120000 Psi Of Waterjet Cutting: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for 120000 psi of waterjet cutting

In the fast-evolving landscape of industrial manufacturing, sourcing reliable solutions for 120,000 psi waterjet cutting presents unique challenges for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe increasingly adopt this advanced cutting technology, understanding the nuances of high-pressure waterjet systems becomes imperative. This guide offers a comprehensive overview of waterjet cutting, detailing the types of systems available, their diverse applications, and key considerations for supplier vetting and cost analysis.

Waterjet cutting stands out for its precision and versatility, capable of processing a wide range of materials from metals to composites without compromising structural integrity. However, selecting the right equipment and vendor requires a thorough understanding of specific needs and market dynamics. This guide empowers B2B buyers by equipping them with actionable insights into the benefits and limitations of waterjet technology, enabling informed purchasing decisions tailored to their operational requirements.

From navigating supplier credentials to evaluating the cost-effectiveness of different waterjet systems, this resource serves as a vital tool for decision-makers. By addressing common concerns and providing practical advice, this guide ensures that businesses can harness the full potential of 120,000 psi waterjet cutting, driving efficiency and innovation in their manufacturing processes. Whether you’re in Brazil, Vietnam, or any other emerging market, the insights within will help you make strategic investments that align with your business goals.

Understanding 120000 psi of waterjet cutting Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pure Waterjet Cutting | Utilizes high-pressure water only, no abrasives. | Aerospace, food processing, and soft materials. | Pros: Clean cuts, no heat-affected zone. Cons: Limited to softer materials. |

| Abrasive Waterjet Cutting | Combines water with abrasive materials for cutting. | Metals, ceramics, and hard materials. | Pros: Versatile, can cut hard materials. Cons: More wear on equipment, higher operational costs. |

| Micro Abrasive Waterjet | Uses ultra-fine abrasive particles for precision. | Electronics, medical devices, and intricate designs. | Pros: High precision, minimal kerf. Cons: Slower cutting speed, specialized equipment needed. |

| Dynamic Waterjet Cutting | Features zero taper technology for edge quality. | Industrial components, automotive parts. | Pros: Superior edge quality, high accuracy. Cons: Higher initial investment for machinery. |

| Robotic Waterjet Cutting | Integrated with robotic arms for automation. | Large-scale manufacturing and complex geometries. | Pros: Increased efficiency, reduced labor costs. Cons: Requires significant upfront investment and maintenance. |

What Are the Key Characteristics of Pure Waterjet Cutting?

Pure waterjet cutting employs a high-pressure stream of water to slice through softer materials like plastics and rubber. This method is particularly advantageous in industries such as aerospace and food processing, where maintaining material integrity is crucial. Buyers should consider the operational costs and the types of materials they need to cut, as this technique is not suitable for harder substrates.

How Does Abrasive Waterjet Cutting Expand Material Options?

Abrasive waterjet cutting enhances the capabilities of pure waterjet cutting by adding abrasives like garnet to the water stream. This allows for the processing of a broader range of materials, including metals and ceramics. Key B2B applications include industrial equipment fabrication and automotive parts. However, buyers should be aware of the increased wear on machinery and the higher operational costs associated with abrasives.

Why Opt for Micro Abrasive Waterjet Cutting for Precision Tasks?

Micro abrasive waterjet cutting is designed for applications requiring ultra-fine precision, making it ideal for electronics and medical devices. This method utilizes very fine abrasives, resulting in minimal kerf and high accuracy. While it offers exceptional precision, buyers must consider the slower cutting speeds and the need for specialized equipment, which can increase initial investment costs.

What Advantages Does Dynamic Waterjet Cutting Offer?

Dynamic waterjet cutting utilizes advanced technology to achieve zero taper, resulting in superior edge quality and accuracy. This method is particularly suitable for industrial components and automotive parts where precision is paramount. While it offers enhanced performance, buyers should be prepared for a higher initial investment in machinery and potential maintenance costs.

How Can Robotic Waterjet Cutting Transform Manufacturing Efficiency?

Robotic waterjet cutting integrates waterjet technology with robotic arms, allowing for automated cutting of complex geometries and large-scale manufacturing. This method significantly increases efficiency and can reduce labor costs. However, businesses should consider the substantial upfront investment and ongoing maintenance required for robotic systems to ensure a successful implementation.

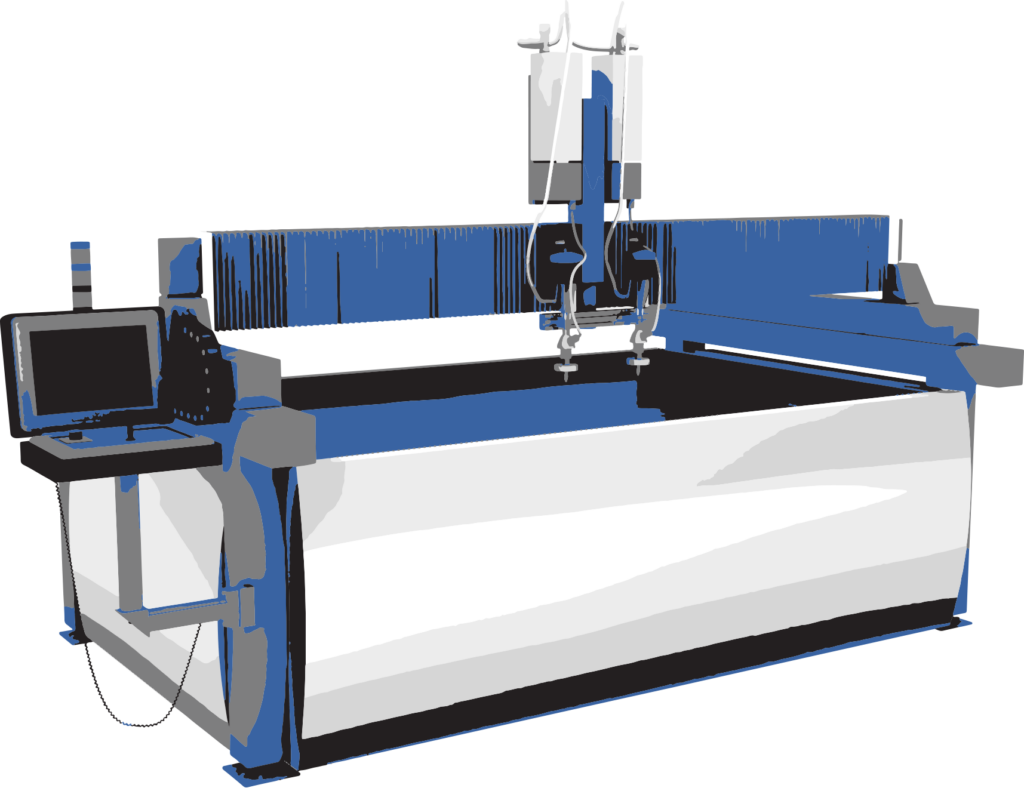

Illustrative image related to 120000 psi of waterjet cutting

Key Industrial Applications of 120000 psi of waterjet cutting

| Industry/Sector | Specific Application of 120000 psi of waterjet cutting | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Cutting turbine blades and aircraft panels | Achieves precise shapes without thermal distortion, enhancing performance and safety | Certification of equipment and operators, adherence to aerospace standards |

