12V Ac Ac Power Supply: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for 12v ac ac power supply

In today’s interconnected marketplace, sourcing a reliable 12V AC power supply can be a daunting challenge for B2B buyers, particularly in emerging markets like Africa, South America, the Middle East, and Europe. With diverse applications ranging from industrial machinery to consumer electronics, the demand for efficient and dependable power solutions is on the rise. However, navigating the complexities of product specifications, supplier reliability, and pricing structures often leaves buyers overwhelmed.

This guide aims to demystify the global market for 12V AC power supplies by offering a comprehensive overview of the various types available, their applications, and essential factors to consider when vetting suppliers. From understanding the technical specifications, such as amperage and plug types, to evaluating the cost-effectiveness of different models, we provide actionable insights tailored to the unique needs of international buyers.

Moreover, we address the significance of regulatory compliance and quality assurance, ensuring that your procurement decisions align with industry standards. By leveraging this guide, B2B buyers will be empowered to make informed purchasing decisions that not only meet their operational requirements but also enhance their competitive edge in the market. Whether you are located in Brazil, Nigeria, or any other region, this resource is designed to streamline your sourcing process and bolster your business’s success in a rapidly evolving landscape.

Understanding 12v ac ac power supply Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wall Adapter | Compact design, plug-in type, typically 1000mA-1200mA | Consumer electronics, small appliances | Pros: Easy installation, portable. Cons: Limited power output. |

| Open Frame Power Supply | Modular design, customizable output, higher wattage | Industrial equipment, automation systems | Pros: Versatile, high efficiency. Cons: Requires additional housing. |

| Encapsulated Power Supply | Sealed design, robust against environmental factors | Outdoor applications, harsh environments | Pros: Durable, moisture-resistant. Cons: Higher cost. |

| Switching Power Supply | High efficiency, lightweight, often adjustable voltage | Telecommunications, medical devices | Pros: Energy-efficient, compact. Cons: May generate noise. |

| Transformers | Step-down voltage, typically larger and heavier | HVAC systems, lighting fixtures | Pros: Reliable, long lifespan. Cons: Bulky, less efficient. |

What Are Wall Adapters and Their Key Features?

Wall adapters are compact, plug-in power supplies that convert AC voltage from a wall outlet to 12V AC. They typically provide output currents ranging from 1000mA to 1200mA. Ideal for consumer electronics and small appliances, they are favored for their ease of use and portability. When purchasing, consider the output specifications to ensure compatibility with the devices they will power, and assess the quality of the components to minimize the risk of overheating or failure.

How Do Open Frame Power Supplies Stand Out?

Open frame power supplies feature a modular design that allows for customization of output voltage and current levels. They are commonly used in industrial applications and automation systems due to their higher wattage capabilities. Buyers should evaluate the efficiency ratings and the need for additional housing, as these units typically require installation into other equipment for protection. Their versatility makes them a solid choice for businesses needing tailored power solutions.

What Advantages Do Encapsulated Power Supplies Offer?

Encapsulated power supplies are designed with sealed enclosures, making them resistant to moisture, dust, and other environmental factors. This durability makes them suitable for outdoor applications and in harsh environments such as factories or construction sites. When selecting an encapsulated power supply, consider the environmental conditions of the intended use. The initial investment may be higher, but the longevity and reliability can lead to lower total costs over time.

Why Choose a Switching Power Supply?

Switching power supplies are known for their high efficiency and lightweight design. They are often adjustable, allowing for various output voltages, making them ideal for telecommunications and medical devices. Buyers should assess the noise levels, as some switching supplies can generate electromagnetic interference. The compact nature of these supplies can save space in equipment designs, making them an attractive option for manufacturers looking to optimize product size.

What Are the Characteristics of Transformers?

Transformers are traditional power supplies that step down voltage from higher AC levels to 12V AC. They are typically larger and heavier than other types but are known for their reliability and long lifespan. Commonly used in HVAC systems and lighting fixtures, buyers should be mindful of their bulkiness and lower efficiency compared to modern alternatives. Understanding the specific power requirements of the application is crucial to ensure the selected transformer meets operational needs effectively.

Key Industrial Applications of 12v ac ac power supply

| Industry/Sector | Specific Application of 12v ac ac power supply | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Powering LED lighting systems in residential and commercial spaces | Provides consistent energy supply for lighting solutions, enhancing ambiance and energy efficiency | Ensure compatibility with local voltage standards and plug types; consider bulk purchasing for cost savings |

| Security Systems | Operating surveillance cameras and alarm systems | Enhances security infrastructure reliability, reducing downtime and maintenance costs | Look for power supplies with robust safety certifications; prioritize suppliers with a track record in security applications |

| Telecommunications | Supporting low-power devices such as routers and modems | Maintains uninterrupted communication services, crucial for business operations | Evaluate suppliers based on delivery times and warranty options; ensure adaptability to different regional power specifications |

| Industrial Automation | Driving sensors and control systems in manufacturing processes | Improves operational efficiency and reduces equipment failure rates | Source from manufacturers with proven reliability; consider long-term supply agreements to ensure consistent availability |

| Healthcare Equipment | Powering medical devices like infusion pumps and monitors | Ensures patient safety and equipment reliability, critical in healthcare settings | Prioritize suppliers with strict quality control and compliance with medical device regulations; assess local service support options |

In the Consumer Electronics sector, 12v ac power supplies are frequently employed to power LED lighting systems in both residential and commercial applications. These power supplies ensure that lighting solutions operate efficiently and reliably, contributing to energy savings and enhanced ambiance. For international buyers, especially in regions like Africa and South America, it is essential to ensure compatibility with local voltage standards and plug types, as well as to consider bulk purchasing options to maximize cost efficiency.

