10 Pack Greenlighting Reflective Road Studs Red Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for 10 pack greenlighting reflective road studs red

In an increasingly interconnected world, sourcing reliable safety solutions like the 10 pack greenlighting reflective road studs red presents both opportunities and challenges for international B2B buyers. The growing demand for effective road safety products, especially in regions such as Africa, South America, the Middle East, and Europe, highlights the importance of making informed purchasing decisions. With road safety being a critical concern, these reflective road studs serve as vital components in enhancing visibility and reducing accidents, particularly in low-light conditions.

This comprehensive guide delves into the myriad aspects of sourcing reflective road studs, including various types, applications, and key specifications. Buyers will gain insights into evaluating suppliers, understanding cost structures, and identifying the most suitable products for their specific needs. Additionally, the guide addresses critical factors such as durability, weather resistance, and energy efficiency, which are paramount in selecting the right road safety products.

By equipping B2B buyers with the knowledge to navigate the global market effectively, this guide empowers them to make strategic decisions that not only enhance road safety but also align with budgetary constraints and logistical considerations. Whether you are a procurement officer in Nigeria or a safety manager in Vietnam, understanding the nuances of reflective road studs will enable you to secure high-quality solutions that meet your operational requirements.

Understanding 10 pack greenlighting reflective road studs red Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heavy-Duty Aluminum Road Studs | High load capacity (up to 30 tons), durable aluminum alloy | High-traffic roads, construction sites | Pros: Exceptional durability; Cons: Higher upfront cost. |

| Solar-Powered LED Road Studs | Integrated solar panels, LED lights for visibility | Urban areas, pedestrian crossings, highways | Pros: Energy-efficient; Cons: Dependent on sunlight for optimal performance. |

| Reflective Plastic Road Studs | Lightweight, cost-effective, good reflectivity | Parking lots, driveways, low-traffic areas | Pros: Affordable; Cons: Less durable than metal options. |

| Multicolor LED Road Studs | Offers various LED colors (red, green, blue) | Traffic management, event venues, construction zones | Pros: Versatile visibility options; Cons: May require more maintenance. |

| Blinking Road Studs | Flashing light feature, customizable frequency | High-risk areas, emergency zones | Pros: Increased visibility in critical areas; Cons: Battery replacement may be needed. |

What are the Characteristics of Heavy-Duty Aluminum Road Studs?

Heavy-duty aluminum road studs are designed to withstand significant pressure, making them ideal for high-traffic environments. Their robust construction allows them to handle loads of up to 30 tons, ensuring longevity and reliability. These studs are often used in construction zones and main roadways where durability is paramount. When purchasing, consider the installation environment and the potential need for replacement in case of damage from heavy vehicles.

How Do Solar-Powered LED Road Studs Enhance Road Safety?

Solar-powered LED road studs feature integrated solar panels that charge during the day and provide illumination at night. This energy-efficient solution is particularly suitable for urban areas and pedestrian crossings where visibility is crucial. Buyers should evaluate the solar panel efficiency and battery life, especially in regions with varying sunlight exposure. The initial investment may be higher, but the long-term energy savings can be significant.

What Makes Reflective Plastic Road Studs a Cost-Effective Choice?

Reflective plastic road studs are lightweight and economical, making them a popular choice for parking lots and residential driveways. They offer good visibility at night due to their reflective surfaces, but they may not withstand heavy loads as effectively as metal alternatives. B2B buyers should consider their specific application needs and whether the trade-off in durability justifies the lower price point.

Why Choose Multicolor LED Road Studs for Traffic Management?

Multicolor LED road studs allow for versatile applications in traffic management and event venues. They can be customized to emit different colors, enhancing visibility and signaling in various situations. While they offer aesthetic and functional benefits, buyers should be aware of potential maintenance needs associated with the LED lights and the power source.

What Advantages Do Blinking Road Studs Offer in High-Risk Areas?

Blinking road studs are particularly effective in high-risk areas, as their flashing light feature significantly increases visibility. These studs can be customized for different flashing frequencies to suit specific needs, such as emergency zones. However, buyers should consider the maintenance aspects, including battery life and replacement, to ensure consistent performance in critical applications.

Key Industrial Applications of 10 pack greenlighting reflective road studs red

| Industry/Sector | Specific Application of 10 pack greenlighting reflective road studs red | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation | Used along highways and roads to delineate lanes and enhance visibility at night. | Improves road safety, reducing accident rates and liability. | Ensure compliance with local traffic regulations and standards. |

| Construction | Implemented in construction sites for safe navigation and worker protection. | Minimizes accidents on site, promoting a safer working environment. | Consider durability and load-bearing capacity to withstand heavy machinery. |

| Logistics & Warehousing | Applied in parking lots and loading docks to guide vehicle movements. | Enhances operational efficiency and reduces damage to vehicles and infrastructure. | Look for options that can withstand heavy traffic and environmental conditions. |

| Municipal Services | Utilized in public parks and pedestrian pathways for safety and guidance. | Increases public safety and satisfaction, leading to improved community relations. | Assess weather resistance and longevity to minimize maintenance costs. |

| Agriculture | Used to mark boundaries and pathways in agricultural fields. | Aids in effective land management and prevents accidental crop damage. | Evaluate visibility in various weather conditions and terrains. |

How Are ’10 Pack Greenlighting Reflective Road Studs Red’ Used in Transportation?

