16 Oz Copper Sheet Metal Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for 16 oz copper sheet metal

Navigating the complexities of sourcing 16 oz copper sheet metal can pose significant challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The primary concern lies in identifying reliable suppliers while ensuring quality, cost-effectiveness, and compliance with regional specifications. This comprehensive guide serves as a crucial resource, offering insights into various types of 16 oz copper sheet metal, their diverse applications—from roofing and flashing to electrical components—and essential supplier vetting processes.

In this guide, we delve into the nuances of selecting the right copper sheet metal to meet your project needs. You’ll learn about the unique properties of 16 oz copper, including its malleability, durability, and suitability for different manufacturing processes. Additionally, we provide actionable tips on how to evaluate suppliers based on quality certifications, pricing structures, and customer service.

Understanding the intricacies of the copper sheet market is vital for making informed purchasing decisions. By leveraging the insights offered in this guide, B2B buyers will be empowered to navigate the global marketplace confidently, ensuring they secure the best materials for their projects while optimizing costs and meeting project timelines. Whether you’re based in Brazil, Nigeria, or anywhere across Europe, this resource will enhance your procurement strategy and streamline your sourcing efforts.

Understanding 16 oz copper sheet metal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Architectural Copper | Smooth, malleable finish; often used in decorative elements | Roofing, gutters, architectural accents | Pros: Aesthetic appeal, corrosion resistance. Cons: Higher initial cost. |

| Electrical Copper | High conductivity, typically 99.9% pure | Electrical applications, RF shielding | Pros: Excellent electrical properties. Cons: Limited to specific applications. |

| Craft Copper | Available in various sizes; often sold in sheets | Arts, crafts, DIY projects | Pros: Easy to work with, versatile. Cons: Not suitable for heavy-duty applications. |

| Roofing Copper | Preferred thickness for roofing; durable and weather-resistant | Roofing, flashing, and gutter systems | Pros: Long lifespan, effective in harsh conditions. Cons: Requires skilled installation. |

| Heavy Gauge Copper | Thicker than standard options; robust and sturdy | Industrial applications, heavy-duty projects | Pros: High durability, impact-resistant. Cons: More challenging to cut and handle. |

What are the Characteristics of Architectural Copper Sheets?

Architectural copper sheets are recognized for their smooth, malleable finish, making them ideal for decorative elements in construction projects. Typically used in roofing and gutters, these sheets offer aesthetic appeal alongside functional benefits, such as corrosion resistance. B2B buyers should consider the initial cost versus long-term benefits, as architectural copper enhances property value and durability, especially in high-end applications.

How Does Electrical Copper Differ in Use?

Electrical copper sheets are characterized by their high conductivity and purity, often reaching 99.9%. They are primarily utilized in electrical applications, including RF shielding, where superior conductivity is paramount. B2B purchasers should evaluate the specific electrical requirements of their projects, as electrical copper is tailored for high-performance scenarios. While it provides excellent electrical properties, its use is limited to specific applications, which may require careful planning.

Why Choose Craft Copper for DIY Projects?

Craft copper sheets are available in various sizes and are favored for arts, crafts, and DIY projects due to their ease of use. They can be easily shaped and cut, allowing for creative applications in smaller-scale endeavors. B2B buyers should consider the versatility of craft copper, as it is suitable for a range of projects, but it’s essential to note that it may not withstand heavy-duty applications typically required in industrial settings.

What Makes Roofing Copper Ideal for Construction?

Roofing copper is the preferred thickness for roofing applications, valued for its durability and weather resistance. It is commonly used in flashing and gutter systems, ensuring effective water management in construction. B2B buyers must consider the installation expertise required, as roofing copper often necessitates skilled labor to achieve optimal results. Despite the higher upfront investment, its long lifespan and effectiveness in harsh conditions make it a worthwhile consideration.

When Should You Use Heavy Gauge Copper?

Heavy gauge copper sheets are thicker than standard options, providing robust and sturdy solutions for industrial applications and heavy-duty projects. Their impact resistance and durability make them suitable for environments where strength is critical. B2B buyers should assess the handling and cutting challenges associated with heavy gauge copper, as its thickness may require specialized tools and techniques. While it can be more challenging to work with, the long-term benefits in durability and performance often justify the investment.

Key Industrial Applications of 16 oz copper sheet metal

| Industry/Sector | Specific Application of 16 oz copper sheet metal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Roofing and Flashing | Durable and weather-resistant roofing solutions | Ensure compliance with local building codes and standards. |

| Electrical Engineering | RF Shielding and Electrical Components | Enhanced signal integrity and reduced interference | Verify material purity (CDA Alloy 110) for electrical applications. |

| Art and Craftsmanship | Decorative Elements and Sculptures | High aesthetic appeal and malleability for designs | Consider custom sizes and thickness requirements for projects. |

| HVAC and Plumbing | Ductwork and Pipe Fabrication | Corrosion resistance and long lifespan | Confirm compatibility with existing systems and installation methods. |

| Renewable Energy | Solar Panel Mounting and Components | Lightweight yet strong support structures | Assess weight and load-bearing capacities for specific installations. |

How is 16 oz Copper Sheet Metal Used in Construction?

In the construction industry, 16 oz copper sheet metal is primarily utilized for roofing and flashing applications. Its durability and resistance to weather elements make it an ideal choice for long-lasting roofs. For international buyers, especially in regions like Africa and the Middle East, sourcing copper that meets local building codes is crucial. Additionally, understanding the specific thickness and size needed for various roofing projects can prevent costly installation errors.

What Role Does 16 oz Copper Sheet Metal Play in Electrical Engineering?

In electrical engineering, 16 oz copper sheet metal serves as an effective material for RF shielding and other electrical components. Its high conductivity ensures minimal signal loss, which is vital for communication systems. Buyers from South America and Europe must verify the purity of the copper (CDA Alloy 110) to meet stringent electrical performance requirements. Furthermore, understanding the specific applications within their projects can optimize sourcing and reduce costs.

How Can Artists and Craftsmen Utilize 16 oz Copper Sheet Metal?

Artists and craftsmen leverage 16 oz copper sheet metal for creating decorative elements and sculptures. The metal’s malleability allows for intricate designs, while its natural patina adds character over time. For buyers in the art sector, particularly in Europe and Africa, sourcing custom sizes is often necessary to meet unique project specifications. Understanding the aesthetic qualities and potential for customization can enhance the value of their artistic creations.

What Are the Applications of 16 oz Copper Sheet Metal in HVAC and Plumbing?

In the HVAC and plumbing industries, 16 oz copper sheet metal is often used in ductwork and pipe fabrication due to its corrosion resistance and longevity. This metal ensures reliable performance in various environmental conditions. Buyers from regions like Brazil and Nigeria should consider compatibility with existing systems and installation methods to ensure seamless integration. Proper sourcing can lead to significant cost savings by minimizing maintenance and replacement needs.

How is 16 oz Copper Sheet Metal Important for Renewable Energy Solutions?

16 oz copper sheet metal plays a critical role in renewable energy applications, particularly in solar panel mounting systems. Its lightweight yet sturdy nature provides essential support for solar arrays. International buyers in emerging markets must assess the weight and load-bearing capabilities of the copper to ensure efficient installation. Understanding local regulations and sourcing standards can facilitate smoother project execution and compliance with safety norms.