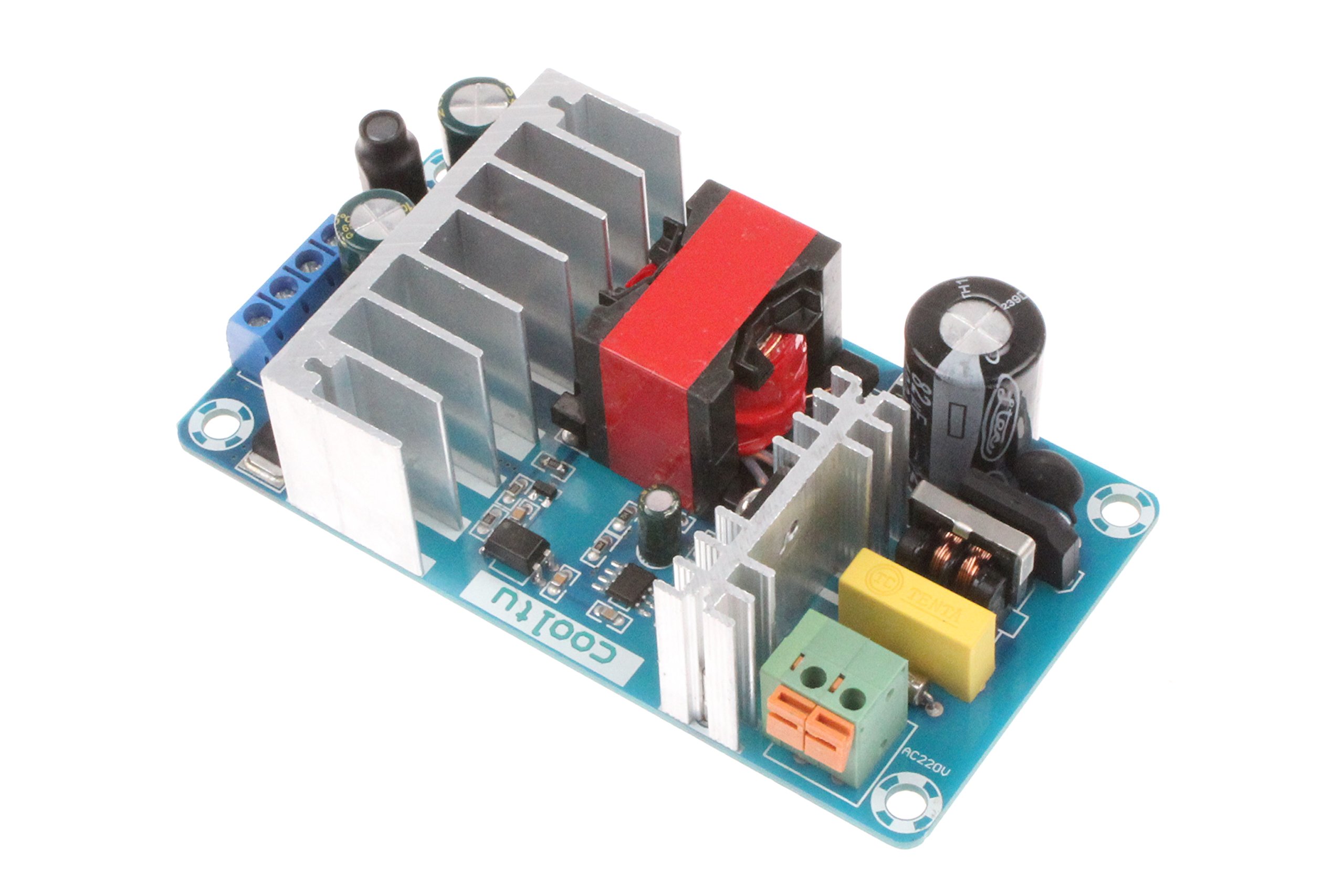

Illustrative image related to 12v ac ac power supply

In Security Systems, 12v ac power supplies are vital for operating surveillance cameras and alarm systems. A dependable power source is crucial for maintaining the integrity of security infrastructure, as any interruptions can lead to vulnerabilities. Buyers should prioritize sourcing power supplies that have robust safety certifications and a proven track record in the security sector, particularly in regions with emerging security needs.

The Telecommunications industry utilizes 12v ac power supplies to support low-power devices such as routers and modems. This consistent power supply is essential for uninterrupted communication services, which are critical for business operations. When sourcing these supplies, it is important for buyers to evaluate suppliers based on their delivery times and warranty options, ensuring that they can meet the demands of their operational environment.

In Industrial Automation, 12v ac power supplies are used to drive sensors and control systems in manufacturing processes. These supplies play a significant role in improving operational efficiency and minimizing equipment failure rates. For buyers, sourcing from manufacturers with a proven reliability record is crucial, and establishing long-term supply agreements can help ensure consistent availability of these essential components.

In the Healthcare Equipment sector, 12v ac power supplies are necessary for powering medical devices such as infusion pumps and patient monitors. The reliability of these power supplies directly impacts patient safety and the functionality of medical equipment. Buyers should prioritize suppliers that adhere to strict quality control measures and comply with medical device regulations, while also assessing the availability of local service support to address any potential issues promptly.

