10600 W Mitchel St: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for 10600 w mitchel st

In today’s fast-paced global economy, sourcing high-quality composite solutions from locations like 10600 W Mitchell St can pose significant challenges for international B2B buyers. Industries across Africa, South America, the Middle East, and Europe often grapple with the need for reliable, lightweight materials that can withstand demanding applications, from aerospace to oil and gas. This guide offers an in-depth exploration of the offerings available at this key address, including types of composite products, their various applications, and the critical aspects of supplier vetting and cost considerations.

Understanding the nuances of purchasing from a leading manufacturer such as Amalga Composites can empower decision-makers to navigate the complexities of international trade with confidence. By providing comprehensive insights into product specifications, industry standards, and customization options, this guide equips buyers with the knowledge necessary to make informed purchasing decisions.

Whether you are in Saudi Arabia seeking durable materials for telecommunications or in Germany looking for innovative solutions for the automotive sector, this resource is designed to enhance your sourcing strategy. By leveraging the expertise and capabilities of suppliers at 10600 W Mitchell St, businesses can not only meet their operational needs but also gain a competitive edge in their respective markets.

Understanding 10600 w mitchel st Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Composite Pneumatic Tubing | Lightweight, corrosion-resistant, custom sizes | Aerospace, automotive, military | Pros: Durable, customizable, lightweight. Cons: Initial cost may be higher than metals. |

| Hydraulic Cylinder Tubing | High pressure tolerance, engineered for strength | Oil & gas, construction, heavy machinery | Pros: Reliable under pressure, tailored solutions. Cons: Requires precise specifications for optimal performance. |

| Food Grade Tubing | Compliant with health standards, non-reactive | Food processing, pharmaceuticals | Pros: Safety compliant, easy to clean. Cons: Limited to specific applications, potentially higher regulatory costs. |

| Custom Coatings and Paints | Specialized finishes for durability and aesthetics | Automotive, military, industrial | Pros: Enhances product longevity, aesthetic appeal. Cons: Additional lead time for custom orders. |

| Engineered Composite Components | Tailored designs for specific applications | Telecommunications, electronics | Pros: High performance, lightweight. Cons: Complexity in design may lead to longer development times. |

What Are the Key Characteristics of Composite Pneumatic Tubing?

Composite pneumatic tubing is notable for its lightweight and corrosion-resistant properties, making it ideal for applications in aerospace, automotive, and military sectors. This type of tubing can be customized in size and shape to meet specific operational requirements. When purchasing, consider the tubing’s compatibility with existing systems and the anticipated operational environment, as these factors can significantly influence performance and longevity.

How Does Hydraulic Cylinder Tubing Stand Out in B2B Markets?

Hydraulic cylinder tubing is engineered to withstand high-pressure environments, making it essential for industries such as oil and gas, construction, and heavy machinery. Its strength and reliability under pressure make it a preferred choice for critical applications. Buyers should assess the tubing’s pressure ratings and ensure compatibility with hydraulic systems to maximize efficiency and safety in operations.

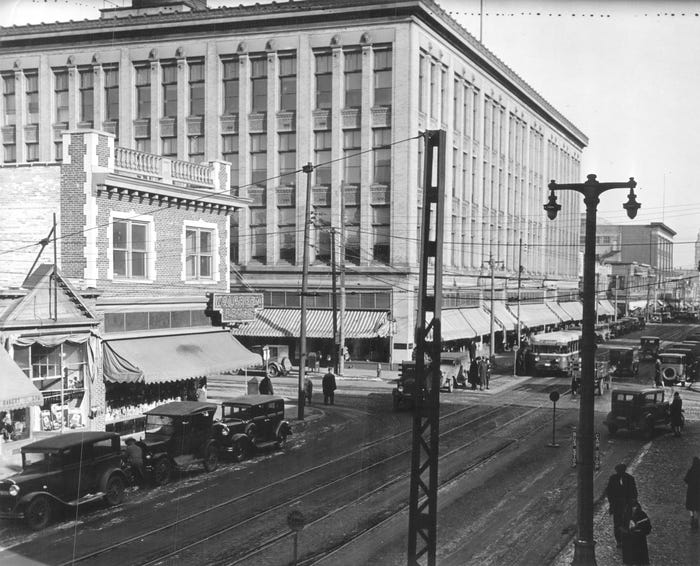

Illustrative image related to 10600 w mitchel st

Why Is Food Grade Tubing Important for Compliance?

Food grade tubing is designed to meet stringent health and safety standards, ensuring that it is non-reactive and safe for use in food processing and pharmaceuticals. This type of tubing is easy to clean and maintain, reducing the risk of contamination. B2B buyers must consider regulatory compliance and the specific requirements of their industry when selecting food grade tubing, as these factors can impact their operations and product safety.

What Are the Benefits of Custom Coatings and Paints?

Custom coatings and paints provide specialized finishes that enhance both the durability and aesthetic appeal of products. This is particularly valuable in industries such as automotive and military, where appearance and longevity are critical. Buyers should be aware of potential lead times associated with custom orders and ensure that the coatings meet the specific environmental and operational demands of their applications.

How Do Engineered Composite Components Enhance Performance?

Engineered composite components are tailored for specific applications, offering high performance and lightweight solutions in telecommunications and electronics. These components can significantly improve product efficiency and functionality. Buyers should focus on the design complexity and development timelines, as these factors can affect the overall project schedule and costs. Understanding the intended application will also help in making informed purchasing decisions.

