15 Series Aluminum Extrusion Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for 15 series aluminum extrusion

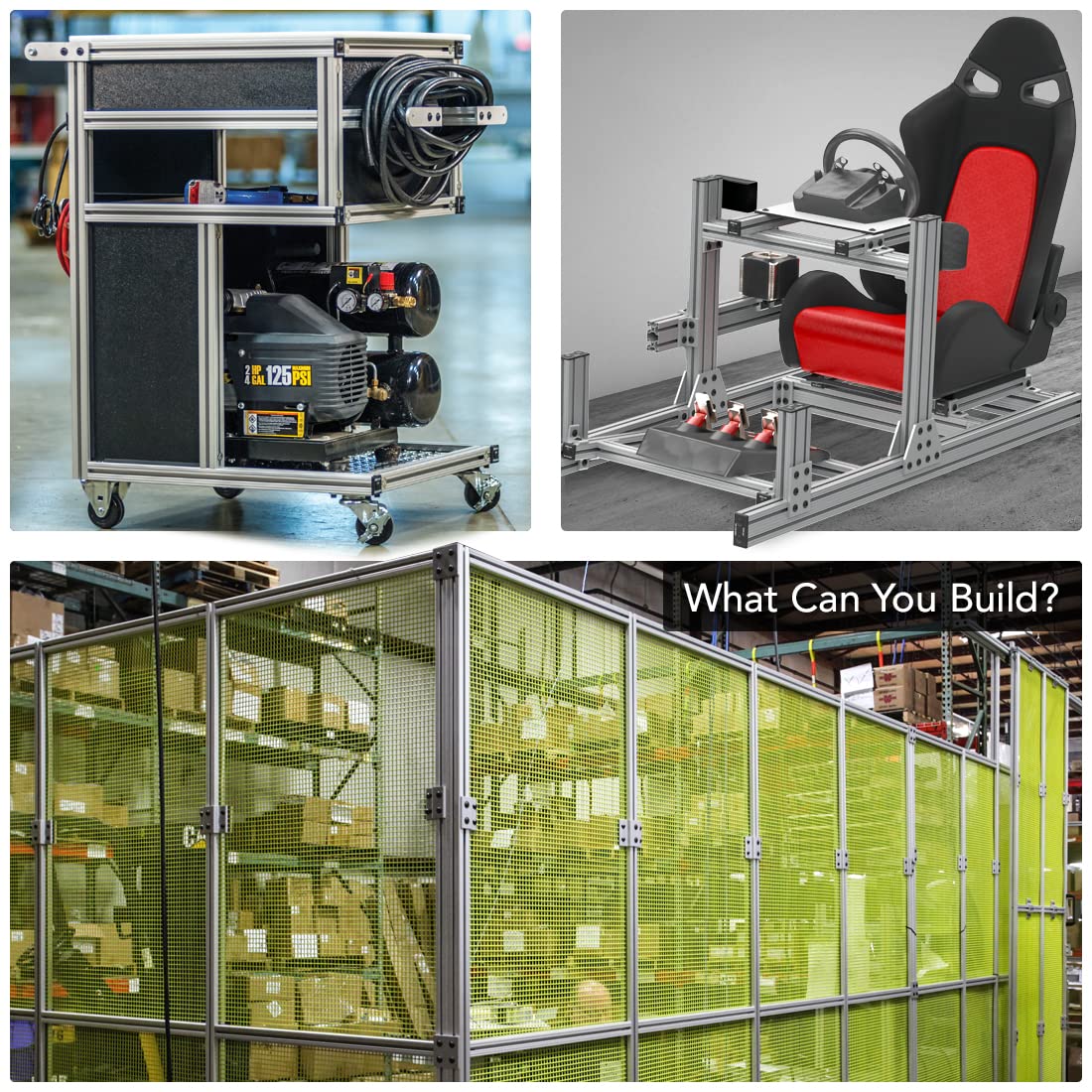

In today’s competitive landscape, sourcing 15 series aluminum extrusion presents a unique challenge for international B2B buyers. As companies seek to optimize their operations while maintaining cost-effectiveness, understanding the nuances of this versatile material becomes paramount. This guide is designed to equip you with essential insights into the various types of 15 series aluminum extrusions, their applications across industries, and strategies for supplier vetting.

From construction frameworks to manufacturing equipment, the applications of 15 series aluminum extrusion are vast, making it a crucial component in many sectors. This guide not only outlines the key specifications and benefits of different extrusion profiles but also delves into pricing structures, enabling you to make informed purchasing decisions. Additionally, it highlights the importance of assessing suppliers based on quality, reliability, and delivery capabilities, particularly for buyers in diverse markets such as Africa, South America, the Middle East, and Europe, including Brazil and Vietnam.

By leveraging the comprehensive information provided in this guide, you can navigate the complexities of the global market for 15 series aluminum extrusion with confidence. Gain a competitive edge as you streamline your sourcing process, ensuring that you select the right materials to meet your business needs while maximizing value and performance.

Understanding 15 series aluminum extrusion Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 1. 1515 Profile | 1.5” x 1.5” size, four open T-slots | Machine frames, workstations | Pros: Versatile, easy assembly. Cons: Heavier than lighter profiles. |

| 2. 1530 Profile | 1.5” x 3” size, six open T-slots | Conveyor systems, automation equipment | Pros: Increased strength for longer spans. Cons: May require additional support. |

| 3. Lite Series | Available in various dimensions, reduced weight | Lightweight structures, portable equipment | Pros: Cost-effective, ideal for weight-sensitive applications. Cons: Less structural integrity than standard profiles. |

| 4. Ultra-Lite Series | Ultra-lightweight, designed for minimal load-bearing | Temporary structures, displays | Pros: Extremely lightweight, easy to transport. Cons: Limited load capacity. |

| 5. Grooved Profiles | Grooved surface for enhanced fastening options | Custom machinery, specialized applications | Pros: Greater flexibility in design. Cons: May require specialized fasteners. |

What Are the Key Characteristics of the 1515 Profile?