Illustrative image related to 12v ac ac power supply

3 Common User Pain Points for ’12v ac ac power supply’ & Their Solutions

Scenario 1: Compatibility Issues with Existing Equipment

The Problem: B2B buyers often face compatibility challenges when sourcing 12V AC power supplies for their equipment. Many devices require specific voltage and amperage ratings, and if the power supply does not match these requirements, it can lead to device malfunction or failure. This is particularly concerning for businesses that rely on consistent performance, such as manufacturers or service providers in sectors like telecommunications or medical equipment. A mismatch not only causes operational delays but can also result in increased costs due to returns, replacements, or even damage to sensitive equipment.

The Solution: To ensure compatibility, B2B buyers should conduct thorough research on the specifications of the devices needing power supplies. This includes verifying the voltage, current, plug size, and polarity. When sourcing a 12V AC power supply, it is crucial to select products that meet or exceed the required specifications. Buyers can consult technical documentation or reach out to manufacturers directly for guidance. Additionally, utilizing reputable distributors who provide detailed product information and customer support can further mitigate risks. Keeping a checklist of specifications can streamline the sourcing process and help avoid costly mistakes.

Scenario 2: Fluctuating Power Supply Performance

The Problem: Another common issue faced by B2B buyers is the inconsistency in power supply performance. Many power supplies may advertise stable voltage output but can fluctuate under varying load conditions. This can create challenges for businesses that depend on precise voltage levels for their operations, such as in laboratory settings or in powering delicate electronics. Inconsistent performance can lead to equipment damage, data loss, or even safety hazards, making this a critical concern for procurement teams.

The Solution: To address this issue, buyers should opt for high-quality 12V AC power supplies that are designed for stable output across a range of load conditions. Checking for products with built-in voltage regulation features can help ensure consistent performance. Additionally, conducting load tests in a controlled environment before full deployment can provide insights into how the power supply performs under actual operating conditions. It’s also advisable to choose suppliers who offer warranties and customer support to assist with any performance-related concerns. Establishing a relationship with trusted manufacturers can also lead to better insights on product reliability and performance.

Scenario 3: Sourcing Reliable Suppliers in Diverse Markets

The Problem: In regions such as Africa, South America, the Middle East, and Europe, B2B buyers often struggle with sourcing reliable suppliers for 12V AC power supplies. Factors such as local regulations, import duties, and varying product standards can complicate the purchasing process. This lack of reliable suppliers can lead to delays in delivery and increased costs, ultimately impacting the operational efficiency of businesses that require consistent power supply solutions.

The Solution: To navigate these challenges, B2B buyers should establish a diverse network of suppliers, including local and international vendors, to ensure a steady flow of products. Engaging in regional trade shows, industry conferences, and online marketplaces can help identify reputable suppliers. Additionally, leveraging technology to conduct thorough supplier evaluations—including checking reviews, certifications, and compliance with local standards—can enhance sourcing decisions. Forming partnerships with suppliers who have established local presence can also facilitate smoother logistics and compliance with regional regulations. Keeping abreast of market trends and supplier performance can further strengthen procurement strategies, ensuring businesses remain competitive and efficient.

Strategic Material Selection Guide for 12v ac ac power supply

When selecting materials for a 12V AC power supply, it is crucial to consider properties that influence performance, durability, and compliance with international standards. Below, we analyze four common materials used in the construction of these power supplies, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Plastic in 12V AC Power Supplies?

Plastic, particularly thermoplastics like polycarbonate and ABS, is widely used for the casing of 12V AC power supplies. These materials offer excellent electrical insulation properties, which are critical for safety and performance. They typically have good temperature resistance (up to 100°C) and can withstand moderate mechanical stress.

Pros: Plastics are lightweight, cost-effective, and easy to mold into complex shapes, which simplifies manufacturing. They also provide good chemical resistance, making them suitable for various environments.

Cons: However, plastics may not be as durable as metals, particularly in extreme temperatures or harsh conditions. They can also be susceptible to UV degradation if used outdoors without adequate protection.

Impact on Application: The use of plastic is suitable for applications where weight and cost are primary concerns, such as consumer electronics. However, buyers should ensure that the plastic used meets relevant safety standards like UL94 for flammability.

How Does Metal Influence the Performance of 12V AC Power Supplies?

Metals such as aluminum and steel are often utilized in the construction of 12V AC power supplies, particularly for their enclosures. These materials provide excellent mechanical strength and thermal conductivity, which is essential for heat dissipation.

Pros: Metals are highly durable and can withstand higher temperatures and physical impacts. They also offer superior electromagnetic shielding, which can enhance the performance of sensitive electronic components.

Cons: The downside is that metals are heavier and more expensive than plastics, which can increase shipping costs. Additionally, they may require more complex manufacturing processes, such as stamping or machining.

Impact on Application: Metal enclosures are ideal for industrial applications where robustness is critical. Buyers in regions with high humidity, such as parts of Africa and South America, should consider corrosion-resistant coatings to prolong the lifespan of metal components.

What Role Does Copper Play in 12V AC Power Supply Wiring?

Copper is the preferred material for wiring in 12V AC power supplies due to its excellent electrical conductivity and thermal properties. It is essential for minimizing energy loss and ensuring efficient power delivery.