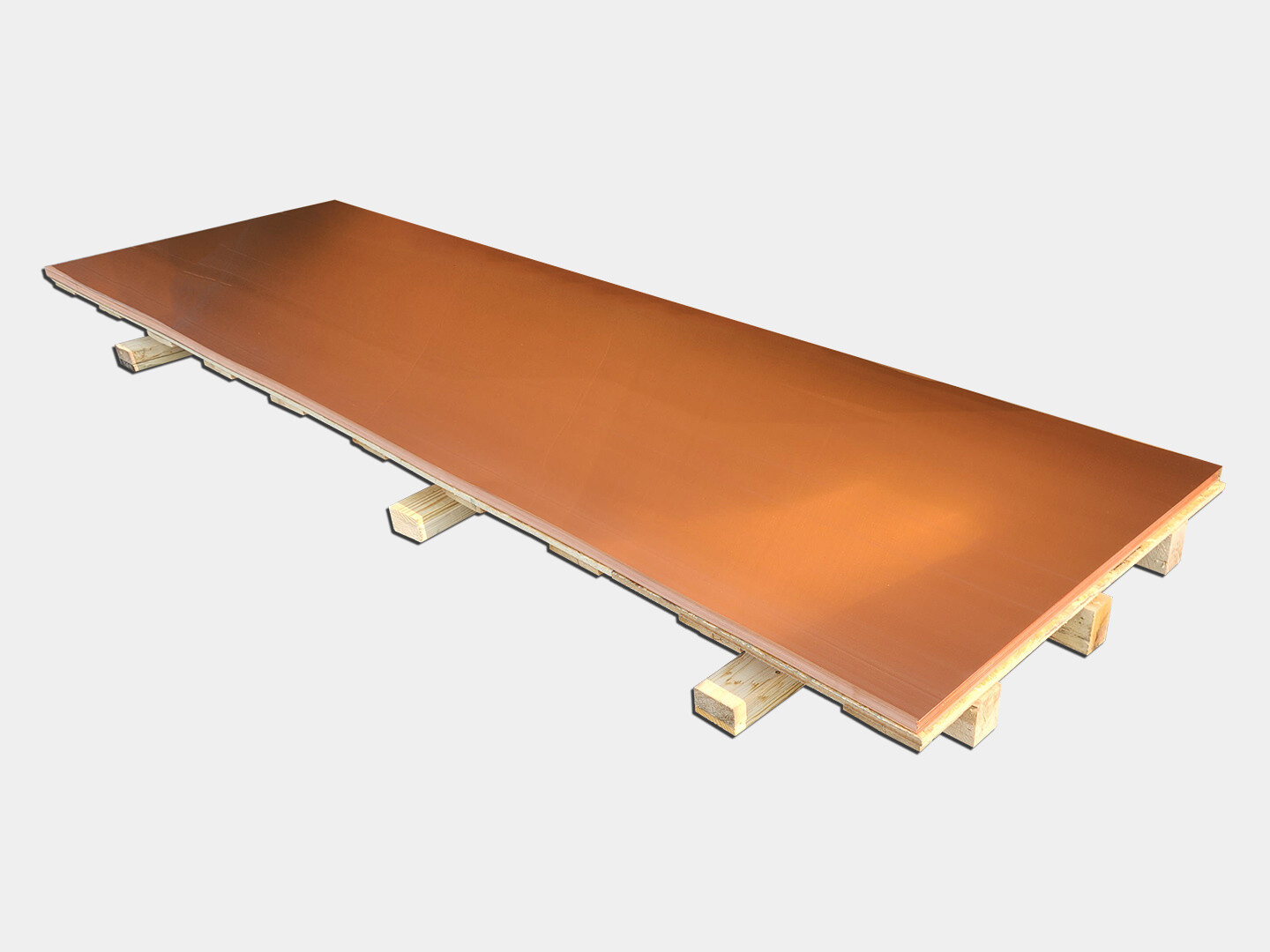

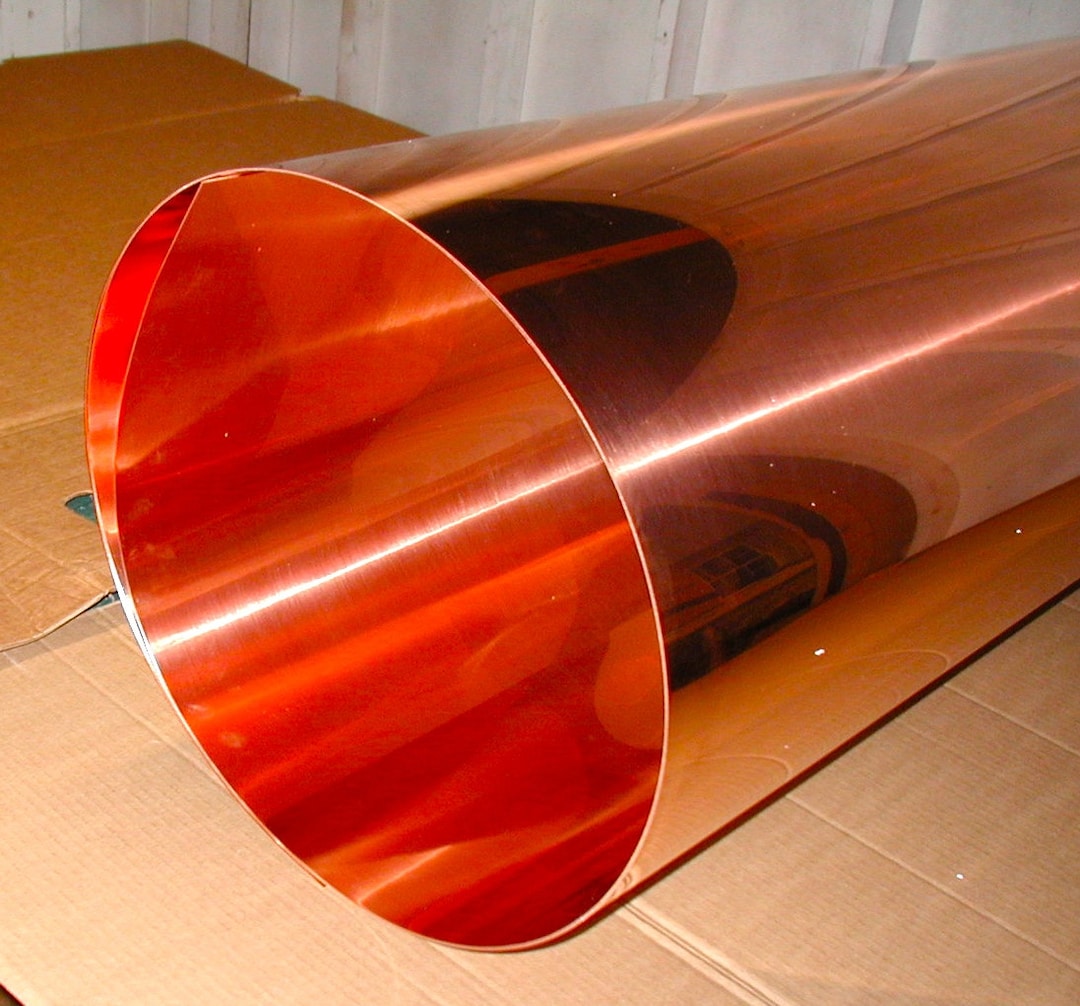

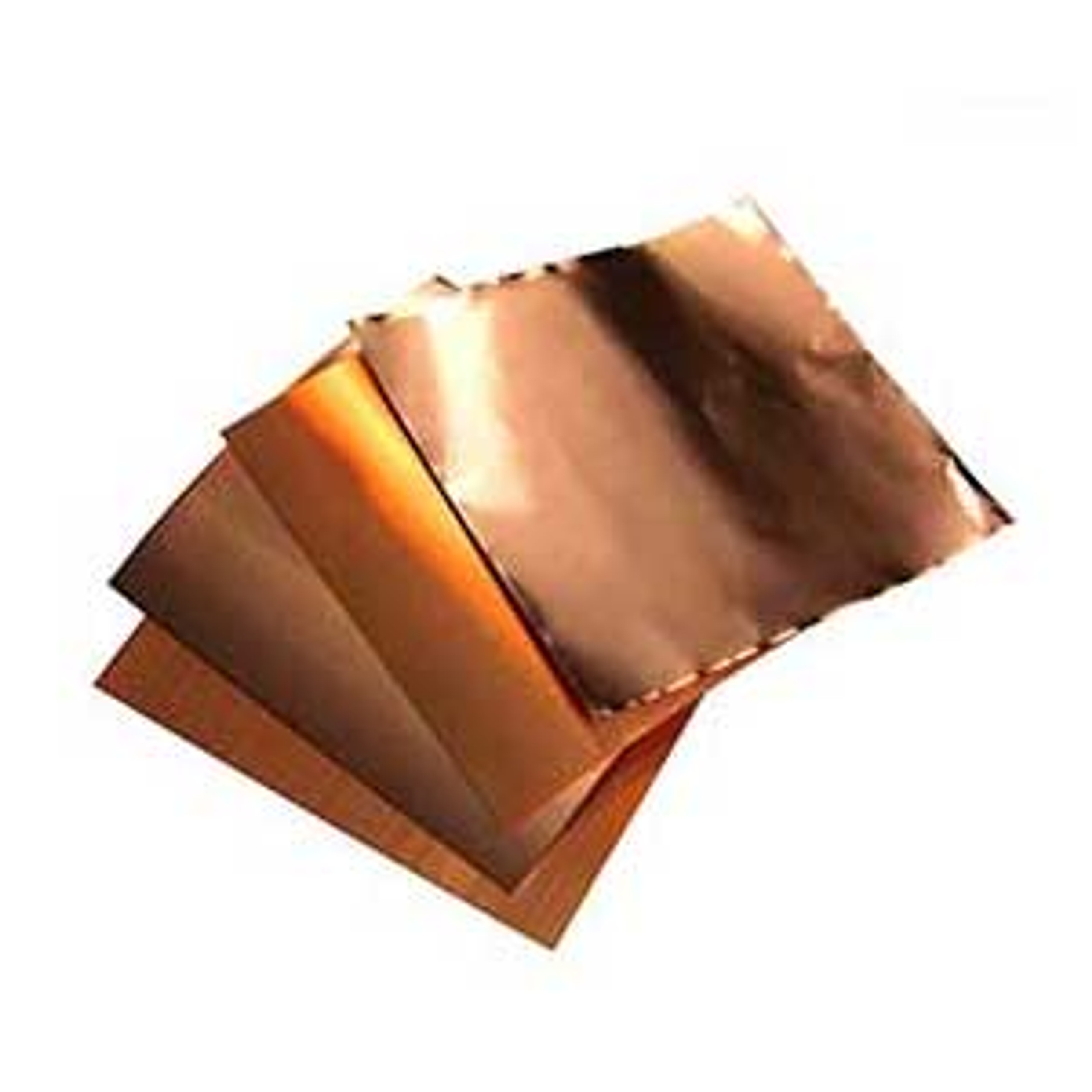

Illustrative image related to 16 oz copper sheet metal

3 Common User Pain Points for ’16 oz copper sheet metal’ & Their Solutions

Scenario 1: Sourcing Quality 16 oz Copper Sheet Metal

The Problem: B2B buyers often struggle to find reliable suppliers who provide high-quality 16 oz copper sheet metal. In regions like Africa or South America, the availability of pure copper sheets can be limited, leading to concerns about sourcing materials that meet industry standards. Buyers may encounter suppliers offering subpar products that do not adhere to specifications, resulting in project delays and increased costs. Additionally, fluctuating market prices can complicate budgeting and long-term planning.

The Solution: To effectively source high-quality 16 oz copper sheet metal, buyers should establish relationships with reputable suppliers who have a proven track record in the industry. Conduct thorough research to identify suppliers that comply with ASTM-B152 specifications, ensuring that the copper sheets are made from at least 99.9% pure copper. Utilize platforms that provide verified supplier ratings and reviews to gauge reliability. Moreover, consider forming partnerships with multiple suppliers to mitigate risks associated with price volatility. When negotiating, request sample sheets to assess quality before committing to larger orders. By taking these proactive steps, buyers can secure dependable sources for their copper sheet needs.

Scenario 2: Managing Shipping and Delivery Challenges

The Problem: International shipping of 16 oz copper sheet metal can present logistical challenges, particularly for buyers in remote areas of the Middle East or Africa. Issues such as delays in freight delivery, high shipping costs, and the risk of damage during transit can lead to significant project setbacks. Additionally, some suppliers may not provide adequate support for unloading large shipments, creating further complications for buyers without the necessary resources.