The 1515 profile is a foundational element in the 15 series aluminum extrusions. Measuring 1.5” x 1.5”, it features four open T-slots on each face, allowing for versatile connections. This profile is ideal for constructing machine frames and workstations, providing a balance between strength and ease of assembly. When purchasing, buyers should consider the profile’s compatibility with existing systems and its weight, which may be a factor in applications requiring mobility.

How Does the 1530 Profile Enhance Structural Applications?

The 1530 profile, measuring 1.5” x 3”, offers six open T-slots, providing additional structural support for applications like conveyor systems and automation equipment. Its increased width allows for longer spans without compromising stability. Buyers should evaluate the loading requirements of their projects, as this profile can handle heavier applications compared to standard profiles, but may necessitate additional support structures for optimal performance.

Why Choose the Lite Series for Weight-Sensitive Projects?

The Lite Series profiles are designed to be lightweight while still maintaining functionality. These profiles come in various dimensions, making them suitable for lightweight structures and portable equipment. They are cost-effective, providing a good balance between performance and price. However, buyers should be cautious about the reduced structural integrity compared to standard profiles, ensuring that the application does not exceed the recommended load limits.

What Are the Advantages of Using Ultra-Lite Series Profiles?

Ultra-Lite Series profiles are exceptionally lightweight and are tailored for applications where portability and ease of transport are critical, such as temporary structures and displays. Their minimal load-bearing capacity makes them suitable for non-structural applications. Buyers should consider the trade-off between weight and strength, ensuring that the chosen profile aligns with the intended use without compromising safety.

How Do Grooved Profiles Improve Customization in Machinery?

Grooved profiles feature a specialized surface that enhances fastening options, making them ideal for custom machinery and specialized applications. This flexibility allows for innovative designs that can be tailored to specific needs. However, buyers must be aware that these profiles may require specialized fasteners, which could increase overall costs. Understanding the compatibility with existing components is essential for effective implementation.

Key Industrial Applications of 15 series aluminum extrusion

| Industry/Sector | Specific Application of 15 series aluminum extrusion | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Machine frames and supports | Lightweight yet durable construction | Ensure compatibility with existing machinery |

| Automation & Robotics | Custom automation equipment and robotic arms | Flexibility in design and ease of modification | Look for suppliers offering customization options |

| Construction | Modular building systems and scaffolding | Quick assembly and disassembly, reducing labor costs | Verify structural integrity and load-bearing capacity |

| Material Handling | Conveyor systems and material transport solutions | Improved efficiency in material flow | Assess the weight capacity and surface finish needed |

| Furniture & Displays | Custom workstations and display stands | Aesthetic appeal combined with functionality | Consider color finishes and ease of assembly |

How is 15 Series Aluminum Extrusion Used in Manufacturing?

In the manufacturing sector, 15 series aluminum extrusions are commonly utilized to create machine frames and supports. These profiles provide a lightweight yet robust structure that can withstand rigorous operational demands. For businesses, this means reduced energy costs during transport and installation, alongside enhanced durability. International buyers should consider sourcing from manufacturers who offer precise dimensions and tolerances to ensure compatibility with existing machinery and equipment.

What Role Does 15 Series Aluminum Extrusion Play in Automation & Robotics?

In automation and robotics, 15 series aluminum extrusions are integral for building custom automation equipment and robotic arms. Their modular design allows for easy adjustments and modifications, facilitating the rapid prototyping and development of complex systems. This flexibility can lead to significant time and cost savings for manufacturers. Buyers should prioritize suppliers that provide customization options and support to meet specific project requirements.

How Can 15 Series Aluminum Extrusion Enhance Construction Projects?

The construction industry benefits from 15 series aluminum extrusions through their application in modular building systems and scaffolding. These profiles enable quick assembly and disassembly, which can significantly reduce labor costs and project timelines. Businesses should ensure that the sourced materials meet stringent structural integrity standards and load-bearing capacities, especially for projects in diverse environments across Africa, South America, the Middle East, and Europe.

Why are 15 Series Aluminum Extrusions Essential for Material Handling?

In material handling, 15 series aluminum extrusions are used to construct efficient conveyor systems and material transport solutions. Their design allows for smooth movement of goods, improving overall efficiency in operations. For companies in this sector, it is crucial to assess the weight capacity and surface finish of the extrusions to ensure they align with the specific needs of their operational environment.

How Do 15 Series Aluminum Extrusions Contribute to Furniture & Displays?

The furniture and displays sector leverages 15 series aluminum extrusions for creating custom workstations and display stands. The combination of aesthetic appeal and functionality makes these profiles a preferred choice for modern design. When sourcing, businesses should consider the availability of various color finishes and the ease of assembly, which can enhance the overall user experience and satisfaction.

3 Common User Pain Points for ’15 series aluminum extrusion’ & Their Solutions

Scenario 1: Sourcing Quality and Cost-Effective Materials for Projects

The Problem: B2B buyers often face the dilemma of sourcing high-quality 15 series aluminum extrusions at competitive prices. In regions such as Africa and South America, where market fluctuations can impact availability and costs, buyers may find themselves overwhelmed by the variety of suppliers and the inconsistency in product quality. This situation leads to challenges in budgeting, project timelines, and the overall integrity of the final product.

The Solution: To navigate this issue effectively, buyers should focus on establishing relationships with reputable suppliers who have a proven track record in delivering quality aluminum extrusions. Conduct thorough market research to identify suppliers with positive reviews and a history of reliability. Additionally, consider leveraging digital platforms that specialize in B2B transactions, allowing for easy comparison of prices and quality certifications. Request samples to evaluate the extrusion profiles and ensure they meet your specifications before placing larger orders. Building a local supply chain can also mitigate costs and reduce lead times, making it easier to manage project budgets effectively.