| Automotive | Shaping body panels and engine components | Reduces material waste and improves production speed, leading to cost savings | Supplier reliability and ability to handle high-volume orders |

| Industrial Equipment Fabrication | Production of machine frames and wear-resistant parts | Increases durability and reduces downtime due to component failure | Material compatibility and the ability to meet tight tolerances |

| Food Processing | Precise slicing of food products and packaging components | Ensures hygienic processing and minimizes contamination risks | Compliance with food safety regulations and certifications |

| Art & Design | Creation of intricate sculptures and architectural elements | Allows for unique designs and high precision, appealing to high-end markets | Customization capabilities and material variety offered |

How is 120000 psi of waterjet cutting utilized in aerospace applications?

In the aerospace sector, 120000 psi waterjet cutting is essential for producing turbine blades and aircraft panels. This method allows for intricate designs without introducing thermal distortion, which can compromise material integrity. For international buyers, especially from regions like Africa and South America, sourcing involves ensuring that the waterjet cutting service adheres to stringent aerospace standards and certifications, which are critical for safety and compliance.

What are the benefits of using waterjet cutting in automotive manufacturing?

The automotive industry benefits significantly from 120000 psi waterjet cutting for shaping body panels and engine components. This technique minimizes waste and accelerates production timelines, leading to cost efficiency. Buyers from Europe and the Middle East should prioritize suppliers with proven reliability and the capacity to fulfill high-volume orders, ensuring that production schedules remain uninterrupted.

How does waterjet cutting enhance industrial equipment fabrication?

In industrial equipment fabrication, 120000 psi waterjet cutting is used for crafting machine frames and wear-resistant components. This method enhances the durability of parts, reducing the frequency of replacements and maintenance, which can be costly. Buyers should consider the compatibility of materials and the ability of suppliers to meet tight tolerances, ensuring that the final products perform optimally in demanding environments.

Why is waterjet cutting crucial for the food processing sector?

Waterjet cutting is particularly valuable in food processing for its ability to slice food products and packaging materials with precision. This method maintains hygiene standards, significantly lowering the risk of contamination. International buyers must ensure that their chosen suppliers comply with food safety regulations and possess the necessary certifications to guarantee that the cutting processes meet health standards.

How can artists and designers leverage waterjet cutting for their projects?

Artists and designers utilize 120000 psi waterjet cutting to create intricate sculptures and architectural elements. This technology allows for unique and complex designs that traditional methods cannot achieve, catering to high-end markets. Buyers looking for custom solutions should assess suppliers based on their ability to offer diverse materials and customization options, ensuring that the final product aligns with their creative vision.

3 Common User Pain Points for ‘120000 psi of waterjet cutting’ & Their Solutions

Scenario 1: High Material Waste from Inadequate Precision

The Problem:

B2B buyers often encounter significant material waste when using waterjet cutting systems that lack the precision required for their specific applications. For instance, in industries like aerospace or automotive manufacturing, where every gram of material counts, imprecise cuts can lead to excessive scrap and increased costs. This situation not only strains budgets but also affects timelines, as re-manufacturing or sourcing additional material can result in project delays.

The Solution:

To mitigate this issue, buyers should invest in high-quality, well-calibrated waterjet systems capable of operating at 120,000 psi. It is crucial to work with reputable suppliers that provide detailed specifications and support for their equipment. When selecting a waterjet cutting machine, prioritize features such as CNC integration, dynamic waterjet capabilities, and advanced nozzle designs that enhance precision. Additionally, conducting regular maintenance and calibration checks will help maintain the machine’s accuracy over time. Collaborating with technical experts can also lead to customized cutting strategies that minimize waste, such as optimizing cutting paths and utilizing advanced software for design validation before actual production.

Scenario 2: Challenges in Cutting Complex Materials

The Problem:

Another common pain point for B2B buyers is the difficulty in cutting complex or composite materials, which are increasingly used in high-performance applications like aerospace and automotive sectors. These materials often require specific cutting techniques and pressures to avoid delamination or structural damage. Buyers may find that their existing waterjet cutting capabilities are insufficient, leading to compromised product integrity or production slowdowns.

The Solution:

To address this challenge, it is advisable to engage with suppliers who specialize in cutting complex materials and can provide tailored solutions. Buyers should inquire about the latest advancements in abrasive waterjet technology, which can enhance the cutting of difficult materials at 120,000 psi. Additionally, investing in training for operators on the specific requirements of different materials will ensure that they can adjust parameters such as abrasive flow rate and cutting speed accordingly. It may also be beneficial to conduct trial runs or prototype testing with small batches to refine the cutting process before full-scale production, ensuring that the selected methods meet quality standards.

Scenario 3: Equipment Downtime Due to Maintenance Issues

The Problem:

Equipment downtime is a critical concern for B2B manufacturers relying on waterjet cutting technology, particularly at high pressures like 120,000 psi. Buyers often face unexpected maintenance needs that can halt production and lead to financial losses. The complexity of high-pressure systems means that even minor issues can escalate quickly, resulting in extended downtime and the need for costly repairs.

The Solution:

To reduce the risk of downtime, buyers should implement a proactive maintenance program that includes routine inspections and preventative measures tailored to their specific waterjet cutting systems. Partnering with suppliers who offer comprehensive service contracts that include regular maintenance and emergency support can be invaluable. Buyers should also invest in training their staff on basic troubleshooting and maintenance procedures, empowering them to address minor issues before they become major problems. Finally, keeping a stock of essential spare parts, such as nozzles and pumps, can ensure that minor repairs can be handled swiftly, minimizing disruption to production schedules. By taking these steps, buyers can significantly improve operational efficiency and reduce the impact of equipment downtime.

Strategic Material Selection Guide for 120000 psi of waterjet cutting

What Are the Key Properties of Metals for 120000 psi Waterjet Cutting?

Metals such as stainless steel and aluminum are among the most commonly processed materials using waterjet cutting technology at 120000 psi. Stainless steel, known for its excellent corrosion resistance and high-temperature tolerance, is ideal for applications requiring durability and hygiene, such as in the food processing and medical industries. Aluminum, while lighter and more malleable, offers good strength-to-weight ratios and is often used in automotive and aerospace applications.

