resistance and durability, making it suitable for harsh environments.

Pros: The thicker coating provides superior protection against rust and wear, making it ideal for long-term outdoor use. It is also relatively cost-effective compared to stainless steel.

Cons: The heavier weight of hot-dipped galvanized wire can complicate installation. Additionally, it may not be as aesthetically pleasing as vinyl-coated options.

Considerations for International Buyers: Compliance with standards such as ASTM A123 for hot-dipped galvanizing is essential. Buyers in regions with high humidity, such as parts of Africa, should prioritize this material for its enhanced durability.

Illustrative image related to 1×1 hardware cloth

Summary Table of Material Properties

| Material | Typical Use Case for 1×1 hardware cloth | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Agricultural fencing, garden enclosures | Cost-effective, durable | Prone to rust over time | Low |

| Stainless Steel | Coastal fencing, decorative applications | Superior corrosion resistance | Higher cost, complex manufacturing | High |

| Vinyl-Coated Wire | Residential fencing, garden protection | Attractive finish, excellent protection | Prone to chipping, higher cost | Med |

| Hot-Dipped Galvanized Wire | Long-term outdoor use | Superior rust protection | Heavier weight, less aesthetic appeal | Med |

This strategic material selection guide provides B2B buyers with critical insights into the properties and considerations of various materials for 1×1 hardware cloth, enabling informed purchasing decisions tailored to specific regional and application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for 1×1 hardware cloth

What Are the Key Manufacturing Processes for 1×1 Hardware Cloth?

The manufacturing of 1×1 hardware cloth involves several critical stages, each designed to ensure the production of a durable and reliable product suitable for various applications, from fencing to gardening. Understanding these processes can help B2B buyers assess the quality and reliability of their suppliers.

Material Preparation: What Raw Materials Are Used?

The primary raw material for 1×1 hardware cloth is steel wire, which can be either galvanized or coated for added protection against corrosion. The wire is typically produced using high-quality low-carbon steel, which ensures strength and flexibility. Before manufacturing begins, the wire is processed to remove any impurities and prepare it for subsequent stages. This may include annealing, which softens the wire, making it easier to work with.

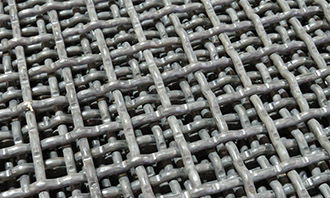

How Is the Wire Formed into Mesh?

The forming stage is crucial for creating the characteristic mesh structure of hardware cloth. The prepared wire is fed into a mesh weaving machine, where it is woven together to form a grid with 1-inch by 1-inch openings. This process can be achieved through various techniques, including welding or weaving.

Illustrative image related to 1×1 hardware cloth

- Welding: In welded wire mesh production, wires are joined at the intersections through an electric welding process, creating a robust bond. This method is preferred for its strength and uniformity.

- Weaving: Alternatively, the weaving process interlaces the wires without welding, which can be suitable for lighter applications but may not offer the same level of durability.

What Are the Finishing Techniques for Enhanced Durability?

After forming, the hardware cloth undergoes finishing processes that enhance its durability and functionality. These can include:

- Galvanization: The most common finishing technique is hot-dip galvanization, where the mesh is coated with a layer of zinc to protect against rust and corrosion. This is crucial for outdoor applications where exposure to moisture is a concern.

- Vinyl Coating: Some manufacturers apply a vinyl coating over the galvanized mesh to provide additional protection and aesthetic appeal. This coating helps prevent rust while also reducing visibility and enhancing the product’s lifespan.

How Is Quality Assurance Implemented During Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the final product meets industry standards and customer expectations. Various international and industry-specific standards guide these QA processes.

What International Standards Are Relevant for 1×1 Hardware Cloth?

B2B buyers should be aware of several international standards that govern the manufacturing of hardware cloth:

Illustrative image related to 1×1 hardware cloth

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers aiming to demonstrate their commitment to quality and customer satisfaction. Compliance with ISO 9001 indicates that the manufacturer has established a systematic approach to quality assurance.

- CE Marking: In Europe, the CE marking indicates that the product meets EU safety, health, and environmental protection standards. This is particularly important for buyers in the European market.

- API Standards: For applications in the oil and gas industry, adherence to American Petroleum Institute (API) standards may be required, ensuring that the product can withstand harsh conditions.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated throughout the manufacturing process, with several checkpoints to ensure product integrity:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Manufacturers verify that the wire meets specified standards before processing begins.