In the transportation sector, the 10 pack greenlighting reflective road studs red are strategically placed along highways and roads to improve visibility during nighttime or adverse weather conditions. This application significantly enhances road safety by clearly delineating lanes and guiding drivers, thereby reducing the likelihood of accidents. For international buyers, especially from regions like Africa and South America where road safety can be a pressing issue, it is crucial to ensure that these studs comply with local regulations and can withstand the environmental conditions specific to their regions.

What Role Do Reflective Road Studs Play in Construction Sites?

Reflective road studs are essential in construction zones, where they help to guide vehicles and workers safely through potentially hazardous areas. By marking pathways and delineating work zones, these studs minimize accidents and enhance overall site safety. B2B buyers in the construction industry should prioritize sourcing durable studs that can handle the weight of heavy machinery and resist damage from construction activities, ensuring they meet the rigorous demands of a construction environment.

How Do Reflective Road Studs Benefit Logistics and Warehousing Operations?

In logistics and warehousing, the 10 pack greenlighting reflective road studs red are utilized to mark parking lots and loading docks, facilitating the safe and efficient movement of vehicles. Their reflective nature helps prevent collisions and damage to property, ultimately improving operational efficiency. Companies in this sector should consider the studs’ ability to withstand heavy traffic and varying weather conditions, which are critical for maintaining safety and operational continuity in busy logistics environments.

What Are the Applications of Reflective Road Studs in Municipal Services?

Municipal services employ reflective road studs to enhance safety in public parks and pedestrian pathways. By providing clear visual guidance, these studs help prevent accidents and increase public confidence in using communal spaces. For international buyers, especially in Europe and the Middle East, assessing the weather resistance and longevity of these studs is vital to ensure they remain effective and reduce long-term maintenance costs.

How Are Reflective Road Studs Used in Agriculture?

In agricultural settings, the 10 pack greenlighting reflective road studs red serve to mark boundaries and pathways within fields, aiding farmers in effective land management. This application helps prevent accidental damage to crops and ensures safe navigation for vehicles. Buyers in the agricultural sector should evaluate the visibility of these studs in diverse weather conditions, ensuring they provide reliable guidance throughout the year, especially in regions prone to heavy rainfall or fog.

3 Common User Pain Points for ’10 pack greenlighting reflective road studs red’ & Their Solutions

Scenario 1: Difficulty in Ensuring Long-Term Durability in Varied Climates

The Problem: B2B buyers, particularly in regions with extreme weather conditions, often express concerns about the durability and longevity of reflective road studs. For instance, buyers from Africa or the Middle East might face challenges with high temperatures and intense UV exposure, which can degrade materials and reduce the effectiveness of the studs over time. Additionally, heavy rainfall can lead to water ingress, compromising the functionality of solar-powered models. Such conditions raise questions about the reliability of their investment in road safety measures.

The Solution: To mitigate these concerns, it is crucial to select ’10 pack greenlighting reflective road studs red’ that are constructed from high-quality materials such as aluminum alloy or polycarbonate with robust waterproof ratings (IP68 or higher). When sourcing these products, buyers should inquire about the materials used and request testing certifications that prove their resistance to UV light and water. Additionally, implementing regular maintenance checks can help identify early signs of wear or malfunction, allowing for timely replacements. Investing in road studs with a proven track record in similar climates can also provide peace of mind regarding their durability.

Scenario 2: Navigating Compliance with Local Regulations

The Problem: Another significant pain point for international B2B buyers is ensuring that the reflective road studs comply with local traffic regulations and safety standards. For example, a construction firm in South America may find that regulations vary widely between countries, and failing to comply can lead to legal issues or project delays. Buyers often struggle with understanding the specific requirements for reflective materials, colors, and brightness levels that are mandated by local authorities.

The Solution: To address this challenge, buyers should conduct thorough research on local traffic safety regulations before making a purchase. Collaborating with local regulatory bodies or consulting with experienced suppliers who have a deep understanding of the market can provide insights into compliance requirements. Moreover, when ordering ’10 pack greenlighting reflective road studs red’, ensure that the products meet or exceed the local standards. Request documentation or certification from manufacturers that confirms compliance with specified regulations. This proactive approach will not only facilitate smoother project execution but also enhance safety on the roads.

Scenario 3: Managing Cost-Effectiveness and Return on Investment

The Problem: For many B2B buyers, especially those managing public works or large-scale infrastructure projects, budget constraints are a constant concern. The initial cost of purchasing reflective road studs can seem high, especially when factoring in maintenance and potential replacements. Buyers often worry about whether these road studs will provide adequate return on investment in terms of safety improvements and visibility enhancements.

The Solution: To ensure cost-effectiveness, buyers should consider the total cost of ownership rather than just the upfront price. This includes evaluating the longevity, maintenance needs, and energy efficiency of the ’10 pack greenlighting reflective road studs red’. Opt for models that utilize solar energy and have long-lasting LED technology to reduce ongoing operational costs. Furthermore, analyze case studies or seek testimonials from previous customers to understand the performance and durability of the products over time. By choosing high-quality, energy-efficient products, buyers can reduce long-term costs while enhancing road safety, thereby justifying the initial investment.

Strategic Material Selection Guide for 10 pack greenlighting reflective road studs red

What Are the Best Materials for 10 Pack Greenlighting Reflective Road Studs Red?