Pros: Copper wires are highly conductive, which reduces resistance and heat generation during operation. They are also flexible, making them easy to work with during installation.

Cons: However, copper is relatively expensive compared to alternatives like aluminum. Additionally, it is susceptible to corrosion, which can impact performance over time.

Impact on Application: The use of copper is vital in applications requiring high efficiency, such as in renewable energy systems. Buyers must consider the local availability and cost of copper, especially in regions like Africa and South America, where market fluctuations can affect pricing.

How Do Insulating Materials Affect 12V AC Power Supply Safety?

Insulating materials, such as silicone rubber and PVC, are critical for ensuring safety in 12V AC power supplies. These materials prevent electrical shorts and protect users from electric shocks.

Pros: They provide excellent dielectric properties and can withstand high temperatures. Silicone rubber, in particular, is known for its flexibility and resilience against environmental factors.

Cons: The main drawback is that high-quality insulating materials can increase production costs. Additionally, some insulating materials may not be suitable for high-temperature applications.

Impact on Application: Insulating materials are essential for compliance with safety standards such as IEC 60950 or UL 60950. Buyers should ensure that the insulating materials used meet local regulations, especially in regions with stringent safety requirements.

Summary Table of Material Selection for 12V AC Power Supplies

| Material | Typical Use Case for 12V AC Power Supply | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Enclosures for consumer electronics | Lightweight and cost-effective | Less durable under extreme conditions | Low |

| Metal | Industrial power supply enclosures | High durability and thermal conductivity | Heavier and more expensive | Medium |

| Copper | Wiring for power delivery | Excellent conductivity | Higher cost and corrosion susceptibility | High |

| Insulating Material | Safety insulation for components | Superior dielectric properties | Can increase production costs | Medium |

This material selection guide provides insights into the various materials used in 12V AC power supplies, helping international B2B buyers make informed decisions based on performance, cost, and compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 12v ac ac power supply

What Are the Key Manufacturing Processes for 12V AC Power Supplies?

Manufacturing a 12V AC power supply involves several critical stages, each designed to ensure that the final product meets both functional and safety standards. Understanding these stages can help B2B buyers evaluate potential suppliers effectively.

How Are Raw Materials Prepared for 12V AC Power Supplies?

The manufacturing process begins with the selection and preparation of raw materials. Common materials used include high-quality copper for wiring, durable plastics for casing, and various electronic components such as transformers, diodes, and capacitors. Suppliers must source these materials from reputable vendors to ensure quality.

Once sourced, the materials undergo rigorous inspection to verify their compliance with industry standards. This initial quality check, known as Incoming Quality Control (IQC), ensures that any defective materials are identified and excluded from the production line.

Illustrative image related to 12v ac ac power supply

What Techniques Are Used in Forming and Assembling 12V AC Power Supplies?

The forming stage involves shaping the raw materials into usable components. Techniques such as stamping, molding, and machining are commonly employed. For example, plastic casings are typically produced through injection molding, which allows for precise shapes and dimensions.

Following the forming stage, assembly begins. This phase involves the integration of various components into a single unit. Automated assembly lines are often used for efficiency, allowing for consistent quality and speed. Skilled technicians may also perform manual assembly for complex components, ensuring that each power supply unit is assembled according to strict specifications.

What Are the Finishing Processes for 12V AC Power Supplies?

The finishing stage includes several processes aimed at enhancing the product’s durability and aesthetics. This can involve painting, labeling, and applying protective coatings. The final assembly is followed by a visual inspection to catch any cosmetic defects.

Additionally, units undergo functional testing to ensure they perform as expected under load conditions. This testing simulates real-world use, verifying that the power supply provides stable voltage and current without overheating or failing.

How Is Quality Assurance Implemented in 12V AC Power Supply Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final product meets both international standards and customer expectations. Various standards, such as ISO 9001, guide organizations in establishing effective quality management systems.

Which International Standards Are Relevant for 12V AC Power Supplies?

ISO 9001 outlines requirements for a quality management system, promoting consistent quality in products and services. In addition to ISO, certifications such as CE (Conformité Européenne) and UL (Underwriters Laboratories) are crucial for ensuring safety and compliance in the European and North American markets, respectively.

For international B2B buyers, understanding these certifications is essential. Products bearing these marks have undergone rigorous testing and meet specific safety standards, reducing the risk of defects.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is typically implemented at various checkpoints during the manufacturing process:

Illustrative image related to 12v ac ac power supply

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they enter production.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, QC personnel monitor production to ensure compliance with specifications. This can include checking solder joints, component placements, and assembly integrity.

-

Final Quality Control (FQC): After assembly, every unit undergoes final testing to check functionality and safety. Common testing methods include electrical testing (voltage and current checks), thermal imaging (to identify overheating), and load testing.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those operating in diverse international markets like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is vital. Here are several actionable steps:

-

Conduct Supplier Audits: Regular audits of suppliers can reveal their adherence to quality standards. Buyers should inquire about the audit frequency and the criteria used.

-

Request Quality Assurance Reports: Suppliers should provide documentation detailing their QC processes, including results from previous inspections and tests.

-

Engage Third-Party Inspection Services: Utilizing independent inspection agencies can offer an unbiased assessment of a supplier’s manufacturing processes and product quality.

-

Review Certifications: Buyers should verify that suppliers hold relevant certifications such as ISO 9001, CE, or UL. This provides assurance that the supplier adheres to recognized quality standards.