- In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor production parameters, ensuring that the mesh is being formed correctly and that welding or weaving techniques are applied consistently.

- Final Quality Control (FQC): Once the hardware cloth is completed, a final inspection is performed. This includes checking for any defects, measuring the mesh dimensions, and confirming that the finishing processes (like galvanization) meet quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying a supplier’s quality control processes is crucial to ensuring product reliability and compliance with standards. Here are some strategies:

What Audits and Reports Should Buyers Request?

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, equipment, and adherence to quality standards firsthand. This can provide valuable insights into the supplier’s operational capabilities.

- Quality Control Reports: Request detailed QC reports that document the findings from IQC, IPQC, and FQC checkpoints. These reports should include data on defect rates, compliance with standards, and corrective actions taken for any identified issues.

Are Third-Party Inspections Useful?

Engaging third-party inspection services can add an additional layer of assurance. These independent inspectors can conduct random sampling and testing of products to verify compliance with specified standards. This is particularly important for buyers from regions with stringent import regulations, such as the EU or North America.

What Nuances Should International Buyers Consider?

When sourcing 1×1 hardware cloth from international suppliers, especially from Africa, South America, the Middle East, and Europe, several nuances can affect the purchasing decision:

Illustrative image related to 1×1 hardware cloth

- Compliance with Local Regulations: Ensure that the product complies with local regulations and standards in the buyer’s region. This may include specific certifications or testing requirements.

- Cultural and Logistical Factors: Understanding the cultural context and logistical challenges in different regions can help in negotiating terms and ensuring timely delivery.

- Language and Communication: Clear communication regarding quality expectations, specifications, and compliance requirements is essential to avoid misunderstandings.

By understanding the manufacturing processes and quality assurance measures, B2B buyers can make informed decisions, ensuring that they source high-quality 1×1 hardware cloth that meets their specific needs and industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1×1 hardware cloth’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure 1×1 hardware cloth. By following these steps, you can ensure that you select the right materials from reliable suppliers, ultimately meeting your project requirements while optimizing cost and quality.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that the hardware cloth meets your specific needs. Consider factors such as wire gauge (commonly 16 or 12), coating type (galvanized or vinyl), and mesh size. This will help you avoid costly mistakes and ensure compatibility with your intended application.

Step 2: Research Market Trends and Prices

Conduct thorough market research to understand current pricing trends and demand for 1×1 hardware cloth. This involves checking multiple suppliers and comparing prices, taking into account shipping costs and potential tariffs. Understanding market dynamics will empower you to negotiate better deals and make informed purchasing decisions.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request company profiles, product certifications, and references from other businesses in your industry or region. Assess their reputation through reviews and feedback to ensure reliability and quality.

Illustrative image related to 1×1 hardware cloth

- Check for Certifications: Verify that suppliers comply with international standards such as ISO or ASTM.

- Inspect Quality Assurance Processes: Understand the supplier’s quality control measures to ensure consistent product quality.

Step 4: Request Samples for Testing

Prior to bulk purchasing, request samples of the hardware cloth to evaluate its quality and suitability for your application. This allows you to assess the material’s durability, flexibility, and resistance to environmental factors. Testing samples can prevent potential issues in the long run.

Step 5: Negotiate Terms and Conditions

Engage in negotiations with your chosen supplier to establish favorable terms and conditions. This includes pricing, payment terms, delivery schedules, and return policies. Clear agreements can minimize risks and protect your interests throughout the procurement process.

- Discuss Bulk Pricing: Inquire about discounts for larger orders to optimize your budget.

- Clarify Delivery Times: Ensure that timelines align with your project schedule to avoid delays.

Step 6: Finalize the Purchase Order

Once all terms are agreed upon, finalize the purchase order (PO). Ensure that the PO includes all agreed-upon details, including specifications, quantities, prices, and delivery dates. This serves as a formal agreement and can be referenced in case of disputes.

Step 7: Plan for Logistics and Delivery

Prepare for the logistics involved in receiving your order. Coordinate with your supplier regarding shipping methods and track delivery timelines to ensure that the hardware cloth arrives on schedule. Effective logistics planning can help you avoid operational disruptions.

By following this checklist, B2B buyers can streamline the sourcing process for 1×1 hardware cloth, ensuring that they select the right products from reputable suppliers while optimizing costs and timelines.

Illustrative image related to 1×1 hardware cloth

Comprehensive Cost and Pricing Analysis for 1×1 hardware cloth Sourcing

What Are the Key Cost Components in Sourcing 1×1 Hardware Cloth?