Scenario 2: Ensuring Compatibility with Existing Systems

The Problem: Many buyers struggle with ensuring that new 15 series aluminum extrusions are compatible with their existing assembly systems and machinery. This challenge is particularly prevalent in industries like manufacturing and automation, where precise measurements and compatibility are critical for operational efficiency. A mismatch can lead to increased downtime and additional costs associated with modifications or replacements.

The Solution: To prevent compatibility issues, buyers should conduct a detailed assessment of their current systems before selecting aluminum extrusions. Create a comprehensive list of specifications, including dimensions, slot configurations, and weight capacities, that align with existing components. When sourcing, communicate these requirements clearly to suppliers and seek out those who offer customizable solutions. Utilizing CAD software to visualize potential assemblies with the new extrusions can also help identify potential conflicts early in the design phase. Finally, consider engaging with suppliers who provide technical support or design services to ensure that your selections will integrate seamlessly into your current operations.

Scenario 3: Navigating Complex Design Requirements

The Problem: B2B buyers often encounter complex design requirements that necessitate customized solutions when working with 15 series aluminum extrusions. Industries such as robotics and specialized machinery require unique configurations that standard profiles may not fulfill, leading to delays and increased costs if not addressed properly.

The Solution: To tackle this design challenge, buyers should invest time in collaborating with engineers and design professionals early in the project development stage. Engage with suppliers that offer design consultation services or have an in-house engineering team to assist in creating custom solutions. Utilize prototyping methods to test designs before full-scale production; this allows for adjustments without significant financial implications. Additionally, employing modular design principles can maximize the use of standard 15 series profiles while accommodating specific needs through minor customizations. By prioritizing collaboration and iterative design processes, buyers can effectively meet complex requirements while optimizing costs and timelines.

Strategic Material Selection Guide for 15 series aluminum extrusion

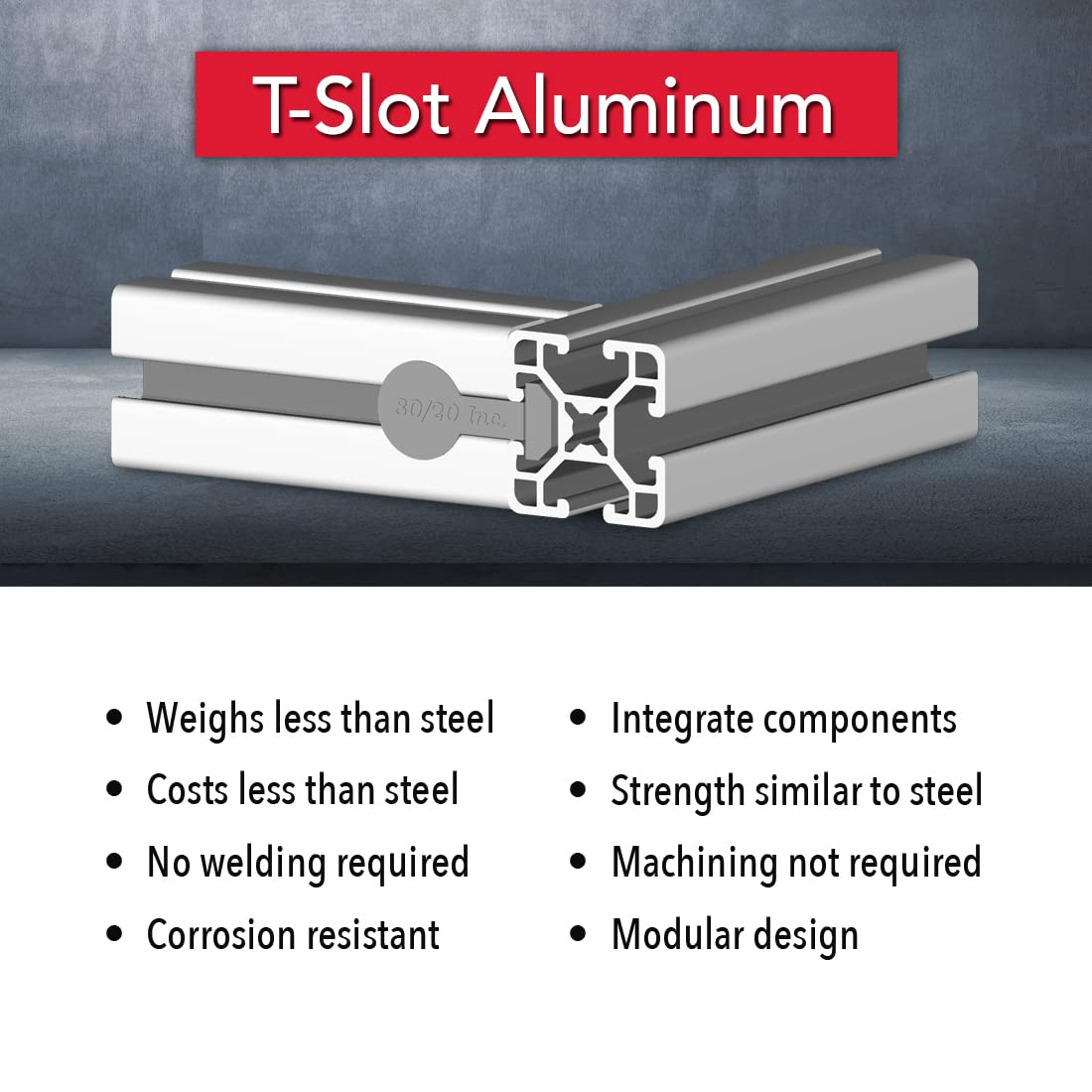

When selecting materials for 15 series aluminum extrusion, it is crucial to consider the specific requirements of your application, including performance, cost, and compliance with international standards. Here, we analyze four common materials used in 15 series aluminum extrusion, focusing on their properties, advantages, disadvantages, and implications for international buyers.

What Are the Key Properties of Standard Aluminum Alloy (6063)?