The Solution: To manage shipping and delivery challenges effectively, buyers should work closely with suppliers who offer comprehensive shipping options, including freight services that cater to international clients. Prior to placing an order, clarify shipping terms, including responsibilities for unloading and any additional costs associated with delivery. It may be beneficial to partner with a logistics provider experienced in handling metal products to ensure smooth transit. Additionally, opting for suppliers that offer tracking services can help buyers stay informed about shipment status, allowing for better project planning. By addressing shipping logistics early on, buyers can minimize disruptions and maintain project timelines.

Scenario 3: Ensuring Proper Specification for Project Requirements

The Problem: Many B2B buyers encounter difficulties when specifying the correct dimensions and thickness of 16 oz copper sheet metal for their projects. Inadequate specifications can lead to purchasing the wrong size, which may necessitate costly returns or modifications. This is particularly critical in sectors such as construction, where precise measurements are essential for roofing, guttering, or electrical applications.

The Solution: To ensure proper specification, buyers should invest time in understanding the exact requirements of their projects. This includes consulting with engineers or project managers to determine the necessary thickness, width, and length of the copper sheets. Utilizing comprehensive thickness guides and project advice resources available from suppliers can provide clarity on the options available. Before finalizing an order, buyers should double-check their specifications and consider ordering slightly larger sheets to accommodate any adjustments during installation. Additionally, engaging with suppliers for technical advice can enhance understanding of the product’s applications, ensuring that the right materials are sourced for the intended use. By taking these steps, buyers can avoid costly mistakes and optimize their purchasing decisions.