When sourcing 1×1 hardware cloth, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The choice of materials significantly impacts pricing. Common options include galvanized steel and vinyl-coated wire, with the latter typically commanding a higher price due to additional processing and durability features. Buyers should consider the long-term benefits of investing in higher-quality materials, especially in harsher environments.

-

Labor: Labor costs vary by region and can influence the overall price. In countries with higher wages, such as those in Europe, labor costs may contribute more significantly to the total price compared to regions in Africa or South America where labor might be cheaper.

-

Manufacturing Overhead: This encompasses utilities, rent, and other operational costs associated with production. Efficient manufacturers with streamlined operations can offer more competitive pricing.

-

Tooling and QC: The cost of tooling for specific configurations can add to the price, especially for custom orders. Quality control processes ensure product reliability, which can also be a cost factor, but investing in QC can prevent future costs related to product failures.

-

Logistics: Shipping and handling costs are significant, particularly for international transactions. Factors such as distance, shipping method, and destination country tariffs can greatly influence logistics costs.

-

Margin: The supplier’s margin will vary based on their operational costs and market positioning. Understanding this can provide insight into potential negotiation areas.

How Do Price Influencers Affect 1×1 Hardware Cloth Sourcing?

Several factors can influence the price of 1×1 hardware cloth:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Negotiating for lower prices based on higher order quantities can significantly reduce costs.

-

Specifications and Customization: Custom specifications, such as different gauges or coatings, can increase costs. Buyers should evaluate the necessity of such specifications against their budget.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO, ASTM) can drive up costs. However, these certifications can provide assurance of durability and compliance with local regulations, which may justify the higher price.

-

Supplier Factors: Supplier reputation, reliability, and location can affect pricing. Established suppliers may charge more due to their perceived reliability, while newer suppliers might offer competitive rates to enter the market.

-

Incoterms: Understanding Incoterms is essential for international buyers. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks, impacting the overall price.

What Buyer Tips Can Enhance Cost-Efficiency in 1×1 Hardware Cloth Procurement?

To enhance cost-efficiency in sourcing 1×1 hardware cloth, buyers should consider the following strategies:

-

Negotiation: Always negotiate pricing and terms. Suppliers may have room for flexibility, especially for larger orders or repeat business.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the TCO, which includes maintenance, replacement, and potential losses from product failures. Investing in higher-quality options can lead to lower TCO.

-

Pricing Nuances for International Buyers: Be aware of fluctuations in currency exchange rates, import duties, and taxes that can affect overall costs. It may be beneficial to work with suppliers who provide stable pricing structures or consider hedging against currency risks.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and preferential treatment in terms of delivery and payment terms.

-

Market Research: Conduct thorough market research to compare prices and product specifications from different suppliers. This can help identify the best value for money.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and regional factors. Buyers should conduct their due diligence to obtain accurate and current pricing information.

Alternatives Analysis: Comparing 1×1 hardware cloth With Other Solutions

In the competitive landscape of fencing and enclosure solutions, B2B buyers must weigh various options to determine the most suitable for their needs. Among these solutions, 1×1 hardware cloth stands out for its versatility and strength. However, there are several alternatives that may offer different benefits depending on the application. This analysis will explore how 1×1 hardware cloth compares with other viable solutions, including welded wire fencing and vinyl-coated wire mesh.

| Comparison Aspect | 1X1 Hardware Cloth | Welded Wire Fencing | Vinyl-Coated Wire Mesh |

|---|---|---|---|

| Performance | High durability; resistant to pests | Strong, ideal for livestock | Corrosion-resistant; aesthetic |

| Cost | Moderate cost per square foot | Generally lower cost per foot | Higher initial cost |

| Ease of Implementation | Requires tools for cutting and installation | Easy installation; pre-rolled options available | Moderate; requires care during installation |

| Maintenance | Minimal; occasional checks needed | Low; check for rust or damage | Low; vinyl coating reduces rust |

| Best Use Case | Garden enclosures, pest barriers | Livestock fencing, property lines | Decorative fencing, garden borders |

What Are the Advantages and Disadvantages of Welded Wire Fencing?

Welded wire fencing is a strong alternative to 1×1 hardware cloth, typically constructed from thicker gauge wire. This option excels in applications requiring robust barriers, such as livestock enclosures or larger properties. The primary advantage is its lower cost compared to 1×1 hardware cloth, making it attractive for extensive projects. However, welded wire fencing may not be as effective in preventing smaller pests from accessing gardens or delicate areas, limiting its use in specific applications.