The standard aluminum alloy used in 15 series extrusions is typically 6063. This alloy offers excellent corrosion resistance, good weldability, and medium strength. It performs well in temperatures up to 150°C and has a tensile strength of around 240 MPa. Its lightweight nature makes it suitable for various structural applications, including frames and supports.

Illustrative image related to 15 series aluminum extrusion

Pros & Cons: The primary advantage of 6063 aluminum is its excellent extrudability, allowing for complex shapes and profiles. However, it can be more expensive than other materials and may not be suitable for high-stress applications due to its moderate strength.

Impact on Application: 6063 is compatible with a wide range of environments, making it ideal for outdoor applications. However, it may require additional coatings or treatments for enhanced durability in harsh conditions.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards, as 6063 is widely recognized under ASTM and EN standards.

How Does Aluminum Alloy 6061 Compare for Structural Applications?

Aluminum alloy 6061 is another popular choice for 15 series extrusions, known for its higher strength and versatility. It has a tensile strength of approximately 310 MPa and performs well in temperatures up to 200°C. Its corrosion resistance is also commendable, although not as high as 6063.

Pros & Cons: The key advantage of 6061 is its strength-to-weight ratio, making it suitable for structural applications. However, it is generally more expensive and may require more complex manufacturing processes.

Impact on Application: This alloy is particularly effective in applications requiring higher load-bearing capabilities, such as machinery frames and automotive components. Its compatibility with welding and machining enhances its usability.

Considerations for International Buyers: Buyers should check for compliance with ASTM and JIS standards, especially in the Middle East, where stringent regulations may apply.

What Are the Benefits of Using Anodized Aluminum in 15 Series Extrusions?

Anodized aluminum is a surface treatment that enhances the corrosion resistance and aesthetic appeal of aluminum extrusions. This process increases surface hardness and provides a protective layer that can withstand harsh environments.

Pros & Cons: The primary benefit of anodized aluminum is its improved durability and resistance to wear and corrosion. However, the anodizing process can add to manufacturing costs and may limit the range of colors available.

Impact on Application: Anodized aluminum is particularly suitable for outdoor applications and environments with high moisture or chemical exposure, such as marine or industrial settings.

Considerations for International Buyers: Buyers in Europe and South America should consider local anodizing capabilities and standards to ensure the quality of the finish meets their specific needs.

Why Choose Lightweight Aluminum Alloys for Specialized Applications?

Lightweight aluminum alloys, such as the ultra-lite variants, are designed for applications where weight savings are critical. These materials maintain a good balance between strength and weight, making them suitable for portable structures and equipment.

Illustrative image related to 15 series aluminum extrusion

Pros & Cons: The main advantage of lightweight alloys is their reduced mass, which can lead to lower shipping costs and easier handling. However, they may not be as durable as standard alloys and can be more susceptible to deformation under heavy loads.

Impact on Application: These alloys are ideal for applications like modular systems, where ease of assembly and transport is essential. They are also beneficial in industries focusing on energy efficiency.

Considerations for International Buyers: Buyers should evaluate the structural integrity requirements of their specific applications, especially in regions like Africa, where load-bearing capacities may vary.

Summary Table of Material Selection for 15 Series Aluminum Extrusion

| Material | Typical Use Case for 15 series aluminum extrusion | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Standard Aluminum 6063 | Frames, supports, general structures | Excellent extrudability | Moderate strength | Medium |

| Aluminum Alloy 6061 | Structural applications, machinery frames | High strength | Higher cost, complex manufacturing | High |

| Anodized Aluminum | Outdoor applications, marine environments | Enhanced corrosion resistance | Higher manufacturing costs | Medium |

| Lightweight Alloys | Portable structures, modular systems | Reduced weight | Lower durability | Medium |

This guide provides a comprehensive overview of material selection for 15 series aluminum extrusion, helping international B2B buyers make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 15 series aluminum extrusion

What are the Key Stages in the Manufacturing Process of 15 Series Aluminum Extrusion?

The manufacturing process for 15 series aluminum extrusion involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential to ensure that the final product meets the required specifications and quality standards.

1. Material Preparation

The first step in the manufacturing process is selecting the right aluminum alloy, typically 6063 or 6061, known for their excellent mechanical properties and corrosion resistance. The aluminum is then heated to a specific temperature to achieve the desired malleability. This process, known as billet heating, prepares the material for the extrusion phase.

2. Forming: How is Aluminum Extruded into Profiles?

During the extrusion process, the heated aluminum billet is forced through a die that shapes it into the desired profile, such as the T-slot designs characteristic of the 15 series. This is accomplished using a hydraulic press, which applies significant force to push the aluminum through the die. The resulting profile is then cooled, often through air or water quenching, to solidify its shape.

3. Assembly: What Techniques are Used in Joining Components?

After the extrusion is completed, various assembly techniques may be employed to create larger structures or systems. These can include mechanical fastening, welding, or adhesive bonding, depending on the specific application. For instance, T-slot profiles allow for easy assembly using compatible fasteners, making them ideal for modular systems used in automation, machinery frames, and workstations.

4. Finishing: How is Surface Quality Enhanced?

Finishing processes are crucial for enhancing the aesthetic and functional properties of aluminum extrusions. Common finishing techniques include anodizing, powder coating, and painting. Anodizing not only improves corrosion resistance but also allows for color customization, which can be particularly appealing to B2B buyers looking for specific branding or design needs.

What Quality Assurance Measures are in Place for 15 Series Aluminum Extrusion?

Quality assurance (QA) is vital in the production of aluminum extrusions to ensure that they meet both international standards and customer specifications. This involves implementing various quality control (QC) checkpoints throughout the manufacturing process.

1. What International Standards Apply to Aluminum Extrusion Quality?

International standards such as ISO 9001 provide a framework for establishing an effective quality management system. For aluminum extrusion manufacturers, adherence to these standards ensures consistent quality, operational efficiency, and customer satisfaction. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) can be essential for certain applications, particularly in the construction and automotive sectors.