Strategic Material Selection Guide for 16 oz copper sheet metal

What Are the Key Properties of 16 oz Copper Sheet Metal?

When considering 16 oz copper sheet metal, one of the primary materials is Copper Alloy 110, which is 99.9% pure copper. This alloy exhibits excellent electrical conductivity, making it ideal for electrical applications such as RF shielding and wiring. Additionally, it has good thermal conductivity, which is beneficial for heat transfer applications. The material is also highly malleable and ductile, allowing for easy shaping and forming, which is advantageous in various construction and artistic applications.

What Are the Pros and Cons of Using 16 oz Copper Sheet Metal?

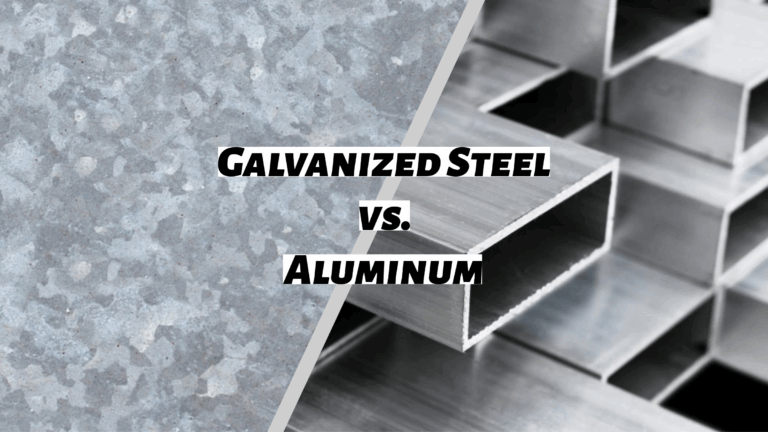

The advantages of 16 oz copper sheet metal include its durability and resistance to corrosion, particularly in outdoor environments. This makes it a preferred choice for roofing, flashing, and gutter applications. However, the cost of copper can be a significant drawback, as it tends to be higher than other materials like aluminum or galvanized steel. Additionally, while copper is easy to work with, it requires specific tools for cutting and shaping, which may add to manufacturing complexity.

How Does 16 oz Copper Sheet Metal Impact Specific Applications?

In roofing and flashing applications, 16 oz copper sheet metal provides long-lasting performance due to its resistance to rust and corrosion. It can withstand various environmental conditions, making it suitable for regions with extreme weather, such as heavy rains or intense sunlight. However, international buyers must consider the patina that develops over time, which can alter the aesthetic appeal of the product. For electrical applications, the high conductivity of copper ensures efficient performance, but buyers should ensure compatibility with other materials to avoid galvanic corrosion.

What Should International B2B Buyers Consider When Sourcing 16 oz Copper Sheet Metal?

International buyers, particularly from Africa, South America, the Middle East, and Europe, must be aware of compliance with local standards such as ASTM, DIN, or JIS. This ensures that the materials meet the necessary quality and performance criteria. Additionally, understanding the local market dynamics, including price volatility and availability, is crucial. Buyers should also consider logistical aspects such as shipping costs and the need for specialized handling due to the weight and fragility of copper sheets.

Illustrative image related to 16 oz copper sheet metal

Summary Table of Material Selection for 16 oz Copper Sheet Metal

| Material | Typical Use Case for 16 oz copper sheet metal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper Alloy 110 | Roofing, flashing, electrical applications | Excellent conductivity and durability | Higher cost compared to alternatives | High |

| Aluminum | Lightweight roofing and decorative applications | Cost-effective and lightweight | Lower durability than copper | Medium |

| Galvanized Steel | Construction and structural applications | Good strength and lower cost | Prone to rust without proper coating | Low |

| Stainless Steel | High-end architectural applications | Corrosion-resistant and aesthetic | More challenging to work with | High |

This guide provides a comprehensive overview of the strategic material selection for 16 oz copper sheet metal, enabling B2B buyers to make informed decisions based on specific application needs and regional considerations.

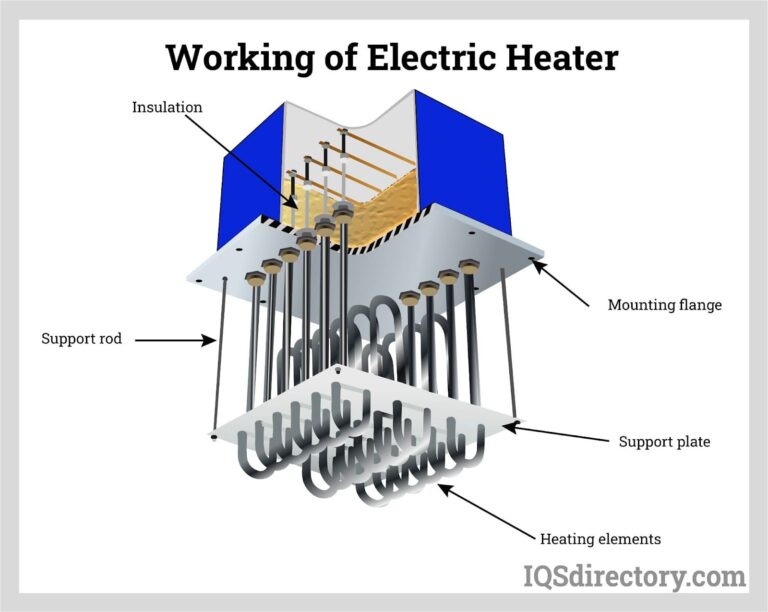

In-depth Look: Manufacturing Processes and Quality Assurance for 16 oz copper sheet metal

What Are the Key Stages in the Manufacturing Process of 16 oz Copper Sheet Metal?

The manufacturing process of 16 oz copper sheet metal involves several critical stages that ensure the final product meets the quality and performance expectations of various applications, particularly in construction, electrical, and artistic endeavors.

Material Preparation

The process begins with material preparation, where high-purity copper is sourced, typically alloy 110, which contains 99.9% copper. This raw material is carefully inspected for impurities and inconsistencies. The copper is then melted in a controlled environment to maintain its quality. After melting, the copper is cast into large slabs or billets.

Forming Techniques

Once the copper is prepared, the next step is forming. This involves rolling the copper slabs into sheets. The rolling process can be hot or cold, depending on the desired properties of the final product. For 16 oz copper sheets, a cold rolling technique is often employed to achieve the precise thickness of 0.0216 inches (0.549 mm). This method enhances the malleability and durability of the sheets, making them suitable for bending and forming into various shapes.

Illustrative image related to 16 oz copper sheet metal

Assembly and Cutting

Following the rolling process, the sheets are cut into specific dimensions based on customer requirements. Common sizes for 16 oz copper sheets include 24″x120″, 36″x120″, and others. This stage may involve the use of shears or metal snips, ensuring clean cuts without compromising the material’s integrity.