Pros and Cons: The primary advantage of using metals is their strength and versatility, allowing for the production of intricate parts with tight tolerances. However, the cost of high-quality metals can be significant, and their machining complexity may require advanced waterjet systems to achieve optimal results.

How Do Composites Perform Under High-Pressure Waterjet Cutting?

Composites, including carbon fiber and fiberglass, are increasingly popular due to their lightweight and high-strength properties. These materials are particularly beneficial in the aerospace and automotive sectors, where reducing weight while maintaining structural integrity is crucial. Composites can withstand high pressures and temperatures, making them suitable for demanding applications.

Pros and Cons: The key advantage of composites is their ability to be tailored for specific applications, offering excellent performance and durability. However, they can be more expensive than traditional materials, and the cutting process may require specialized techniques to avoid delamination or damage.

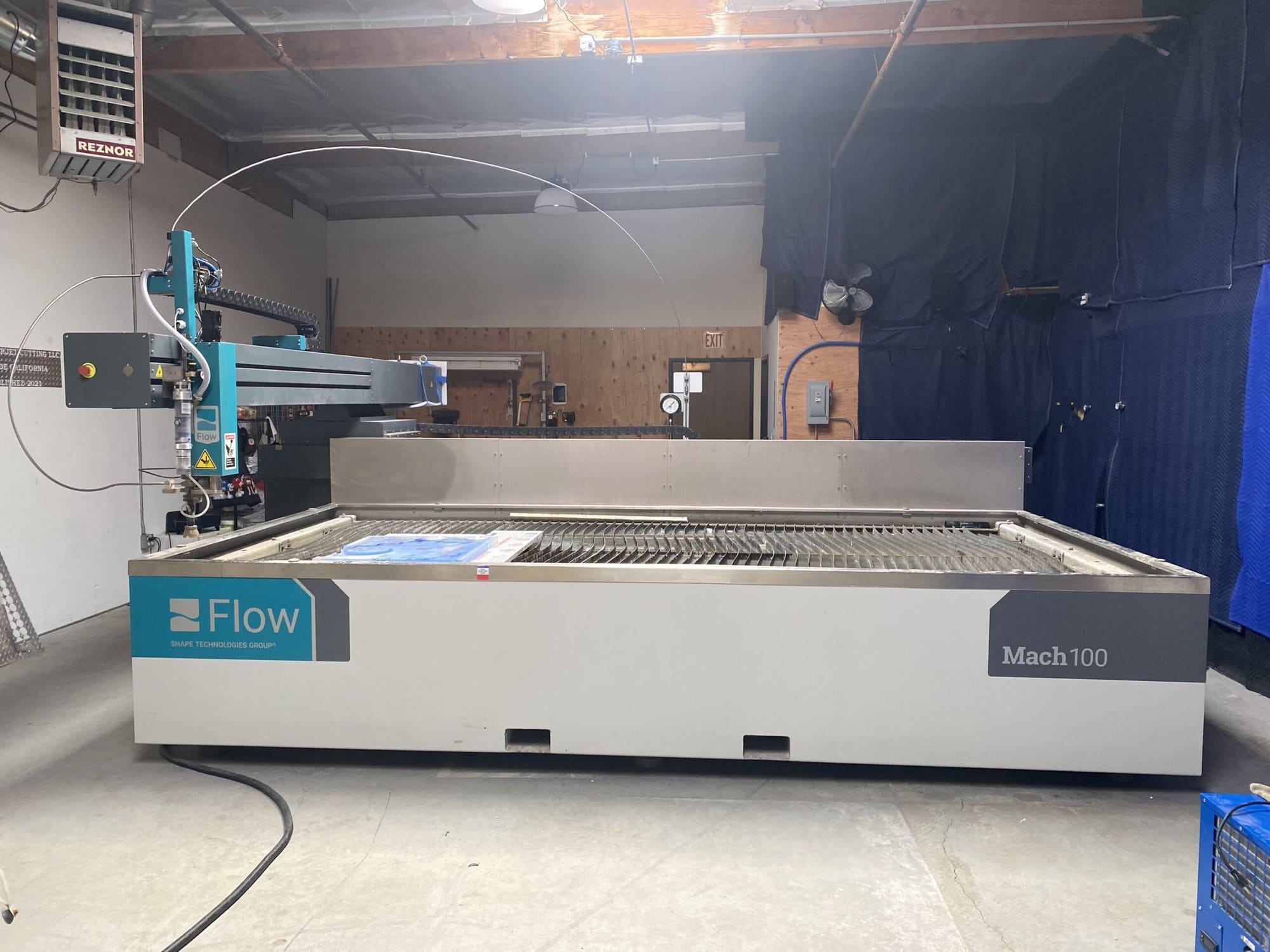

Illustrative image related to 120000 psi of waterjet cutting

What Are the Considerations for Cutting Stone and Glass?

Stone materials like granite and marble, as well as various types of glass, are also viable options for waterjet cutting at 120000 psi. Stone is often used in architectural applications, while glass is popular for artistic and decorative purposes. Both materials benefit from the precision of waterjet cutting, which minimizes waste and maximizes aesthetic appeal.

Pros and Cons: The advantages include the ability to achieve intricate designs and high-quality finishes without the risk of thermal distortion. However, the brittleness of these materials can pose challenges, as they may shatter under certain conditions during cutting. Additionally, the cost of high-quality stone and glass can be a limiting factor for some projects.

What Should International Buyers Consider When Selecting Materials?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, compliance with local and international standards is critical. Understanding the specific regulations, such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards), can help ensure that the materials selected meet the necessary quality and safety requirements. Preferences for certain materials may vary by region, influenced by local availability and market trends.

Summary Table of Material Selection for Waterjet Cutting

| Material | Typical Use Case for 120000 psi of waterjet cutting | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Metals | Aerospace components, automotive parts | High strength and durability | Higher cost and machining complexity | High |

| Composites | Aerospace structures, automotive applications | Lightweight with high strength | Expensive and requires specialized cutting | High |

| Stone | Architectural elements, countertops | Intricate designs with high-quality finish | Brittle and can shatter | Med |

| Glass | Decorative panels, art installations | Aesthetic appeal with precise cuts | Fragile and may require careful handling | Med |

This strategic material selection guide provides essential insights for international B2B buyers considering waterjet cutting at 120000 psi, ensuring informed decisions that align with industry standards and regional preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for 120000 psi of waterjet cutting

What Are the Key Stages in the Manufacturing Process of 120000 psi Waterjet Cutting?