When selecting materials for the production of reflective road studs, particularly the 10 pack greenlighting reflective road studs in red, it is crucial to analyze various options from a performance, durability, and cost perspective. This guide examines four common materials: Polycarbonate (PC), Aluminum Alloy, Acrylic, and Stainless Steel.

How Does Polycarbonate (PC) Perform in Road Stud Applications?

Polycarbonate (PC) is a popular choice for road studs due to its high impact resistance and lightweight nature. It can withstand temperatures ranging from -40°C to 120°C and has excellent UV resistance, making it suitable for various environmental conditions.

Pros:

– High durability and resistance to impact.

– Lightweight, which simplifies installation.

– Cost-effective compared to metals.

Cons:

– Less resistant to scratching compared to glass or acrylic.

– May degrade under prolonged exposure to certain chemicals.

Impact on Application:

Polycarbonate road studs are ideal for regions with extreme weather conditions, as they can maintain their integrity over time. However, buyers should ensure compatibility with local UV exposure levels.

Considerations for International Buyers:

Compliance with international standards like ASTM or DIN is essential. Buyers from regions such as Africa and South America should consider the local climate and potential chemical exposure when selecting PC road studs.

What Advantages Does Aluminum Alloy Offer for Reflective Road Studs?

Aluminum alloy is another widely used material for road studs, known for its strength and lightweight properties. It can handle loads of up to 30 tons, making it suitable for high-traffic areas.

Pros:

– Excellent corrosion resistance, especially with anodized finishes.

– High strength-to-weight ratio.

– Can be easily manufactured into various shapes.

Cons:

– Higher initial cost compared to plastic materials.

– Requires protective coatings to enhance longevity.

Impact on Application:

Aluminum alloy road studs are particularly effective in urban environments where they face heavy traffic and potential exposure to corrosive substances.

Considerations for International Buyers:

Aluminum road studs must meet specific standards for durability and safety. Buyers in Europe and the Middle East should verify compliance with local regulations, especially concerning load-bearing capabilities.

How Does Acrylic Compare as a Material for Road Studs?

Acrylic is often used for the reflective components of road studs due to its high clarity and excellent light transmission. It is less durable than PC and aluminum but offers good aesthetic qualities.

Pros:

– High optical clarity, enhancing visibility.

– Lightweight and easy to mold into various shapes.

– Cost-effective for reflective applications.

Cons:

– More susceptible to scratching and impact damage.

– Limited temperature resistance compared to PC and aluminum.

Impact on Application:

Acrylic road studs are suitable for low-traffic areas where aesthetics and visibility are prioritized over durability.

Considerations for International Buyers:

Buyers should ensure that acrylic road studs meet local safety standards. Regions with harsher climates may find acrylic less suitable due to its lower temperature resistance.

Why Consider Stainless Steel for High-End Applications?

Stainless steel is an excellent choice for road studs requiring high durability and resistance to harsh environmental conditions. It is highly resistant to corrosion and can withstand extreme temperatures.

Pros:

– Exceptional strength and durability.

– Corrosion-resistant, ideal for coastal areas.

– Low maintenance requirements.

Cons:

– High cost compared to other materials.

– Heavier, which can complicate installation.

Impact on Application:

Stainless steel road studs are perfect for high-end applications where longevity and performance are critical, such as highways and industrial areas.

Considerations for International Buyers:

International buyers must ensure that stainless steel road studs comply with local standards for safety and performance, particularly in regions with diverse environmental challenges.

Summary Table of Material Selection for Road Studs

| Material | Typical Use Case for 10 pack greenlighting reflective road studs red | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | General road applications in varied climates | High impact resistance | Less scratch-resistant | Low |

| Aluminum Alloy | High-traffic urban areas | Excellent corrosion resistance | Requires protective coatings | Medium |

| Acrylic | Low-traffic decorative areas | High optical clarity | Susceptible to scratching | Low |

| Stainless Steel | High-end, industrial applications | Exceptional strength and durability | High cost and heavier weight | High |

This strategic material selection guide provides B2B buyers with insights into the best materials for reflective road studs, ensuring informed decisions based on performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 10 pack greenlighting reflective road studs red

What Are the Key Manufacturing Processes for 10 Pack Greenlighting Reflective Road Studs Red?

The manufacturing of reflective road studs involves several critical stages, ensuring the final product meets quality and performance standards suitable for various environments. Here’s a breakdown of the typical manufacturing process:

Material Preparation: What Materials Are Used in Manufacturing Road Studs?

The primary materials for manufacturing reflective road studs include high-quality aluminum alloy, polycarbonate (PC), and reflective acrylic. The choice of materials is crucial, as they must withstand heavy loads, environmental stress, and provide high visibility at night. Aluminum is favored for its strength and resistance to corrosion, while polycarbonate offers excellent impact resistance. Reflective acrylic is used for its ability to enhance visibility through light reflection.

During material preparation, raw materials are sourced from certified suppliers, ensuring compliance with international standards. This stage may also involve cutting and shaping the materials to meet specific design requirements.

