10 Series Aluminum Extrusion: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for 10 series aluminum extrusion

The global market for 10 series aluminum extrusion presents significant opportunities for businesses aiming to enhance their operational efficiency and product offerings. However, sourcing the right aluminum profiles can be a daunting task, especially for international B2B buyers navigating diverse supplier landscapes across regions like Africa, South America, the Middle East, and Europe. With their versatile applications ranging from industrial machinery to custom framing solutions, 10 series aluminum extrusions serve as a cornerstone for various manufacturing processes.

This comprehensive guide is designed to address the key challenges faced by buyers in this market. It covers essential aspects such as types and dimensions of 10 series profiles, common applications, and effective supplier vetting strategies. Additionally, the guide delves into cost considerations and best practices for negotiating favorable terms. By providing insights into the nuances of aluminum extrusion sourcing, this resource empowers B2B buyers to make informed purchasing decisions, ensuring they select the right materials that align with their operational needs and budget constraints.

Whether you are a manufacturer in Brazil looking to build custom equipment or a distributor in Nigeria seeking reliable suppliers, this guide offers actionable information tailored to your unique market context. Equip yourself with the knowledge to navigate the complexities of the 10 series aluminum extrusion market and drive your business forward with confidence.

Understanding 10 series aluminum extrusion Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 1″ x 1″ T-Slotted Profile | Standard profile size, versatile for various assemblies | Custom machinery, workstation frames | Pros: High compatibility with accessories; Cons: Limited load capacity compared to larger profiles. |

| 1″ x 2″ T-Slotted Profile | Increased width for enhanced strength and stability | Automation frames, protective enclosures | Pros: Greater strength; Cons: May require more space for installation. |

| 1″ x 3″ T-Slotted Profile | Long profile suitable for extensive frameworks | Large-scale structures, conveyor systems | Pros: Excellent for long spans; Cons: Heavier, which may increase shipping costs. |

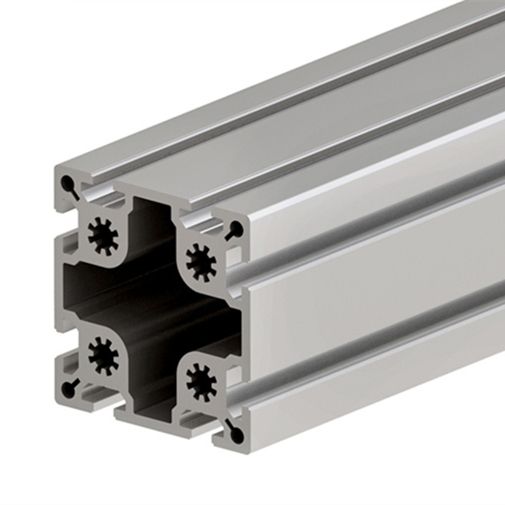

| 2″ x 2″ T-Slotted Profile | Square shape offering enhanced rigidity | Heavy-duty applications, industrial equipment | Pros: Higher load-bearing capacity; Cons: Bulkier, may require specialized connectors. |

| 1″ x 1″ Quarter Round Profile | Rounded edges for aesthetic applications | Display stands, furniture frames | Pros: Visually appealing; Cons: Less versatile than standard profiles. |

What Are the Key Characteristics of the 1″ x 1″ T-Slotted Profile?

The 1″ x 1″ T-slotted profile is the foundation of the 10 series aluminum extrusions, known for its versatility in various applications. This profile is commonly used in constructing modular systems, such as workstations and equipment frames. Its compatibility with a wide range of accessories makes it a go-to choice for businesses looking to create customizable solutions. However, while it is easy to assemble and modify, its load capacity is limited compared to larger profiles.

How Does the 1″ x 2″ T-Slotted Profile Enhance Structural Integrity?

The 1″ x 2″ T-slotted profile offers a balance between size and strength, making it ideal for applications requiring more support than the 1″ x 1″ variant. It is often used in automation systems and protective enclosures, where durability is paramount. This profile accommodates more extensive hardware, allowing for robust configurations. Buyers should consider the additional space required for installation, which may impact layout in smaller facilities.

What Advantages Does the 1″ x 3″ T-Slotted Profile Provide for Large-Scale Projects?

The 1″ x 3″ T-slotted profile is particularly suited for large-scale projects, such as conveyor systems and extensive structural frameworks. Its longer length allows for fewer joints, reducing potential weak points in assemblies. While it provides excellent spanning capabilities, the increased weight can lead to higher shipping costs. B2B buyers must evaluate their logistical considerations alongside the structural benefits this profile offers.

Why Choose the 2″ x 2″ T-Slotted Profile for Heavy-Duty Applications?

The 2″ x 2″ T-slotted profile is a robust option designed for heavy-duty applications, such as industrial machinery and equipment. Its square shape enhances rigidity and load-bearing capacity, making it suitable for high-stress environments. While it offers significant advantages in strength, its bulkiness may require specialized connectors and more substantial support structures. Buyers should assess their specific load requirements to ensure optimal performance.

What Makes the 1″ x 1″ Quarter Round Profile Unique?

The 1″ x 1″ quarter round profile stands out due to its rounded edges, which provide a more aesthetically pleasing finish for applications like display stands and furniture frames. While it is less versatile than the standard T-slotted profiles, it serves niche markets where design is a priority. Buyers should weigh the aesthetic benefits against the potential limitations in compatibility with standard accessories.

Key Industrial Applications of 10 series aluminum extrusion

| Industry/Sector | Specific Application of 10 series aluminum extrusion | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Machine framing and guarding systems | Enhances safety and operational efficiency while reducing downtime. | Ensure compliance with local safety regulations and standards. |

| Automation & Robotics | Custom automation equipment and robotic arms | Increases productivity and flexibility in manufacturing processes. | Assess compatibility with existing systems and automation tools. |

| Construction & Architecture | Structural frames for modular buildings and installations | Provides durability and lightweight solutions for easy transport and assembly. | Evaluate local climate conditions and material specifications. |

| Material Handling | Conveyor systems and storage solutions | Optimizes space utilization and streamlines logistics operations. | Consider load capacity and scalability for future needs. |

| Renewable Energy | Frameworks for solar panel installations | Supports sustainability initiatives while ensuring structural integrity. | Check for corrosion resistance and compatibility with solar technologies. |

How is 10 Series Aluminum Extrusion Used in Manufacturing?