What Are the Unique Quality Control Considerations for International Buyers?

International B2B buyers must navigate specific nuances in QC due to regional regulations and standards. For example, products sold in Europe must comply with the CE marking, while those in North America may require UL certification. Understanding these differences is essential for ensuring compliance and avoiding costly delays.

Furthermore, buyers should consider the logistics of shipping and customs regulations that may affect the quality of products upon arrival. Packaging should be robust enough to withstand international transit, and buyers should verify that suppliers have measures in place to protect products during shipping.

Conclusion

A comprehensive understanding of the manufacturing processes and quality assurance practices for 12V AC power supplies is crucial for B2B buyers seeking reliable suppliers. By focusing on material preparation, assembly techniques, and stringent QC measures, buyers can ensure that they procure high-quality power supplies that meet international standards. Engaging in thorough supplier audits and leveraging third-party inspections will further safeguard against potential quality issues, fostering trust and reliability in business partnerships.

Illustrative image related to 12v ac ac power supply

Practical Sourcing Guide: A Step-by-Step Checklist for ’12v ac ac power supply’

Introduction:

In the competitive landscape of B2B procurement, sourcing the right 12V AC power supply is essential for ensuring operational efficiency and product reliability. This guide provides a practical checklist to assist international buyers in identifying, evaluating, and securing the best power supply solutions tailored to their specific needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical requirements for your 12V AC power supply. This includes voltage, current rating (e.g., 1000mA), plug type (e.g., 2.1 x 5.5mm), and any specific features such as wall-mount capabilities. Accurate specifications help in narrowing down options and prevent costly errors in compatibility.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in 12V AC power supplies. Use industry directories, trade shows, and online marketplaces to compile a list of potential vendors. Focus on suppliers with a strong reputation, positive customer feedback, and a history of serving your region, as this can enhance communication and logistics.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications such as UL, CE, or ISO. These certifications indicate adherence to international safety and quality standards, which is crucial for ensuring the reliability and safety of the power supplies. Additionally, inquire about any testing protocols they follow to guarantee product quality.

Illustrative image related to 12v ac ac power supply

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of their 12V AC power supplies. Testing samples allows you to evaluate performance under real-world conditions and check for compatibility with your equipment. Pay attention to parameters such as voltage stability and heat generation during prolonged use.

Step 5: Assess Pricing and Payment Terms

Gather pricing information from multiple suppliers and compare their quotes. While cost is a critical factor, ensure that you consider the overall value, including product quality and service. Additionally, clarify payment terms, such as upfront deposits, credit options, and potential discounts for bulk orders, to avoid any financial surprises.

Step 6: Inquire About Warranty and Support

Understand the warranty conditions offered by suppliers for their 12V AC power supplies. A solid warranty can protect your investment and provide peace of mind. Additionally, assess the level of customer support available, including responsiveness to inquiries and assistance with technical issues post-purchase.

Step 7: Finalize and Place Your Order

After evaluating all factors, select the supplier that best meets your requirements and place your order. Ensure that you have a written agreement that outlines product specifications, delivery timelines, and payment terms. This step is crucial for establishing clear expectations and accountability throughout the procurement process.

By following these steps, B2B buyers can streamline their sourcing process for 12V AC power supplies, ensuring they acquire reliable products that meet their operational needs efficiently.

Comprehensive Cost and Pricing Analysis for 12v ac ac power supply Sourcing

What Are the Key Cost Components of a 12V AC Power Supply?

When sourcing a 12V AC power supply, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality of materials significantly impacts the cost. Components such as transformers, capacitors, and casings dictate the durability and efficiency of the power supply. Higher-grade materials may lead to a higher upfront cost but can enhance longevity and performance.

-

Labor: Labor costs can vary based on the region and the complexity of assembly. In regions with higher wages, such as parts of Europe, labor costs may be a significant part of the overall expense. Conversely, sourcing from regions with lower labor costs can reduce manufacturing expenses.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these overheads, contributing to a more competitive pricing structure.

-

Tooling: For customized or specialized power supplies, tooling costs can be substantial. This includes the expense of molds and dies used in the production process. Buyers should consider whether they need standard products or custom solutions, as this can affect the total cost.

-

Quality Control (QC): Implementing rigorous QC processes is essential for ensuring product reliability. While this adds to the cost, it can prevent future expenses related to returns and customer dissatisfaction, particularly critical for international buyers.

-

Logistics: Shipping costs can vary widely depending on the supplier’s location, shipping method, and destination. This is especially relevant for international transactions where tariffs and duties may apply.

-

Margin: Suppliers will typically include a margin to ensure profitability. Understanding the typical margins in your industry can help gauge whether a supplier’s pricing is competitive.

What Influences Pricing for 12V AC Power Supplies?

Several factors can influence the pricing of 12V AC power supplies:

-

Volume/MOQ: Purchasing in bulk often leads to significant discounts. Suppliers are generally more willing to negotiate prices with buyers who commit to larger orders.

-

Specifications and Customization: Custom specifications can increase costs due to the need for specialized components or production processes. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Higher-quality materials and certifications (such as UL or CE) can raise costs but may also be necessary for compliance in certain markets. Buyers should evaluate the importance of these certifications for their applications.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms can affect the total landed cost of goods. Buyers should be aware of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to understand how shipping costs and responsibilities are allocated.

What Tips Can Help Buyers Negotiate Better Prices?