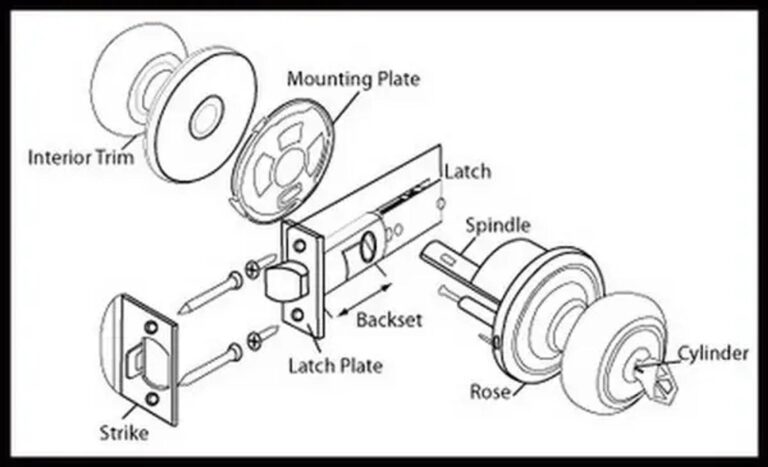

How Are Reflective Road Studs Formed and Assembled?

The forming process typically involves techniques such as die casting for aluminum components and injection molding for plastic parts. These methods allow for precise shaping and high-volume production, essential for meeting large orders from B2B buyers.

After forming, the assembly stage combines the individual components. This may include embedding LED lights within the studs and sealing them to ensure waterproof functionality. Advanced techniques such as ultrasonic welding may be utilized to secure components without compromising their integrity.

What Finishing Processes Are Employed to Enhance Product Durability?

Finishing processes are critical for enhancing the durability and aesthetic appeal of the road studs. Common techniques include powder coating, which provides a protective layer against UV radiation and corrosion. Additionally, reflective surfaces are treated to enhance their visibility in low-light conditions. The final inspection is conducted to ensure all studs meet design specifications and quality standards before packaging.

How Is Quality Assurance Maintained Throughout the Manufacturing Process?

Quality assurance is a vital aspect of the manufacturing process, ensuring that each batch of road studs complies with industry standards and customer expectations. Here’s how quality is maintained:

Which International Standards Are Relevant for Reflective Road Studs?

Manufacturers typically adhere to international standards such as ISO 9001, which outlines quality management systems. Compliance with CE marking ensures that products meet European safety, health, and environmental protection requirements. Other relevant certifications may include API (American Petroleum Institute) standards for materials used in road construction.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, various tests and inspections are conducted to monitor quality at each stage, from forming to assembly. This may include checking dimensions, weight, and material properties.

-

Final Quality Control (FQC): Before packaging, a comprehensive assessment is conducted to ensure the finished product meets all specifications. This includes functionality tests, such as assessing light output for LED studs and checking for waterproof integrity.

What Testing Methods Are Commonly Used to Ensure Product Reliability?

Manufacturers employ several testing methods to ensure road studs are reliable and durable:

-

Load Testing: Road studs must withstand significant weight (often up to 30 tons). Load tests simulate real-world conditions to verify that the studs maintain structural integrity.

-

Waterproof Testing: IP68 ratings are often targeted, indicating that products are dust-tight and can withstand immersion in water. Testing involves submerging the studs in water for a specified duration.

-

Reflectivity Testing: This assesses how well the studs reflect light under various conditions. High visibility is paramount for road safety.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are some strategies:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request documentation of quality management practices, including ISO certifications and audit reports. A reputable supplier should be transparent about their QC processes and willing to share results from internal audits or third-party inspections.

How Can Third-Party Inspections Enhance Trust?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s manufacturing processes and product quality. This can be especially beneficial when sourcing from overseas, as it helps mitigate risks associated with quality and compliance.

What Are the Nuances of QC and Certification for International Buyers?

B2B buyers should be aware of the specific certification requirements in their region. For instance, products sold in the EU must comply with CE marking, while buyers in Africa or South America may have different standards. Understanding these nuances can facilitate smoother transactions and ensure that products meet local regulations.

Conclusion

Understanding the manufacturing processes and quality assurance practices for reflective road studs is crucial for B2B buyers. By focusing on material selection, production techniques, and rigorous quality control measures, buyers can ensure they source reliable products that meet their needs. Engaging with suppliers who prioritize quality and compliance will ultimately lead to safer road environments and enhanced operational efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ’10 pack greenlighting reflective road studs red’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure ’10 pack greenlighting reflective road studs red’. Reflective road studs play a crucial role in enhancing road safety and visibility, especially in low-light conditions. Following this checklist will ensure that you make informed purchasing decisions, aligning with your specific requirements and standards.

Step 1: Define Your Technical Specifications

Clearly outline the specifications you need for the reflective road studs. Consider factors such as size, material, color, and LED type. This step is vital to ensure that the products you source meet your performance requirements and local regulations.

- Size and Shape: Standard dimensions are typically around 117mm in diameter, but confirm the specific size needed for your application.

- Material Considerations: Look for durable materials like aluminum alloy or high-strength polycarbonate to withstand environmental conditions.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in reflective road studs. This step is essential to ensure product quality and reliability.

- Check Company Background: Look for suppliers with a solid history and positive reviews in the industry.

- Evaluate Product Range: A supplier offering a variety of products may indicate their expertise and capability to meet diverse needs.

Step 3: Verify Supplier Certifications

Before engaging with a supplier, verify their certifications and compliance with international standards. This is critical for ensuring that the products are safe and reliable.

- Quality Standards: Check for ISO certifications or equivalent quality assurance processes.

- Environmental Compliance: Ensure that the products meet environmental regulations, especially if sourcing from different regions.