In the manufacturing sector, 10 series aluminum extrusions are commonly utilized for constructing machine frames and safety guarding systems. These profiles offer a robust yet lightweight solution, enhancing safety by providing a secure enclosure around machinery. By minimizing downtime associated with accidents, businesses can significantly improve operational efficiency. For international buyers, it is crucial to consider local safety regulations and ensure that the extrusion profiles meet industry standards.

What Role Does 10 Series Aluminum Extrusion Play in Automation & Robotics?

In the automation and robotics industry, 10 series aluminum extrusions are essential for creating custom automation equipment and robotic arms. Their versatility allows for easy integration into existing systems, facilitating increased productivity and adaptability in manufacturing processes. Buyers should evaluate the compatibility of these extrusions with their current automation tools to ensure seamless implementation, particularly in diverse markets across Africa, South America, and Europe.

How is 10 Series Aluminum Extrusion Applied in Construction & Architecture?

10 series aluminum extrusions serve as structural frames in modular buildings and architectural installations. Their lightweight nature simplifies transport and assembly, while their durability ensures long-lasting performance. For buyers in regions with varying climates, it is important to assess the specific material specifications to guarantee that the extrusions can withstand local environmental conditions.

In What Ways Does 10 Series Aluminum Extrusion Benefit Material Handling?

In the material handling sector, 10 series aluminum extrusions are widely used to design conveyor systems and storage solutions. Their customizable nature allows businesses to optimize space utilization and improve logistics operations. When sourcing these extrusions, companies should consider their load capacity and scalability to ensure they can accommodate future growth and changes in operational needs.

How is 10 Series Aluminum Extrusion Relevant to Renewable Energy?

The renewable energy sector employs 10 series aluminum extrusions to create frameworks for solar panel installations. These profiles not only support sustainability initiatives but also provide necessary structural integrity against environmental stresses. Buyers should verify that the extrusions possess adequate corrosion resistance and compatibility with solar technologies, especially in regions with high humidity or saline environments.

3 Common User Pain Points for ’10 series aluminum extrusion’ & Their Solutions

Scenario 1: Sourcing the Right Dimensions for Custom Applications

The Problem: A manufacturing company in Brazil requires custom aluminum frames for their assembly line, but they struggle with selecting the correct dimensions of the 10 series aluminum extrusions. The variety of options available, such as 1″ x 1″, 1″ x 2″, and larger profiles, can be overwhelming. This uncertainty leads to delays in production timelines, increased costs due to incorrect orders, and potential disruptions in their manufacturing process.

The Solution: To effectively source the right dimensions, buyers should start by conducting a thorough needs assessment, which includes measuring existing structures and understanding load requirements. Collaborating with suppliers who can provide CAD models of the aluminum profiles can also aid in visualizing how different sizes can be integrated into existing setups. Additionally, buyers should inquire about sample orders to test various dimensions before making a bulk purchase. This approach not only reduces the risk of costly mistakes but also ensures that the selected profiles will meet specific operational requirements.

Scenario 2: Managing Lead Times and Inventory Challenges

The Problem: An engineering firm in Nigeria faces significant lead time issues when ordering 10 series aluminum extrusions, resulting in project delays. Due to the fluctuating demand and limited local suppliers, they often find that the materials they need are either out of stock or take longer to arrive than anticipated. This situation not only affects their current projects but also undermines their reputation with clients who depend on timely deliveries.

The Solution: To address lead time issues, buyers should establish strong relationships with multiple suppliers to create a diversified supply chain. By negotiating agreements for priority access or bulk purchasing discounts, companies can ensure that they have the necessary inventory on hand. Implementing a just-in-time inventory system can also help in maintaining optimal stock levels without overcommitting to excess inventory. Additionally, utilizing digital tools to track inventory and order statuses can provide better visibility and allow for proactive planning, minimizing the impact of delays on project timelines.

Scenario 3: Difficulty in Assembly and Integration with Existing Systems

The Problem: A company in South America is implementing a new automation system that requires the integration of 10 series aluminum extrusions into their existing framework. However, they encounter difficulties during assembly due to a lack of clear instructions and compatibility issues with their current components. This not only leads to frustration among the engineering team but also results in wasted resources and time.

The Solution: To mitigate assembly issues, companies should invest time in comprehensive training sessions that cover the assembly process of the 10 series aluminum extrusions. Suppliers often provide detailed installation guides and access to online resources, including videos and assembly tutorials, that can facilitate the integration process. Additionally, utilizing modular design principles can enhance flexibility, allowing teams to adapt and modify assembly setups as needed. Regular communication with suppliers for technical support can also provide insights into best practices and troubleshooting techniques, ensuring smoother integration with existing systems.

Strategic Material Selection Guide for 10 series aluminum extrusion

When selecting materials for 10 series aluminum extrusion, it’s essential to consider various factors that influence performance, cost, and suitability for specific applications. Below is an analysis of four common materials used in conjunction with 10 series aluminum extrusions, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of 6061 Aluminum Alloy for 10 Series Extrusion?

6061 aluminum alloy is one of the most widely used materials for 10 series aluminum extrusions. It offers excellent mechanical properties, including good weldability and corrosion resistance. This alloy can withstand temperatures up to 200°C and has a yield strength of approximately 240 MPa, making it suitable for structural applications.

Pros: The alloy’s lightweight nature contributes to lower shipping costs, while its strength-to-weight ratio makes it ideal for various applications, including frames and supports.

Cons: However, 6061 can be more expensive than other aluminum alloys and may require more complex manufacturing processes, which could affect lead times.

Impact on Application: This alloy is compatible with various media, making it suitable for automotive, aerospace, and industrial applications.