How Does Vinyl-Coated Wire Mesh Compare?

Vinyl-coated wire mesh provides an aesthetically pleasing option with added corrosion resistance. The vinyl coating extends the life of the wire and makes it suitable for decorative applications, such as garden borders or fencing around pools. While it has a higher initial cost than 1×1 hardware cloth, its long-term durability and visual appeal can justify this investment. However, installation can be slightly more complex due to the coating, which may require careful handling to avoid damage.

What Should B2B Buyers Consider When Choosing Between These Options?

When selecting the right fencing solution, B2B buyers should consider the specific application requirements, budget constraints, and desired longevity. For projects involving gardens or areas with smaller animals, 1×1 hardware cloth might be the best option due to its fine mesh design. Conversely, for larger properties or livestock enclosures, welded wire fencing could provide a more economical solution. Vinyl-coated wire mesh serves well in scenarios where aesthetics and corrosion resistance are priorities, despite its higher upfront costs.

In conclusion, each fencing solution has distinct advantages and limitations, making it crucial for B2B buyers to align their choice with their project goals. Understanding the specific needs of their operations will enable buyers to make informed decisions that maximize both functionality and cost-efficiency.

Essential Technical Properties and Trade Terminology for 1×1 hardware cloth

What Are the Key Technical Properties of 1×1 Hardware Cloth?

-

Material Composition

The primary materials used for 1×1 hardware cloth include galvanized steel and vinyl-coated wire. Galvanized steel is treated with a zinc coating to prevent rust and corrosion, making it ideal for outdoor applications. Vinyl-coated options offer additional protection and aesthetic appeal, making them suitable for visible installations. Understanding the material composition is crucial for B2B buyers to ensure the product meets durability and environmental resistance requirements. -

Wire Gauge

The wire gauge indicates the thickness of the wire used in the mesh. Common gauges for 1×1 hardware cloth range from 12 to 16. A lower gauge number denotes thicker wire, which generally offers increased strength and longevity. Buyers should consider the wire gauge in relation to the intended application, such as livestock containment or garden protection, as it directly affects the mesh’s structural integrity. -

Mesh Size and Opening

The mesh size refers to the dimensions of the openings in the wire mesh, with 1×1 indicating one inch by one inch openings. This specification is vital for determining what can pass through the mesh, impacting its suitability for various applications, from keeping small animals contained to allowing airflow while preventing pests. Buyers must ensure that the mesh size aligns with their specific project requirements. -

Coating and Finish

Hardware cloth can come with different finishes, including galvanized and vinyl-coated options. Galvanization provides a robust defense against environmental factors, while vinyl coatings can enhance aesthetics and add an extra layer of protection against wear and tear. When sourcing, B2B buyers should evaluate the coating’s suitability based on the installation environment, whether it be harsh weather or high-traffic areas. -

Length and Roll Width

Standard roll dimensions for 1×1 hardware cloth vary, with common lengths reaching up to 100 feet and widths typically around 4 feet. Understanding these dimensions is essential for project planning, as it helps in estimating the quantity required and minimizing waste. B2B buyers should consider their specific application needs when selecting roll sizes. -

Durability and Longevity

The overall durability of the hardware cloth is influenced by its material, wire gauge, and coating. Products designed for heavy-duty applications will have higher durability ratings, making them suitable for long-term use in demanding environments. For B2B buyers, assessing the expected lifespan can help in budgeting and ensuring the product meets the intended use without frequent replacements.

What Are Common Trade Terms Related to 1×1 Hardware Cloth?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of hardware cloth, OEM suppliers often provide customized solutions tailored to specific industrial needs, allowing B2B buyers to source unique products for their projects. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it directly impacts inventory management and cost-effectiveness. Buyers must evaluate their needs against MOQ to avoid overstocking or incurring higher per-unit costs. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products. For hardware cloth, issuing an RFQ allows buyers to compare pricing, specifications, and terms from multiple vendors, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to clarify shipping costs, risk transfer, and delivery obligations, thereby ensuring smoother international trade operations. -

Lead Time

Lead time refers to the time taken from placing an order until its delivery. In the hardware cloth industry, lead times can vary significantly based on production schedules and shipping logistics. B2B buyers should factor lead time into their project timelines to avoid delays. -

Bulk Pricing

Bulk pricing refers to discounted rates offered for purchasing larger quantities of products. This term is particularly relevant for B2B buyers looking to optimize their costs, as buying in bulk can lead to significant savings and improved profit margins for resale.