To achieve cost-efficiency in sourcing 12V AC power supplies, consider the following tips:

-

Negotiate: Don’t hesitate to negotiate prices, especially for larger orders. Suppliers may have room to adjust their margins, particularly if you are a repeat customer.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, potential failures, and the lifespan of the power supplies when assessing overall costs.

-

Be Aware of Pricing Nuances for International Purchases: International buyers, particularly from regions like Africa and South America, should consider currency fluctuations, import duties, and local market conditions when evaluating prices.

-

Request Samples: Before committing to a large order, request samples to assess quality. This can help avoid costly mistakes if the product does not meet your specifications.

Conclusion

In summary, understanding the cost structure and pricing influencers of 12V AC power supplies is vital for B2B buyers. By considering material quality, labor, and logistics alongside negotiation tactics, buyers can optimize their sourcing strategy and achieve better pricing outcomes. Keep in mind that prices can vary significantly based on regional factors and specific requirements. Always conduct thorough research to ensure you are making informed purchasing decisions.

Alternatives Analysis: Comparing 12v ac ac power supply With Other Solutions

In the ever-evolving landscape of power solutions, B2B buyers often seek alternatives to the traditional 12V AC power supply. Understanding the various options available can help organizations make informed decisions that align with their operational needs, budget constraints, and application requirements. This analysis compares the 12V AC power supply with two viable alternatives: the 12V DC power supply and battery power systems.

| Comparison Aspect | 12V AC Power Supply | 12V DC Power Supply | Battery Power Systems |

|---|---|---|---|

| Performance | Stable voltage output | Steady and regulated output | Variable voltage output |

| Cost | Moderate, around $13-$20 | Typically lower, around $10-$15 | Higher initial cost, varies by type |

| Ease of Implementation | Plug-and-play, minimal setup | Requires compatible devices | Requires charging systems |

| Maintenance | Low, minimal upkeep | Low, but needs monitoring | Moderate, battery replacement needed |

| Best Use Case | Home appliances, lighting | Electronics, devices needing stable voltage | Portable devices, remote applications |

What Are the Advantages and Disadvantages of Using a 12V DC Power Supply?

The 12V DC power supply is an attractive alternative due to its regulated output, which is ideal for sensitive electronic devices. It provides a stable voltage, making it suitable for applications that require consistent power, such as LED lighting and electronic circuits. Additionally, the cost of DC power supplies is generally lower than that of AC supplies, making them a budget-friendly option. However, they require devices that are compatible with DC voltage, which may limit their use in certain applications.

How Do Battery Power Systems Compare to 12V AC Power Supplies?

Battery power systems are an excellent choice for applications requiring portability and independence from the electrical grid. They provide flexibility and can be used in remote locations where conventional power sources are unavailable. However, they come with higher initial costs and ongoing maintenance needs, including regular monitoring and battery replacement. The performance can also vary depending on the battery type and charge status, which can be a disadvantage for applications needing consistent power.

Conclusion: How Can B2B Buyers Choose the Right Power Solution?

Choosing the right power supply solution depends on various factors including application requirements, budget constraints, and operational environments. For businesses focused on stability and reliability in fixed installations, the 12V AC power supply remains a robust option. In contrast, organizations requiring portability or specific device compatibility may find the 12V DC power supply or battery systems more advantageous. Conducting a thorough analysis of operational needs and potential future requirements will empower B2B buyers to select the most suitable power solution for their specific applications.

Essential Technical Properties and Trade Terminology for 12v ac ac power supply

Understanding the technical properties and terminology associated with 12V AC power supplies is crucial for B2B buyers, especially when making informed purchasing decisions. Below, we delve into essential specifications and common trade terms that will aid in navigating the market effectively.

What Are the Key Technical Specifications of a 12V AC Power Supply?

-

Output Voltage

The output voltage of 12V AC is a fundamental specification, as it dictates the compatibility of the power supply with various devices. An output that slightly exceeds or falls short of this voltage can affect device performance or even cause damage. Buyers should always verify that the power supply meets the exact voltage requirements of their applications. -

Current Rating (Amperage)

Measured in milliamperes (mA), the current rating indicates how much current the power supply can deliver continuously. For instance, a 1000mA rating means the supply can support devices that require up to 1 amp of current. Understanding this specification is crucial for ensuring that the power supply can handle the load without overheating or failing. -

Connector Type

The connector type, such as a 2.1 x 5.5mm plug, is another vital specification. Different devices may require specific connector sizes and configurations. Ensuring compatibility minimizes the risk of connection issues and enhances operational efficiency, making it essential for buyers to confirm connector specifications before procurement. -

Input Voltage Range

This specification defines the range of input voltages the power supply can accept, often expressed in volts (e.g., 100-240V AC). A wider input voltage range allows for greater flexibility in deployment across different regions, particularly important for international buyers who may deal with varying electrical standards. -

Efficiency Rating

Efficiency ratings measure how well a power supply converts input power to output power, with higher ratings indicating less energy waste. Energy-efficient models not only lower operational costs but also align with sustainability goals, making this a significant consideration for environmentally conscious businesses. -

Operating Temperature Range

The operating temperature range indicates the environmental conditions under which the power supply can function optimally. Extreme temperatures can affect performance and longevity, so understanding this range is crucial for applications in varying climates, particularly in regions like Africa and the Middle East.