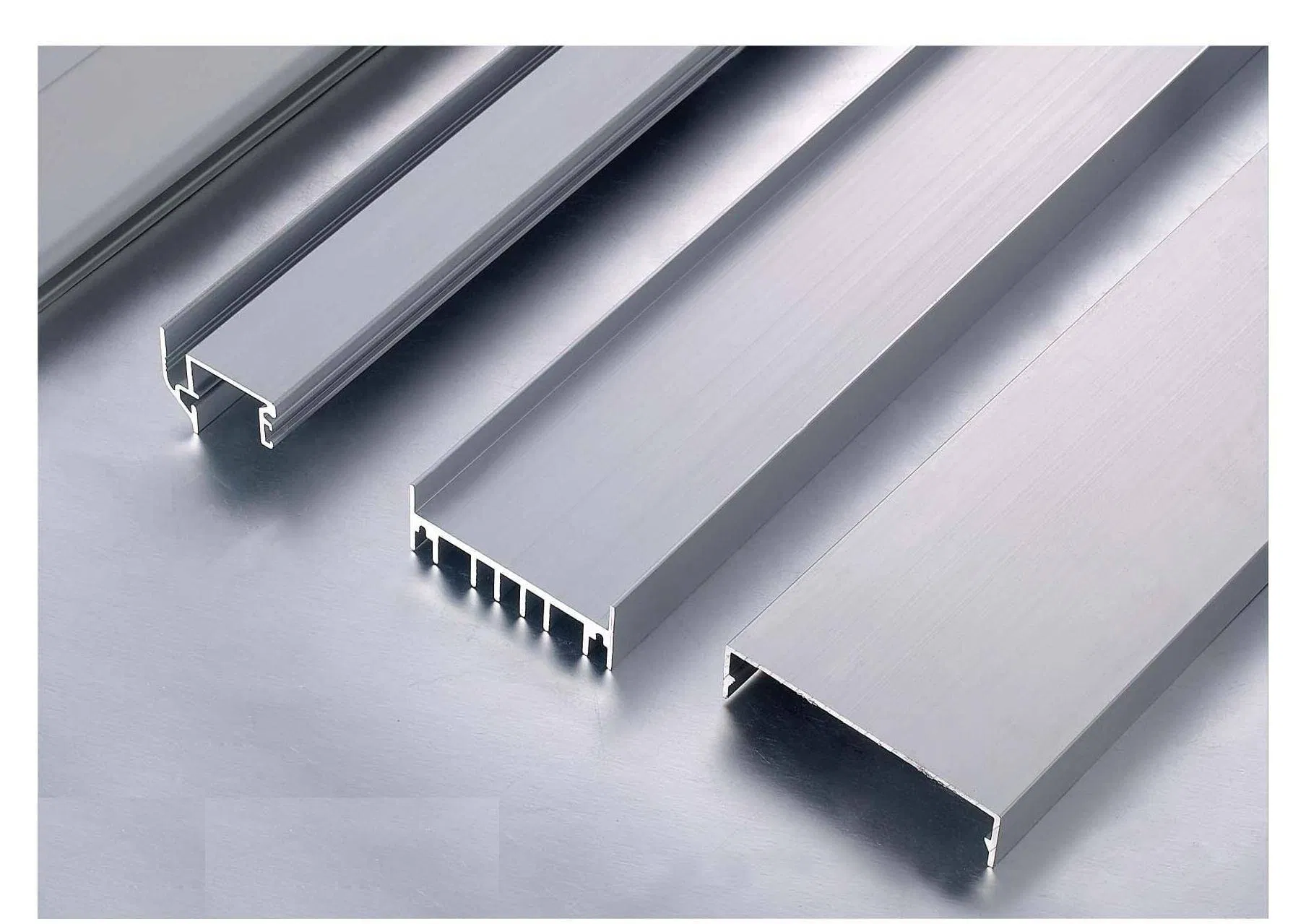

Illustrative image related to 10 series aluminum extrusion

Considerations for International Buyers: Compliance with standards such as ASTM and ISO is crucial, particularly in regions like Europe and the Middle East, where stringent regulations are enforced.

How Does 6063 Aluminum Alloy Compare for 10 Series Extrusion?

6063 aluminum alloy is known for its excellent finish and aesthetic appeal, making it a popular choice for architectural applications. It offers good corrosion resistance and can be extruded into complex shapes, which is beneficial for design flexibility.

Pros: Its ability to provide a smooth surface finish makes it ideal for decorative applications, while its lower cost compared to 6061 can be advantageous for budget-conscious projects.

Cons: The strength of 6063 is lower than that of 6061, with a yield strength of around 210 MPa, which may limit its use in high-stress applications.

Impact on Application: This alloy is particularly suitable for applications where appearance is important, such as in building facades and furniture.

Illustrative image related to 10 series aluminum extrusion

Considerations for International Buyers: Buyers should ensure that the alloy meets local standards, such as DIN in Europe, to guarantee quality and compliance.

What Are the Benefits of Using Anodized Aluminum for 10 Series Extrusion?

Anodized aluminum refers to aluminum that has undergone an electrochemical process to enhance its surface properties. This treatment increases corrosion resistance and wear resistance, making it ideal for outdoor applications.

Pros: The anodization process allows for various color finishes, which can enhance aesthetic appeal and branding opportunities.

Cons: The anodization process can add to manufacturing costs and may not be suitable for all applications due to potential brittleness in certain conditions.

Impact on Application: Anodized aluminum is well-suited for applications exposed to harsh environments, such as outdoor signage and equipment housings.

Considerations for International Buyers: Compliance with international anodizing standards is essential, particularly for buyers in regions with strict environmental regulations.

Why Consider Structural Steel as an Alternative Material for 10 Series Extrusion?

While aluminum is often preferred for its lightweight properties, structural steel can also be used in applications where higher strength is required. Steel has a much higher yield strength, often exceeding 250 MPa, making it suitable for heavy-duty applications.

Pros: The primary advantage of structural steel is its strength and durability, which can lead to longer-lasting structures.

Cons: However, steel is significantly heavier than aluminum, which can increase shipping costs and complicate installation processes.

Impact on Application: Steel is ideal for applications requiring high load-bearing capabilities, such as industrial machinery and heavy frames.