Step 4: Request Product Samples

Always request samples of the road studs before placing a bulk order. This allows you to evaluate the product’s quality and performance firsthand.

- Testing for Durability: Assess the samples under various conditions to ensure they meet your expectations for durability and visibility.

- Check Reflectivity: Verify that the reflective properties are adequate for your specific application needs.

Step 5: Assess Pricing and Payment Terms

Compare pricing among shortlisted suppliers while considering the total cost of ownership. Understanding payment terms is equally important for cash flow management.

- Negotiate Bulk Discounts: Many suppliers offer reduced rates for larger orders, which can significantly lower your costs.

- Review Payment Options: Look for flexible payment terms that align with your procurement process, such as letters of credit or installment plans.

Step 6: Evaluate Shipping and Delivery Options

Confirm the supplier’s shipping capabilities and delivery timelines. This step ensures that you can meet your project deadlines.

- Shipping Costs: Get detailed quotes to understand the total logistics expenses involved.

- Delivery Timeframes: Ensure that the supplier can meet your required delivery dates to avoid project delays.

Step 7: Establish After-Sales Support and Warranty Terms

Finally, inquire about the after-sales support and warranty offered by the supplier. This is important for long-term satisfaction and maintenance of the products.

- Warranty Coverage: Ensure that the warranty covers defects and performance issues for an adequate duration.

- Support Services: Look for suppliers who provide ongoing technical support or replacement services if needed.

By following this structured checklist, B2B buyers can confidently navigate the procurement process for ’10 pack greenlighting reflective road studs red’, ensuring quality, compliance, and value for their investment.

Comprehensive Cost and Pricing Analysis for 10 pack greenlighting reflective road studs red Sourcing

What Are the Key Cost Components for 10 Pack Greenlighting Reflective Road Studs?

When analyzing the cost structure for a 10 pack of greenlighting reflective road studs in red, several key components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The primary material used in these road studs is typically high-quality aluminum alloy or durable polycarbonate. These materials ensure longevity and resistance to harsh weather conditions. The choice of materials greatly influences the overall cost, with premium materials potentially increasing unit prices.

-

Labor: Labor costs encompass the wages of workers involved in production, assembly, and quality assurance. In regions with lower labor costs, such as parts of Asia and Africa, manufacturers may offer competitive pricing. However, labor costs in Europe or North America can be significantly higher, affecting the overall cost structure.

-

Manufacturing Overhead: This includes the costs of utilities, equipment maintenance, and factory rent. Efficient manufacturing processes can help reduce these overhead costs, which can vary widely depending on the country of production.

-

Tooling: Initial tooling costs for molds and production machinery can be substantial. These costs are often amortized over a larger production run, making them less impactful on unit costs for bulk orders.

-

Quality Control (QC): Investment in QC processes is crucial for ensuring product reliability. This involves testing and inspections, which can add to the overall cost but are essential for maintaining safety standards.

-

Logistics: Shipping and handling costs can vary significantly based on the shipping method, distance, and volume of the order. International shipments may incur customs duties and taxes, which should be factored into the total cost.

-

Supplier Margin: Suppliers typically add a margin to cover their operating expenses and profit. This margin can vary based on market dynamics and the supplier’s position in the supply chain.

How Do Price Influencers Affect the Cost of Reflective Road Studs?

Several factors influence the pricing of reflective road studs, particularly for international buyers. Understanding these can aid in making informed purchasing decisions.

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk orders, reducing the per-unit cost. It’s advisable for buyers to negotiate MOQs to achieve better pricing.

-

Specifications and Customization: Customized road studs, such as those featuring specific LED colors or additional reflective capabilities, can increase costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, CE) may elevate costs but can be crucial for safety and regulatory compliance. Buyers should assess the importance of these factors relative to their project needs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding the agreed Incoterms (International Commercial Terms) is vital. They define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, significantly impacting total costs.

What Tips Can Help Buyers Achieve Cost-Efficiency?

B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, can benefit from strategic approaches to sourcing reflective road studs.

-

Negotiation: Engage suppliers in discussions about pricing, particularly for bulk orders or long-term contracts. Flexibility in payment terms can also lead to better deals.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, replacement, and energy efficiency. For instance, solar-powered studs may have higher upfront costs but lower energy expenses over time.

-

Local Market Insights: Buyers should be aware of local market conditions that can affect pricing, such as tariffs, shipping costs, and currency fluctuations. This knowledge can aid in negotiating better terms.

-

Quality vs. Cost: While it may be tempting to opt for the cheapest option, consider the long-term benefits of investing in higher-quality products. Cheaper studs may need more frequent replacements, leading to higher overall costs.

-

Research and Due Diligence: Conduct thorough research on potential suppliers, including checking references and previous projects. This can help avoid costly mistakes and ensure reliable partnerships.

Conclusion

In summary, the cost and pricing analysis for a 10 pack of greenlighting reflective road studs involves various components and influencing factors. By understanding these elements, B2B buyers can make more informed decisions that align with their budgets and project requirements. As market dynamics vary, remaining adaptable and strategic will enhance cost-efficiency in sourcing these essential safety products.

Alternatives Analysis: Comparing 10 pack greenlighting reflective road studs red With Other Solutions

In the realm of road safety and visibility, the selection of road studs is critical for effective traffic management. The ’10 Pack Greenlighting Reflective Road Studs Red’ offers a reliable solution, but various alternatives are available that may better suit specific needs and environments. This analysis will compare the Greenlighting road studs with two alternatives: solar-powered road studs and traditional reflective road markers.