What Are Common Trade Terms in the 12V AC Power Supply Market?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of power supplies, OEMs often design and manufacture products for other brands, which is vital for buyers looking for custom solutions or bulk purchasing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers as it impacts inventory management and cost considerations. Smaller businesses may face challenges if the MOQ exceeds their immediate needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for a specific product. For B2B buyers, issuing an RFQ is a critical step in the procurement process, enabling them to compare prices and terms from multiple suppliers efficiently. -

Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers. They clarify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is crucial for international transactions, particularly for buyers in regions like South America and Europe. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This term is significant for supply chain planning, as longer lead times can affect project timelines and inventory levels. -

Certification Standards

Certification standards, such as UL or CE markings, indicate that a product has met specific safety and quality standards. For B2B buyers, ensuring that power supplies comply with relevant certifications is crucial for maintaining safety and regulatory compliance in their operations.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing 12V AC power supplies, ensuring compatibility, reliability, and efficiency in their applications.

Navigating Market Dynamics and Sourcing Trends in the 12v ac ac power supply Sector

What Are the Key Market Dynamics and Sourcing Trends in the 12V AC Power Supply Sector?

The 12V AC power supply market is experiencing significant growth, driven by increasing demand across various sectors, including consumer electronics, industrial automation, and renewable energy applications. As global economies evolve, regions such as Africa, South America, the Middle East, and Europe are emerging as critical markets. For instance, Brazil and Nigeria are ramping up infrastructure projects that require reliable power solutions, which bolsters the demand for 12V AC power supplies.

A key trend in the B2B sector is the shift towards customization and modularity in power supply solutions. Buyers are increasingly seeking products that can be tailored to specific applications, which necessitates suppliers to offer a range of configurations, such as different plug sizes and voltage outputs. Additionally, the rise of smart technologies is influencing the demand for power supplies that integrate with IoT devices, requiring manufacturers to innovate continuously.

Sourcing trends also indicate a growing preference for local suppliers that can ensure quicker delivery times and lower shipping costs. This trend is particularly relevant in emerging markets, where logistics can pose challenges. Moreover, the adoption of digital platforms for procurement is gaining traction, allowing international buyers to access a wider array of suppliers and streamline their purchasing processes.

How Can Sustainability and Ethical Sourcing Impact B2B Purchases of 12V AC Power Supplies?

Sustainability is becoming a pivotal consideration in the sourcing of 12V AC power supplies. With increasing regulatory pressure and consumer awareness regarding environmental impacts, B2B buyers are prioritizing suppliers that adhere to sustainable practices. This includes using eco-friendly materials, reducing carbon footprints, and ensuring that manufacturing processes are compliant with international environmental standards.

Ethical sourcing is equally important, as businesses strive to establish transparent supply chains. Buyers are increasingly scrutinizing their suppliers for compliance with labor laws and ethical standards, which can impact their brand reputation. Certifications such as ISO 14001 for environmental management and Fair Trade can enhance a supplier’s credibility and appeal to conscientious buyers.

Illustrative image related to 12v ac ac power supply

Furthermore, the industry is seeing a rise in ‘green’ certifications for products, which not only signify compliance with environmental standards but also provide a competitive edge in the market. B2B buyers are likely to favor products that are certified as energy-efficient, which can lead to cost savings in the long run and contribute to corporate sustainability goals.

What Is the Brief Evolution of the 12V AC Power Supply Market?

The evolution of the 12V AC power supply market can be traced back to the early days of electrical engineering, where power supplies were primarily used for basic household appliances and lighting. As technology advanced, the demand for more complex power solutions grew, leading to the development of versatile AC adapters capable of meeting the diverse needs of modern electronics.

The late 20th century marked a significant turning point with the rise of consumer electronics. Devices such as televisions, gaming consoles, and home automation systems began to proliferate, creating an increased demand for reliable power supplies. In the 21st century, the integration of smart technology and renewable energy solutions has further transformed the landscape, pushing manufacturers to innovate and adapt to new market needs.

Today, the 12V AC power supply sector is characterized by rapid technological advancements, a focus on sustainability, and a growing emphasis on customization, reflecting the dynamic nature of global markets and consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of 12v ac ac power supply

-

1. How do I choose the right 12V AC power supply for my application?

Selecting the appropriate 12V AC power supply involves evaluating your device’s specifications, including the required voltage, current rating (mA), and plug type. It’s crucial to confirm that the power supply’s output matches your equipment’s needs, as an incorrect voltage can damage your devices. Additionally, consider the power supply’s efficiency, safety certifications, and reliability. For international buyers, ensure that the product complies with local electrical standards and regulations. -

2. What is the best 12V AC power supply for outdoor use?

For outdoor applications, look for a weatherproof or waterproof 12V AC power supply designed to withstand environmental elements. Ensure it has a robust casing and meets IP ratings for moisture and dust resistance. Additionally, check for features like surge protection and temperature regulation to maintain performance under varying conditions. Brands known for durability and reliability in outdoor settings should be prioritized. -

3. What are the typical lead times for ordering 12V AC power supplies internationally?

Lead times for international orders can vary based on the supplier’s location, production capacity, and shipping method. Generally, expect a lead time of 2-6 weeks for standard orders, but this can extend during peak seasons or for customized products. It’s advisable to discuss lead times upfront with your supplier and explore expedited shipping options if necessary to meet your project deadlines. -