Considerations for International Buyers: Buyers should be aware of local regulations regarding steel use, including compliance with ASTM standards in the U.S. and EN standards in Europe.

Summary of Material Selection for 10 Series Aluminum Extrusions

| Material | Typical Use Case for 10 series aluminum extrusion | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 6061 Aluminum Alloy | Structural frames and supports | Excellent mechanical properties and weldability | Higher cost and complex manufacturing | High |

| 6063 Aluminum Alloy | Architectural applications | Aesthetic appeal and good corrosion resistance | Lower strength compared to 6061 | Medium |

| Anodized Aluminum | Outdoor signage and equipment housings | Enhanced corrosion and wear resistance | Higher manufacturing costs and brittleness | Medium |

| Structural Steel | Heavy-duty machinery and frames | High strength and durability | Increased weight and shipping costs | Low |

This strategic material selection guide provides a comprehensive overview of the materials commonly used in 10 series aluminum extrusions, helping international B2B buyers make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 10 series aluminum extrusion

What Are the Key Manufacturing Processes for 10 Series Aluminum Extrusion?

The manufacturing of 10 series aluminum extrusions involves several key stages that ensure the final product meets the stringent demands of various industrial applications. Understanding these processes is essential for B2B buyers, particularly those sourcing from diverse regions such as Africa, South America, the Middle East, and Europe.

How Is Material Prepared for Aluminum Extrusion?

The first step in the manufacturing process is material preparation. This typically involves selecting high-quality aluminum alloy, often 6063 or 6061, which is known for its excellent mechanical properties and corrosion resistance. The raw aluminum is heated to a specific temperature, usually between 350°F to 900°F, depending on the alloy, to enhance its malleability. This heating process is critical because it allows the aluminum to be easily shaped during the extrusion process.

What Techniques Are Used in the Forming Stage?

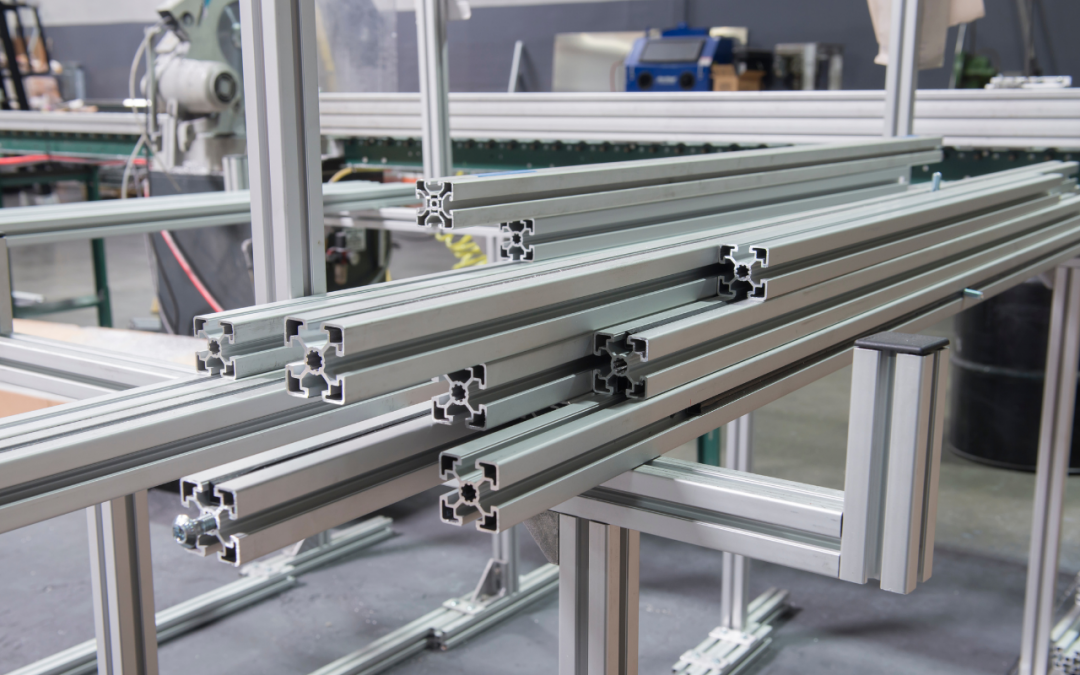

The forming stage is where the actual extrusion takes place. The heated aluminum billet is placed into an extrusion press, where a hydraulic ram pushes it through a die. This die is engineered to create the desired cross-sectional profile, which for the 10 series includes various dimensions such as 1″ x 1″, 1″ x 2″, and more. Advanced techniques like direct and indirect extrusion may be used, depending on the complexity of the profile and the intended application.

After the extrusion, the profiles are cooled, typically through air or water cooling, to solidify their shape. This stage is crucial as it affects the final properties of the aluminum, including strength and surface finish.

How Is Assembly Conducted for 10 Series Extrusions?