Key Industrial Applications of 10600 w mitchel st

| Industry/Sector | Specific Application of 10600 w mitchel st | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Custom composite components for aircraft structures | Lightweight, durable materials enhance fuel efficiency and performance | Compliance with aviation standards and certifications |

| Oil & Gas | Filament-wound pressure vessels for deep-sea exploration | High strength-to-weight ratio reduces operational costs and increases safety | Resistance to corrosive environments and high-pressure requirements |

| Automotive | Lightweight composite parts for vehicle manufacturing | Improved fuel efficiency and lower emissions through reduced vehicle weight | Customization capabilities for varying vehicle models |

| Military | Advanced composite materials for military applications | Enhanced durability and performance in extreme conditions | Need for rapid prototyping and adherence to defense specifications |

| Renewable Energy | Composite solutions for wind turbine components | Increased energy efficiency and longevity of turbine systems | Sustainability and environmental compliance considerations |

How Are Aerospace Industries Leveraging 10600 W Mitchell St Solutions?

In the aerospace sector, 10600 W Mitchell St is pivotal for producing custom composite components that contribute to aircraft structures. These lightweight materials significantly enhance fuel efficiency and overall aircraft performance. International buyers, particularly from regions like Europe and the Middle East, must ensure that the products meet strict aviation standards and certifications. Customization capabilities allow for tailored solutions that fit specific aircraft models, addressing unique engineering challenges.

What Role Does 10600 W Mitchell St Play in the Oil & Gas Sector?

The oil and gas industry benefits from the filament-wound pressure vessels manufactured at 10600 W Mitchell St, designed for deep-sea exploration. These vessels are engineered to withstand extreme pressures and corrosive environments, providing a high strength-to-weight ratio that reduces operational costs and enhances safety. Buyers from Africa and South America should prioritize sourcing materials that comply with industry-specific regulations and ensure reliability under challenging conditions.

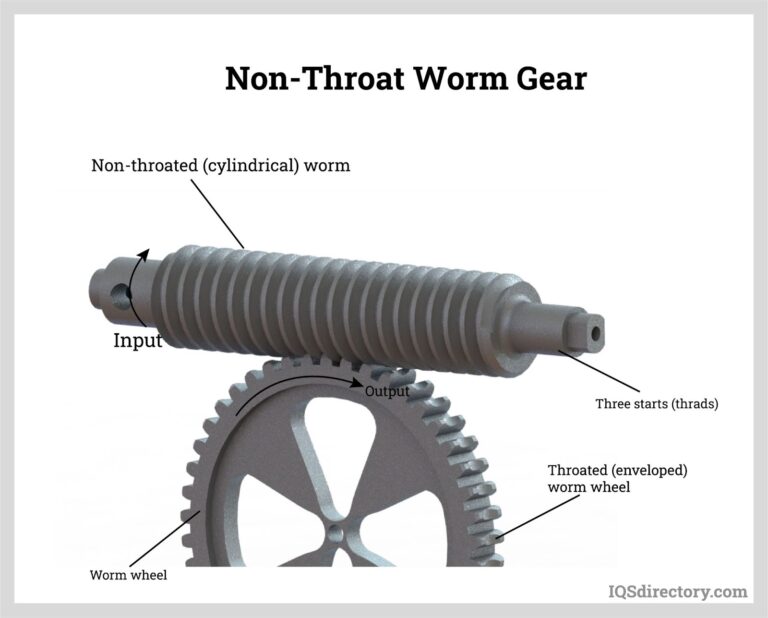

Illustrative image related to 10600 w mitchel st

How Are Automotive Manufacturers Utilizing Solutions from 10600 W Mitchell St?

Automotive manufacturers are increasingly turning to the lightweight composite parts produced at 10600 W Mitchell St to improve vehicle efficiency. By incorporating these materials, manufacturers can reduce vehicle weight, leading to better fuel efficiency and lower emissions. For B2B buyers in Europe and South America, it’s essential to consider customization options that align with different vehicle models and specifications, ensuring that the components integrate seamlessly into their production lines.

In What Ways Are Military Applications Enhanced by 10600 W Mitchell St?

Military applications require advanced composite materials that can withstand extreme conditions, and 10600 W Mitchell St excels in this area. The facility produces high-performance composite solutions that meet rigorous defense specifications. International buyers, particularly in the Middle East, should focus on rapid prototyping capabilities and the ability to customize products for specific military requirements, ensuring they receive durable and reliable materials for their operations.

How Does 10600 W Mitchell St Contribute to Renewable Energy Solutions?

In the renewable energy sector, 10600 W Mitchell St is a key player in manufacturing composite solutions for wind turbine components. These advanced materials not only increase the energy efficiency of turbines but also extend their operational lifespan. Buyers from Africa and South America should consider sustainability and environmental compliance when sourcing these materials, as the industry moves towards greener practices and technologies.

Illustrative image related to 10600 w mitchel st

3 Common User Pain Points for ‘10600 w mitchel st’ & Their Solutions

Scenario 1: Difficulty in Sourcing Custom Composite Solutions

The Problem: B2B buyers often face challenges in sourcing custom composite solutions that meet their specific operational requirements. For companies in industries like oil and gas, aerospace, or automotive, the need for lightweight, durable materials that can withstand harsh environments is critical. However, many suppliers offer generic products that do not cater to unique specifications, leading to delays in production and increased costs.

The Solution: To effectively source from 10600 W Mitchell St, buyers should initiate direct communication with Amalga Composites’ team of experts. By sharing detailed project requirements, including dimensions, materials, and performance expectations, buyers can collaborate to develop bespoke solutions. Amalga’s extensive experience and state-of-the-art manufacturing capabilities allow for the creation of tailored composite materials that enhance product performance. Additionally, leveraging their in-house engineering support can streamline the prototyping process, ensuring that the final product aligns perfectly with project demands.