Finishing Processes

The final stage of manufacturing involves finishing processes such as annealing, which softens the copper and improves its workability. A smooth commercial finish is typically applied, ensuring the sheets are free of defects and surface imperfections. This finish is essential for applications where aesthetics are important, such as in architectural designs or art projects.

How Is Quality Assurance Implemented During Copper Sheet Metal Production?

Quality assurance is critical in the manufacturing of 16 oz copper sheet metal, ensuring that the product meets international standards and customer specifications.

What International Standards Apply to Copper Sheet Metal Manufacturing?

Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards is crucial for ensuring consistent product quality and customer satisfaction. Additionally, industry-specific certifications such as CE marking (for products sold in Europe) and API standards (for applications in the oil and gas industry) may also apply, depending on the intended use of the copper sheets.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. Any defective materials are rejected before processing begins.

-

In-Process Quality Control (IPQC): During production, samples are taken at regular intervals to monitor the thickness, tensile strength, and surface finish of the copper sheets. This allows for immediate corrective actions if any deviations from specifications are detected.

-

Final Quality Control (FQC): Once the sheets are produced, a final inspection is conducted. This includes verifying dimensions, surface quality, and overall appearance. Random sampling may also be performed to ensure batch consistency.

What Testing Methods Are Commonly Used for Quality Assurance in Copper Sheets?

Several testing methods are employed to ensure the quality of 16 oz copper sheets:

-

Visual Inspection: A thorough visual inspection is conducted to identify any surface defects, discoloration, or imperfections.

-

Dimensional Testing: Tools such as calipers and micrometers are used to verify that the thickness and dimensions of the sheets meet specified tolerances.

-

Mechanical Testing: Tensile testing is performed to assess the strength and ductility of the copper. This ensures that the sheets can withstand the demands of their intended applications.

-

Chemical Analysis: Spectrometry may be used to verify the composition of the copper, ensuring that it meets the required alloy specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential for ensuring reliability and performance in copper sheet metal products.

What Steps Can Buyers Take to Ensure Supplier Credibility?

-

Supplier Audits: Conducting audits of suppliers’ manufacturing facilities can provide insights into their quality control processes. This includes reviewing their compliance with international standards and assessing their production capabilities.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality control reports, including information on testing methods, results, and any corrective actions taken for non-conforming products.

-

Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased evaluation of the supplier’s quality management practices and product quality.

-

Certifications and Documentation: Verifying that suppliers possess relevant certifications (e.g., ISO 9001, CE marking) and maintaining documentation of these certifications can provide additional assurance of product quality.

What Are the Quality Control Nuances for International Buyers?

International buyers should be aware of specific nuances when dealing with suppliers in different regions. These can include variations in local regulations, standards compliance, and shipping logistics.

-

Cultural Differences: Understanding cultural nuances can improve communication and negotiation with suppliers. Establishing a rapport can facilitate better quality control practices.

-

Logistical Considerations: Different regions may have unique shipping and handling requirements that can impact product quality. Buyers should ensure that suppliers are knowledgeable about these factors and can provide appropriate packaging and transportation methods.

-

Market-Specific Standards: Buyers should be informed about the standards that apply in their own markets to ensure that the products received will meet local regulations and expectations.

In conclusion, understanding the manufacturing processes and quality assurance measures for 16 oz copper sheet metal is essential for B2B buyers. By being informed about these processes, buyers can make better decisions, ensuring they procure high-quality materials that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ’16 oz copper sheet metal’

Introduction:

Navigating the procurement of 16 oz copper sheet metal can be a complex task, especially for international B2B buyers. This guide provides a step-by-step checklist designed to streamline your sourcing process, ensuring you select the right product and supplier to meet your specific needs.

Step 1: Define Your Technical Specifications

Before you begin sourcing, clearly define the technical specifications of the 16 oz copper sheet metal you require. This includes understanding the dimensions (length, width), thickness (0.0216 inches), and finish (mill finish is common).

– Why it Matters: Accurate specifications prevent costly errors and ensure that the product meets your project requirements.

– What to Look For: Confirm the gauge number and ensure it aligns with industry standards (like ASTM-B152) for quality assurance.

Step 2: Research Potential Suppliers

Compile a list of potential suppliers specializing in copper sheet metal. Look for companies with a solid reputation in the industry, particularly those who have experience with international shipping and compliance.

– Why it Matters: A well-vetted supplier can significantly reduce risks associated with quality and delivery timelines.

– What to Look For: Supplier reviews, certifications, and their experience in dealing with B2B transactions, especially in your target regions.

Step 3: Evaluate Supplier Certifications

Once you have identified potential suppliers, verify their certifications and compliance with international quality standards. This may include ISO certifications and adherence to local regulations.

– Why it Matters: Certifications ensure that the supplier maintains quality control and follows industry best practices, which can affect the performance of the copper sheets.

– What to Look For: Request documentation that demonstrates their compliance and ask about their quality assurance processes.

Illustrative image related to 16 oz copper sheet metal

Step 4: Request Samples

Always request samples of the 16 oz copper sheet metal before making a bulk purchase. This allows you to assess the material’s quality, finish, and suitability for your specific applications.

– Why it Matters: Samples can help you avoid purchasing materials that do not meet your quality expectations.

– What to Look For: Examine the sample for any defects, surface scratches, or inconsistencies in thickness.

Step 5: Understand Pricing Structures

Engage with suppliers to understand their pricing structures, including bulk discounts, shipping costs, and potential price volatility.

– Why it Matters: Knowing the full cost upfront allows for better budget management and helps you avoid unexpected expenses.

– What to Look For: Request a detailed quote that outlines the pricing for various quantities and any additional fees.

Step 6: Confirm Delivery and Logistics

Before finalizing your order, discuss the delivery options and logistics with your chosen supplier. Ensure that they can meet your required timelines and understand any customs regulations that may apply.

– Why it Matters: Timely delivery is crucial for project schedules, especially in international transactions where delays can occur.

– What to Look For: Clarify shipping methods, estimated delivery times, and who is responsible for customs duties.

Step 7: Establish Clear Payment Terms

Finally, negotiate and establish clear payment terms with the supplier. This should include payment methods, timelines, and conditions for payment upon delivery.

– Why it Matters: Clear payment terms help to prevent disputes and ensure a smooth transaction process.

– What to Look For: Ensure that the terms are mutually agreeable and provide protection for both parties involved in the transaction.

By following this checklist, you can effectively navigate the procurement process for 16 oz copper sheet metal, ensuring a successful purchase that meets your business needs.

Comprehensive Cost and Pricing Analysis for 16 oz copper sheet metal Sourcing

When sourcing 16 oz copper sheet metal, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis delves into the various cost components, price influencers, and strategic buyer tips to optimize procurement.

What Are the Key Cost Components of 16 oz Copper Sheet Metal?

-

Materials: The primary cost driver is the raw copper itself. As of October 2023, copper prices are volatile due to global demand fluctuations and supply chain challenges. Buyers should monitor commodity markets to gauge material costs effectively.

-

Labor: Labor costs encompass the workforce required for manufacturing, cutting, and finishing the copper sheets. In regions with higher labor costs, such as Europe, this may significantly impact pricing compared to emerging markets in Africa or South America.