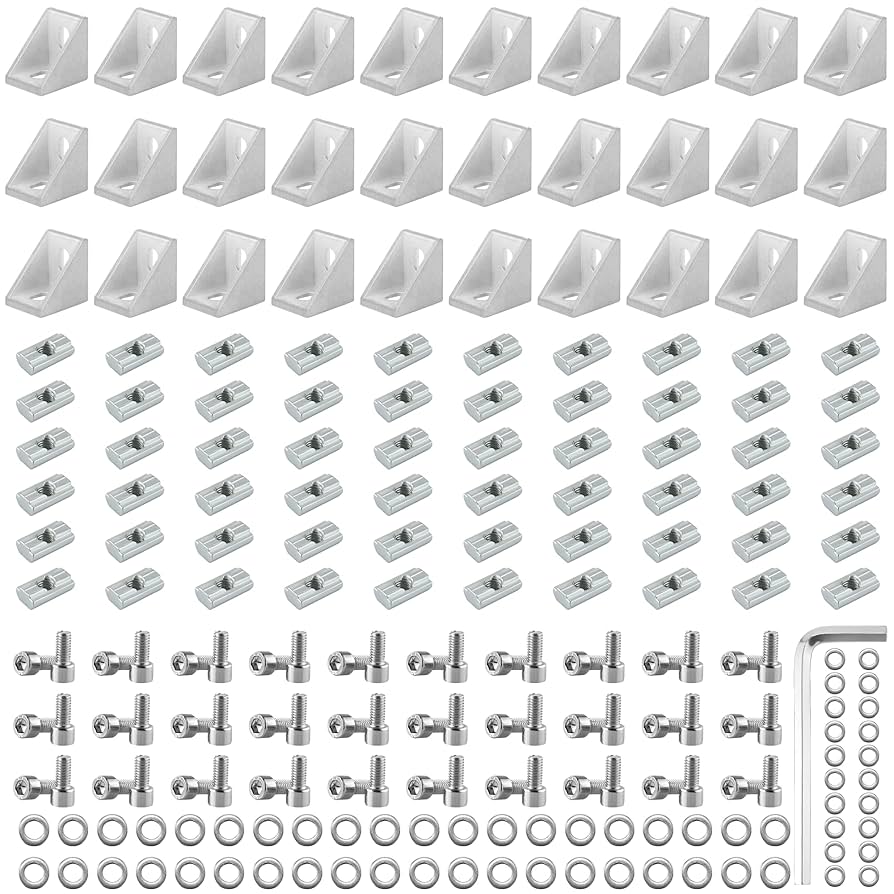

Once the profiles are extruded and cooled, they may undergo assembly, especially if they are part of a larger framework or structure. This involves cutting the profiles to specific lengths and joining them using various methods such as mechanical fasteners, welding, or adhesive bonding. The modular nature of 10 series aluminum extrusions allows for easy assembly and reconfiguration, making them popular in diverse applications from machine frames to workstations.

What Finishing Processes Are Commonly Applied?

Finishing processes are vital to enhance the appearance and durability of aluminum extrusions. Common finishing techniques include anodizing, powder coating, and applying protective films. Anodizing not only improves corrosion resistance but can also enhance the aesthetic appeal of the extrusions by providing various color options. Powder coating offers a robust finish that is resistant to scratching and UV rays, which is particularly beneficial for outdoor applications.

How Is Quality Assurance Implemented in the Manufacturing of Aluminum Extrusions?

Quality assurance (QA) is a critical component in the manufacturing of 10 series aluminum extrusions to ensure that the products meet international standards and customer specifications. A comprehensive QA program typically involves multiple checkpoints throughout the production process.

Which International Standards Are Relevant for Quality Assurance?

B2B buyers should be aware of various international standards that govern the quality of aluminum extrusions. ISO 9001 is the most recognized standard for quality management systems, ensuring that manufacturers maintain consistent quality in their processes. Additionally, industry-specific certifications such as CE marking for European markets or API standards for certain applications may also apply.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are implemented at several stages of production:

- Incoming Quality Control (IQC): Raw materials, including aluminum billets, are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the extrusion process, parameters such as temperature, pressure, and die wear are continuously monitored to ensure that the profiles are produced within tolerances.

- Final Quality Control (FQC): Finished products undergo final inspections for dimensional accuracy, surface defects, and overall quality before shipment.

What Testing Methods Are Commonly Used in Quality Assurance?

Common testing methods for aluminum extrusions include:

- Dimensional Inspection: Utilizing calipers and gauges to ensure that the extrusions meet specified dimensions.

- Mechanical Testing: Conducting tensile tests and hardness tests to evaluate the strength and durability of the materials.

- Visual Inspection: Checking for surface defects, such as scratches, dents, or discoloration.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from regions like Africa, South America, and the Middle East, verifying supplier quality control practices is essential to ensure that they are sourcing high-quality products.

What Steps Can Buyers Take to Verify QC?

- Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control systems.

- Requesting Quality Reports: Suppliers should be able to provide documentation demonstrating compliance with international standards and results from QC testing.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality management practices.

What Nuances Should Buyers Consider for International Sourcing?

When sourcing from international suppliers, buyers should be cognizant of cultural and regulatory differences that may affect quality assurance practices. For instance, some regions may have different standards for environmental or safety compliance, which can impact the quality of aluminum extrusions. Establishing clear communication regarding quality expectations and compliance with applicable standards is vital for successful international procurement.

Conclusion

Understanding the manufacturing processes and quality assurance practices for 10 series aluminum extrusions is crucial for B2B buyers looking to source reliable and high-quality components. By familiarizing themselves with the stages of production, relevant standards, and effective verification methods, buyers can ensure they make informed purchasing decisions that meet their operational needs. This knowledge is particularly valuable in a global market where quality and reliability are paramount.

Practical Sourcing Guide: A Step-by-Step Checklist for ’10 series aluminum extrusion’

In the competitive landscape of B2B procurement, sourcing 10 series aluminum extrusion requires a strategic approach to ensure you obtain the best products for your applications. This guide provides a step-by-step checklist to streamline your sourcing process, ensuring that you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is crucial before initiating the sourcing process. Clearly outline the dimensions, weight capacities, and surface finishes you need for your projects. Consider the following:

– Profile Sizes: Determine whether you require 1″ x 1″, 1″ x 2″, or larger profiles based on your intended application.

– Surface Treatments: Decide between smooth or grooved finishes depending on the aesthetic and functional requirements of your assembly.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in 10 series aluminum extrusions. Look for companies with a proven track record in the industry and positive customer feedback. Key considerations include:

– Supplier Experience: Evaluate how long the supplier has been in business and their expertise in aluminum extrusion.

– Product Range: Ensure they offer a variety of profiles and accessories to meet your diverse needs.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that potential suppliers hold necessary industry certifications. This step is essential to ensure product quality and compliance with international standards. Focus on:

– ISO Certifications: Look for suppliers with ISO 9001 certification, indicating a commitment to quality management.

– Material Certifications: Request certifications for the aluminum alloy used, ensuring it meets your specifications for strength and durability.

Step 4: Request Samples

Always request samples of the aluminum extrusions you are considering. This allows you to assess the quality of the material firsthand. When evaluating samples, pay attention to:

– Finish and Appearance: Check for consistency in color and surface finish.