Scenario 2: Concerns Over Product Quality and Reliability

The Problem: Quality assurance is a significant concern for B2B buyers, especially when dealing with composite materials used in critical applications such as military and aerospace. Many suppliers may not provide adequate information about their manufacturing processes or quality control measures, leading to uncertainty about the reliability and longevity of the products.

The Solution: Buyers should inquire about Amalga Composites’ quality assurance protocols when considering sourcing from 10600 W Mitchell St. Understanding their rigorous testing processes and certifications can provide peace of mind. Requesting samples or pilot runs can also be beneficial; this allows buyers to assess the quality and performance of the products before committing to larger orders. Furthermore, engaging in discussions about their patented technologies and innovations can highlight how Amalga’s commitment to excellence differentiates them in the market, ensuring that buyers receive durable and reliable solutions.

Scenario 3: Navigating Complex Logistics and Supply Chain Issues

The Problem: International B2B buyers often encounter logistical challenges when importing composite materials, including customs delays, shipping costs, and the complexity of coordinating with multiple suppliers. These issues can disrupt project timelines and increase operational costs, particularly for businesses that rely on just-in-time delivery.

Illustrative image related to 10600 w mitchel st

The Solution: To mitigate these logistical challenges when sourcing from 10600 W Mitchell St, buyers should leverage Amalga Composites’ established supply chain and distribution networks. Engaging with their logistics team can provide insights into optimizing shipping routes and reducing costs. Additionally, buyers can explore options for consolidated shipping, which can streamline the import process and minimize delays. Establishing clear communication channels for tracking orders and shipping updates can also help manage expectations and ensure timely delivery, ultimately supporting smoother project execution.

Strategic Material Selection Guide for 10600 w mitchel st

What Are the Key Properties of Common Materials for Applications at 10600 W Mitchell St?

When selecting materials for applications at 10600 W Mitchell St, it is essential to consider the unique properties and performance characteristics of each material. Below, we analyze four common materials used in the manufacturing of composite solutions, particularly focusing on their suitability for various industrial applications.

1. Carbon Fiber Reinforced Polymer (CFRP)

Key Properties: CFRP is known for its high strength-to-weight ratio, excellent fatigue resistance, and thermal stability. It typically withstands temperatures up to 120°C and pressures exceeding 400 psi, making it suitable for demanding applications.

Pros & Cons: The primary advantage of CFRP is its lightweight nature, which enhances fuel efficiency in automotive and aerospace applications. However, it is relatively expensive compared to traditional materials like steel or aluminum, and its manufacturing process can be complex, requiring specialized equipment and expertise.

Impact on Application: CFRP is highly compatible with various media, including corrosive substances, making it ideal for applications in the oil and gas industry. Its durability ensures longevity, reducing the frequency of replacements.

Illustrative image related to 10600 w mitchel st

Considerations for International Buyers: Buyers from regions such as the Middle East and Europe should ensure compliance with international standards like ASTM D7264 and DIN EN 2561, which govern the mechanical properties of CFRP. Understanding local regulations regarding importation and material specifications is crucial for successful procurement.

2. Glass Fiber Reinforced Polymer (GFRP)

Key Properties: GFRP offers good mechanical properties, with a temperature rating of up to 80°C and pressure capabilities around 300 psi. It is less expensive than CFRP while still providing significant strength and corrosion resistance.

Pros & Cons: GFRP is cost-effective and easier to manufacture, making it suitable for high-volume applications. However, it is heavier than CFRP and may not perform as well under extreme conditions, limiting its use in high-performance sectors.

Impact on Application: GFRP is particularly effective in environments where chemical exposure is a concern, such as in the telecommunications and renewable energy sectors. Its resilience against moisture and chemicals enhances its suitability for outdoor applications.

Considerations for International Buyers: Buyers from Africa and South America should be aware of compliance with international standards like ASTM D638. Understanding local market preferences for material durability can influence purchasing decisions.

3. Aluminum Alloys

Key Properties: Aluminum alloys are lightweight, with excellent corrosion resistance and a temperature rating of up to 150°C. They can withstand pressures of about 200 psi, making them versatile for various applications.

Pros & Cons: The primary advantage of aluminum is its availability and lower cost compared to advanced composites. However, it is less durable than CFRP and GFRP under high-stress conditions, which may lead to more frequent replacements.

Illustrative image related to 10600 w mitchel st

Impact on Application: Aluminum is commonly used in automotive and aerospace applications where weight savings are critical, but its susceptibility to corrosion in harsh environments can be a drawback.

Considerations for International Buyers: Buyers in Europe, particularly Germany, should consider compliance with DIN EN 573 standards for aluminum alloys. Additionally, understanding local preferences for lightweight materials in transportation can guide purchasing strategies.

4. Steel Alloys

Key Properties: Steel alloys provide high tensile strength and can withstand temperatures up to 300°C. They are robust and can handle high-pressure applications, typically exceeding 500 psi.

Pros & Cons: The strength and durability of steel make it suitable for heavy-duty applications. However, it is heavier and more prone to corrosion unless treated, which can increase maintenance costs.

Impact on Application: Steel is ideal for structural components in construction and heavy machinery. Its compatibility with various media is excellent, but corrosion resistance must be managed through coatings or galvanization.

Considerations for International Buyers: Buyers from the Middle East should ensure compliance with international standards such as ASTM A36 for structural steel. Understanding the local market’s requirements for corrosion resistance will be vital for successful applications.

Summary Table of Material Selection

| Material | Typical Use Case for 10600 W Mitchell St | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Fiber Reinforced Polymer (CFRP) | Aerospace components, high-performance automotive parts | Lightweight and high strength-to-weight ratio | High cost and complex manufacturing | High |

| Glass Fiber Reinforced Polymer (GFRP) | Telecommunications, renewable energy structures | Cost-effective and good chemical resistance | Heavier and less durable than CFRP | Medium |

| Aluminum Alloys | Automotive frames, aerospace structures | Lightweight and corrosion-resistant | Less durable under high stress | Medium |

| Steel Alloys | Heavy machinery, construction materials | High strength and durability | Heavier and prone to corrosion | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions that align with their specific operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 10600 w mitchel st

What Are the Main Stages of Manufacturing Processes at 10600 W Mitchell St?