2. What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integrated at various stages of production:

-

Incoming Quality Control (IQC): This initial phase involves inspecting raw materials and components for compliance with specifications before they enter the production line. This ensures that only high-quality materials are used in the manufacturing process.

-

In-Process Quality Control (IPQC): During the extrusion process, real-time monitoring of variables such as temperature, pressure, and extrusion speed is conducted. This helps in identifying any deviations from set parameters that could affect the final product quality.

-

Final Quality Control (FQC): Once the extrusion and finishing processes are complete, the final products undergo thorough inspections. This may include dimensional checks, visual inspections, and tests for mechanical properties to ensure they meet the required specifications.

3. How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are several strategies to ensure supplier compliance:

-

Audits: Conducting regular audits of suppliers can help verify their adherence to quality standards. This includes reviewing their manufacturing processes, quality assurance protocols, and compliance with relevant certifications.

-

Reports and Documentation: Requesting detailed QC reports, including inspection records and test results, can provide insights into the supplier’s quality management practices.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s manufacturing capabilities and quality control measures. This is particularly beneficial for buyers unfamiliar with the local manufacturing landscape.

What Testing Methods Are Commonly Used for 15 Series Aluminum Extrusions?

To ensure that 15 series aluminum extrusions meet the required performance criteria, several testing methods are employed:

-

Tensile Testing: This method assesses the strength and ductility of the aluminum alloy. It involves pulling a sample until it fails, providing critical data on the material’s mechanical properties.

-

Hardness Testing: Hardness tests, such as the Rockwell or Brinell methods, are conducted to evaluate the material’s resistance to deformation and wear.

-

Visual Inspections: These are performed to identify surface defects, such as scratches, dents, or discoloration, which may affect the product’s aesthetics or functionality.

-

Dimensional Checks: Precision measuring tools are used to ensure that the extrusions meet the specified dimensions and tolerances.

What Are the Unique Quality Control and Certification Nuances for International Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is essential for successful procurement. This includes being aware of:

-

Regional Standards: Different regions may have specific regulatory requirements or standards. For example, European buyers may prioritize CE marking, while buyers in the Middle East may look for compliance with local standards.

-

Cultural Factors: Building relationships with suppliers can be crucial in regions where personal connections influence business practices. Understanding local customs and communication styles can facilitate better collaboration.

-

Supply Chain Reliability: Given the varied economic landscapes in regions like Africa and South America, assessing the stability and reliability of the supply chain is vital. Buyers should consider factors such as lead times, transportation logistics, and the supplier’s ability to scale production as needed.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing 15 series aluminum extrusions, ultimately leading to successful partnerships and high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ’15 series aluminum extrusion’

This guide serves as a practical checklist for B2B buyers looking to procure 15 series aluminum extrusions. By following these steps, you can ensure that your sourcing process is efficient, cost-effective, and meets your technical requirements.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly define your technical specifications. This includes determining the dimensions, weight, and surface finish of the aluminum extrusions you require. For 15 series profiles, options typically range from 1.5″ x 0.75″ to 1.5″ x 4.5″, with finishes such as smooth or grooved. Documenting these specifications will streamline discussions with suppliers and ensure you receive the correct products.

Step 2: Research Suppliers and Distributors

Conduct thorough research to identify potential suppliers and distributors of 15 series aluminum extrusions. Look for companies with a solid reputation in your target markets, such as Africa, South America, the Middle East, and Europe. Pay attention to customer reviews, industry certifications, and longevity in the market, as these factors can indicate reliability and quality.

Step 3: Evaluate Supplier Certifications

Once you’ve shortlisted potential suppliers, verifying their certifications is crucial. Ensure that suppliers adhere to international quality standards such as ISO 9001, which reflects their commitment to quality management. Additionally, check if they comply with local regulations in your region, as this can significantly affect your purchasing decision.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples of the aluminum extrusions to evaluate their quality. Testing samples allows you to assess aspects such as durability, finish, and compatibility with your existing systems. This step is vital for preventing costly errors and ensuring that the product meets your operational requirements.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with your selected suppliers to secure the best pricing and terms. Discuss volume discounts, payment terms, and shipping options to optimize your total cost of ownership. A well-negotiated agreement can lead to significant savings, especially for larger orders.

Step 6: Establish Communication Channels

Effective communication is key to a successful sourcing process. Establish clear channels for ongoing dialogue with your supplier to address any questions or issues that may arise. Regular updates and feedback loops will help maintain transparency and build a strong working relationship.

Step 7: Finalize Logistics and Delivery Schedules

Once the order is confirmed, finalize the logistics and delivery schedules. Ensure that the supplier understands your timeline and that you have clarity on shipping methods, customs duties, and any potential delays. This proactive approach minimizes disruptions to your operations and ensures timely project execution.

By following this checklist, B2B buyers can navigate the procurement of 15 series aluminum extrusions with confidence, ensuring they meet both technical and logistical requirements efficiently.

Illustrative image related to 15 series aluminum extrusion

Comprehensive Cost and Pricing Analysis for 15 series aluminum extrusion Sourcing

Analyzing the cost structure and pricing of 15 series aluminum extrusions is crucial for B2B buyers looking to optimize their sourcing strategies. Understanding the various cost components, price influencers, and negotiation tactics can help international buyers make informed decisions and achieve cost efficiencies.

What Are the Key Cost Components in 15 Series Aluminum Extrusion?

The cost of 15 series aluminum extrusions typically consists of several components:

-

Materials: The primary cost driver is the aluminum itself, with prices fluctuating based on global market conditions. Secondary materials, like coatings or finishes, may also impact costs, especially if custom colors or textures are required.

-

Labor: Labor costs encompass the workforce involved in manufacturing, handling, and assembling the extrusions. In regions with higher labor costs, such as Europe, this can significantly affect the final price.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: The initial investment in tooling, especially for custom profiles, is a one-time cost that can be amortized over larger production runs. However, for small orders, this can inflate per-unit costs.