-

Manufacturing Overhead: This includes indirect costs such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer competitive pricing.

-

Tooling: Custom tooling for specific sheet sizes or configurations can add to upfront costs. Buyers should consider whether standard sizes will suffice or if custom tooling is necessary for their projects.

-

Quality Control (QC): Ensuring that sheets meet industry standards (e.g., ASTM-B152) involves quality assurance processes that contribute to costs. Certifications for purity and quality can also influence pricing.

-

Logistics: Shipping costs are particularly relevant for international buyers. Factors such as distance, mode of transport, and customs duties can significantly impact the total cost.

-

Margin: Suppliers will include a margin on top of their costs to ensure profitability. Understanding the market dynamics can help buyers negotiate better terms.

How Do Price Influencers Affect the Cost of 16 oz Copper Sheet Metal?

-

Volume and Minimum Order Quantity (MOQ): Pricing is often tiered based on order volume. Larger orders typically receive discounts, which can lead to significant savings for buyers planning long-term projects.

-

Specifications and Customization: Custom specifications can lead to higher costs. Buyers should assess whether standard products meet their needs or if the additional expense of customization is justified.

-

Quality and Certifications: Higher-quality copper sheets with certifications may command premium pricing. It’s essential to balance quality requirements with budget constraints.

-

Supplier Factors: Supplier reputation, reliability, and geographical location can influence pricing. Local suppliers may reduce shipping costs but may not always offer the best prices compared to international sources.

-

Incoterms: Understanding Incoterms is crucial for international transactions. The chosen term (e.g., FOB, CIF) will determine who bears shipping and insurance costs, impacting the overall price.

What Buyer Tips Can Help Optimize Sourcing of 16 oz Copper Sheet Metal?

-

Negotiation Strategies: Engage in discussions with suppliers about pricing, especially when placing large orders. Leverage competitive quotes from multiple suppliers to enhance negotiation power.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes procurement, maintenance, and disposal costs. A cheaper upfront price may lead to higher long-term costs due to quality issues.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and import/export regulations that may affect costs. Factor in potential tariffs and duties when calculating total expenses.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and insights into future price changes. Regular communication can foster trust and collaboration.

-

Stay Informed: Monitor market trends and economic indicators that influence copper prices. Being proactive can help buyers make timely purchasing decisions that capitalize on favorable market conditions.

Conclusion

In conclusion, a comprehensive understanding of the cost structure and pricing dynamics for 16 oz copper sheet metal is essential for international B2B buyers. By considering the various cost components, price influencers, and employing strategic sourcing tips, businesses can optimize their procurement processes and achieve significant cost savings. Always remember that prices can fluctuate, and it’s advisable to seek multiple quotes and maintain flexibility in sourcing strategies.

Alternatives Analysis: Comparing 16 oz copper sheet metal With Other Solutions

Introduction: Exploring Alternatives to 16 Oz Copper Sheet Metal

When evaluating materials for roofing, flashing, or various construction applications, it’s essential to consider alternatives to 16 oz copper sheet metal. While copper is renowned for its durability and aesthetic appeal, other materials may offer comparable performance at different price points or with unique properties. This analysis will compare 16 oz copper sheet metal to two viable alternatives: aluminum sheet metal and galvanized steel.

Comparison Table

| Comparison Aspect | 16 Oz Copper Sheet Metal | Aluminum Sheet Metal | Galvanized Steel Sheet |

|---|---|---|---|

| Performance | Excellent corrosion resistance, highly malleable, and conducts electricity well | Good corrosion resistance; lightweight and easy to form | Strong and durable; prone to rust without proper maintenance |

| Cost | Higher initial cost (approximately $279 for a standard sheet) | Generally lower cost (around $100-$150 for similar dimensions) | Moderate cost (approximately $80-$120 per sheet) |

| Ease of Implementation | Requires special tools for cutting; easy to bend by hand | Lightweight and easy to cut; can be shaped easily | Heavier, requiring more robust tools for cutting and installation |

| Maintenance | Develops a patina over time; minimal maintenance required | Low maintenance; corrosion-resistant | Requires regular maintenance to prevent rusting |

| Best Use Case | Ideal for roofing, flashing, and decorative elements in high-end applications | Suitable for residential and commercial roofing where weight is a concern | Best for structural applications and environments prone to heavy wear |

Detailed Breakdown of Alternatives

Aluminum Sheet Metal

Aluminum is a lightweight and versatile alternative to copper. It offers excellent corrosion resistance, making it suitable for various outdoor applications. The lower cost compared to copper makes aluminum an attractive choice for budget-conscious projects. However, while aluminum is easier to work with due to its lightness, it lacks the aesthetic appeal and longevity of copper, particularly in high-end architectural applications. Furthermore, it does not conduct electricity as effectively as copper, which may be a consideration for electrical applications.

Galvanized Steel Sheet

Galvanized steel is another alternative that combines strength and durability. This material is coated with a layer of zinc to prevent rust and corrosion, making it suitable for construction and roofing projects. Its lower cost and availability make it a preferred choice for many projects. However, galvanized steel can be prone to rust if the protective coating is scratched, which requires regular maintenance. Additionally, its weight may necessitate more robust installation methods, making it less convenient than lighter alternatives like aluminum.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a material for construction or roofing projects, the choice between 16 oz copper sheet metal, aluminum, and galvanized steel should align with your specific requirements. If aesthetics, longevity, and electrical conductivity are paramount, copper remains an excellent choice despite its higher cost. For projects with budget constraints or where weight is a consideration, aluminum may serve as a viable alternative. Lastly, if strength and cost-effectiveness are essential, galvanized steel could be the optimal solution, provided you are prepared for its maintenance needs. Assessing these factors will help international B2B buyers make informed decisions tailored to their project requirements.

Essential Technical Properties and Trade Terminology for 16 oz copper sheet metal

Understanding the technical specifications and industry terminology associated with 16 oz copper sheet metal is crucial for B2B buyers engaged in construction, manufacturing, or metal fabrication. This section outlines essential properties and terms that will facilitate informed purchasing decisions.

What Are the Key Technical Specifications of 16 oz Copper Sheet Metal?

-

Material Grade (Copper Alloy 110)

The most common grade for 16 oz copper sheet metal is Copper Alloy 110, which is 99.9% pure copper. This high purity level ensures excellent electrical conductivity, thermal conductivity, and corrosion resistance. For B2B buyers, selecting the right alloy is vital, as it directly influences the performance and longevity of the final product. -

Thickness (0.0216 inches / 0.549 mm)

The thickness of 16 oz copper sheet metal is standardized at 0.0216 inches. This specification is critical for applications requiring specific strength and durability, such as roofing and flashing. Buyers should consider the thickness in relation to the intended use, as it affects weight, flexibility, and ease of installation. -

Tolerance

Tolerance refers to the permissible limit of variation in dimensions and thickness. For 16 oz copper sheets, maintaining tight tolerances is important to ensure a proper fit in construction applications. Understanding the tolerance levels can help buyers avoid costly rework or material wastage. -

Surface Finish (Mill Finish)

16 oz copper sheets typically come with a mill finish, which means they have not been treated with any protective coating. This finish allows for easy soldering and welding but may result in surface scratches or discoloration. Buyers should factor in the surface finish when determining aesthetic and functional requirements for their projects. -

Weight

The nominal weight of 16 oz copper sheet metal is approximately 1.00 lb per square foot. Knowing the weight is essential for logistical planning, as it affects shipping costs and handling requirements. Buyers should consider how the weight will influence their project and installation methods. -

Malleability

16 oz copper is known for its malleability, allowing it to be easily bent and formed without breaking. This property is particularly advantageous for custom applications where intricate shapes are required. Buyers should assess the malleability in relation to their specific project needs, especially in artistic or architectural designs.