Comparison Table

| Comparison Aspect | 10 Pack Greenlighting Reflective Road Studs Red | Solar-Powered Road Studs | Traditional Reflective Markers |

|---|---|---|---|

| Performance | High visibility under various conditions | Excellent visibility at night | Good visibility but less effective in poor lighting |

| Cost | Moderate initial investment | Higher upfront cost due to technology | Low cost, widely available |

| Ease of Implementation | Easy to install with basic tools | Requires careful placement and solar exposure | Simple installation, minimal tools required |

| Maintenance | Low maintenance; durable materials | Moderate; battery replacement may be needed | Very low; minimal upkeep required |

| Best Use Case | Urban areas, parking lots, and driveways | High-traffic roads and remote areas without lighting | Residential areas, low-traffic roads |

Detailed Breakdown of Alternatives

Solar-Powered Road Studs

Solar-powered road studs utilize solar panels to charge built-in batteries, which power LED lights for enhanced visibility during nighttime. These studs are particularly effective in areas lacking street lighting and can last for many hours after a full charge. However, they come with a higher upfront cost and require optimal placement to ensure sufficient solar exposure. The maintenance involves periodic checks to ensure the solar panels are clean and functional, and battery replacements may be necessary over time.

Traditional Reflective Markers

Traditional reflective markers are cost-effective and easy to install, making them a popular choice for residential and low-traffic areas. These markers rely solely on reflective materials to enhance visibility at night or in low-light conditions. While they are low-maintenance and readily available, their performance is often compromised in poorly lit environments, as they do not actively emit light. Thus, while they may suffice for less demanding applications, they are not suitable for high-traffic or hazardous areas where enhanced visibility is paramount.

Conclusion

When selecting the right road stud solution, B2B buyers must consider the specific requirements of their projects. The ’10 Pack Greenlighting Reflective Road Studs Red’ is an excellent choice for urban applications, offering durability and visibility. However, for areas lacking adequate lighting, solar-powered road studs may provide superior nighttime visibility despite their higher cost. Conversely, traditional reflective markers serve well in low-traffic areas where budget constraints are a priority. By evaluating performance, cost, ease of implementation, maintenance, and use cases, buyers can make informed decisions that best suit their operational needs.

Essential Technical Properties and Trade Terminology for 10 pack greenlighting reflective road studs red

What Are the Key Technical Properties of 10 Pack Greenlighting Reflective Road Studs Red?

When considering the procurement of 10 pack greenlighting reflective road studs red, several technical properties are crucial for ensuring product performance and compliance with safety regulations. Here are some of the most significant specifications:

1. Material Composition

The primary material used in these road studs is typically high-grade aluminum alloy or polycarbonate (PC). The choice of material affects durability, resistance to environmental factors, and overall lifespan. Aluminum alloys provide excellent strength-to-weight ratios and are resistant to corrosion, making them suitable for various climates, while polycarbonate offers impact resistance.

2. Load Resistance

Road studs must withstand substantial weight without deformation. For example, a load resistance rating of over 20 tons is common, ensuring that the studs can endure the pressure from vehicles without compromising visibility or structural integrity. This property is critical for safety in high-traffic areas, reducing the risk of accidents.

3. Waterproof Rating

An IP68 waterproof rating is essential for outdoor applications, indicating that the studs can be submerged in water without failure. This feature is particularly important in regions prone to heavy rainfall, ensuring that the reflective properties remain effective over time.

4. LED Performance

The studs typically incorporate ultra-bright LED lights that are available in various colors, including red. The number of LEDs (e.g., 10 LEDs) and their brightness level directly impact visibility at night or in low-light conditions. This specification is vital for enhancing road safety and guiding drivers effectively.

5. Recharge Time and Operating Duration

Solar-powered options may require specific charging periods (e.g., 8 hours of sunlight for up to 120 hours of illumination). Understanding these parameters helps buyers evaluate the efficiency and reliability of the products, ensuring they meet operational needs.

6. Size and Design Specifications

The dimensions of the road studs (e.g., φ117*23mm) affect installation and visibility. The design should be optimized for maximum reflectivity and light capture, which is critical for ensuring that they are easily seen by drivers.

What Common Trade Terminology Should Buyers Understand?

Understanding trade terminology is essential for international B2B buyers to navigate procurement processes effectively. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end products. Buyers should be aware of whether the road studs are OEM or aftermarket products, as this can affect quality and compatibility.

2. MOQ (Minimum Order Quantity)

This term indicates the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to ensure they can meet their budgetary and inventory needs without overcommitting.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and other details for specific products. This process helps in comparing costs and features among different suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers for the delivery of goods under sales contracts. Familiarity with these terms helps buyers understand shipping costs, risk management, and insurance responsibilities.

5. Lead Time

Lead time refers to the duration between the placement of an order and its delivery. Understanding lead times is essential for project planning and ensuring that road safety measures are implemented on schedule.

6. Certification Standards

These are regulatory benchmarks that products must meet to ensure safety and quality, such as ISO or CE certifications. Buyers should verify that the road studs comply with relevant standards in their region to ensure reliability and legal compliance.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed purchasing decisions regarding 10 pack greenlighting reflective road studs red, ensuring they select products that meet their operational needs and safety requirements.