– Dimensional Accuracy: Measure the samples to ensure they match your specified dimensions.

Step 5: Discuss Customization Options

Explore whether the supplier can accommodate any customization needs you may have. Customization can significantly enhance the suitability of the aluminum extrusion for your specific application. Consider:

– Custom Lengths and Cuts: Inquire if they can provide extrusions cut to your required lengths.

– Accessory Compatibility: Ensure that the profiles can be integrated with other components or systems you may be using.

Step 6: Compare Pricing and Terms

Once you have shortlisted potential suppliers, compare their pricing structures and payment terms. This step is vital to ensure you are getting the best value for your investment. Look for:

– Bulk Discounts: Ask about pricing structures for larger orders to maximize savings.

– Payment Flexibility: Consider suppliers who offer favorable payment terms that align with your cash flow.

Step 7: Finalize the Order and Establish Communication

After selecting a supplier, finalize your order and establish clear lines of communication. This will help facilitate a smooth procurement process. Key actions include:

– Confirm Order Details: Double-check specifications, quantities, and delivery timelines.

– Set Up Regular Updates: Agree on a communication plan for updates on production and shipping status, ensuring you remain informed throughout the process.

By following this checklist, you can enhance your sourcing process for 10 series aluminum extrusions, ensuring that your procurement aligns with your operational needs and strategic goals.

Comprehensive Cost and Pricing Analysis for 10 series aluminum extrusion Sourcing

What Are the Key Cost Components in 10 Series Aluminum Extrusion?

When evaluating the cost structure of 10 series aluminum extrusion, several key components contribute to the overall pricing. The primary cost components include:

-

Materials: The base material, aluminum, is subject to fluctuations in global market prices. The specific alloy used can also impact costs; for instance, higher-grade alloys may be more expensive but offer better performance characteristics.

-

Labor: This encompasses the workforce required for manufacturing, assembly, and quality assurance. In regions with higher labor costs, such as parts of Europe, the overall price may be elevated compared to regions with lower labor costs, like certain areas in Africa or South America.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment maintenance, and facility management. Efficient production processes can help minimize these costs.

-

Tooling: Custom tooling for specific extrusion profiles can represent a significant upfront investment. Buyers should consider the amortization of these costs over the expected production volume.

-

Quality Control (QC): Ensuring high standards through rigorous QC measures is essential, particularly for international buyers who may require certifications. This can add to the overall cost but is critical for maintaining product integrity.

-

Logistics: Shipping costs can vary widely based on the destination, mode of transport, and current freight rates. Buyers should factor in potential tariffs and import duties, especially when sourcing from different continents.

-

Margin: Suppliers will typically add a margin to cover their operating costs and profit. Understanding the margin expectations of suppliers can help buyers negotiate better pricing.

How Do Price Influencers Affect 10 Series Aluminum Extrusion Costs?

Several factors can influence the pricing of 10 series aluminum extrusions:

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs. Understanding the minimum order quantities (MOQ) set by suppliers can help buyers optimize their procurement strategy.

-

Specifications/Customization: Custom profiles or specific surface finishes can increase costs. Buyers should assess whether standard profiles meet their needs or if customization is necessary.

-

Materials and Quality/Certifications: The choice of materials and the required quality certifications (e.g., ISO standards) can significantly impact pricing. Buyers should clarify their quality requirements upfront to avoid unexpected costs.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can influence pricing. Established suppliers may command higher prices due to their track record of quality and service.

-

Incoterms: Understanding the delivery terms (e.g., FOB, CIF) can affect total costs. Buyers should be clear on who bears responsibility for shipping, insurance, and customs duties to avoid surprises.

What Are Effective Tips for Negotiating Prices for 10 Series Aluminum Extrusion?

B2B buyers should adopt several strategies when negotiating prices for 10 series aluminum extrusions:

-

Leverage Volume Discounts: When feasible, consolidate orders to achieve better pricing through volume discounts. Suppliers are often more willing to negotiate when they see a commitment to larger orders.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with the extrusion, including maintenance, durability, and potential waste. A lower upfront cost may not always translate to better value.

-

Understand Pricing Nuances for International Sourcing: Factors such as currency fluctuations, international shipping costs, and local taxes can affect pricing. Buyers in regions like Africa and South America should account for these variables when sourcing from Europe or North America.

-

Build Relationships with Suppliers: Establishing a strong relationship with suppliers can lead to better terms and pricing. Regular communication and trust can facilitate negotiations and lead to more favorable agreements.

-

Request Quotations from Multiple Suppliers: Gathering quotes from various suppliers can provide leverage during negotiations. It also allows buyers to compare not just prices but also service levels and product quality.

Disclaimer on Indicative Prices

While this analysis provides a comprehensive overview of cost components and pricing influencers, actual prices for 10 series aluminum extrusion can vary significantly based on market conditions, supplier negotiations, and specific project requirements. Buyers are encouraged to conduct their due diligence and obtain updated quotes to ensure accurate budgeting.

Alternatives Analysis: Comparing 10 series aluminum extrusion With Other Solutions

Introduction

In the world of industrial applications, selecting the right structural materials is crucial for optimizing performance and cost efficiency. Among the various options available, 10 series aluminum extrusions stand out due to their versatility and strength. However, it’s essential for B2B buyers to explore alternatives that may offer specific advantages depending on their unique requirements. This analysis will compare 10 series aluminum extrusion against two viable alternatives: steel framing and plastic modular systems.

| Comparison Aspect | 10 Series Aluminum Extrusion | Steel Framing | Plastic Modular Systems |

|---|---|---|---|

| Performance | High strength-to-weight ratio; excellent corrosion resistance | Very strong; suitable for heavy loads | Lightweight; good for non-load-bearing applications |

| Cost | Moderate; cost-effective for custom solutions | Generally higher due to material costs and fabrication | Lower initial costs; can be cost-efficient for simple structures |

| Ease of Implementation | Easy to assemble; requires minimal tools | Requires welding and specialized labor | Simple assembly; often requires no tools |

| Maintenance | Low; resistant to rust and corrosion | Moderate; may require painting or protective coatings | Very low; resistant to chemicals and weathering |

| Best Use Case | Custom machinery, frames, and enclosures | Heavy-duty structures, industrial buildings | Temporary setups, lightweight enclosures, and displays |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Steel Framing?