-

Quality Control (QC): Ensuring that extrusions meet specified quality standards involves additional costs for testing and certification. Certifications may be particularly important for buyers in industries with strict compliance requirements.

-

Logistics: Shipping costs can vary widely based on the origin of the product and the destination. International shipping, customs fees, and insurance all contribute to logistics costs.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary depending on the supplier’s market position and the complexity of the order.

How Do Price Influencers Affect the Cost of Aluminum Extrusions?

Several factors influence the pricing of 15 series aluminum extrusions:

-

Volume/MOQ: Suppliers often offer discounts for larger orders due to economies of scale. Understanding the minimum order quantities (MOQ) and negotiating for bulk discounts can lead to significant cost savings.

-

Specifications and Customization: Custom profiles or specific tolerances can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality: The choice of alloy and surface finish can impact pricing. Higher-quality materials or specialized finishes will typically command higher prices.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can influence pricing. Established suppliers may offer better quality assurance but at a premium.

-

Incoterms: The agreed-upon shipping terms can significantly affect total costs. Familiarity with Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for understanding who bears the costs at various stages of shipping.

What Buyer Tips Can Help Optimize Sourcing Costs?

International buyers can leverage several strategies to optimize their sourcing of 15 series aluminum extrusions:

-

Negotiation: Build strong relationships with suppliers and negotiate terms that reflect your purchasing volume and loyalty. This can lead to better pricing and payment terms.

-

Total Cost of Ownership (TCO): Consider all costs associated with the purchase, including shipping, customs duties, and potential tariffs. TCO analysis helps in selecting suppliers that offer the best overall value, not just the lowest price.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, local market conditions, and geopolitical factors that can affect pricing. Engaging local partners or agents can provide valuable insights.

-

Quality Assurance: Invest in pre-shipment inspections or quality certifications to avoid costly rework or returns. This is particularly important when sourcing from countries with varying quality standards.

Disclaimer on Indicative Prices

Prices for 15 series aluminum extrusions can vary based on market conditions, supplier pricing strategies, and order specifications. The figures provided in this analysis are indicative and should be verified with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing 15 series aluminum extrusion With Other Solutions

Introduction to Alternatives for 15 Series Aluminum Extrusion

When selecting structural components for manufacturing and assembly processes, businesses often look for versatile and efficient solutions. The 15 series aluminum extrusion is a popular choice due to its adaptability and strength. However, it is essential to consider alternative solutions that might better meet specific requirements, such as cost-effectiveness, ease of implementation, or specialized applications. This analysis compares the 15 series aluminum extrusion against two viable alternatives: Steel Tubing and Plastic Extrusions.

Comparison Table

| Comparison Aspect | 15 Series Aluminum Extrusion | Steel Tubing | Plastic Extrusions |

|---|---|---|---|

| Performance | High strength-to-weight ratio, corrosion-resistant | Extremely strong, durable | Lightweight, less durable |

| Cost | Moderate cost, varies with dimensions | Generally lower cost | Lower initial cost |

| Ease of Implementation | Easy to assemble with T-slot design | Requires welding or additional fixtures | Simple assembly, but limited structural integrity |

| Maintenance | Low maintenance, resistant to corrosion | Moderate maintenance, prone to rust | Low maintenance, but can degrade over time |

| Best Use Case | Modular structures, machine frames, workstations | Heavy-duty applications, structural frames | Lightweight products, non-load-bearing applications |

Detailed Breakdown of Alternatives

Steel Tubing

Steel tubing is a robust alternative that is often used for heavy-duty applications. It offers superior strength and durability, making it suitable for structural frameworks that need to support significant loads. However, the downside is that steel is heavier than aluminum, which can increase shipping costs and complicate installation. Additionally, steel is prone to rusting if not properly coated or maintained, which can lead to higher long-term maintenance costs. Overall, steel tubing is ideal for projects requiring high strength but may not be suitable for modular or lightweight applications.

Plastic Extrusions

Plastic extrusions present a lightweight and cost-effective alternative to aluminum extrusions. They are easily shaped into complex designs, allowing for flexibility in applications like enclosures and non-load-bearing structures. The primary advantage of plastic is its resistance to corrosion and lower initial costs, making it an attractive option for certain projects. However, plastic lacks the structural integrity and durability of aluminum or steel, limiting its use in applications where strength is critical. For businesses focused on cost and lightweight designs, plastic extrusions can be a viable choice, but they should consider the limitations in strength and longevity.

Conclusion: Choosing the Right Solution for Your Needs

When deciding between 15 series aluminum extrusion and its alternatives, B2B buyers must assess their specific requirements carefully. The choice between aluminum, steel, and plastic should be based on the application’s performance needs, budget constraints, and long-term maintenance considerations. For modular and versatile structures, aluminum is often the best option. However, for heavy-duty applications, steel may be preferable, while plastic can serve well for lightweight and cost-sensitive projects. Evaluating these factors will help businesses make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for 15 series aluminum extrusion

What Are the Key Technical Properties of 15 Series Aluminum Extrusion?

When selecting 15 series aluminum extrusion for your projects, understanding its technical properties is essential. Here are some critical specifications that impact both performance and application:

-

Material Grade: The most common material grade for aluminum extrusions is 6063, known for its excellent corrosion resistance and good mechanical properties. This grade is ideal for structural applications, making it a preferred choice in manufacturing and assembly. For B2B buyers, selecting the right grade ensures durability and longevity of the final product.

-

Weight: The weight of aluminum extrusions varies based on their dimensions and design. For instance, 1.5” x 1.5” profiles are lighter than 1.5” x 4.5” profiles. Understanding weight is crucial for logistics and handling, as it affects shipping costs and installation efforts.

-

Tolerance: Tolerance refers to the allowable deviation from specified dimensions during manufacturing. Standard tolerances for 15 series extrusions typically range from ±0.005 inches to ±0.015 inches. Accurate tolerances are vital for ensuring compatibility with other components, reducing assembly time, and minimizing waste.