At the facility located at 10600 W Mitchell St, the manufacturing process is meticulously designed to ensure high-quality composite products. The process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves selecting and preparing the raw materials, which typically include composite fibers and resins. The quality of these materials is critical, as they directly influence the final product’s performance. Advanced techniques such as fiber alignment and resin impregnation are employed to optimize the material properties.

-

Forming: The forming stage utilizes cutting-edge filament winding technology, a specialty at Amalga Composites. This process involves winding composite fibers around a mandrel to create cylindrical structures like pressure vessels and hydraulic cylinders. The precision of this technique allows for the production of lightweight yet durable components tailored to specific industry needs.

-

Assembly: Once the components are formed, they undergo assembly, where various parts are integrated into the final product. This stage may involve the addition of fittings, seals, and other essential components. The assembly process is closely monitored to ensure that all elements fit together seamlessly, maintaining the structural integrity and performance of the product.

-

Finishing: The finishing stage involves surface treatment and coating to enhance the product’s durability and aesthetics. Techniques such as painting, coating, and polishing are employed to ensure that the final product meets both functional and visual standards. Quality checks are performed at this stage to guarantee that products are ready for shipment.

What Key Techniques Are Used in the Manufacturing Process?

Amalga Composites employs several key techniques throughout its manufacturing processes to achieve excellence. Notable among these are:

- Filament Winding: This advanced technique allows for precise control over fiber orientation and resin application, resulting in optimized strength-to-weight ratios.

- CNC Machining: Computer Numerical Control (CNC) machines are utilized for precision cutting and shaping of composite materials, ensuring high accuracy and repeatability.

- In-House Coating: The facility features specialized zones for coating and painting, providing tailored surface treatments that enhance product performance and longevity.

These techniques are complemented by a robust production environment, which includes multiple production lines and overhead crane bays, enabling high-volume output and efficient manufacturing workflows.

What Quality Assurance Practices Are Implemented at 10600 W Mitchell St?

Quality assurance (QA) is a cornerstone of the manufacturing process at 10600 W Mitchell St, ensuring that products meet both international standards and customer expectations.

-

International Standards Compliance: The facility adheres to ISO 9001, which outlines a framework for quality management systems. This certification demonstrates a commitment to consistent quality and continual improvement. Additionally, specific industry standards such as CE marking for compliance with European health and safety regulations and API standards for oil and gas components are strictly followed.

-

Quality Control Checkpoints: Throughout the manufacturing process, several quality control checkpoints are established:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified quality standards before production begins.

– In-Process Quality Control (IPQC): Ongoing inspections are conducted during the manufacturing process to identify any deviations from quality standards in real-time, allowing for immediate corrective actions.

– Final Quality Control (FQC): Before products are shipped, final inspections are carried out to verify that they meet all specifications and quality criteria. -

Testing Methods: Common testing methods include mechanical testing (tensile, compression, and fatigue tests), non-destructive testing (ultrasonic and radiographic testing), and environmental testing (temperature and humidity resistance). These tests ensure that products perform reliably under various conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are effective strategies:

- Conducting Audits: Buyers should request regular audits of the manufacturing facility. An on-site audit allows buyers to assess the quality management systems and manufacturing practices firsthand.

- Requesting Quality Reports: Suppliers should provide detailed quality reports, including results from IQC, IPQC, and FQC stages. These documents can offer insights into the effectiveness of the quality assurance practices employed.

- Utilizing Third-Party Inspection Services: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control processes. These agencies can conduct inspections and testing according to international standards, offering additional assurance to buyers.

What Quality Control and Certification Nuances Should International Buyers Consider?

International buyers should be aware of several nuances when it comes to quality control and certification:

Illustrative image related to 10600 w mitchel st

- Understanding Regional Standards: Different regions may have varying standards for product quality and safety. For instance, CE marking is essential for products sold in the European Union, while API certifications are crucial for the oil and gas industry. Buyers must ensure that their suppliers are compliant with the relevant standards for their target markets.

- Cultural and Language Barriers: Effective communication regarding quality expectations is vital. Buyers should consider language differences and cultural nuances when discussing quality standards and requirements with suppliers.

- Logistical Considerations: International shipping can complicate quality assurance. Buyers should discuss logistics with suppliers to ensure that products maintain their quality during transit and are compliant with local regulations upon arrival.

By understanding these manufacturing processes and quality assurance practices at 10600 W Mitchell St, B2B buyers can make informed decisions that align with their needs and ensure they receive high-quality products tailored to their specifications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘10600 w mitchel st’

Introduction

This sourcing guide is designed for international B2B buyers interested in procuring products or services from the location at 10600 W Mitchell St, Milwaukee, WI. The goal is to provide a structured approach to ensure that your procurement process is efficient, effective, and aligned with your business needs. Follow these steps to navigate the sourcing landscape confidently and make informed decisions.

Step 1: Define Your Technical Specifications

Clearly articulate the technical requirements and specifications of the products or services you need. This step is crucial as it sets the foundation for all subsequent discussions with suppliers.

– Key Considerations:

– Identify material requirements, dimensions, and performance standards.

– Consider any industry-specific regulations or certifications that must be met.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers located at or associated with 10600 W Mitchell St. Utilize online resources, industry publications, and trade directories to create a list of viable candidates.

– What to Look For:

– Company history and reputation in the market.