What Are Common Trade Terms Used in the Copper Sheet Metal Industry?

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of copper sheet metal, understanding OEM specifications can help buyers identify compatible materials for their existing products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it helps in budgeting and inventory planning. Knowing the MOQ can also lead to negotiations for better pricing or terms. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request price quotes for specific products. For 16 oz copper sheet metal, an RFQ helps buyers obtain competitive pricing and terms from multiple vendors, facilitating better decision-making. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms can help B2B buyers navigate complex logistics and ensure smooth international transactions. -

Lead Time

Lead time refers to the duration from placing an order to receiving the product. In industries where timing is critical, understanding lead times for 16 oz copper sheets can help buyers schedule projects and manage client expectations effectively. -

Freight Shipping

This term refers to the transportation of goods via commercial means, often involving large quantities. For 16 oz copper sheet metal, which may require special handling due to weight and size, understanding freight shipping options can aid in cost management and delivery scheduling.

By grasping these essential properties and trade terms, B2B buyers can make more informed decisions and enhance their procurement processes in the competitive copper sheet metal market.

Navigating Market Dynamics and Sourcing Trends in the 16 oz copper sheet metal Sector

What Are the Current Market Dynamics for 16 oz Copper Sheet Metal?

The 16 oz copper sheet metal market is influenced by various global drivers, including an increasing demand for high-quality materials in construction and manufacturing sectors. The construction boom in regions like Africa and South America is propelling demand, particularly for roofing and flashing applications. International buyers are increasingly sourcing copper sheets for their durability and aesthetic appeal, which are crucial in both residential and commercial projects. As urbanization continues, the need for reliable building materials will escalate, creating opportunities for suppliers.

Illustrative image related to 16 oz copper sheet metal

Emerging technologies are reshaping the sourcing landscape, with digital platforms facilitating easier access to suppliers and fostering competitive pricing. B2B buyers are leveraging online marketplaces to compare prices and specifications efficiently, streamlining procurement processes. Additionally, advancements in logistics and supply chain management are enhancing delivery timelines, making it easier for international buyers to acquire 16 oz copper sheets from manufacturers across different continents.

How Is Sustainability Shaping the Sourcing of 16 oz Copper Sheet Metal?

Sustainability is becoming a pivotal consideration in the B2B sourcing of 16 oz copper sheet metal. The environmental impact of copper mining and production necessitates a shift towards ethical sourcing practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as reducing carbon footprints and utilizing recycled materials. This trend is particularly significant for international buyers from regions like Europe, where stringent environmental regulations are in place.

The importance of ethical supply chains cannot be overstated. Many businesses are seeking suppliers who hold certifications that attest to sustainable practices, such as the Responsible Copper Initiative or ISO 14001. These certifications not only enhance a company’s reputation but also align with the growing consumer preference for environmentally friendly products. As a result, buyers are encouraged to engage with suppliers that can provide transparency about their sourcing practices and material origins.

What Is the Historical Context of 16 oz Copper Sheet Metal in B2B Markets?

The use of copper in construction dates back thousands of years, with evidence of its application in ancient architecture. In modern contexts, the 16 oz copper sheet has become synonymous with quality and reliability, particularly in roofing and flashing applications. This thickness, often referred to as “roofing copper,” has been favored for its durability and malleability, making it suitable for a variety of projects ranging from residential homes to large commercial buildings.

Historically, copper was valued not only for its physical properties but also for its aesthetic appeal. As design trends evolved, the use of copper in architectural applications expanded, leading to its increased popularity in the B2B sector. Today, the 16 oz copper sheet metal remains a staple for contractors and builders, reflecting a blend of tradition and innovation in construction materials.

Conclusion: Navigating the Future of 16 oz Copper Sheet Metal Sourcing

The landscape for sourcing 16 oz copper sheet metal is dynamic, characterized by evolving market demands and a pressing need for sustainable practices. B2B buyers must stay informed about industry trends and prioritize ethical sourcing to maintain competitiveness in a global market. Engaging with suppliers that adhere to sustainable practices and offer transparency will be essential for businesses aiming to thrive in this sector.

Frequently Asked Questions (FAQs) for B2B Buyers of 16 oz copper sheet metal

-

How do I determine the right thickness of 16 oz copper sheet metal for my project?

To determine the appropriate thickness for your project, consider the specific application and the stresses the material will face. The 16 oz copper sheet is 0.0216 inches thick, making it suitable for roofing, flashing, and decorative applications. If the sheet will be subjected to heavy loads or extreme environmental conditions, you might want to consider thicker options. Always consult project specifications or an expert to ensure you select the correct thickness. -

What are the primary uses of 16 oz copper sheet metal in construction and manufacturing?

16 oz copper sheet metal is commonly used in construction for roofing, gutter systems, and flashing due to its durability and aesthetic appeal. In manufacturing, it serves in electrical applications, RF shielding, and artistic projects. Its malleability allows it to be easily shaped and formed, making it versatile for a variety of applications, including HVAC systems and decorative elements. -

How can I verify the quality of copper sheets before purchasing?

To ensure quality, request a Material Test Report (MTR) from the supplier, which verifies that the copper meets ASTM-B152 specifications. Look for copper alloy designation, specifically Alloy 110, which indicates high purity (99.9%). Additionally, check for surface quality, ensuring it is free from significant scratches or blemishes. A reputable supplier should provide clear documentation regarding the material’s properties. -

What is the minimum order quantity (MOQ) for 16 oz copper sheet metal?

Minimum order quantities can vary significantly by supplier. Typically, MOQs may range from a single sheet to several hundred square feet, especially for bulk orders. It is advisable to discuss your requirements with the supplier directly, as many offer discounts for larger quantities, which can lead to cost savings on your purchase. -

What payment terms should I expect when sourcing copper sheets internationally?

Payment terms can vary based on the supplier and your location. Common terms include net 30 or net 60 days, but many suppliers may require a deposit upfront, especially for larger orders. Be prepared to discuss options like letters of credit or escrow services, especially when dealing with international transactions. Always clarify payment terms before finalizing the purchase to avoid misunderstandings. -

How do I ensure timely delivery of my copper sheet metal order?

To ensure timely delivery, communicate your project timelines clearly with the supplier. Discuss shipping methods, as freight delivery may be necessary for larger orders, and confirm lead times. It’s also wise to account for potential customs delays when ordering internationally. Establishing a reliable logistics partner can further streamline the delivery process. -

What factors should I consider when vetting suppliers for copper sheet metal?