Navigating Market Dynamics and Sourcing Trends in the 10 pack greenlighting reflective road studs red Sector

What Are the Key Market Dynamics Affecting the 10 Pack Greenlighting Reflective Road Studs Red Sector?

The market for 10 pack greenlighting reflective road studs, particularly in regions such as Africa, South America, the Middle East, and Europe, is witnessing significant growth due to increasing urbanization and the need for improved road safety measures. Global drivers include the rise in vehicular traffic, stringent regulations regarding road safety, and the growing emphasis on sustainable infrastructure solutions. Emerging trends indicate a shift towards smart technology integration, where road studs are being equipped with solar-powered LEDs and IoT capabilities to enhance visibility and connectivity. This evolution is particularly relevant for international B2B buyers looking for innovative products that not only meet safety standards but also offer long-term cost savings.

Furthermore, as countries ramp up investments in infrastructure, the demand for durable and reliable road safety products is surging. Buyers are increasingly seeking suppliers that can provide high-quality materials capable of withstanding harsh weather conditions and heavy loads. For instance, reflective road studs made from aluminum alloy and those featuring IP68 waterproof ratings are becoming popular choices. This shift towards durability aligns with the current focus on minimizing maintenance costs and enhancing product longevity.

How Is Sustainability Influencing the Sourcing of 10 Pack Greenlighting Reflective Road Studs Red?

Sustainability is a critical consideration for B2B buyers in the road safety products market. The environmental impact of manufacturing processes and material sourcing is under scrutiny, leading to a heightened demand for ethically sourced and eco-friendly products. In the context of 10 pack greenlighting reflective road studs, suppliers are increasingly adopting sustainable practices by utilizing recyclable materials and energy-efficient production methods.

Buyers are encouraged to seek suppliers who can provide certifications related to environmental standards, such as ISO 14001 or other green certifications. This not only ensures compliance with local and international regulations but also enhances the brand reputation among environmentally conscious consumers. Additionally, many suppliers are integrating renewable energy sources, such as solar panels, into their products, reducing reliance on traditional energy and minimizing carbon footprints.

By prioritizing sustainability in their procurement strategies, B2B buyers can contribute to a greener economy while also benefiting from potential cost savings associated with energy-efficient products.

How Has the 10 Pack Greenlighting Reflective Road Studs Red Sector Evolved Over Time?

The evolution of reflective road studs can be traced back to traditional materials like glass and concrete, which were primarily used for visibility purposes. Over time, advancements in technology have led to the development of more efficient materials such as aluminum alloy and high-grade polycarbonate, which offer enhanced durability and resistance to environmental factors.

The introduction of solar-powered options marked a significant milestone in the sector, allowing for self-sustaining road markers that do not require external power sources. This shift not only improved functionality but also aligned with the growing emphasis on sustainability and energy efficiency. Today, the 10 pack greenlighting reflective road studs are not only essential for safety but also symbolize a commitment to innovative and eco-friendly practices in road infrastructure development.

As the sector continues to innovate, B2B buyers can expect ongoing enhancements in design, functionality, and sustainability, further solidifying the role of reflective road studs in modern transportation safety solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of 10 pack greenlighting reflective road studs red

-

How do I determine the appropriate specifications for reflective road studs in my region?

To select the right specifications for reflective road studs, consider the local climate, road conditions, and visibility requirements. Ensure that the studs meet international safety standards and are designed for high traffic areas. Additionally, consult with local traffic authorities to understand any specific regulations or requirements for road safety products in your region. Analyzing these factors will help you choose road studs that enhance safety and longevity. -

What is the best reflective road stud option for low-light conditions?

For low-light conditions, choose reflective road studs that feature high-quality materials and powerful LED lights. The GreenLighting reflective road studs are designed with ultra-bright LEDs that provide excellent visibility at night or during inclement weather. Ensure that the studs have a robust battery life and are made from durable materials that can withstand harsh environmental conditions, ensuring they remain effective over time. -

What are the minimum order quantities (MOQs) for the 10 pack greenlighting reflective road studs red?

Minimum order quantities can vary by supplier. Typically, for bulk purchases of reflective road studs, the MOQ ranges from 100 to 500 units. It is advisable to discuss your specific needs with the supplier to negotiate MOQs that suit your budget and project requirements. Suppliers may also offer discounts for larger orders, which can be beneficial for ongoing projects. -

How can I verify the quality of reflective road studs before placing a bulk order?

To verify the quality of reflective road studs, request samples from the supplier before making a bulk purchase. Examine the materials, durability, and performance of the studs in various conditions. Additionally, check for certifications that indicate compliance with international safety standards. Customer reviews and case studies can also provide insights into the product’s performance in real-world applications. -

What payment terms should I expect when sourcing road studs internationally?

Payment terms can vary widely based on the supplier and the transaction size. Common options include upfront payments, 30% deposits with the balance upon delivery, or net 30/60 days after invoice. Always clarify payment terms during negotiations and ensure they align with your cash flow capabilities. Secure payment methods, such as letters of credit or escrow services, can provide additional protection in international transactions. -

What logistics considerations should I keep in mind when importing reflective road studs?

When importing reflective road studs, consider shipping costs, delivery times, and customs regulations in your country. Work with reliable logistics partners to ensure timely delivery and manage potential delays. Additionally, verify that the supplier provides necessary documentation, such as certificates of origin and compliance, to facilitate smooth customs clearance. Understanding local import duties and taxes is also crucial to budgeting your total costs. -

Can I customize the reflective road studs with my branding or specific features?