– Specialization in your required products, such as composite materials or custom engineering solutions.

Step 3: Evaluate Supplier Capabilities

Before committing to a supplier, it’s crucial to vet their capabilities thoroughly. Request detailed company profiles, case studies, and references from buyers in similar industries or regions.

– Key Evaluation Areas:

– Manufacturing capacity and technology used, such as state-of-the-art machinery and production lines.

– Quality assurance processes and certifications that demonstrate their commitment to excellence.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers possess the necessary certifications relevant to your industry. This step is essential for compliance and quality assurance.

– Important Certifications:

– ISO certifications for quality management.

– Industry-specific certifications that validate their expertise in composite manufacturing or engineering solutions.

Step 5: Request Samples or Prototypes

Ask for samples or prototypes of the products you are interested in. This allows you to assess the quality, durability, and suitability of the materials before making a large-scale commitment.

– What to Evaluate:

– The performance of the samples in real-world conditions.

– The responsiveness of the supplier in addressing any concerns or modifications required.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a preferred supplier, it’s time to negotiate terms and conditions. This includes pricing, delivery schedules, payment terms, and warranties.

– Negotiation Tips:

– Be clear about your expectations and requirements.

– Consider long-term partnership benefits, including volume discounts or service agreements.

Step 7: Establish Communication Protocols

Set up clear communication protocols with your chosen supplier. Effective communication is vital for a smooth procurement process and ongoing relationship management.

– Key Elements:

– Determine primary points of contact and preferred communication channels.

– Establish regular check-ins to monitor project progress and address any issues promptly.

By following this structured checklist, B2B buyers can effectively navigate the sourcing process at 10600 W Mitchell St, ensuring they select the right partners to meet their business needs and drive success.

Comprehensive Cost and Pricing Analysis for 10600 w mitchel st Sourcing

What Are the Key Cost Components for Sourcing from 10600 W Mitchell St?

When sourcing from 10600 W Mitchell St, particularly from Amalga Composites, understanding the cost structure is critical. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of raw materials, especially for composite manufacturing, is a significant factor. Prices can fluctuate based on the type of composite used, such as carbon fiber or fiberglass, and global supply chain dynamics.

-

Labor: Skilled labor is essential for the precision required in composite manufacturing. Labor costs can vary depending on the region and the expertise level of the workforce. In the U.S., labor costs tend to be higher than in emerging markets, which can influence the overall pricing strategy.

-

Manufacturing Overhead: This encompasses facility costs, utilities, and equipment maintenance. Amalga’s extensive manufacturing facility and advanced machinery contribute to a higher overhead, which may be reflected in product pricing.

-

Tooling: Custom tooling is often necessary for bespoke solutions, and the cost can be significant. Tooling expenses should be factored into the initial pricing, especially for low-volume orders.

-

Quality Control: Rigorous QC processes ensure product reliability, particularly for industries like aerospace and automotive. The costs associated with these processes can impact the final price but are essential for maintaining high standards.

-

Logistics: Shipping and handling costs vary based on the destination and chosen Incoterms. International logistics can become complex, impacting delivery times and overall costs.

-

Margin: Manufacturers typically include a profit margin that reflects the quality of service, expertise, and market conditions. This margin can vary widely based on competition and demand.

How Do Price Influencers Affect Sourcing Costs?

Several factors can influence the pricing of products sourced from 10600 W Mitchell St:

-

Volume and Minimum Order Quantities (MOQ): Higher volumes often lead to lower per-unit costs due to economies of scale. However, MOQs can vary based on the product and manufacturer.

-

Specifications and Customization: Customized products usually come at a premium. The complexity of the specifications can significantly affect pricing, especially in sectors that require unique solutions.

-

Quality and Certifications: Products with higher quality standards or specific certifications (e.g., ISO) may incur additional costs. Buyers should evaluate whether these certifications align with their needs.

-

Supplier Factors: The relationship with suppliers can affect pricing flexibility. Long-term partnerships may yield better pricing terms due to established trust and volume commitments.

-

Incoterms: Understanding the terms of shipment (e.g., FOB, CIF) is crucial, as they determine the responsibility for shipping costs and risks, which can influence the total cost.

What Buyer Tips Should International B2B Buyers Consider?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, navigating the cost landscape requires strategic insight:

-

Negotiation: Leverage your position as a buyer to negotiate better terms. Understanding the cost structure allows for informed discussions about pricing.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors like durability and maintenance, which can lead to long-term savings.

-

Pricing Nuances: Be aware of currency fluctuations and potential tariffs that can affect the final price. Establishing contracts in stable currencies may help mitigate risks.

-

Supply Chain Transparency: Request detailed breakdowns of costs from suppliers. Transparency can facilitate better decision-making and foster trust in the supplier relationship.

-

Cultural Sensitivity: Understanding cultural differences in negotiation styles and business practices can enhance communication and foster better partnerships.

Disclaimer on Indicative Prices

Prices and cost structures provided in this analysis are indicative and can vary based on market conditions, specific project requirements, and negotiations with suppliers. Always seek updated quotes and detailed proposals to ensure accurate budgeting for your sourcing needs.

Alternatives Analysis: Comparing 10600 w mitchel st With Other Solutions

Understanding Alternatives for Composite Solutions

In the competitive landscape of composite manufacturing, businesses often seek solutions that enhance performance, reduce costs, and streamline operations. At 10600 W Mitchell St, Amalga Composites provides advanced filament-wound composite solutions tailored to various industries. However, exploring alternative options can help international B2B buyers make informed decisions that align with their specific operational needs and budget constraints.