Understanding these technical properties and trade terminology can empower B2B buyers to make informed purchasing decisions regarding 1×1 hardware cloth, ensuring they select the right products for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the 1×1 hardware cloth Sector

What are the Key Trends Influencing the 1×1 Hardware Cloth Market?

The global market for 1×1 hardware cloth is experiencing significant growth, driven by several factors that international B2B buyers should consider. The rising demand for agricultural fencing and enclosures in regions like Africa and South America is propelled by an increasing focus on livestock protection and sustainable farming practices. In the Middle East, the construction sector is booming, leading to an uptick in demand for durable fencing solutions that can withstand harsh climates.

Emerging technologies in sourcing, such as online marketplaces and digital supply chain management platforms, are reshaping how buyers procure materials. This shift allows for greater transparency and efficiency in the procurement process, enabling buyers to compare prices and quality more easily. Additionally, advancements in manufacturing processes, such as automated welding and improved galvanization techniques, are enhancing product durability and reducing lead times, which is crucial for international buyers who require timely deliveries.

Market dynamics are also influenced by fluctuating raw material prices, particularly steel, which can impact overall costs. Buyers should keep an eye on global supply chain trends, as geopolitical factors and trade policies may affect availability and pricing. Understanding these dynamics will empower buyers to make informed decisions that align with their operational needs and budget constraints.

How Can Sustainability and Ethical Sourcing Impact Your Purchase of 1×1 Hardware Cloth?

Sustainability has become a cornerstone of procurement strategies for B2B buyers, particularly in the hardware cloth sector. The environmental impact of sourcing practices is under scrutiny, with buyers increasingly favoring suppliers who demonstrate commitment to sustainable practices. For instance, opting for hardware cloth made from recycled materials or produced through energy-efficient processes can significantly reduce the carbon footprint associated with manufacturing.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers should ensure that their suppliers adhere to fair labor practices and provide safe working conditions. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Incorporating ‘green’ certifications into the procurement process not only enhances brand reputation but can also lead to long-term cost savings through reduced waste and improved operational efficiencies. B2B buyers in regions such as Europe and the Middle East are particularly attuned to these factors, as regulatory frameworks increasingly mandate sustainable practices.

What is the Historical Context of 1×1 Hardware Cloth in the B2B Market?

The evolution of 1×1 hardware cloth can be traced back to the early 20th century, when it emerged as a versatile solution for fencing and agricultural applications. Initially used primarily in rural settings, its durability and adaptability quickly made it a preferred choice for a wide array of applications, from gardening to industrial uses.

Over the decades, advancements in materials and manufacturing techniques, such as the introduction of galvanized and vinyl-coated options, have expanded its usability and lifespan. This evolution has made 1×1 hardware cloth not only a practical choice for buyers but also a cost-effective investment in long-term infrastructure. As the global market continues to evolve, understanding this historical context helps buyers appreciate the reliability and versatility of 1×1 hardware cloth in modern applications.

Illustrative image related to 1×1 hardware cloth

By aligning procurement strategies with current market dynamics, sustainability considerations, and the historical significance of hardware cloth, international B2B buyers can make informed decisions that bolster their operational success while contributing positively to the environment and society.

Frequently Asked Questions (FAQs) for B2B Buyers of 1×1 hardware cloth

-

How do I select the right gauge for my 1×1 hardware cloth needs?

Choosing the appropriate gauge for your 1×1 hardware cloth depends on the specific application and the level of durability required. Generally, a 16-gauge wire is suitable for light applications such as garden fencing or animal enclosures, while a 12-gauge wire provides greater strength for more demanding environments, like livestock fencing or industrial uses. Consider factors such as the type of animals, environmental conditions, and potential wear and tear to make an informed choice. -

What are the best applications for 1×1 hardware cloth?

1×1 hardware cloth is versatile and can be utilized in various applications, including garden fencing, animal enclosures, and property dividers. It is also effective for construction projects, such as reinforcing walls or ceilings, and in agricultural settings for pest control. Additionally, it can be used for crafting and DIY projects, making it a valuable material for both commercial and residential uses. -

How do I ensure the quality of 1×1 hardware cloth from suppliers?

To ensure quality, start by vetting suppliers through reviews and testimonials from previous clients. Request samples to assess the material’s durability, gauge, and coating. Additionally, inquire about the manufacturing process, including any certifications or standards they adhere to, such as ISO or ASTM. Establishing clear quality assurance protocols and communicating your specific requirements can also help ensure you receive high-quality products. -

What are the typical minimum order quantities (MOQ) for 1×1 hardware cloth?