-

Surface Finish: 15 series aluminum extrusions can come in various surface finishes, such as smooth, anodized, or powder-coated. These finishes not only enhance aesthetic appeal but also improve corrosion resistance. B2B buyers should consider the finish for applications exposed to harsh environments, as it can significantly impact the lifespan of the product.

-

Dimensions and Slot Configuration: The 15 series typically features profiles based on a 1.5” width, with various configurations such as T-slots. The slot design facilitates easy assembly with fasteners and other components. Understanding the dimensions and available configurations helps buyers choose the right profiles for their specific applications, whether for framing, structural supports, or machinery.

What Are Common Trade Terms Used in 15 Series Aluminum Extrusion?

Familiarity with trade terminology is equally important for effective communication and negotiation in the B2B aluminum extrusion market. Here are some key terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, partnering with an OEM can provide access to high-quality components tailored for specific applications.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for managing inventory and ensuring cost-effectiveness, especially for smaller businesses or projects with limited budgets.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. This process allows buyers to compare offers and make informed purchasing decisions, ensuring they receive the best value for their investment.

-

Incoterms (International Commercial Terms): These are standardized terms that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms is essential for understanding shipping costs, risks, and delivery obligations, which can significantly impact overall project budgets.

-

Lead Time: This term refers to the time taken from placing an order to the delivery of the product. For B2B buyers, knowing lead times helps in planning production schedules and ensuring timely project completion.

-

Customization: This refers to tailoring products to meet specific needs or specifications. In the aluminum extrusion industry, customization can include alterations in length, finish, or slot configuration. Understanding customization options allows buyers to optimize their designs for unique applications.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding 15 series aluminum extrusion, enhancing both operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the 15 series aluminum extrusion Sector

What Are the Current Market Dynamics and Key Trends Influencing the 15 Series Aluminum Extrusion Sector?

The global market for 15 series aluminum extrusions is witnessing robust growth, driven by increasing demand across various industries such as automotive, aerospace, and construction. This surge is largely attributed to the lightweight and corrosion-resistant properties of aluminum, making it an ideal choice for manufacturers looking to improve efficiency and reduce costs. In regions like Africa, South America, the Middle East, and Europe, there is a notable shift towards modular construction and automation, fueling the demand for versatile and customizable aluminum profiles.

Emerging technologies such as advanced manufacturing processes, including 3D printing and automation, are revolutionizing the sourcing landscape. B2B buyers are increasingly leveraging digital platforms for procurement, enhancing transparency and reducing lead times. Moreover, the rise of Industry 4.0 is prompting manufacturers to adopt smart solutions, optimizing production and logistics. Buyers are advised to remain vigilant about these trends, as they can significantly impact pricing, availability, and overall supply chain efficiency.

How Is Sustainability Shaping Sourcing Practices in the 15 Series Aluminum Extrusion Market?

Sustainability is no longer a peripheral concern but a central tenet in sourcing strategies for B2B buyers in the aluminum extrusion sector. The environmental impact of manufacturing processes, particularly regarding energy consumption and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers that adhere to sustainable practices, such as recycling aluminum and minimizing carbon footprints.

Moreover, ethical sourcing has gained traction, with companies seeking suppliers that comply with social responsibility standards. Certifications like ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) are becoming prerequisites for many buyers. Using materials that are certified as sustainable not only aligns with corporate social responsibility goals but also enhances brand reputation in a marketplace that values environmental stewardship. Therefore, B2B buyers should consider these factors when selecting suppliers in the 15 series aluminum extrusion sector.

What Is the Brief Evolution of the 15 Series Aluminum Extrusion Sector?

The 15 series aluminum extrusion has evolved significantly since its inception, adapting to the changing needs of various industries. Initially developed for basic structural applications, it has expanded to serve more specialized purposes, including automation frameworks and custom machinery. The introduction of t-slot profiles has revolutionized the way manufacturers approach assembly and design, enabling modular systems that are easy to modify and scale.

As industries have increasingly prioritized efficiency and flexibility, the 15 series has positioned itself as a go-to solution for businesses looking to innovate. The ongoing advancements in extrusion technology and materials science continue to enhance the capabilities of 15 series profiles, ensuring they remain relevant in an ever-evolving market. For international B2B buyers, understanding this evolution can provide critical insights into product applications and sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of 15 series aluminum extrusion

-

How do I choose the right 15 series aluminum extrusion for my project?

Selecting the appropriate 15 series aluminum extrusion involves understanding your project requirements, including load-bearing capacity, dimensions, and environmental conditions. Consider the specific profiles available, such as the 1.5” x 1.5” or 1.5” x 3” options, depending on your structural needs. Evaluate the surface finish (smooth or grooved) for compatibility with your assembly processes. Additionally, assess weight considerations, especially if you need lightweight solutions for mobile applications. Consulting with suppliers for technical specifications can also aid in making an informed decision. -

What customization options are available for 15 series aluminum extrusions?

Many suppliers offer customization for 15 series aluminum extrusions, allowing you to specify lengths, finishes, and additional features such as pre-drilled holes or integrated connectors. Custom lengths are particularly valuable for minimizing waste and ensuring a perfect fit in your application. Discuss your requirements with the supplier to explore available options, such as anodizing for enhanced corrosion resistance or special colors for aesthetic needs. Ensure that the supplier can accommodate your customization requests without significantly increasing lead times. -

What are the minimum order quantities (MOQ) for 15 series aluminum extrusions?

Minimum order quantities for 15 series aluminum extrusions can vary significantly by supplier and region. Typically, MOQs range from 50 to 200 units, depending on the product type and the supplier’s production capabilities. For smaller projects or prototyping, some suppliers may offer more flexible options, such as lower MOQs or even single-unit purchases at a higher cost. When sourcing, clarify the MOQ with potential suppliers early in the negotiation process to avoid any surprises. -

What payment terms should I expect when sourcing aluminum extrusions internationally?