Comparison Table

| Comparison Aspect | ‘10600 W Mitchel St’ | Alternative 1: Fiberdome Inc. | Alternative 2: New Berlin Plastics |

|---|---|---|---|

| Performance | High durability and customizability for diverse applications | Strong fiberglass solutions with a focus on quality | Versatile mold design and rapid prototyping capabilities |

| Cost | Competitive pricing for high-volume orders | Generally lower costs, but limited customizability | Moderate pricing, with added costs for advanced tooling |

| Ease of Implementation | Comprehensive support from design to production | Requires significant client input for custom solutions | Streamlined processes but may involve longer lead times |

| Maintenance | Low maintenance due to durable materials | Regular maintenance needed for fiberglass products | Minimal maintenance, but tooling may require updates |

| Best Use Case | Aerospace, oil & gas, and military applications | Industrial applications needing strong fiberglass components | Projects requiring rapid prototyping and product development |

Analyzing Alternative Solutions

Fiberdome Inc.

Fiberdome specializes in fiberglass design and manufacturing, boasting over 40 years of experience in producing high-quality components. This alternative is ideal for industries that prioritize cost-effectiveness and are less focused on custom solutions. While Fiberdome’s products generally come at a lower price point, they may not offer the same level of customization as Amalga Composites. Businesses looking for reliable, strong fiberglass solutions will benefit from Fiberdome’s extensive capabilities but must be prepared for regular maintenance due to the nature of fiberglass.

New Berlin Plastics

New Berlin Plastics focuses on mold design and rapid prototyping, catering to businesses that require quick turnaround times. Their versatile capabilities allow them to provide a broad range of solutions from concept to production. However, this alternative may involve higher costs for advanced tooling and longer lead times, which can be a disadvantage for companies needing immediate solutions. The strength of New Berlin lies in their ability to adapt to client needs, making them suitable for industries that value innovation and speed.

Illustrative image related to 10600 w mitchel st

Conclusion: How to Choose the Right Composite Solution

When selecting a composite solution, B2B buyers should consider their specific operational requirements, including performance needs, budget constraints, and timelines. While 10600 W Mitchell St offers robust, tailored composite solutions suitable for demanding applications, alternatives like Fiberdome and New Berlin Plastics present viable options depending on cost, maintenance, and implementation ease. Ultimately, the choice should align with the buyer’s strategic goals, ensuring that the selected solution not only meets current needs but also supports long-term growth and efficiency.

Essential Technical Properties and Trade Terminology for 10600 w mitchel st

What Are the Key Technical Properties Relevant to 10600 W Mitchell St?

Understanding the technical properties of products manufactured at 10600 W Mitchell St is essential for international B2B buyers, especially those in sectors such as oil and gas, automotive, and telecommunications. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the classification of the composite materials used, which can significantly impact the performance and durability of the final product. For instance, high-strength composite materials are often required in aerospace applications, while food-grade composites are essential for the food and beverage industry. Selecting the appropriate material grade ensures compliance with industry standards and enhances the product’s lifespan.

2. Tolerance

Tolerance defines the permissible limits of variation in a physical dimension of a product. In manufacturing, maintaining tight tolerances is crucial for ensuring that components fit together correctly and function as intended. For B2B buyers, understanding tolerance specifications can prevent costly reworks and ensure compatibility with existing systems.

3. Weight-to-Strength Ratio

This property describes the relationship between the weight of a material and its strength. Lightweight composite materials with high strength-to-weight ratios are particularly valuable in industries like automotive and aerospace, where reducing weight can lead to improved fuel efficiency and performance. For buyers, this means selecting materials that not only meet performance criteria but also contribute to overall cost savings.

Illustrative image related to 10600 w mitchel st

4. Corrosion Resistance

Corrosion resistance is a critical property, especially in industries such as oil and gas, where components are exposed to harsh environments. Composites are often favored over metals due to their inherent resistance to corrosion, which translates into lower maintenance costs and longer service life. Buyers should prioritize products that offer superior corrosion resistance to ensure reliability and safety.

5. Thermal Stability

Thermal stability refers to a material’s ability to maintain its properties under varying temperature conditions. In applications like military and aerospace, where extreme temperatures are common, selecting materials with high thermal stability is essential. For B2B buyers, this property ensures that products will perform consistently, reducing the risk of failure in critical applications.

What Are Common Trade Terms Used in the Context of 10600 W Mitchell St?

Familiarity with trade terminology can facilitate smoother transactions and clearer communication between buyers and suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of 10600 W Mitchell St, understanding OEM relationships is vital for buyers looking to integrate composite solutions into their products without compromising quality or performance.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers to effectively manage inventory and costs, particularly when entering new markets or launching new products.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit pricing and terms from suppliers. This term is particularly relevant for buyers looking to compare offers from different manufacturers at 10600 W Mitchell St. A well-structured RFQ can lead to better pricing and terms, facilitating more favorable purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for navigating logistics and ensuring that both parties are clear on cost responsibilities, delivery methods, and risk management.

5. Lead Time

Lead time is the period between the initiation of an order and its fulfillment. For B2B buyers, knowing the lead time for products from 10600 W Mitchell St can help in planning production schedules and managing supply chain logistics effectively.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and drive business success.

Navigating Market Dynamics and Sourcing Trends in the 10600 w mitchel st Sector

What Are the Key Market Dynamics and Trends Impacting Sourcing at 10600 W Mitchell St?

The sector surrounding 10600 W Mitchell St, particularly through companies like Amalga Composites, is characterized by rapid innovation and a shift towards advanced composite materials. Global drivers such as the increasing demand for lightweight, durable materials in industries like aerospace, automotive, and renewable energy are reshaping sourcing strategies for international B2B buyers. As firms prioritize operational efficiency and sustainability, there is a marked trend toward integrating advanced manufacturing technologies, including automation and digital twins, which enhance production capabilities and reduce time-to-market.