Many suppliers offer customization options for reflective road studs, including branding with your company logo, specific colors, and additional features like different LED configurations. Discuss your customization needs with the supplier during the initial stages of negotiation. Keep in mind that custom orders may have higher MOQs and longer lead times, so plan accordingly to ensure alignment with your project timelines. -

What are the common applications for reflective road studs in different regions?

Reflective road studs are commonly used in various applications, including highways, parking lots, pedestrian crossings, and rural roads. In regions with heavy rainfall or fog, they enhance road safety by improving visibility. In urban areas, they help delineate lanes and guide traffic during nighttime. Understanding the specific needs of your region will help you implement the most effective road safety measures using reflective road studs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 10 Pack Greenlighting Reflective Road Studs Red Manufacturers & Suppliers List

1. GreenLighting – 10 Pack Reflective Road Studs

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “10 Pack GreenLighting Reflective Road Studs Heavy Duty Markers RED TN-1217548”, “Condition”: “Open box”, “Price”: “$45.99”, “Quantity Available”: “4”, “Shipping”: “Free USPS First Class”, “Delivery Estimate”: “Between Thu, Sep 11 and Wed, Sep 17”, “Returns”: “30 days returns, buyer pays for return shipping”, “Brand”: “GreenLighting”, “Type”: “Pavement Markers”, “Seller”: “O opsst…

2. Solar Road Markers – Heavy Duty Reflective Pavement Markers

Domain: solarroadmarkers.com

Registered: 2020 (5 years)

Introduction: Tunnel Solar Road Markers Heavy Duty Road Pavement Markers are commercial grade, DOT approved, peel-n-stick red reflective road markers designed for locating driveways and roadways in low visibility conditions. Each marker measures 4 inches by 4 inches and is constructed from hard acrylic for maximum strength. They come pre-coated with a sticky adhesive butyl pad for easy bonding.

3. Nokin – Waterproof Reflective Solar Road Stud

Domain: nokinsolarroadstud.com

Registered: 2020 (5 years)

Introduction: Waterproof Reflective Aluminum Alloy Solar Road Stud Marker

– Manufacturer: Shenzhen Nokin Traffic Facilities Co., Ltd.

– Material: Aluminum alloy

– Features: Waterproof, reflective, energy-saving, enhances road visibility at night

– Function: Reduces street lighting needs, promotes environmental protection

– Applications: Used in pedestrian crossing systems, highways, and road safety

– Establishe…

4. Traffic Thingz – 10 Pack Commercial Road Reflector

Domain: trafficthingz.com

Registered: 2018 (7 years)

Introduction: {“name”: “10 Pack – Commercial Road Reflector – 4″ x 4″ Red with Red Reflector”, “SKU”: “REFL-02-RD”, “price”: “$29.99”, “shipping_weight”: “4.00 pounds”, “dimensions”: “4 x 4 x 1 Inches”, “housing_material”: “Enhanced modified engineering plastics”, “reflector”: “Super bright reflector covered with glass abrasion proof protection film.”, “colors_available”: [“Yellow”, “White”, “Red”, “Blue”], “fa…

5. Merhoff & Larkin – Red Road Reflectors 10 Pack

Domain: merhoffandlarkin.com

Registered: 2020 (5 years)

Introduction: {“product_name”: “Red Road Reflectors 10 Pack”, “brand”: “Merhoff & Larkin”, “price”: “$32.95”, “sku”: “AF-K2JX-F477”, “category”: “Business”, “tags”: [“Road Reflectors”], “features”: {“high_reflectivity”: “Great for ensuring that roads, streets, sidewalks and anything else you need these red road studs for are clearly visible at night with high grade reflective lining.”, “durability”: “Capable of…

6. Firehose Direct – Red Reflective Road Marker (2 Pack)

Domain: firehosedirect.com

Registered: 2011 (14 years)

Introduction: Red Reflective Road Marker (2 Pack)

7. Reflective Road Stud – Enhanced Visibility Solutions

Domain: reflectiveroadstud.com

Registered: 2020 (5 years)

Introduction: Reflective Road Stud, Aluminum Dock Light, price details not specified, designed for enhanced visibility, durable construction, suitable for various applications.

Strategic Sourcing Conclusion and Outlook for 10 pack greenlighting reflective road studs red

As international B2B buyers increasingly seek innovative solutions for road safety, the strategic sourcing of products like the 10 pack greenlighting reflective road studs in red becomes essential. These road studs not only enhance visibility and safety during night-time or adverse weather conditions, but they also represent a cost-effective investment in long-term infrastructure. With their robust construction, including materials that withstand heavy loads and harsh environments, these reflective road studs are well-suited for diverse applications across various regions.

The value of strategic sourcing lies in its ability to streamline procurement processes, ensuring quality and reliability while minimizing costs. By partnering with reputable suppliers, buyers can access superior products that meet international safety standards, thereby enhancing their operational efficiency and reducing liability risks.

Looking ahead, the demand for effective road safety solutions will continue to grow, particularly in developing markets like Africa, South America, the Middle East, and Europe. Now is the time for businesses to invest in high-quality reflective road studs. By prioritizing reliable suppliers and innovative products, you can contribute to safer roadways while positioning your organization as a leader in responsible infrastructure development. Engage with trusted suppliers today to secure your order and pave the way for a brighter, safer future.