Steel framing is a robust alternative that excels in strength and durability, making it an ideal choice for heavy-duty applications. It can support significant loads, making it suitable for industrial buildings and large machinery. However, the cost of steel, coupled with the need for skilled labor for welding and installation, can make it a more expensive option. Additionally, steel may require protective coatings to prevent rust, leading to higher maintenance costs over time.

How Does Plastic Modular Systems Compare to 10 Series Aluminum Extrusion?

Plastic modular systems offer a lightweight and cost-effective alternative, particularly for applications that do not require heavy structural support. These systems are easy to assemble, often without tools, making them highly accessible for quick setups. However, they may lack the strength and longevity of aluminum or steel, making them less suitable for heavy-duty applications. Their resistance to chemicals and weather conditions is a strong advantage, particularly in industries where exposure to harsh environments is common.

Illustrative image related to 10 series aluminum extrusion

Conclusion

Choosing the right structural solution involves evaluating specific project requirements, including load-bearing needs, budget constraints, and installation conditions. For B2B buyers, 10 series aluminum extrusion provides a balanced option with high strength, ease of use, and low maintenance. However, if the application demands heavy-duty support, steel framing might be more appropriate despite its higher costs. Conversely, for lightweight and temporary setups, plastic modular systems may offer the best value. By carefully assessing these alternatives, buyers can make informed decisions that align with their operational goals and project specifications.

Essential Technical Properties and Trade Terminology for 10 series aluminum extrusion

What Are the Key Technical Properties of 10 Series Aluminum Extrusion?

When evaluating 10 series aluminum extrusions for B2B applications, understanding the technical specifications is crucial for making informed purchasing decisions. Here are the essential properties that buyers should consider:

-

Material Grade

Aluminum extrusions typically use 6063 or 6061 alloys. The 6063 grade is popular for its excellent surface finish and is commonly used for architectural applications. In contrast, 6061 is known for its strength and is often employed in structural applications. Selecting the appropriate material grade ensures the extrusion meets the specific strength, corrosion resistance, and workability required for your application. -

Tolerance

Tolerance refers to the allowable deviation from specified dimensions. For 10 series aluminum extrusions, standard tolerances range from ±0.005 inches to ±0.015 inches, depending on the profile size. Understanding tolerances is vital for ensuring that extrusions will fit seamlessly into existing designs, minimizing assembly issues and costs associated with modifications. -

Surface Finish

The surface finish of aluminum extrusions can vary significantly, with options including smooth, anodized, and powder-coated finishes. A smooth finish is ideal for aesthetic applications, while anodized finishes provide enhanced corrosion resistance and durability. Buyers must assess the environmental conditions and aesthetic requirements of their projects to choose the most suitable surface finish. -

Weight

The weight of aluminum extrusions is a critical factor for shipping and handling, especially for international B2B transactions. For example, 10 series profiles like the 1” x 1” T-slotted profile weigh approximately 0.4 lbs per foot. Understanding the weight of these components helps in calculating shipping costs and determining the feasibility of installation. -

Load Capacity

Each aluminum extrusion profile has a specified load capacity, which indicates the maximum weight it can support without structural failure. This property is crucial for applications involving machinery, frames, or supports. Knowing the load capacity ensures that the selected profiles will safely support the intended loads in various operational environments.

What Are Common Trade Terms Related to 10 Series Aluminum Extrusion?

Familiarity with industry jargon is essential for effective communication and negotiation in the aluminum extrusion market. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of aluminum extrusions, OEMs often require specific profiles for their machinery, which underscores the importance of customization in manufacturing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for B2B buyers, as it can impact inventory management and cash flow. Suppliers may set MOQs based on production costs, which can vary widely depending on the complexity of the extrusions. -

RFQ (Request for Quotation)

An RFQ is a formal document used to solicit price quotes from suppliers. It typically includes detailed specifications, quantities, and delivery requirements. For buyers, issuing an RFQ can streamline the procurement process and ensure they receive competitive pricing from multiple vendors. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. They specify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers to avoid misunderstandings and ensure smooth international transactions. -

Customization

Customization in aluminum extrusions allows buyers to specify unique dimensions, profiles, and finishes tailored to their specific needs. This flexibility is essential for industries requiring specialized solutions, such as automation or construction.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 10 series aluminum extrusions, ultimately enhancing their operational efficiency and project outcomes.

Navigating Market Dynamics and Sourcing Trends in the 10 series aluminum extrusion Sector

What Are the Current Market Dynamics and Key Trends Affecting the 10 Series Aluminum Extrusion Sector?

The global market for 10 series aluminum extrusions is witnessing significant growth, driven by the increasing demand for lightweight, durable materials across various industries, including automotive, aerospace, and construction. In regions like Africa, South America, the Middle East, and Europe, the push for modernization and infrastructural development is enhancing the demand for aluminum extrusions. Notably, the adoption of advanced manufacturing technologies, such as 3D printing and automation, is reshaping sourcing strategies. These technologies enable manufacturers to create customized solutions more efficiently and cost-effectively, catering to specific buyer needs.

Emerging trends include the rise of modular construction techniques, which leverage the flexibility of aluminum extrusion profiles to create adaptable structures. Additionally, the integration of digital platforms for procurement is streamlining the sourcing process for international buyers. This shift not only enhances transparency but also facilitates quicker decision-making, allowing businesses to respond rapidly to market changes. Furthermore, the growing trend towards localization in supply chains is prompting buyers to seek regional suppliers that can provide timely deliveries and reduced shipping costs, particularly in developing markets.

How Is Sustainability and Ethical Sourcing Impacting the 10 Series Aluminum Extrusion Market?