Emerging technologies such as additive manufacturing and IoT are also influencing sourcing decisions. B2B buyers are increasingly seeking suppliers who not only provide high-quality products but also leverage these technologies to offer customization and scalability. For international buyers from Africa, South America, the Middle East, and Europe, particularly in regions like Saudi Arabia and Germany, the ability to source innovative solutions that align with local regulations and market demands is crucial. This includes navigating complex supply chains and ensuring compliance with international standards, which can vary significantly across regions.

In addition, the push for resilience in supply chains has led to greater collaboration among suppliers and buyers, emphasizing the importance of transparent communication and relationship building. As businesses adapt to fluctuating market conditions and consumer expectations, sourcing strategies that emphasize flexibility and agility will be paramount.

How Is Sustainability Shaping B2B Sourcing Practices at 10600 W Mitchell St?

Sustainability and ethical sourcing are increasingly critical considerations for B2B buyers operating in the vicinity of 10600 W Mitchell St. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt more sustainable practices. In the composite materials sector, this includes a shift towards eco-friendly raw materials and manufacturing techniques that minimize waste and energy consumption.

Buyers are now looking for suppliers who can demonstrate their commitment to sustainability through certifications such as ISO 14001 for environmental management and materials that are recyclable or derived from renewable resources. This is particularly relevant for international buyers, who often face pressure to align with global sustainability standards and expectations from consumers in their respective markets.

Moreover, ethical supply chains are becoming a priority. Transparency in sourcing practices not only enhances brand reputation but also mitigates risks associated with unethical labor practices. By prioritizing suppliers who adhere to fair labor standards and environmental regulations, B2B buyers can foster trust and long-term partnerships, which are essential in today’s competitive landscape.

Illustrative image related to 10600 w mitchel st

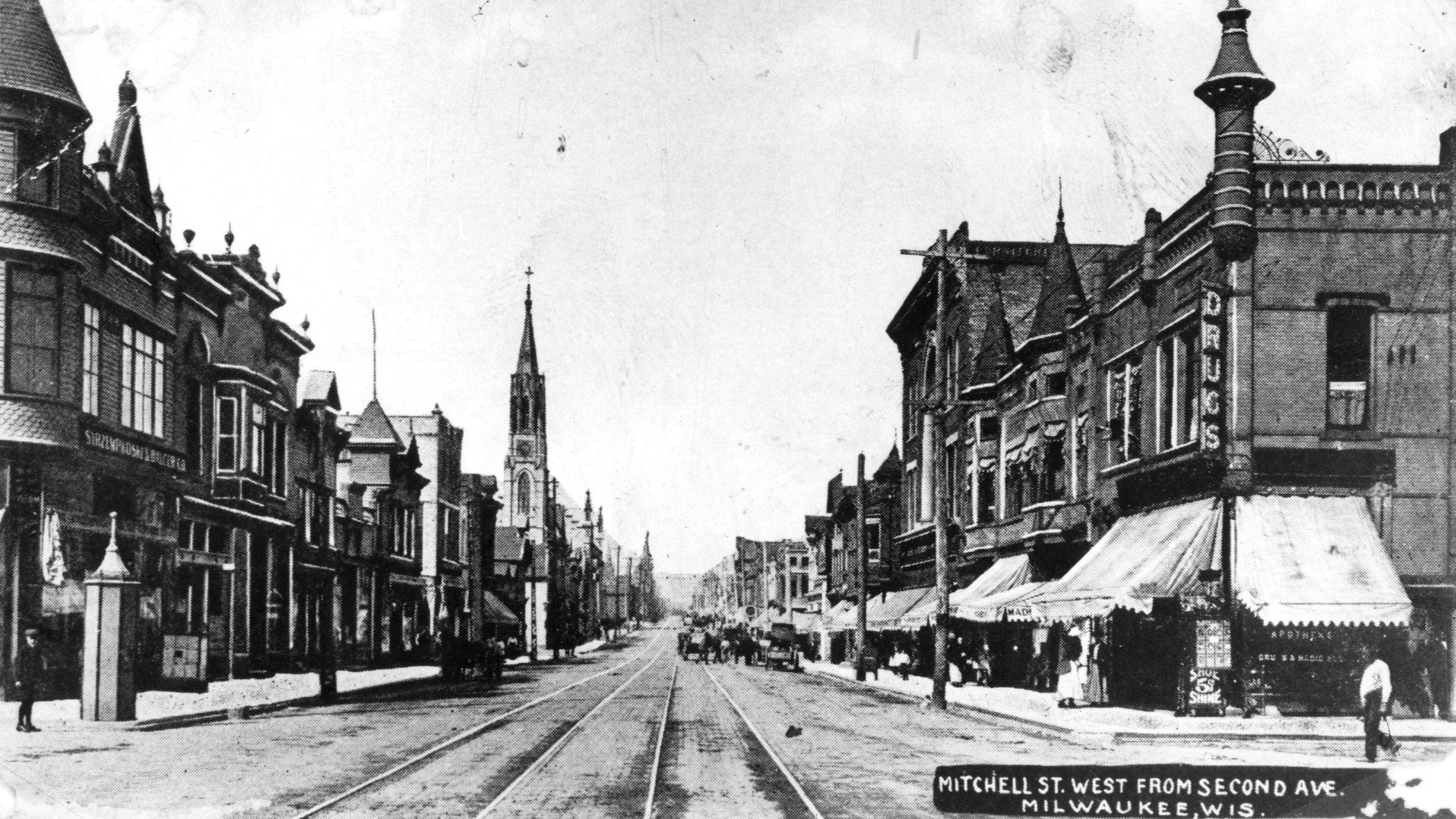

What Historical Context Should B2B Buyers Consider for the 10600 W Mitchell St Sector?