Minimum order quantities for 1×1 hardware cloth can vary by supplier and region. Generally, MOQs range from 500 to 1,000 square feet for bulk orders. However, many suppliers offer flexible options for smaller orders, especially for initial trial purchases. Always discuss your needs with potential suppliers to negotiate MOQs that align with your purchasing plans. -

What payment terms should I expect when sourcing 1×1 hardware cloth internationally?

Payment terms can vary significantly among suppliers, but common arrangements include upfront payment, partial payment upon order confirmation, and balance upon shipment. For international transactions, options such as letters of credit or PayPal might be offered. Ensure you clarify payment terms before finalizing contracts to avoid any misunderstandings and protect your financial interests. -

How do shipping and logistics work for international orders of 1×1 hardware cloth?

Shipping logistics for international orders typically involve selecting a freight forwarder who can handle customs clearance and delivery. Costs will depend on the volume, weight, and destination. It’s crucial to discuss shipping options with your supplier and confirm delivery timelines. Additionally, ensure that all necessary documentation, such as invoices and shipping manifests, is prepared to facilitate smooth customs processes. -

Can I customize my order of 1×1 hardware cloth?

Many suppliers offer customization options, including different gauges, coatings (such as vinyl or galvanized), and roll sizes. If you have specific requirements, communicate these to your supplier at the outset. Custom orders may have different lead times and pricing, so it’s advisable to confirm all details before proceeding. -

What are the best practices for storing 1×1 hardware cloth before installation?

To maintain the integrity of 1×1 hardware cloth, store it in a dry, sheltered area to prevent rust and corrosion. Avoid direct contact with the ground to minimize moisture exposure. If the rolls are large, consider stacking them to save space, but ensure they are secured to prevent them from unrolling. Proper storage conditions will help prolong the product’s lifespan and performance.

Top 3 1X1 Hardware Cloth Manufacturers & Suppliers List

1. Fencer Wire – 16 Gauge Black Vinyl Coated Welded Wire Mesh

Domain: fencerwire.com

Registered: 2012 (13 years)

Introduction: {“Product Name”: “16 Gauge Black Vinyl Coated Welded Wire Mesh”, “Size”: “1 inch by 1 inch”, “Material”: “16 gauge heavy duty galvanized wire”, “Coating”: “Vinyl coated for extra protection”, “Uses”: “Home and garden uses include property dividers and enclosures”, “Installation”: “Designed for fast and easy installation”, “SKU”: “WV16-BM11”, “UPC”: “Not specified”, “Shipping”: “Free Shipping”, “Bu…

2. McNICHOLS® – Metal Wire Mesh

Domain: mcnichols.com

Registered: 1996 (29 years)

Introduction: This company, McNICHOLS® – Metal Wire Mesh, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Backyard Chickens – Hardware Cloth Options

Domain: backyardchickens.com

Registered: 2000 (25 years)

Introduction: 1/2 inch and 1 inch hardware cloth options discussed for chicken run protection. 1/2 inch is recommended for keeping out snakes and small predators, while 1 inch may allow raccoons and other animals to reach in. 19 gauge wire is suggested as a minimum for durability. The discussion includes considerations for using 1 inch wire as an apron to prevent digging and the importance of a secure coop.

Strategic Sourcing Conclusion and Outlook for 1×1 hardware cloth

In the dynamic landscape of international trade, strategic sourcing of 1×1 hardware cloth presents significant opportunities for B2B buyers. This versatile material, characterized by its robust construction and adaptability, serves numerous applications across industries—from agriculture and construction to landscaping and home improvement. By prioritizing quality and durability, buyers can ensure their investments yield long-term benefits, such as reduced maintenance costs and enhanced performance.

As you navigate sourcing options, consider the importance of evaluating suppliers based on their product specifications, such as gauge, coating, and mesh size. Engaging with manufacturers that offer bulk discounts and flexible shipping options can also optimize your procurement process, ensuring timely delivery while managing costs effectively.

Looking ahead, the demand for 1×1 hardware cloth is expected to grow, driven by increasing infrastructure development and agricultural expansion in regions like Africa, South America, the Middle East, and Europe. Now is the time to align your sourcing strategy with these market trends. Explore partnerships with reputable suppliers to secure competitive pricing and superior product quality. By making informed sourcing decisions today, you position your business for success in tomorrow’s marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.