When vetting suppliers, consider their industry reputation, years of experience, and customer reviews. Verify certifications related to quality standards, such as ISO 9001, and request references from other businesses that have sourced similar materials. Additionally, assess their responsiveness and willingness to provide detailed information about their products and services. -

Can I customize the size and finish of 16 oz copper sheets?

Many suppliers offer customization options for size and finish. Standard dimensions are available, but you can often request specific lengths and widths to suit your project needs. Additionally, you can inquire about finishes, such as mill or polished, based on your aesthetic requirements. Always confirm the customization options with the supplier before placing your order to ensure they can meet your specifications.

Top 8 16 Oz Copper Sheet Metal Manufacturers & Suppliers List

1. Basic Copper – 22 Mil Copper Sheet

Domain: basiccopper.com

Registered: 2006 (19 years)

Introduction: Product Name: 22 Mil/16 Oz. Copper Sheet

Thickness: 22 Mil (0.0216″)

Gauge: 24 gauge

Material: Copper Alloy 110 (99.9% pure copper)

Finish: Smooth Commercial Finish/Annealed (Soft and Very Malleable)

Manufactured to: ASTM-B152 specifications

Common Use: Roofing and flashing projects

Available Widths: 1″, 2″, 3″, 6″, 12″, 18″, 24″, 36″

Durability: Can be bent and formed by hand; requires metal snip…

2. KMSheetMetal – Copper Sheets

Domain: kmsheetmetal.com

Registered: 2012 (13 years)

Introduction: {“Product Name”: “Copper Sheets”,”Available Thicknesses”: [“16 oz. (0.0216\” / 0.549 mm)”, “20 oz. (0.027\” / 0.686 mm)”, “24 oz. (0.0323\” / 0.820 mm)”, “32 oz. (0.0413\” / 1.05 mm)”, “48 oz. (0.0646\” / 1.64 mm)”],”Widths”: [“36\” (3′ x 10′)”, “48\” (4′ x 10′)”],”Material Type”: “Copper”,”Finish”: “Mill finish, no protective film, normal surface scratches and discoloration”,”Price”: “$279.00”,”D…

3. Gutter Supply – Copper Sheets

Domain: guttersupply.com

Registered: 2000 (25 years)

Introduction: Copper Sheets – Purchase Per Sheet

Item # COS2412016H | 2×10 16 oz Sheet (H) | Copper 24 x 120 x 16oz

Item # COS2496X16H | 2×8 16 oz Sheet (H) | Copper 24 x 96 x 16 oz

Item # COS3612016H | 3×10 16 oz Sheet (H) | Copper 36 x 120 x 16 oz

Sizes Available: 2×10, 2×8, 3×10

List Prices:

– 2×10 16 oz Sheet: $145.83 / EACH

– 2×8 16 oz Sheet: $116.66 / EACH

– 3×10 16 oz Sheet: $218.71 / EACH

Material: Copp…

4. Metals Depot – Copper Sheet & Plate

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: { “Product Name”: “Copper Sheet & Plate”, “Material”: “C11000 Copper”, “Finish”: “Standard Mill Finish, Not Polished”, “Specifications”: { “ASTM”: “B152” }, “Characteristics”: { “Brazing/Soldering”: “Excellent”, “Machining/Grinding”: “Poor”, “Bending/Forming”: “Excellent”, “Wear Resistance”: “Poor”, “Corrosion Resistance”: “Excellent” }, “Mechanical Properties”: { “Tensile Strength”: “42 ksi”, “Yi…

5. Concord Sheet Metal – Copper Sheets and Products

Domain: concordsheetmetal.com

Registered: 1998 (27 years)

Introduction: Copper is typically used for gutters, downspouts, countertops, hoods, deco tops, and standing seam roofs. Available weights: 16 oz, 20 oz, 32 oz, and 48 oz. Typical sheet sizes: 36″ x 120″ and 48″ x 120″. Smaller width coils in 16 and 20 oz are also stocked. Copper is measured by weight (ounces per square foot). All copper is minimum 99.5% pure (ASTM B 370). Weight per square foot and thickness: 1…

6. Parawire – Copper Sheets

Domain: parawire.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “Copper Sheets”, “price_range”: “$3.77 – $283.40”, “purity”: “99.9% Pure Copper”, “melting_point”: “1981°F”, “gauge_options”: [“8 gauge (.128″)”, “12 gauge (.081″)”, “14 gauge (.064″)”, “16 gauge (.050″)”, “18 gauge (.040″)”, “20 gauge (.032″)”, “22 gauge (.025″)”, “24 gauge (.020″)”, “26 gauge (.016″)”, “28 gauge (.013″)”], “sheet_size_options”: [“6″ x 6″”, “6” x 12″”, “12” x 12″…

7. Slate Roof Warehouse – 16oz Soft Copper Rolls

Domain: slateroofwarehouse.com

Registered: 2010 (15 years)

Introduction: {“product_name”: “16oz Soft Copper Rolls”, “sku”: “67320”, “categories”: [“Copper Rolls and Sheets”], “sizes”: [{“width”: “14”, “length”: “10′”, “sku”: “67314”, “weight”: “11.67 lbs”}, {“width”: “14”, “length”: “25′”, “sku”: “67514”, “weight”: “29.17 lbs”}, {“width”: “20”, “length”: “10′”, “sku”: “67320”, “weight”: “16.67 lbs”}, {“width”: “20”, “length”: “25′”, “sku”: “67520”, “weight”: “41.67 lbs…

8. Riverside Sheet Metal – Copper Sheets & Coils

Domain: riversidesheetmetal.net

Registered: 2007 (18 years)

Introduction: Copper sheets & coils available in 16 oz, 20 oz, 24 oz, and 48 oz. Offered in sheets of 3′ x 8′, 3′ x 10′, 4′ x 8′, and 4′ x 10′. Available in coil sizes of 10″, 11.75″, 12″, 15″, 18″, 20″, 24″, 36″, and 48″. Copper is used for various applications including roofing, gutters, chimney caps, and more. Finishes available include: Brushed Finish, Satin Finish, Dark Patina, Green Patina, and Burnished …

Strategic Sourcing Conclusion and Outlook for 16 oz copper sheet metal

In the world of strategic sourcing for 16 oz copper sheet metal, understanding its applications and sourcing options is paramount for international buyers. This versatile material, primarily recognized for its durability and malleability, serves critical functions in roofing, flashing, and electrical applications. As markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for high-quality copper sheet metal is expected to rise significantly.

By leveraging strategic sourcing practices, businesses can not only secure competitive pricing but also ensure the quality and reliability of their copper supplies. Establishing relationships with reputable suppliers who adhere to ASTM-B152 specifications will provide peace of mind regarding product integrity and performance. Furthermore, bulk purchasing options and understanding shipping logistics can enhance cost efficiency and streamline operations.

Looking ahead, now is the time for international B2B buyers to capitalize on the growing market for 16 oz copper sheet metal. Engage with suppliers, explore diverse product offerings, and consider the long-term value of investing in quality materials. Together, we can build a robust supply chain that meets the evolving needs of industries across the globe.

Illustrative image related to 16 oz copper sheet metal

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.