Waterjet cutting at 120,000 psi is a precise and versatile manufacturing process. It involves several critical stages that ensure high-quality output. The main stages typically include material preparation, forming, assembly, and finishing.

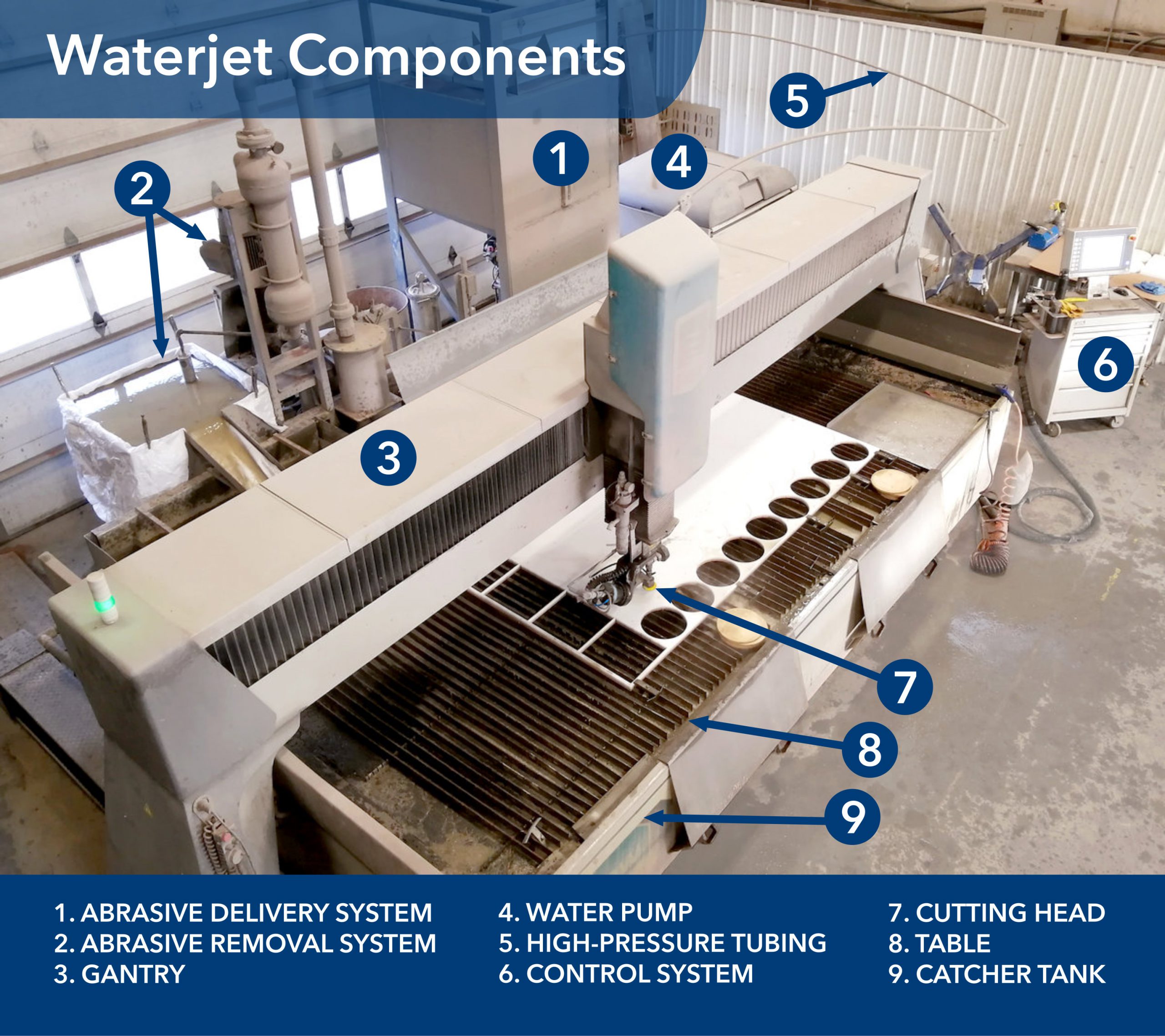

Illustrative image related to 120000 psi of waterjet cutting

Material Preparation

This initial stage is crucial for ensuring optimal cutting performance. Materials must be inspected for quality and suitability for waterjet cutting. This involves checking for impurities, thickness, and any pre-existing defects. Additionally, materials may need to be cut into manageable sizes before processing. Depending on the end application, materials can range from metals and plastics to glass and ceramics, each requiring specific handling techniques to avoid damage.

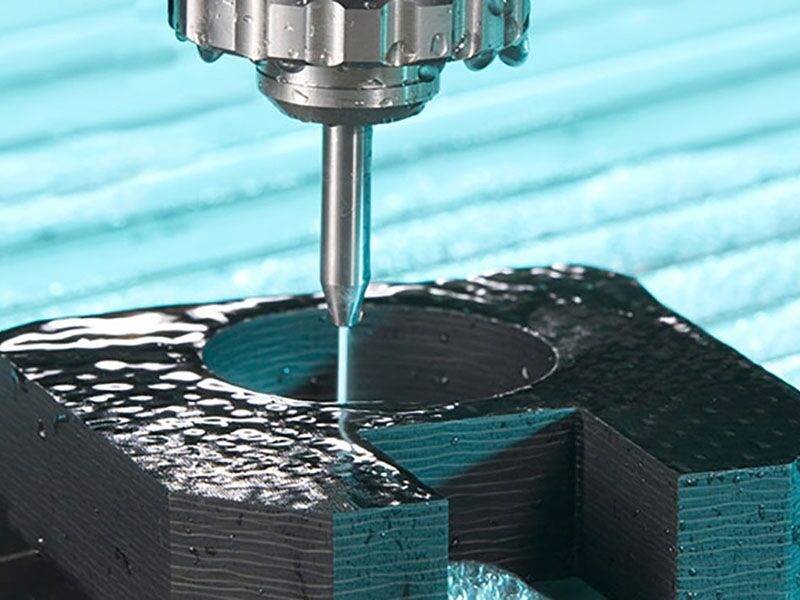

Forming

The core of the manufacturing process is the cutting operation itself. At 120,000 psi, water is expelled through a nozzle, creating a high-velocity stream that can cut through various materials with precision. This stage involves programming the CNC (Computer Numerical Control) system to execute intricate designs. The use of abrasive materials may also be necessary, particularly for harder substances like titanium or stainless steel, where garnet or other abrasives are mixed with water to enhance cutting efficiency.

Assembly

Once the cutting is completed, the next step involves assembling the cut parts if required. This may include fitting components together or preparing them for further processing. This stage is particularly important in applications like aerospace or automotive manufacturing, where precision assembly is critical to product integrity.