Payment terms for international orders of aluminum extrusions often vary by supplier and country. Common terms include 30% upfront payment with the balance due upon delivery or a net 30/60 days payment option. In some cases, suppliers may offer letter of credit or escrow arrangements to protect both parties. Be sure to discuss and negotiate payment terms that suit your cash flow needs while ensuring compliance with international trade regulations. Understanding currency exchange rates can also affect your total cost. -

How can I ensure quality assurance (QA) for my aluminum extrusion orders?

To ensure quality assurance for your aluminum extrusion orders, it’s essential to establish clear specifications and standards with your supplier. Request certifications such as ISO 9001 or specific material compliance documents. Conducting factory visits or third-party inspections can further validate the supplier’s production processes. Additionally, implementing a clear return policy for defective items and maintaining open communication throughout the production phase will help mitigate quality issues. -

What logistics considerations should I keep in mind when importing aluminum extrusions?

When importing 15 series aluminum extrusions, logistics considerations include shipping methods, customs clearance, and delivery timelines. Evaluate whether to use air freight for speed or sea freight for cost efficiency, depending on your urgency and budget. Familiarize yourself with customs regulations in your country to avoid delays and additional fees. It’s also wise to work with a reliable freight forwarder who can navigate the complexities of international shipping and provide updates throughout the process. -

What are the common applications for 15 series aluminum extrusions in various industries?

15 series aluminum extrusions are versatile and widely used across multiple industries, including manufacturing, automation, and construction. Common applications include structural frames for machinery, conveyor systems, and modular workstations. Their lightweight yet sturdy nature makes them ideal for creating custom enclosures, safety barriers, and display systems. Understanding the specific needs of your industry can help you choose the right profile and configuration for optimal performance. -

How do I evaluate and vet suppliers for 15 series aluminum extrusions?

When evaluating suppliers for 15 series aluminum extrusions, start by researching their industry reputation through reviews and testimonials. Request references from previous clients to assess reliability and quality. It’s also beneficial to compare product catalogs, pricing, and lead times among multiple suppliers. Additionally, consider their customer service responsiveness and willingness to accommodate your specific needs. Establishing a good relationship with a trustworthy supplier can be crucial for long-term collaboration and success in your projects.

Top 3 15 Series Aluminum Extrusion Manufacturers & Suppliers List

1. Aluminum Profiles – 15-Series & 40-Series Connectors

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 15-series aluminum is the American version with a size of 1.5 inches, while 40-series aluminum is the European version measuring 40mm or 1.57 inches. 15-series connectors can be used with 40-series aluminum, allowing for mixing and matching of profiles, although there will be a slight size difference. It is important to match bolts and nuts (either SAE or metric) when using these series together. …

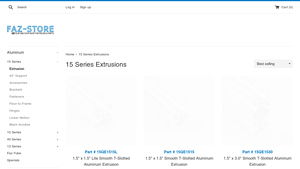

2. Faz Store – Lite Smooth T-Slotted Aluminum Extrusion

Domain: faz-store.net

Registered: 2018 (7 years)

Introduction: [{‘part_number’: ’15QE1515L’, ‘dimensions’: ‘1.5″ x 1.5″‘, ‘type’: ‘Lite Smooth T-Slotted Aluminum Extrusion’, ‘price’: ‘From $ 1.68’}, {‘part_number’: ’15QE1515′, ‘dimensions’: ‘1.5″ x 1.5″‘, ‘type’: ‘Smooth T-Slotted Aluminum Extrusion’, ‘price’: ‘From $ 2.04’}, {‘part_number’: ’15QE1530′, ‘dimensions’: ‘1.5″ x 3.0″‘, ‘type’: ‘Smooth T-Slotted Aluminum Extrusion’, ‘price’: ‘From $ 3.39’}, {‘part…

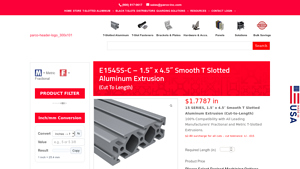

3. Parco – Aluminum Slot Profile E1545S-C

Domain: parco-inc.com

Registered: 2004 (21 years)

Introduction: {“SKU”: “E1545S-C”, “Dimensions”: “1.5” x 4.5″”, “Weight”: “0.311 lbs”, “Material”: “Aluminum”, “Color”: “Clear”, “Series”: “15”, “Number of Slots”: “8”, “Price”: “$1.7787”, “Cut Tolerance”: “+/- .015”, “Surcharge for Cuts”: “$2.80”, “Applications”: [“Conveyor systems”, “Linear motion”, “Material handling”, “Large machine frames”], “Hollow Centers”: “Good for dual air manifolds up to 150 p.s.i.”, …

Strategic Sourcing Conclusion and Outlook for 15 series aluminum extrusion

In the rapidly evolving landscape of industrial manufacturing, the strategic sourcing of 15 series aluminum extrusions presents substantial opportunities for international B2B buyers. With their versatility, these extrusions cater to a wide range of applications, from automation and material handling to custom structural solutions. The array of profiles available—varying in dimensions, surface finishes, and weights—enables businesses to tailor their purchases to specific project requirements, enhancing both efficiency and cost-effectiveness.

Moreover, leveraging strategic sourcing allows companies to build robust supply chains that are not only responsive to market demands but also capable of fostering long-term partnerships with reliable suppliers. This is particularly crucial for buyers in Africa, South America, the Middle East, and Europe, where regional market dynamics may differ significantly. By prioritizing quality and compatibility with existing systems, businesses can mitigate risks and enhance operational agility.

Looking ahead, the demand for 15 series aluminum extrusions is poised for growth, fueled by ongoing advancements in technology and increasing emphasis on sustainability in manufacturing. Now is the time for B2B buyers to engage with suppliers, explore innovative solutions, and seize the competitive edge that strategic sourcing can provide. Embrace the future of manufacturing with confidence and purpose.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.