Amalga Composites, established in 1966, has evolved into a leader in the composite materials industry, with a rich history of innovation and adaptation to market demands. This history is significant for B2B buyers, as it reflects the company’s commitment to quality and customer-focused solutions over decades. The firm’s extensive experience in filament winding and composite engineering positions it as a reliable partner for international buyers seeking bespoke solutions tailored to their unique needs.

Understanding this evolution is crucial for buyers looking to engage with suppliers in this sector. Amalga’s long-standing reputation and track record of innovation not only highlight its capability to meet complex engineering challenges but also signify its resilience in adapting to changing market dynamics. As B2B buyers navigate their sourcing strategies, leveraging the expertise and historical context of suppliers like Amalga can provide a competitive advantage in achieving operational excellence and sustainable growth.

Frequently Asked Questions (FAQs) for B2B Buyers of 10600 w mitchel st

-

How do I solve challenges related to sourcing composite materials from international suppliers?

When sourcing composite materials from international suppliers like those at 10600 W Mitchell St, it’s essential to establish clear communication channels. Start by defining your specifications, including material properties and performance standards. Engage in discussions about the supplier’s capabilities and experience in your industry. Consider conducting a site visit or virtual audit to evaluate their facilities and quality control processes. Additionally, request samples to assess material quality before committing to larger orders. -

What is the best approach for vetting suppliers in the composite manufacturing industry?

To effectively vet suppliers in the composite manufacturing sector, start with a thorough background check. Look for reviews, case studies, and testimonials from previous clients. Evaluate their certifications, such as ISO standards, which indicate adherence to quality management practices. Schedule meetings with their engineering teams to discuss their production processes and technological capabilities. Finally, request references from similar projects to gauge their reliability and responsiveness. -

How can I customize composite solutions to meet specific industry needs?

Customizing composite solutions involves collaborating closely with the supplier’s engineering team. Begin by outlining your specific requirements, such as dimensions, material properties, and performance criteria. Discuss the desired applications and any regulatory standards that must be met. Suppliers like those at 10600 W Mitchell St typically have extensive experience in tailoring products, so leverage their expertise in recommending material types and manufacturing techniques that align with your needs. -

What are the minimum order quantities (MOQ) for composite materials, and how can I negotiate them?

Minimum order quantities (MOQ) vary by supplier and the complexity of the product. For composite materials, MOQs can be influenced by production costs and material availability. It’s beneficial to have a clear understanding of your project scope before discussing MOQs. If your needs are below the MOQ, consider negotiating with the supplier by discussing long-term partnership potential or exploring ways to consolidate orders with other buyers to meet the MOQ. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary significantly based on supplier policies and the nature of the transaction. Common terms include upfront payments, partial payments before shipment, or net payment terms after delivery. It’s advisable to establish clear terms before placing an order. Consider using secure payment methods like letters of credit for larger transactions, which can offer protection for both parties. Discussing payment terms early in the negotiation process can help prevent misunderstandings. -

How do suppliers ensure quality assurance in composite manufacturing?

Quality assurance in composite manufacturing typically involves a series of stringent testing and inspection processes. Suppliers at 10600 W Mitchell St employ techniques such as material testing, dimensional inspections, and performance evaluations to ensure products meet specifications. Inquire about their quality management systems, including any certifications like ISO 9001. Regular audits and feedback loops are also essential for maintaining high-quality standards throughout production. -

What logistics considerations should I keep in mind when sourcing composites internationally?

When sourcing composites internationally, logistics play a critical role in ensuring timely delivery. Consider the shipping methods available, including air freight for faster delivery or sea freight for cost efficiency. Understand the customs regulations and tariffs applicable to your order, which can impact overall costs. It’s also wise to work with logistics partners who have experience in handling composite materials to mitigate risks associated with damage during transit. -

How can I build a long-term partnership with suppliers in the composite industry?

Building a long-term partnership with composite suppliers involves consistent communication and collaboration. Regularly engage with your suppliers to discuss upcoming projects, feedback on past orders, and areas for improvement. Establish trust through transparency in your business dealings and by honoring agreements. Consider exploring joint development projects to innovate new products together, which can strengthen your partnership and align both parties’ goals for mutual growth.

Top 2 10600 W Mitchel St Manufacturers & Suppliers List

1. Amalga Composites – Business Verification

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Amalga Composites – Business Verification, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Amalga Composites Inc – Plastics Pipe Manufacturing

Domain: manufacturedinwisconsin.com

Registered: 2012 (13 years)

Introduction: Amalga Composites Inc specializes in manufacturing plastics pipe. The company is located in Milwaukee, WI, and has an annual revenue of $21,172,000. They target both B2B and B2C markets.

Strategic Sourcing Conclusion and Outlook for 10600 w mitchel st

As we conclude our examination of strategic sourcing at 10600 W Mitchell St, it is evident that the capabilities offered by Amalga Composites represent a significant opportunity for international B2B buyers. Their extensive expertise in custom composite solutions, particularly in sectors such as aerospace, oil and gas, and automotive, positions them as a leader in delivering innovative, lightweight, and durable products tailored to client specifications.

The strategic sourcing of composites not only enhances operational efficiency but also provides a competitive edge in diverse markets. By leveraging Amalga’s state-of-the-art manufacturing facilities and technical support, companies can expect superior quality and reliability, essential in today’s fast-paced industrial landscape.

Looking ahead, the potential for collaboration with Amalga Composites is vast. International buyers from Africa, South America, the Middle East, and Europe can benefit from their commitment to excellence and innovation. We encourage you to reach out to their expert team to explore how bespoke composite solutions can elevate your operations and help you stay ahead in your respective industries. Engage with Amalga today, and take the first step toward transforming your business with cutting-edge composite technology.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.