Finishing

The finishing stage focuses on refining the cut edges and ensuring that the final product meets the required specifications. This may involve secondary processes such as deburring, polishing, or coating. Additionally, quality checks are performed to ensure that tolerances and surface finishes meet industry standards.

How Is Quality Assurance Implemented in Waterjet Cutting Processes?

Quality assurance (QA) in waterjet cutting is vital to ensure that the final products meet stringent industry standards and customer expectations. B2B buyers should be aware of the relevant international and industry-specific standards, as well as the quality control checkpoints that manufacturers typically follow.

Illustrative image related to 120000 psi of waterjet cutting

What International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is the most recognized international standard for quality management systems. Compliance with ISO 9001 indicates that a manufacturer has established processes to ensure consistent quality and continuous improvement. Additionally, industry-specific standards, such as CE marking for products sold in Europe or API standards for oil and gas applications, may also apply, depending on the end-use of the waterjet cut parts.

What Are the Key QC Checkpoints in Waterjet Cutting?

Quality control involves several checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This initial checkpoint ensures that all materials received meet specified quality standards before they enter the production line. Any non-conforming materials are rejected.

-

In-Process Quality Control (IPQC): During the cutting process, operators perform regular checks to ensure that the equipment is functioning correctly and that the cuts are accurate. This includes monitoring pressures, flow rates, and nozzle conditions.

-

Final Quality Control (FQC): After the cutting and finishing processes, final inspections are conducted to verify that the parts meet the specified tolerances and quality standards. This may include dimensional checks, surface finish evaluations, and functional testing.

What Testing Methods Are Commonly Used to Ensure Quality in Waterjet Cutting?

Various testing methods can be employed to ensure the quality of waterjet cut parts. Common methods include:

-

Dimensional Inspection: Utilizing tools such as calipers and coordinate measuring machines (CMM) to ensure parts meet specified dimensions.

-

Surface Roughness Testing: This involves measuring the texture of the cut surfaces to confirm they meet the required standards.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or dye penetrant inspection can be used to identify internal defects without damaging the parts.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify the quality control processes of their suppliers. Here are some effective strategies:

-

Conduct Audits: Regular supplier audits can help assess compliance with quality standards and operational practices. This may include reviewing documentation, process flows, and actual production conditions.

-

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including inspection reports, test results, and certifications. These documents should reflect adherence to relevant standards like ISO 9001 or specific industry requirements.

-

Utilize Third-Party Inspection Services: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. This is particularly useful for international transactions, where direct oversight may be challenging.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must consider specific nuances when it comes to quality control:

-

Cultural Differences: Different regions may have varying standards and expectations regarding quality. Buyers should communicate their requirements clearly and understand the local practices of their suppliers.

-

Regulatory Compliance: Ensure that suppliers are aware of and compliant with the regulations that apply in the buyer’s country, such as import standards or safety certifications.

-

Logistical Considerations: Shipping and handling can affect the quality of waterjet cut parts. Buyers should discuss packaging and transportation methods with suppliers to mitigate risks during transit.

In conclusion, understanding the manufacturing processes and quality assurance practices for 120000 psi waterjet cutting is essential for B2B buyers. By focusing on the key stages of production, relevant quality standards, and verification methods, businesses can make informed decisions that ensure they receive high-quality products tailored to their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘120000 psi of waterjet cutting’

To assist B2B buyers in effectively procuring high-pressure waterjet cutting services at 120,000 psi, this guide outlines essential steps to ensure a successful sourcing process. The following checklist will help you navigate the complexities of selecting the right supplier for your cutting needs.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your waterjet cutting project. Consider factors such as material types, thickness, tolerances, and desired finishes. Defining these specifications helps in identifying suppliers who can meet your unique needs and ensures that you receive accurate quotes.

Illustrative image related to 120000 psi of waterjet cutting

- Material Compatibility: Ensure that the supplier can handle the materials you intend to cut, such as metals, plastics, or composites.

- Precision Requirements: Specify the tolerances you need, as this will affect the choice of technology and supplier capabilities.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in high-pressure waterjet cutting. Look for companies with a solid reputation and relevant industry experience, particularly in your specific sector.

- Industry Experience: Focus on suppliers with a proven track record in your industry (e.g., aerospace, automotive, or manufacturing).

- Customer Reviews: Check online reviews, testimonials, and case studies to gauge customer satisfaction and reliability.

Step 3: Evaluate Supplier Certifications

Before finalizing your selection, verify that potential suppliers possess the necessary certifications and comply with industry standards. This step is crucial for ensuring quality and reliability.

- ISO Certifications: Look for ISO 9001 or equivalent certifications, which demonstrate a commitment to quality management.

- Safety Standards: Ensure compliance with relevant safety and environmental regulations, which may vary by region.

Step 4: Request Detailed Proposals

Once you have shortlisted suppliers, request detailed proposals that include pricing, timelines, and any additional services. This will facilitate a fair comparison between potential partners.

- Breakdown of Costs: Ensure that the proposal provides a clear breakdown of costs, including setup, material, and labor.

- Lead Times: Confirm the expected lead times for production and delivery, as this can significantly impact your project schedule.

Step 5: Conduct Site Visits or Virtual Tours

If feasible, conduct site visits to the suppliers’ facilities or request virtual tours. This allows you to assess their equipment, technology, and operational capabilities firsthand.

Illustrative image related to 120000 psi of waterjet cutting

- Equipment Condition: Evaluate the state of their waterjet cutting machines, as well-maintained equipment is crucial for quality outcomes.

- Work Environment: Observe the overall working environment to ensure it meets safety and quality standards.

Step 6: Check for After-Sales Support and Maintenance Services

Inquire about the after-sales support and maintenance services offered by your shortlisted suppliers. Reliable support can significantly enhance your operational efficiency.

- Technical Support: Ensure that the supplier offers ongoing technical assistance and troubleshooting.

- Maintenance Plans: Inquire about maintenance agreements to keep equipment running optimally.

Step 7: Finalize Contracts and Agreements

Once you have selected a supplier, ensure that all agreements are clearly outlined in a formal contract. This should include terms of service, pricing, and delivery expectations.

- Clear Terms: Make sure all terms are clearly defined to avoid misunderstandings later.

- Flexibility Clauses: Include clauses that allow for adjustments in case of unforeseen circumstances.

By following this step-by-step checklist, B2B buyers can confidently navigate the procurement process for 120,000 psi waterjet cutting services, ensuring they choose a supplier that meets their technical and operational needs.

Illustrative image related to 120000 psi of waterjet cutting

Comprehensive Cost and Pricing Analysis for 120000 psi of waterjet cutting Sourcing

What Are the Key Cost Components in 120000 psi Waterjet Cutting?