Sustainability has become a pivotal consideration for international B2B buyers in the 10 series aluminum extrusion sector. The environmental impact of aluminum production, including energy consumption and greenhouse gas emissions, is prompting buyers to prioritize suppliers who demonstrate commitment to sustainable practices. Ethical sourcing has emerged as a critical factor, with companies increasingly seeking partners that adhere to responsible sourcing guidelines and provide transparency in their supply chains.

Illustrative image related to 10 series aluminum extrusion

Buyers are also looking for aluminum extrusions that meet ‘green’ certifications, such as LEED (Leadership in Energy and Environmental Design) or ISO 14001, which verify a company’s commitment to environmental management. The use of recycled aluminum in the production of 10 series profiles not only reduces the carbon footprint but also aligns with the circular economy principles that many businesses are adopting. As a result, buyers can enhance their brand reputation while contributing to a more sustainable future.

What Is the Historical Context of the 10 Series Aluminum Extrusion Sector for B2B Buyers?

The evolution of the 10 series aluminum extrusion sector can be traced back to the increasing need for lightweight and versatile materials in industrial applications. Introduced in the late 20th century, these profiles were designed to offer a standardized solution that could be easily adapted for various applications, from simple framing to complex machinery. Over the years, advancements in extrusion technology have led to improved strength and durability, making 10 series profiles a preferred choice in diverse sectors.

As the market has matured, suppliers have expanded their offerings to include a wide range of sizes, finishes, and accessories, enabling buyers to customize their solutions further. This evolution has been crucial for international B2B buyers, as it provides them with the flexibility needed to meet the demands of an increasingly competitive global market. The continued innovation in this sector will likely support further growth and adaptation to emerging market needs in the future.

Frequently Asked Questions (FAQs) for B2B Buyers of 10 series aluminum extrusion

-

How do I determine the right size of 10 series aluminum extrusion for my project?

To select the appropriate size of 10 series aluminum extrusion, first assess your project’s structural requirements, including load-bearing capacity and dimensional constraints. Common sizes include 1″ x 1″, 1″ x 2″, and 2″ x 2″, each offering different strengths and flexibility. It’s advisable to consult with your supplier or an engineering professional to evaluate the specific application, ensuring the chosen profile meets both strength and functionality needs. -

What is the best way to customize 10 series aluminum extrusion for my specific needs?

Customization options for 10 series aluminum extrusion include length, surface finish, and additional features like pre-drilled holes or grooves. Engage with your supplier to discuss design specifications and available modifications. Additionally, utilizing CAD software can help visualize custom designs, allowing for adjustments before finalizing orders. Most suppliers are open to custom requests, especially for bulk purchases, enabling you to create tailored solutions. -

What are the minimum order quantities (MOQ) for 10 series aluminum extrusion?

Minimum order quantities for 10 series aluminum extrusion vary by supplier and can depend on the specific profile or customization requested. Typically, MOQs may range from 50 to 100 units for standard profiles. It’s beneficial to inquire directly with potential suppliers to understand their MOQ policies and explore options for bulk discounts, especially if you require larger quantities for extensive projects. -

What payment terms should I expect when sourcing 10 series aluminum extrusion internationally?

Payment terms for international orders of 10 series aluminum extrusion can vary significantly between suppliers. Common practices include payment upfront, 30% deposit with the balance due upon delivery, or letter of credit arrangements. It’s crucial to clarify payment terms before finalizing orders to avoid misunderstandings. Additionally, consider any international transaction fees and currency exchange rates that may affect your overall costs. -

How can I ensure quality assurance (QA) when sourcing 10 series aluminum extrusion?

To ensure quality assurance when sourcing 10 series aluminum extrusion, request certifications and quality reports from your suppliers. Look for ISO certifications or other relevant industry standards that indicate compliance with quality management systems. Additionally, consider conducting third-party inspections or audits, especially for larger orders, to verify material quality and dimensional accuracy before shipment. -

What logistics considerations should I keep in mind when importing 10 series aluminum extrusion?

Logistics for importing 10 series aluminum extrusion involves several key considerations: shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder familiar with international shipping to handle customs clearance efficiently. Additionally, factor in potential delays due to customs inspections, especially for specific countries in Africa or South America. It’s advisable to plan shipments well in advance to accommodate any unforeseen logistical challenges. -

What should I look for when vetting suppliers of 10 series aluminum extrusion?

When vetting suppliers, evaluate their experience, reputation, and certifications within the industry. Request references from previous clients and assess their production capabilities, including quality control processes and lead times. Additionally, consider their customer service responsiveness and willingness to accommodate custom orders. Engaging in a trial order can also provide insight into their reliability and product quality before committing to larger purchases. -

How can I compare prices from different suppliers of 10 series aluminum extrusion?

To effectively compare prices, obtain detailed quotations from multiple suppliers that include unit costs, shipping fees, and any additional charges like customs duties. Ensure that the quotes are for identical specifications, including profile sizes, finishes, and any customization. It’s also important to consider the total cost of ownership, which includes long-term durability and performance of the extrusions, not just the initial purchase price.

A Look at 10 Series Aluminum Extrusion Manufacturers & Suppliers

Could not verify enough suppliers for 10 series aluminum extrusion to create a list at this time.

Strategic Sourcing Conclusion and Outlook for 10 series aluminum extrusion

As the demand for versatile and robust solutions continues to rise, strategic sourcing of 10 series aluminum extrusions presents a significant opportunity for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. This series, characterized by its 1-inch profile and compatibility with various accessories, allows for the customization of industrial applications ranging from machinery to structural frameworks.

Investing in these aluminum extrusions not only enhances operational efficiency but also drives cost-effectiveness through their lightweight yet durable nature. Buyers should prioritize suppliers who offer a comprehensive selection, including various sizes and finishes, to cater to specific project requirements.

Looking ahead, the global market for aluminum extrusions is set to expand, driven by innovations in manufacturing and increasing demand across diverse industries. By leveraging strategic sourcing practices and fostering strong supplier relationships, businesses can position themselves to capitalize on emerging trends and technologies in the aluminum sector. Engage with trusted suppliers today to ensure your projects benefit from the best that 10 series aluminum extrusions have to offer.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to 10 series aluminum extrusion