4. What are the minimum order quantities (MOQs) for 12V AC power supplies?

Minimum order quantities (MOQs) can differ significantly between suppliers and depend on factors like product type and customization requirements. Typically, MOQs for 12V AC power supplies range from 50 to 500 units. If you are a small business or just starting, inquire about the possibility of smaller batch orders or samples to assess product quality before committing to larger quantities. -

5. How can I ensure the quality of the 12V AC power supply I purchase?

To ensure product quality, request certifications such as UL, CE, or RoHS from your supplier, indicating compliance with safety and environmental standards. It’s also beneficial to review product specifications and customer testimonials. Conducting a factory audit or requesting product samples can provide insight into manufacturing practices and quality control measures. Establishing a reliable relationship with suppliers known for quality can also mitigate risks. -

6. What payment terms should I expect when sourcing 12V AC power supplies?

Payment terms can vary widely among suppliers, but common arrangements include upfront payment, net 30/60 days, or a deposit followed by the balance upon shipment. When negotiating, consider factors such as order size, supplier reputation, and your own cash flow needs. For international transactions, be aware of currency exchange rates and potential additional fees associated with wire transfers or credit card payments. -

7. What are the shipping options for international orders of 12V AC power supplies?

Shipping options for international orders typically include air freight, sea freight, and express courier services. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Evaluate your budget and delivery timeline to choose the best option. Additionally, confirm whether the supplier handles logistics or if you need to arrange shipping through a third-party provider. -

8. Can I customize the specifications of a 12V AC power supply for my needs?

Many suppliers offer customization options for 12V AC power supplies, including modifications to voltage, current ratings, plug types, and casing designs. When seeking customization, provide detailed specifications and volume estimates to your supplier. Be aware that custom orders may have longer lead times and higher MOQs, so it’s essential to factor this into your planning and budget.

Top 6 12V Ac Ac Power Supply Manufacturers & Suppliers List

1. Jameco – 12V AC Adapter

Domain: jameco.com

Registered: 1998 (27 years)

Introduction: 12v ac/ac adapter available at Jameco Electronics, in-stock and ready to ship. Jameco has been in business for over 50 years, offering over 70,000 electronic components including power supplies and wall adapters.

2. PHC Enterprise – AC-AC Power Supply 12V AC @ 3000mA

Domain: acdcpowershack.com

Registered: 2017 (8 years)

Introduction: {“Product Name”: “AC-AC Power Supply 12V AC @ 3000mA; 2.1 x 5.5mm”, “Brand”: “PHC Enterprise, Inc.”, “Part Number”: “AC-123A”, “Input Voltage”: “120VAC 60 Hz”, “Output Voltage”: “12VAC @ 3000mA”, “Plug Size”: “2.1 x 5.5mm”, “Price”: “$20.00”, “Reviews”: [{“Rating”: “5.0 / 5.0”, “Count”: 2}] }

3. Jameco Reliapro – 12VAC, 1200mA AC-to-AC Wall Adapter

Domain: atbatt.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “12VAC, 1200mA AC-to-AC Wall Adapter Power Supply”, “Brand”: “Jameco Reliapro”, “SKU”: “PWS-33-AC”, “Output Voltage”: “12V”, “Output Current”: “1200mA”, “Price”: “$13.99”, “MSRP”: “$18.95”, “Warranty”: “1 Year”, “Weight”: “0.90 LBS”, “Shipping”: “Calculated at Checkout”, “OEM Part Number”: “AM-121200A”, “Warning”: “This Battery, Battery Posts, Terminals, and Related Accessories ca…

4. All About Circuits – 12V AC Power Supply

Domain: forum.allaboutcircuits.com

Registered: 2003 (22 years)

Introduction: 12V AC Power Supply, Output: 12V, Current: 3A, Type: Transformer-based, Measured AC Output: 14.4V.

5. eBay – 12 V Multipurpose AC/AC Adapters

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 12 V Multipurpose AC/AC Adapters for sale on eBay. Related products include Agilent Power Regulators & Converters, Multipurpose AC to DC Adapters, and various brands like Sony and NETGEAR. Popular searches include AC Adapter 12 V 10 A, 12 V Adapter Plug, and 12 V 3 A Power Adapter. Featured items include Kenwood Ksc-35s Fast Rate Charger, Moen 169031 AC Adapter Service Kit, and ARRIS 579761-017-00…

6. Best Buy – 12V AC Adapter

Domain: bestbuy.com

Registered: 1994 (31 years)

Introduction: This company, Best Buy – 12V AC Adapter, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for 12v ac ac power supply

In conclusion, the strategic sourcing of 12V AC power supplies presents significant opportunities for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Key takeaways include the importance of assessing supplier reliability, understanding product specifications, and ensuring compliance with local regulations to minimize risks and enhance operational efficiency. By fostering strong relationships with reputable manufacturers, businesses can secure quality products that align with their unique needs.

As the demand for reliable power solutions continues to grow, particularly in regions with expanding infrastructure and technology adoption, it is crucial for buyers to stay informed about market trends and innovations. Emphasizing sustainability and cost-effectiveness in procurement strategies will further enhance competitiveness.

Looking ahead, we encourage B2B buyers to actively engage with suppliers, leverage digital platforms for sourcing, and explore collaborative partnerships. By adopting a proactive approach to sourcing 12V AC power supplies, businesses can not only meet their immediate needs but also position themselves for future growth and technological advancements. The time to invest in strategic sourcing is now—empower your business with the right solutions to thrive in a dynamic market landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.