When sourcing waterjet cutting services at 120000 psi, understanding the cost structure is crucial for making informed decisions. The primary cost components include:

-

Materials: The type and thickness of the material significantly impact costs. Harder materials such as titanium or high-strength alloys will incur higher cutting costs compared to softer materials like plastics or rubber.

-

Labor: Skilled operators are essential for high-pressure waterjet cutting. Labor costs may vary based on the complexity of the job and the expertise required to manage the equipment and ensure precision.

-

Manufacturing Overhead: This encompasses operational costs such as maintenance of machinery, utilities, and facilities. High-pressure systems demand stringent maintenance protocols, which can add to overhead costs.

-

Tooling: The wear on nozzles and other consumables should be factored into pricing. Higher pressures may lead to faster wear, necessitating more frequent replacements.

-

Quality Control (QC): Given the precision required in high-pressure cutting, thorough quality checks are vital. These processes can add to the overall cost but ensure the integrity of the final product.

-

Logistics: Shipping costs, especially for heavy or bulky materials, can vary widely based on distance and the chosen mode of transport. Proper logistics planning can reduce costs and lead times.

-

Margin: Suppliers will factor in profit margins based on their operational costs and market conditions. This can vary significantly based on supplier reputation and demand.

How Do Price Influencers Affect Waterjet Cutting Costs?

Several factors influence the pricing of waterjet cutting services, including:

-

Volume/MOQ: Higher volume orders often lead to reduced per-unit costs due to economies of scale. Suppliers are more likely to offer discounts for large orders, making it advantageous for buyers to consolidate their needs.

-

Specifications and Customization: Custom projects requiring specific tolerances or intricate designs may incur higher costs. Buyers should clearly communicate their specifications to receive accurate quotes.

-

Materials: The choice of material not only affects cutting costs but also the type of abrasives required. High-quality abrasives can increase initial costs but may enhance efficiency and reduce cutting time.

-

Quality and Certifications: Certifications (e.g., ISO standards) can influence pricing. Suppliers with recognized quality certifications may charge more, reflecting their commitment to quality and reliability.

-

Supplier Factors: Supplier reputation, location, and market demand can all influence pricing. Engaging local suppliers may reduce logistics costs, while established suppliers may offer better quality assurance.

-

Incoterms: Understanding the Incoterms agreed upon in contracts is crucial. These terms dictate responsibility for shipping costs, insurance, and risk transfer, which can significantly affect overall expenditure.

What Are Effective Buyer Tips for Sourcing Waterjet Cutting Services?

To maximize value when sourcing waterjet cutting services, consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing. Many suppliers are open to negotiations, especially if you can commit to larger orders or longer-term contracts.

-

Cost-Efficiency: Evaluate the total cost of ownership rather than just the upfront price. Consider factors such as durability, maintenance, and operational efficiency in your assessment.

-

Pricing Nuances for International Buyers: When sourcing from different regions, be aware of currency fluctuations and import tariffs. These factors can significantly impact the final cost.

-

Supplier Assessment: Conduct due diligence on suppliers, reviewing their experience, capabilities, and past projects. This can help ensure you select a supplier who can meet your specific needs effectively.

-

Clear Communication: Provide detailed specifications and expectations to avoid misunderstandings that could lead to additional costs or delays.

Disclaimer for Indicative Prices

Prices for waterjet cutting services can vary widely based on the aforementioned factors, and this analysis serves as a guideline rather than a definitive pricing structure. Always request quotes tailored to your specific project requirements for the most accurate pricing.

Alternatives Analysis: Comparing 120000 psi of waterjet cutting With Other Solutions

When considering industrial cutting solutions, it’s essential to evaluate various technologies to determine which best meets specific operational needs. Among these solutions, 120000 psi of waterjet cutting stands out for its precision and versatility. However, alternatives like plasma cutting and laser cutting also offer distinct advantages and may be more suitable for certain applications. This analysis will compare these cutting technologies to assist B2B buyers in making informed decisions.

| Comparison Aspect | 120000 Psi Of Waterjet Cutting | Plasma Cutting | Laser Cutting |

|---|---|---|---|

| Performance | High precision, minimal thermal distortion | Good for thick materials, fast | Excellent precision, fine detail |

| Cost | High initial investment, lower operational costs | Moderate initial costs, higher consumable costs | High initial investment, low operational costs |

| Ease of Implementation | Requires skilled operators, setup can be complex | Easy to implement, less training needed | Requires skilled technicians, complex setup |

| Maintenance | Moderate maintenance, regular checks needed | Low maintenance, consumables need replacement | Moderate maintenance, optics need cleaning |

| Best Use Case | Ideal for complex shapes, sensitive materials | Best for cutting metals, thick sections | Ideal for thin materials, intricate designs |

What Are the Advantages and Disadvantages of Plasma Cutting?

Plasma cutting is a widely used method for cutting conductive metals. It operates by passing an electric current through a gas to create a plasma arc, which melts the metal. One of its primary advantages is speed; plasma cutting is much faster than waterjet cutting, especially for thicker materials. However, it generates heat, which can lead to thermal distortion, making it less suitable for applications requiring precision. Additionally, plasma cutting is limited to conductive materials, excluding non-metal substrates.

Illustrative image related to 120000 psi of waterjet cutting

How Does Laser Cutting Compare to Waterjet Cutting?

Laser cutting utilizes focused light beams to melt or vaporize materials. This technology is known for its exceptional precision and ability to create intricate designs. It is particularly effective for thin materials, providing clean cuts with minimal kerf. However, laser cutting is typically more expensive in terms of initial investment and is less versatile than waterjet cutting, as it may struggle with thicker or reflective materials. Moreover, the operation requires skilled technicians to handle the equipment and ensure safety.

Conclusion: Which Cutting Solution Is Right for Your Business Needs?

Choosing the right cutting solution depends on several factors, including the material type, required precision, production volume, and budget constraints. For businesses focusing on complex shapes and a variety of materials, 120000 psi of waterjet cutting may be the best option despite its higher initial costs. Conversely, if speed and efficiency in cutting metals are paramount, plasma cutting could be more beneficial. For applications demanding intricate detailing in thinner materials, laser cutting is an excellent choice. B2B buyers should carefully assess their operational needs and long-term objectives to select the most suitable cutting technology for their business.

Essential Technical Properties and Trade Terminology for 120000 psi of waterjet cutting

What Are the Key Technical Properties of 120000 psi Waterjet Cutting?

Understanding the technical specifications of waterjet cutting at 120,000 psi is essential for B2B buyers seeking precision and efficiency. Here are some critical properties that define this cutting process:

1. Pressure Rating

The hallmark of waterjet cutting is its high-pressure capability, with 120,000 psi being a benchmark in the industry. This pressure allows for cutting through tough materials like metals, ceramics, and composites with precision. For buyers, knowing the pressure rating is vital as it directly influences cutting speed, edge quality, and the range of materials that can be processed.

Illustrative image related to 120000 psi of waterjet cutting

2. Material Grade Compatibility

Waterjet cutting can effectively handle a variety of materials, including metals (steel, aluminum, titanium), plastics, and stone. The material grade affects not only the cutting parameters but also the final product’s quality and durability. Buyers should ensure that their chosen waterjet service can accommodate the specific grades relevant to their applications, especially in sectors like aerospace and automotive where material integrity is critical.

3. Tolerance Levels

Precision is a key benefit of waterjet cutting, with tolerances often achievable within ±0.001 inches. This level of accuracy is essential for industries that require intricate parts, such as electronics and medical devices. Buyers need to clarify tolerance requirements upfront to ensure that the cutting service aligns with their specifications, which can prevent costly rework and delays.

4. Cutting Speed

The cutting speed of a waterjet system can vary based on material type, thickness, and design complexity. Higher speeds often correlate with lower operational costs and faster turnaround times. Buyers should inquire about the estimated cutting speeds for their specific materials and designs to optimize production schedules and cost efficiency.

5. Edge Quality

Waterjet cutting typically results in smooth edges without the need for secondary finishing processes. This characteristic is particularly beneficial for aesthetic applications or where tight tolerances are required. For B2B buyers, understanding edge quality can influence both product functionality and customer satisfaction.

6. Abrasive vs. Pure Waterjet Cutting

Waterjet cutting can be performed using pure water or an abrasive mix. Abrasive waterjet cutting is preferred for harder materials, while pure waterjet cutting is suitable for softer substances. Buyers must determine which method is appropriate for their needs, as this affects both the cutting process and the final product’s characteristics.

Illustrative image related to 120000 psi of waterjet cutting

What Are the Common Trade Terms Used in Waterjet Cutting?

Navigating the waterjet cutting industry requires familiarity with specific trade terminology. Here are some essential terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In waterjet cutting, understanding OEM relationships can help buyers identify quality standards and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For buyers, knowing the MOQ is crucial for budgeting and inventory management, especially when ordering customized components.

3. RFQ (Request for Quote)

An RFQ is a formal document requesting pricing information from suppliers for specific products or services. For B2B buyers, sending an RFQ can streamline the procurement process by ensuring that all necessary details are communicated upfront.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and costs in international transactions.

5. CNC (Computer Numerical Control)

CNC refers to the automated control of machining tools via computer programming. In waterjet cutting, CNC technology enhances precision and repeatability, making it essential for high-volume production. Buyers should consider suppliers that utilize CNC for optimal results.

6. Abrasive Waterjet Cutting (AWJ)

AWJ combines high-pressure water with abrasive materials to enhance cutting capabilities. This method is particularly effective for hard materials. Buyers should assess whether AWJ is necessary for their applications to ensure they are choosing the right cutting technology.

In summary, understanding these technical properties and trade terminology will empower B2B buyers to make informed decisions when selecting waterjet cutting services that meet their operational needs and specifications.

Navigating Market Dynamics and Sourcing Trends in the 120000 psi of waterjet cutting Sector

What Are the Key Market Dynamics and Trends in the 120000 psi Waterjet Cutting Sector?

The global waterjet cutting market, particularly at the 120000 psi level, is witnessing substantial growth driven by advancements in technology and increasing demand across various industries. Key factors contributing to this growth include the need for precision in manufacturing processes, the versatility of waterjet cutting in handling a wide range of materials, and its ability to produce burr-free edges without thermal distortion. Industries such as aerospace, automotive, and electronics are increasingly adopting waterjet technology for its efficiency in prototyping and low waste generation.

Emerging trends include the integration of automation and IoT within waterjet cutting systems, allowing for enhanced monitoring and control of the cutting process. This not only boosts operational efficiency but also reduces downtime and maintenance costs, making it attractive for international B2B buyers. Moreover, the rise of custom manufacturing demands in markets like Brazil and Vietnam is pushing suppliers to offer tailored solutions, leading to a shift towards smaller batch production.

Additionally, sustainability is becoming a crucial factor in sourcing decisions, as buyers are increasingly looking for suppliers who adhere to eco-friendly practices. The adoption of waterjet cutting is also being influenced by its capability to operate with minimal energy consumption compared to traditional cutting methods, appealing to environmentally conscious organizations.

How Are Sustainability and Ethical Sourcing Influencing the 120000 psi Waterjet Cutting Industry?

Sustainability is a pivotal consideration for B2B buyers in the waterjet cutting sector, particularly as global regulations tighten around environmental impacts. The waterjet cutting process is inherently more sustainable than many traditional methods, as it generates minimal waste and does not produce harmful emissions. However, sourcing practices must also reflect a commitment to ethical standards. This includes ensuring that suppliers utilize environmentally friendly materials and processes, as well as maintaining transparency in their supply chains.

Buyers are increasingly seeking out partners who hold certifications for sustainable practices, such as ISO 14001 or similar ‘green’ certifications. These certifications indicate that a supplier is committed to reducing their environmental footprint and promoting sustainable manufacturing processes. Moreover, the choice of materials plays a significant role in sustainability; for instance, opting for recycled or biodegradable materials can significantly enhance the environmental profile of waterjet cutting applications.

Furthermore, the social responsibility aspect of sourcing is gaining traction. B2B buyers are looking for suppliers that not only adhere to environmental standards but also ensure fair labor practices and community engagement. This holistic approach to sourcing is essential in establishing long-term partnerships and enhancing brand reputation in increasingly competitive global markets.

What Is the Evolution and Historical Context of 120000 psi Waterjet Cutting Technology?

The evolution of waterjet cutting technology has been marked by significant milestones that have shaped its current capabilities. Initially utilized in the 1930s for cutting soft materials, waterjet technology has progressed to handle hard materials, thanks to innovations like abrasive waterjet cutting introduced in the 1980s. The introduction of ultra-high-pressure systems, such as those reaching 120000 psi, has allowed manufacturers to achieve unprecedented precision and efficiency.

The integration of computer numerical control (CNC) technology in the 1990s further revolutionized the industry, enabling intricate designs and complex shapes to be cut with high accuracy. Today, ongoing research and development are focused on enhancing the efficiency and versatility of waterjet systems, such as the development of dynamic waterjets that provide superior edge quality and accuracy.

Understanding this historical context not only highlights the technological advancements but also underscores the importance of choosing suppliers who are at the forefront of innovation, ensuring that B2B buyers can leverage the latest capabilities in their manufacturing processes.

Frequently Asked Questions (FAQs) for B2B Buyers of 120000 psi of waterjet cutting

-

How can I ensure the quality of waterjet cutting services when sourcing internationally?

To ensure quality when sourcing waterjet cutting services internationally, consider requesting certifications such as ISO 9001 or industry-specific standards. Additionally, ask for samples of previous work to assess precision and edge quality. Engaging in virtual or on-site audits can provide deeper insights into the supplier’s capabilities and equipment. Communication is key—establish clear expectations regarding tolerances and specifications. Finally, leverage third-party quality assurance services that can evaluate the supplier’s adherence to quality standards. -

What materials can be effectively cut using 120000 psi waterjet technology?

Waterjet cutting at 120000 psi can effectively cut a wide range of materials, including metals (steel, titanium, aluminum), plastics (PVC, acrylic), composites, glass, stone, and ceramics. The high pressure allows for intricate designs and tight tolerances, making it suitable for complex projects in industries like aerospace, automotive, and architecture. However, very fragile materials and some ultra-hard substances may not be suitable for this method. Always consult with your supplier to confirm material compatibility. -

What factors should I consider when selecting a waterjet cutting supplier?

When selecting a waterjet cutting supplier, evaluate their experience and specialization in your required materials and applications. Assess their technological capabilities, including the types of waterjet systems they operate and their ability to achieve desired tolerances. Consider the supplier’s reputation by checking reviews and case studies. Additionally, inquire about lead times, customer service responsiveness, and their approach to project management. Finally, ensure they can accommodate your specific needs, such as customization and scalability. -

What is the typical minimum order quantity (MOQ) for waterjet cutting services?

Minimum order quantities for waterjet cutting services can vary significantly based on the supplier and the complexity of the project. Generally, MOQs can range from a single prototype to hundreds of units for production runs. Discuss your specific needs with potential suppliers to determine their flexibility on MOQs. Some suppliers may offer lower MOQs for initial projects or prototyping, while others may have stricter requirements for large-scale orders due to material and setup costs. -

How can I negotiate payment terms with international suppliers for waterjet cutting services?

When negotiating payment terms with international suppliers, clarity is essential. Discuss options such as partial upfront payments, milestones based on project completion, or payment upon delivery to mitigate risks. Consider using secure payment methods, such as letters of credit or escrow services, which can provide additional security for both parties. Ensure that all terms are documented in the contract, including currency, due dates, and any penalties for late payments. Understanding the supplier’s financial policies can also aid in negotiations. -

What logistics considerations should I keep in mind when sourcing waterjet cutting services internationally?

Logistics play a crucial role in sourcing waterjet cutting services internationally. Consider shipping methods, costs, and timelines for transporting materials and finished products. Understand customs regulations and any duties or tariffs that may apply to your shipments. It’s also wise to establish clear communication channels for tracking shipments and resolving any issues that arise during transit. Partnering with a supplier that has experience in international logistics can help streamline this process and ensure timely delivery. -

How can I customize my waterjet cutting project to meet specific design requirements?

To customize your waterjet cutting project, begin by providing detailed specifications, including dimensions, tolerances, and material choices. Discuss your design vision with the supplier, as they may offer insights into optimizing the cutting process for efficiency and precision. Some suppliers may also provide design services or CAD support to help refine your ideas. Be open to feedback regarding the feasibility of complex designs, and ensure that any customizations are clearly outlined in the project agreement to avoid misunderstandings. -

What are the common quality assurance practices in waterjet cutting processes?

Quality assurance in waterjet cutting typically involves several practices, including material inspection, in-process monitoring, and final quality checks. Suppliers may use advanced measurement tools such as laser scanners or coordinate measuring machines (CMM) to verify dimensions and tolerances. It’s essential to discuss the supplier’s QA protocols, including any certifications they hold. Regular audits and performance reviews can also help maintain high standards, ensuring that the final products meet your specifications and industry requirements.

Top 3 120000 Psi Of Waterjet Cutting Manufacturers & Suppliers List

1. Water Jet Technologies – Maximum Pressure Insights

Domain: engineering.stackexchange.com

Registered: 2009 (16 years)

Introduction: Maximum water jet pressure: 100,000 psi (4,100 bar) commonly used; theoretical maximum pressure: 150,000 psi with titanium; concerns about metal fatigue at pressures above 60,000 psi; need for increased flow rate for faster cutting; potential methods to increase flow rate: increasing orifice diameter; challenges with material strength for pump construction; importance of understanding pressure vs …

2. eMasterCam – Waterjet Cutting Solutions

Domain: emastercam.com

Registered: 1999 (26 years)

Introduction: Waterjet cutting technology operating at 90,000 PSI. Suitable for cutting thick materials such as 3″ and 4″ blocks of 4330M steel with hardness less than 33 HRC (less than 152 KSI). Approximate IPM (Inches Per Minute) feed rates discussed include 20 IPM for 3.5″ thick material, with varying rates depending on edge quality and material thickness. Waterjet machines can achieve tolerances of .005 in …

3. Jet Edge – Key Products

Domain: blog.jetedgewaterjets.com

Registered: 2018 (7 years)

Introduction: Key Product Details: 1. Waterjet Edge Mid Rail Series: Edge Mid Rail, Edge X3, Edge X5, Edge Mid Rail Dual Carriage. 2. Edge High Rail Series: Edge X3-HR, Edge X5-HR. 3. Jet Start Series: Jet Start 510A, Jet Start 510A5. 4. Custom Configuration Pumps: Hero Series (HERO 50, HERO 50+, HERO 100, HERO 100+, HERO 150, HERO 150+). 5. Pump Specifications: Most Ultra High Pressure Intensifier Pumps operat…

Strategic Sourcing Conclusion and Outlook for 120000 psi of waterjet cutting

How Can Strategic Sourcing Enhance Your Waterjet Cutting Operations?

In conclusion, the integration of 120,000 psi waterjet cutting technology represents a pivotal advancement for manufacturers seeking precision and versatility in their operations. By strategically sourcing high-quality waterjet cutting services, businesses can access a broad range of materials and applications—ranging from aerospace components to intricate designs in art and architecture. This capability not only improves efficiency but also minimizes waste, ensuring that companies can meet their production demands sustainably.

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding the strategic sourcing landscape is essential. Collaborating with experienced providers can lead to enhanced quality control, reduced lead times, and competitive pricing. As the waterjet cutting industry continues to evolve with innovations like micro abrasive technology, now is the opportune moment to invest in these cutting-edge solutions.

We encourage you to explore partnerships with reputable waterjet cutting service providers. By leveraging strategic sourcing, you can enhance your operational capabilities and position your business for future growth. Embrace the potential of waterjet cutting technology to drive your success in today’s dynamic market landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.